Patents

Literature

66 results about "Metglas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

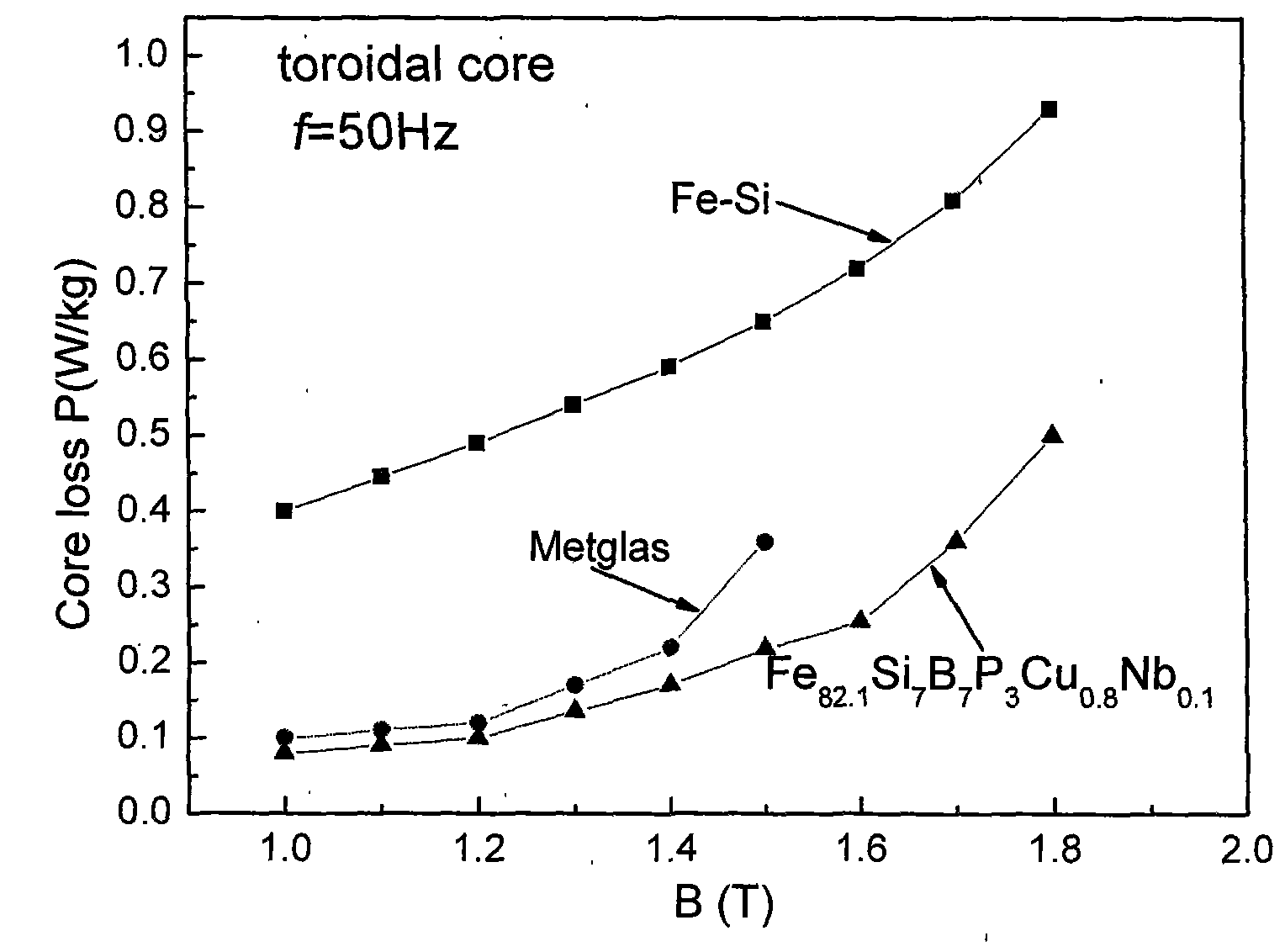

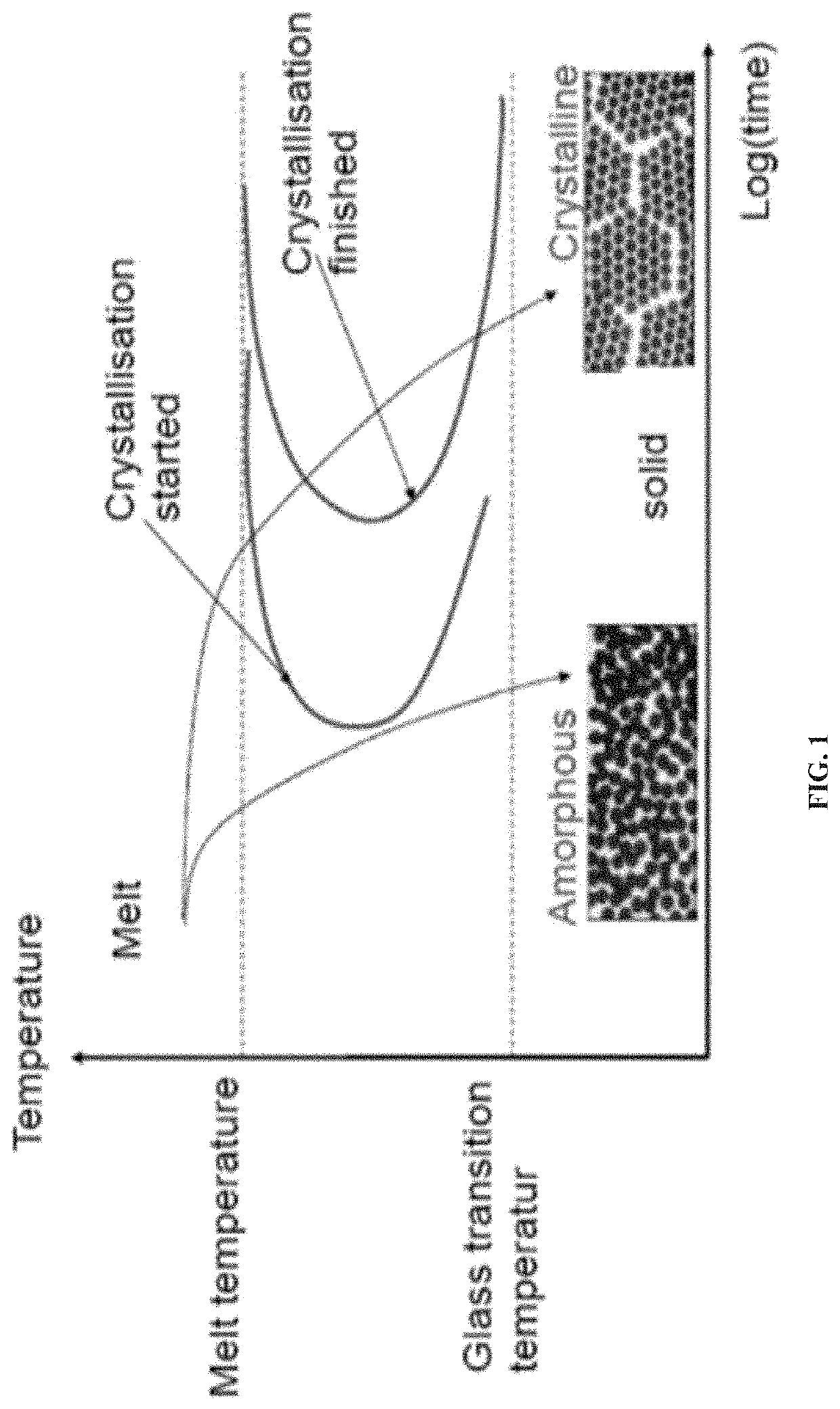

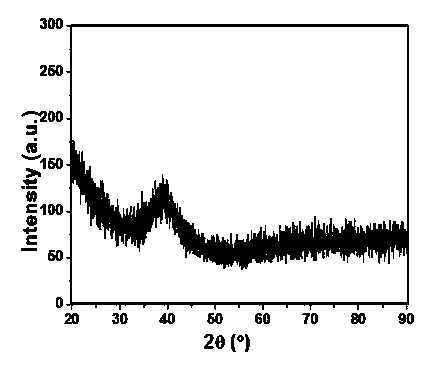

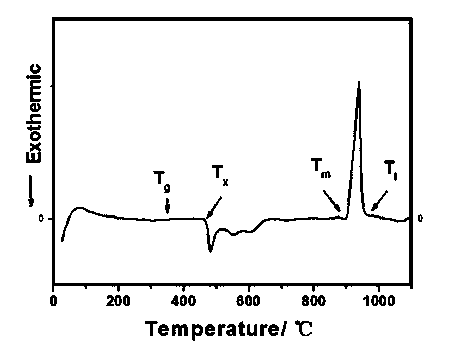

Metglas is a thin amorphous metal alloy ribbon produced by using rapid solidification process of approximately 1,000,000 °C/s (1,800,000 °F/s; 1,000,000 K/s). This rapid solidification creates unique ferromagnetic properties that allows the ribbon to be magnetized and de-magnetized quickly and effectively with very low core losses of approximately 5 mW/kg at 60 Hz and a maximum relative permeability of approximately 1,000,000.

Titanium group powder metallurgy

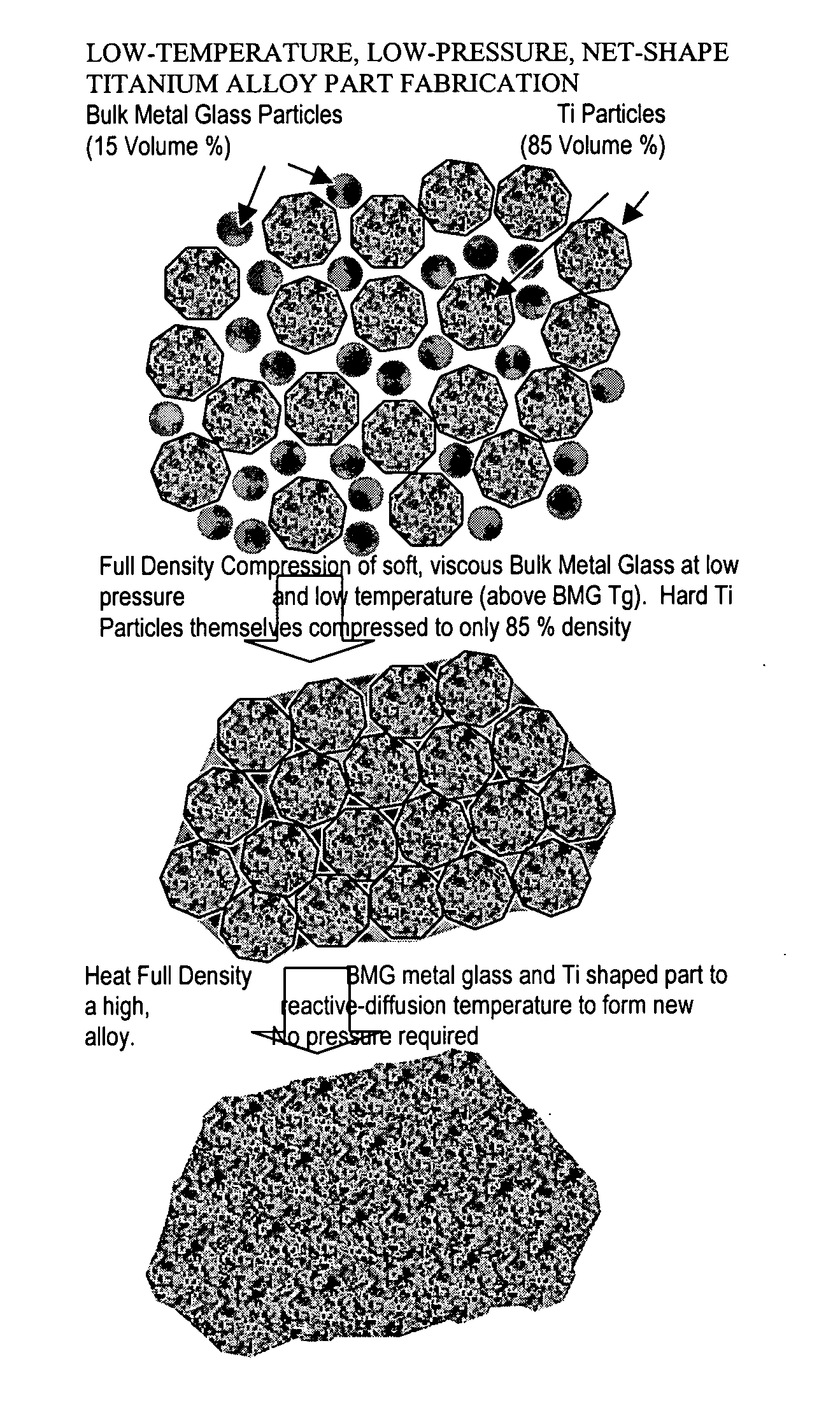

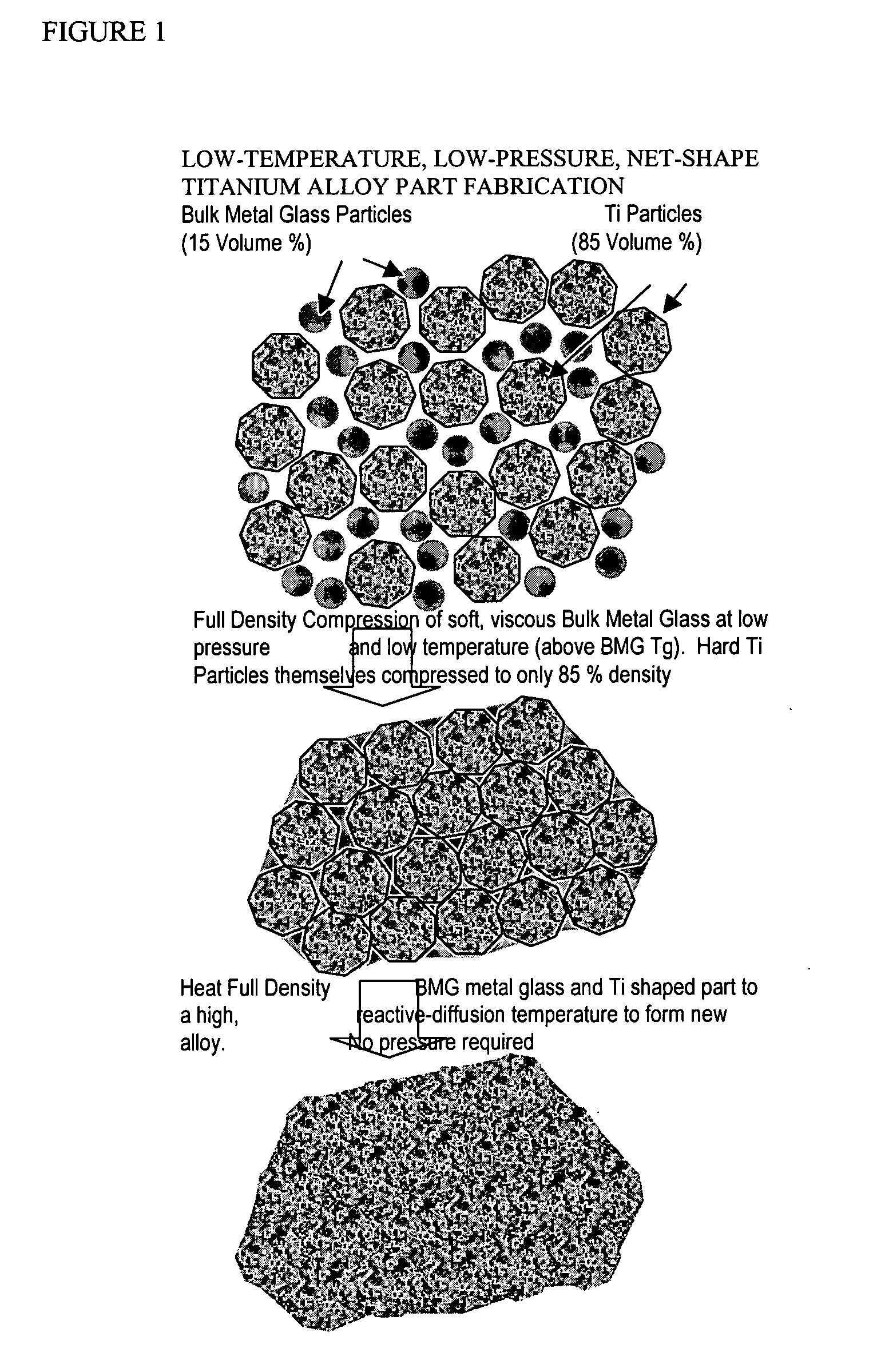

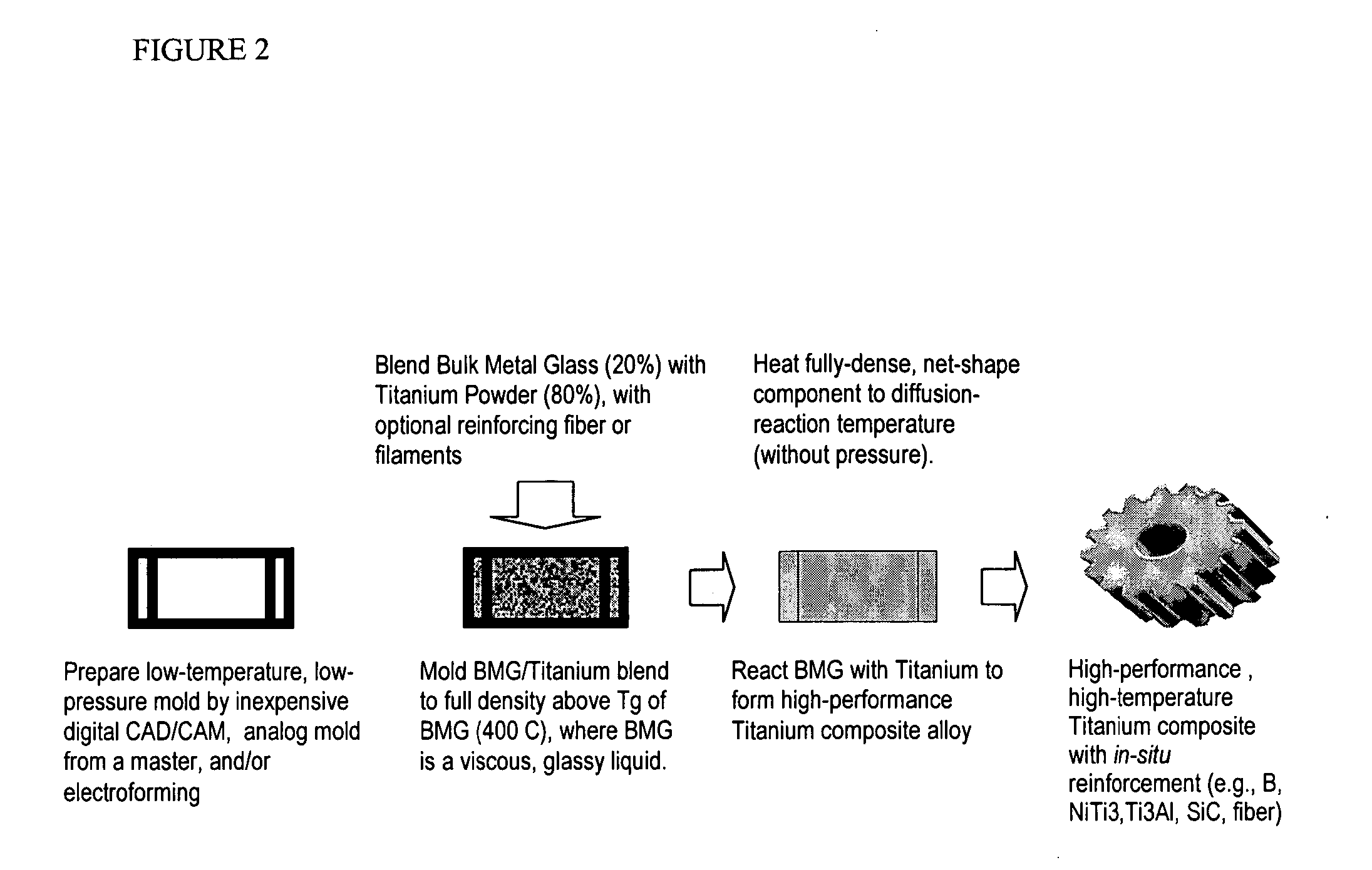

InactiveUS20050084407A1Excellent cold formabilityImprove hardenabilityVitrificationVolumetric Mass Density

Methods and compositions relating to powder metallurgy in which an amorphous-titanium-based metal glass alloy is compressed above its glass transition temperature Tg with a titanium alloy powder which is a solid at the compression temperature, to produce a compact with a relative density of at least 98%.

Owner:MYRICK JAMES J

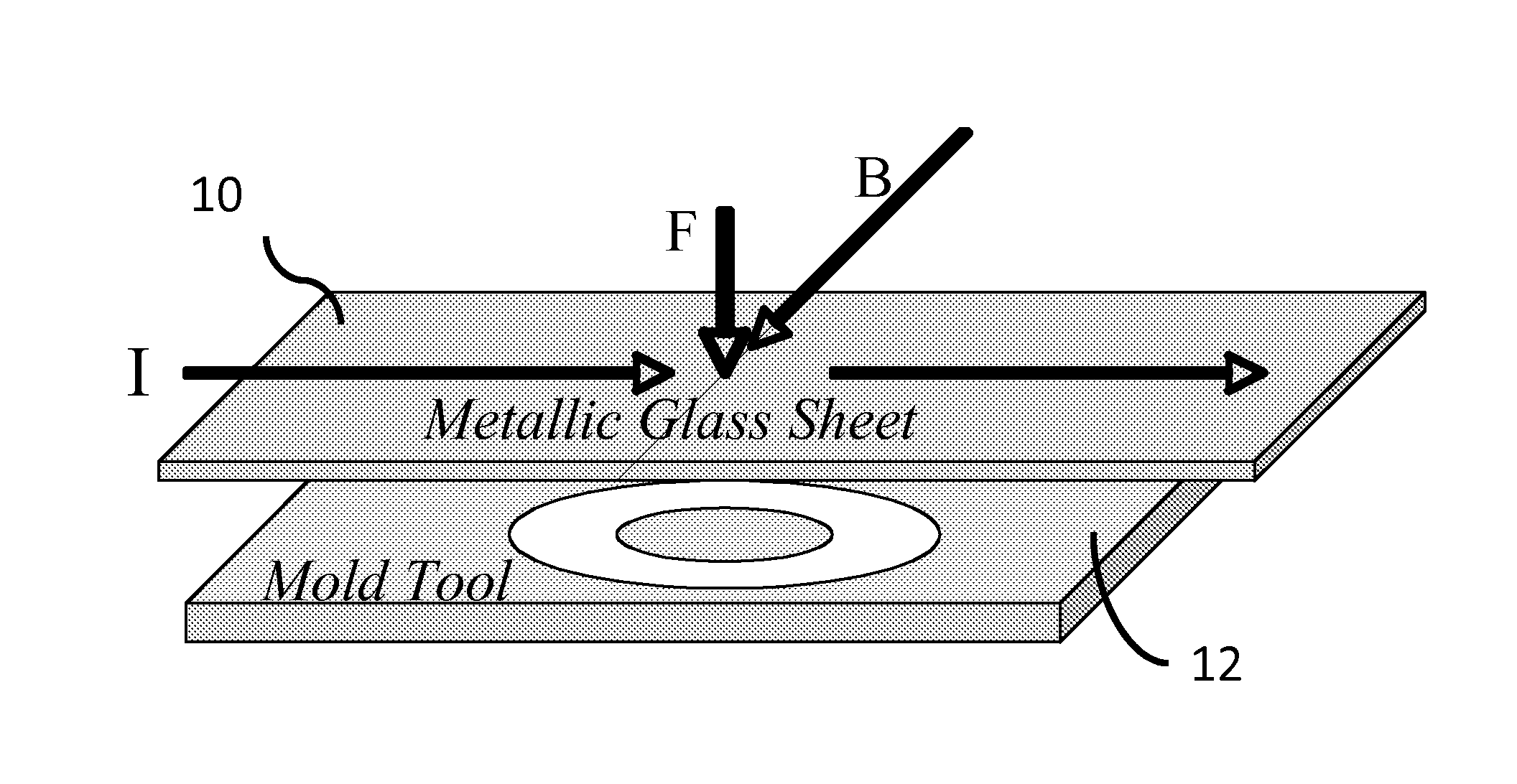

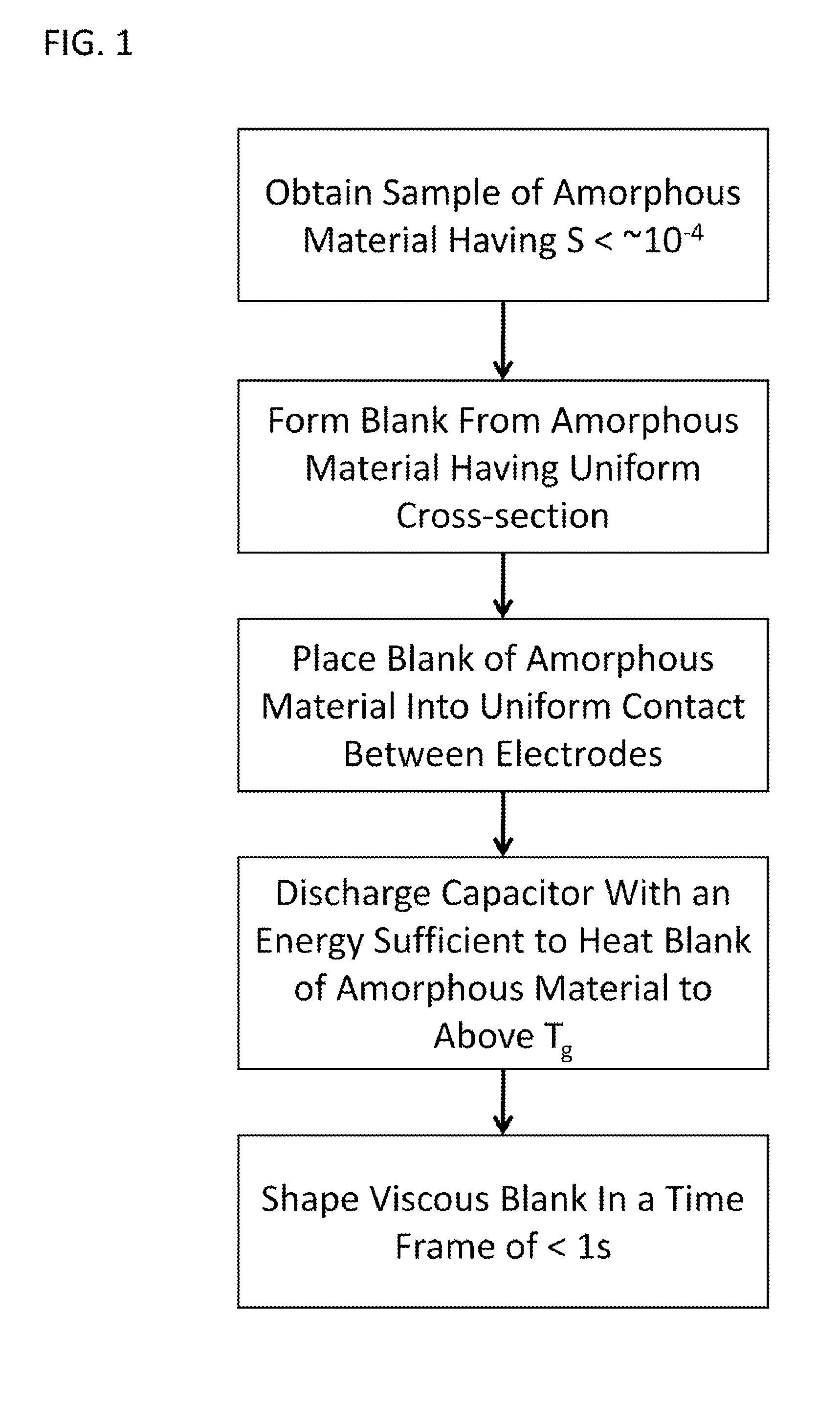

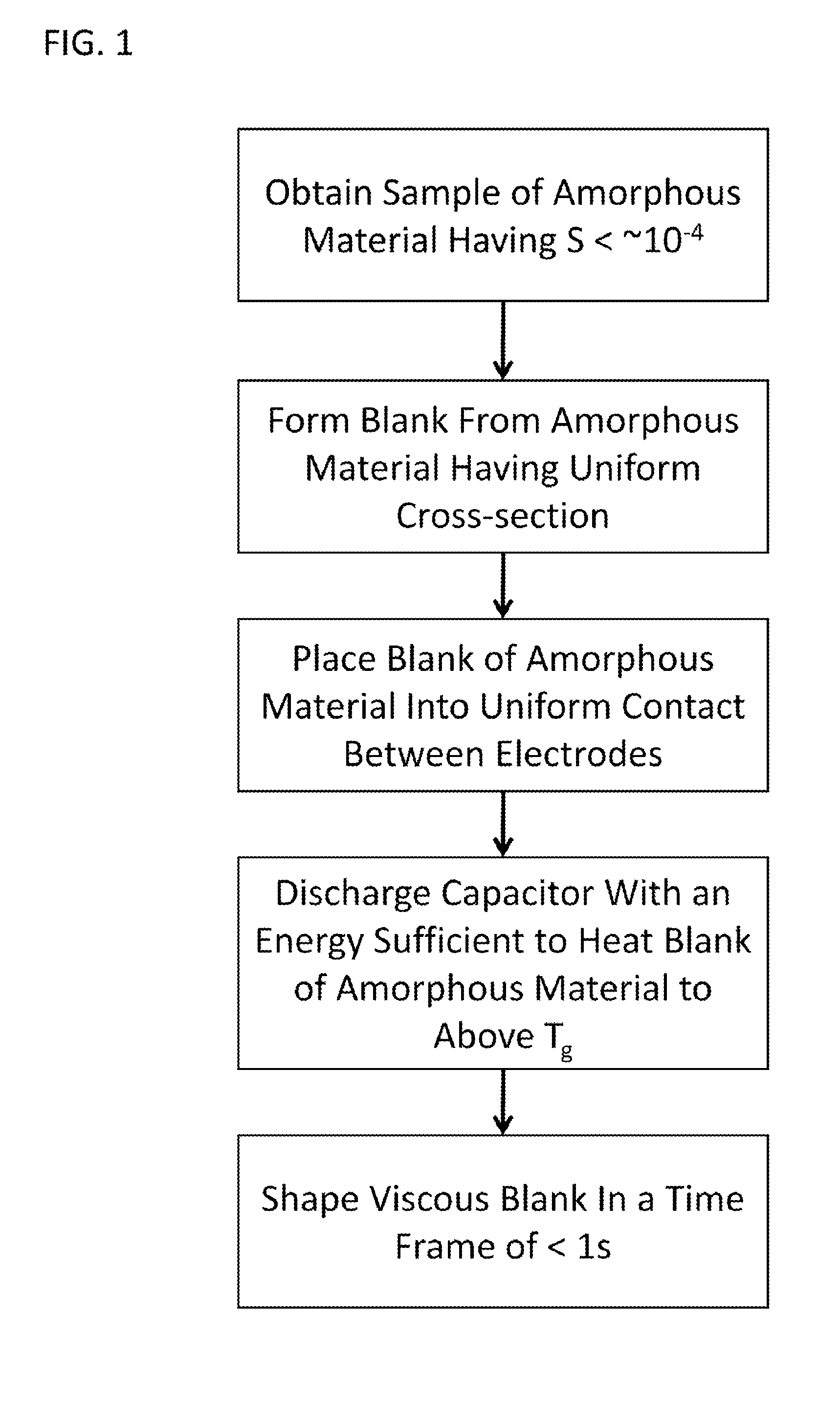

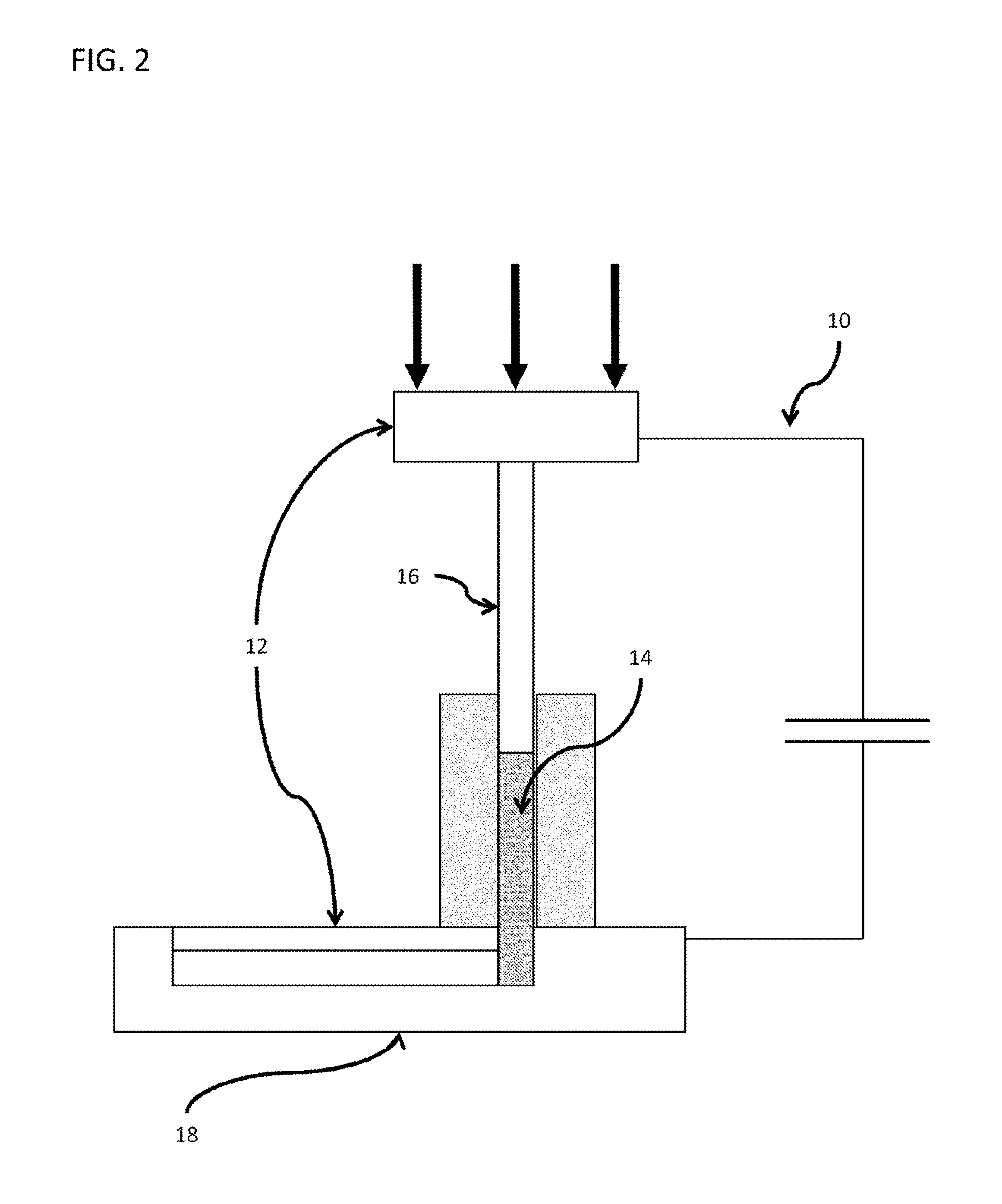

Electromagnetic forming of metallic glasses using a capacitive discharge and magnetic field

ActiveUS20120006085A1Welding/cutting media/materialsSoldering mediaCapacitanceTransverse magnetic field

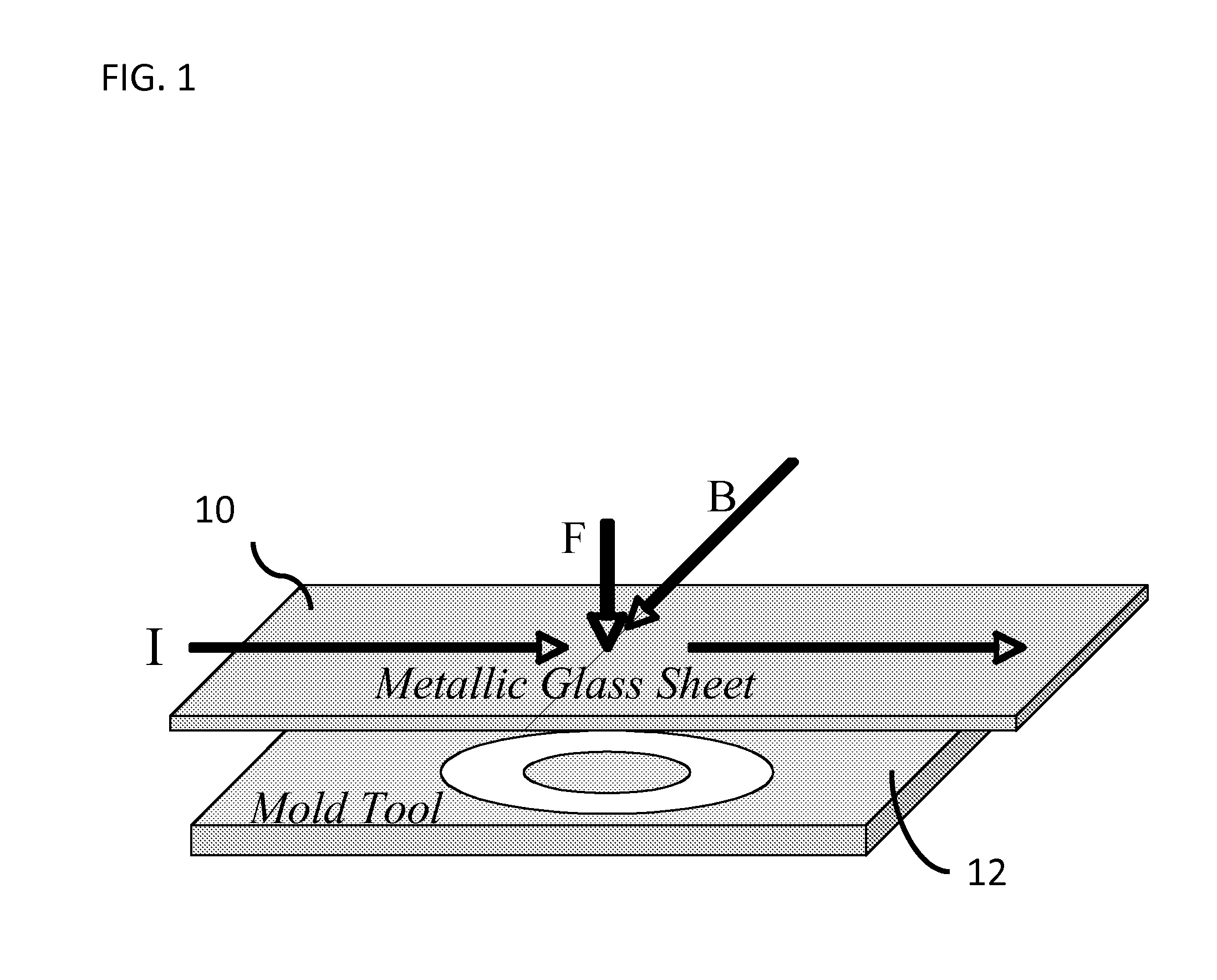

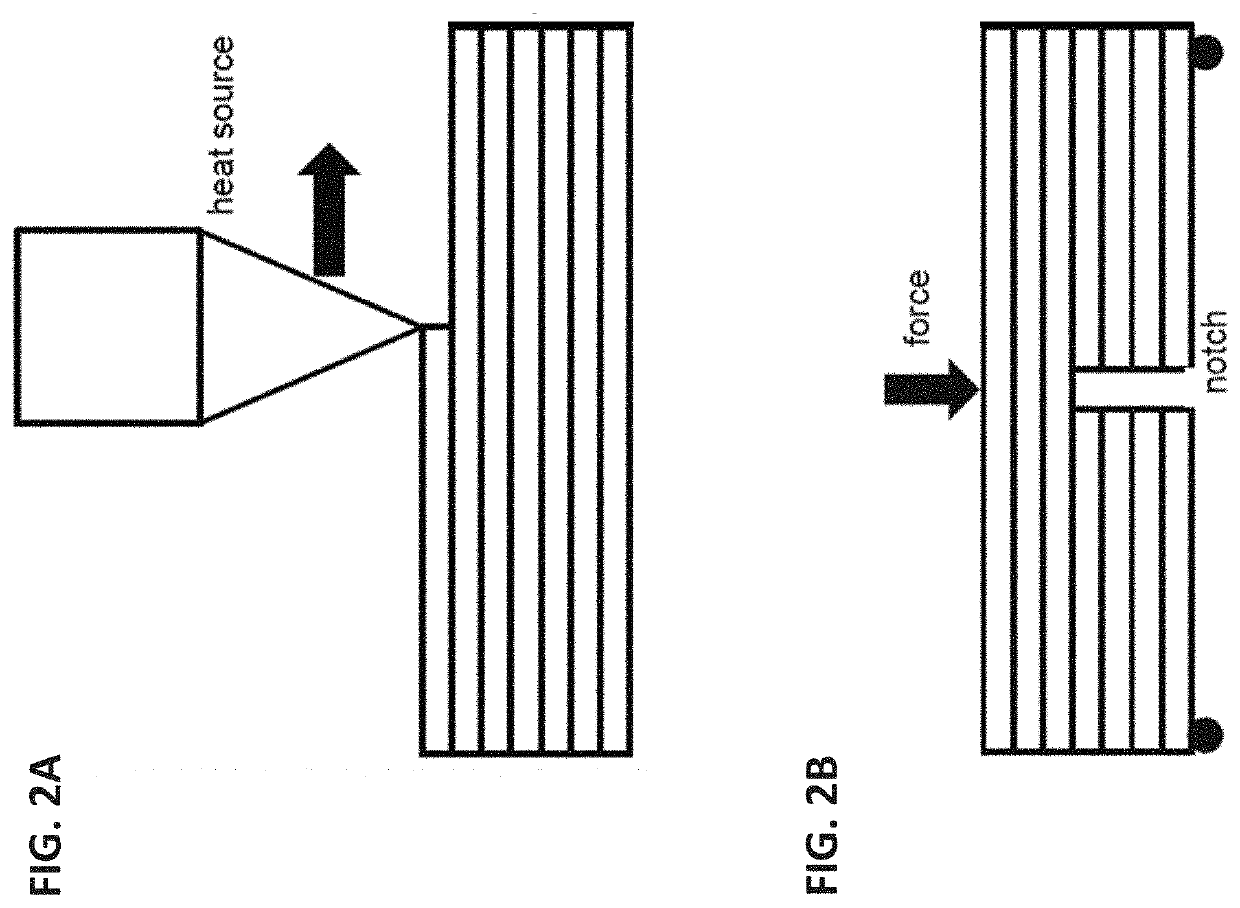

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool in combination with an electromagnetic force generated by the interaction of the applied current with a transverse magnetic field. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous metal and the equilibrium melting point of the alloy in a time scale of several milliseconds or less, at which point the interaction between the electric field and the magnetic field generates a force capable of shaping the heated sample into a high quality amorphous bulk article via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time scale of less than one second.

Owner:CALIFORNIA INST OF TECH

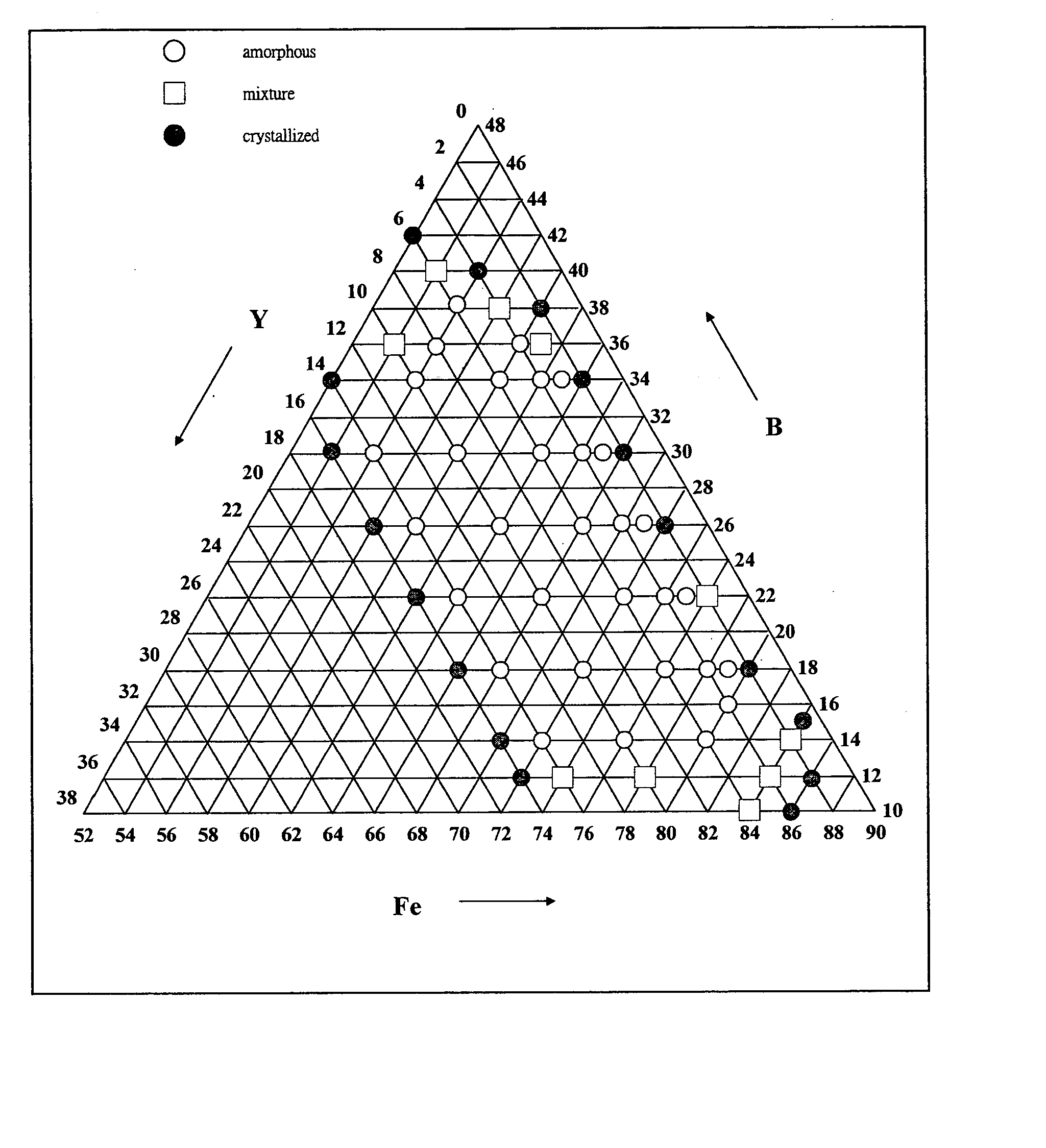

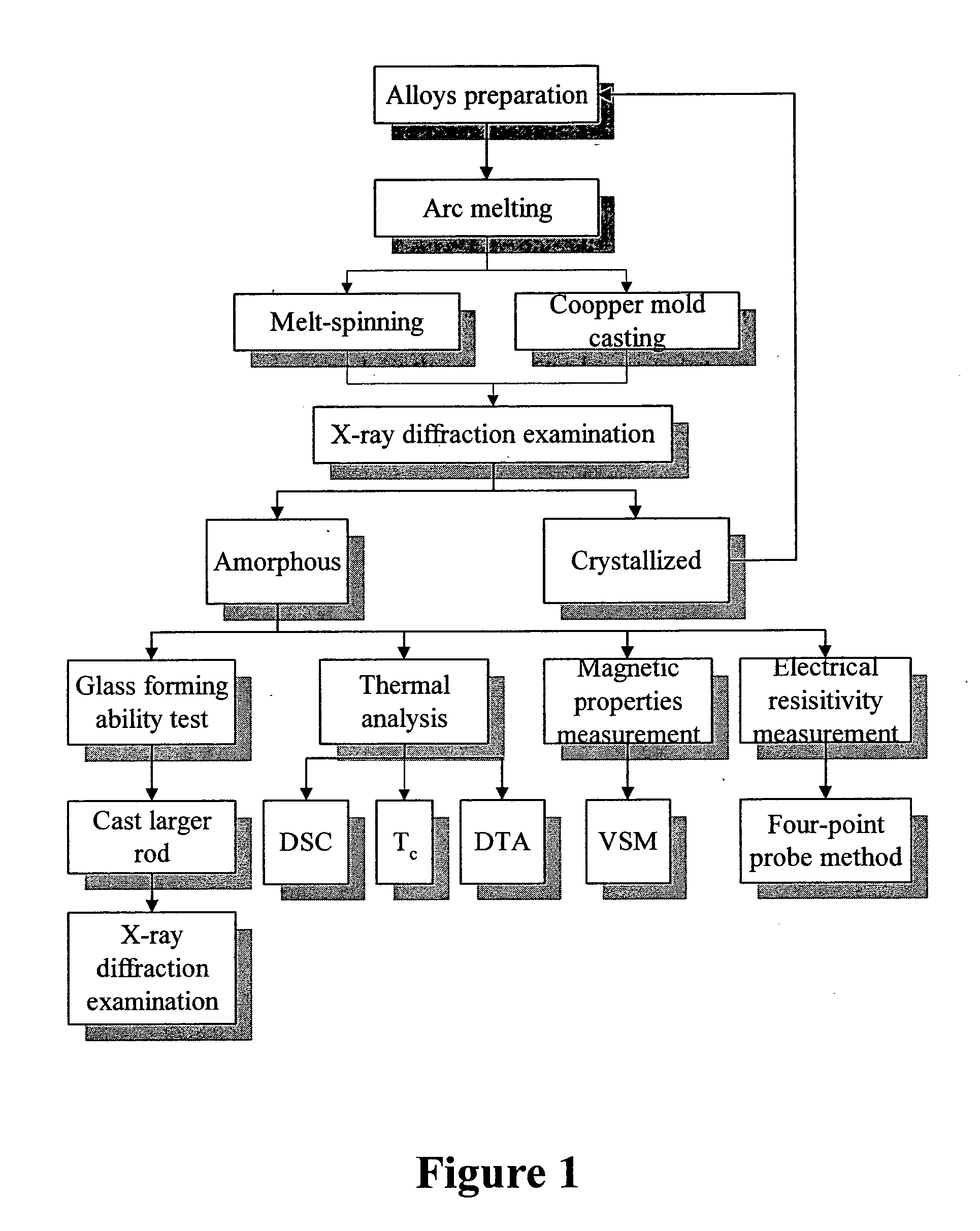

Ternary and multi-nary iron-based bulk glassy alloys and nanocrystalline alloys

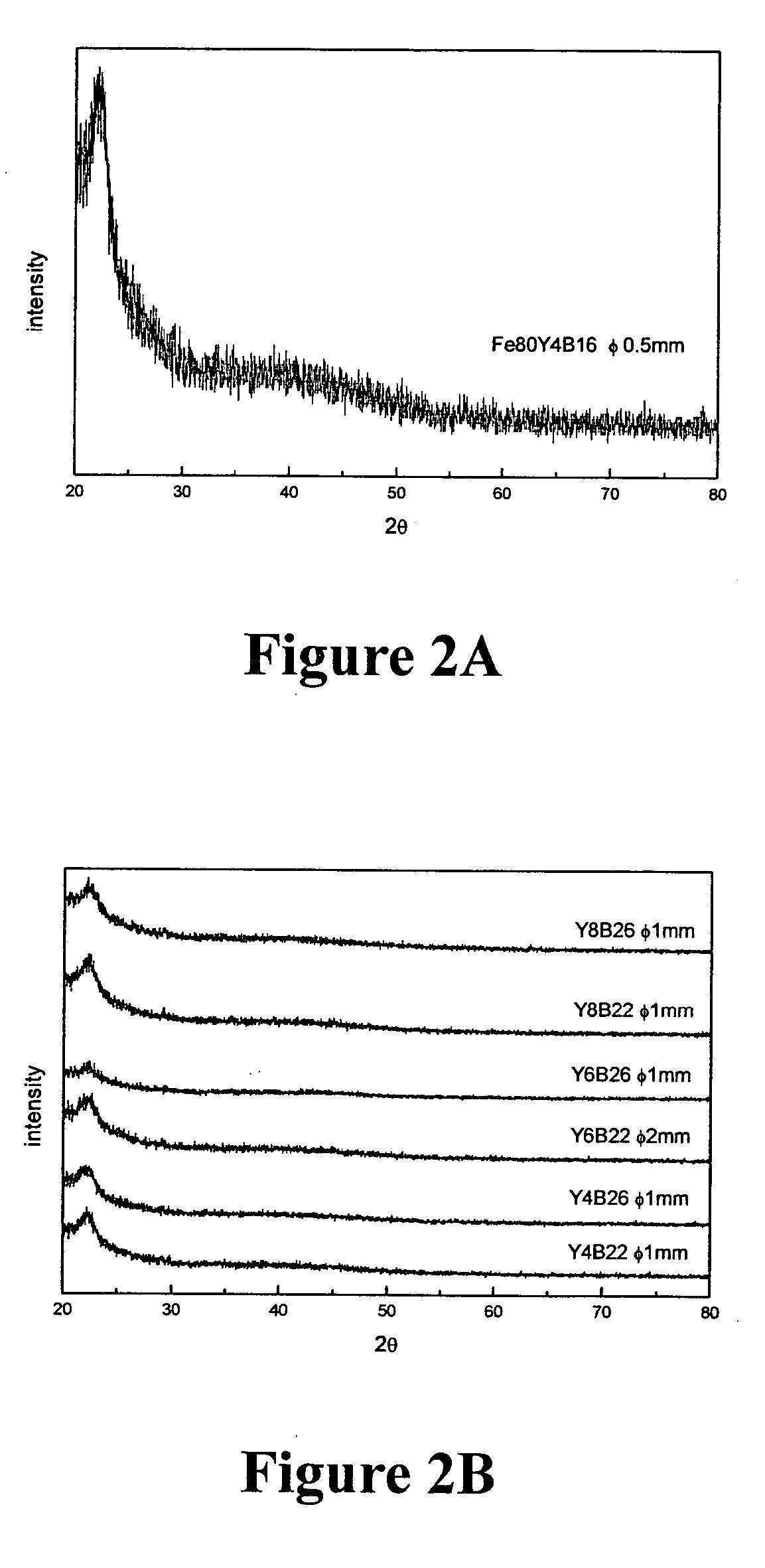

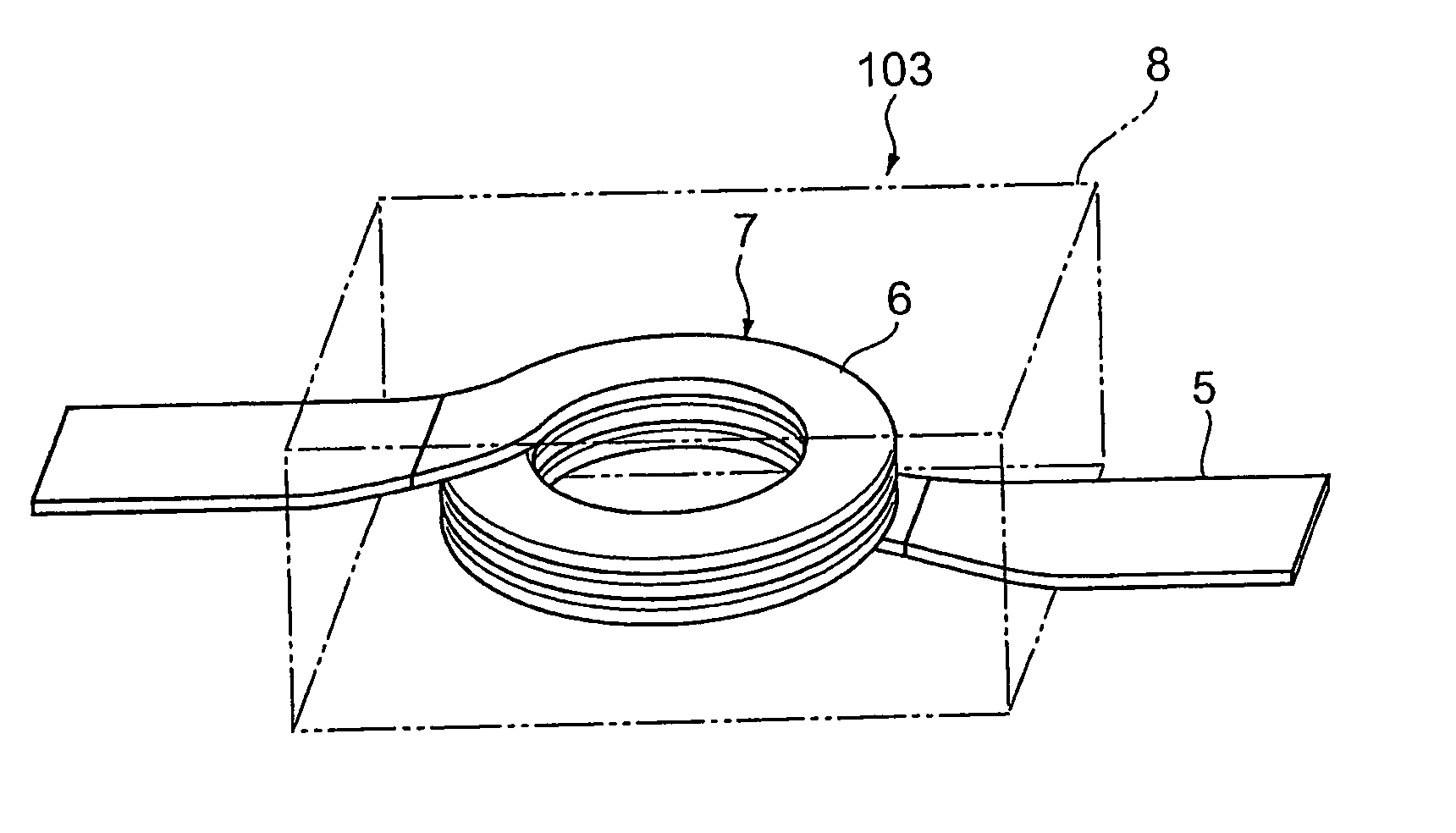

InactiveUS20050263216A1High glass forming abilityIncreased electrical resistivityMagnetic materialsAmorphous phaseAtomic radius

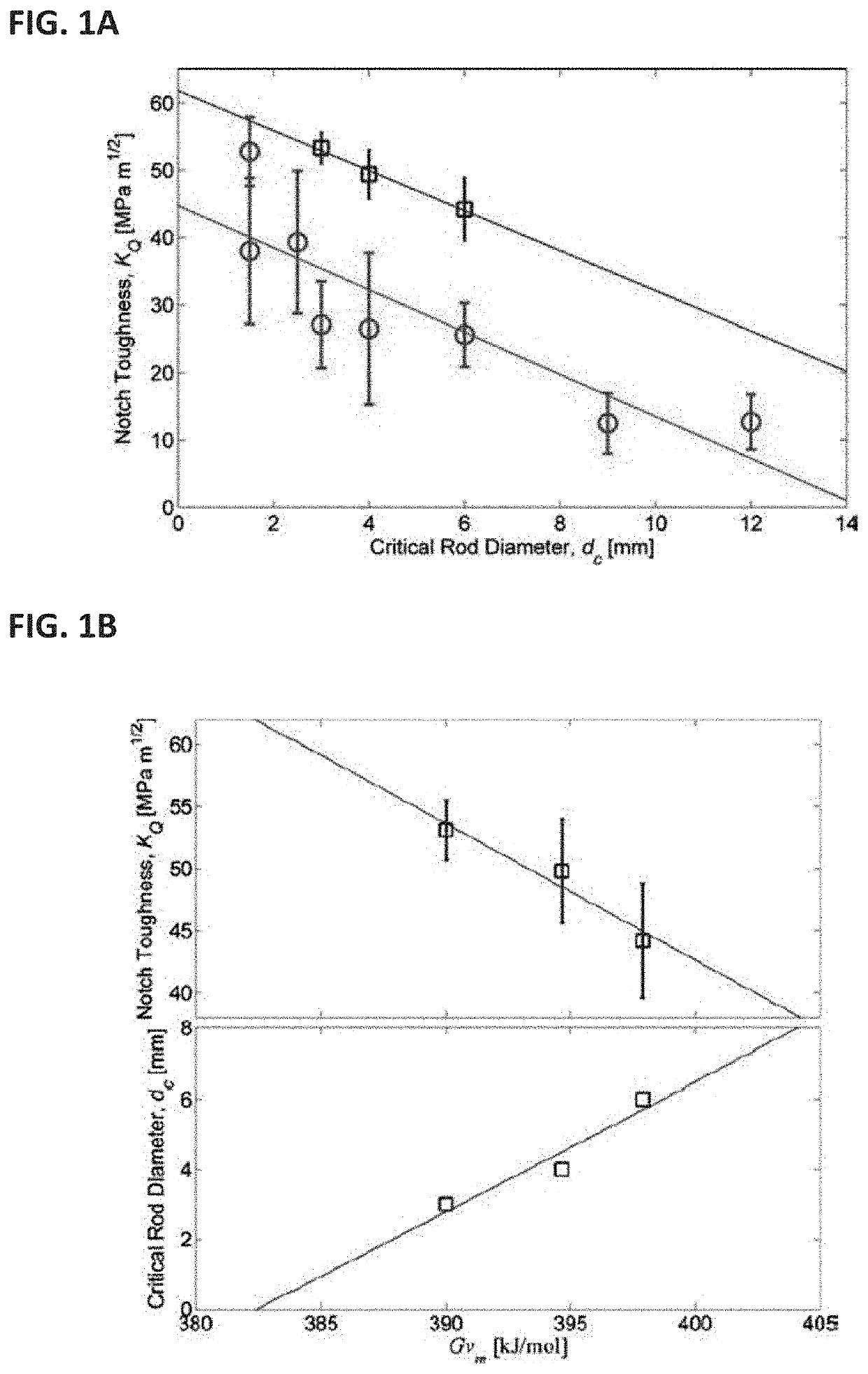

Disclosed in this invention is a family of ternary and multi-nary iron-based new compositions of bulk metallic glasses which possess promising soft magnetic properties, and the composition selection rules that lead to the design of such new compositions. The embodiment alloys are represented by the formula MaXbZc, where M represents at least one of ferromagnetic elements such as iron and may partly be replaced by some other substitute elements; X is an element or combinations of elements selected from those with atomic radius at least 130% that of iron and in the mean time is able to form an M-rich eutectic; and Z is an element or combinations of elements selected from semi-metallic or non-metallic elements with atomic radius smaller than 86% that of iron and in the meantime is able to form an M-Z eutectic; a, b, c are the atomic percentage of M, X, Z, respectively, and a+b+c=100%. When 1%<b<15% and 10%<c<39%, the alloys show a bulk glass forming ability to cast amorphous ribbons / sheets at least 0.1 mm in thickness. When 3%<b<10% and 18%<c<30%, the alloys show a bulk glass forming ability to cast amorphous rods at least 1 mm in diameter. The amorphous phase of these as-cast sheets / rods is at least 95% by volume. This invention also discloses the existence of nano-crystalline phase outside of the outer regime of the bulk glass forming region mentioned above.

Owner:NATIONAL TSING HUA UNIVERSITY

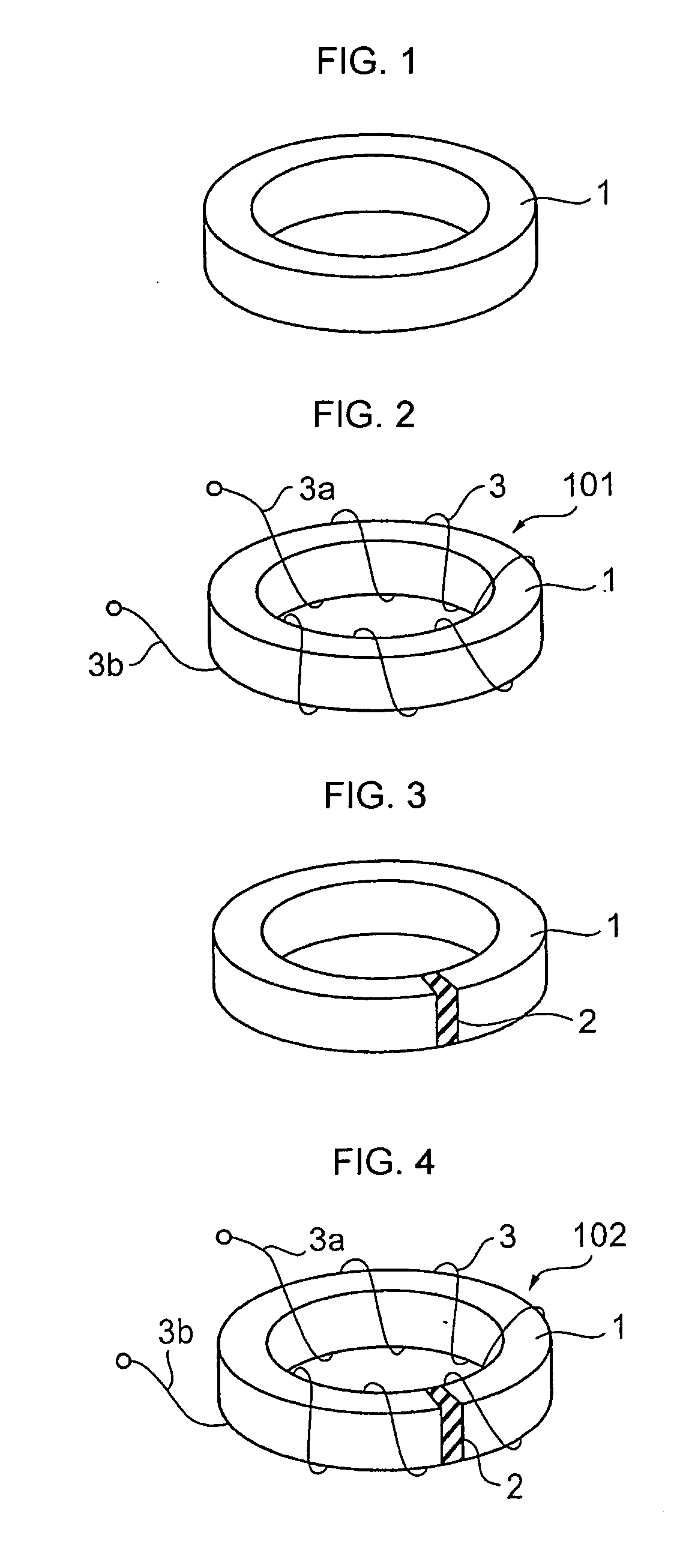

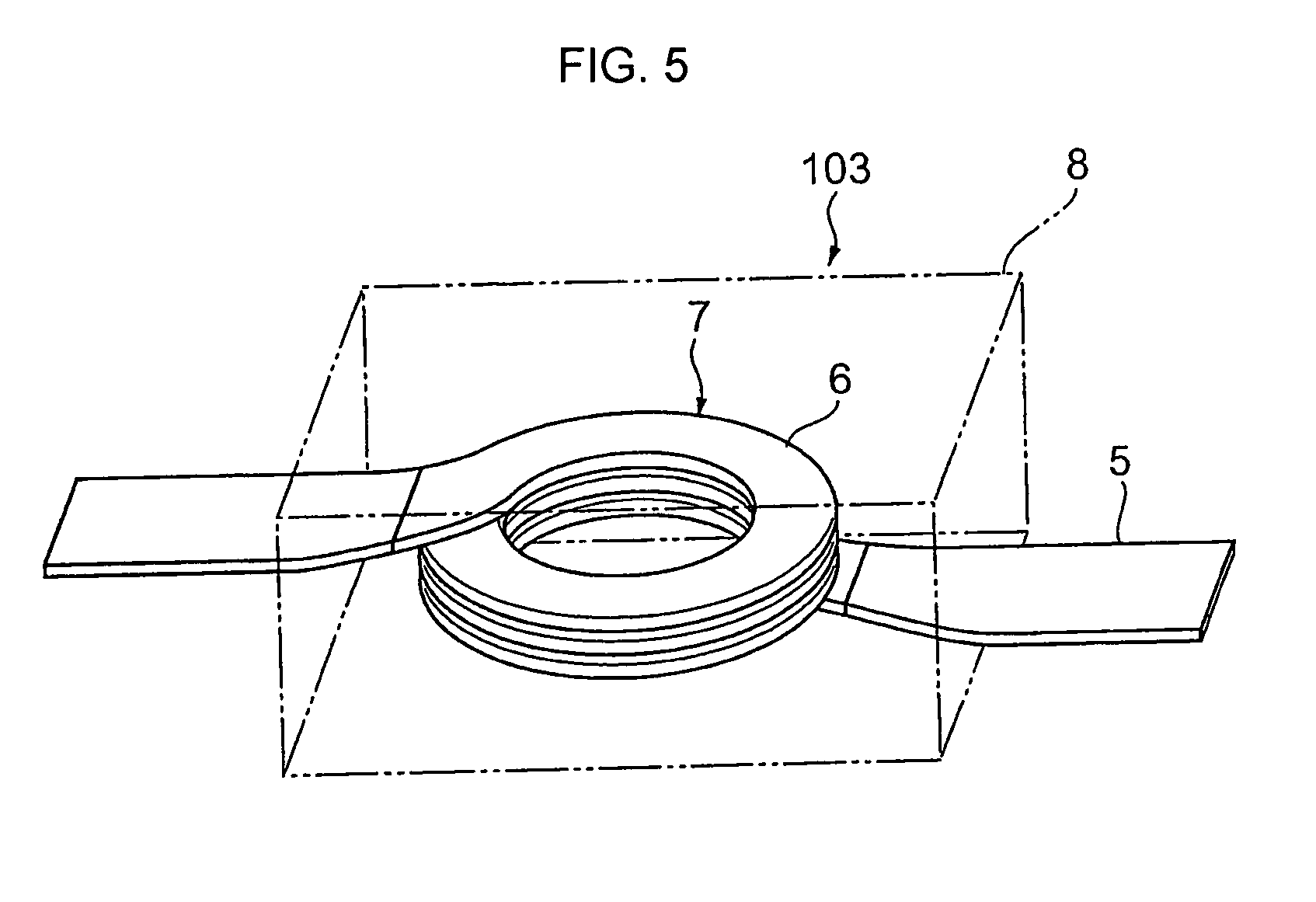

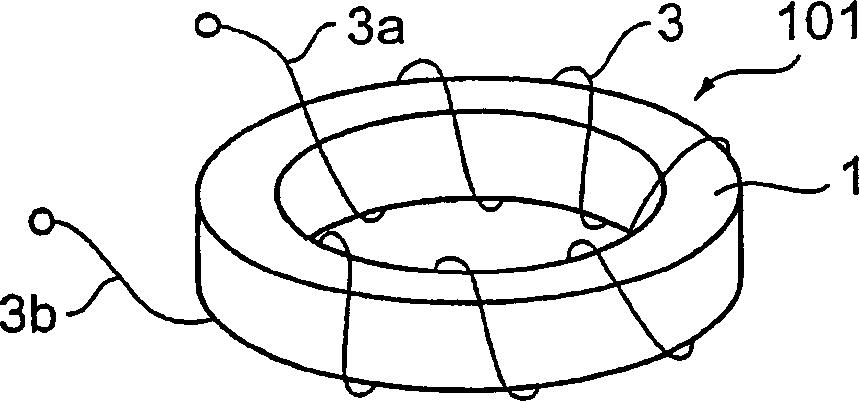

Magnetic core for high frequency and inductive component using same

ActiveUS20060170524A1Transformers/inductances casingsTransformers/inductances coils/windings/connectionsMischmetalRare earth

A high-frequency core is a molded body obtained by molding a mixture of a soft magnetic metallic glass powder and a binder in an amount of 10% or less in mass ratio. The powder has an alloy composition represented by a general formula (Fe1-a-bNiaCob)100-x-y-z(M1-pM′p)xTyBz (where 0≦a≦0.30, 0≦b≦0.50,0≦a+b≦0.50,0≦p≦0.5, 1 atomic %≦x≦5 atomic %, 1 atomic %≦y≦12 atomic %, 12 atomic %≦z≦25 atomic %, 22≦(x+y+z)≦32, M being at least one selected from Zr, Nb, Ta, Hf, Mo, Ti, V, Cr, and W, M′ being at least one selected from Zn, Sn, R (R being at least one element selected from rare earth metals including Y), T being at least one selected from Al, Si, C, and P). An inductance component includes the high-frequency core and at least one turn of winding wound around the core.

Owner:TOKIN CORP +1

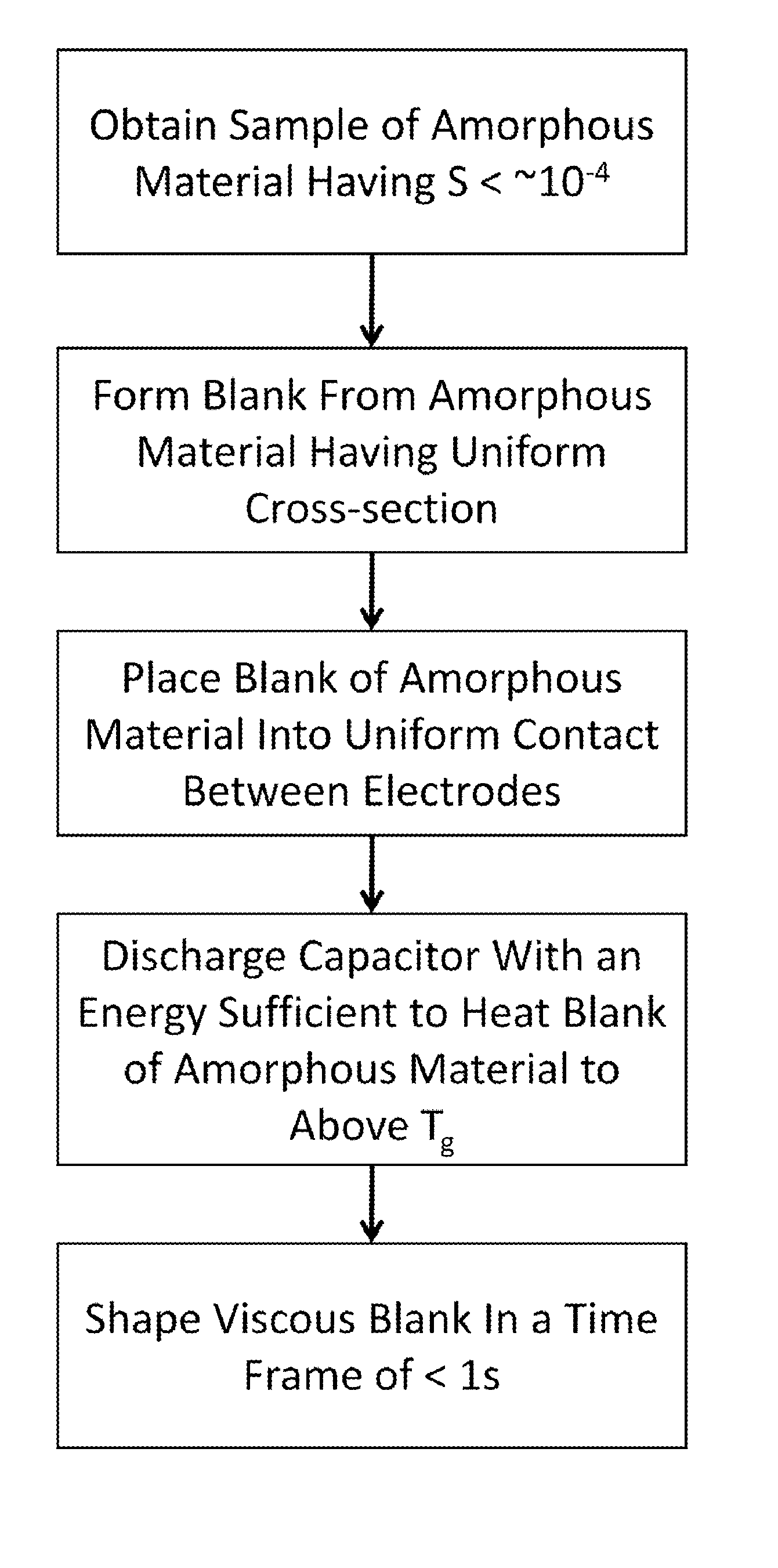

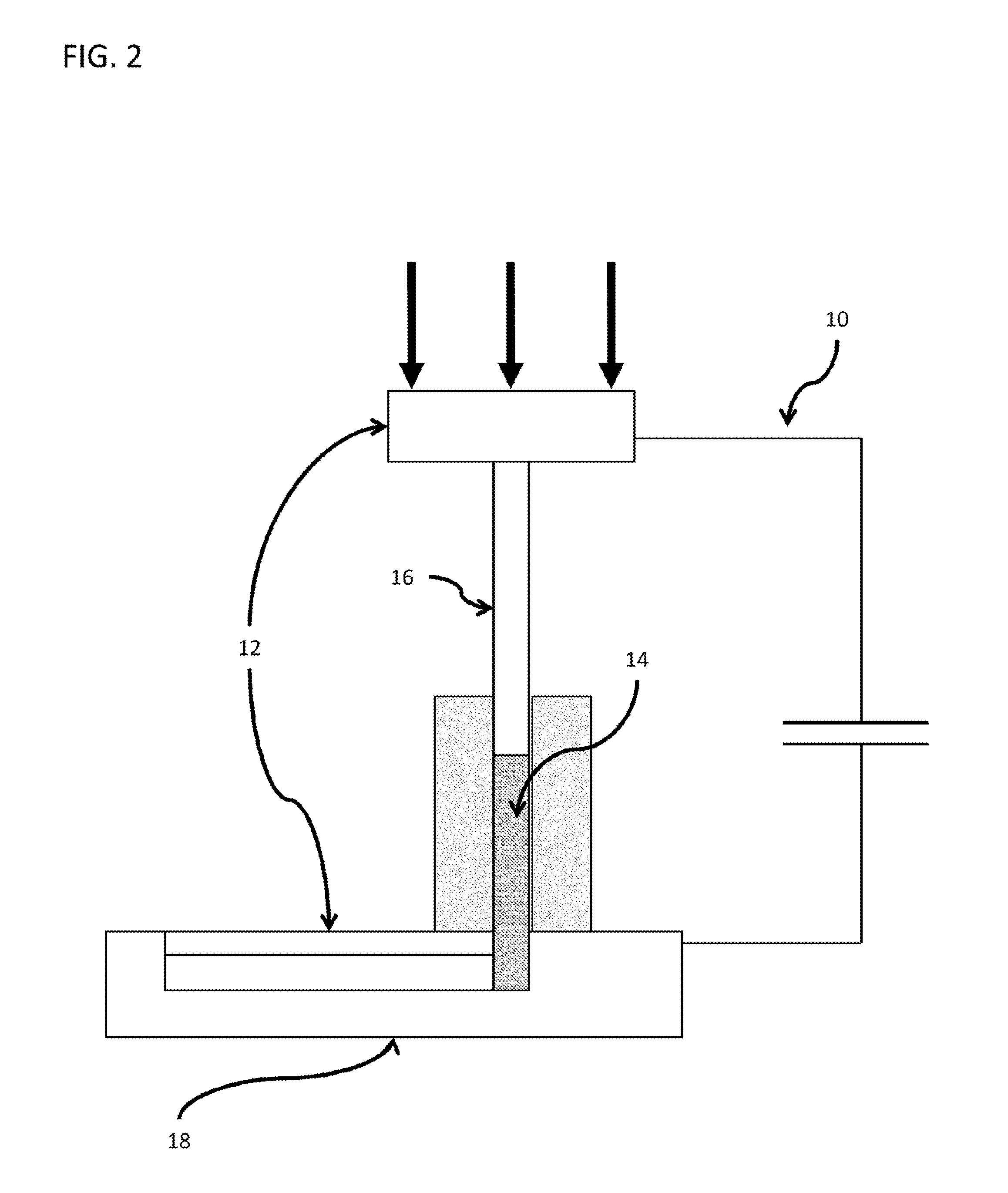

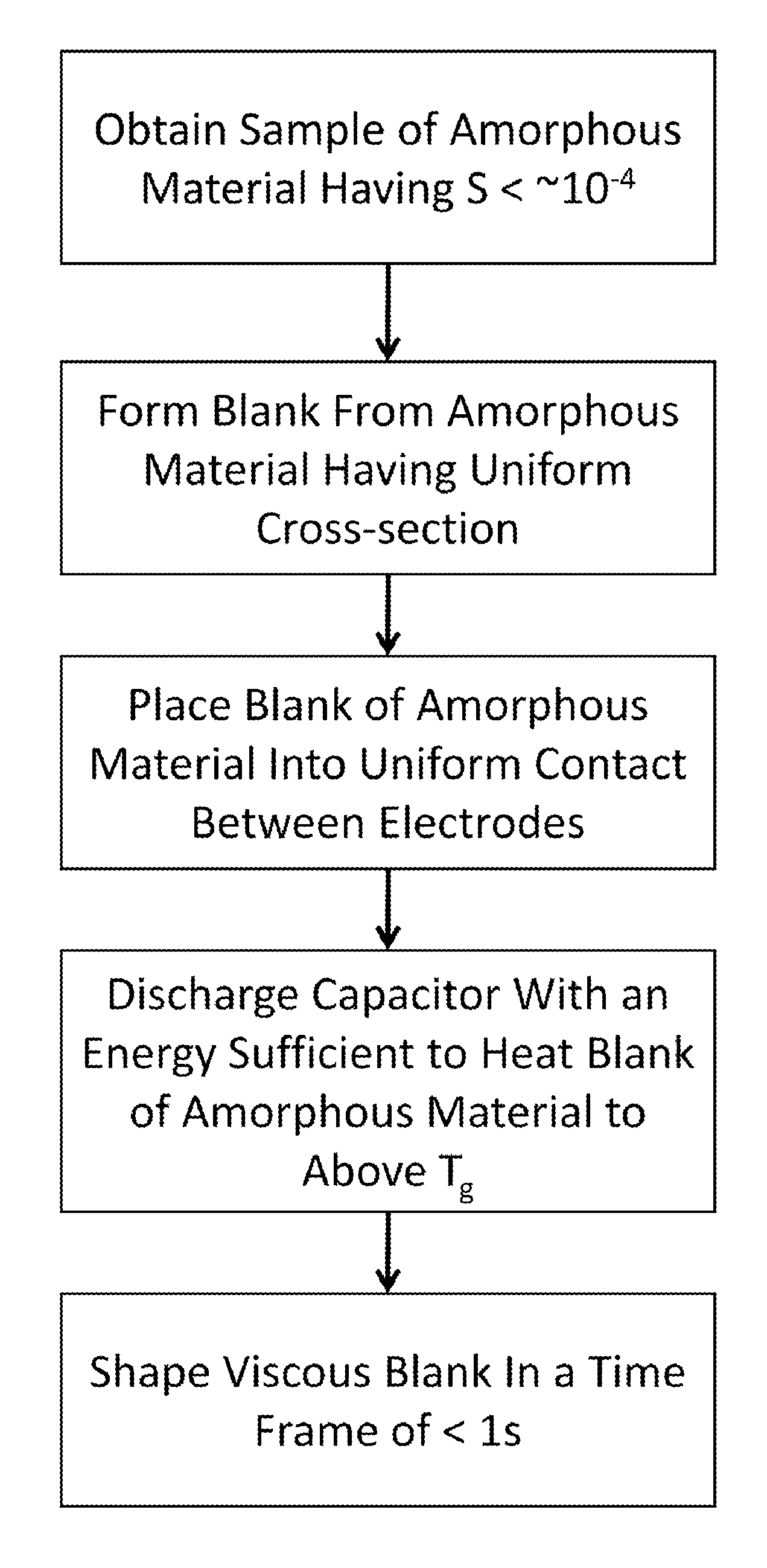

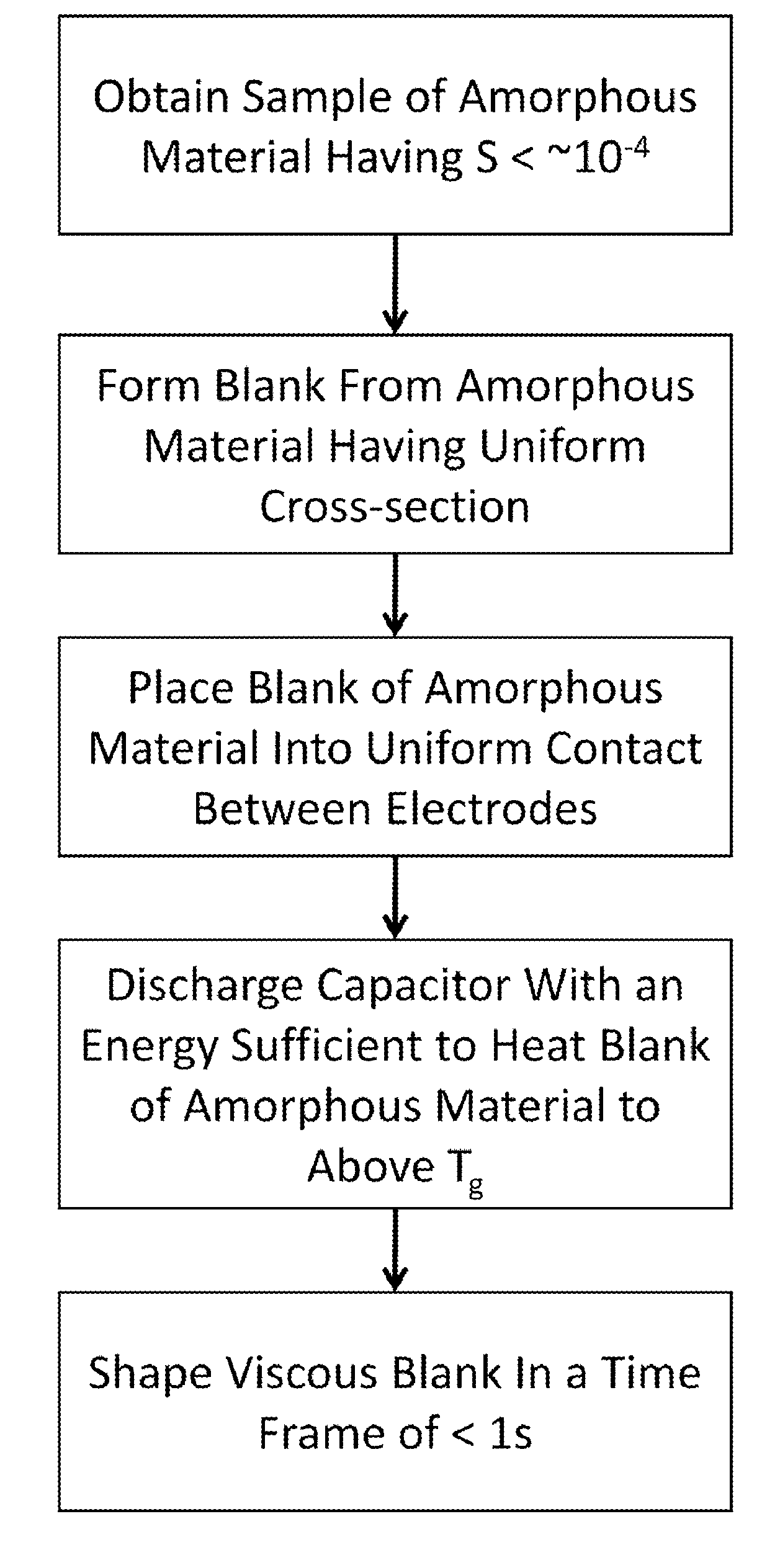

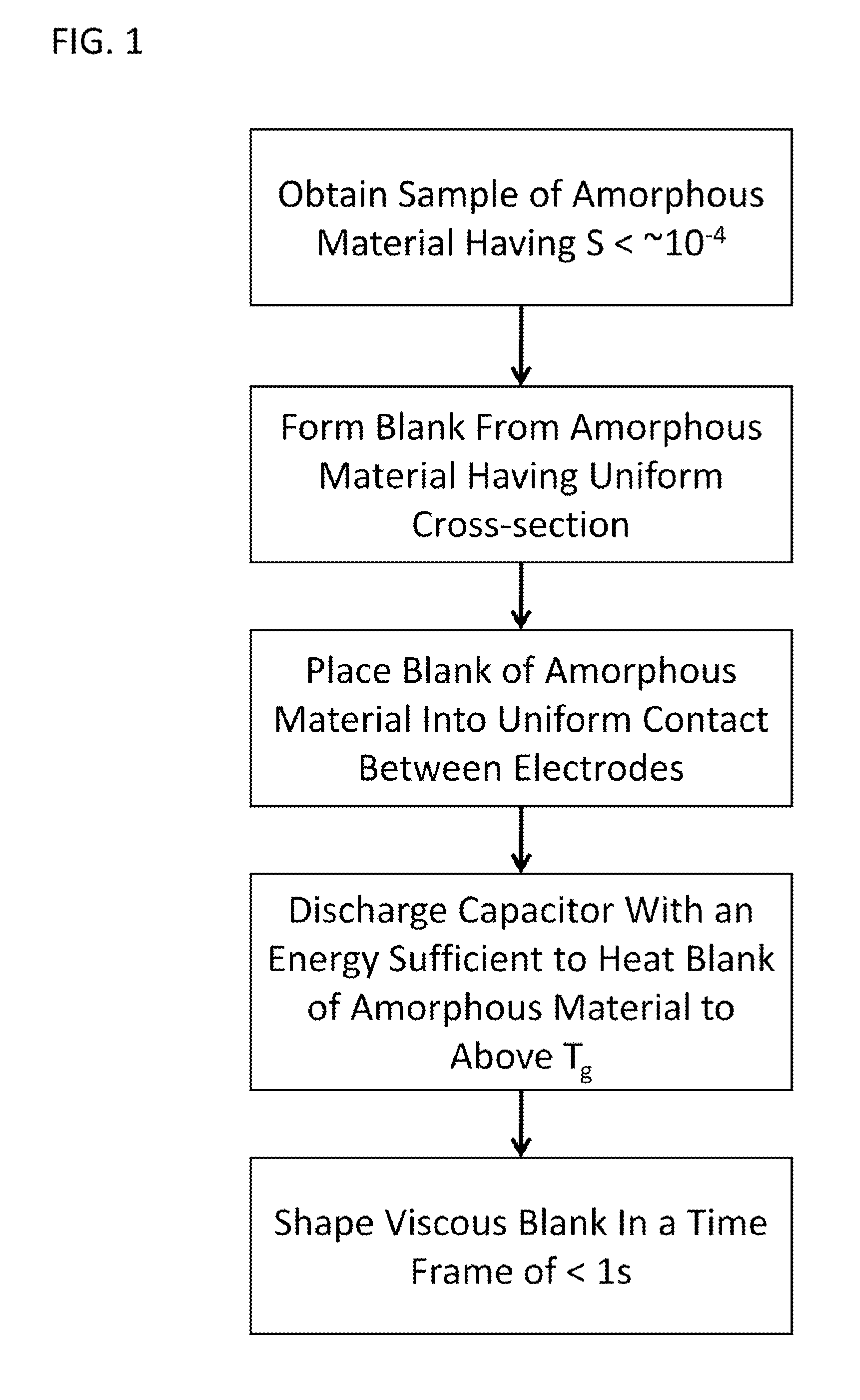

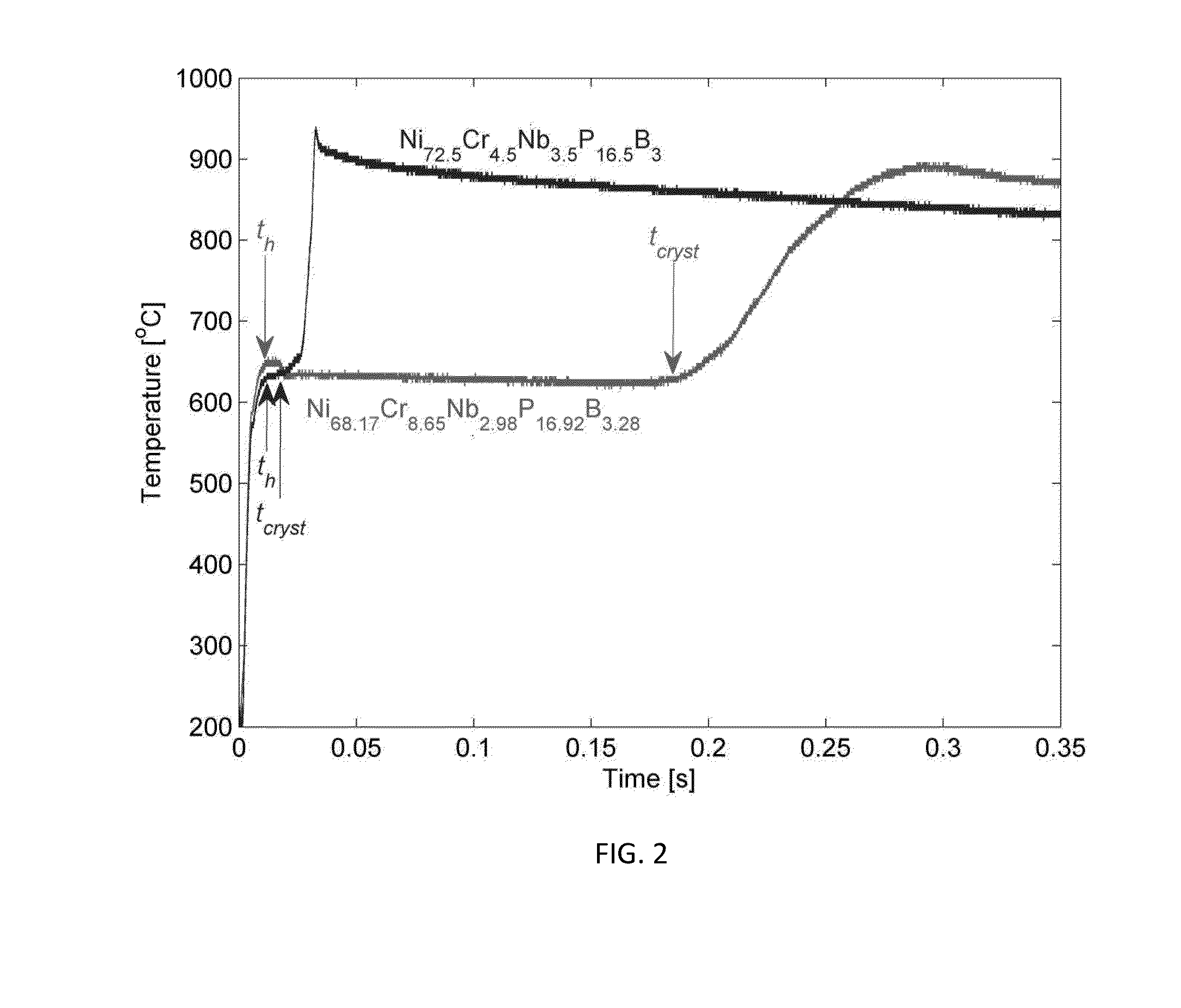

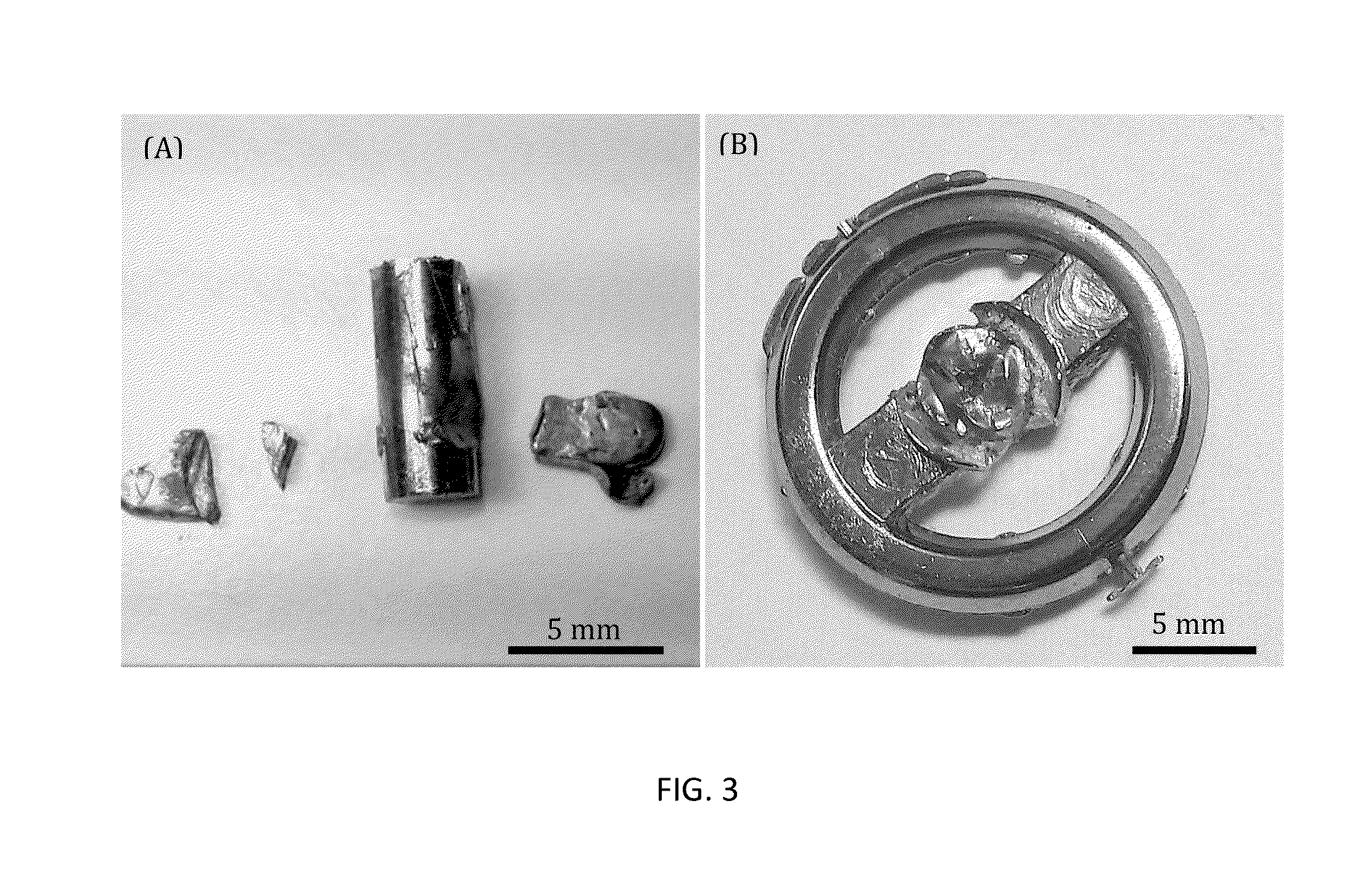

Forming of metallic glass by rapid capacitor discharge forging

ActiveUS20120132625A1High surface finishReduce coolingDielectric heatingShaping toolsVitrificationAlloy

A forging apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via forging in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

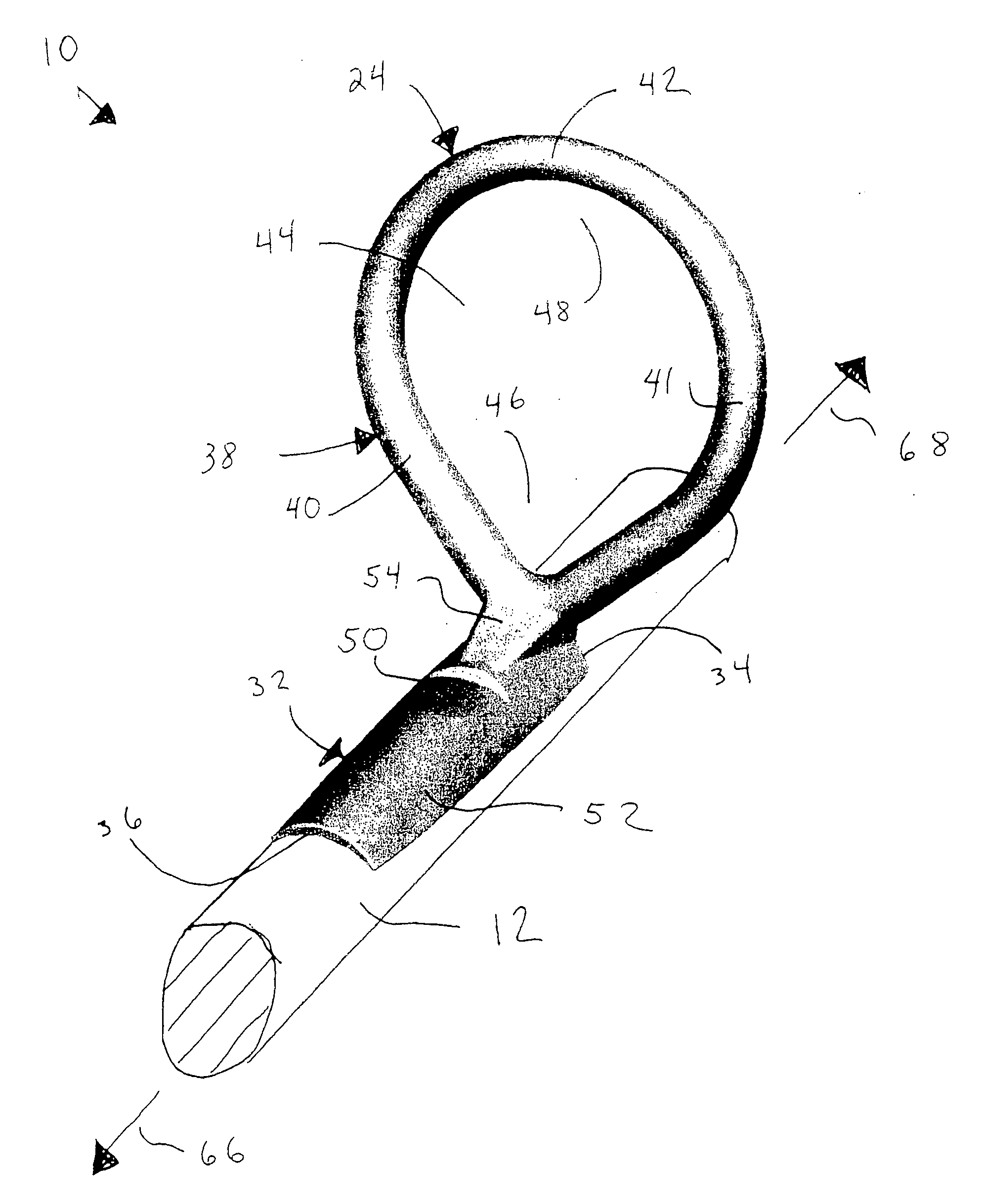

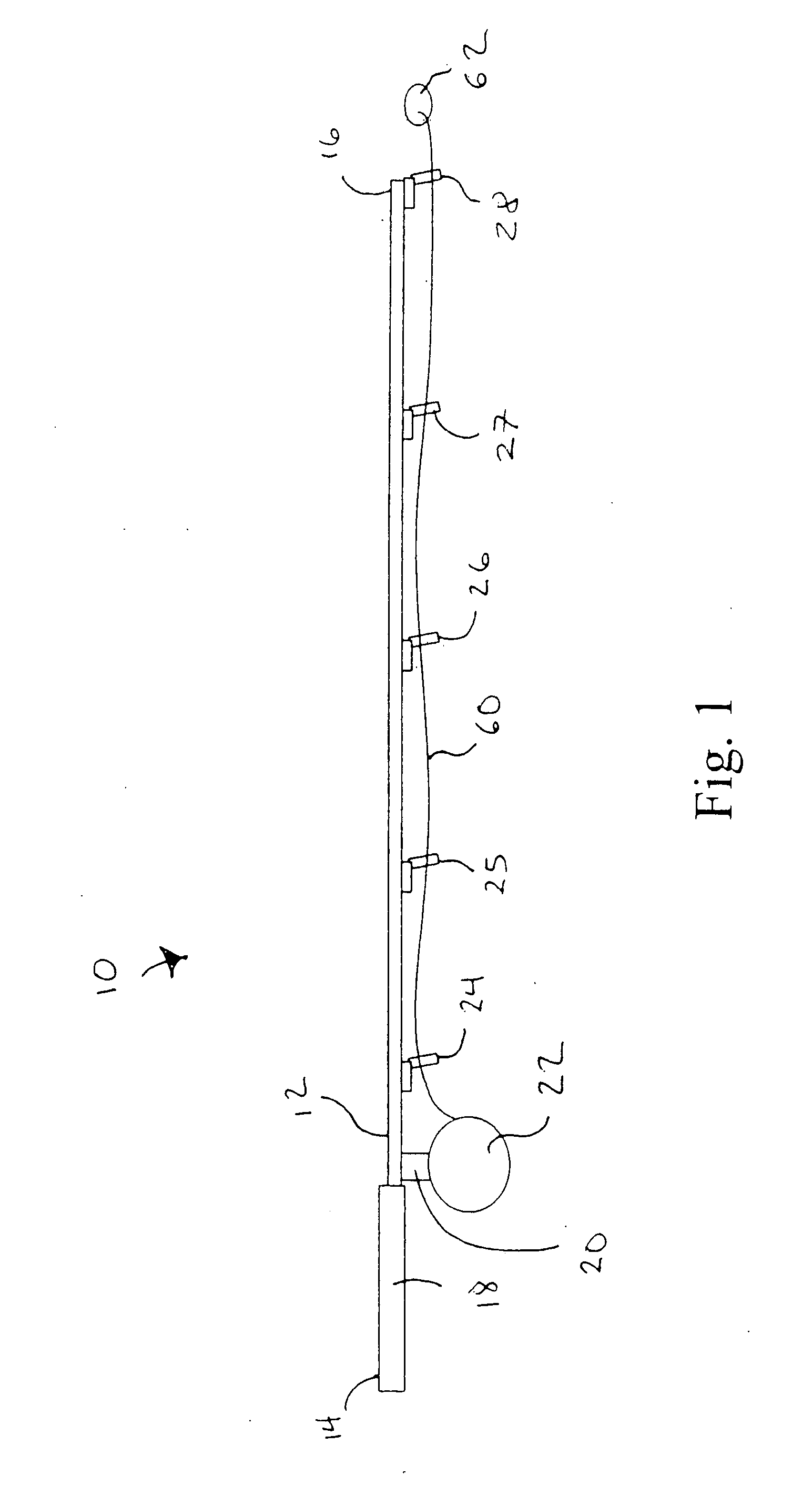

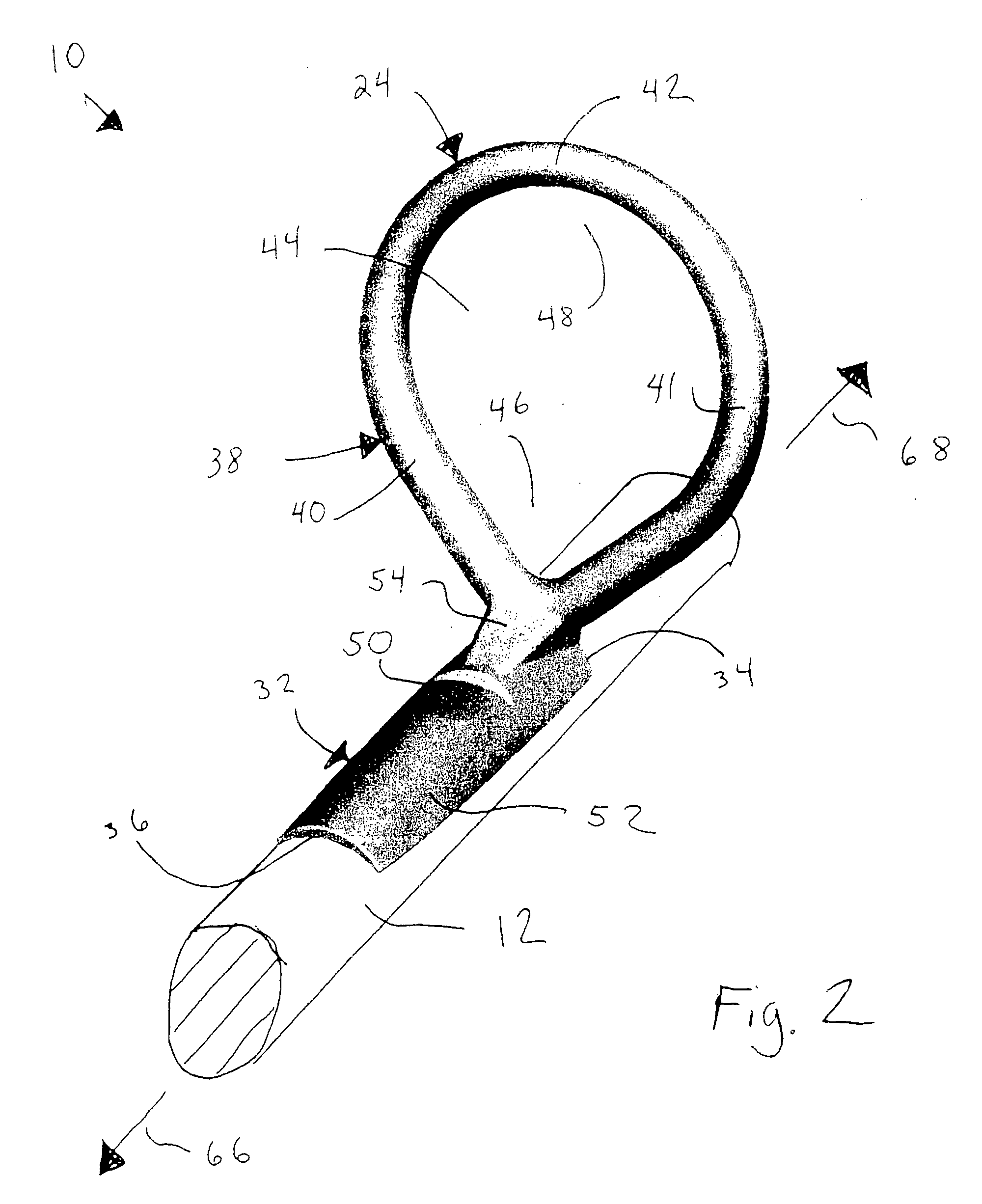

Line guides for fishing rods

Line guides for fishing rods made from one or more materials including an amorphous metallic alloy, sometimes referred to as a metallic glass. In preferred embodiments, the line guide has a one-piece structure and more preferably is formed substantially entirely from metallic glass. The present invention also relates to fishing rods incorporating such line guides.

Owner:ANDERSON TACKLE

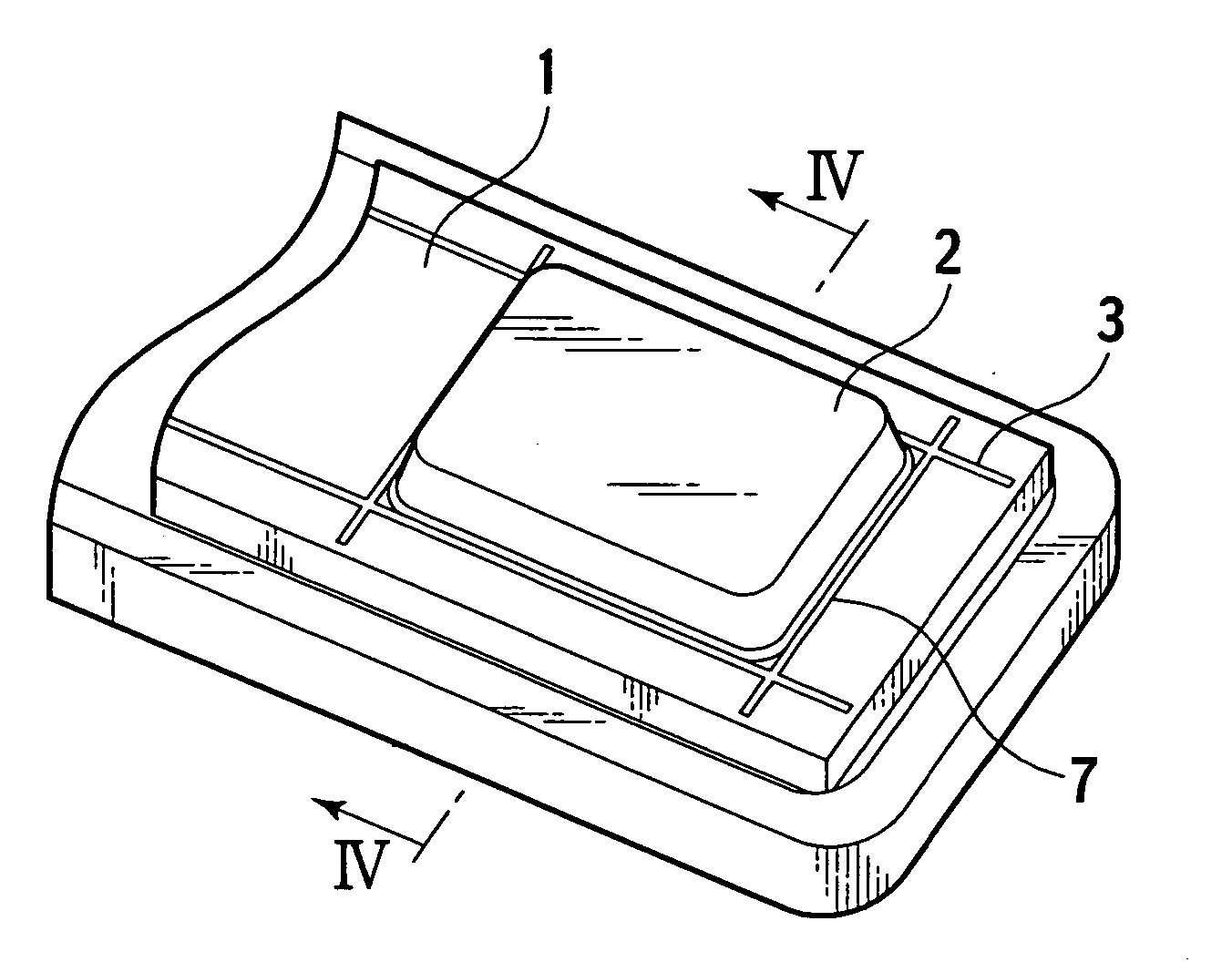

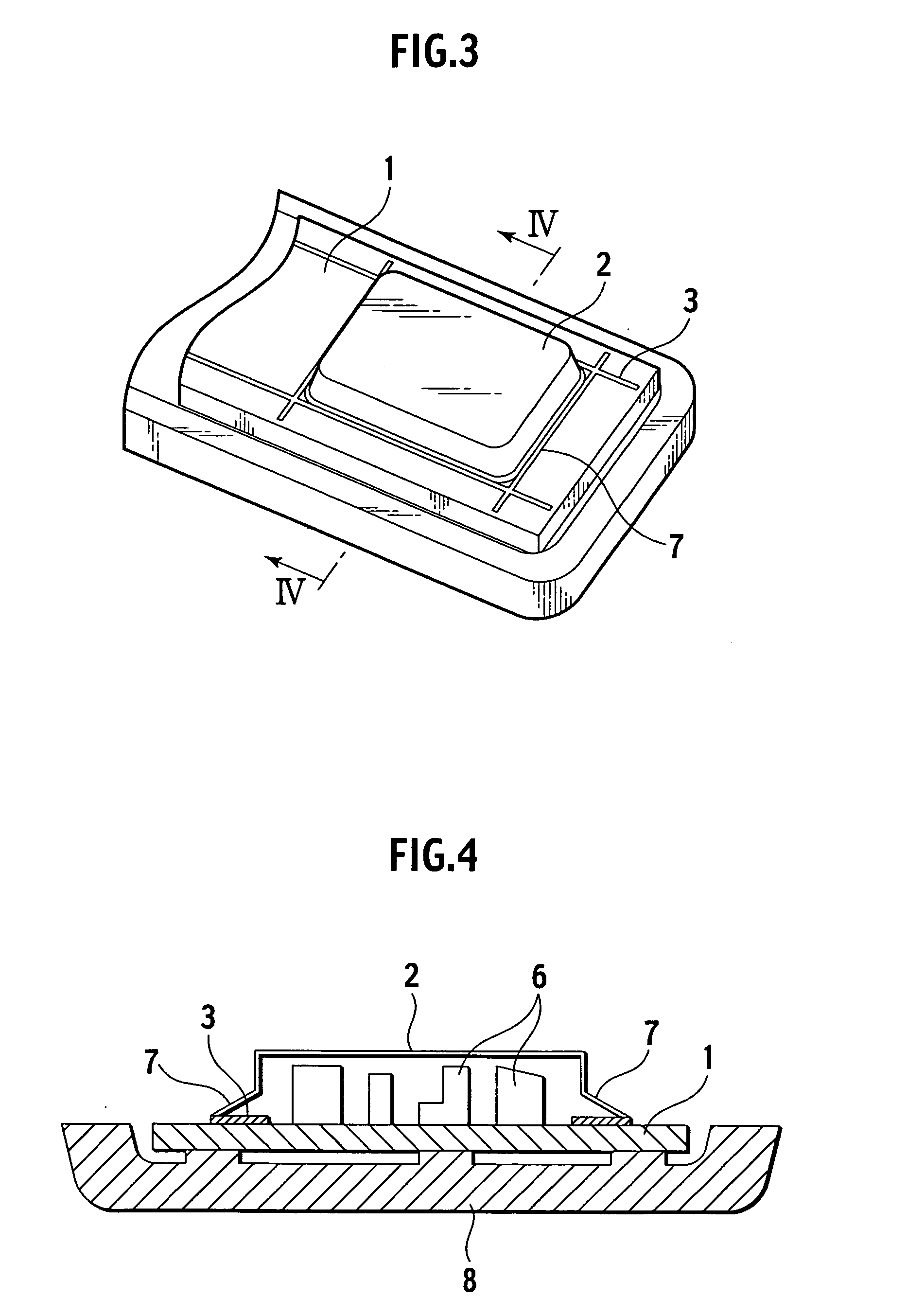

Electromagnetic wave shield case and a method for manufacturing electromagnetic wave shield case

InactiveUS20050162842A1Simple moldingReduce thicknessMagnetic materialsShielding efficiency measurementViscous flowHyper elastic

An objective of the present invention is to form a hyper-elastic flange integrally within a shield case body around a periphery thereof while decreasing an occupied area for grounding. The shield case 2 according to the present invention is disposed to cover electronic parts 6 on a circuit board 1, and which has a flange 7 formed integrally therewith so as to contact with a metallic ground line 3 on the circuit board 1. The flange 7 is elastically deformed to be grounded, thus a leakage of electromagnetic waves to the outside of the shield case 2 is prevented. The flange 7 is made of metallic glass. By forming the flange 7 from metallic glass, a displacement due to viscous flowing on the atomic level, which is different from a plastic deformation, can be utilized, and thus a high precision flange can be formed without a spring-back.

Owner:NGK INSULATORS LTD +1

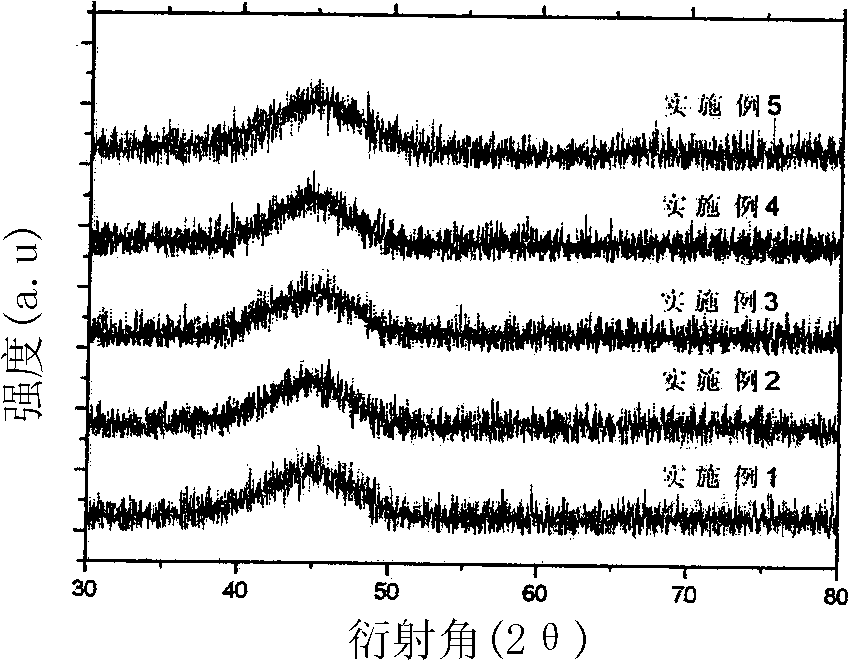

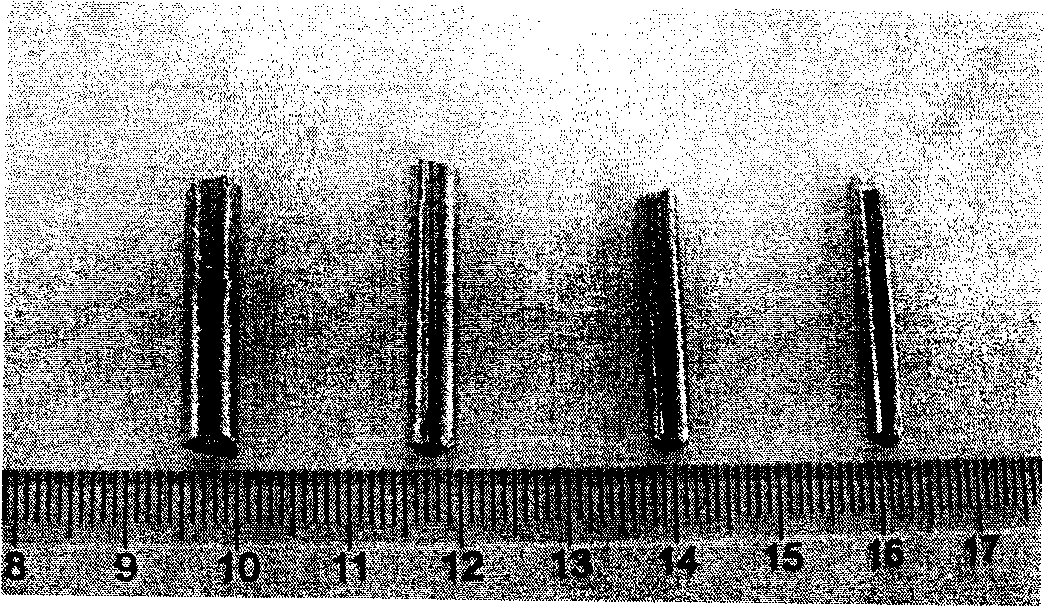

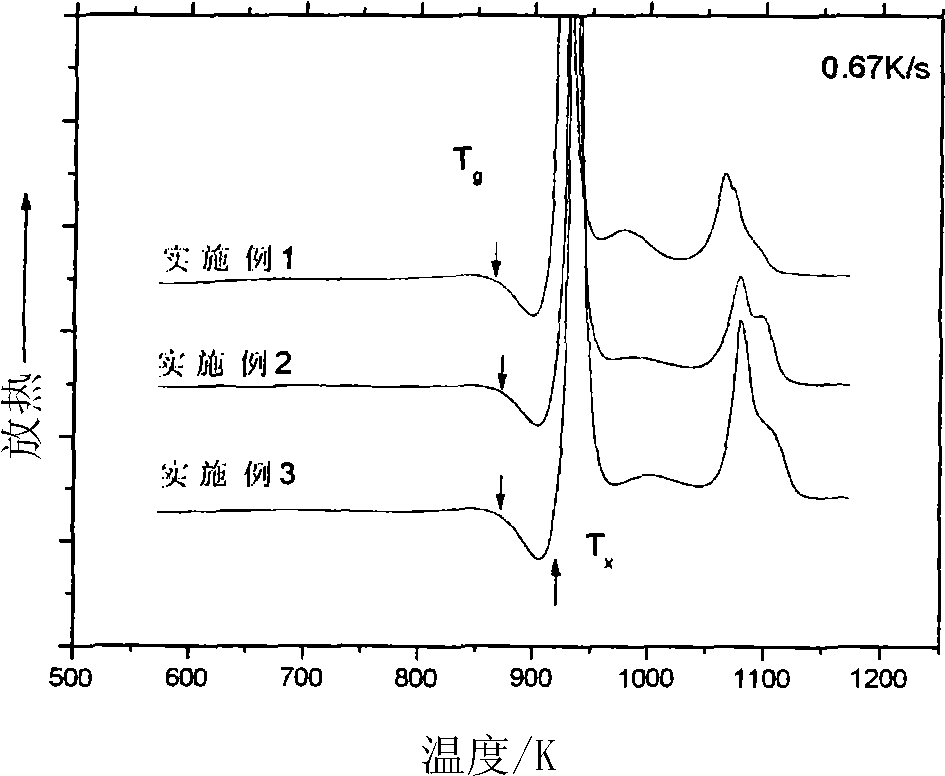

Cobalt-based bulk amorphous alloy and preparation method thereof

The invention relates to a cobalt-based bulk amorphous alloy and a preparation method thereof. The alloy comprises the following components by atomic percentage: 33 to 55 percent of Co, 13 to 34 percent of Fe, 18 to 26 percent of B, 2 to 7 percent of Si, and 3 to 8 percent of Nb. Cobalt-based bulk metallic glass is proportioned according to the atomic mol ratio as required by the components, then the glass is forged for a plurality of times in a vacuum arc furnace, and the bulk amorphous alloy is prepared by casting in a vacuum copper mold. The bulk amorphous alloy has strong amorphous forming ability and excellent soft magnetic property, the size of the prepared amorphous material is not less than 3 millimeters at each dimensionality, the maximum size can reach 5 millimeters, the coercive force is between 1.17 and 2.35 A / m, and the maximum effective magnetic conductivity can reach 36,000 (1KHz 1A / m). The cobalt-based bulk amorphous alloy can be applied to magnetic devices in the fields of information, communication and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

Forming of metallic glass by rapid capacitor discharge forging

ActiveUS8613814B2Avoid thermal transport and development of thermalHeating evenlyDielectric heatingShaping toolsAlloyGlass transition

A forging apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via forging in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

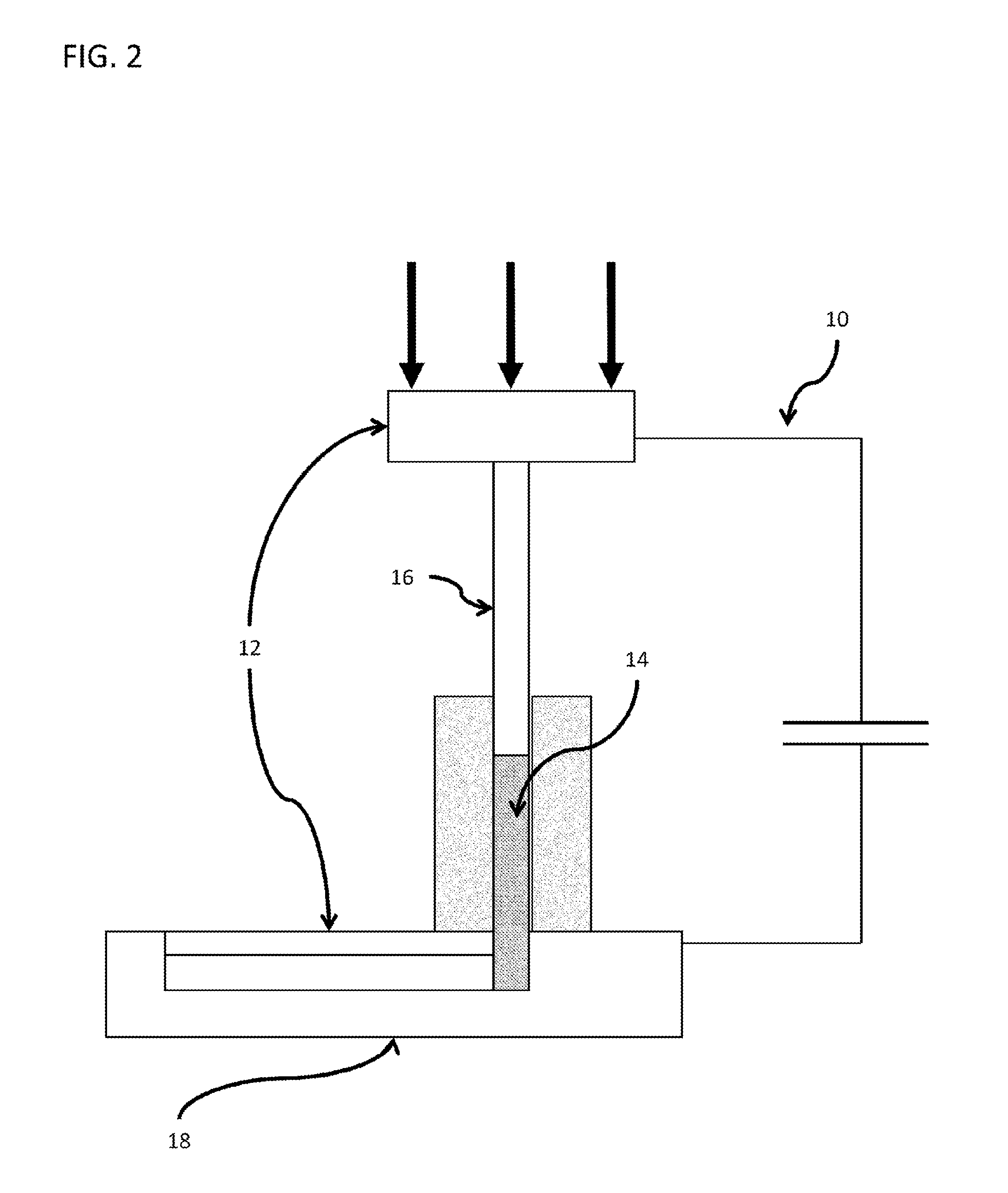

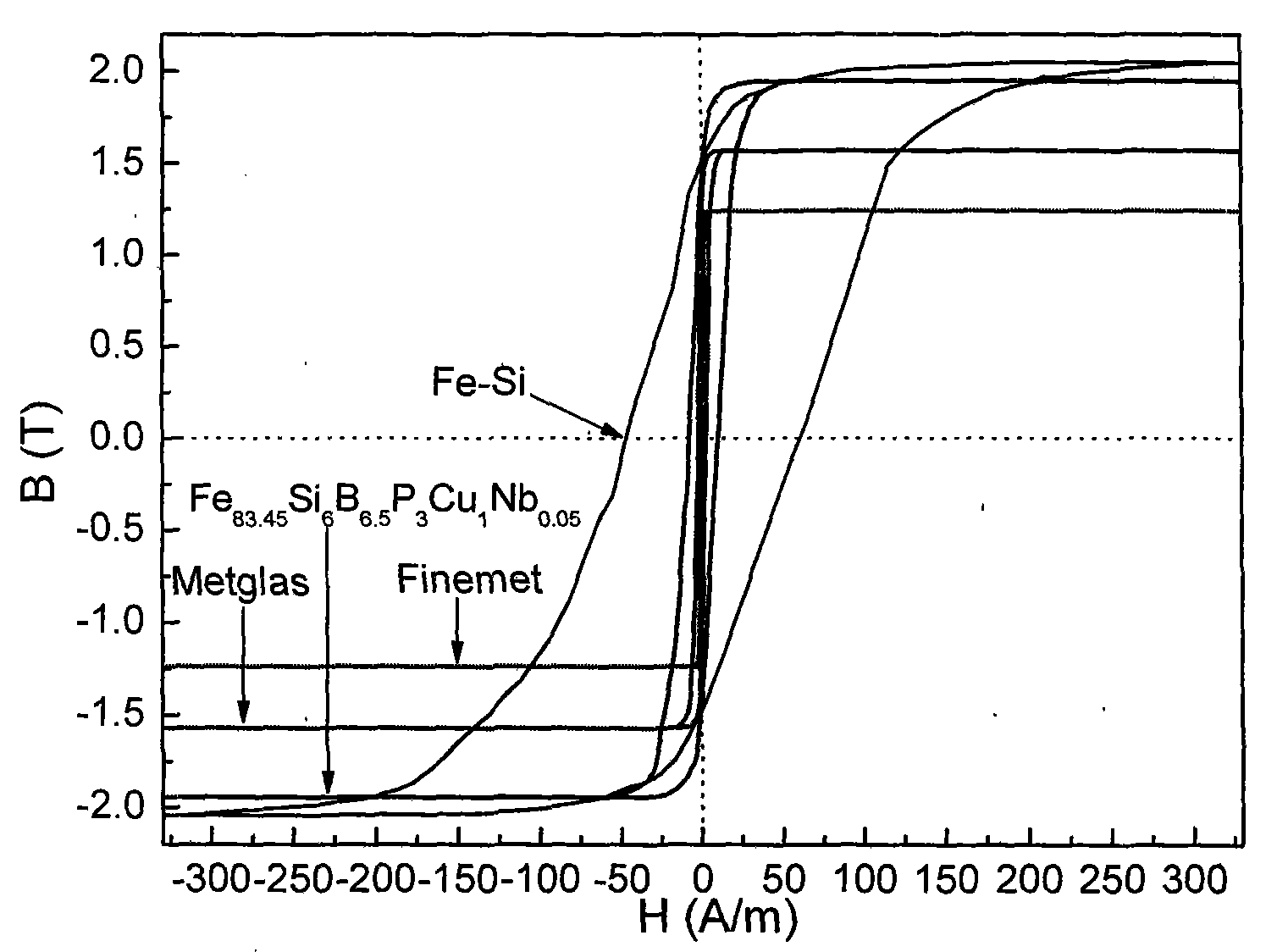

Iron-based nanocrystalline soft magnetic alloy with low cost and high soft magnetic property

InactiveCN101629265AImprove performanceThe ingredients are designed to be simpleMagnetic materialsChemical compositionTransformer

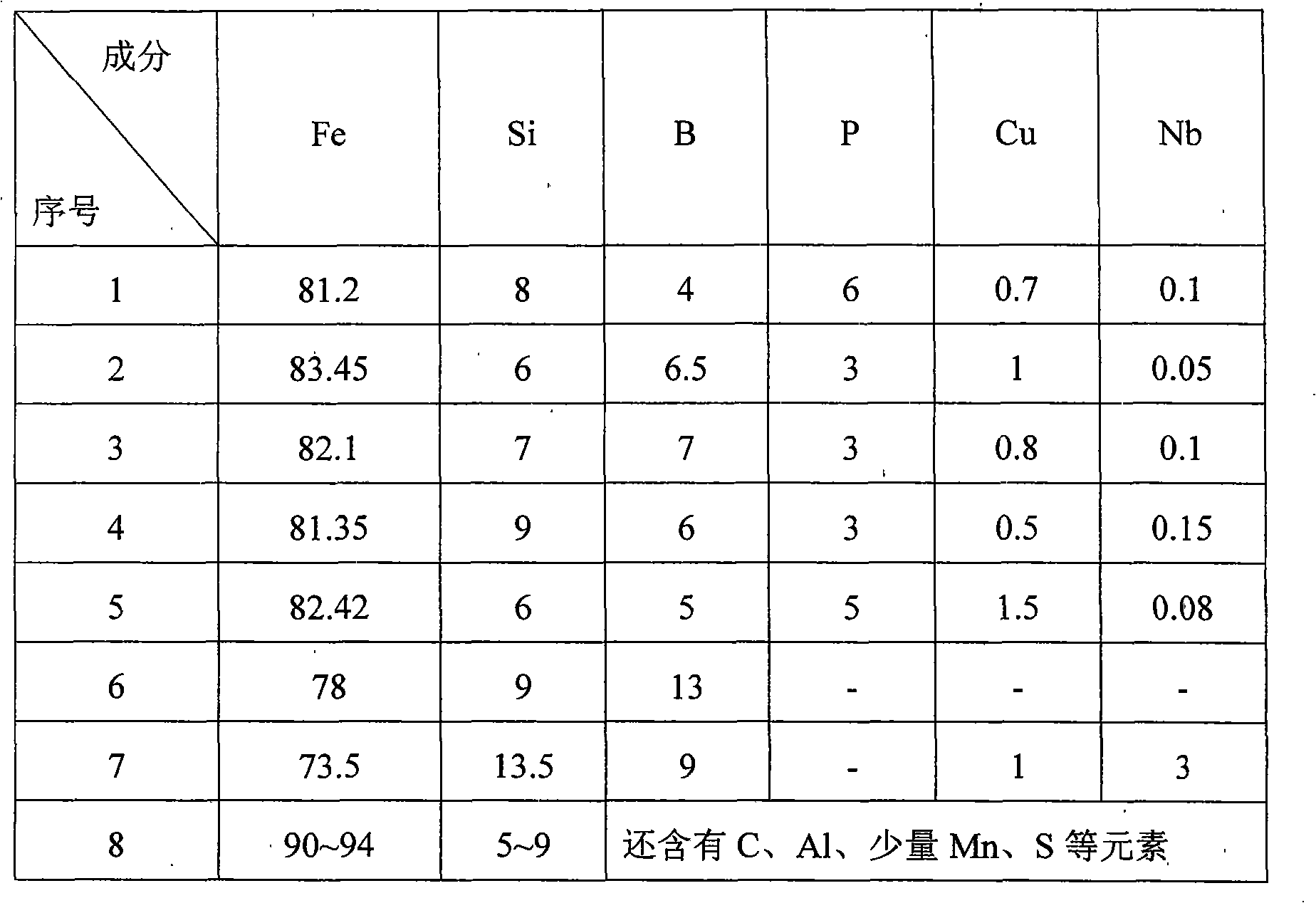

The invention belongs to the field of preparing a soft magnetic alloy in functional materials, in particular relates to a novel iron-based nanocrystalline soft magnetic alloy material with excellent comprehensive performance, such as low cost, high saturation magnetic induction intensity, low loss, and the like. The novel iron-based nanocrystalline soft magnetic alloy material comprises the following chemical constituents by atomic percentage: 6-9 Si, 4-7 B, 3-6 P, 0.5-1.5 Cu, 0.05-0.15 Nb and the balance of Fe. Compared with traditional iron-based amorphous or nanocrystalline soft magnetic alloys, such as Metglas, Finemet, Nanoperm and the like, the iron-based nanocrystalline soft magnetic alloy greatly decreases the consumption of the noble element Nb, has the advantages of simple constituent design, low cost and excellent comprehensive performance of the materials by substituting low-price P for noble B, can substitute the prior silicon-steel sheets and iron-based amorphous or nanocrystalline soft magnetic alloys and can be widely applied to the fields, such as power transformers, mutual inductors, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Metal glass composite material with high-oxygen content and preparation method thereof

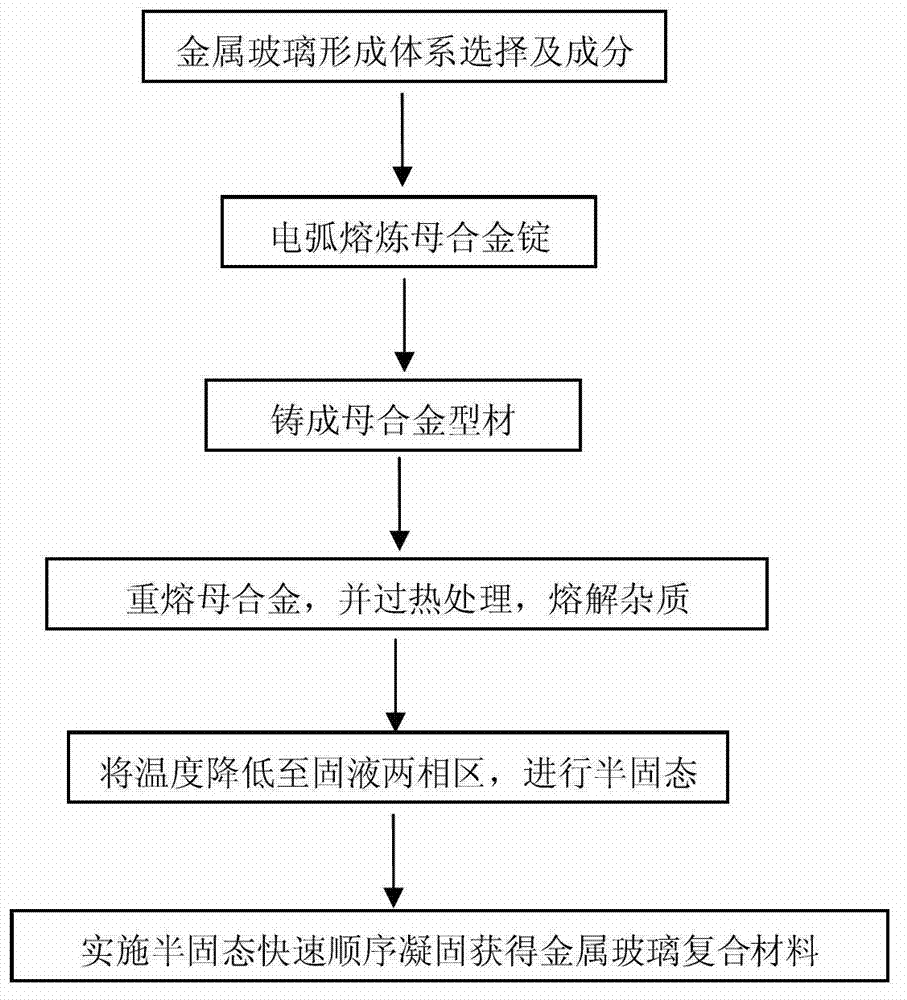

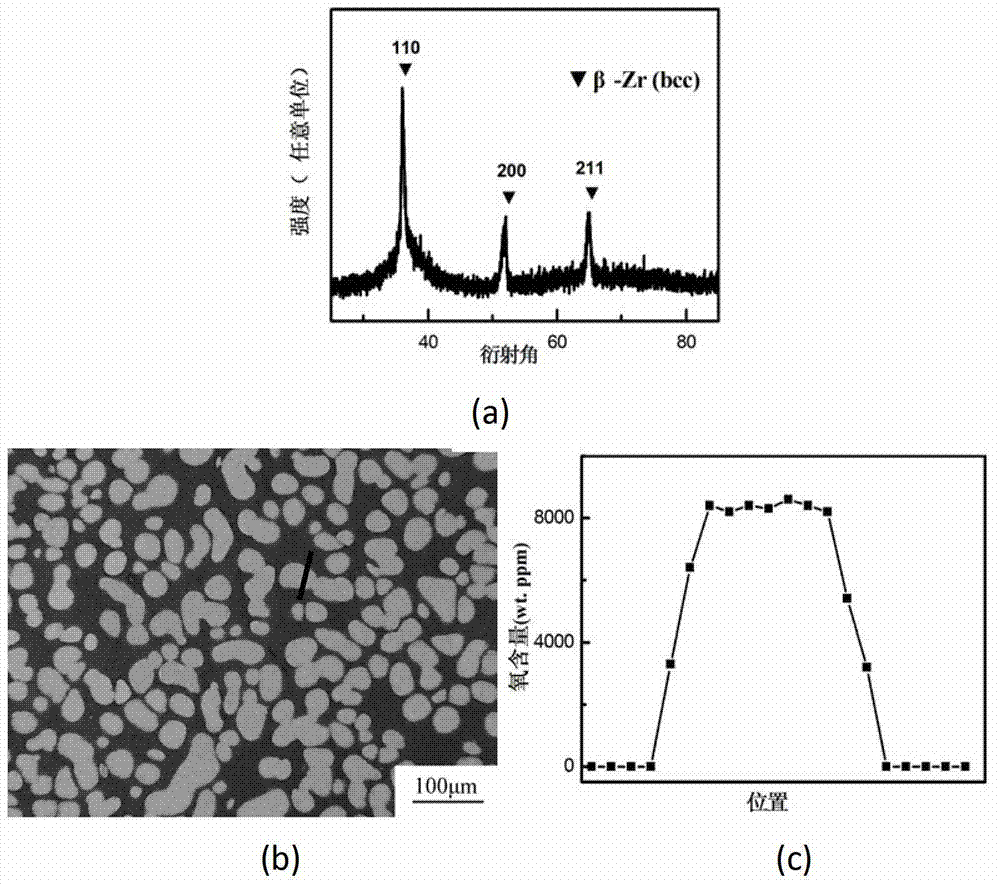

The invention discloses a metal glass composite material with high-oxygen content and a preparation method thereof. The expression of the atomic ratio of the material is Zr[a]Ti[b]M[c]Cu[d]Ni[e]Be[f]O[g], wherein M is one of niobium (Nb), vanadium (V) or hydrogen fluoride (Hf), a is larger than or equal to 10 and smaller than or equal to 70, b is larger than or equal to 10 and smaller than or equal to 70, c is larger than or equal to 4 and smaller than or equal to 15, d is larger than or equal to 2 and smaller than or equal to 12, e is larger than or equal to 0 and smaller than or equal to 10, f is larger than or equal to 5 and smaller than or equal to 15, g is larger than 0 and smaller than or equal to 15, and a plus b plus c plus d plus e plus f plus g equals 100. The preparation method includes the steps of smelting master alloy ingots, casting master alloy profile, placing the master alloy profile into a crucible to heat and smelt, carrying out overheating treatment melting impurities, lowering temperatures to solid and liquid two-phase region, carrying out semi-solid treatment so that oxygen elements segregate and are solute in separated beta- zirconium (Zr) or beta- titanium (Ti) in a solid mode, controlling the shape and size of the separated solid and liquid, carrying out semi-solid progressive solidification to form the large-size metal glass composite material of high strength and high toughness. The large size of 30 millimeters metal glass composite material of the high strength and the high toughness with is prepared, and is remarkable in processing solidification property and good in tensile strength and plasticity.

Owner:NANJING UNIV OF SCI & TECH

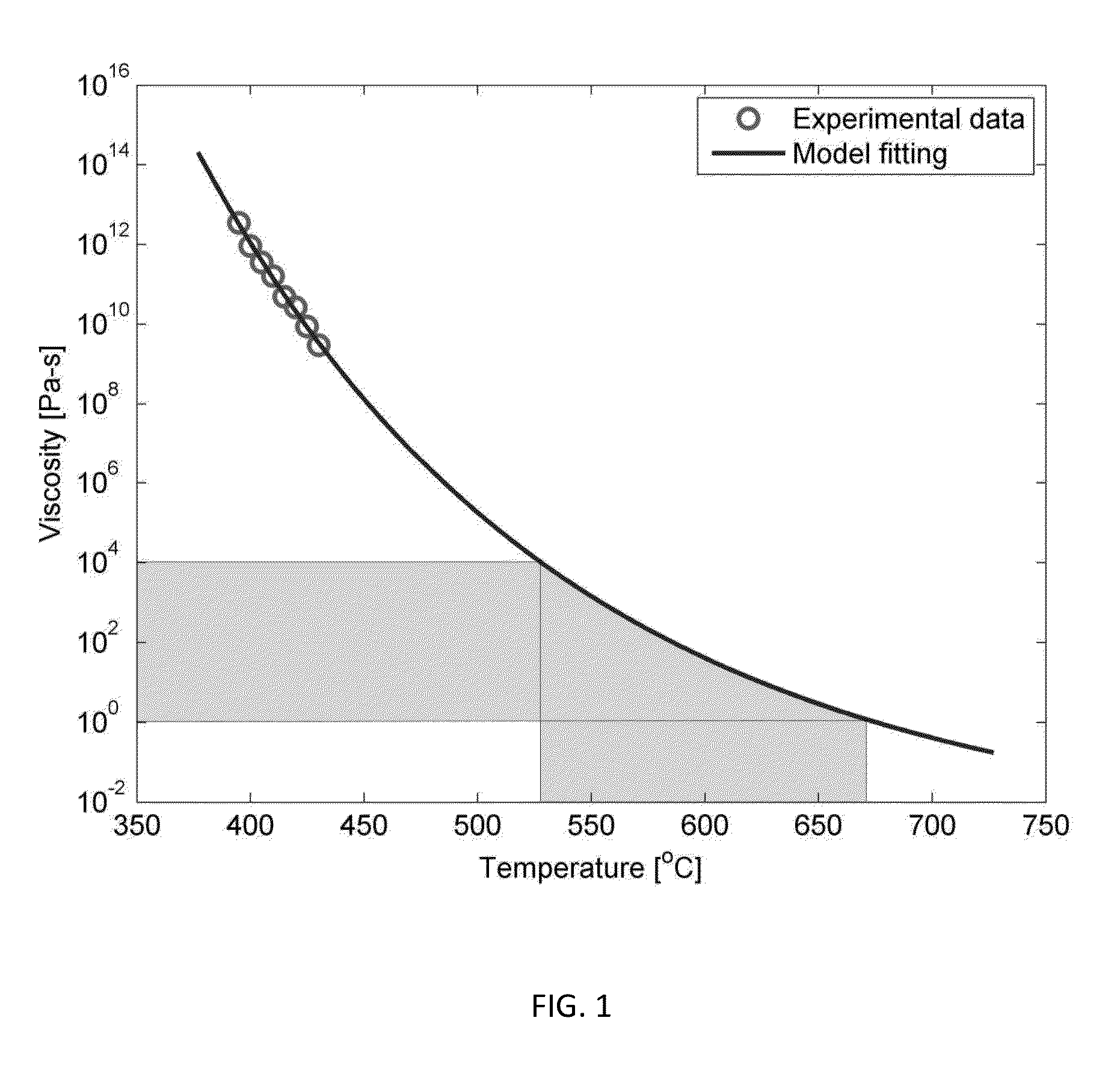

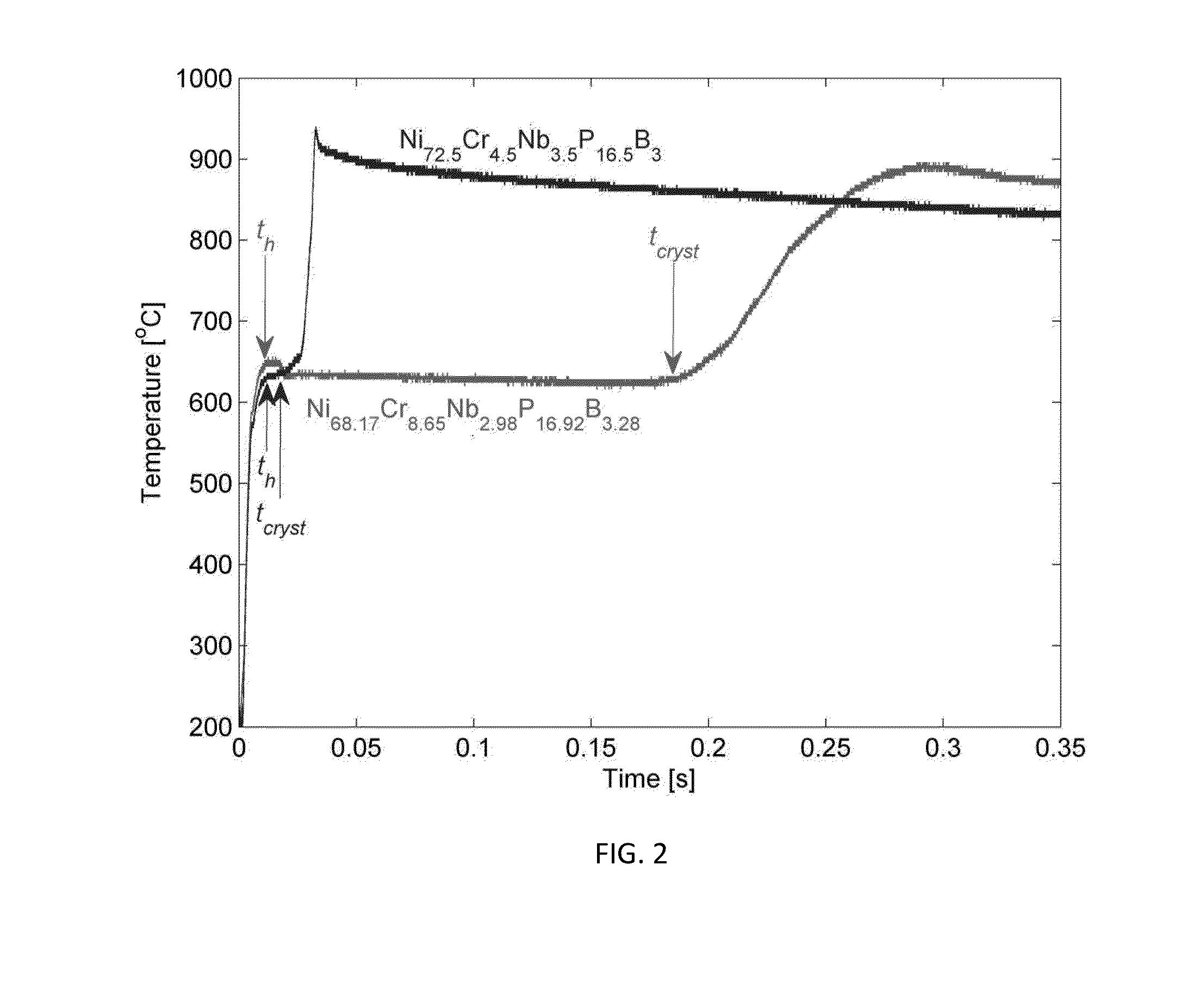

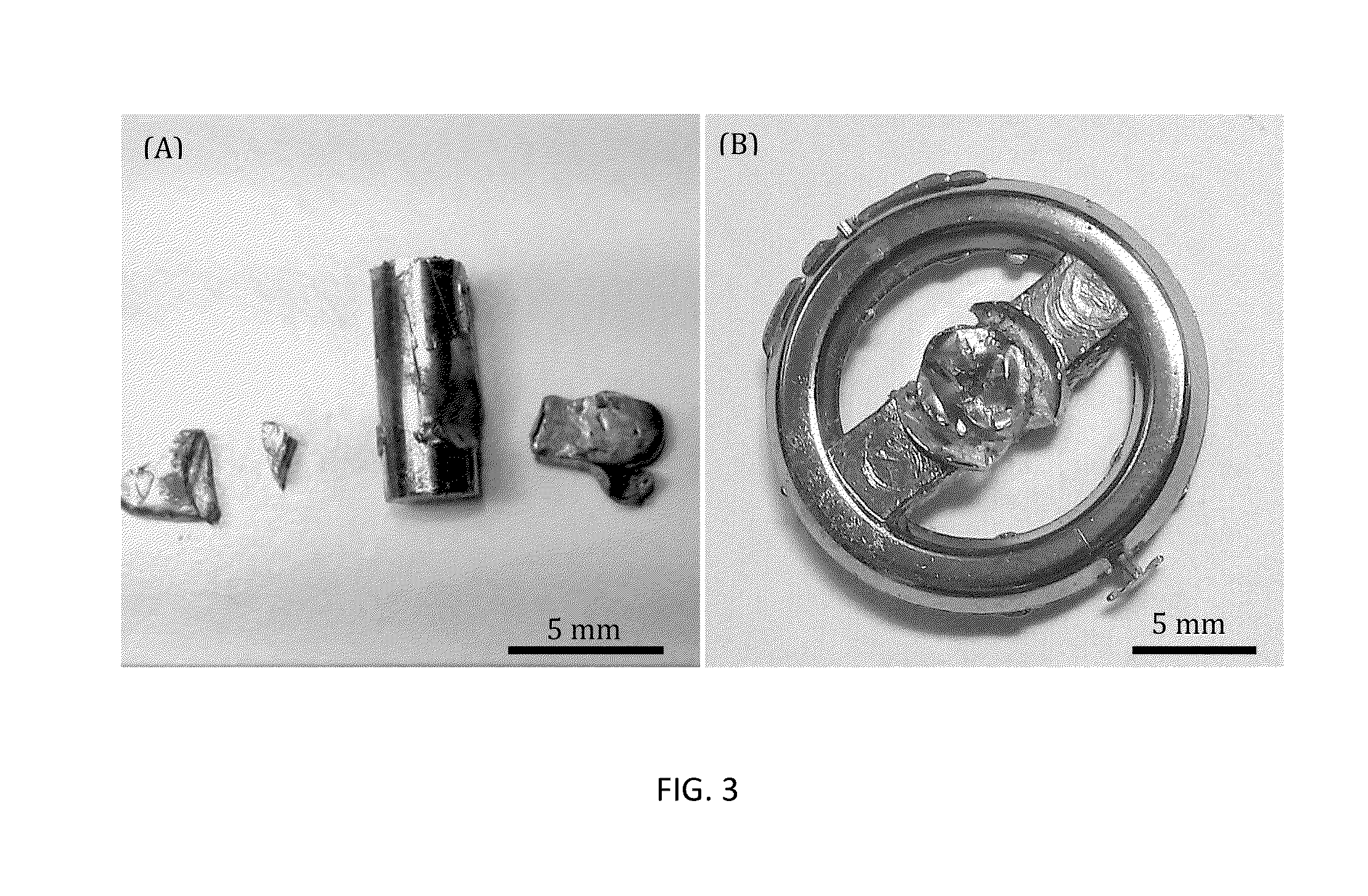

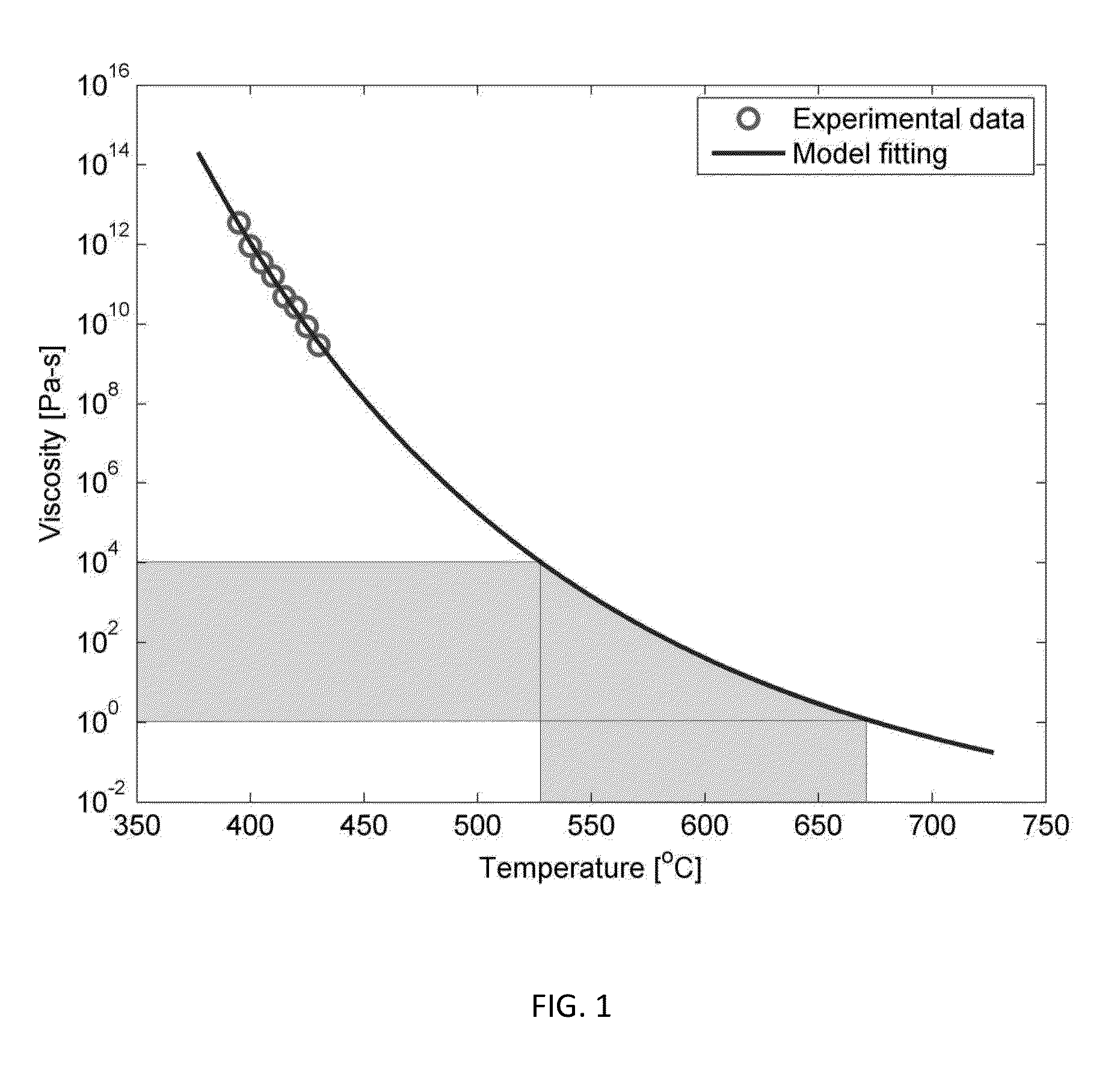

Methods for shaping high aspect ratio articles from metallic glass alloys using rapid capacitive discharge and metallic glass feedstock for use in such methods

The disclosure is directed to a method of forming high-aspect-ratio metallic glass articles that are substantially free of defects and cosmetic flaws by means of rapid capacitive discharge forming. Metallic glass alloys that are stable against crystallization for at least 100 ms at temperatures where the viscosity is in the range of 100 to 104 Pa-s are considered as suitable for forming such high-aspect-ratio articles.

Owner:APPLE INC

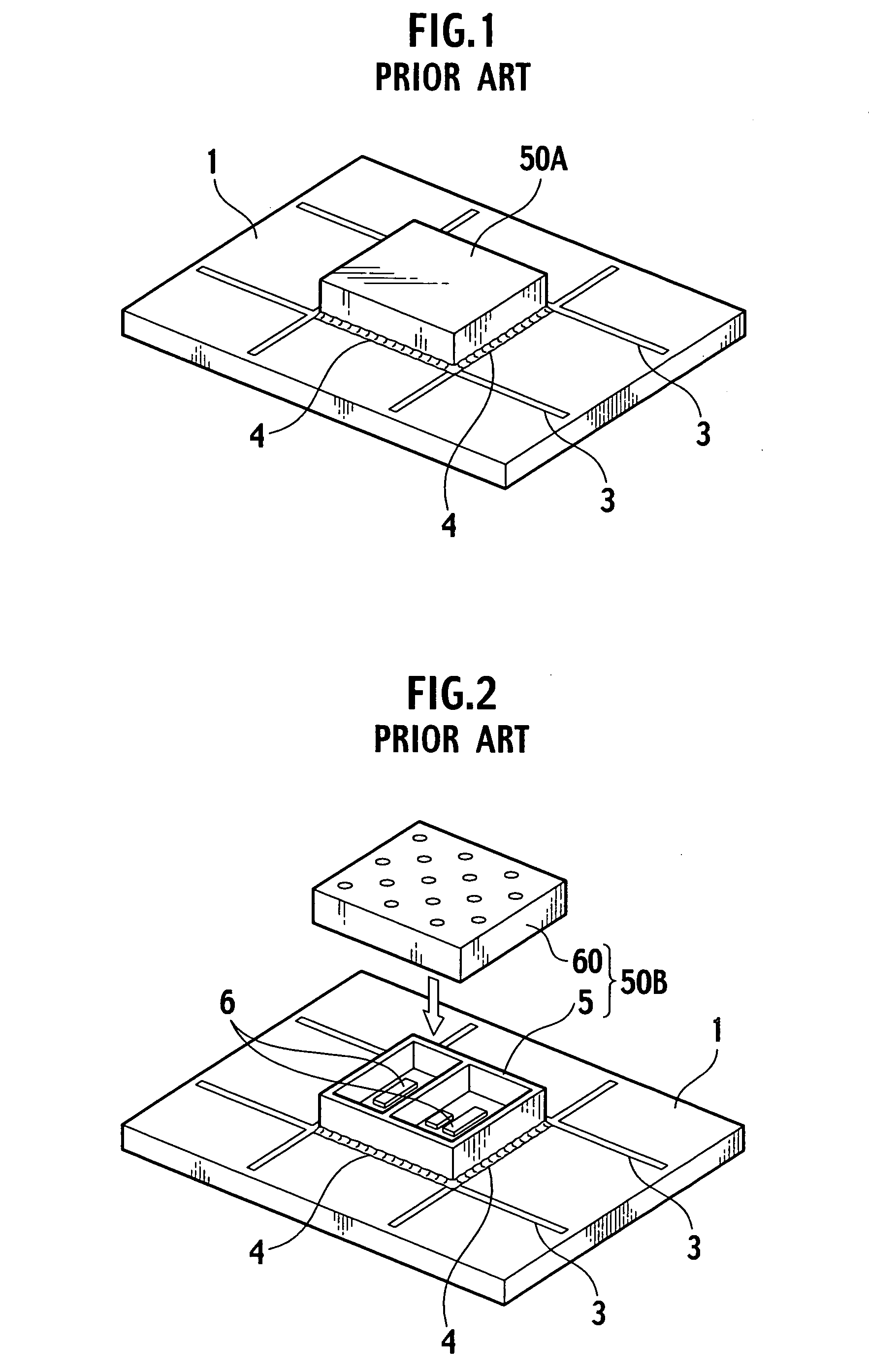

Magnetic core for high frequency and inductive component using same

ActiveCN1774773AInorganic material magnetismTransformers/inductances magnetic coresMass ratioRare earth

A high-frequency magnetic core, which is a molded body obtained by molding a mixture of soft magnetic metallic glass powder and a binder in a mass ratio of 10% or less. The powder has an alloy composition represented by the following general formula: (Fe1-a-bNiaCob)100-x-y-z(M1-pM'p)xTyBz (wherein 0≤a≤0.30, 0≤b≤0.50, 0 ≤a+b≤0.50, 0≤p≤0.5, 1at%≤x≤5at%, 1at%≤y≤12at%, 12at%≤z≤25at%, 22≤(x+y+ z)≤32, M is at least one selected from Zr, Nb, Ta, Hf, Mo, Ti, V, Cr, and W, M' is selected from Zn, Sn and R (wherein R is selected from including Y is at least one of at least one element in rare earth metals), and T is at least one selected from Al, Si, C and P). An inductive element includes a high-frequency magnetic core and at least one coil wound around the high-frequency magnetic core.

Owner:井上 明久

Forming of metallic glass by rapid capacitor discharge forging

ActiveUS20140102163A1Avoid thermal transport and development of thermalHeating evenlyMetal-working apparatusVitrificationAlloy

A forging apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via forging in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

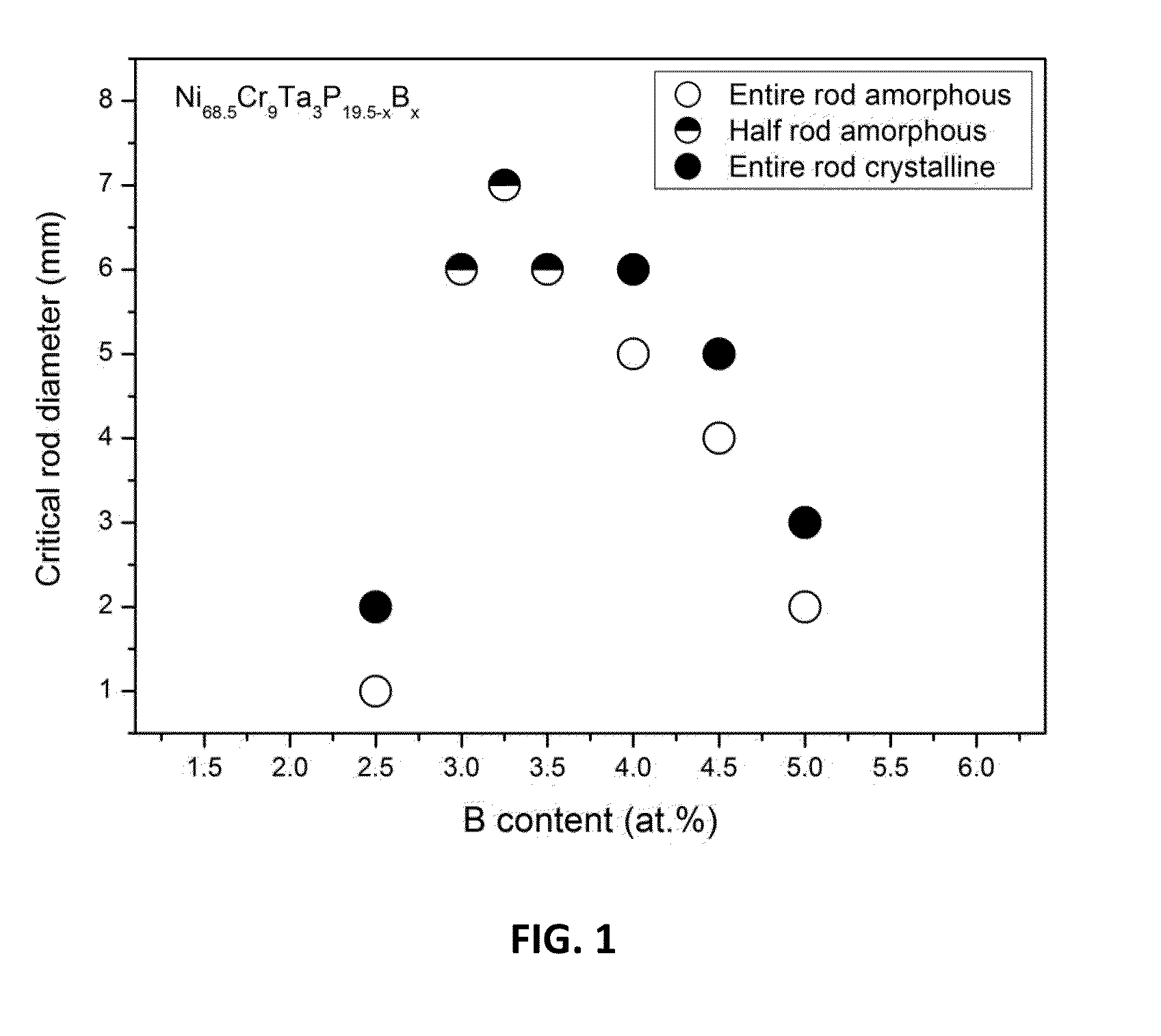

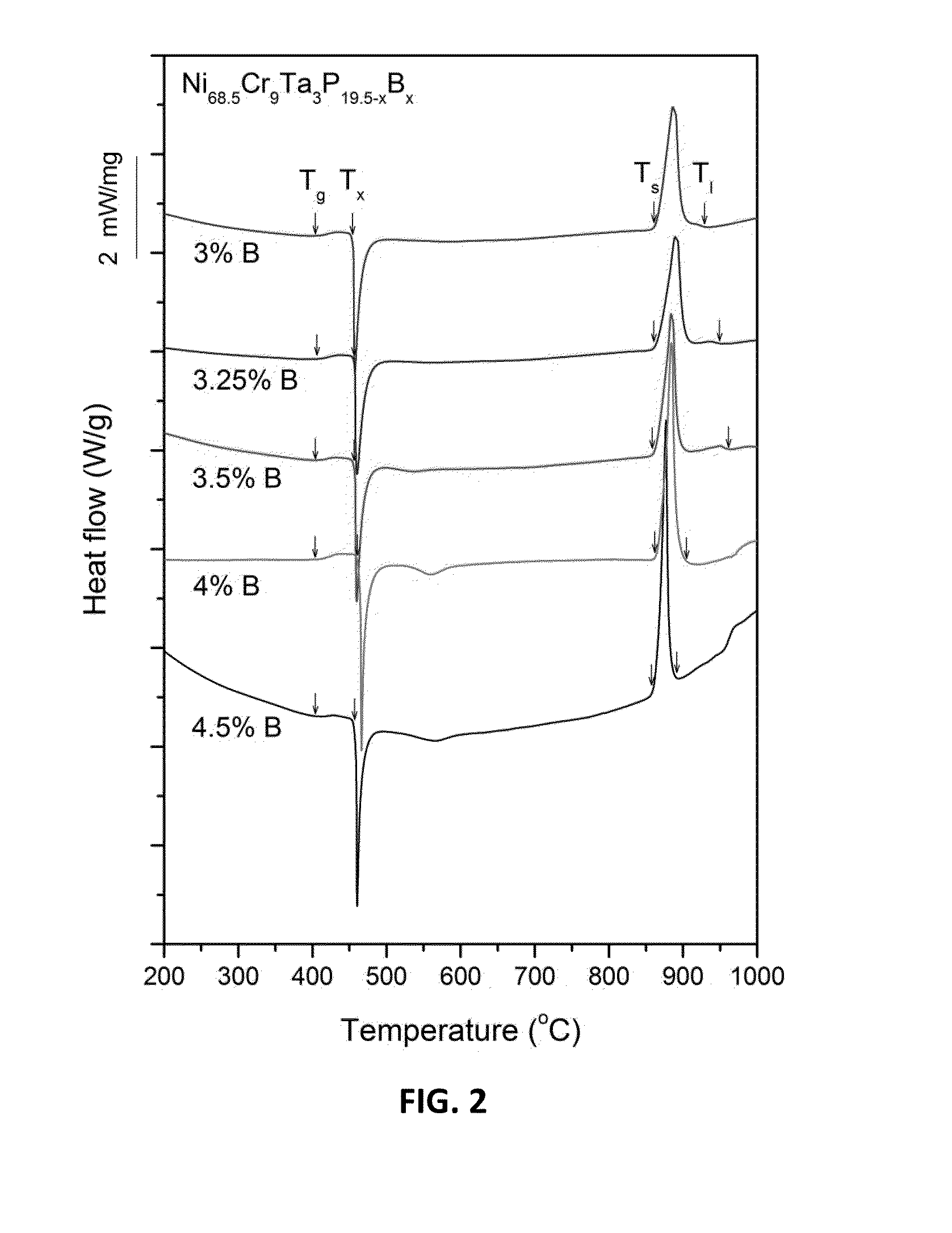

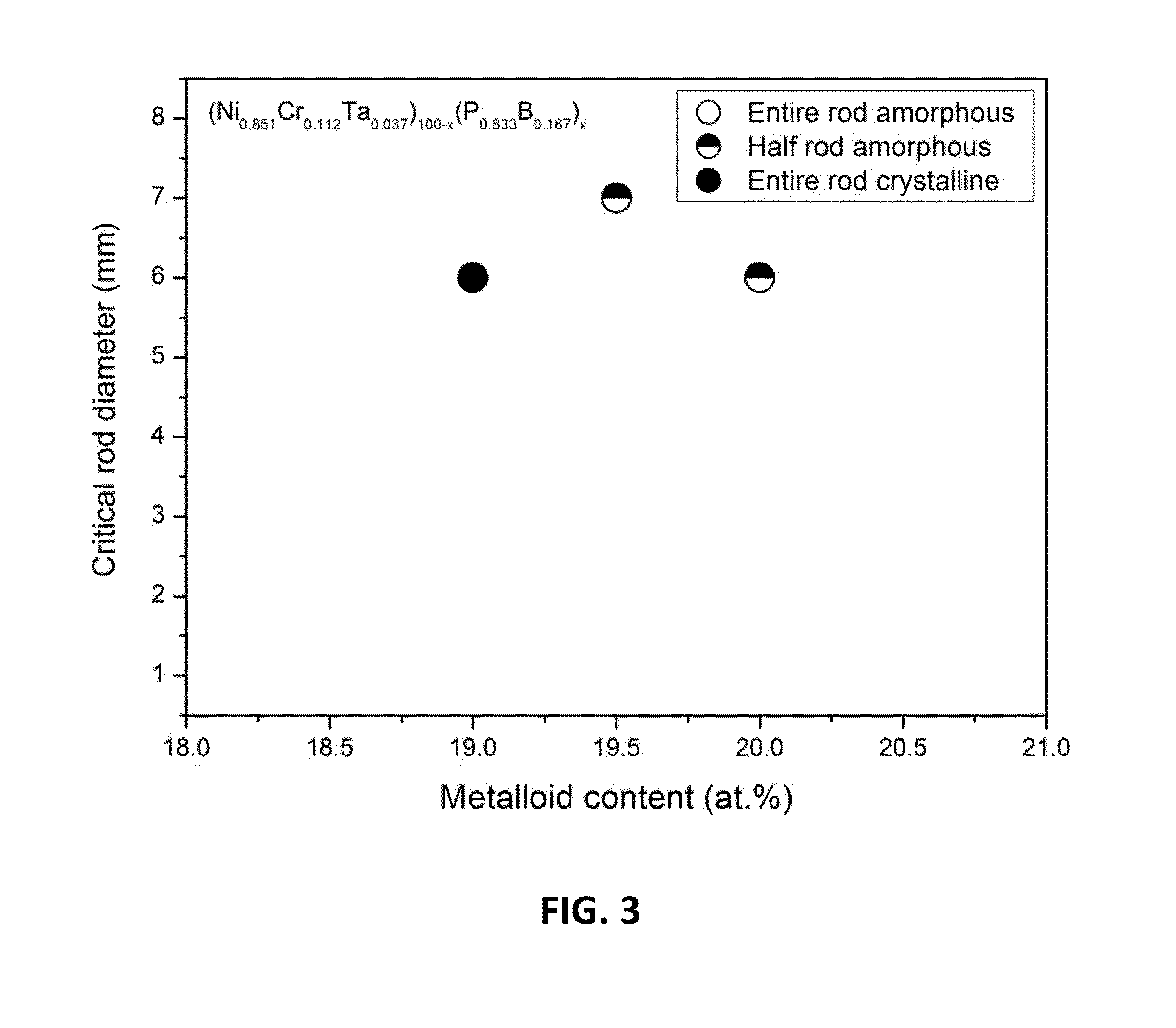

Bulk nickel-phosphorus-boron glasses bearing chromium and tantalum

A bulk-glass forming Ni—Cr—Nb—P—B alloy is provided. The alloy includes Ni(100−a−b−c−d)CraTabPcBd, where the atomic percent a is between 3 and 11, the atomic percent b is between 1.75 and 4, the atomic percent c is between 14 and 17.5, and the atomic percent d is between 2.5 and 5. The alloy is capable of forming a metallic glass having a lateral dimension of at least 3 mm.

Owner:APPLE INC

Methods for shaping high aspect ratio articles from metallic glass alloys using rapid capacitive discharge and metallic glass feedstock for use in such methods

The disclosure is directed to a method of forming high-aspect-ratio metallic glass articles that are substantially free of defects and cosmetic flaws by means of rapid capacitive discharge forming. Metallic glass alloys that are stable against crystallization for at least 100 ms at temperatures where the viscosity is in the range of 100 to 104 Pa-s are considered as suitable for forming such high-aspect-ratio articles.

Owner:APPLE INC

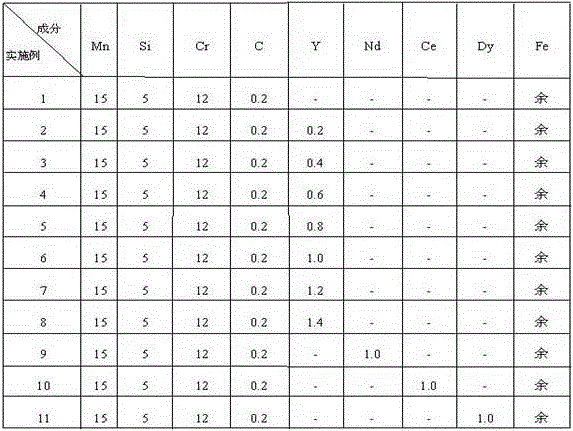

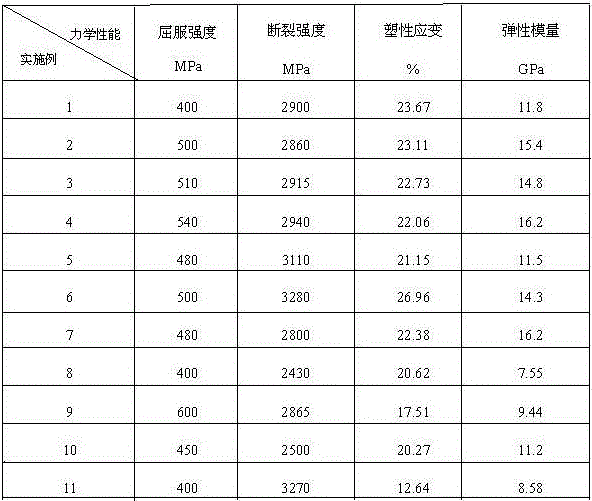

Amorphous composite structure steel

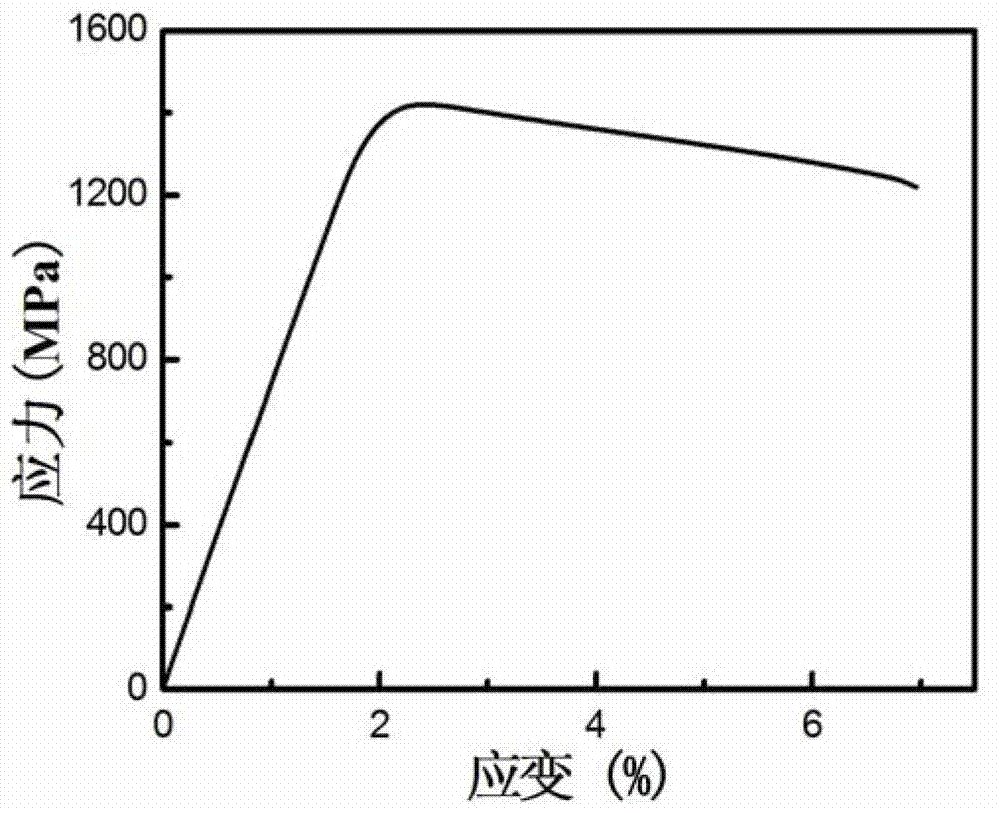

ActiveCN106282849ALow yield ratioProne to plastic deformationMartensite transformationHigh intensity

The invention relates to an amorphous composite structure steel which comprises the following components in percentage by weight: 0.02-0.2% of C, 13-16% of Mn, 3-5% of Si, 10-12% of Cr, 0-2% of Re and the balance of Fe. The structure of the composite material is a gamma austenite phase+amorphous composite structure, and can generate gamma austenite-martensite phase transformation under the induction of stress to strengthen and toughen the metallic glass. The composite material has low yield-tensile ratio, can generate plastic deformation, and can reach high strength through the excellent work hardening capacity.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

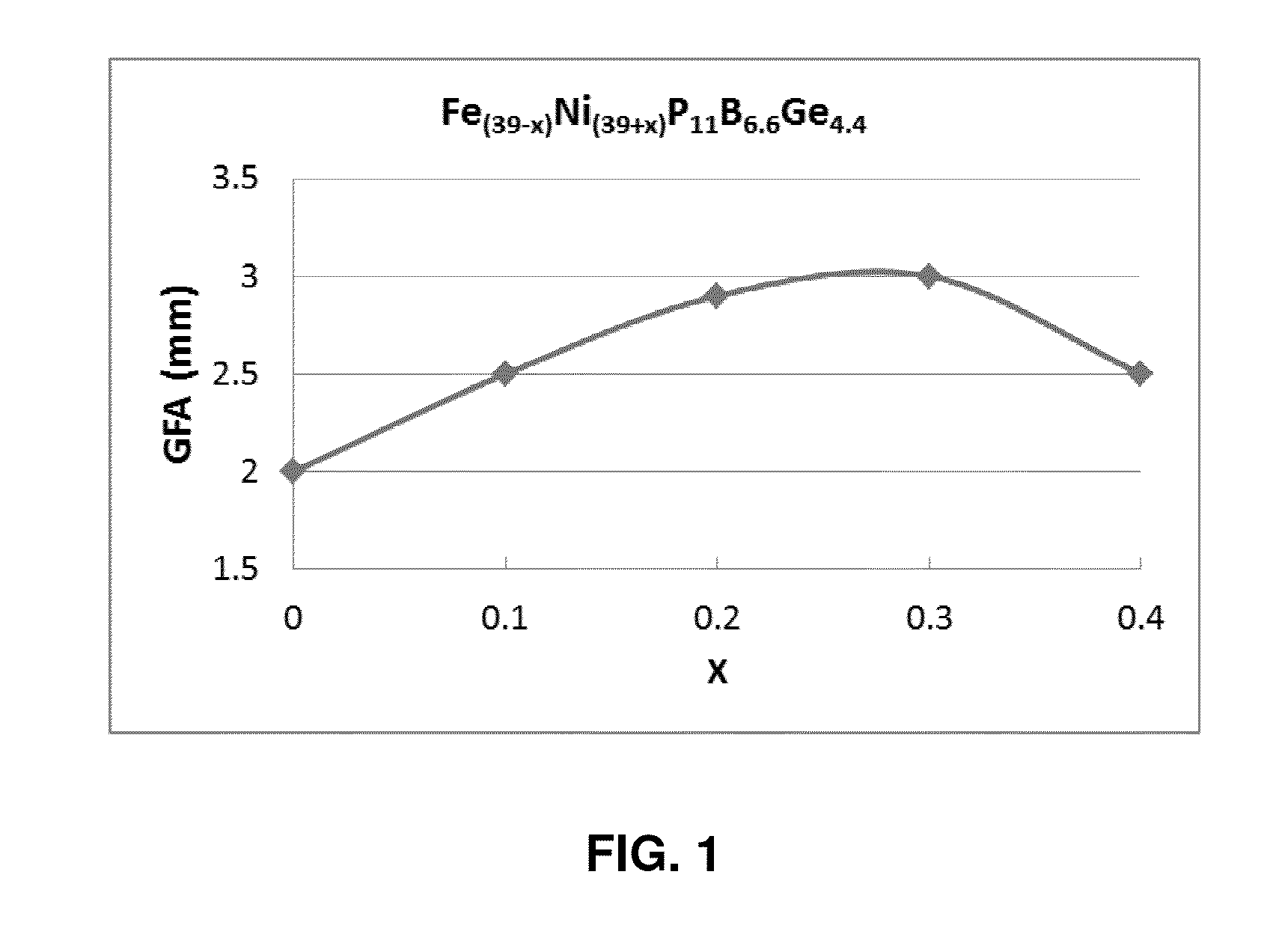

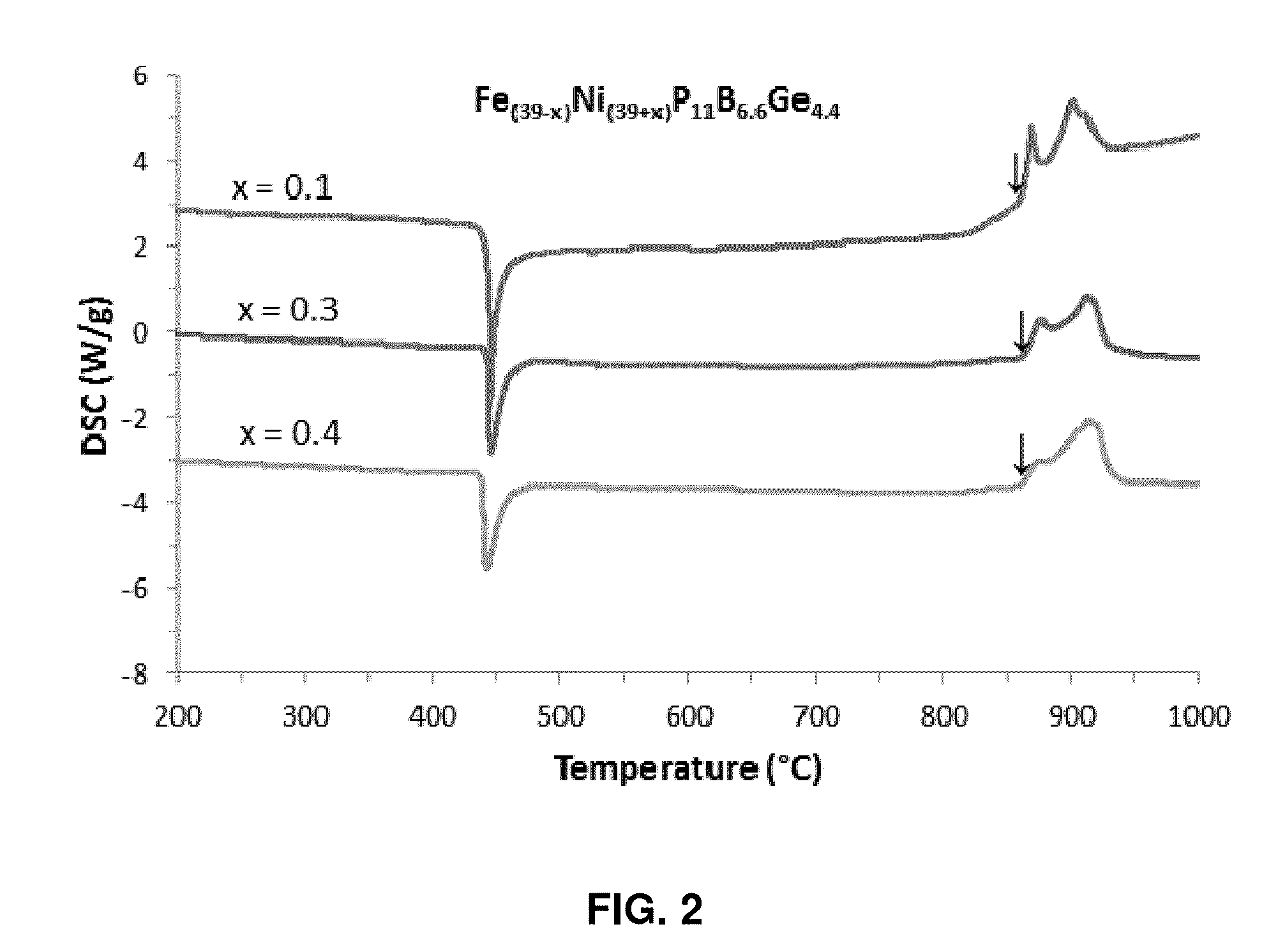

Bulk iron-nickel glasses bearing phosphorus-boron and germanium

An alloy comprising Fe, Ni, P, B and Ge is disclosed, having a composition according to the formula [Fe1-yNiy](100-a-b-c)PaBbGec, where a, b, c subscripts denote atomic percent; y subscript denotes atomic fraction, a is between 9 and 12, b is between 5.5 and 7.5, c is between 2 and 6, and y is between 0.45 and 0.55. Metallic glass rods with diameter of at least 1 mm can be formed from the alloy by rapid quenching from the molten state.

Owner:APPLE INC

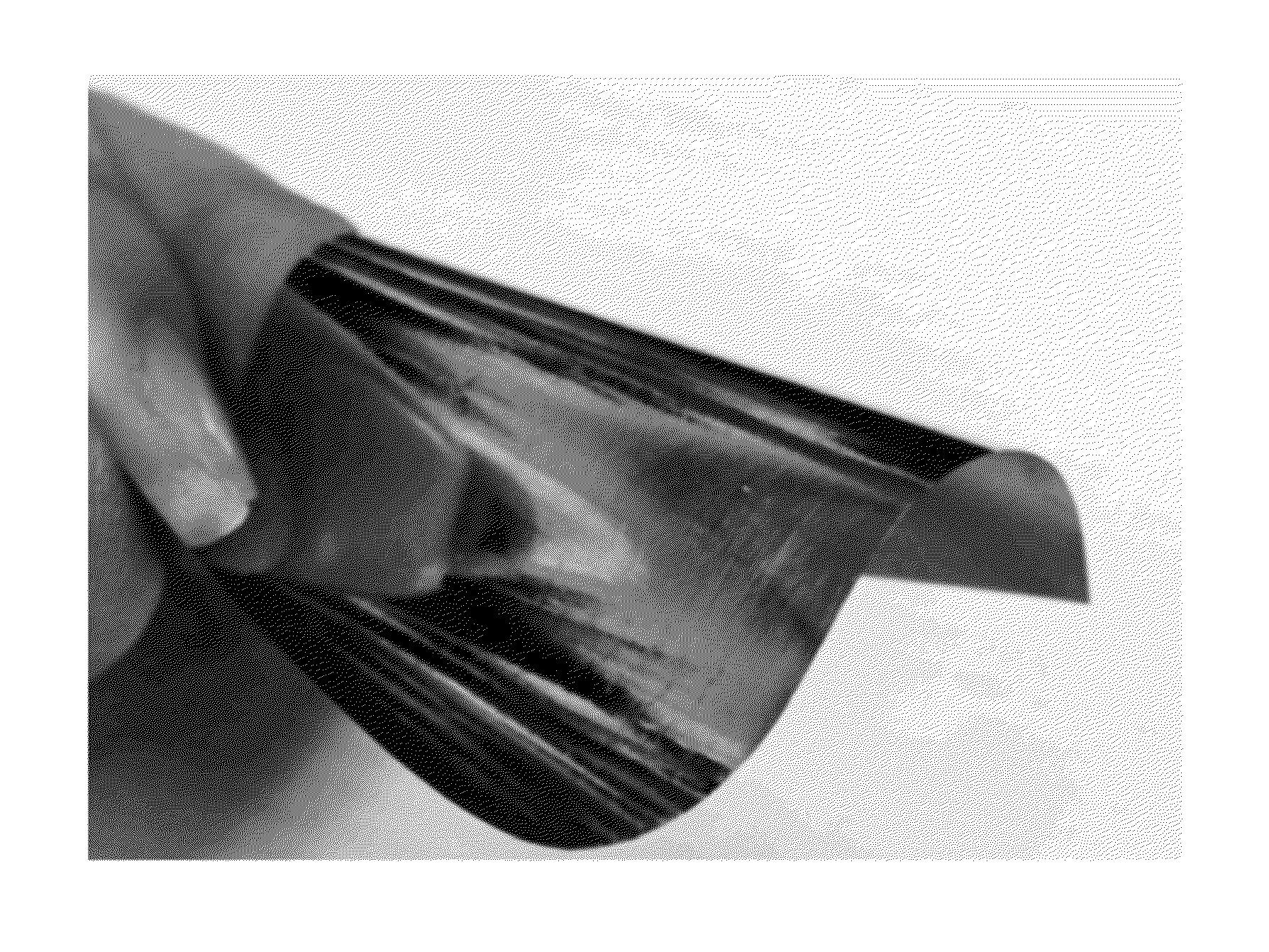

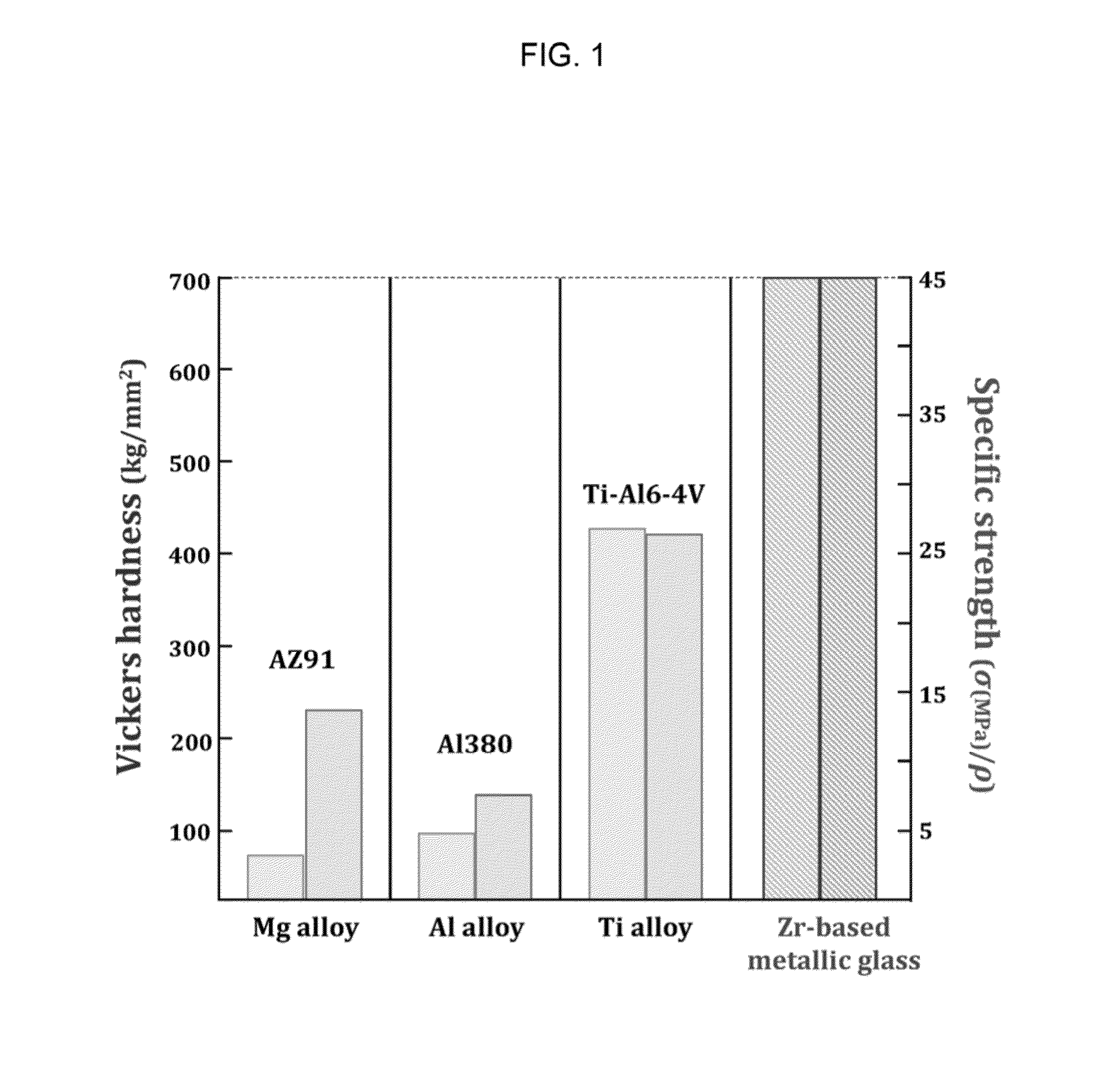

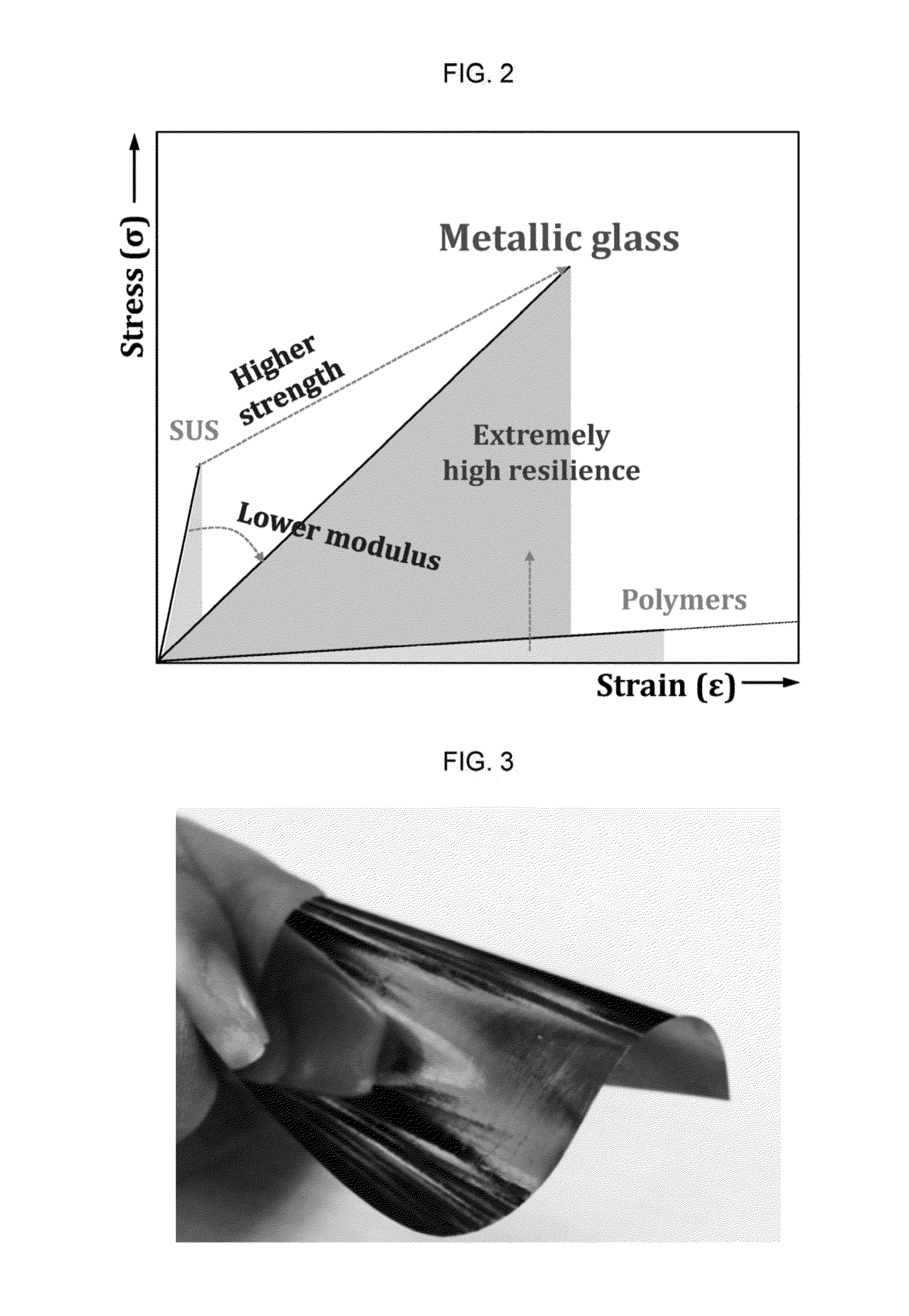

Flexible metallic glass substrate with high resilience, manufacturing method thereof, and electronic device using same

InactiveUS20160045953A1Easy to carryEasy to storePig casting plantsIngot casting plantsCrystallization temperatureThermal expansion

Disclosed herein is a flexible substrate, made of metallic glass that is of high resilience suitable for use in electronic devices. The metallic glass is composed of a commercial alloy that can be produced in a continuous process on a mass scale, and may be selected from among Mg-, Ca-, Al-, Ti-, Zr-, Hf-, Fe-, Co-, Ni-, and Cu-based metallic glass. Preferably, its crystallization temperature, which determines the process allowable temperature, is 200° C. or higher. The flexible metallic glass substrate exhibits excellent fatigue properties as well as resilience of 1.5 MJ / m3 or higher. Its coefficient of thermal expansion is within a small range of 1 to 20 ppm / ° C., so that the flexible metallic glass substrate shows a better interfacial property with electronic devices.

Owner:SK INNOVATION CO LTD +1

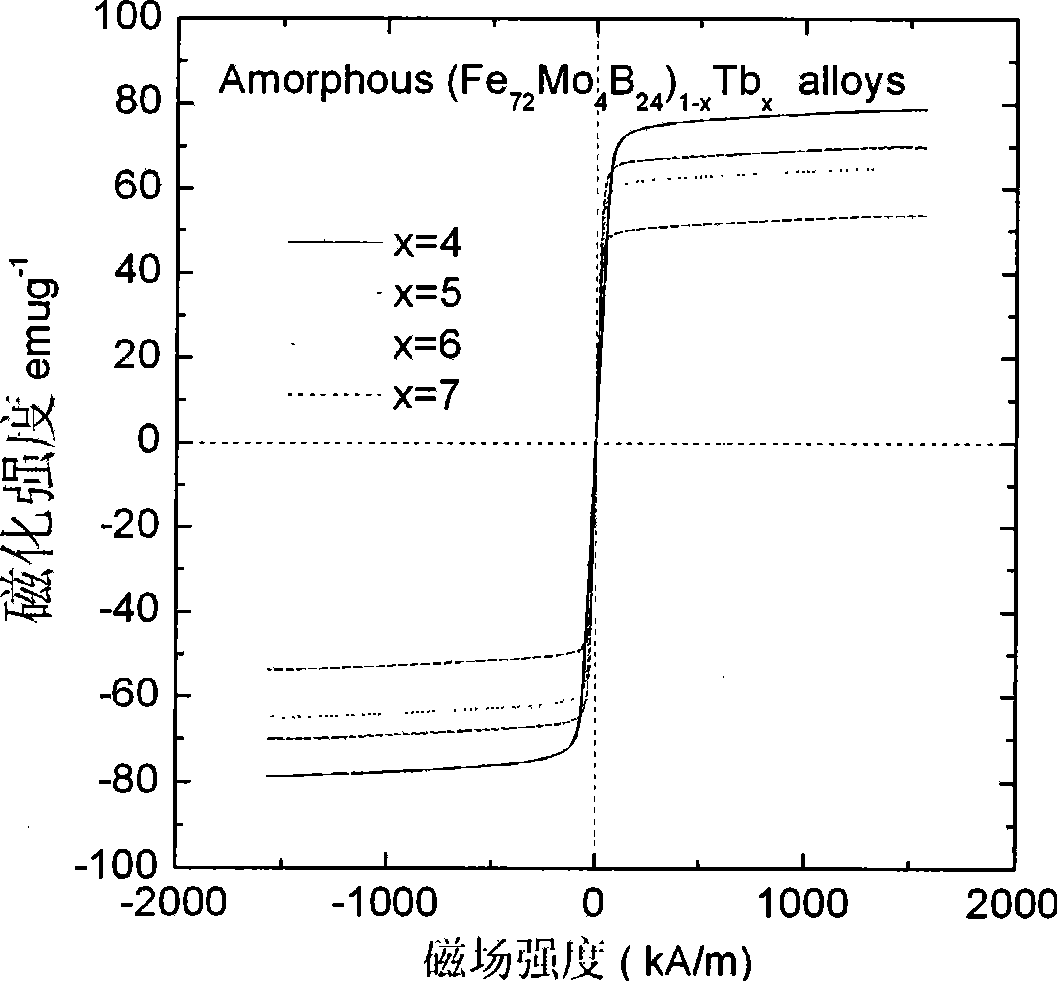

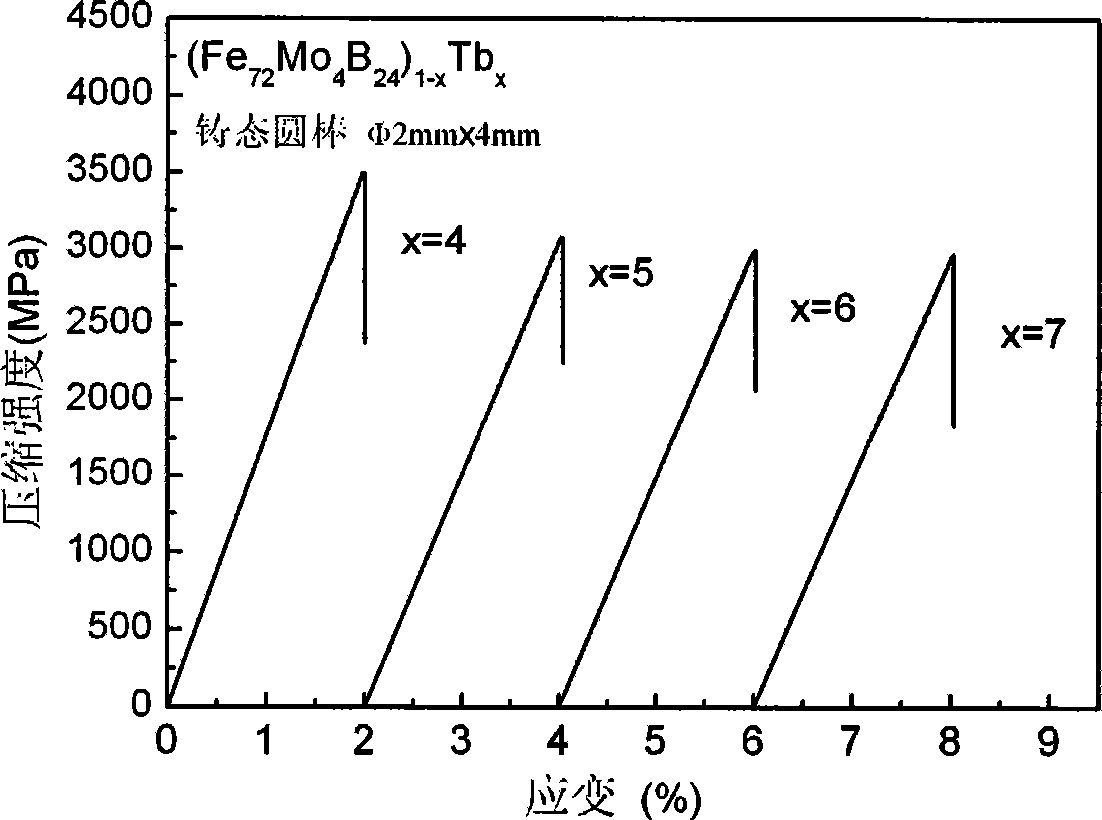

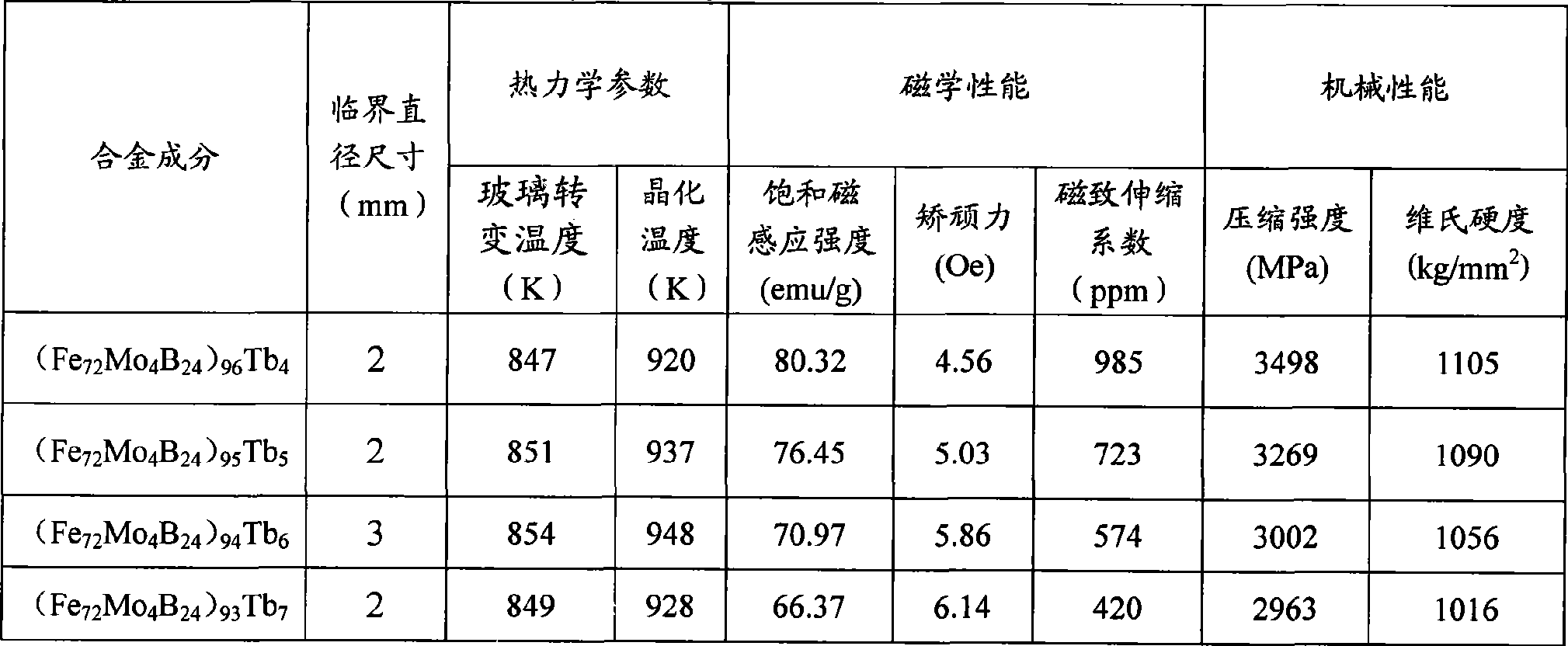

High magnetic striction iron based metallic glass magnetic material and preparation thereof

InactiveCN101487106APurity requirements are not very highHigh magnetostriction coefficientSimple componentTransducer

The invention discloses a high magnetostrictive Fe-based metal glass magnetic material and a preparation method thereof. The chemical formula of the high magnetostrictive Fe-based metal glass alloy is Fe100-x-y-zMozByTbx, wherein, x, y and z are respectively the atomic percents of Tb, B and Mo, 100-x-y-z is the atomic percent of Fe, x is more than 0 and less than or equal to 10, y is more than or equal to 20 and less than or equal to 25, z is more than 0 and less than or equal to 10. The preparation method of the alloy is as follows: the industrial pure metals Fe, Mo, Tb and FeB alloy are proportioned according to the alloy formula and melted repeatedly by induction-arc under the protection of argon to make master alloy, then the high magnetostrictive Fe-based metal glass magnetic material is obtained through casting by using the copper mold spray-casting method. The magnetostrictive coefficient of the magnetic material is 420 ppm to 985 ppm, and the magnetic material has simple components, high thermal stability, and good mechanical properties and amorphous forming ability. The high magnetostrictive Fe-based metal glass magnetic material can be widely applied to the fields of sonar transducer, sensor, ultrasonic technology, communication technology, and the like.

Owner:ZHEJIANG UNIV +1

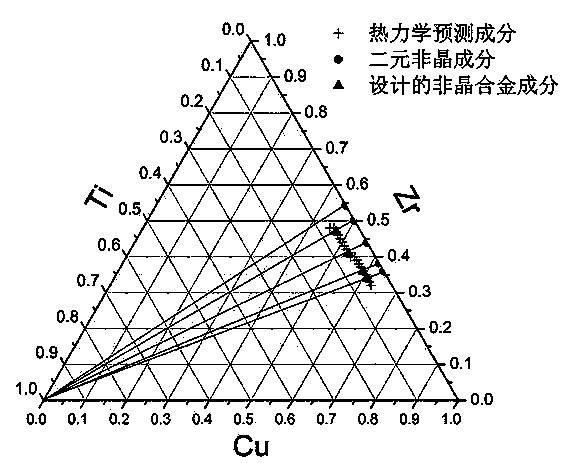

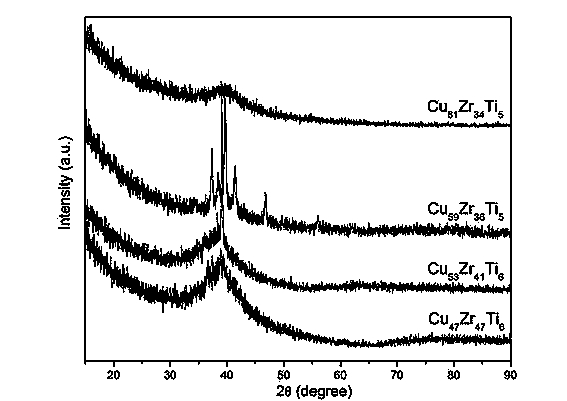

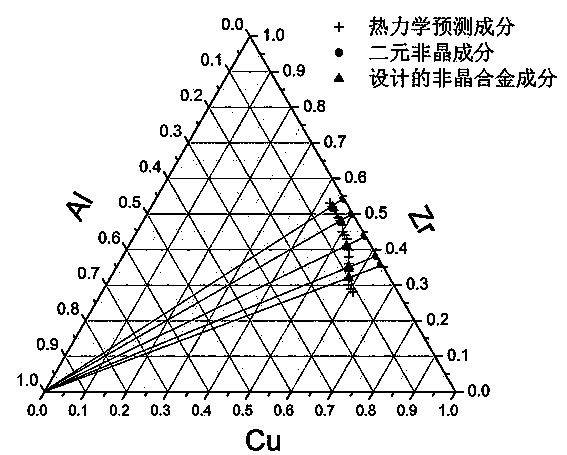

Amorphous alloy composition design method based on thermodynamics factors and structural factors

The invention discloses an amorphous alloy composition design method based on thermodynamics factors and structural factors. The amorphous alloy composition design method comprises the following steps: (1) based on binary block body metal glass, selecting a third component with the principle that the atomic radius difference is about greater than 12%, and connecting a binary amorphous composition point with the third component in a ternary diagram to obtain an atomic structure predicted composition line; (2) based on the binary block body metal glass, calculating the delta Hh.delta Hmix.Sconfig predicted value under different contents of the third component, connecting each minimal value in a ternary alloy diagram to be a line, namely a predicted composition line of thermodynamics; and (3) researching the composition relevance between the alloy at the crossed part of the two predicted composition lines in (1) and (2) and the amorphous forming capacity, and determining the intersection point composition of the two predicted composition lines, namely the amorphous alloy composition of final design. According to the composition design method provided by the invention, the accuracy of amorphous alloy composition design is improved, and the error rate in developing novel amorphous alloys is reduced. The method is simple and clear, and easy to understand and grasp.

Owner:HOHAI UNIV CHANGZHOU

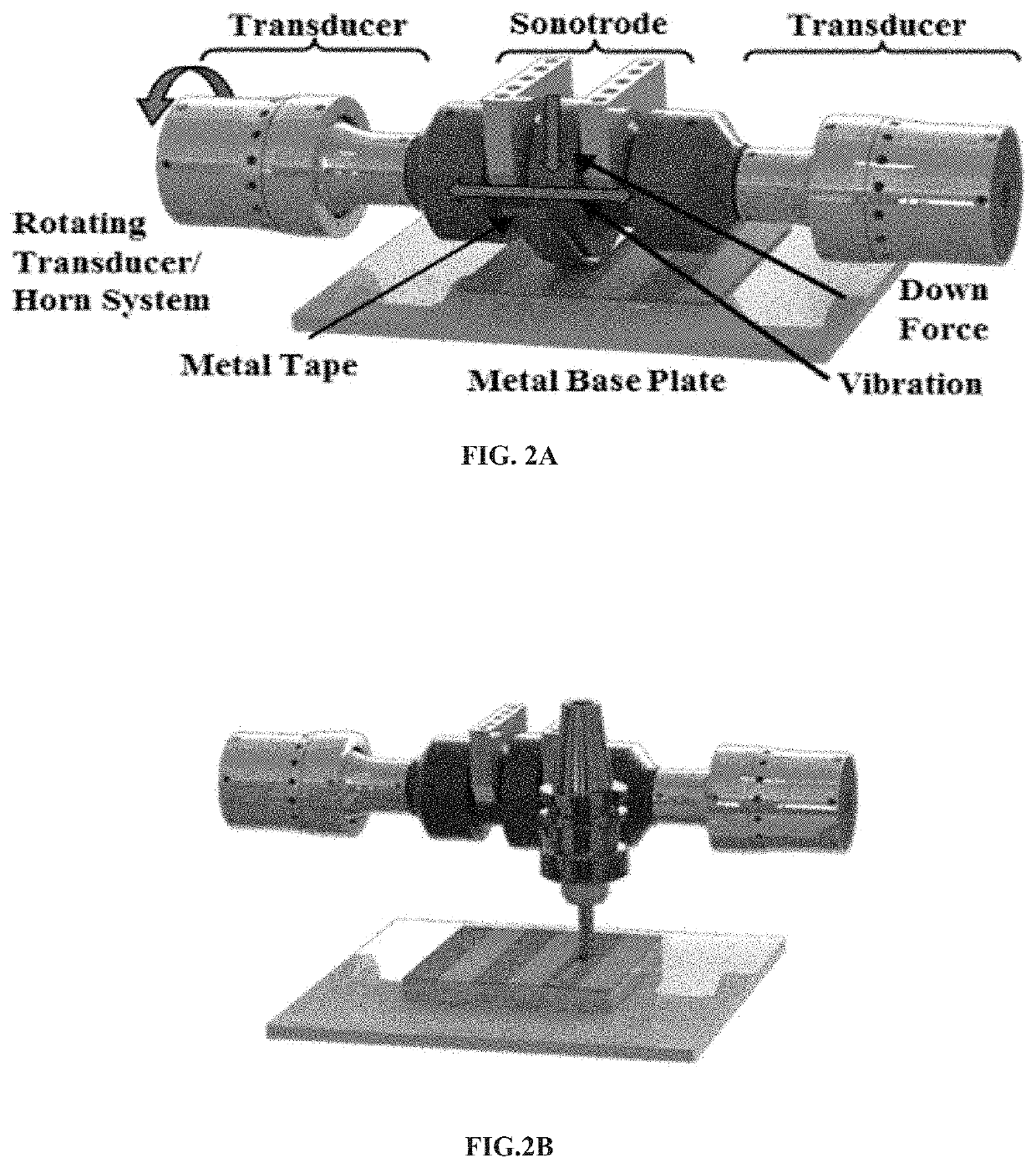

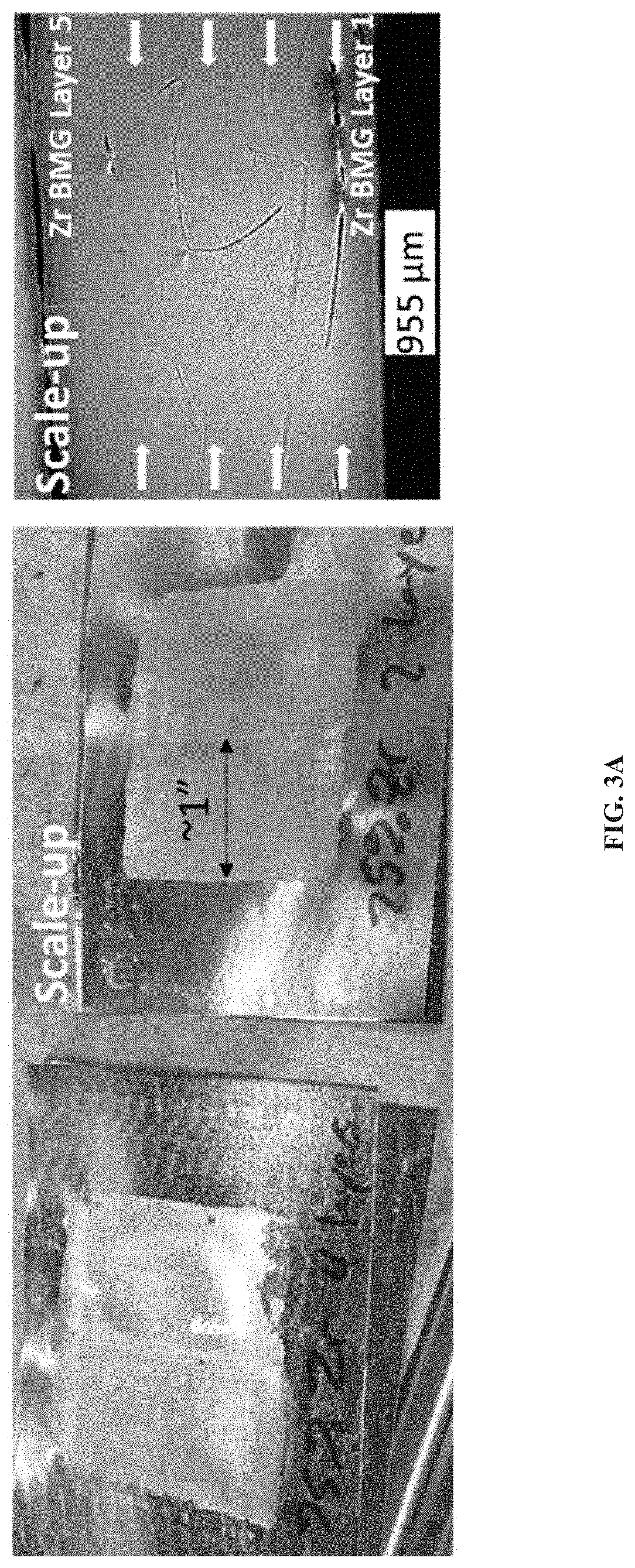

Ultrasonic additive manufacturing of cladded amorphous metal products

ActiveUS20200324362A1Additive manufacturing apparatusMolten spray coatingHeat-affected zoneCrystallinity

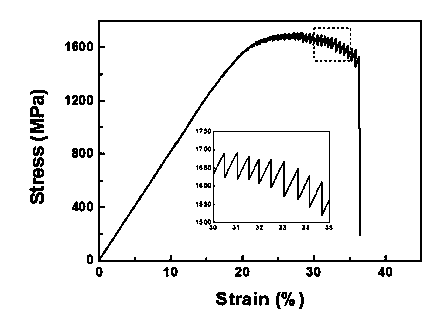

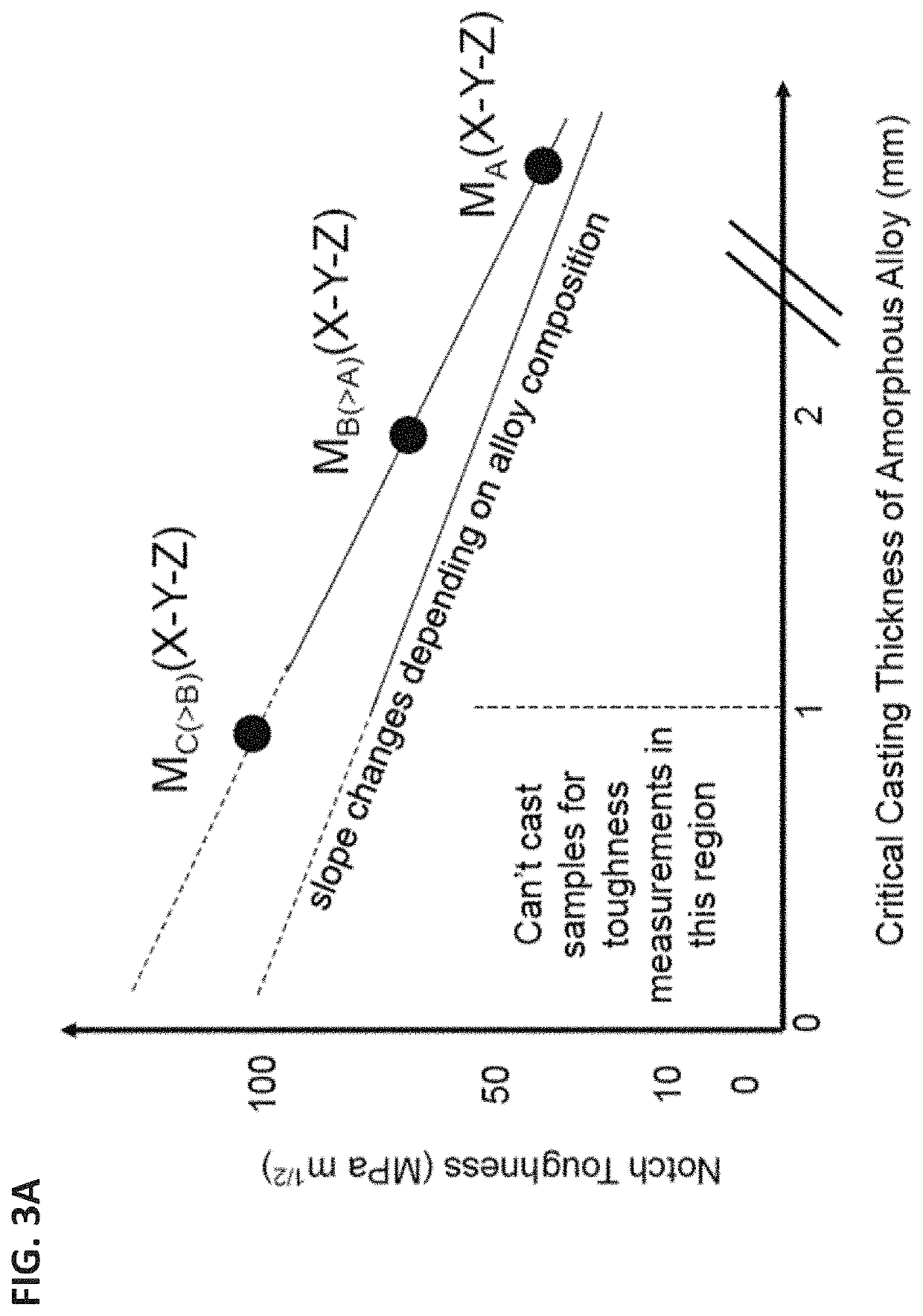

An embodiment relates to an ultrasonic additive manufacturing process, comprising joining a foil comprising a bulk metallic glass to a substrate; and forming a cladded composite comprising the foil and the substrate; wherein a thickness of the cladded composite is greater than a critical casting thickness of the bulk metallic glass, wherein the cladded composite comprises a cladding layer of the bulk metallic glass on the substrate and the bulk metallic glass comprises approximately 0% crystallinity, approximately 0% porosity, less than 50 MPa thermal stress, approximately 0% distortion, approximately 0 inch heat affected zone, approximately 0% dilution, and a strength of about 2,000-3,500 MPa.

Owner:LM GRP HLDG INC +1

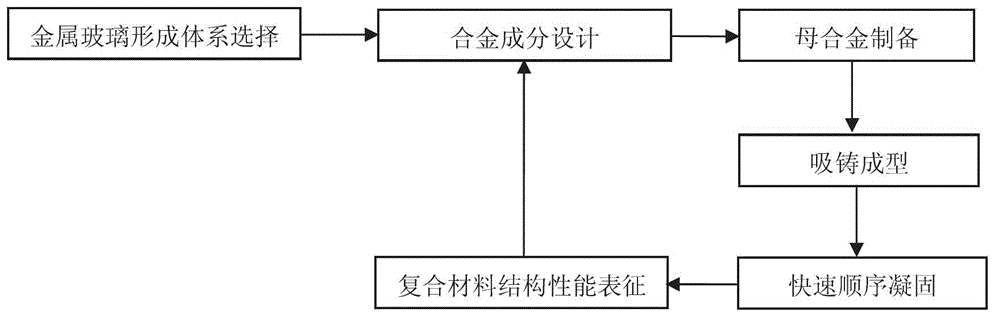

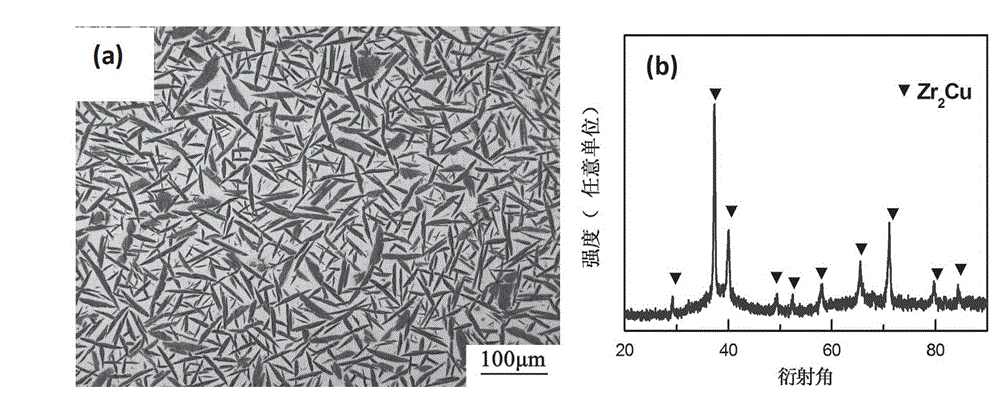

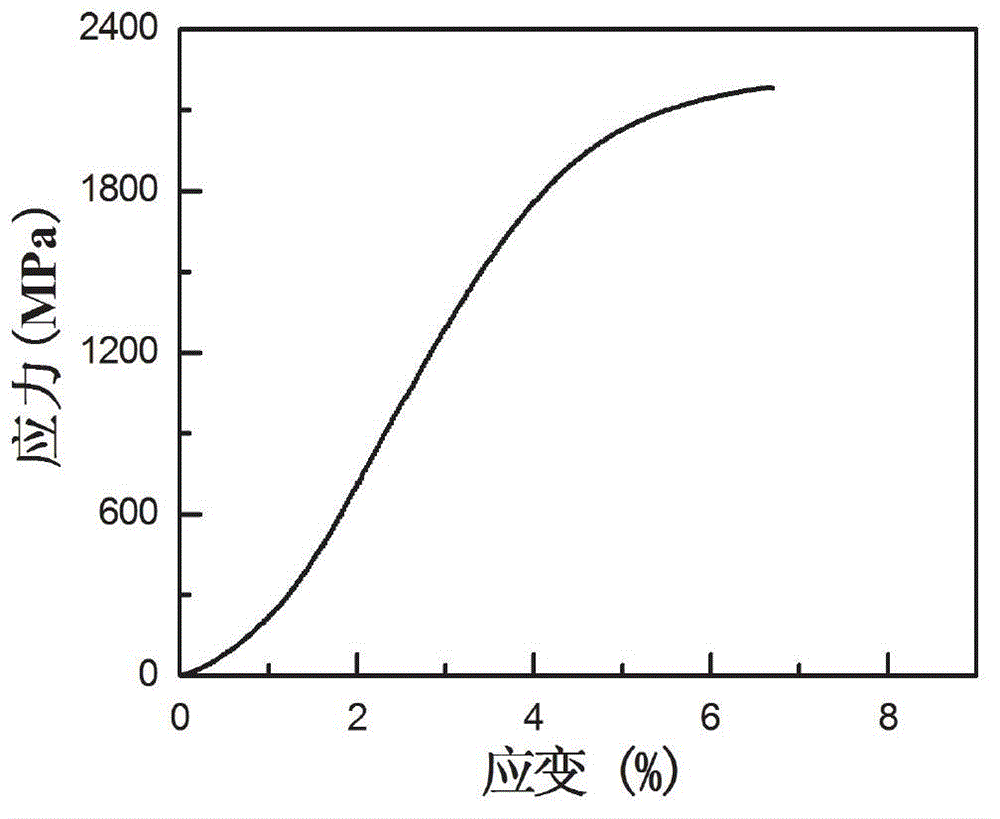

Zirconium-based metal glass endogenic composite material and preparation method thereof

The invention discloses a zirconium-based metal glass endogenic composite material and a preparation method thereof. According to the invention, an atomic percent expression of components of the zirconium-based metal composite material is ZraTibCucNidBee, wherein a is not less than 44 and not more than 49, b is not less than 14 and not more than 16, c is not less than 13 and not more than 17, d is not less than 11 and not more than 13, e is not less than 5 and not more than 18, and a+b+c+d+e=100. A method for preparing the zirconium-based metal glass endogenic composite material comprises the following steps of: selecting a block metal glass alloy system, and adjusting alloy components according to a phase selection principle so as to separate out an intermetallic compound phase in a condensation process; smelting the alloy components obtained in the first step to a mother alloy according to an electric arc smelting method; remelting the mother alloy, and carrying out suction cast through a copper mold so as to obtain a section bar; placing the section bar into a processed crucible, adopting induction smelting to a molten state, thermally insulating and quickly condensing in sequence so as to an as-cast endogenic composite material, wherein a second phase of the intermetallic compound is uniformly distributed on a metal glass substrate. According to the invention, the high intensity and the high hardness of the block metal glass are kept, and the room-temperature plasticity is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

Method for refining aluminum alloy by using metallic glass

The invention discloses a method for refining aluminum alloy by using metallic glass and relates to the field of aluminum alloy processing. The method comprises the four steps of preparation of the metallic glass, preparation of amorphous ribbons, preparation of non-refined aluminum alloy and refinement of the aluminum alloy. By means of the technical scheme, the steps are reasonable; the refinement efficiency is high; the strength and toughness of the aluminum alloy are improved substantially; inoculation is efficient; and the method is low in cost and has huge industrial application potential and value.

Owner:JILIN UNIV

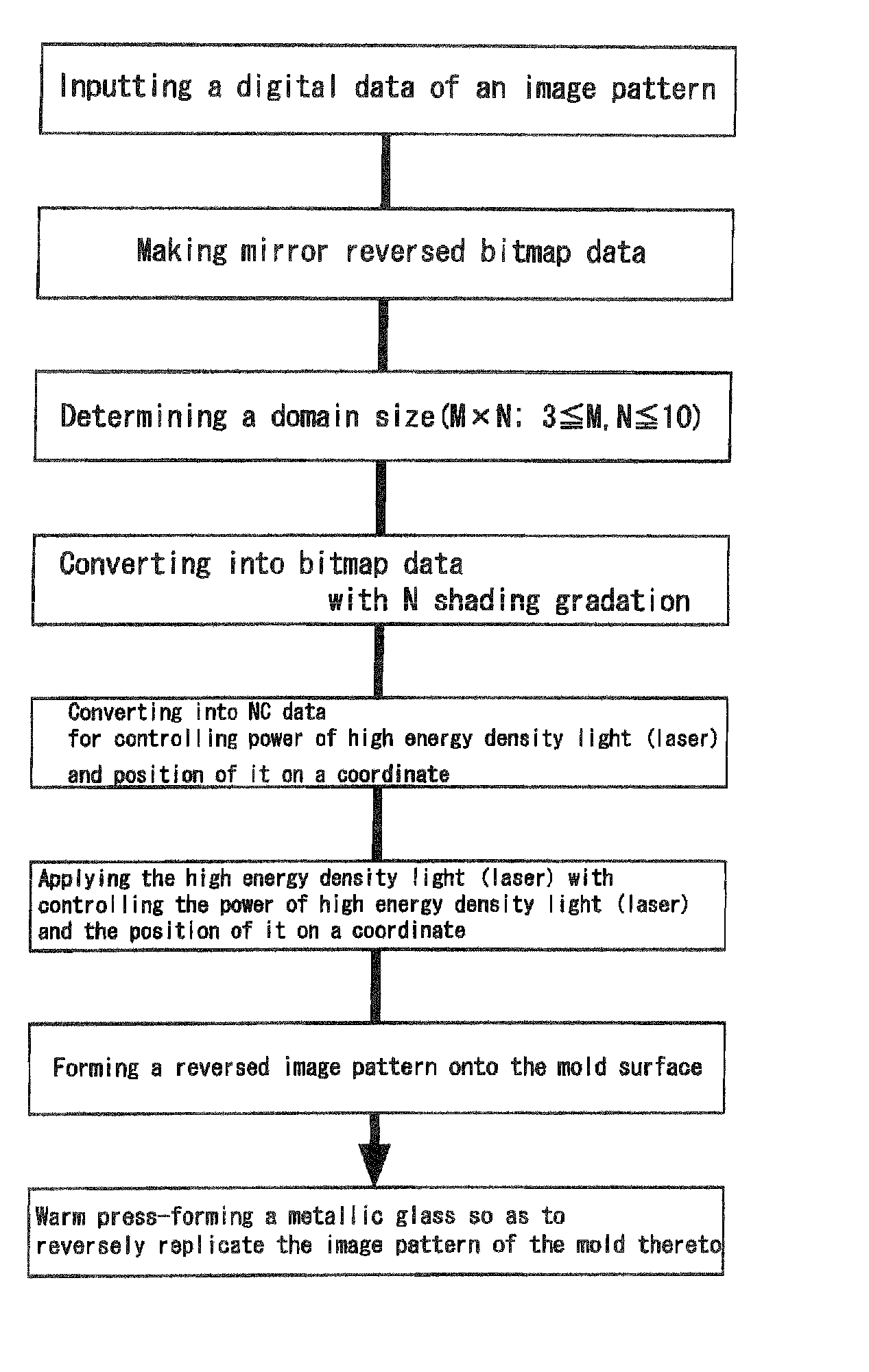

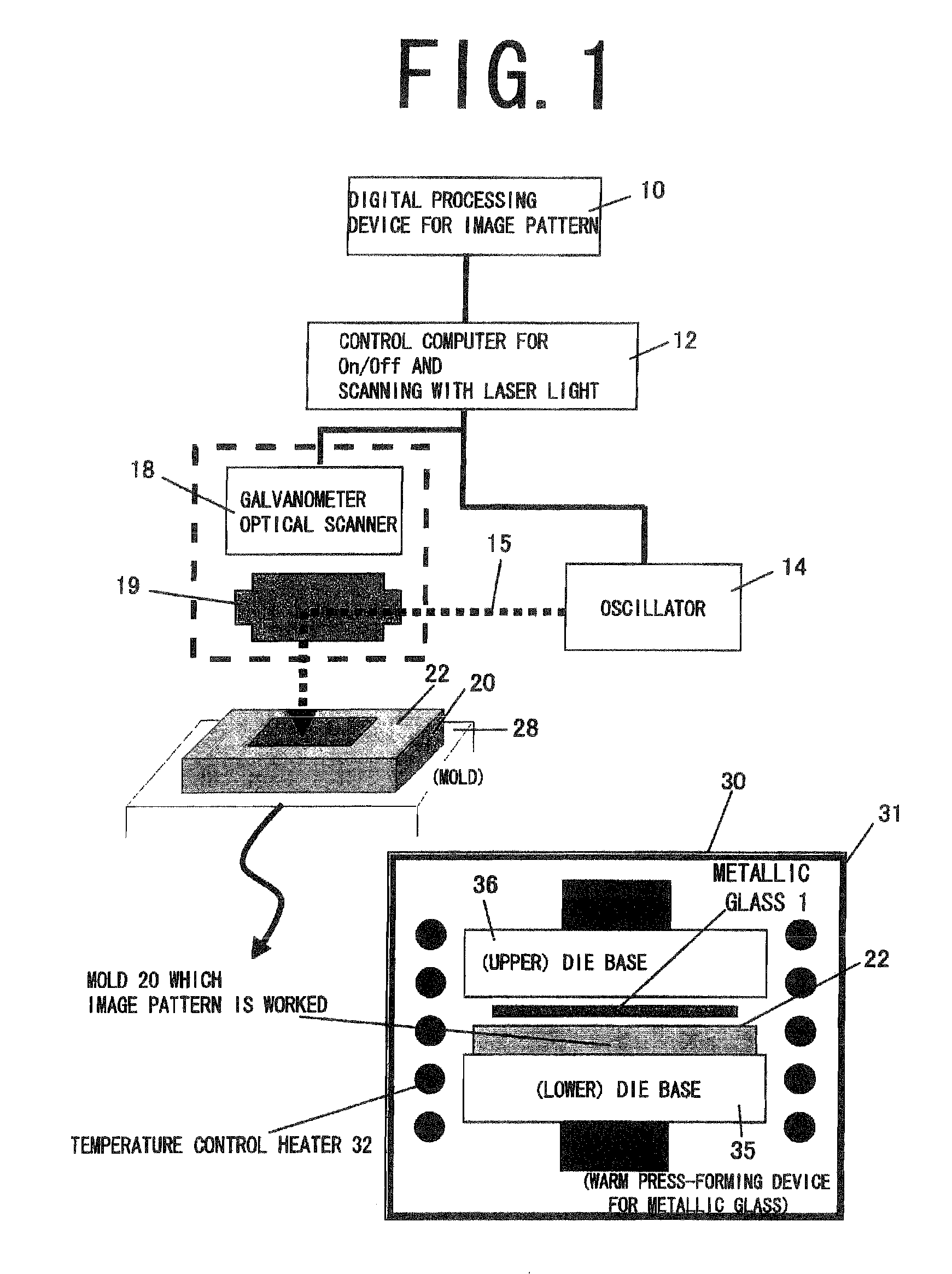

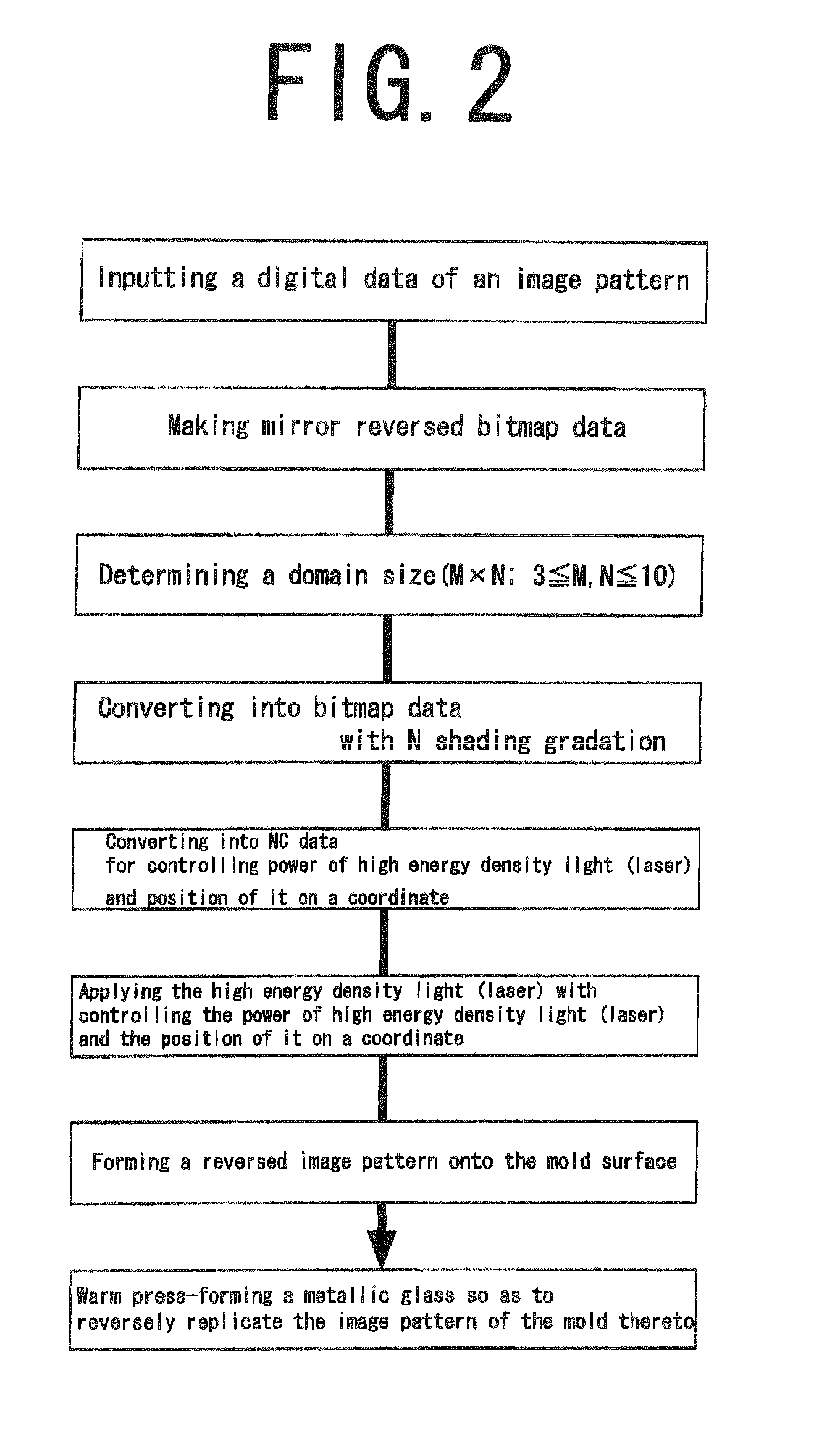

Method for forming image pattern on surface of metallic glass member, apparatus for forming image pattern, and metallic glass member having image pattern on its surface

InactiveUS20090044924A1Efficiently formedEasy to operateDecorative surface effectsFoundry mouldsLiquid temperatureHigh energy

A challenge of the present invention is to develop a method for repeatedly forming a reverse transferred pattern in a simple and efficient manner onto the surfaces of Zr based, Ti based, Cu based, Ni based and Fe based metallic glass that have supercooled liquid temperatures of not lower than 400° C. and are also required to be molded at not lower than 400° C. (a) An image pattern is converted into bitmap data being mirror reversed with respect to a real image, (b) high energy density light 15 is repeatedly flashed, and the surface of a mold 20 is scanned while one of dot holes 24 is formed by one-time irradiation, to form an image pattern as dots assembled pattern 21 onto the surface of the mold 20 in accordance with the bitmap data, and (c) the dots assembled pattern 21 is reverse-transfer molded onto a metallic glass 1 within a supercooled liquid temperature range Tg-Tx by means of the mold 20 which is for dots assembled pattern formation.

Owner:NGK INSULATORS LTD

Zirconium-based alloy metallic glass and method for forming a zirconium-based alloy metallic glass

A class of alloys is provided that form metallic glass upon cooling below the glass transition temperature Tg at a rate below 100° K / sec. The alloys have a high value of temperature difference (DT) between the crystallization temperature (Tx) and the glass transition temperature (Tg) of the intermetallic alloy. Such alloys comprise zirconium in the range of 70 to 80 weight percent, beryllium in the range of 0.8 to 5 weight percent, copper in the range of 1 to 15 weight percent, nickel in the range of 1 to 15 weight percent, aluminum in the range of 1 to 5 weight percent and niobium in the range of 0.5 to 3 weight percent, or narrower ranges depending on other alloying elements and the critical cooling rate and value of DT desired. Furthermore, methods are provided for making such metallic glasses.

Owner:HERAEUS MATERIALS TECH NORTH AMERICA +1

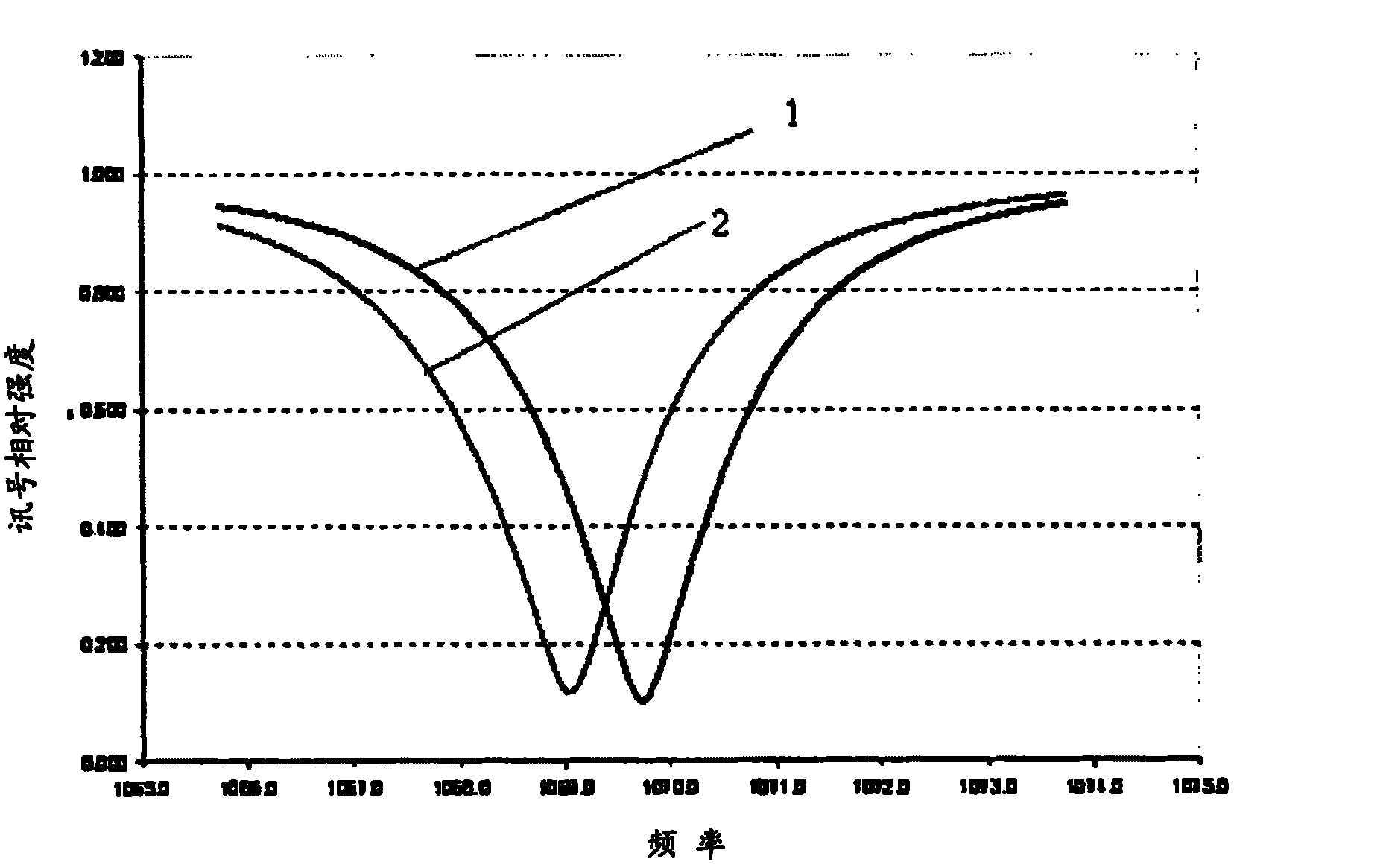

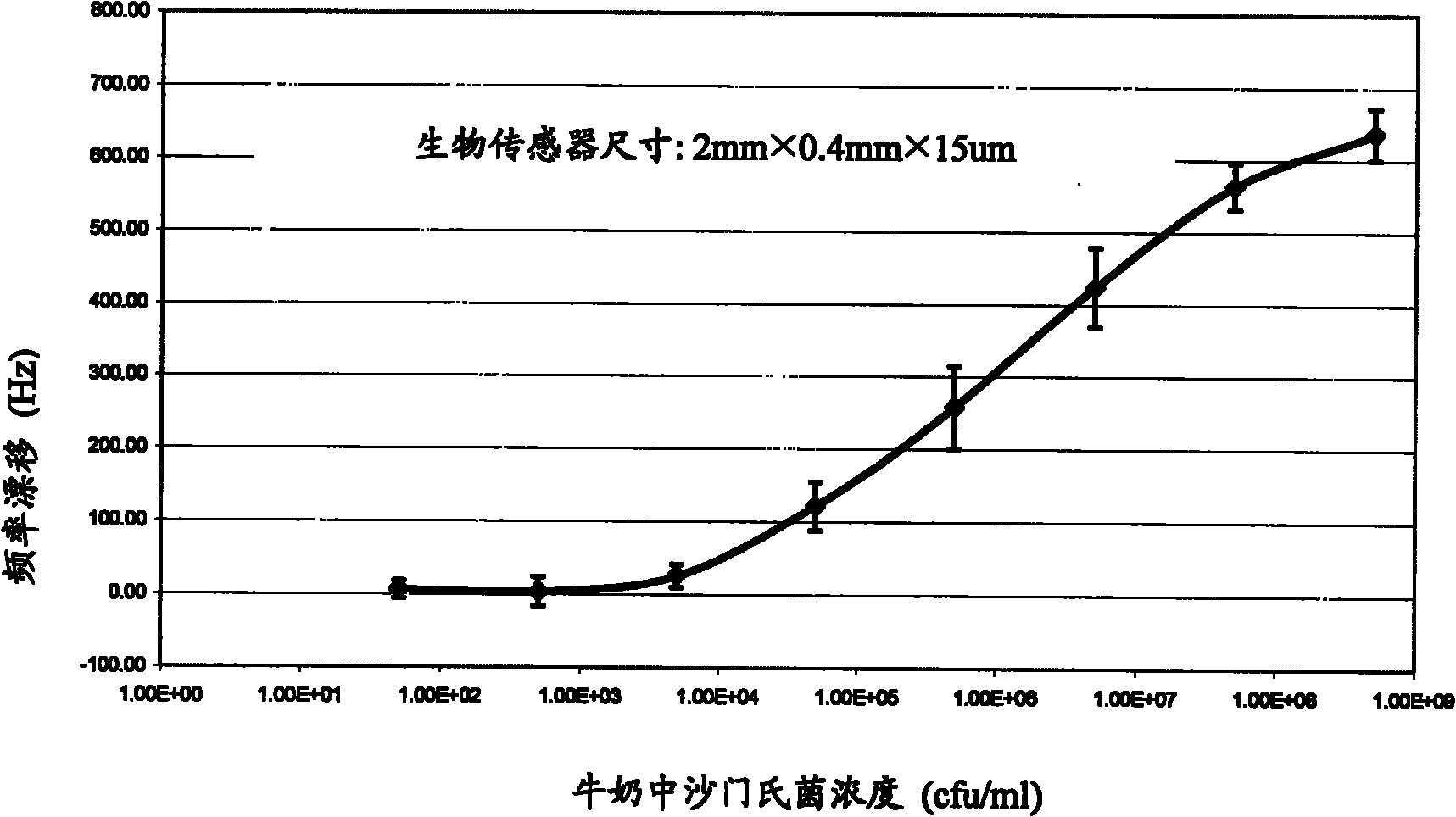

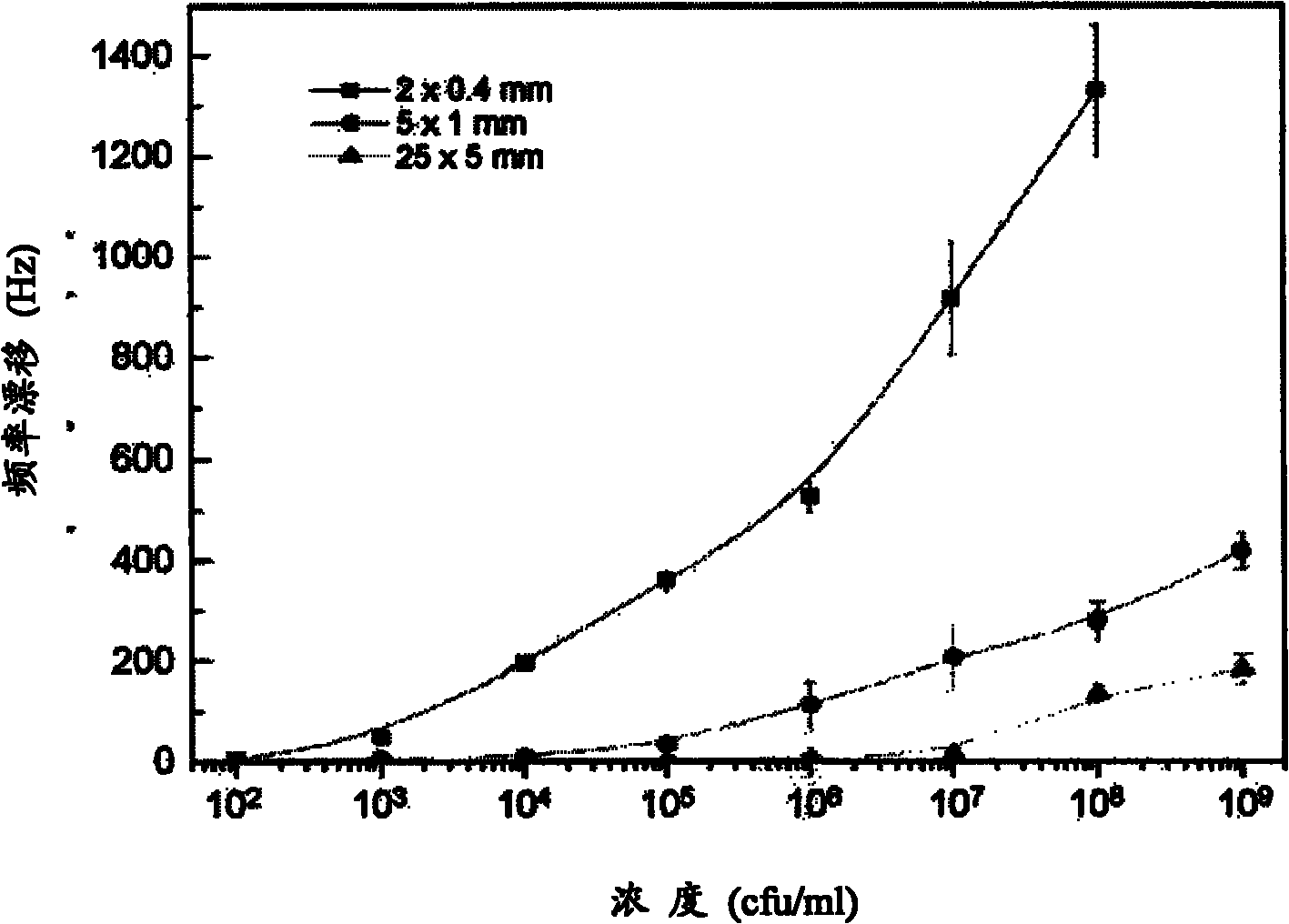

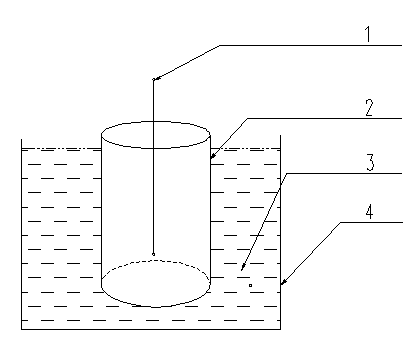

Method for improving sensitivity of magnetostrictive material biosensor

The invention belongs to the field of biosensors, in particular to a method for improving the sensitivity of a magnetostrictive material biosensor. In the invention, a Fe40Ni38Mo4B18(Metglas 2826MB) amorphous film alloy strip magnetostrictive material is selected and cut into a diaphragms, the dimension range of which is (2-25)mm*(04-5mm)*15mum; in the adopted heat treatment process, the heating temperature is 150-300 DEG C, the heating time is 2-4 hours and the vacuum is 10-3 torr. By using the technology of reducing the dimensions of the magnetostrictive material biosensor and carrying out certain process of vacuum annealing heat treatment, the goals of reducing the dead weight of the magnetostrictive material biosensor, removing the internal residual stress and regulating the microstructure are achieved and the target of improving the sensitivity of the magnetostrictive material biosensor is achieved.

Owner:CHANGZHOU UNIV

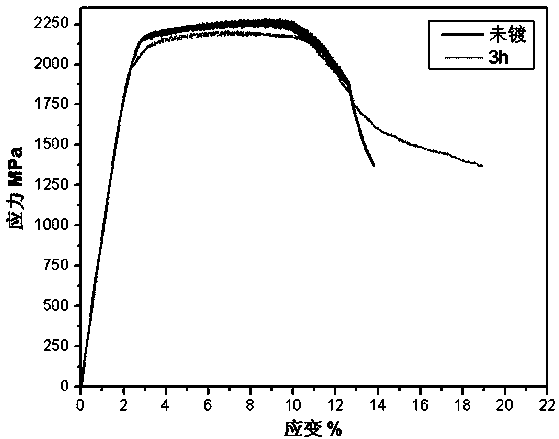

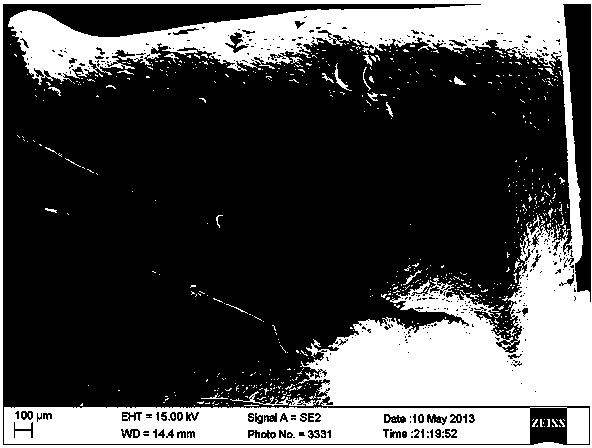

Method for improving room-temperature plasticity of amorphous alloy

InactiveCN103436925AImprove plasticityThe advantage of the plastic method is that: for the brittleness of the amorphousJewelleryAlloyMaterials science

A method for improving room-temperature plasticity of amorphous alloy belongs to the field of material technology research and particularly relates to a method for improving the amorphous plasticity by plating a metallic nickel layer on the surface of an amorphous body aiming to the characteristics that the amorphous body is high in strength, but low in plasticity. The method is characterized in that an electroplating method is adopted to improve the plasticity of formed block metallic glass structural members and comprises the following basic steps: first, preparing required real amorphous test samples by a high-vacuum non-self-consuming arc-melting furnace; second, performing preplating processing on the samples; third, plating a crystal metal layer on the surface of each amorphous sample through an electroplating way. The amorphous composite manufactured by the method is greatly improved in plasticity, and the amorphous body still maintains original glass state structure.

Owner:TAIYUAN UNIV OF TECH

Blocky high-entropy metallic glass and preparation method thereof

The invention discloses blocky high-entropy metallic glass. The blocky high-entropy metallic glass comprises, by atomic percent, 23-31% of copper, 22-32% of zirconium, 9-31% of titanium, 14-31% of nickel, 5-18% of aluminum and less than 0.5% of impurities. The blocky high-entropy metallic glass has high strength, high plasticity and high amorphous material-forming ability. The invention also discloses a preparation method of the blocky high-entropy metallic glass. The preparation method has simple processes. Through the preparation method, high-entropy metallic glass rods of which the diameters greater than or equal to 1.5mm are obtained.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com