Flexible metallic glass substrate with high resilience, manufacturing method thereof, and electronic device using same

a flexible, glass substrate technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic bodies, etc., can solve the problems of limiting the temperature available for the process of fabricating electronic devices, unable to avoid defects causative of surface roughness, and it is difficult to achieve fine surface roughness on metal films. , to achieve the effect of convenient portability and storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

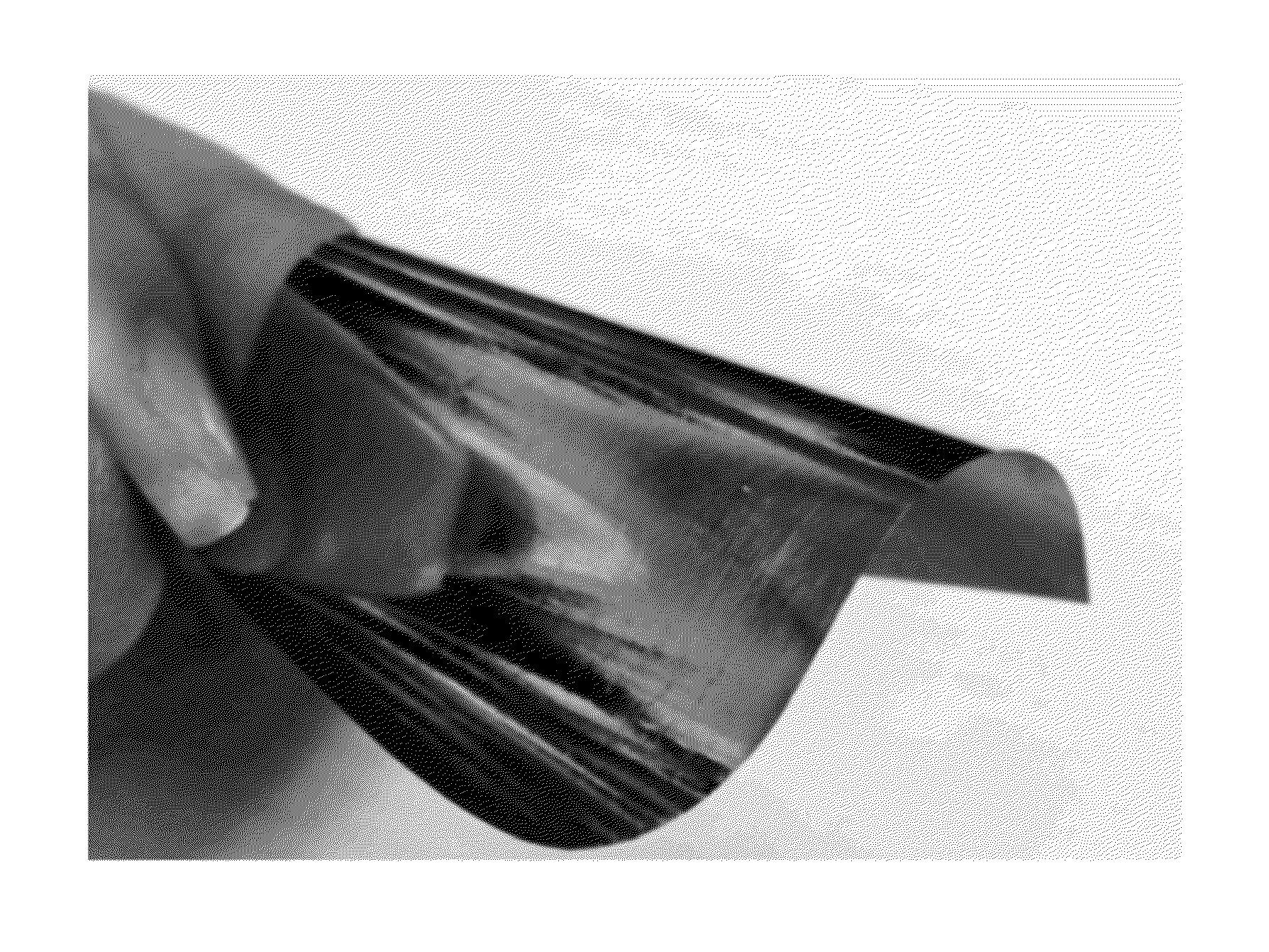

Image

Examples

Embodiment Construction

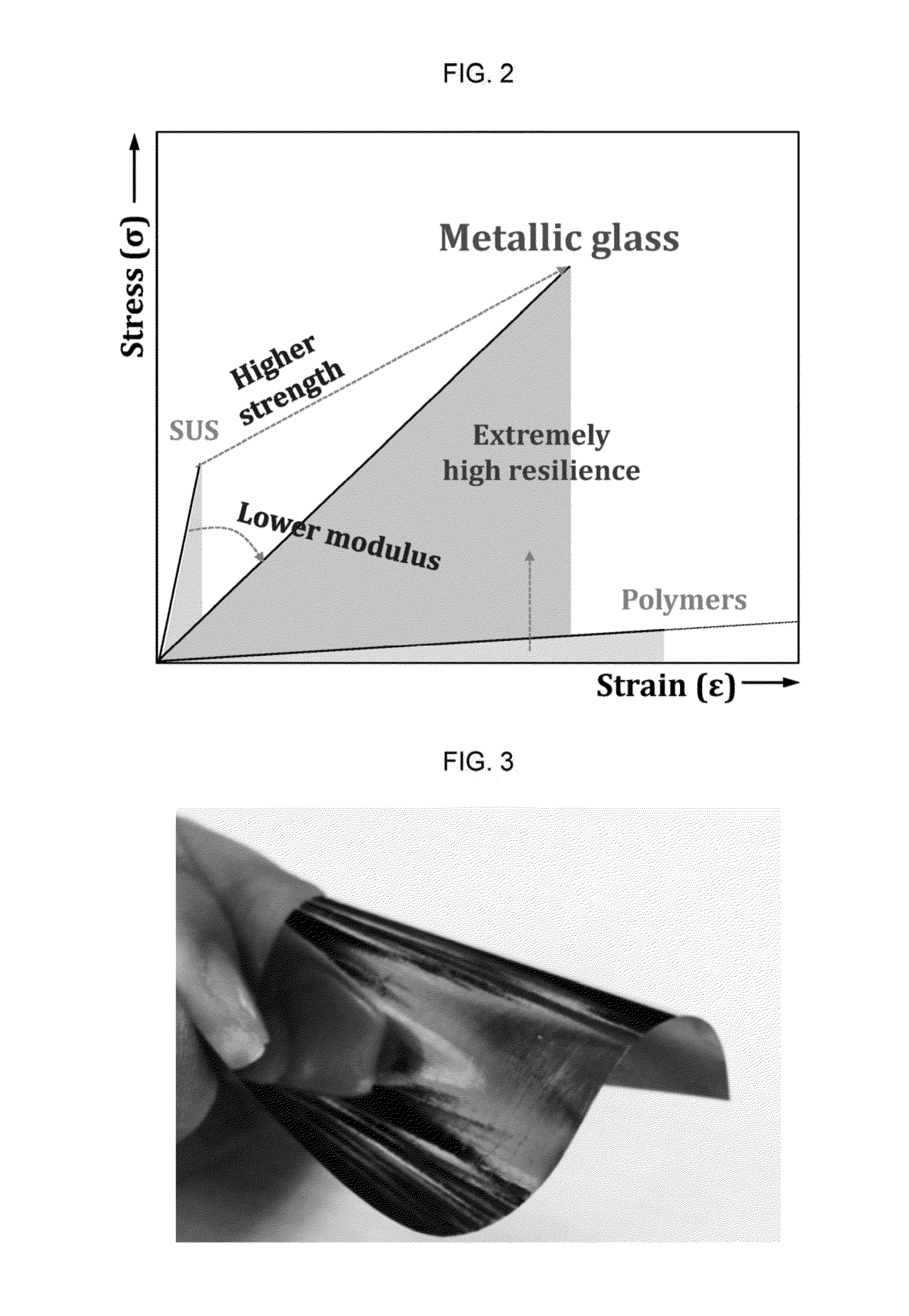

[0040]The flexible metallic glass substrate in accordance with the present invention is described in detail with reference to the drawings.

[0041]The present invention addresses a flexible substrate having high resilience for use in electronic devices, wherein the flexible substrate is made of a commercial amorphous alloy that can be readily produced in a continuous process on a mass scale.

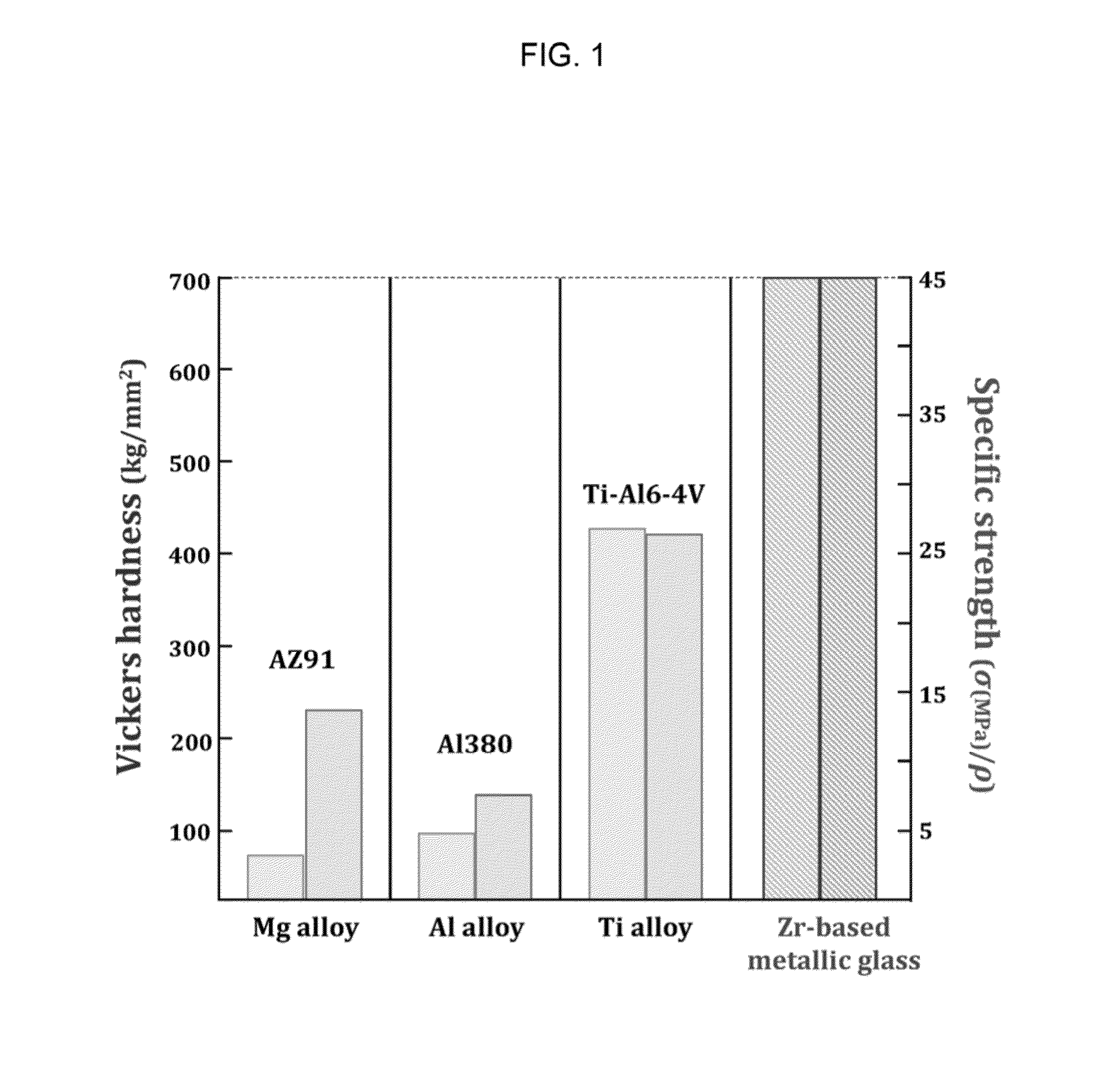

[0042]General metals or alloys form a crystalline structure, that is, a highly ordered structure occurring due to the intrinsic nature of its constituents to form symmetric patterns, whereas metallic glass (amorphous alloy) is a solid in which constituent atoms are in a disordered arrangement. That is, metallic glass is merely a structure in which the positions of constituent atoms in a liquid state are frozen as they are. Metallic glass is typically prepared by heating a master alloy to reach a liquid state and then quenching the molten alloy at a decrease rate of 105 to 106 K / sec into a solid. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com