Method for refining aluminum alloy by using metallic glass

A technology of metallic glass and aluminum alloy, which is applied in the field of aluminum alloy processing, can solve the problems of insignificant structure refinement effect of Al-Si alloy, extremely high purity requirement of aluminum alloy, and narrow application range of alloy system, etc., and achieves huge industrial application Potential and value, optimization of aluminum alloy structure and mechanical properties, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

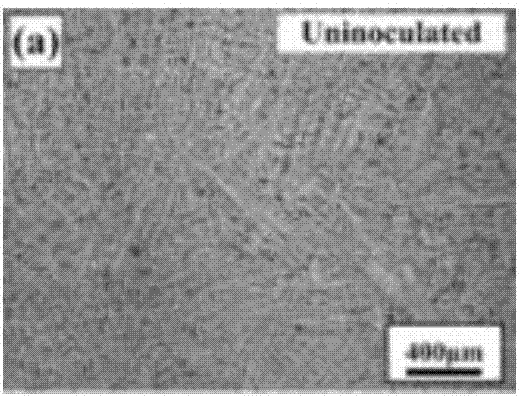

Embodiment 1

[0050] A method for refining aluminum alloys using metallic glass, comprising the steps of:

[0051] Step 1, the preparation of metallic glass:

[0052] a. Polish the surface oxide films of Zr, Cu, Al and Ni, then prepare them in proportion and place them in a beaker filled with absolute alcohol to prevent them from oxidizing;

[0053] b. Stack the prepared Zr, Cu, Al, and Ni in the water-cooled copper mold crucible according to the melting point from low to high, so as to shorten the melting time of high melting point metals and prevent the volatilization of low melting point metals;

[0054] c. Cover the furnace cover and vacuumize twice before the formal smelting, each time the vacuum reaches 6.0×10 -3 Pa and filled with high-purity Ar gas to dilute residual oxygen;

[0055] d. After two times of vacuuming, fill it with high-purity Ar gas of 0.5 atmospheres to dilute the residual oxygen in the furnace;

[0056] e. Turn on the magnetic stirring to smelt the alloy. In orde...

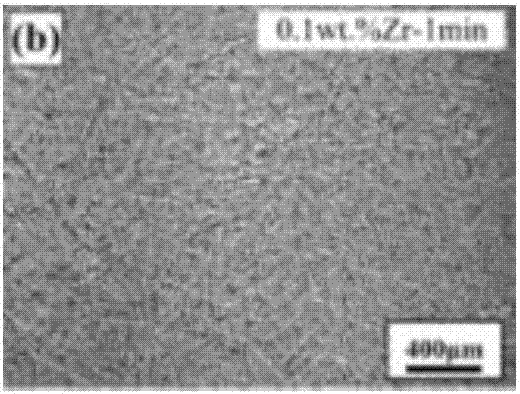

Embodiment 2

[0077] A method for refining aluminum alloys using metallic glass, comprising the steps of:

[0078] Step 1, the preparation of metallic glass:

[0079] a. Polish the surface oxide films of Zr, Cu, Al and Ni, then prepare them in proportion and place them in a beaker filled with absolute alcohol to prevent them from oxidizing;

[0080] b. Stack the prepared Zr, Cu, Al, and Ni in the water-cooled copper mold crucible according to the melting point from low to high, so as to shorten the melting time of high melting point metals and prevent the volatilization of low melting point metals;

[0081] c. Cover the furnace cover and vacuumize twice before the formal smelting, each time the vacuum reaches 6.0×10 -3 Pa and filled with high-purity Ar gas to dilute residual oxygen;

[0082] d. After two times of vacuuming, fill it with high-purity Ar gas of 0.5 atmospheres to dilute the residual oxygen in the furnace;

[0083] e. Turn on the magnetic stirring to smelt the alloy. In orde...

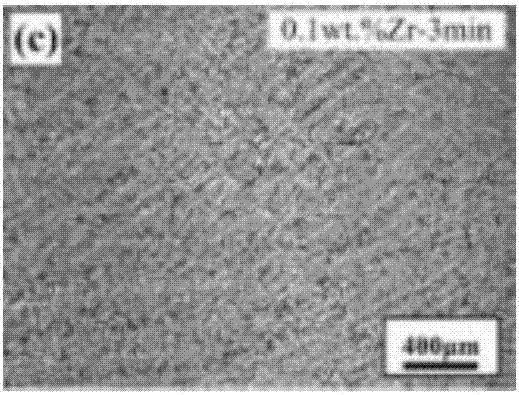

Embodiment 3

[0104] A method for refining aluminum alloys using metallic glass, comprising the steps of:

[0105] Step 1, the preparation of metallic glass:

[0106] a. Polish the surface oxide films of Zr, Cu, Al and Ni, then prepare them in proportion and place them in a beaker filled with absolute alcohol to prevent them from oxidizing;

[0107] b. Stack the prepared Zr, Cu, Al, and Ni in the water-cooled copper mold crucible according to the melting point from low to high, so as to shorten the melting time of high melting point metals and prevent the volatilization of low melting point metals;

[0108] c. Cover the furnace cover and vacuumize twice before the formal smelting, each time the vacuum reaches 6.0×10 -3 Pa and filled with high-purity Ar gas to dilute residual oxygen;

[0109] d. After two times of vacuuming, fill it with high-purity Ar gas of 0.5 atmospheres to dilute the residual oxygen in the furnace;

[0110] e. Turn on the magnetic stirring to smelt the alloy. In orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture strain | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com