Amorphous alloy composition design method based on thermodynamics factors and structural factors

An amorphous alloy and composition design technology, applied in the field of amorphous alloy composition design, can solve the problems of low accuracy of amorphous alloy and difficulty in accurately calculating the value of valence electron concentration, etc., so as to achieve easy understanding and mastery, and reduce errors efficiency, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

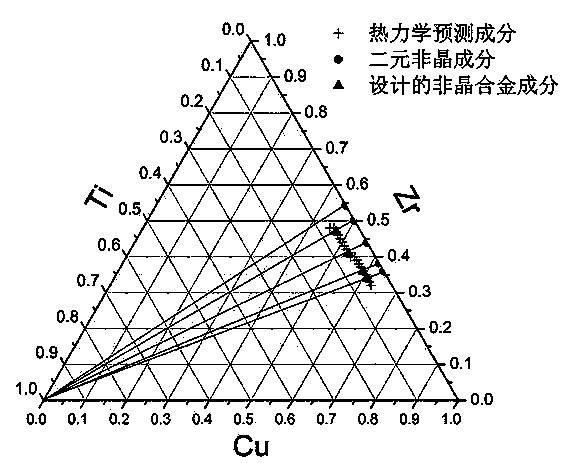

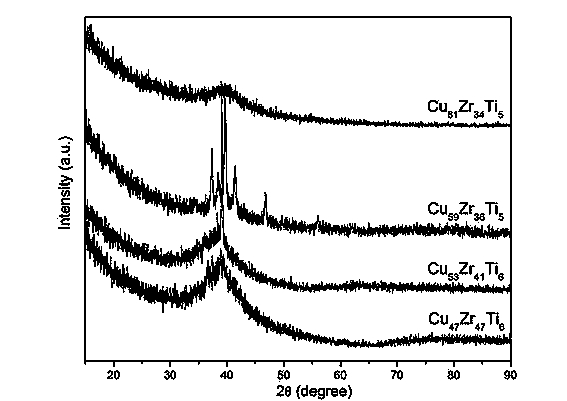

[0028] Taking the Cu-Zr-Ti alloy system as an example, since the Cu-Zr binary alloy has a good ability to form amorphous, Cu-Zr is selected as the basic binary alloy. Then, because the Zr atomic radius is 9.6% larger than the Ti atomic radius, and the Cu atomic radius is 12.6% smaller than the Ti atomic radius, according to the empirical principle that the atomic radius difference between the three main elements in the alloy system is greater than 12%, Ti is selected. element is the third component.

[0029] From the five Cu-Zr binary alloy composition points in the ternary alloy diagram (Cu 61.8 Zr 38.2 , Cu 56 Zr 44 , Cu 45.7 Zr 54.3 , Cu 64 Zr 36 , Cu 50 Zr 50 ) to connect the Ti endpoints to obtain the atomic structure prediction composition line. If the binary alloy has multiple amorphous composition points, then there will be multiple such atomic structure prediction composition lines in the ternary alloy diagram. Then calculate the Cu-Zr-Ti ternary alloy at e...

example 2

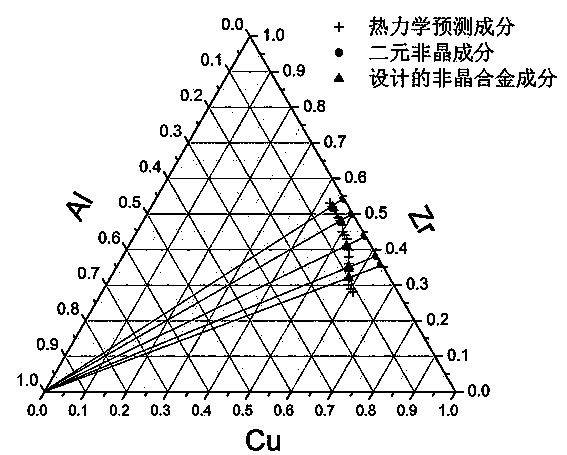

[0033] Taking the Cu-Zr-Al alloy system as an example, Cu-Zr is chosen as the basic binary alloy because of its good amorphous forming ability. Then, because the atomic radius of Zr is 11.9% larger than that of Al, and the atomic radius of Cu is 12.0% smaller than that of Al, according to the empirical principle that the atomic radius difference between the three main elements in the alloy system is greater than 12%, Al is selected. element is the third component.

[0034] From the five Cu-Zr binary alloy composition points in the ternary alloy diagram (Cu 61.8 Zr 38.2 , Cu 56 Zr 44 , Cu 45.7 Zr 54.3 , Cu 64 Zr 36 , Cu 50 Zr 50 ) to connect the Al endpoints to obtain the atomic structure prediction composition line. If the binary alloy has multiple amorphous composition points, then there will be multiple such atomic structure prediction composition lines in the ternary alloy diagram. Then calculate the estimated value of Cu-Zr-Al ternary alloy ΔHh·ΔHmix·Sconfig at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com