High-vacuum high-speed rotating magnetic transmission device of friction testing machine

A high-speed rotation, magnetic transmission technology, applied in the direction of using mechanical devices, measuring devices, testing wear resistance, etc., can solve problems such as difficulty in meeting high sealing and high-speed transmission at the same time, inaccurate speed control, and inconvenient speed adjustment. To achieve the effect of simple structure, easy maintenance and improved transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

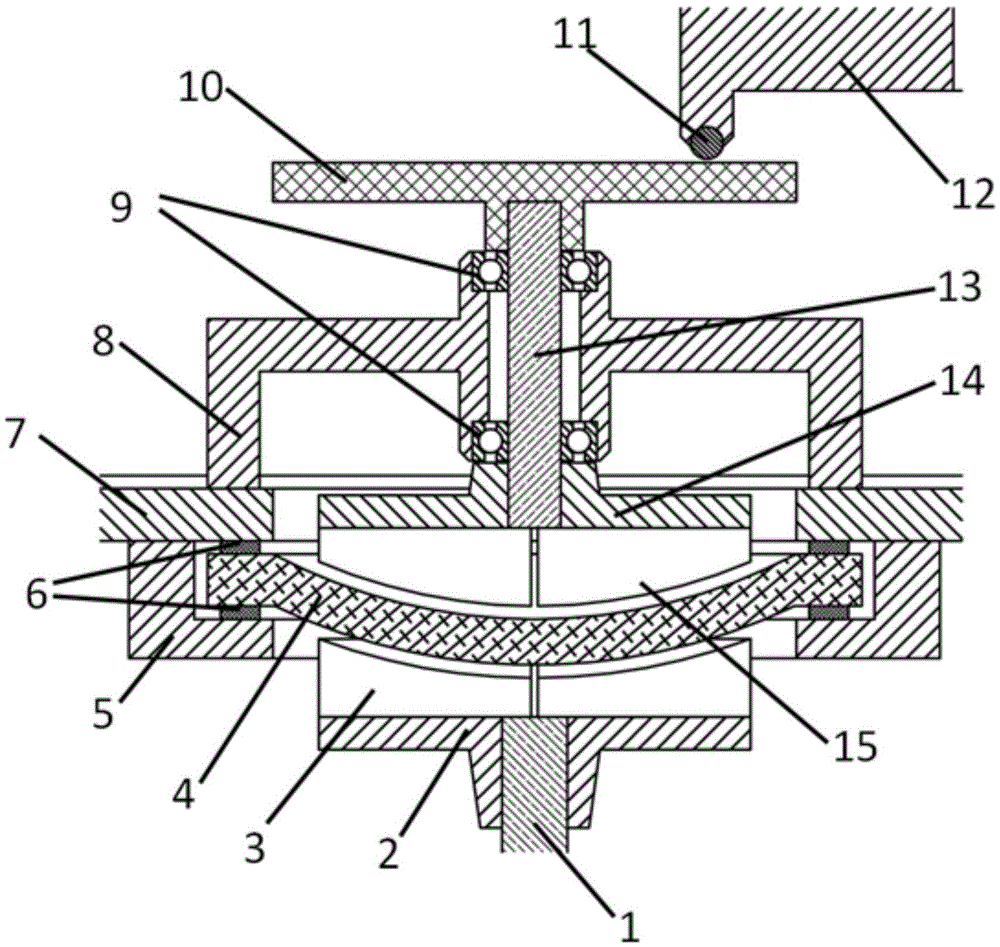

[0025] Such as figure 1 As shown, this embodiment provides a magnetic transmission device for a high-vacuum high-speed rotary friction and wear testing machine, which includes an outer driving shaft 1, an inner driven shaft 13 and a quartz isolation component 4, and also includes an outer permanent magnet fixing seat 2, an outer Permanent magnet 3, end cover 5, gasket 6, vacuum chamber base 7, bearing bracket 8, rolling bearing 9, turntable 10, friction sample 11, loading rod 12, inner permanent magnet fixing seat 14 and inner permanent magnet 15, the concave The outer permanent magnet 3 is fixed on the outer permanent magnet holder 2, the outer permanent magnet holder 2 is fixed on the outer drive shaft 1, the outer drive shaft 1 is connected to the power motor shaft, and the convex inner permanent magnet 15 is fixed on the inner permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com