Constant-pressure vortex pump

A technology of vortex pumps and pump bodies, which is applied in the field of vortex pumps and water pumps, and can solve problems such as head drop, low hydraulic efficiency, and high operating noise, and achieve the effects of increasing liquid kinetic energy, improving operating efficiency, and reducing eddy current losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

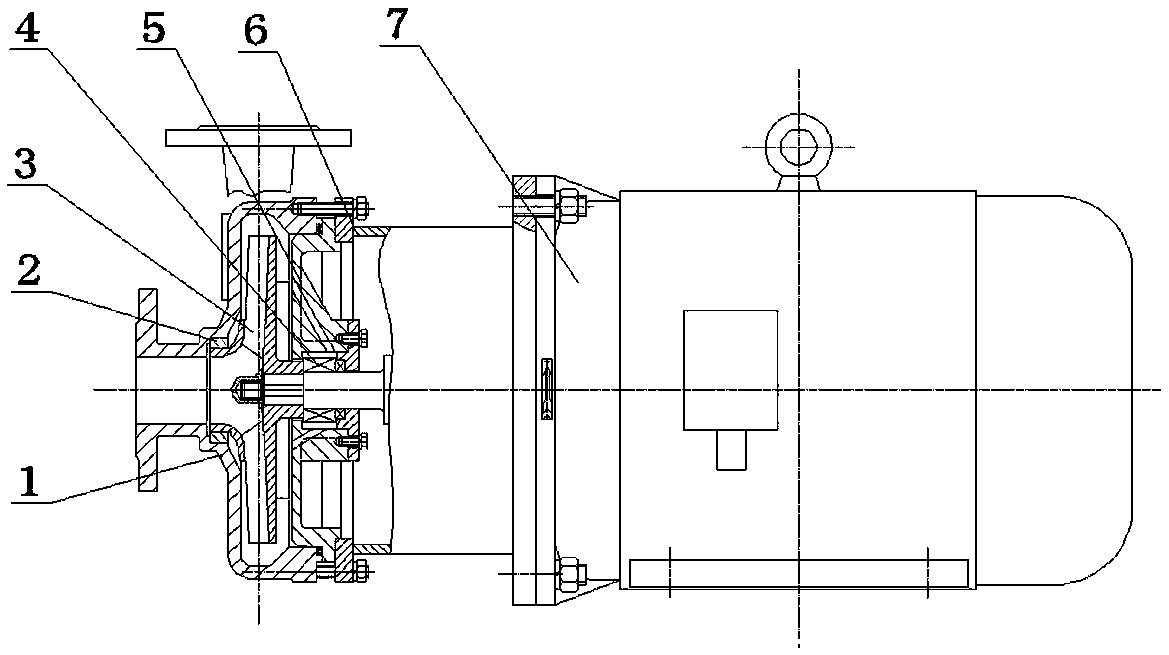

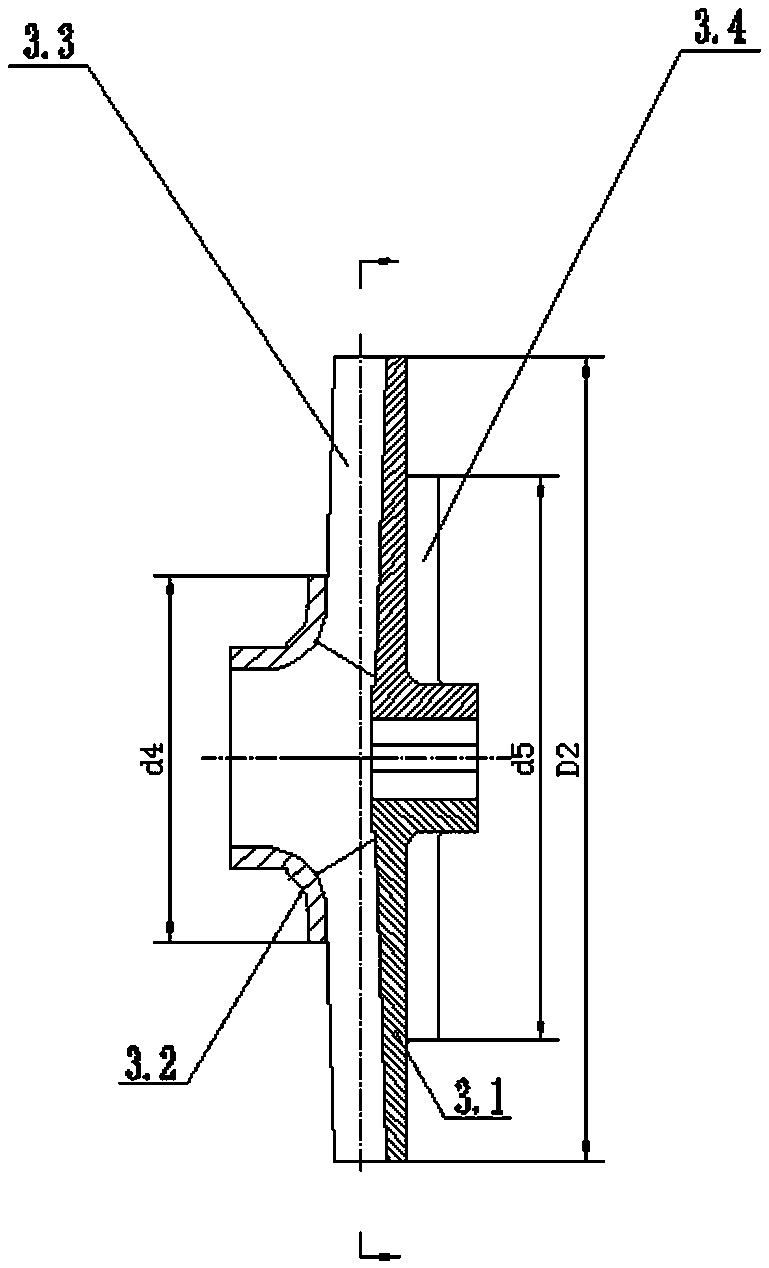

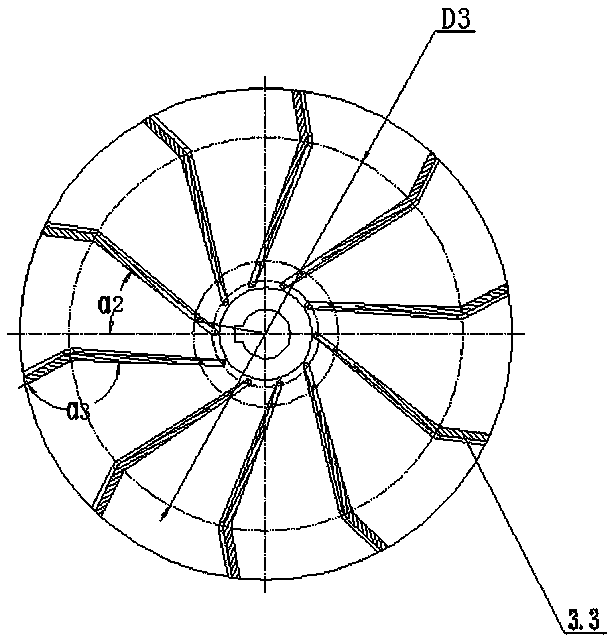

[0018] figure 1 The shown constant pressure vortex pump includes a pump body 1 , a seal ring 2 , an impeller 3 , a mechanical seal 4 , a pump cover 5 , a bracket 6 and a motor 7 . The suction end of the pump body 1 is provided with a seal ring 3 matching with the inlet of the impeller 3, and the pump cover 5 with the built-in mechanical seal 4 is coaxially sealed with the pump body 1, and the pump cover 5 is connected with the motor 7 through the bracket 6 as a whole. The output shaft end of the motor 7 axially passes through the mechanical seal 4 , and the protruding shaft end is used for installing the impeller 3 . The impeller 3 is as figure 2 , image 3 and Figure 4 As shown, it is a disc-shaped member with a diameter of D2 and a semi-open structure. The impeller 3 in this embodiment is mainly composed of 10 main blades 3.3 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com