Patents

Literature

94results about How to "Reduced eddy current loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

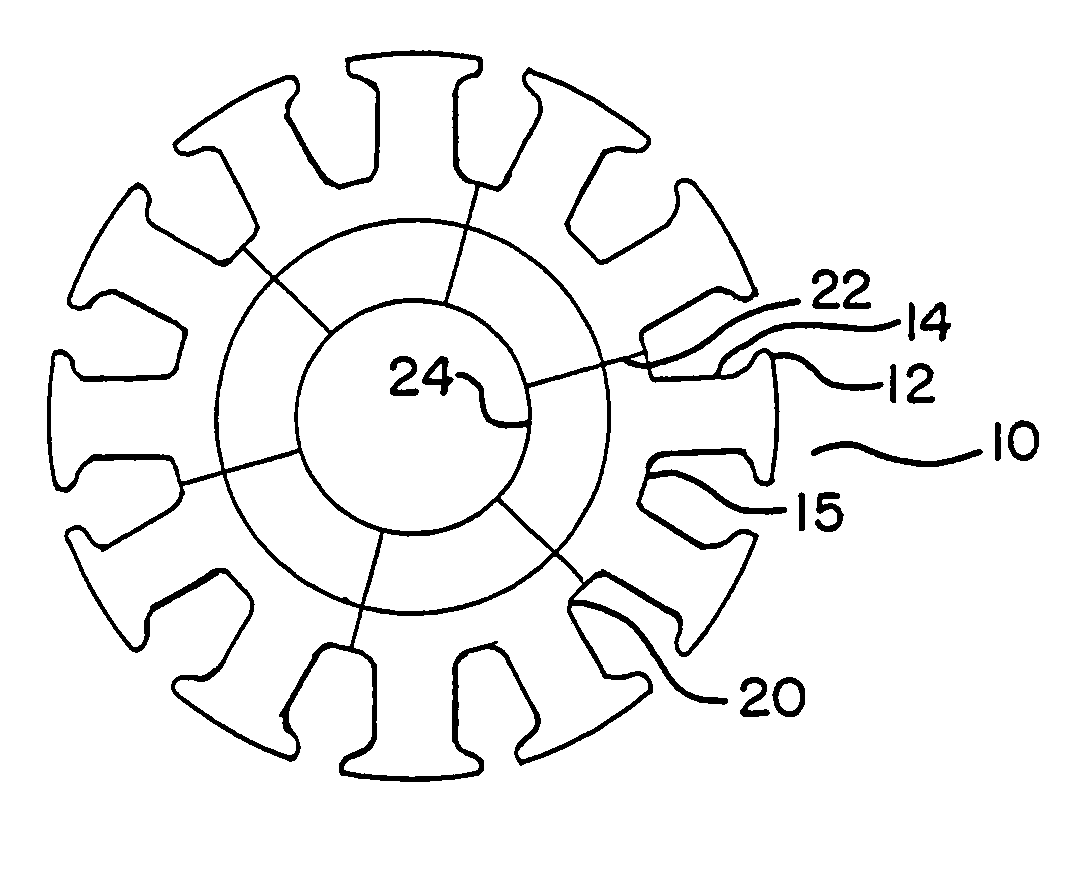

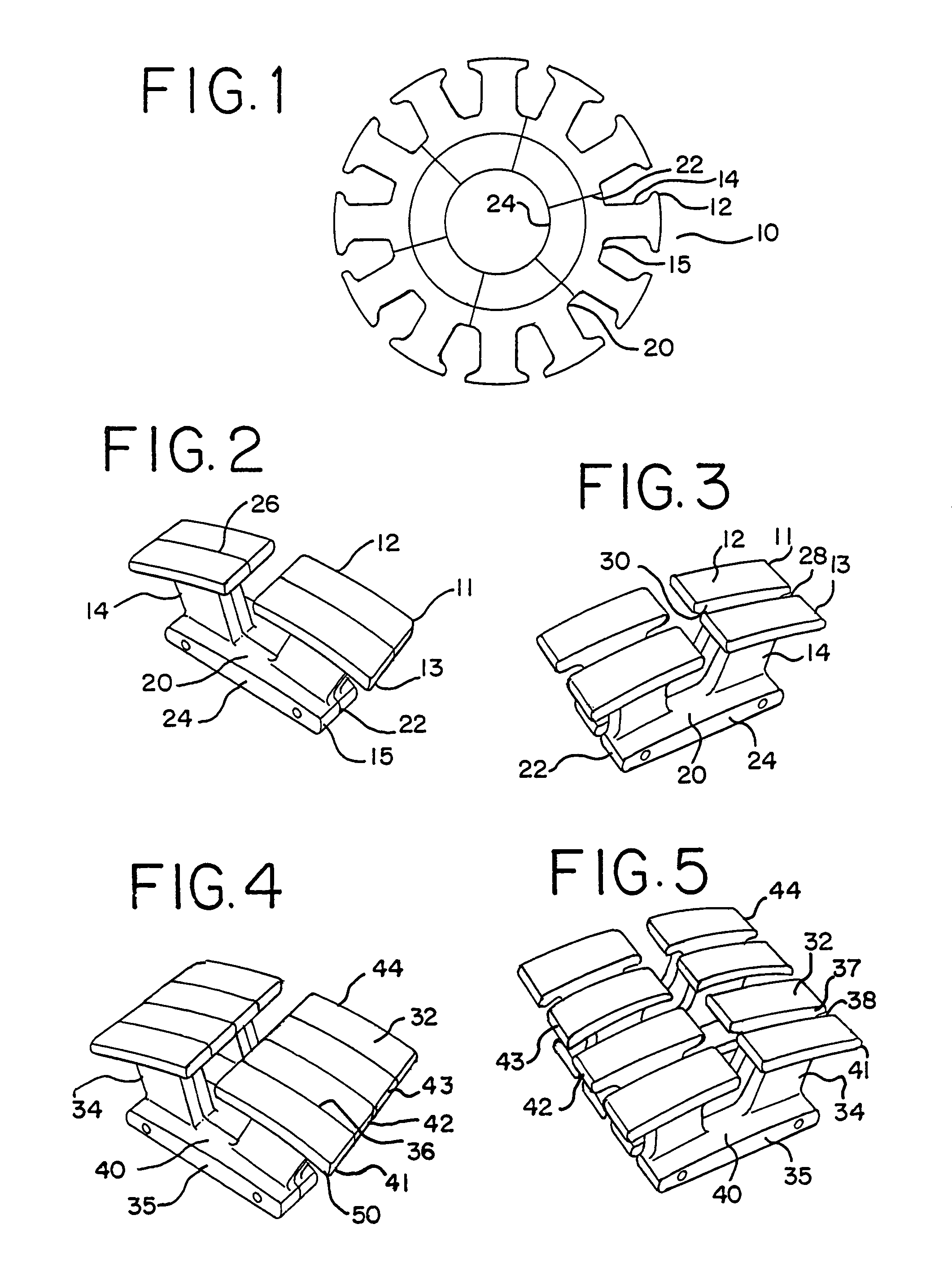

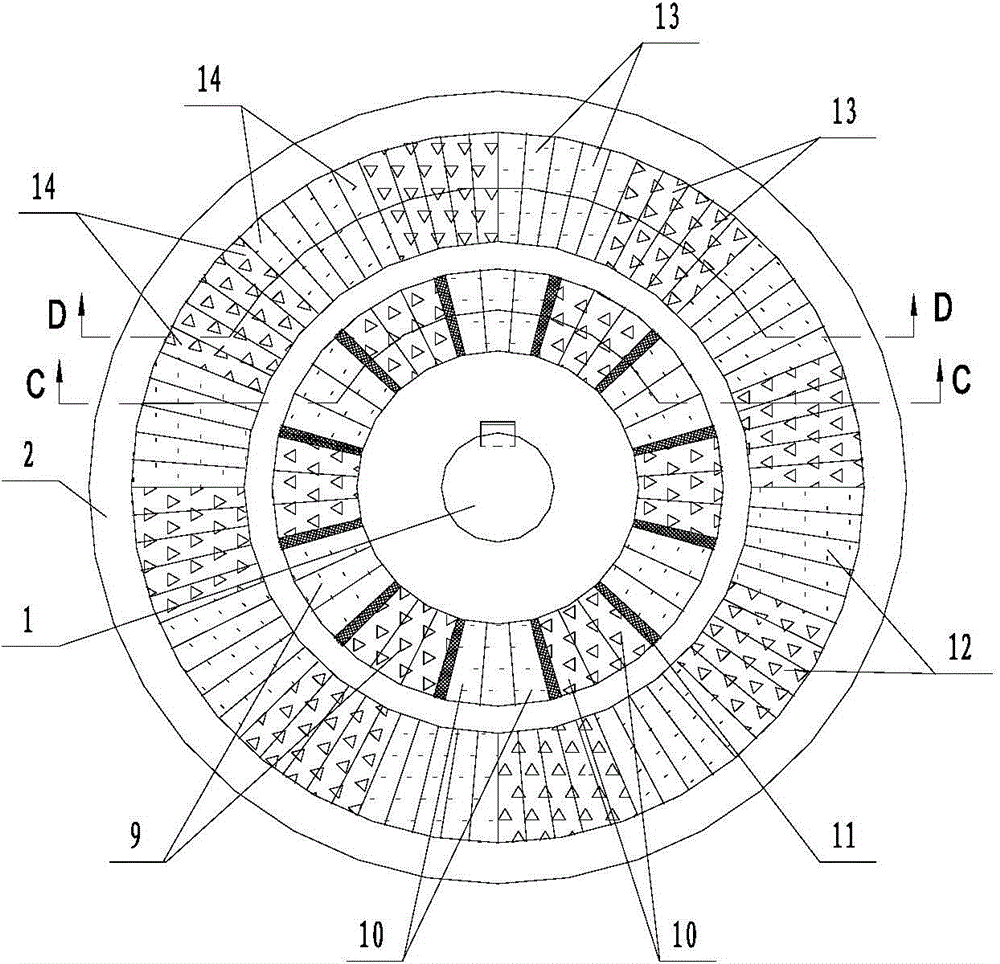

Soft magnetic composite powder metal cores

ActiveUS6956307B2Reduced eddy current lossImprove performanceWindingsMagnetic circuit rotating partsNuclear engineeringCore component

A stator core assembly for use in an electrical machine is provided. The stator core assembly includes a plurality of core components. Each core component forms an arcuate section of the stator core assembly. Each core component is comprised of at least two core component sections, with each core component section adjacent another core component section. Each core component section is formed of a ferrous magnetic powder metal particles which are generally mutually insulated. Such ferrous magnetic powder metal particles are pressure formed into the core component section.

Owner:BURGESS NORTON MFG

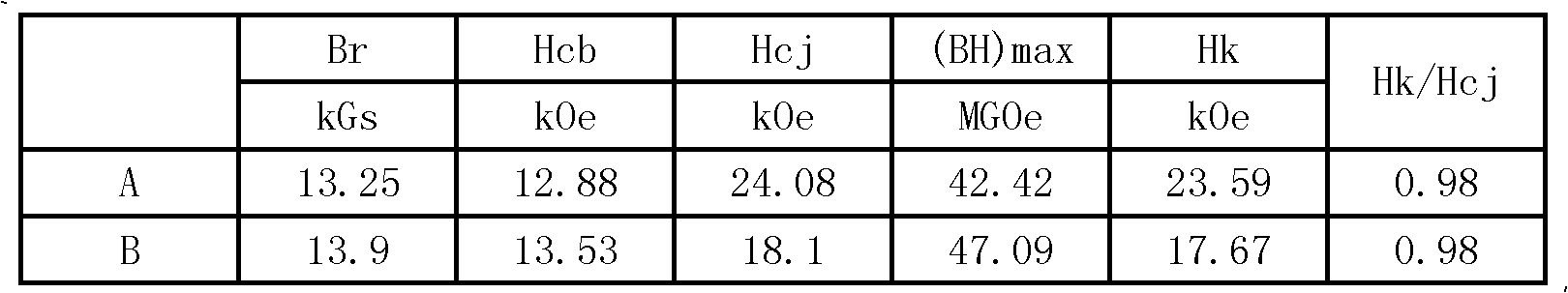

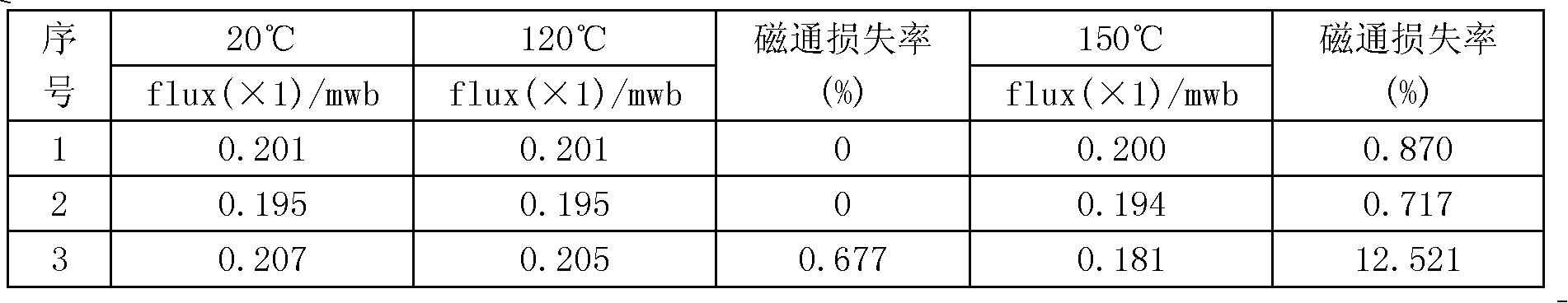

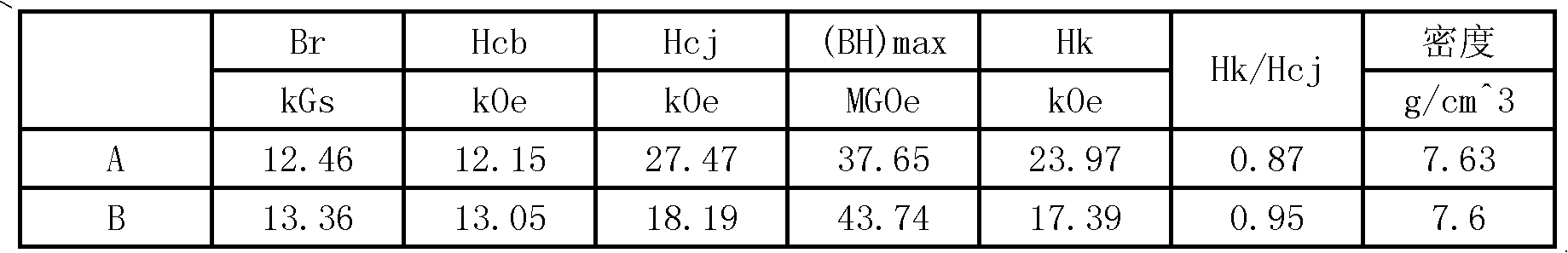

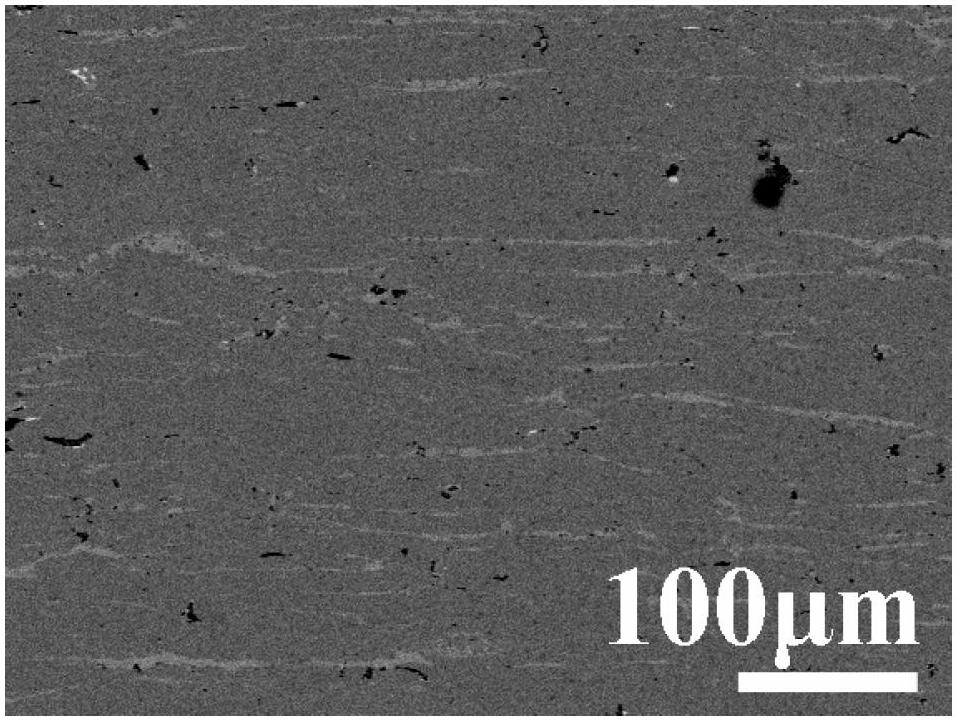

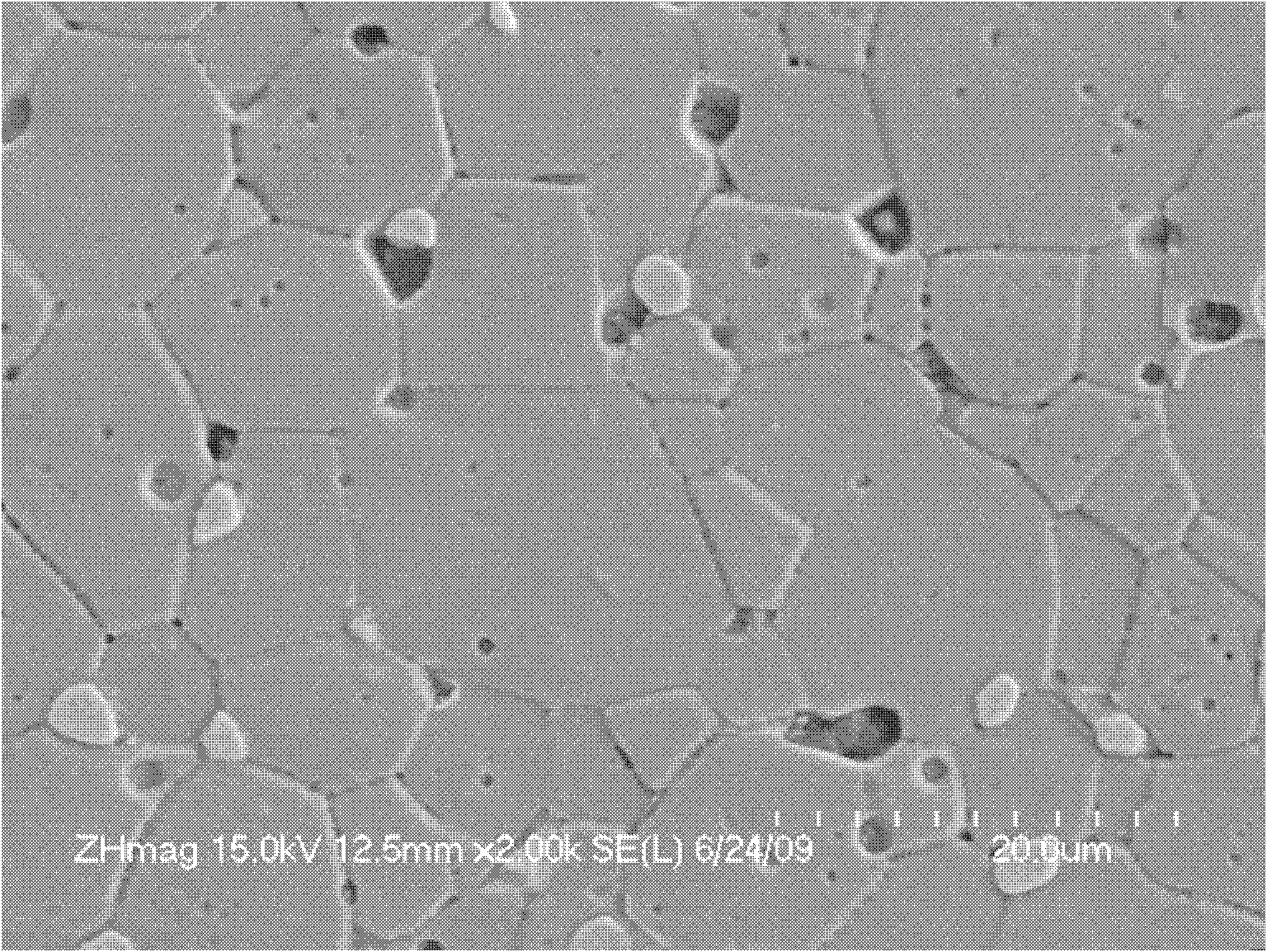

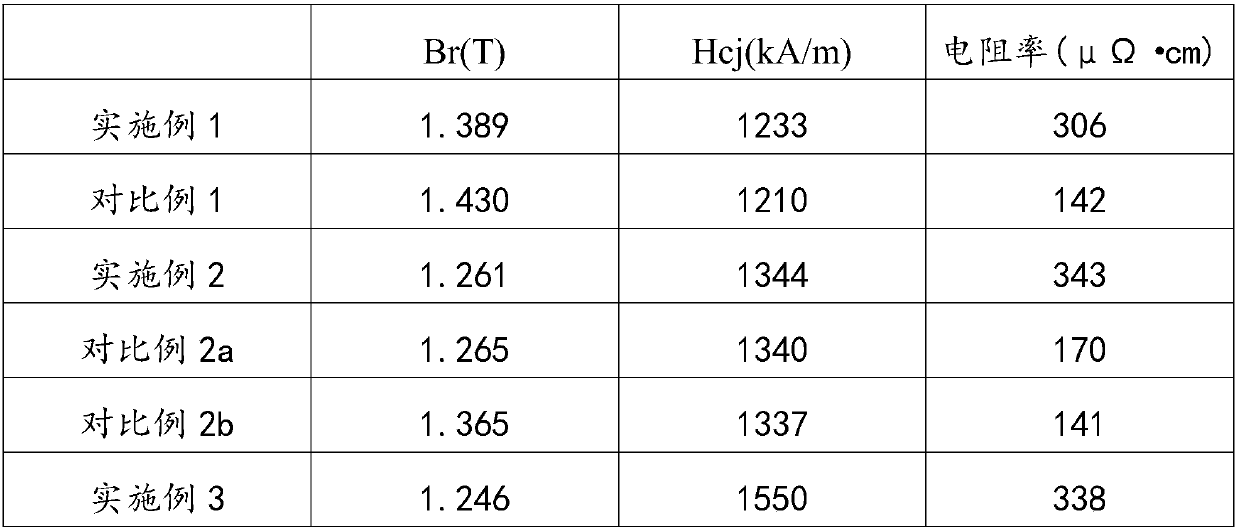

Gradient coercive-force neodymium-ferrum-boron magnet and production method thereof

ActiveCN101847487AReduced eddy current lossReduce thermal demagnetizationPermanent magnetsInorganic material magnetismSurface layerMagnetic characteristic

The invention discloses a gradient coercive-force neodymium-ferrum-boron magnet and a production method thereof, and relates to a neodymium-ferrum-boron permanent-magnet material with the gradient coercive-force. The invention aims to provide the gradient coercive-force neodymium-ferrum-boron magnet with high magnetic characteristics and high demagnetization resistance and the production method thereof. The gradient coercive-force neodymium-ferrum-boron magnet comprises at least two neodymium-ferrum-boron magnetic material layers with different coercive forces, including a high coercive force surface layer and at least one low coercive force middle layer, wherein the high coercive force surface layer is connected with the low coercive force middle layer in the orientating direction through a sintered layer.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

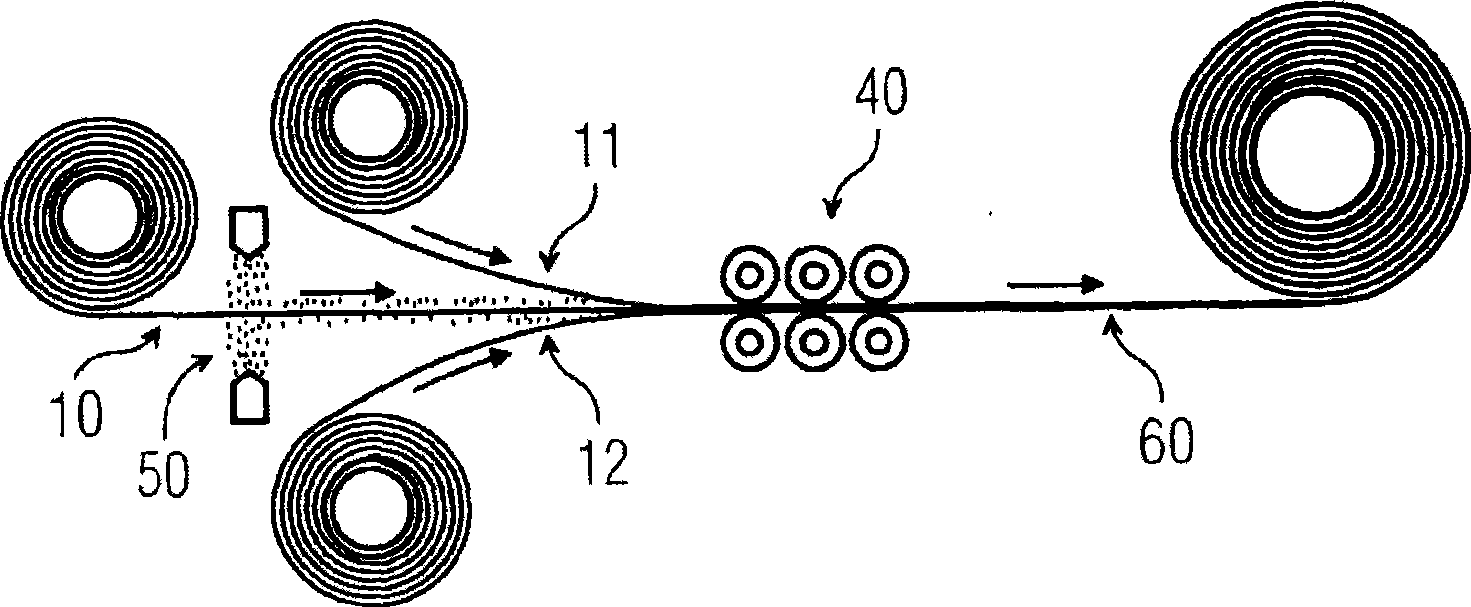

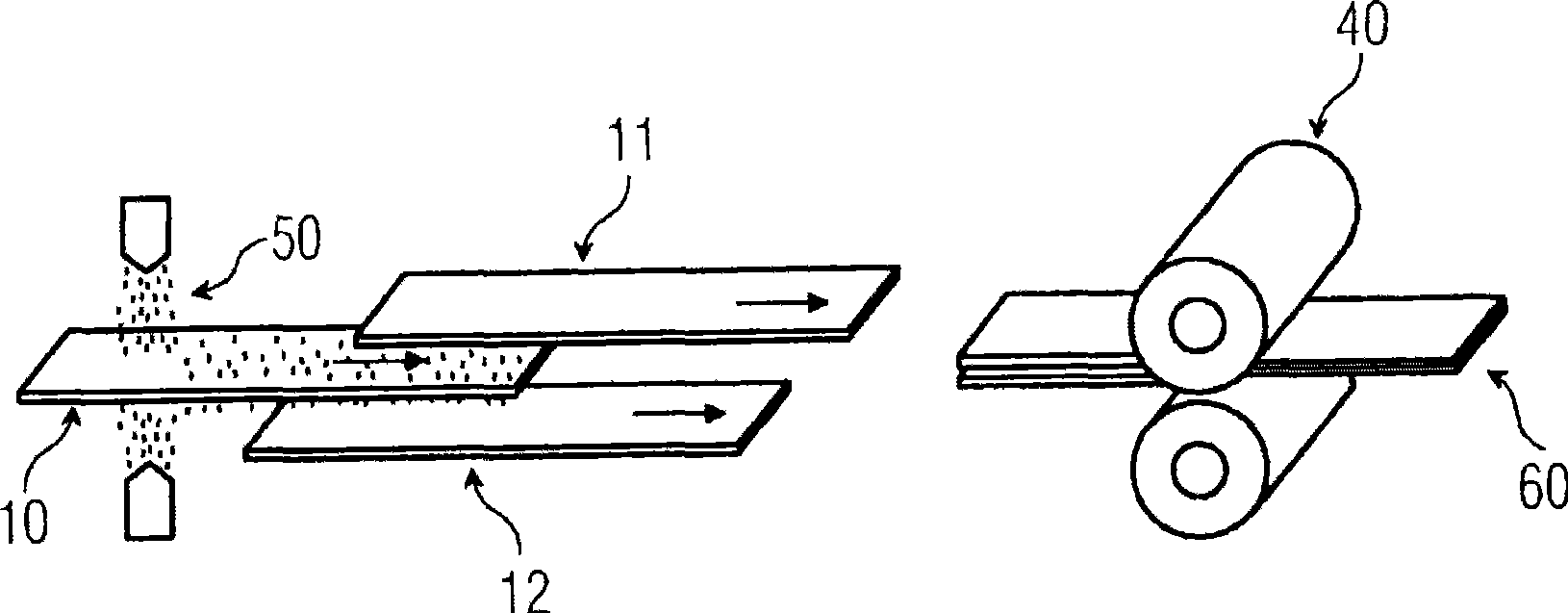

Method for lamination of an electrical strip for transformer cores

InactiveCN101438358AFirmly connectedImprove mechanical stabilityInorganic material magnetismTransformers/inductances detailsTransformerThin layer

The invention relates to a method for production of ferromagnetic core laminates for electrical machines. The invention likewise relates to a ferromagnetic core laminate (16). Core laminates with very thin layers of the individual electrical strips can be produced by a structure formed from layers of the electrical strips (10, 11, 12) and by the electrical strips being connected by means of a connection layer (30), in particular an adhesive layer. This makes it possible to produce cores formed from layers of core laminate for electromagnetic machines, whose eddy-losses are reduced.

Owner:SIEMENS AG

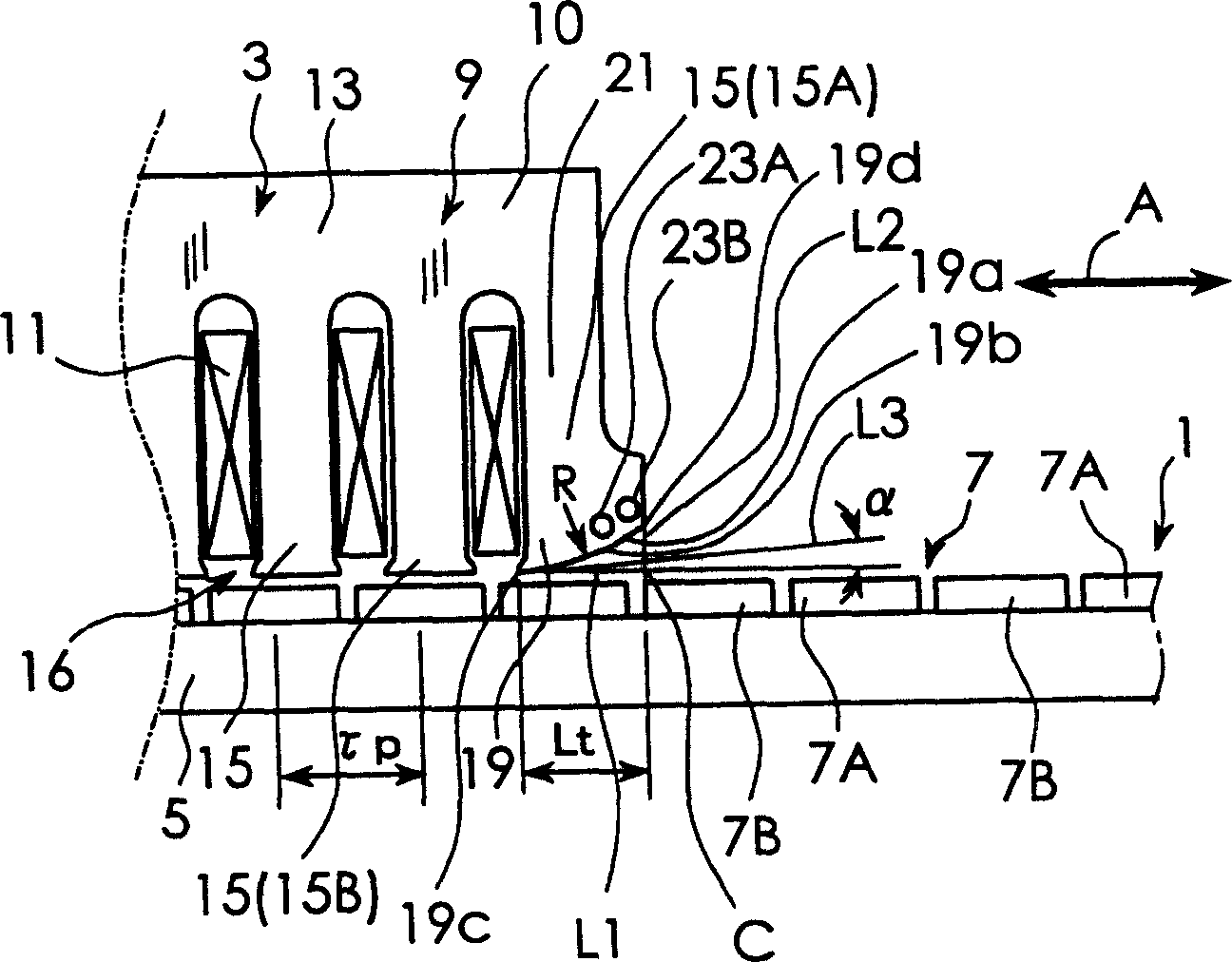

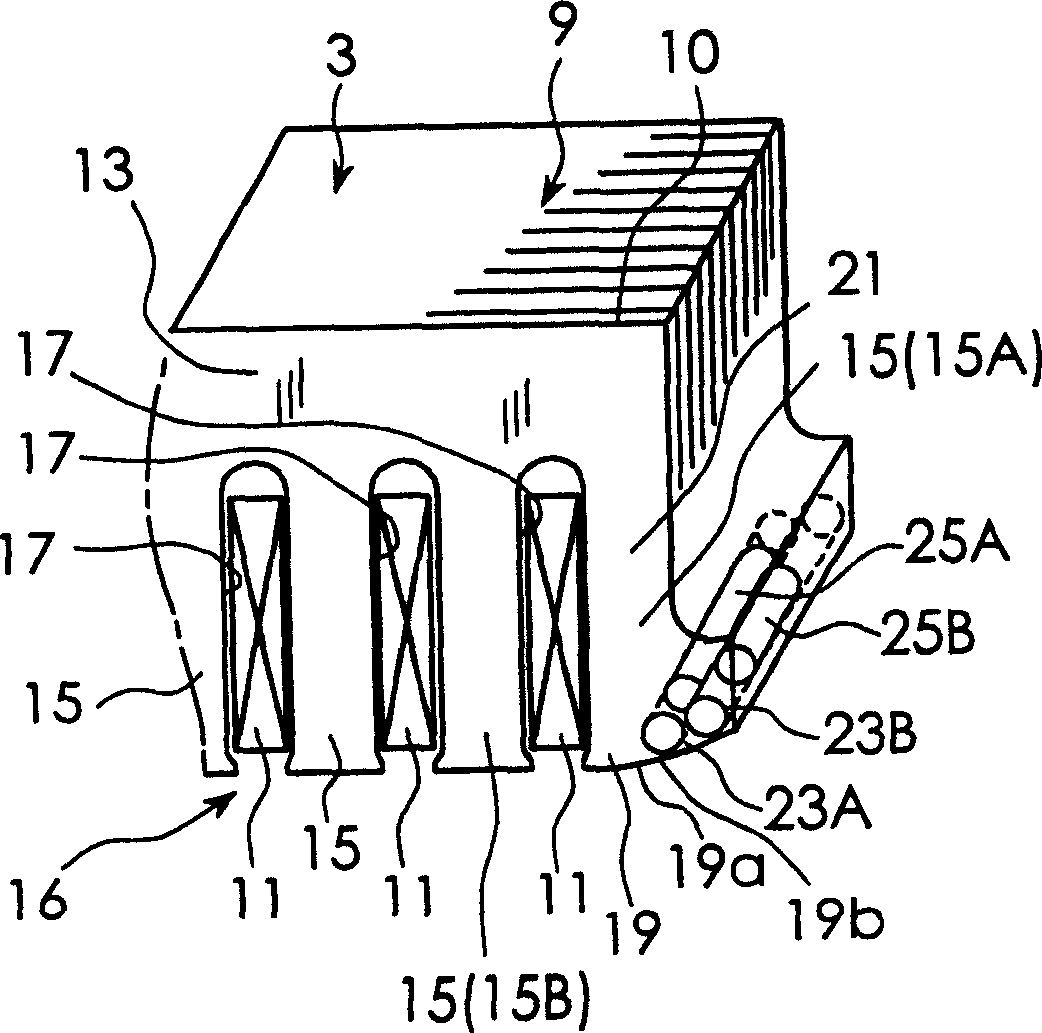

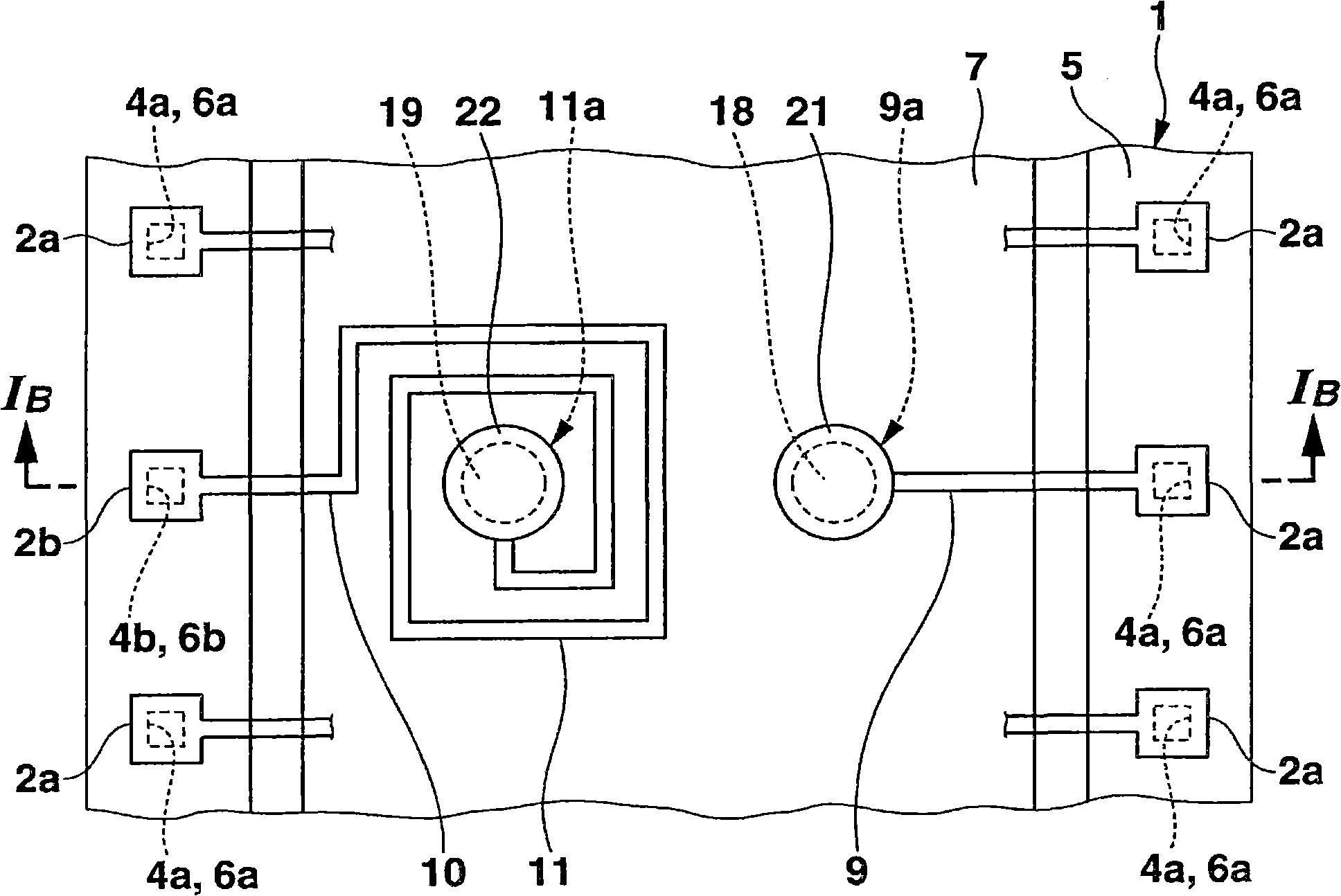

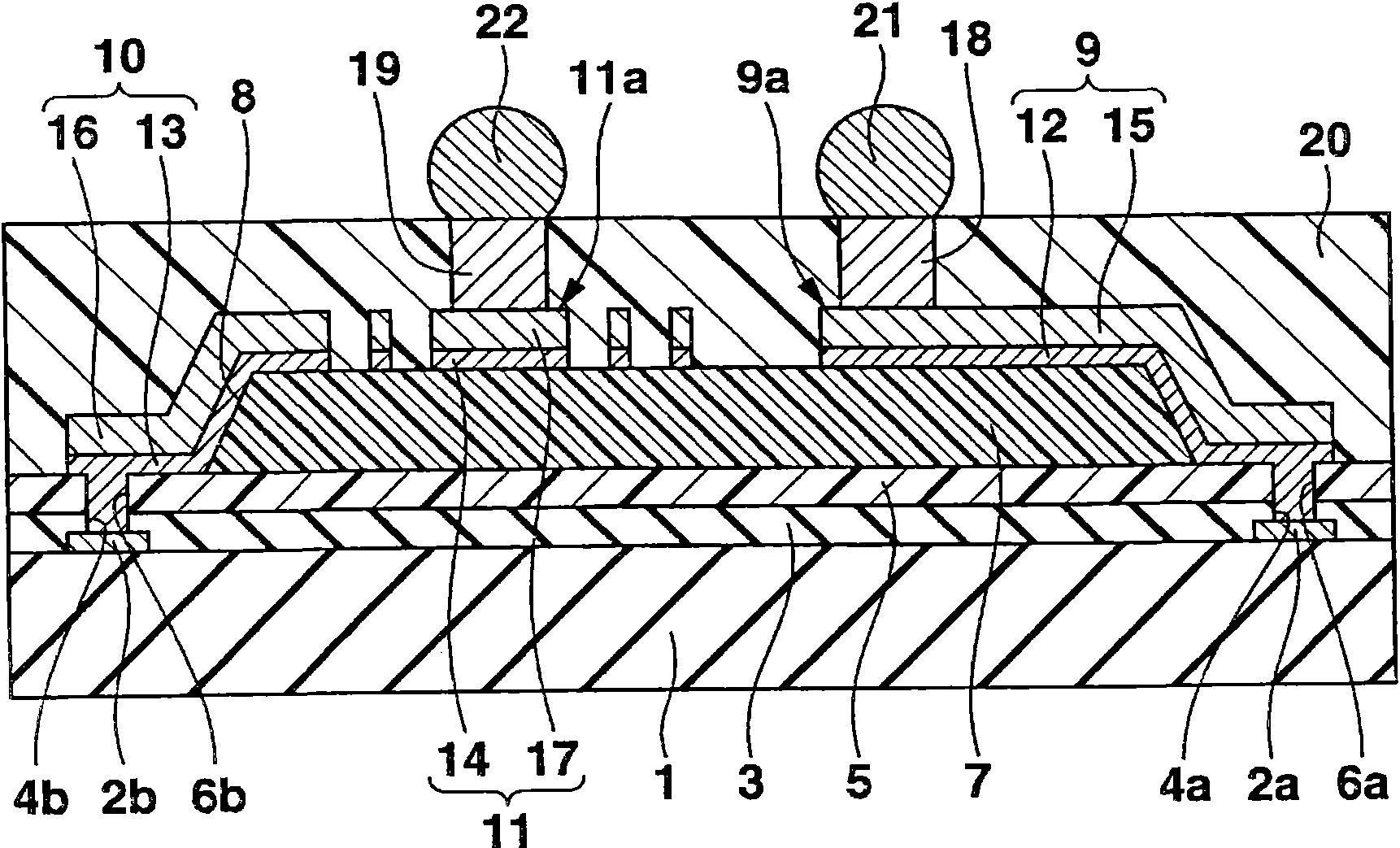

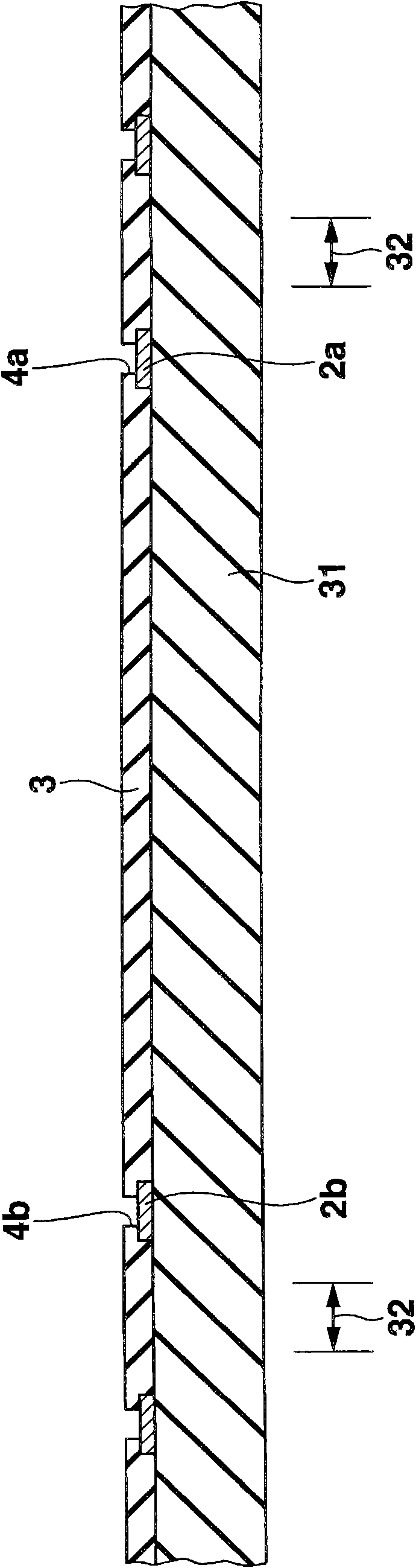

Linear motor

InactiveCN1592051AReduce stressWell formedManufacturing dynamo-electric machinesPropulsion systemsMagnetic polesLinear motor

There is provided a linear motor in which the shape of magnetic pole surfaces of pole teeth located at both ends of a plurality of pole teeth can be easily formed to be suitable for reducing cogging force. Each of magnetic pole surfaces 19a of pole teeth 15A located at both ends of a plurality of pole teeth 15 is constituted by an arc-shaped curved surface so curved that a gap from a stator 1 increases with increasing distance from other adjacent pole tooth 15B. Through holes 23A and 23B that extend in the laminating direction of electromagnetic steel plates 10 are formed in the vicinity of the magnetic pole surfaces 19a of the pole teeth 15A. Inside the through holes 23A and 23B, magnetic pieces shorter than the thickness of the electromagnetic steel plates in their laminating direction are so arranged as to leave spaces at both ends of the through holes 23A and 23B.

Owner:SANYO DENKI CO LTD

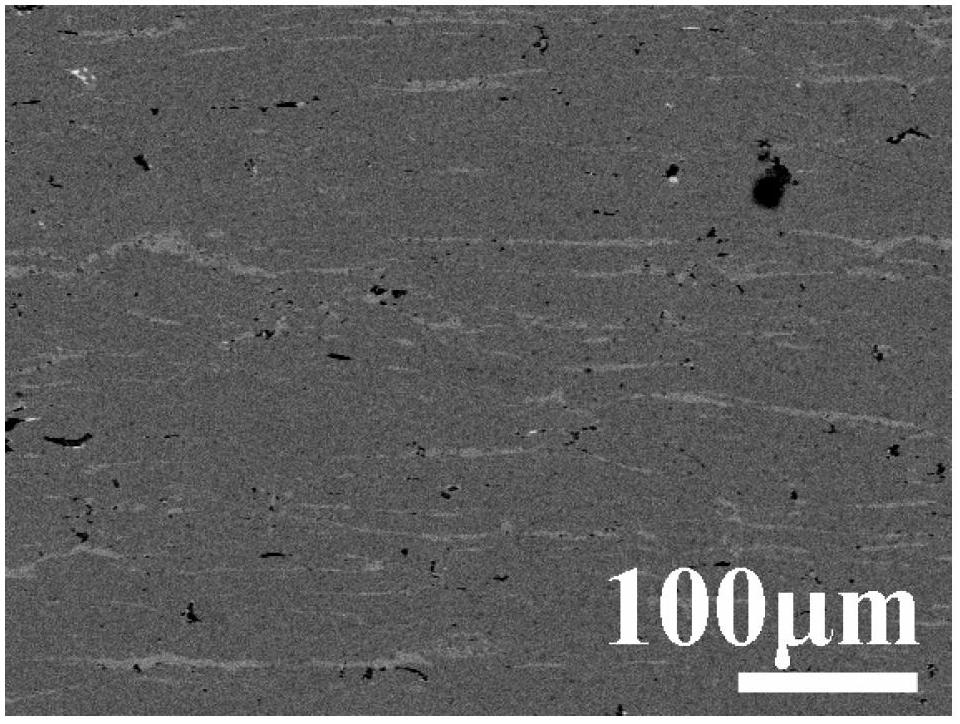

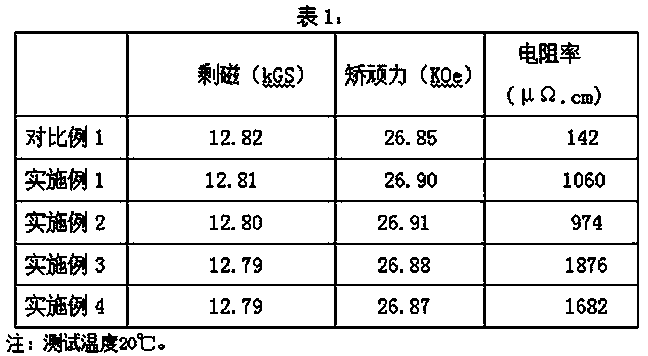

High-resistivity permanent magnetic alloy and preparing method thereof

ActiveCN102682949AHigh resistivityHigh energy productPermanent magnetsMagnetic materialsActive agentHigh energy

The invention belongs to the field of preparation of permanent magnetic materials, and in particular relates to a high-resistivity permanent magnetic alloy and a preparing method thereof. A powder material of the alloy consists of Nd-Fe-B alloy powder and a solid surface active agent insulating layer coated on the surface of the powder, the solid surface active agent is at least one of fluorides or oxides of Li, Na, Mg, Ca, Sr, Ba, Nd, Dy, Tb, Gd and Ho, and is 5-15% of the Nd-Fe-B alloy powder; and the grain diameter of the Nd-Fe-B alloy powder is in a micron stage of 0.5-8 microns, and the grain diameter of the solid surface active agent is in a nanometer stage of 1-100nm. According to the high-resistivity permanent magnetic alloy disclosed by the invention, the resistivity rho is larger than or equal to 1.0m omega cm, and the maximum magnetic energy product (BH) max is larger than or equal to 38MGsOe. The high-resistivity permanent magnetic alloy disclosed by the invention largely reduces vortex loss, simultaneously keeps low costs of a motor and an engine and can be applied to devices, such as high-energy-efficiency motors and high-speed generators.

Owner:CENT IRON & STEEL RES INST

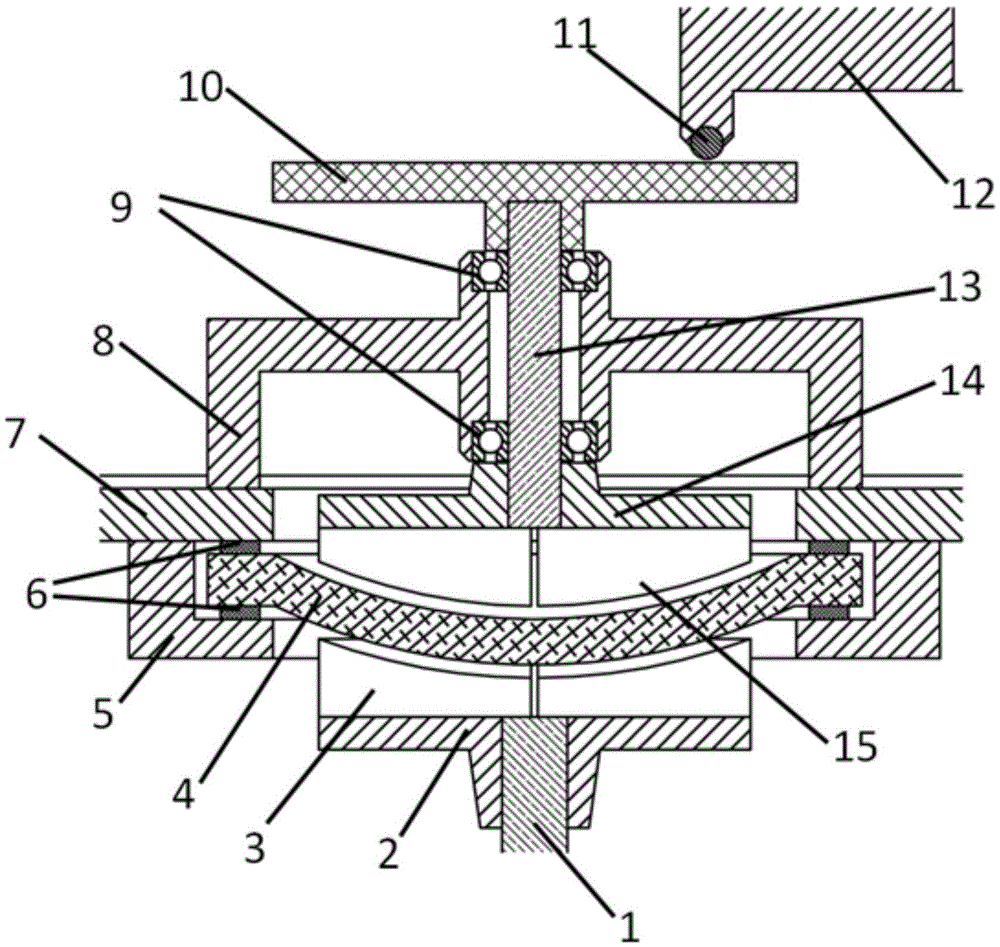

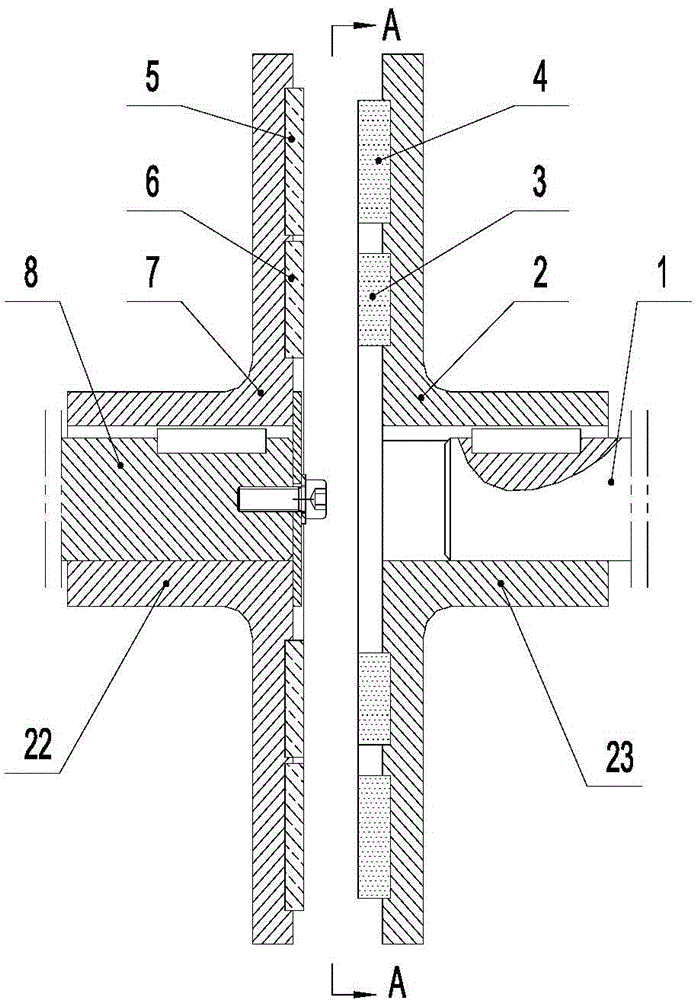

High-vacuum high-speed rotating magnetic transmission device of friction testing machine

ActiveCN105628602AHigh vacuum sealing requirementsReduced eddy current lossUsing mechanical meansInvestigating abrasion/wear resistanceDrive shaftEngineering

The invention relates to a high-vacuum high-speed rotating magnetic transmission device of a friction testing machine. The high-vacuum high-speed rotating magnetic transmission device comprises an outer driving shaft, an inner driven shaft, an inner permanent magnet, an inner permanent magnet fixing seat, an outer permanent magnet, an outer permanent magnet fixing seat, a rotating disc, a bearing support, a quartz separation component and a loading rod. The inner permanent magnet fixing seat is fixed to the lower portion of the inner driven shaft, and the inner permanent magnet is fixed to the lower portion of the inner permanent magnet fixing seat. The outer permanent magnet is opposite to the inner permanent magnet and fixed to the upper portion of the outer permanent magnet fixing seat, the outer permanent magnet fixing seat an the outer driving shaft are fixedly connected, and the inner permanent magnet and the outer permanent magnet are separated through the profiled quartz separation component. The quartz separation component and the bearing support cooperate to seal the inner driven shaft, the inner permanent magnet fixing seat and the inner permanent magnet in a sealed vacuum space. The outer driving shaft and the inner driven shaft are coaxially arranged. The rotating disc and the upper portion of the inner driven shaft are fixedly connected in a sealed mode. The loading rod is arranged above the rotating disc, and a friction test piece on the loading rod makes contact with the rotating disc.

Owner:SHANGHAI JIAO TONG UNIV

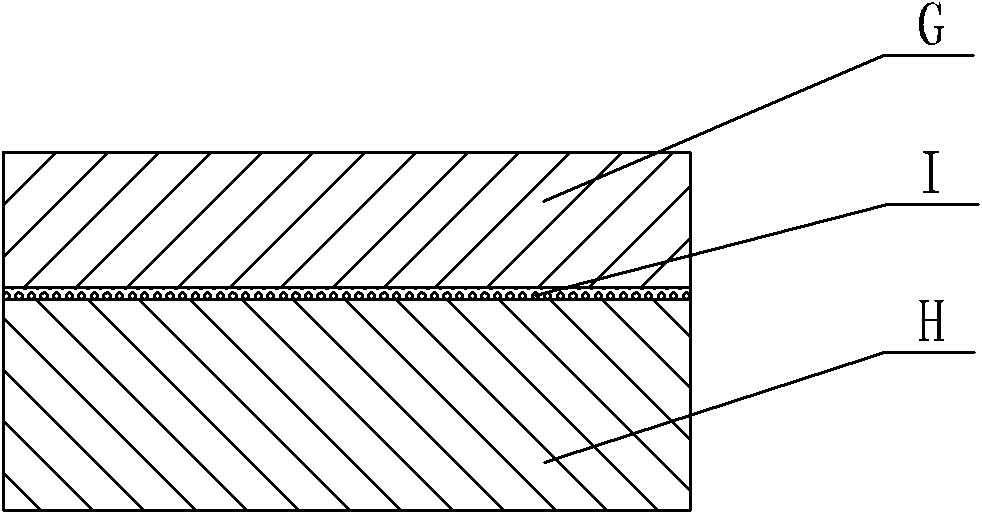

R-Fe-B series magnet of gradient resistance and production method thereof

ActiveCN101859639AIncrease resistanceImprove coercive forcePermanent magnetsInductances/transformers/magnets manufactureHigh resistanceElectrical resistance and conductance

The invention discloses an R-Fe-B series magnet of gradient resistance and a production method thereof, relates to a permanent magnetic material with a high-resistance surface layer and a high-magnetism main body layer and a production method thereof, and aims to provides the R-Fe-B series magnet of gradient resistance capable of simultaneously keeping high resistance and superior magnetic performance and the production method thereof. The R-Fe-B series magnet of gradient resistance comprises the surface layer G and the main body layer H, wherein the surface layer G is connected with the mainbody layer H through a sintered layer I; the oxygen content of the surface layer G is greater than that of the main body layer H; and the resistivity of the surface layer G is no less than that of the main body layer H.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Low-cost high-resistivity cerium magnet and preparation method thereof

ActiveCN102969111AHigh resistivityImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsHigh energyMicrometer

The invention provides a low-cost high-resistivity cerium magnet and a preparation method thereof. The cerium magnet comprise the following materials: Ce-Nd-Fe-B alloy powder and a solid surface activating agent covering the surface of the alloy powder, wherein the solid surface activating agent contains at least one fluorid or oxid of Li, Na, Mg, Ca, Sr, Ba, Nd, Dy, Tb, Gd or Ho; the weight of the solid surface activating agent is 5-15% of that of the Ce-Nd-Fe-B alloy powder; the particle diameter of the Ce-Nd-Fe-B alloy powder is 0.5-8 micrometers; and the particle diameter of the solid surface activating agent is 1-100 nanometers. The resistivity rho of the cerium permanent magnet alloy is greater than or equal to 1.0m omega centimeter, and the maximum magnetic energy product (BH) max is greater than or equal to 32MGsOe. With the adoption of the magnet, the eddy current loss can be reduced greatly, and the low cost of a motor and an engine is maintained at the same time; and the magnet can be applied to equipment, such as the motor with high energy efficiency and the high-speed engine.

Owner:CENT IRON & STEEL RES INST

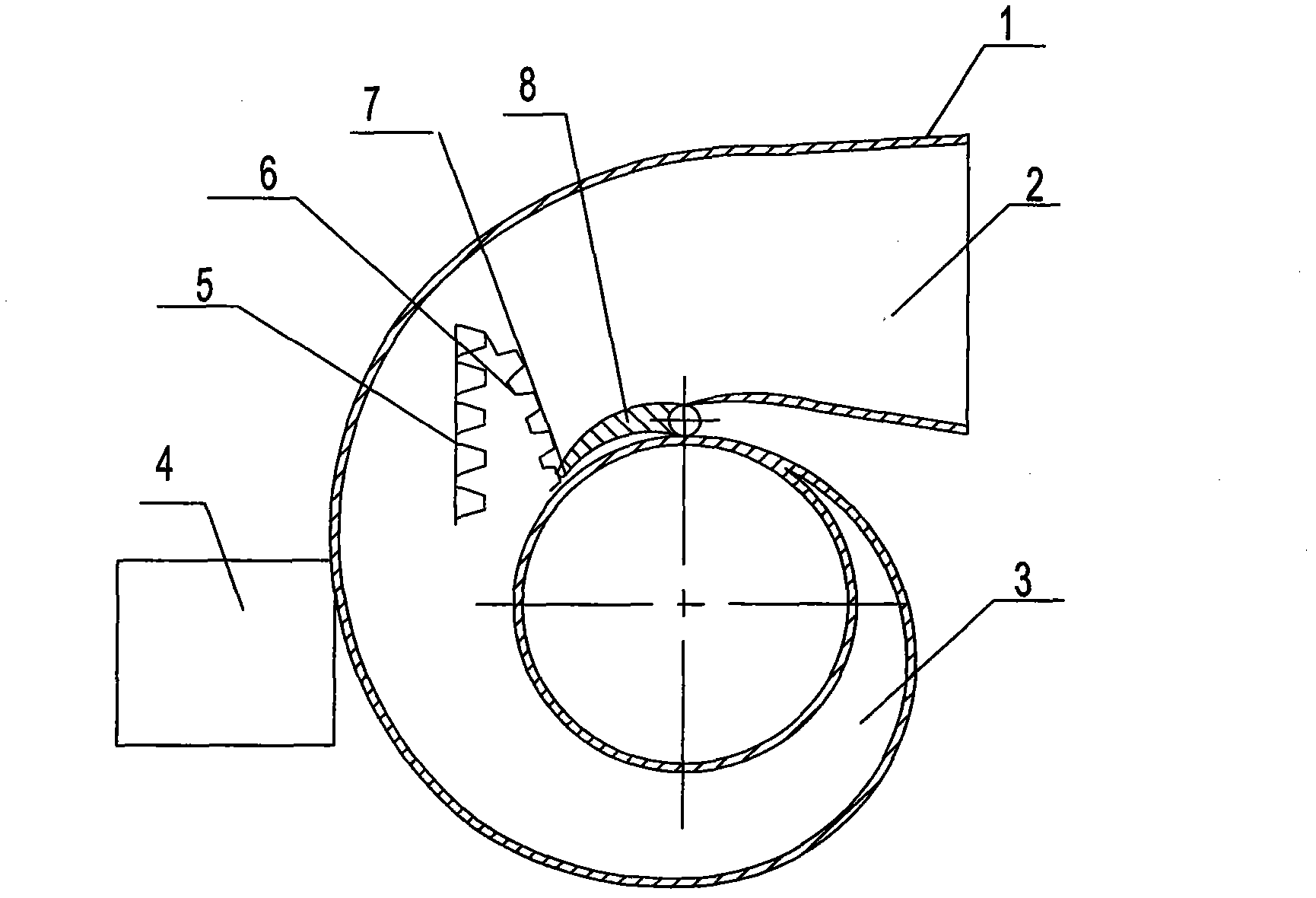

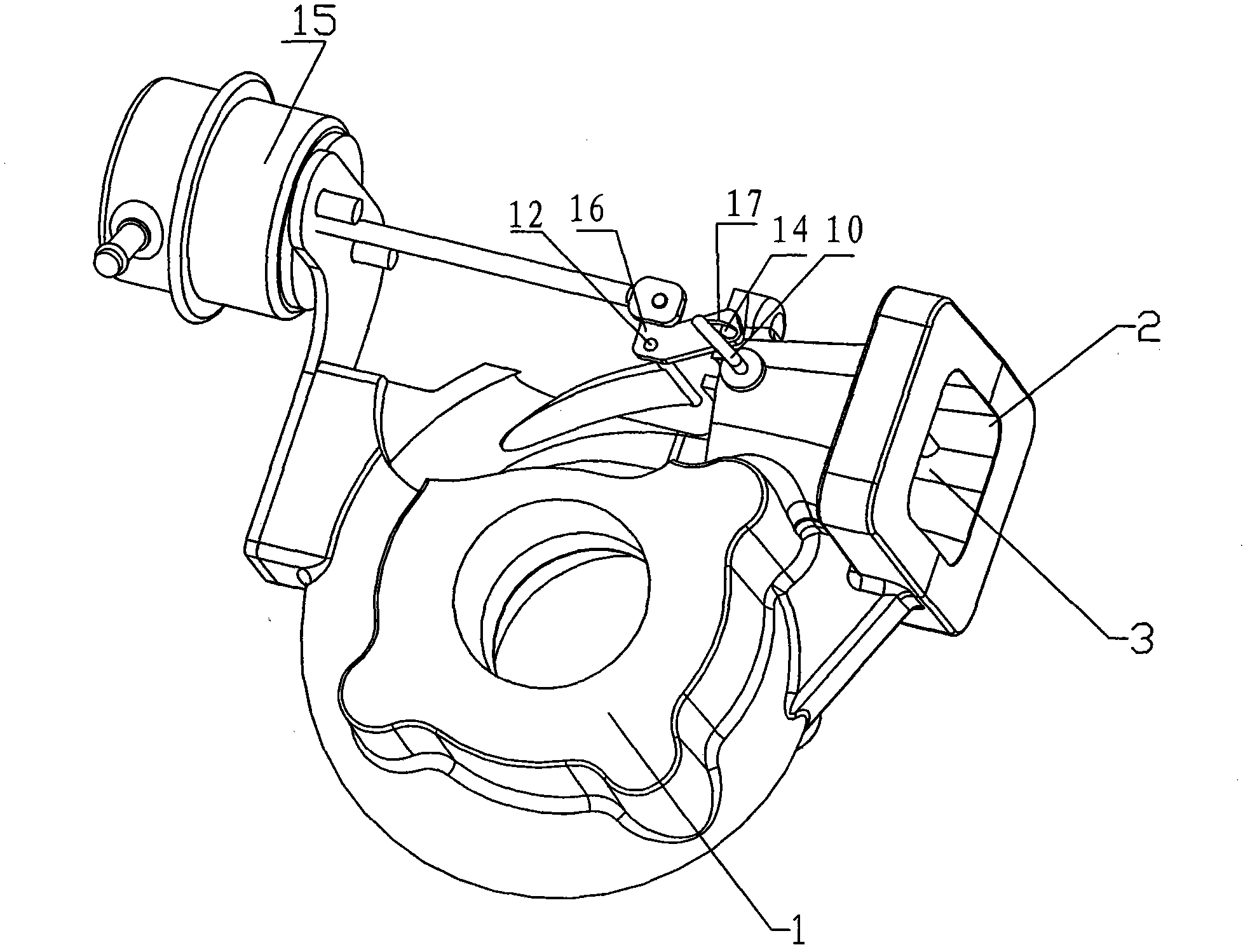

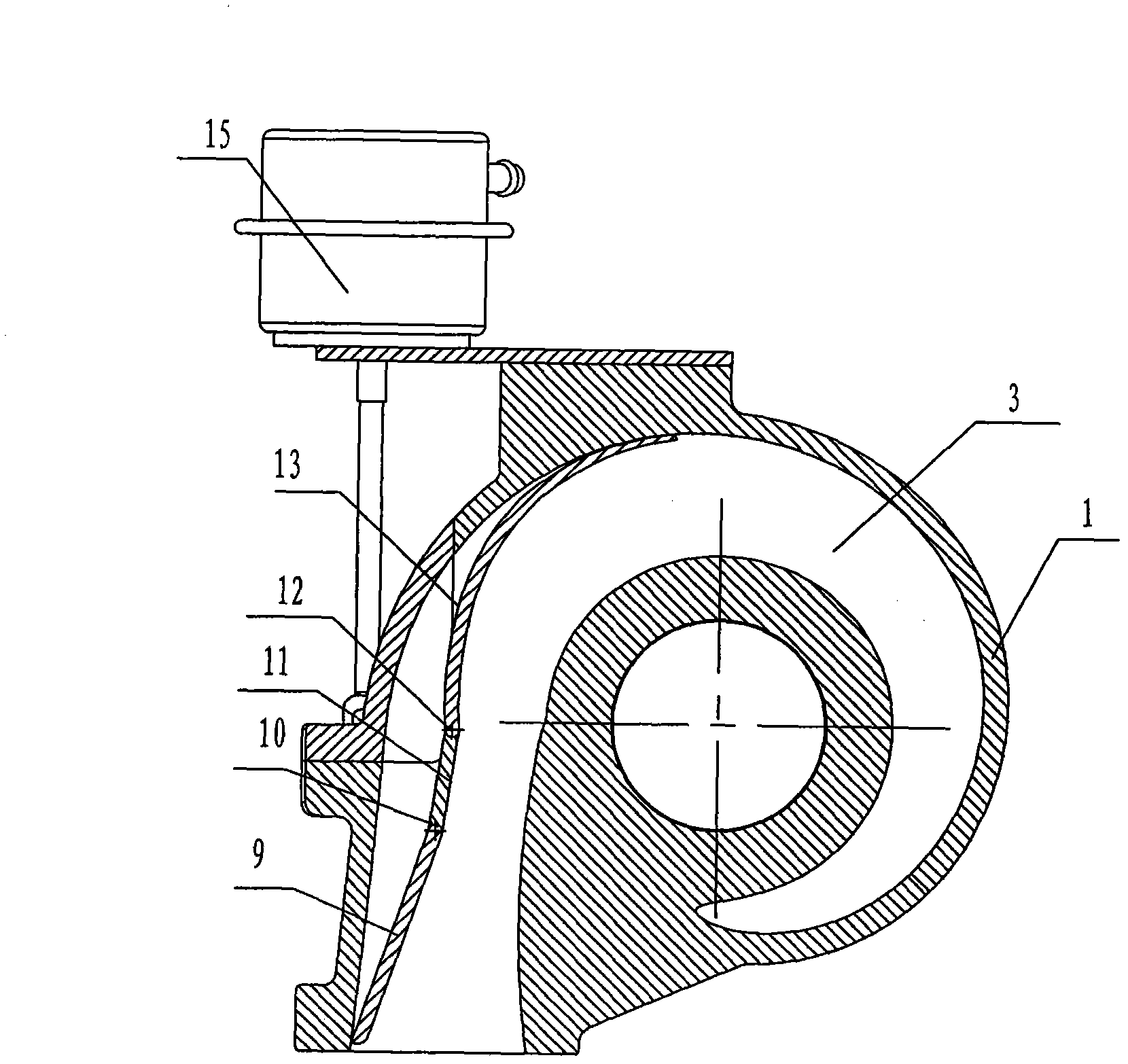

Section-variable turbine

InactiveCN102080577ASimple structureGood inheritanceInternal combustion piston enginesGas turbine plantsTurbochargerInlet flow

The invention discloses a section-variable turbine. The turbine comprises a volute, wherein the volute is provided with an executing mechanism; an annular air flow channel is formed in the volute and is provided with an air inlet; and an air inlet section adjusting mechanism is arranged in the annular air flow channel and is in transmission connection with the executing mechanism. The volute from the inlet to a flow channel area with a 90-degree section is divided into two parts with different upper and lower circulating capabilities, and a gas guide device capable of freely adjusting is used for adjusting and controlling two different flow channels to sequentially work, so that the circulating area of the flow channels is controlled, the fuel gas state of the turbine is entered through adjustment, and the supercharging requirement of an engine in a full working condition range is met; and the executing mechanism can adjust the rotation angle of a movable straight plate and a movable tongue-shaped baffle plate according to the actual working condition of the engine to change the throat section and an air inlet flow channel, so that a turbosupercharger and the engine are well matched under the full working condition.

Owner:KANGYUE TECH

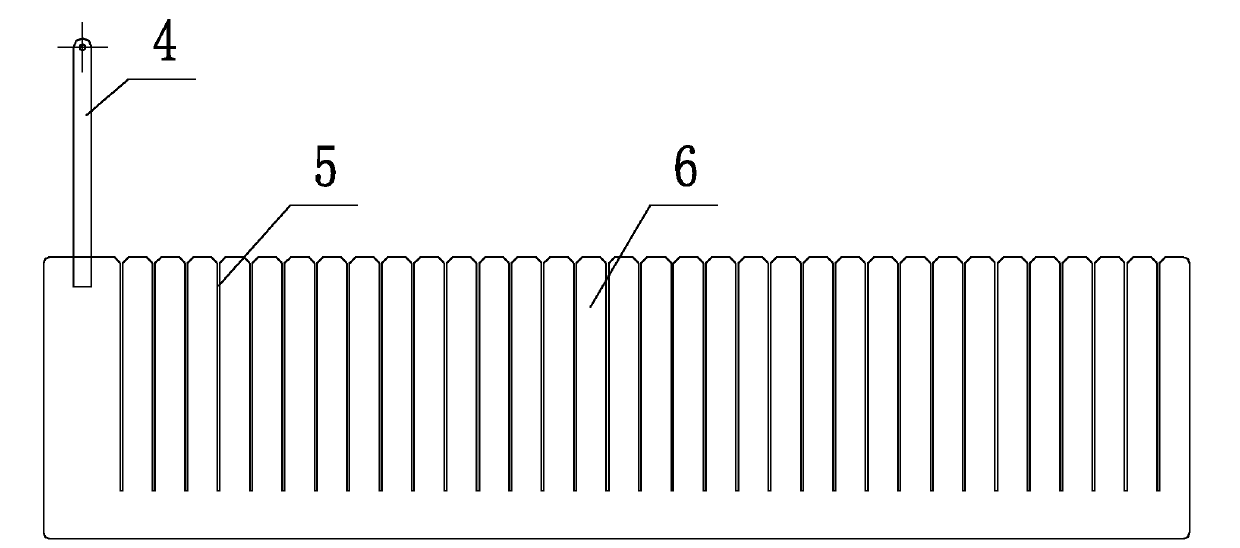

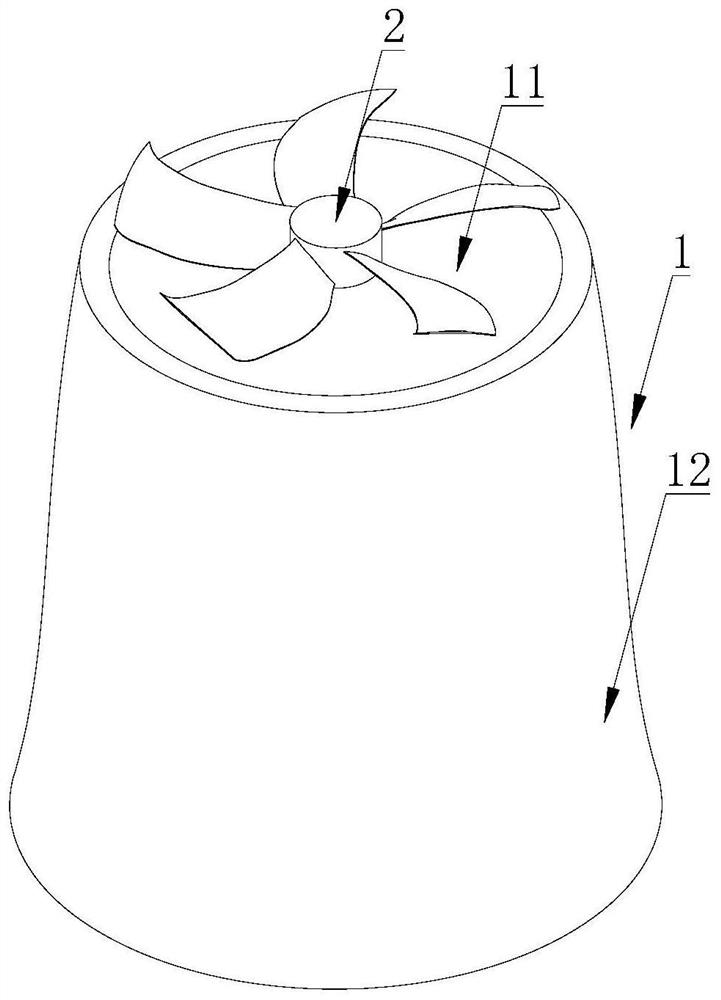

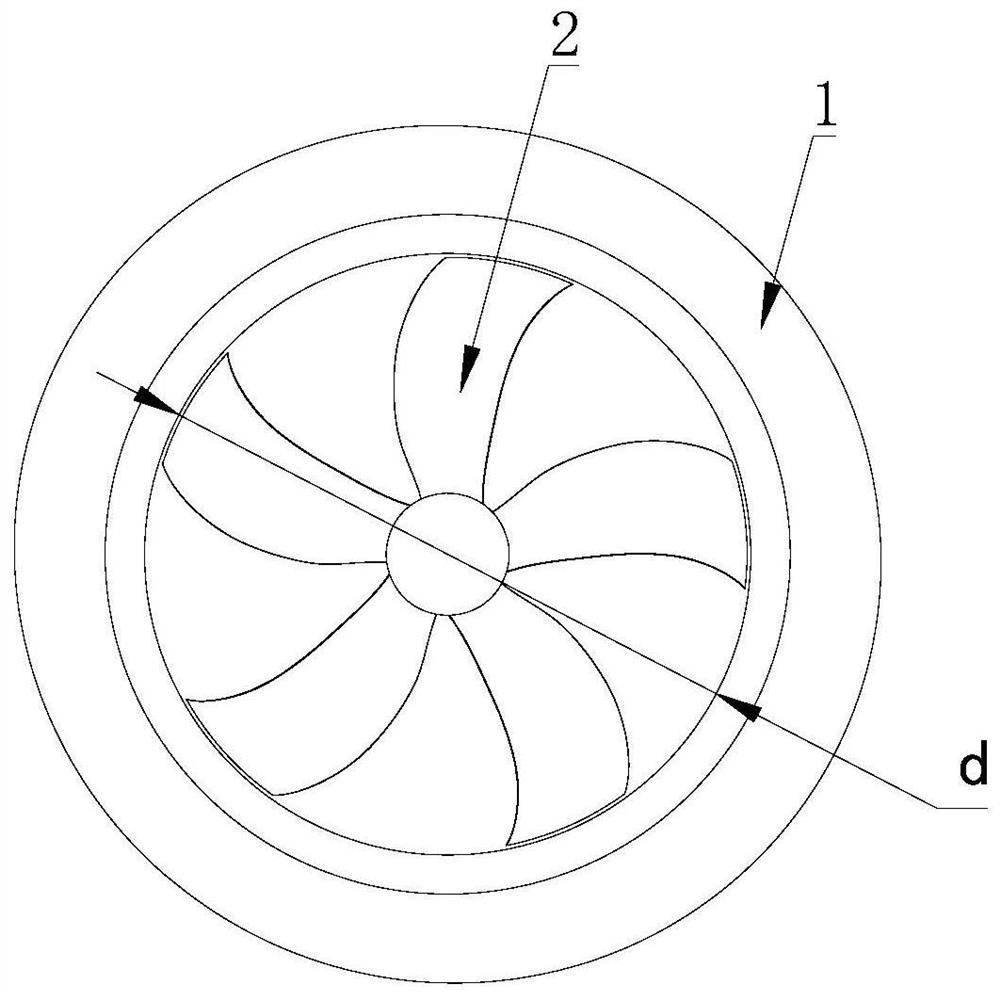

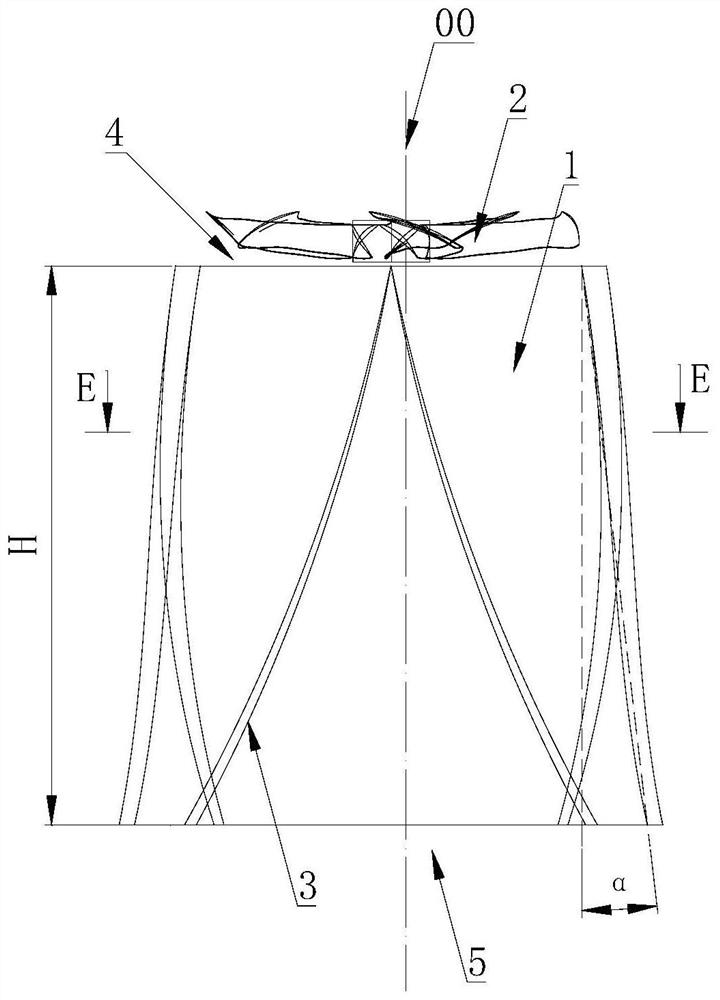

Corrugated bracket of fan

ActiveCN108180154ABeneficial technical effectImprove static pressure efficiencyPump componentsPump installationsFront edgeWave crest

The invention discloses a corrugated bracket of a fan. The corrugated bracket of the fan comprises an air guide ring, a plurality of flow guide blades and a bracket hub, wherein a motor is mounted atone side of the bracket hub; fan blades are connected to the motor through a rotating shaft and are mounted at the other side of the bracket hub. The corrugated bracket of the fan further comprises anopening expansion structure which is arranged at the end part of the air guide ring; the flow guide blades are arranged between the opening expansion structure and the bracket hub; the line of the inner wall of the opening expansion structure is inclined; corrugated noise reducing structures, comprising at least one group of wave crests and wave troughs, are arranged at the rear edges of the flowguide blades; each group of wave crests and wave troughs is arranged in the direction from the rear edges of the flow guide blades to the front edges of the flow guide blades. With the adoption of the corrugated bracket of the fan, the motor can be supported during being mounted, and moreover, the flow guide blades are corrugated, so that air output by the fan can be rectified, and as a result, the fan eddy loss is decreased, the fan efficiency is improved, and the broadband eddy noise is reduced.

Owner:FANS TECH ELECTRIC CO LTD

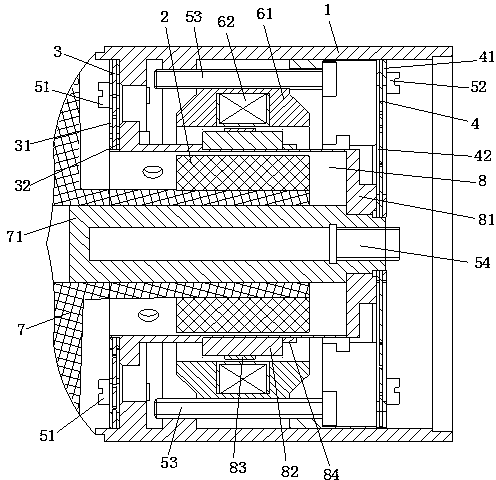

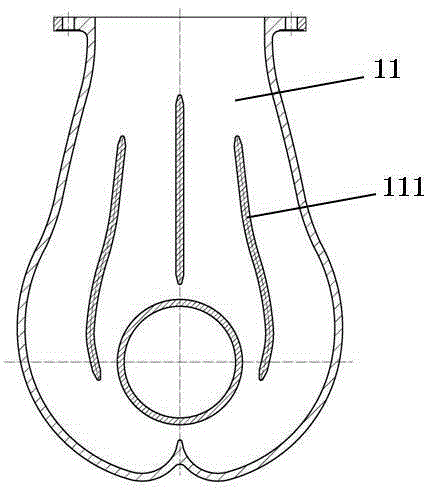

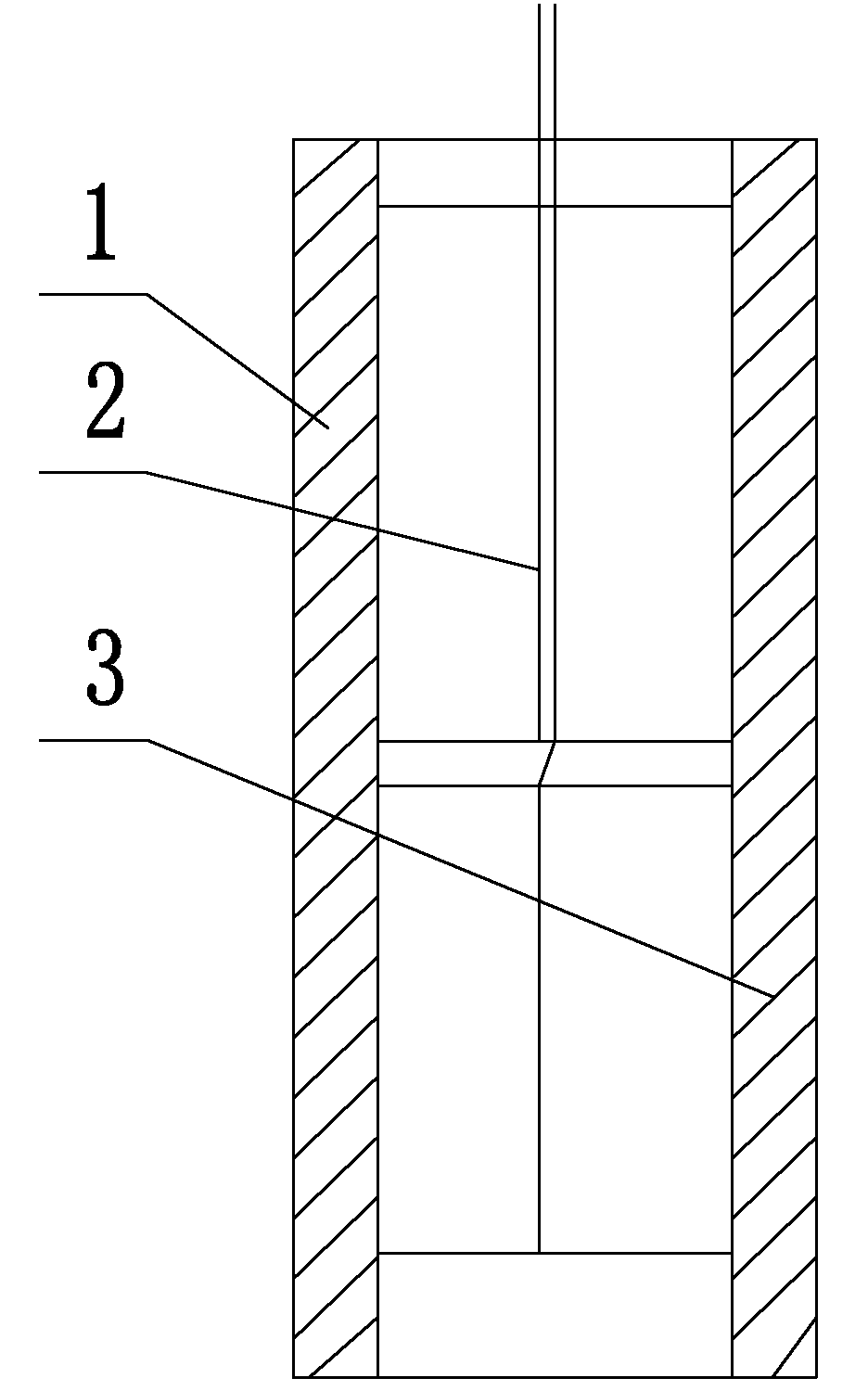

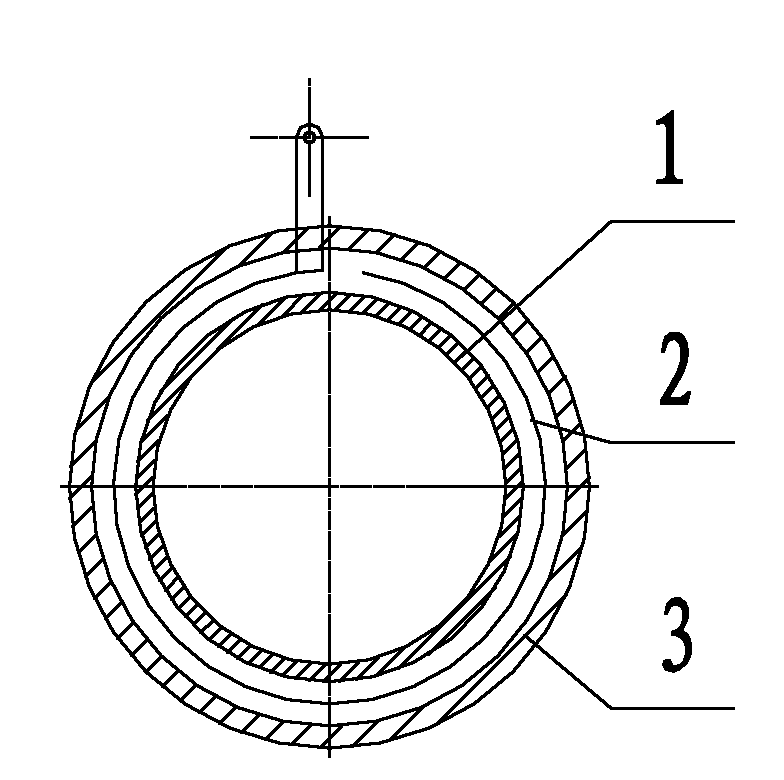

Moving-magnetic-type linear motor used for stirling cryocooler

ActiveCN103762816AEasy to installEasy to fixDynamo-electric machinesArchitectural engineeringMagnetic poles

The invention relates to a moving-magnetic-type linear motor used for a stirling cryocooler. An outer magnetic pole is of a split structure and is formed by splicing two half round magnetic poles, the outer magnetic pole is provided with an inner lead hole and an outer lead hole, the outer circumference of the outer magnetic pole is provided with a fixing hole, the inner circumference of the outer magnetic pole is provided with a notch groove for reducing loss of eddy currents, the inside of the outer magnetic pole is provided with a wiring groove for holding enameled wire coil assemblies, and the inner magnetic pole is attached to the outer diameter of a cylinder in an adhesive mode. The outer magnetic pole is formed by splicing the two half round magnetic poles and is easy to install and fix; meanwhile, due to the fact that the inner lead hole and the outer lead hole of the outer magnetic pole are matched with a wire outlet hole in a coil framework, motor wire leading is greatly facilitated, the outer circumference is provided with the fixing hole which can be used for firm positioning of the outer magnetic pole and weight reducing, the notch groove formed in the inner circumference can reduce the loss of the eddy currents, the inner magnetic pole is directly attached to the outer diameter of the cylinder in an adhesive mode, the mass of a motor is reduced, and accordingly the specific thrust of the motor is increased, and efficiency is improved.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

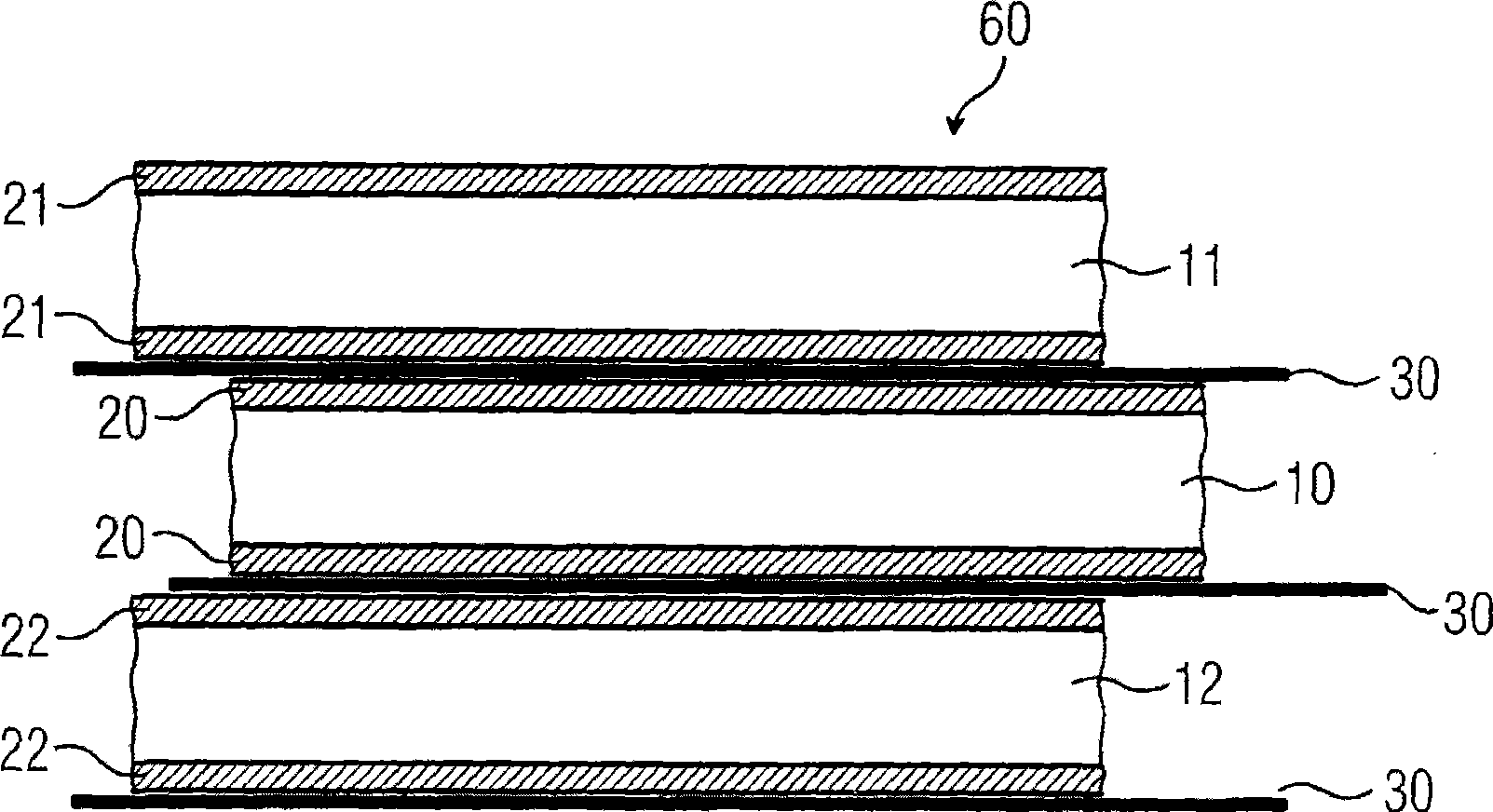

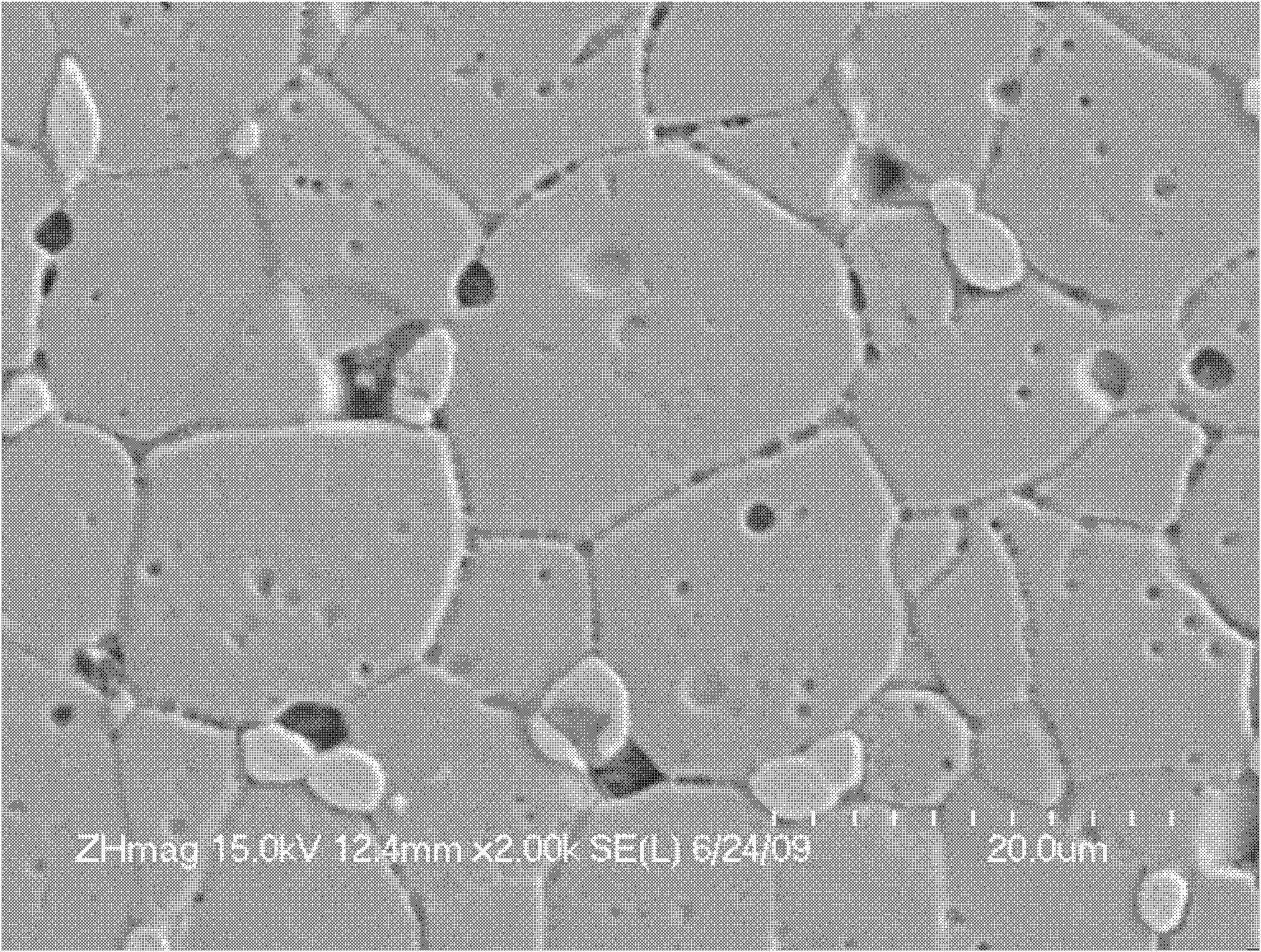

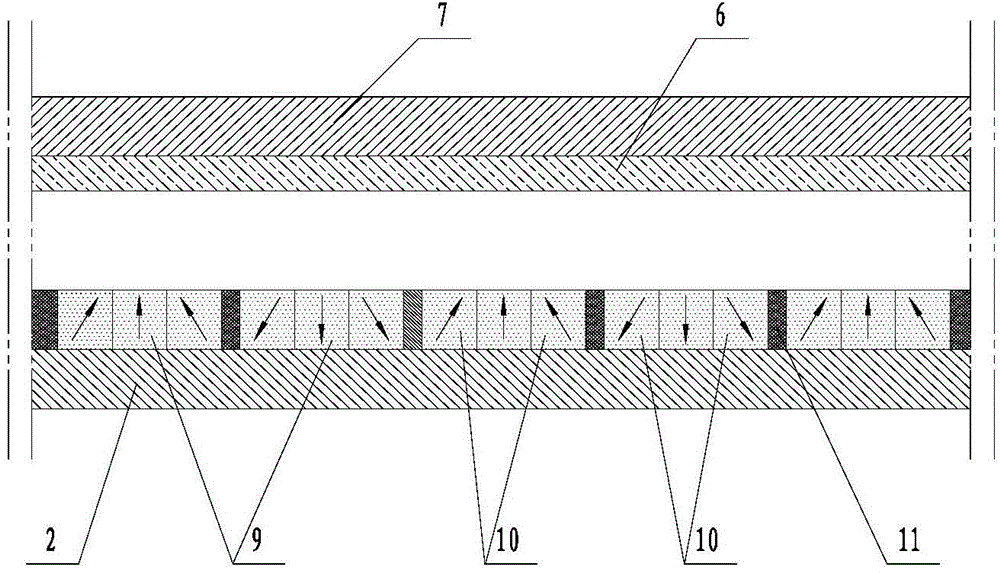

High-resistivity rare earth iron series R-Fe-B magnet and manufacturing method thereof

ActiveCN104167271AHigh resistivityImprove efficiencyInductances/transformers/magnets manufactureMagnetic materialsRemanenceElectric machinery

The invention discloses a high-resistivity rare earth iron series R-Fe-B magnet. The high-resistivity rare earth iron series R-Fe-B magnet is of a sandwich structure which is formed by alternately pressing a plurality of magnetic powder layers of rare earth iron series and a plurality of micro powder layers of oxide or fluoride. The outermost layer of the sandwich structure is the corresponding magnetic power layer. The invention further discloses a manufacturing method of the high-resistivity rare earth iron series R-Fe-B magnet. According to the method, the high-resistivity high-performance magnet can be obtained under the condition that residual magnetism, coercive force and other magnetic properties are not changed basically. When the magnet is applied to a rotor of a motor, especially a medium-high-power high-speed rotation motor, eddy loss in the rotation motor can be greatly reduced, and the efficiency of the motor can be improved. Under the premise that excellent magnetic properties can be kept, the magnet with a high-resistivity thin layer or insulation thin layer separated and the manufacturing and forming method are provided, the high-resistivity magnet is obtained, and therefore the eddy loss and magnetic property reduction caused by heating of the magnet are reduced.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

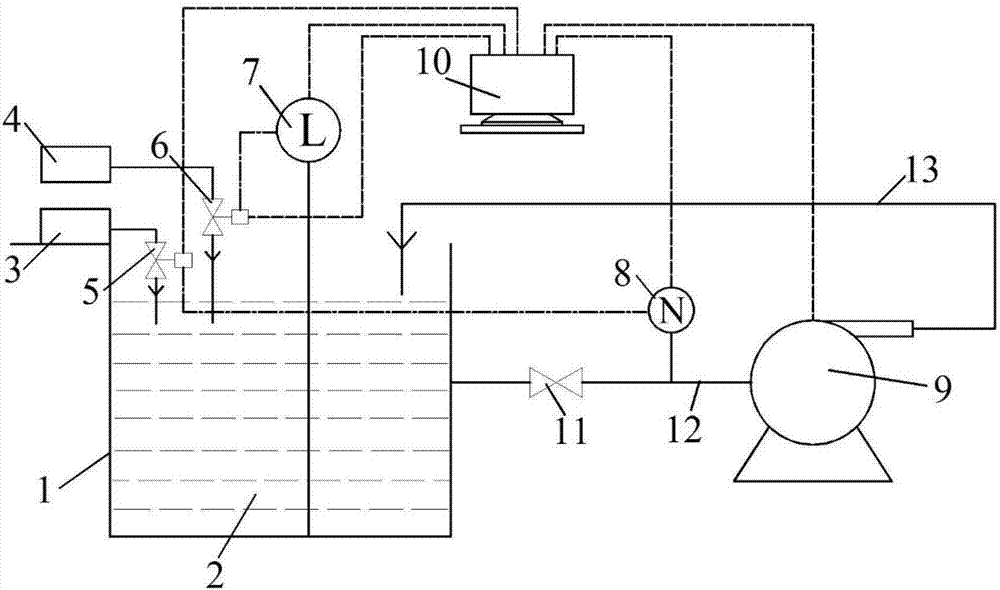

Method for improving efficiency of gas drainage liquid ring vacuum pump through macromolecular drag reduction agent

ActiveCN107152399ASuppressed vortexReduced eddy current lossPump componentsRotary piston pumpsEngineeringVacuum pump

The invention discloses a method for improving the efficiency of a gas drainage liquid ring vacuum pump through a macromolecular drag reduction agent, and belongs to methods for improving the efficiency of liquid ring vacuum pumps. The method comprises the steps that the quantitative macromolecular drag reduction agent is prepared and poured into a circulating pool continuously through a drag reduction agent filling machine till the optimal drag reduction concentration is reached; the gas drainage liquid ring vacuum pump is operated, and the macromolecular drag reduction agent serves as a working medium of the liquid ring vacuum pump to conduct gas drainage; and the viscosity and the liquid level of the drag reduction agent as well as the operation performance of the gas drainage liquid ring vacuum pump are monitored in real time, accordingly, the quantitative drag reduction agent is supplemented in the fixed time, and the drag reduction performance and the liquid level of the drag reduction agent are maintained. The macromolecular drag reduction agent is a polyacrylamide solution with the concentration being 0.1-0.5%. Through the method, the efficiency of the liquid ring vacuum pump can be substantially improved, operation energy consumption can be reduced, and the maintenance period and the service life of the liquid ring vacuum pump are obviously prolonged.

Owner:CHINA UNIV OF MINING & TECH

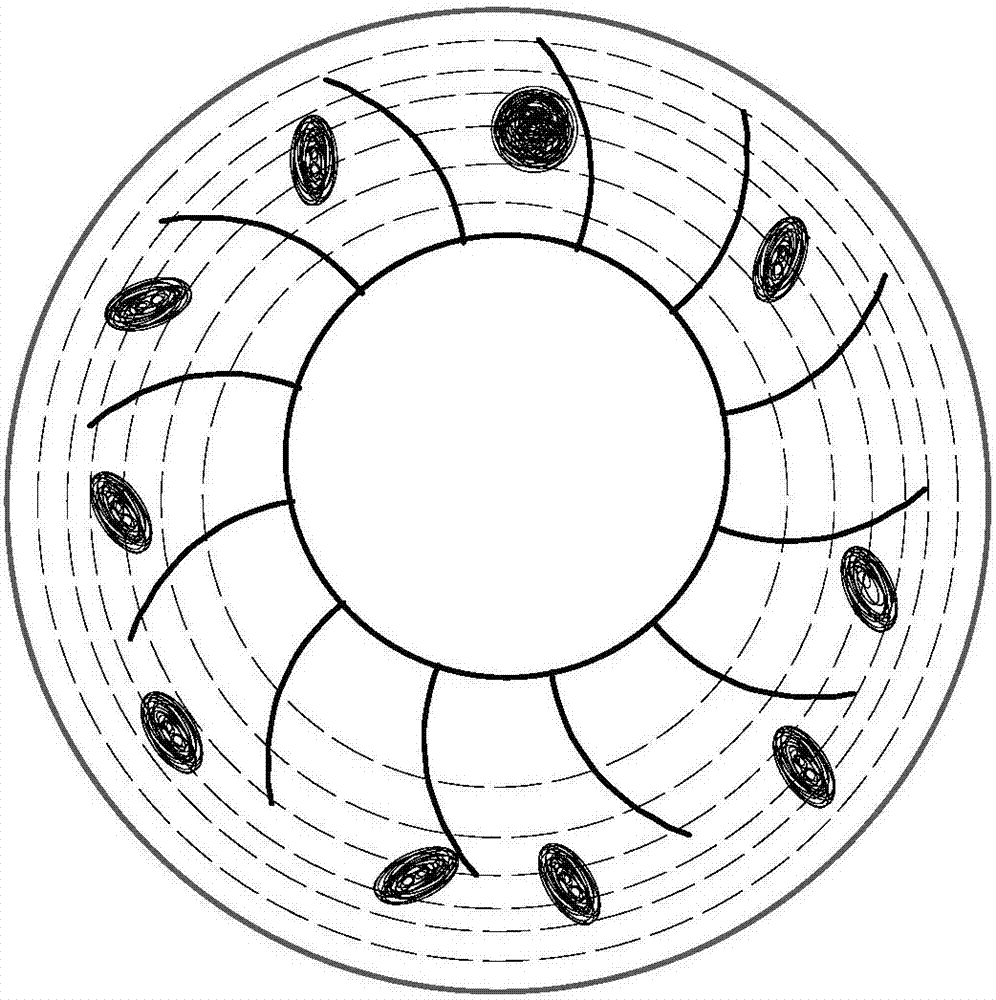

Flat-plate magnetism-gathering magnetic circuit structure used for permanent magnet eddy current transmission device

ActiveCN103607097AReduced eddy current lossSmall structure sizeMagnetic circuit rotating partsDynamo-electric gearsPermanent magnet rotorCoupling

The invention relates to a flat-plate magnetism-gathering magnetic circuit structure used for a permanent magnet eddy current transmission device, and belongs to the technical field of permanent magnet transmission. Compared with a flat-plate permanent magnet eddy current transmission device employing a discrete magnetic circuit structure, permanent magnet material per unit mass of a flat-plate permanent magnet eddy current transmission device employing the magnetic circuit structure provided by the invention can generate larger torque or transmit higher power. The flat-plate magnetism-gathering magnetic circuit structure comprises a permanent magnet rotor and an eddy current conductor rotor which are arranged coaxially, each group of permanent magnets is composed of two to five permanent magnets which are tightly contacted with each other, each group of permanent magnets in the same magnetic coupling ring comprise the same amount of magnets, each magnet is distributed along the radial direction of the flat plate surface of a permanent magnet rotor plate, and magnetizing polarity directions of magnets in the same group of permanent magnets are identical, and magnetizing polarity directions of magnets in two adjacent groups of permanent magnets are opposite. The radial width of each vortex ring is larger than the maximum radial width of a corresponding magnetic coupling ring, i.e., the inner diameter of each vortex ring is smaller than the minimum inner diameter of the corresponding magnetic coupling ring, and the external diameter of each vortex ring is larger than the maximum external diameter of the corresponding magnetic coupling ring.

Owner:LIAOYANG TAIKE LEINUO SCI & TECH

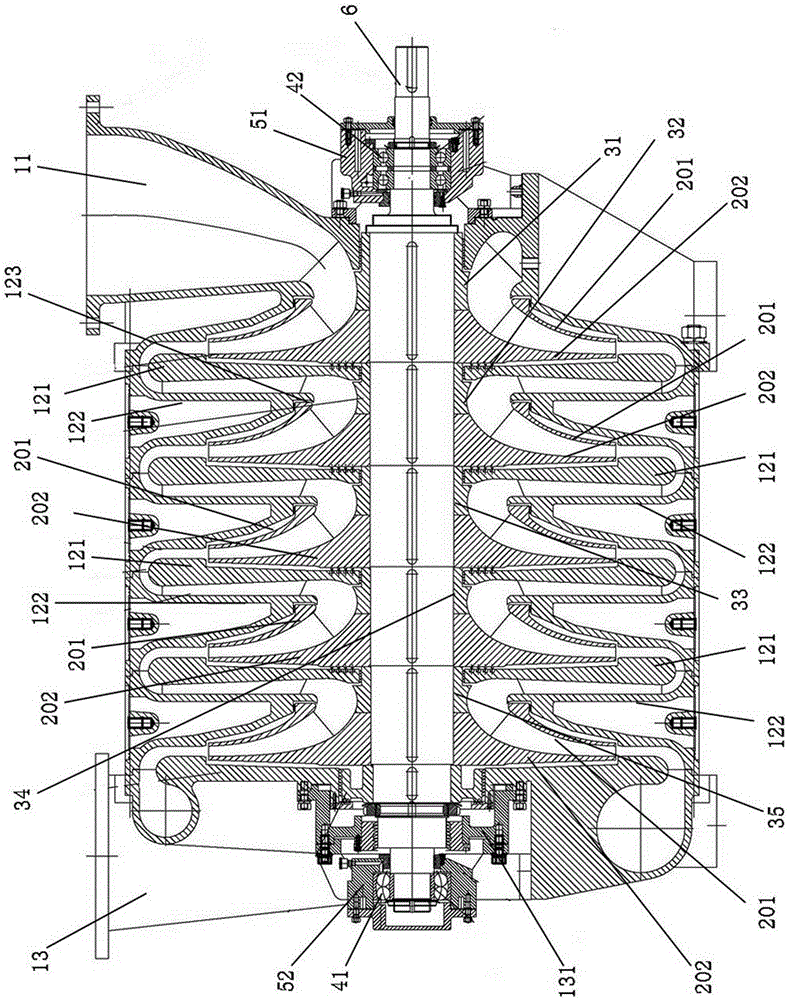

Three-dimensional flow centrifugal blower with low-speed multistage vertical split cylinder structure

ActiveCN105275834ALittle resistance lossReduce flow lossPump componentsRadial flow pumpsImpellerLow speed

The invention relates to a three-dimensional flow centrifugal blower with a low-speed multistage vertical split cylinder structure. The three-dimensional flow centrifugal blower consists of a rotor, a stator and bearings, wherein the stator comprises a three-dimensional flow impeller, a main shaft, a sealing axle sleeve and balance discs; the stator comprises an inlet chamber, an exhaust chamber, separation discs and bearing seats; each separation disc consists of a cover disc and an impeller disc; fixing elements such as a vaneless diffuser, a curve and a backflow device are formed between the separation discs; the rotor is fixed in the stator by a thrust bearing and a support bearing mounted in the bearing seats; and the three-dimensional flow impeller comprises a first stage impeller, a middle stage impeller and a last stage impeller. The flow pass part of the blower is subjected to optimal design based on a CFD technology; a closed type integrated casting structure is adopted by the three-dimensional flow impeller; labyrinth seal structures are added on the end faces of shaft discs of the impellers; flow guide ring structures are added on the impeller inlet ends; flow guide rings and the cover discs are subjected to integrated casting; and labyrinth seal structures are added on the end faces of the balance discs. The three-dimensional flow centrifugal blower with a low-speed multistage vertical split cylinder structure has the characteristics of low cost, high efficiency, stable mechanical property and the like, and is a blower with high cost performance.

Owner:SHANGHAI HUAGU BLOWER CO LTD

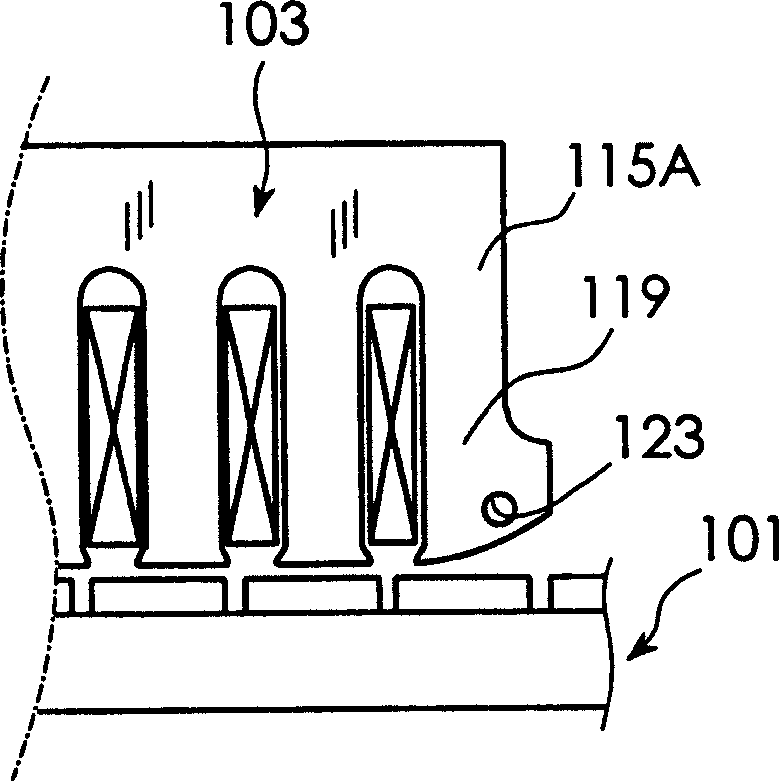

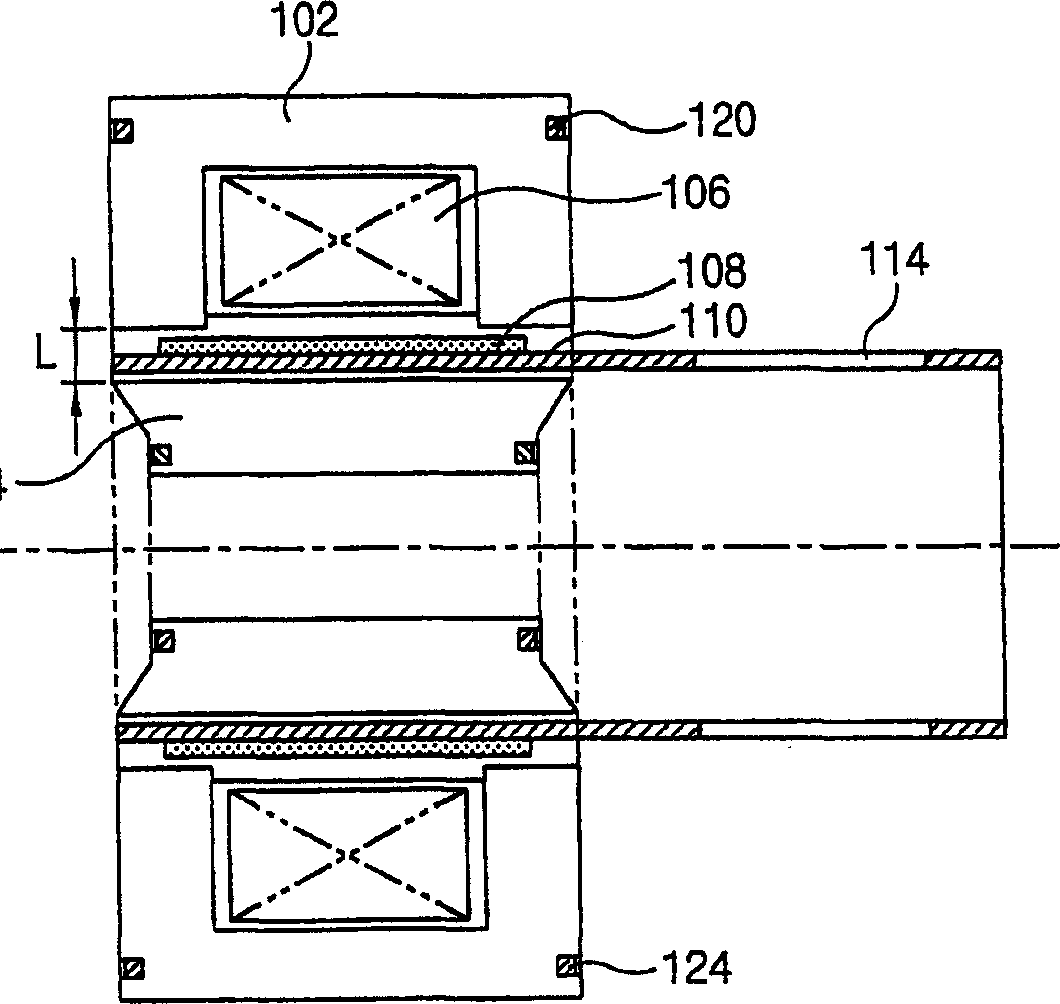

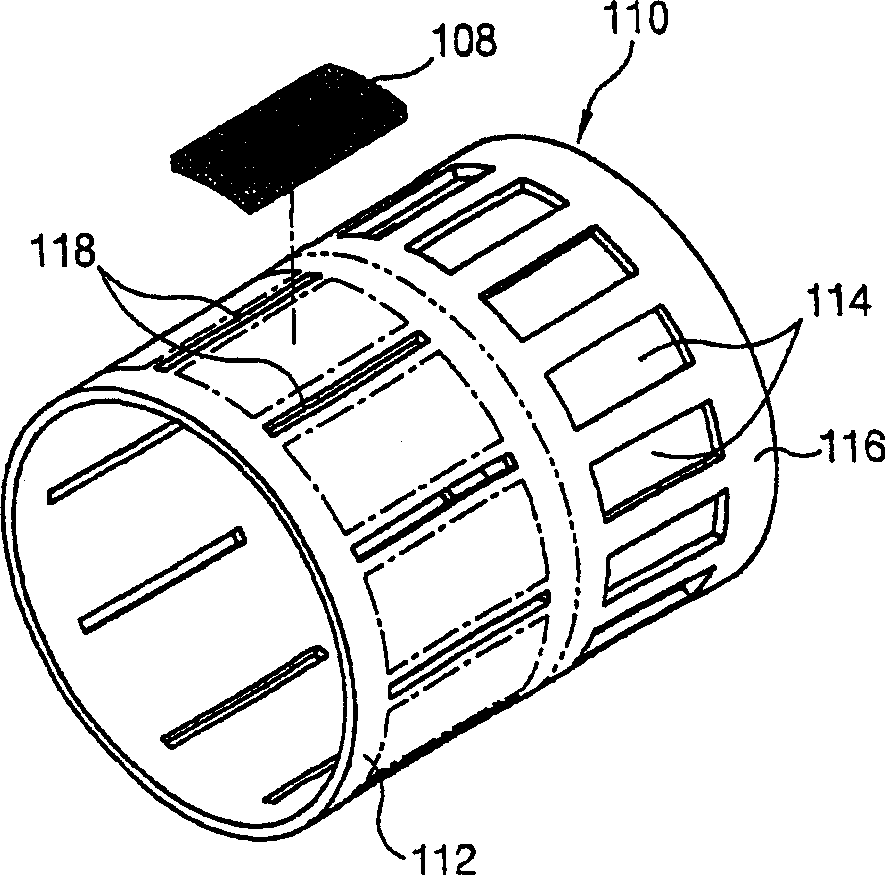

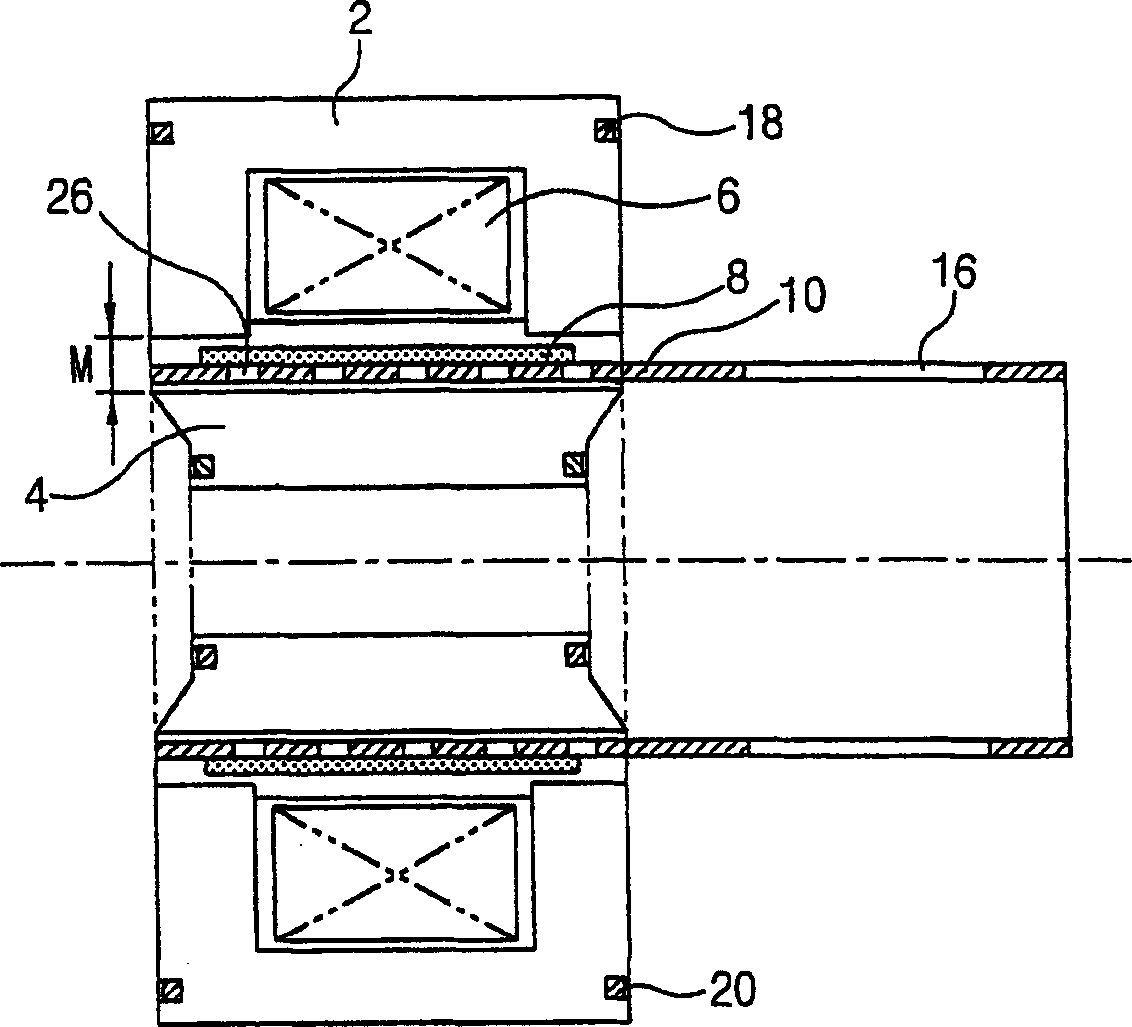

Reciprocating motor

InactiveCN1593000AReduced eddy current lossAvoid deformationReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsEddy currentEngineering

A reciprocating motor in which a plurality of eddy current preventing holes ( 26 ) are formed in the directions of circumference and shaft of a magnet frame ( 10 ) in a magnet mounting portion ( 12 ) of the magnet frame ( 10 )connected between the magnet ( 8 )and component part which will perform a reciprocating movement, for transmitting a reciprocating movement of the magnet ( 8 ) to a component part, to prevent deformation of the magnet frame (10)in molding the eddy current ( 26 ) and maintain roundness of the magnet frame precisely by improving the structure of the eddy current preventing holes which are molded in the magnet frame.

Owner:LG ELECTRONICS INC

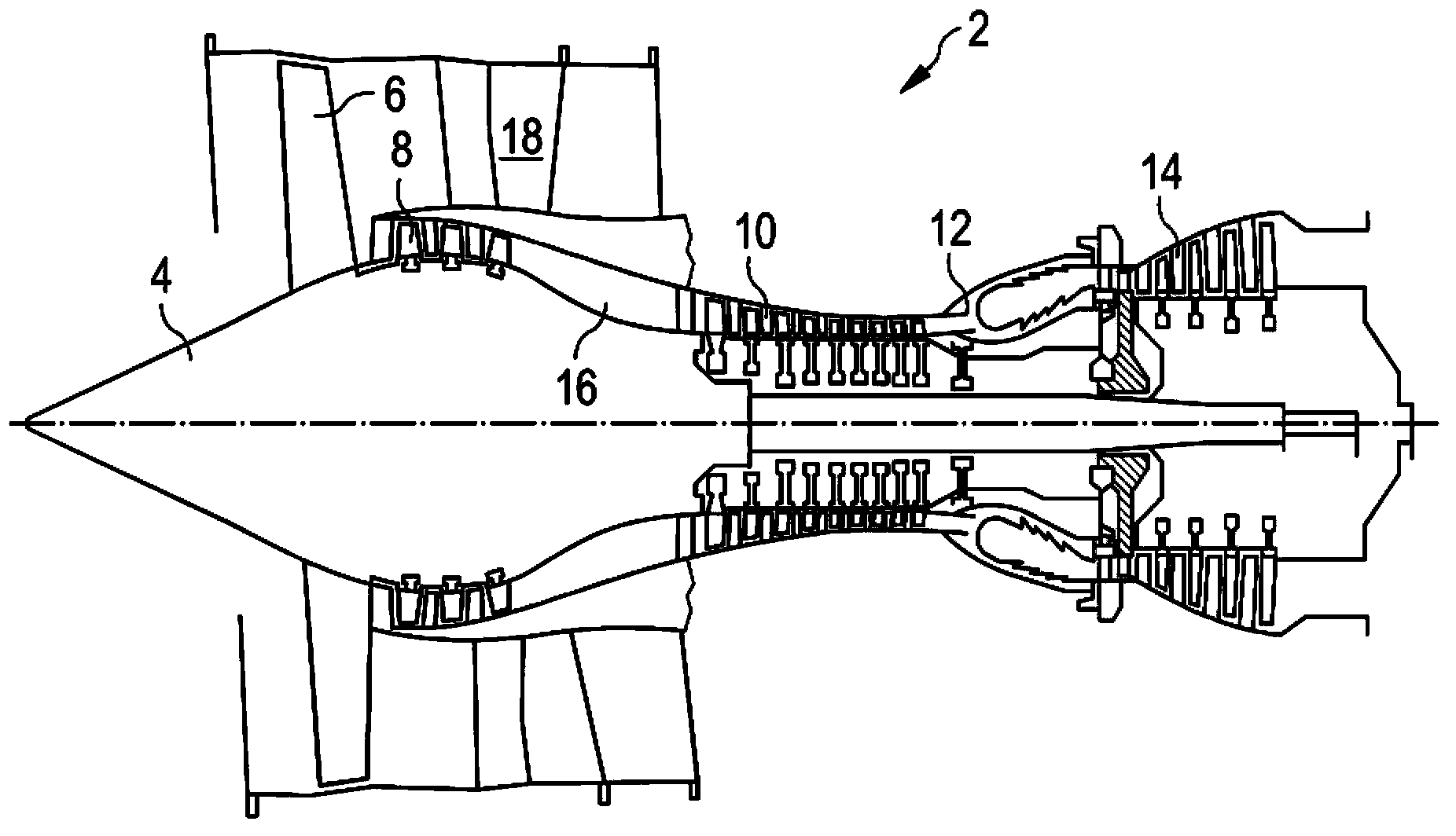

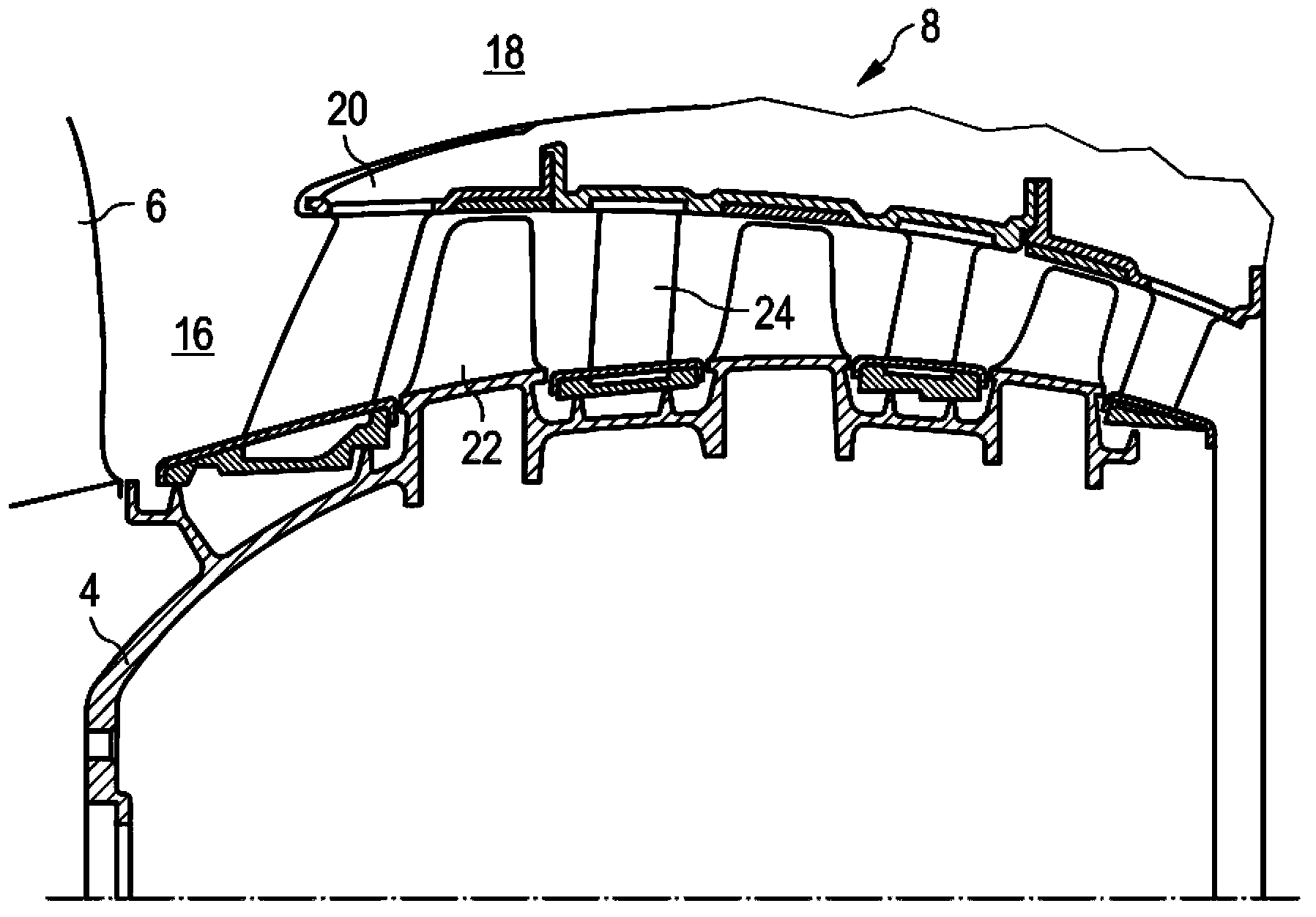

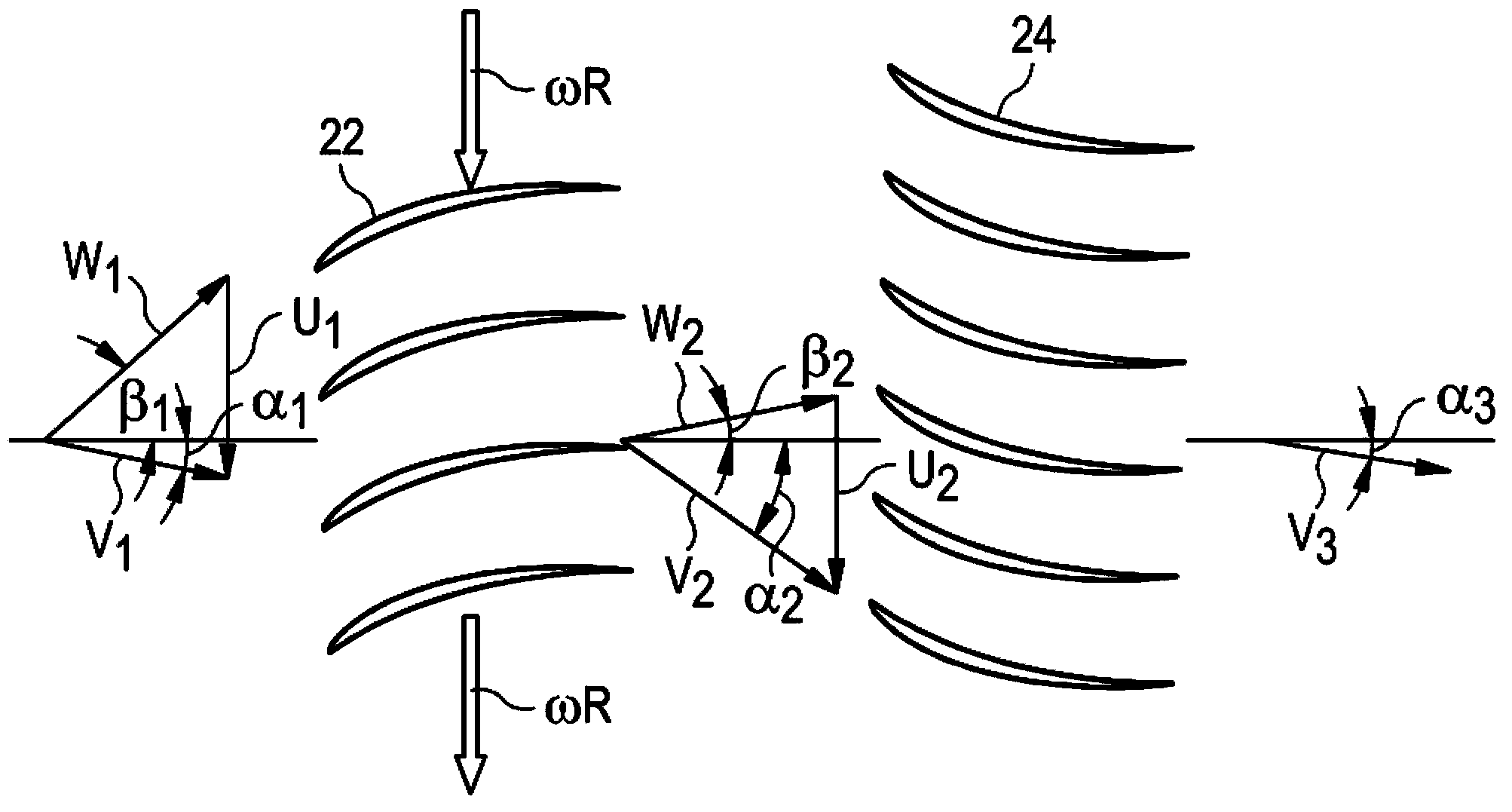

S-shaped profile blade of axial turbomachine compressor, corresponding compressor and turbomachine

InactiveCN103452904AImprove efficiencyReduced eddy current lossEngine manufacturePump componentsLeading edgeEngineering

The invention relates to a subsonic rotor and / or stator blade profile of an axial turbomachine compressor, such as a turbojet. The blade has a leading edge with an S-shaped lateral profile in its mid-plane. Specifically, the profile includes, from its inner end to the outer end, a first convex portion including the foremost part of the blade, and a second concave portion including the rearmost area of the blade. This profile enables the fluid flow between 20% and 80% of the blade's length to be redistributed. This so-called 'sweep' profile increases the performance of the stage with such blades because it reduces blade tip vortex losses as well as secondary losses.

Owner:SAFRAN AERO BOOSTERS SA

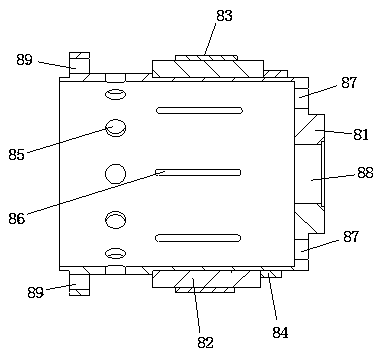

Epoxy resin pouring shielding cylinder of transformer

InactiveCN101996751AReduce eddy currentImprove cooling effectUnwanted magnetic/electric effect reduction/preventionEpoxyTransformer

The invention relates to an epoxy resin pouring shielding cylinder of a transformer, belonging to the technical field of dry type transformers. The epoxy resin pouring shielding cylinder of the transformer is characterized by adopting a structure in the shape of a pouring shielding cylinder; and grounded shields inside the shielding cylinder are a plurality of open type metal straps in winding structures. The invention has the advantages of simple structure, reliable property, high insulating withstand voltage, reduced eddy-current loss, good heat-radiating effect, convenience in operation and assembly, manufacturing cost saving, reliable grounded shielding, safety operation of the transformer, and the like.

Owner:天津市特变电工变压器有限公司

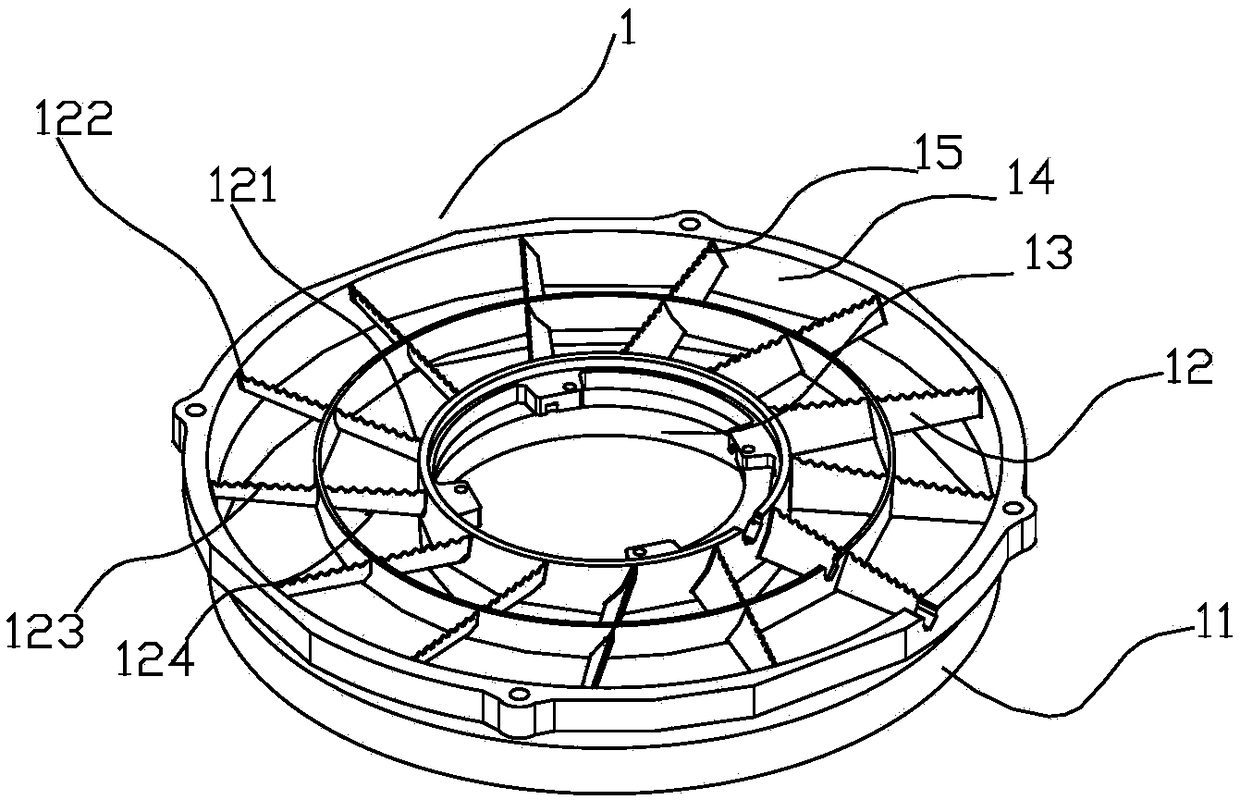

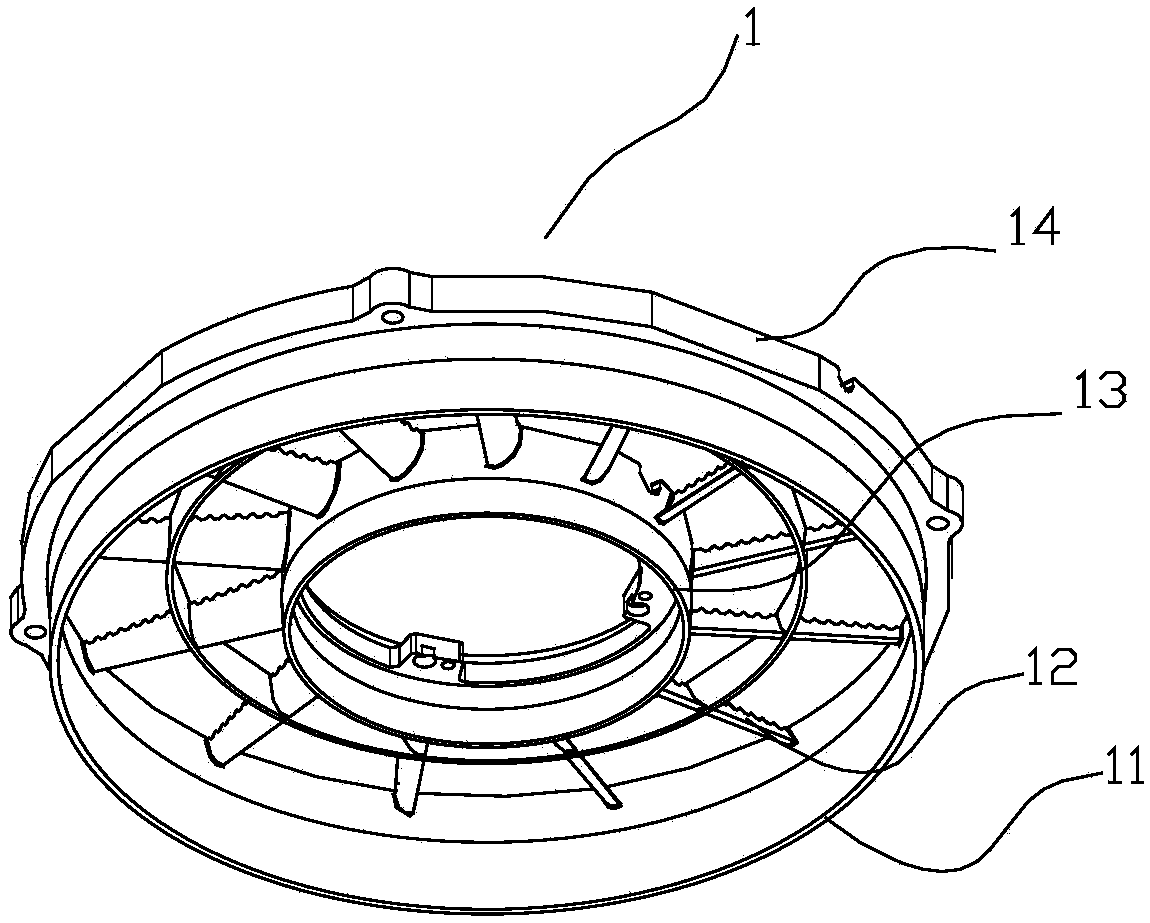

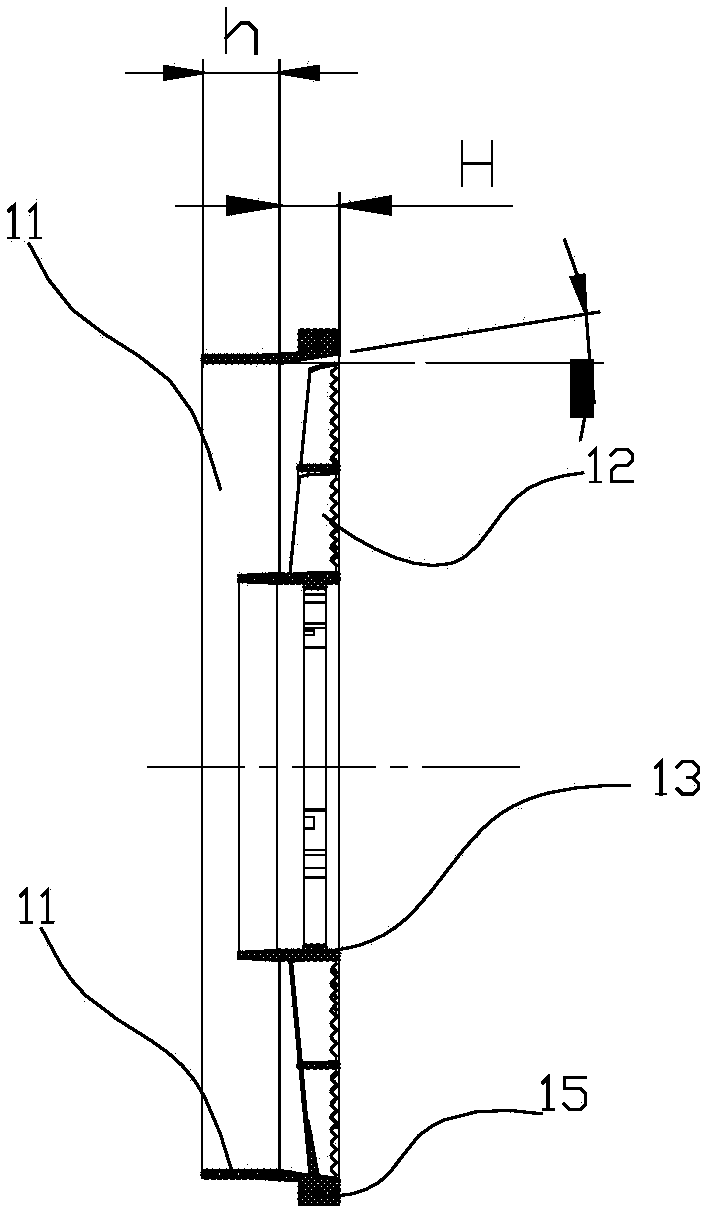

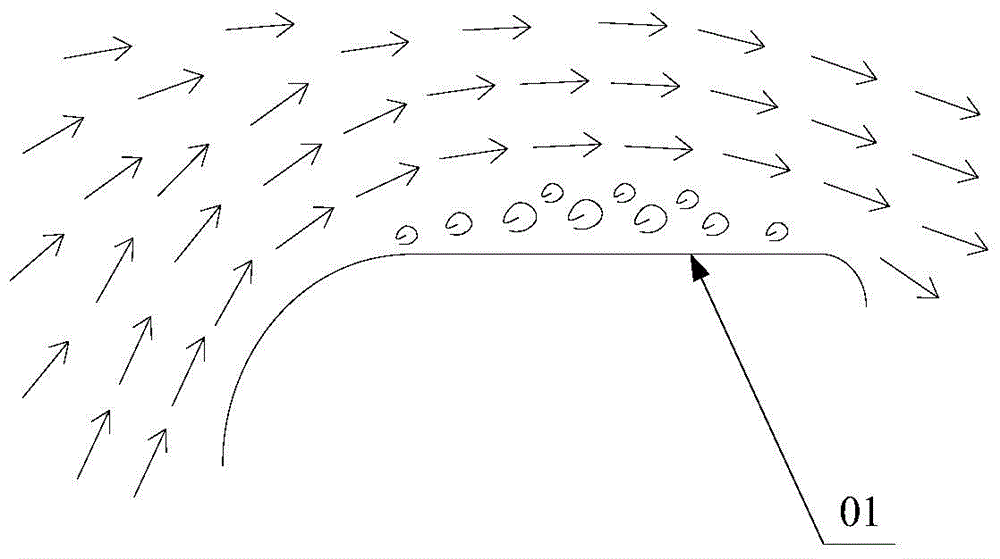

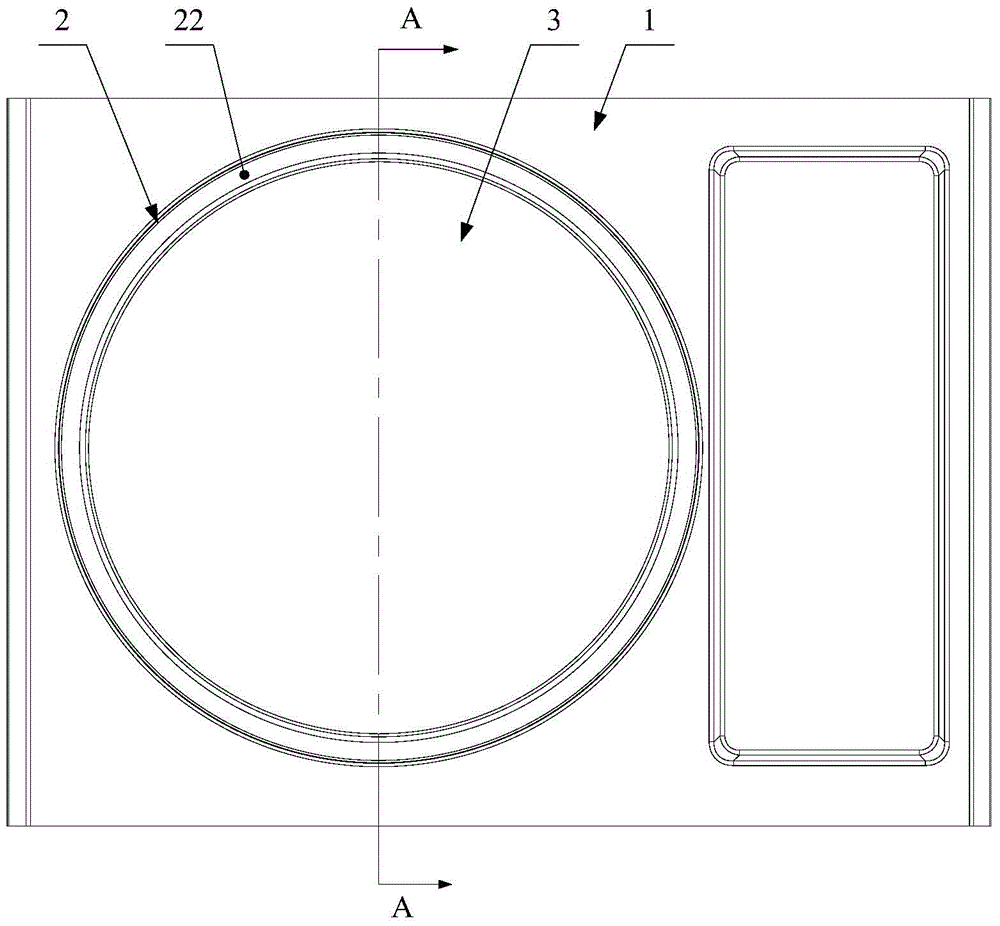

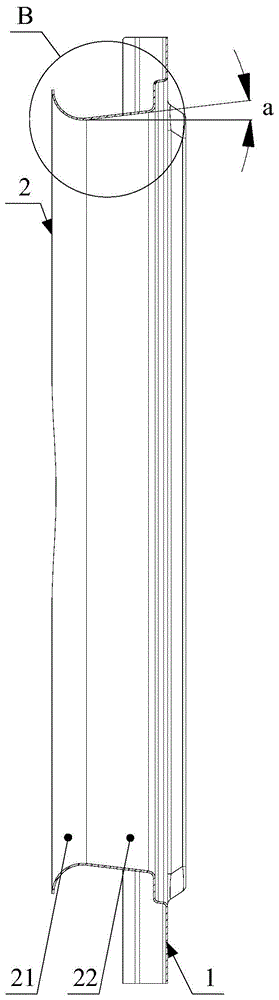

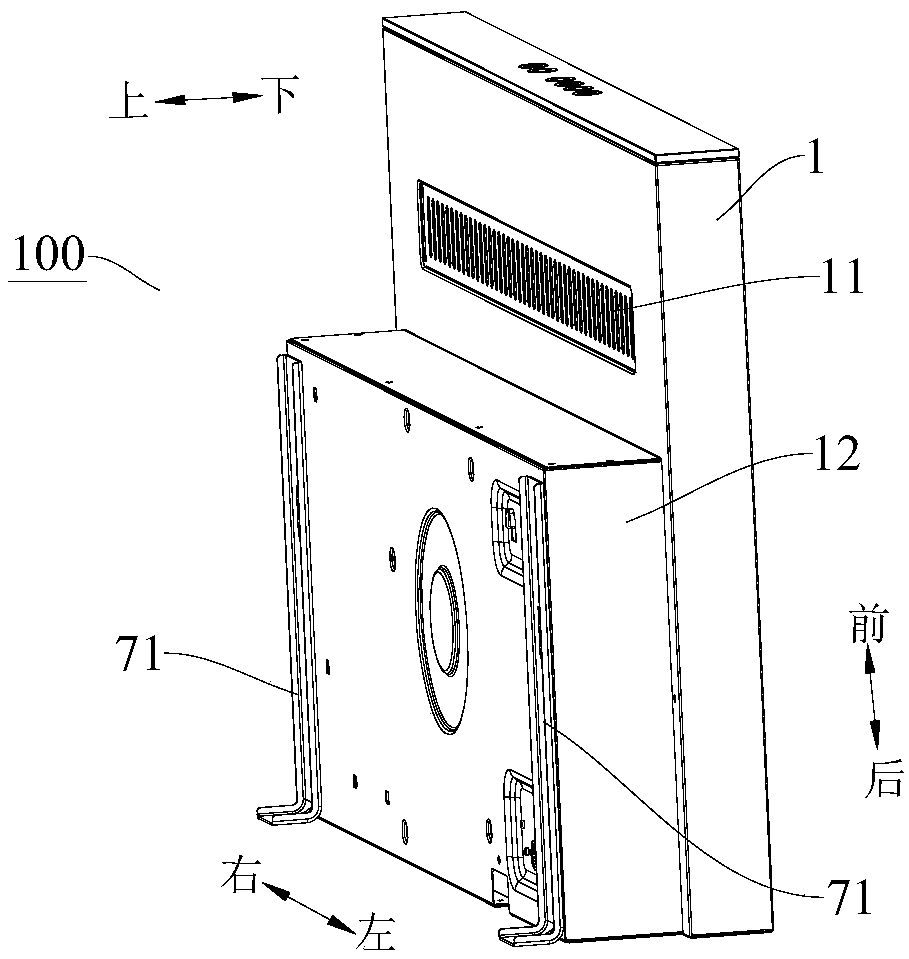

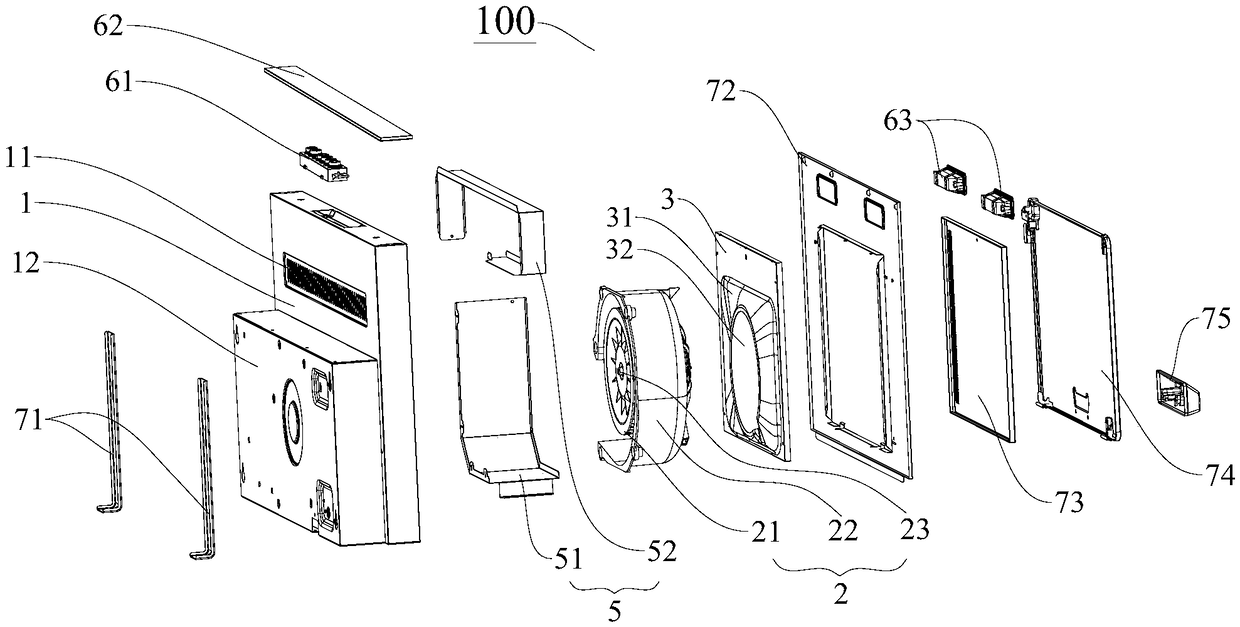

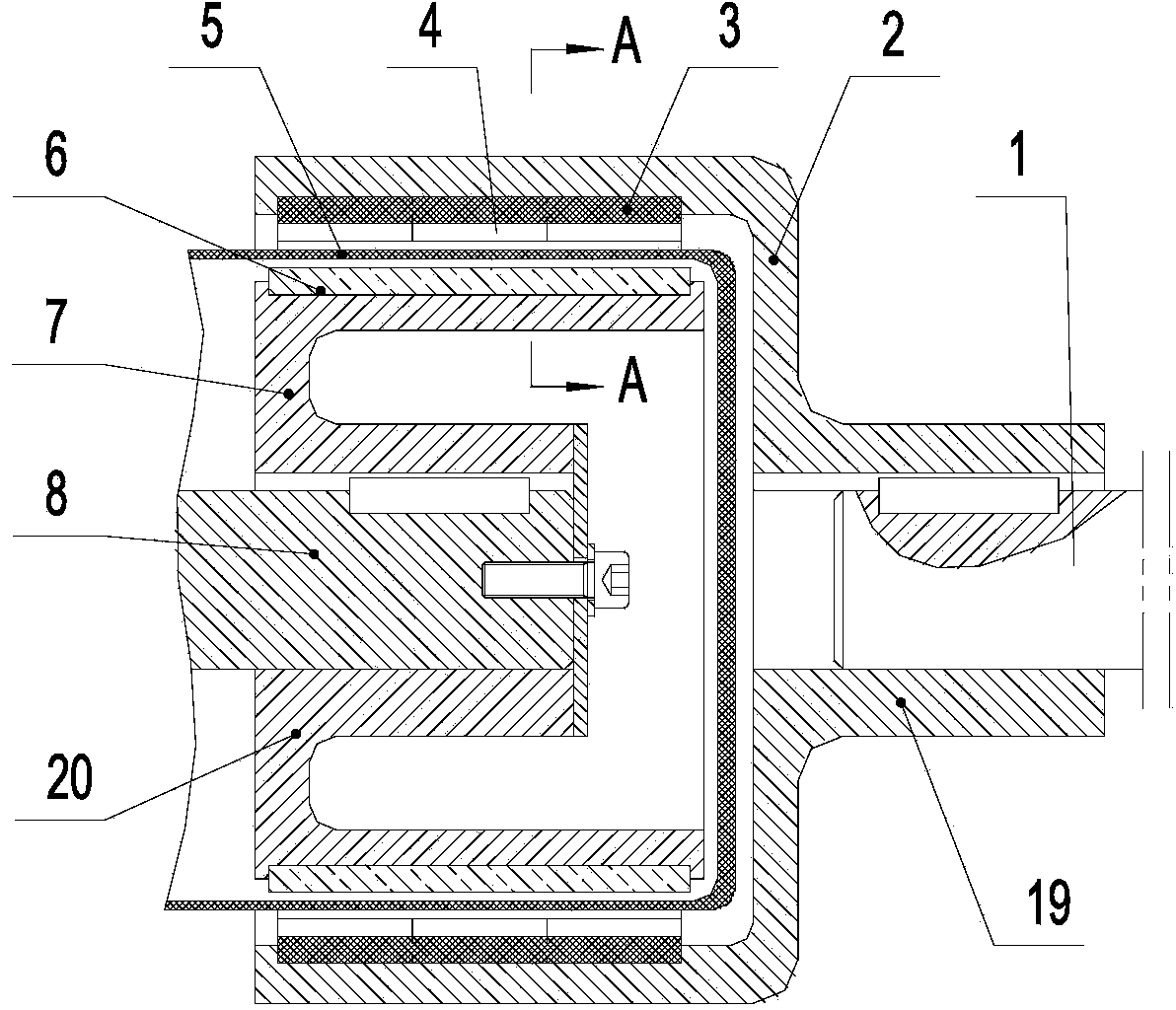

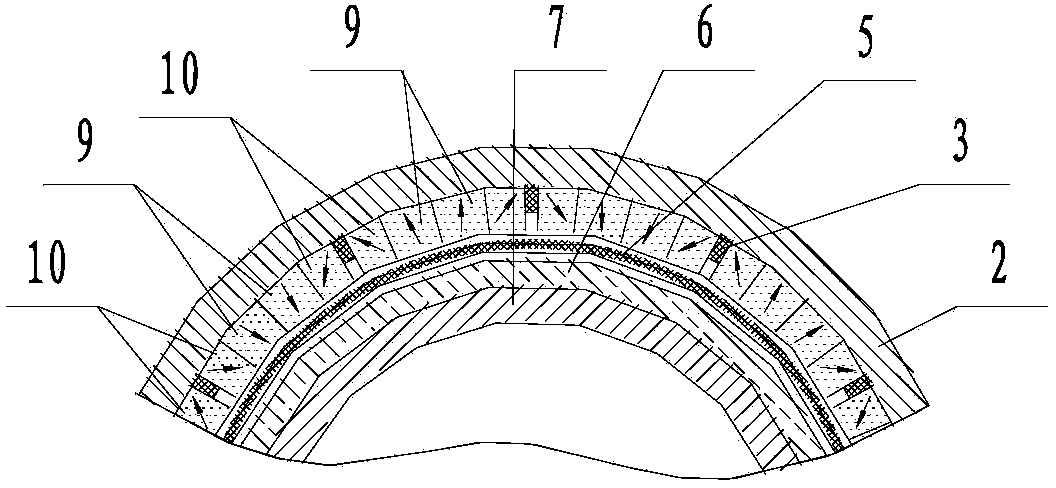

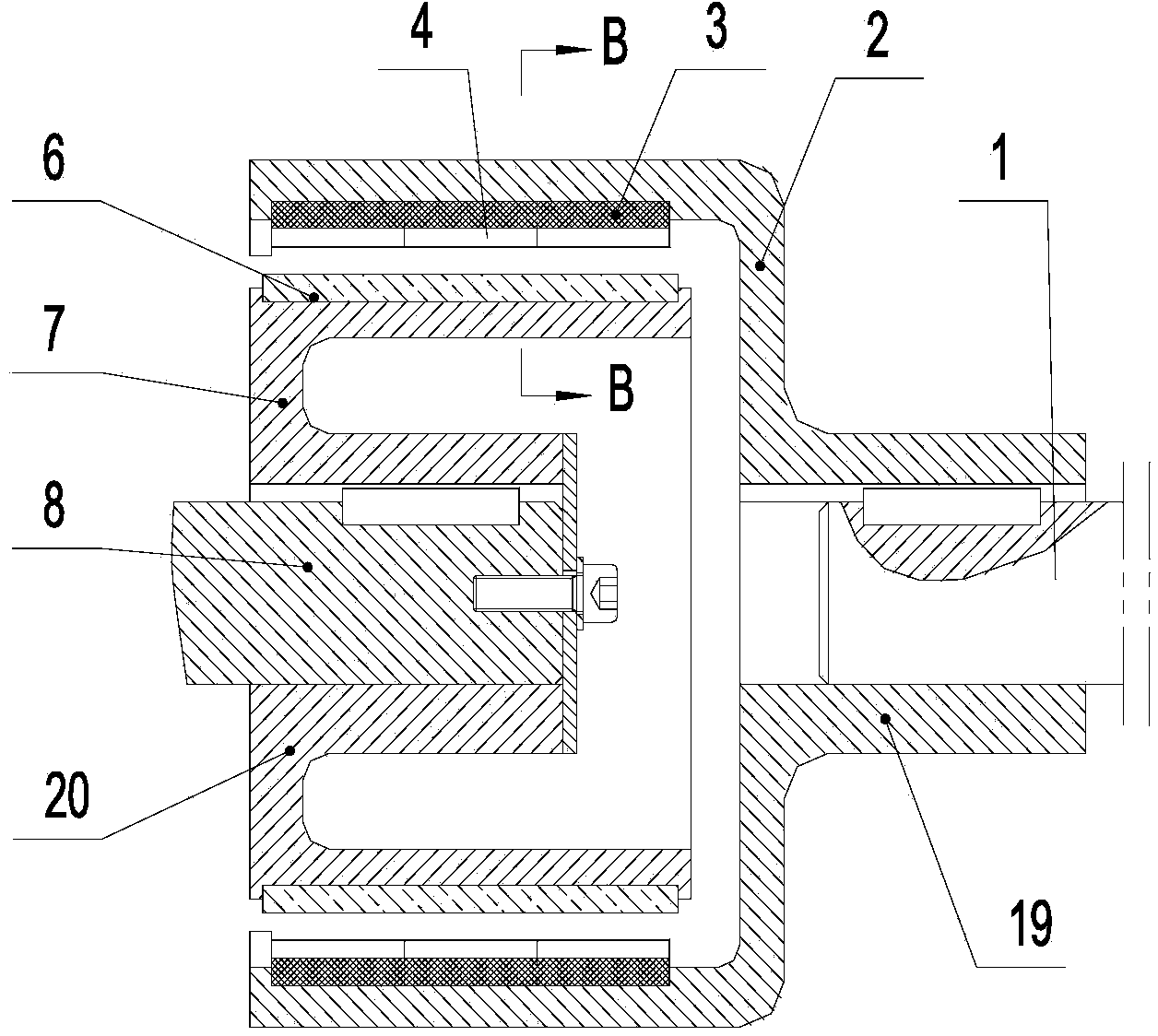

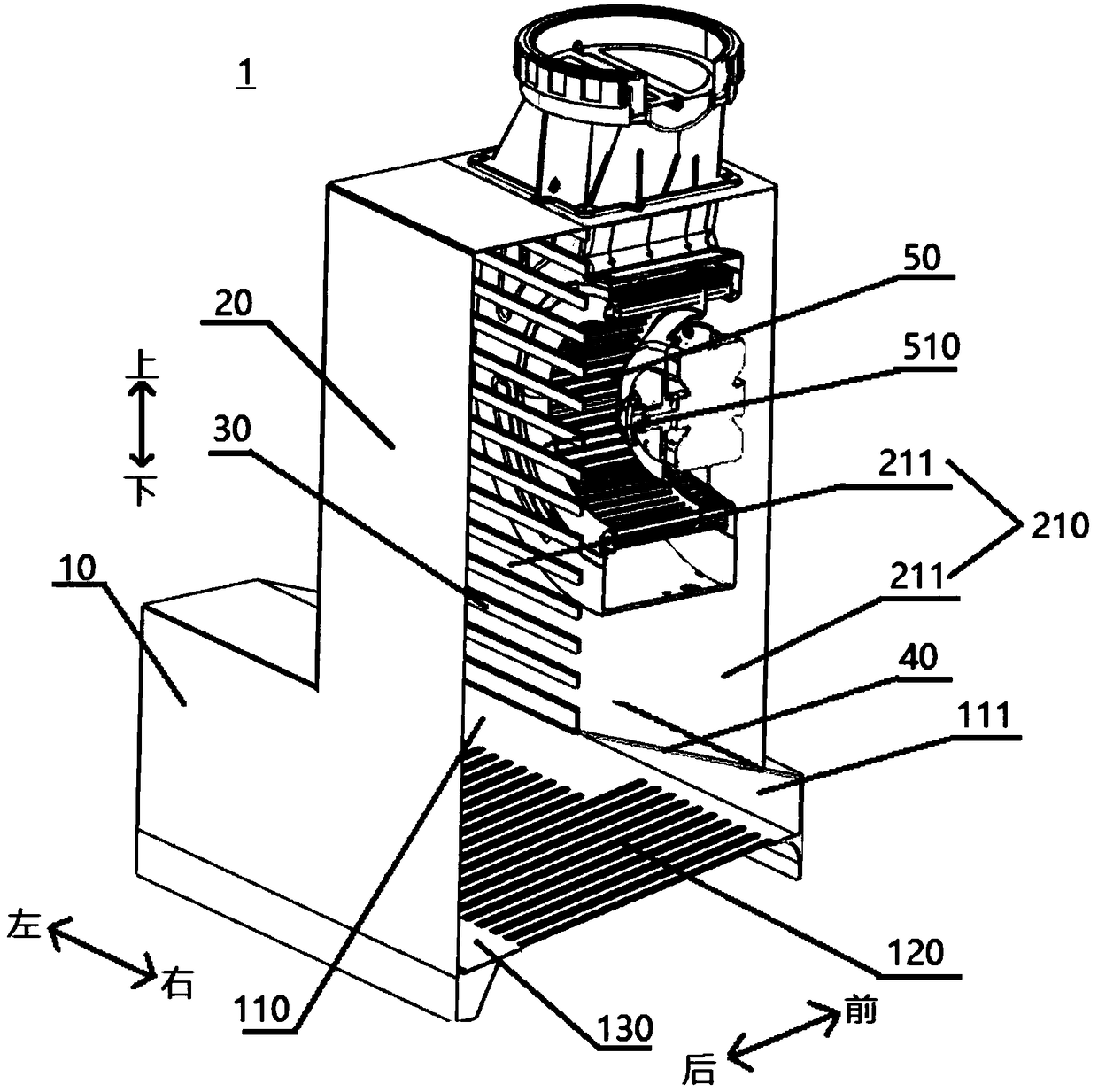

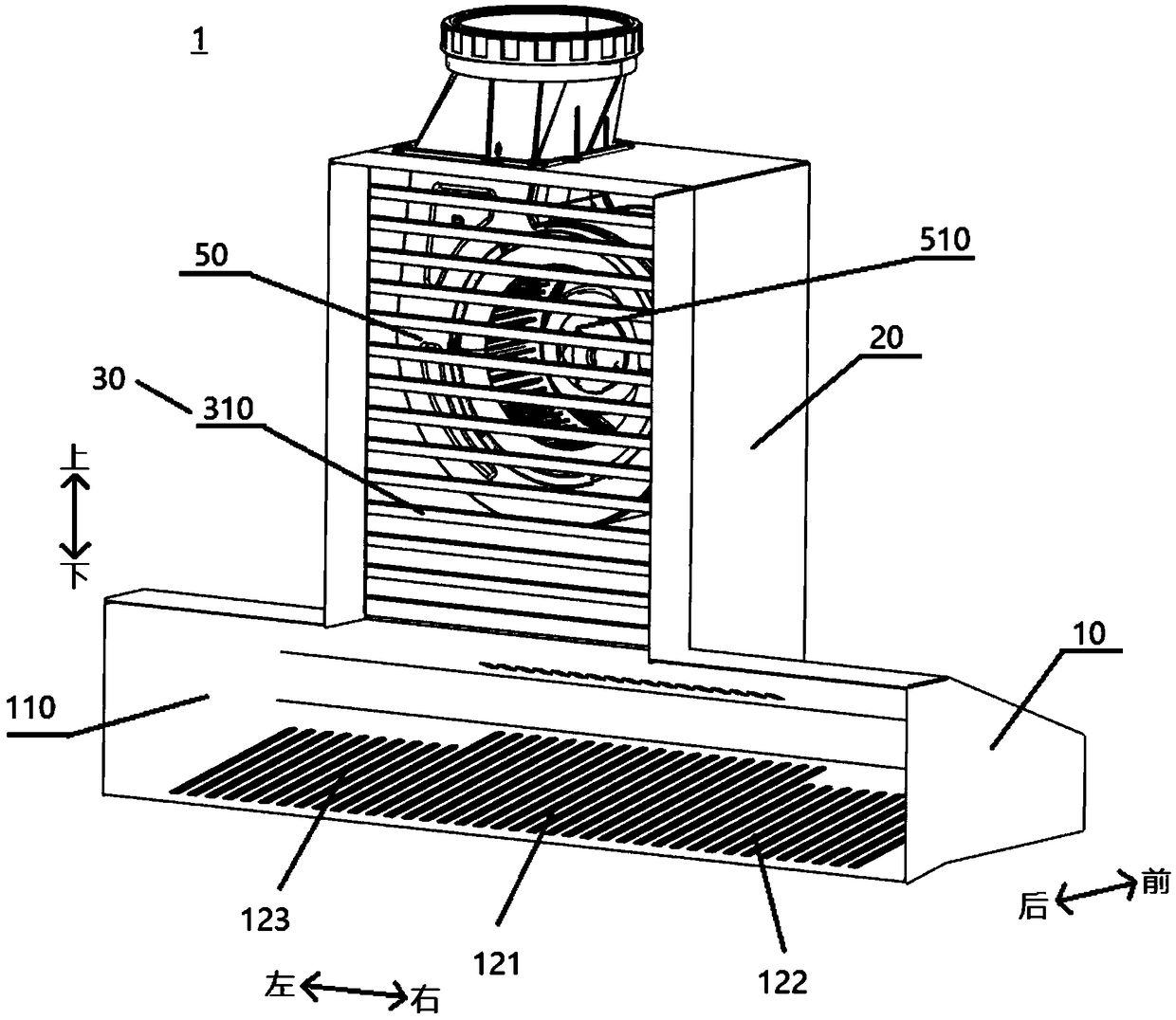

Air-conditioner outdoor unit and outdoor unit faceplate thereof

InactiveCN103982954AAvoid divergenceReduced eddy current lossLighting and heating apparatusNoise suppressionEngineering

The invention discloses an air-conditioner outdoor unit and an outdoor unit faceplate thereof. The outdoor unit faceplate comprises a faceplate body (1) and an air guide ring (2) which is arranged at the air outlet (3) of the faceplate body (1). The air guide ring (2) comprises a first air guide loop (21) on the inner side of the faceplate body (1), and a second air guide ring (22) which connects the first air guide ring (21) and the faceplate body (1), wherein the first air guide loop (21) and the second air guide loop (22) are both coaxial with the air outlet (3) and are respectively provided with a large-diameter end and a small-diameter end, and the small-diameter end of the first air guide loop (21) and the small-diameter end of the second air guide loop (22) are identical in diameter and are connected. The outdoor unit faceplate can improve the air guide effects and reduce the air output noise.

Owner:GREE ELECTRIC APPLIANCES INC

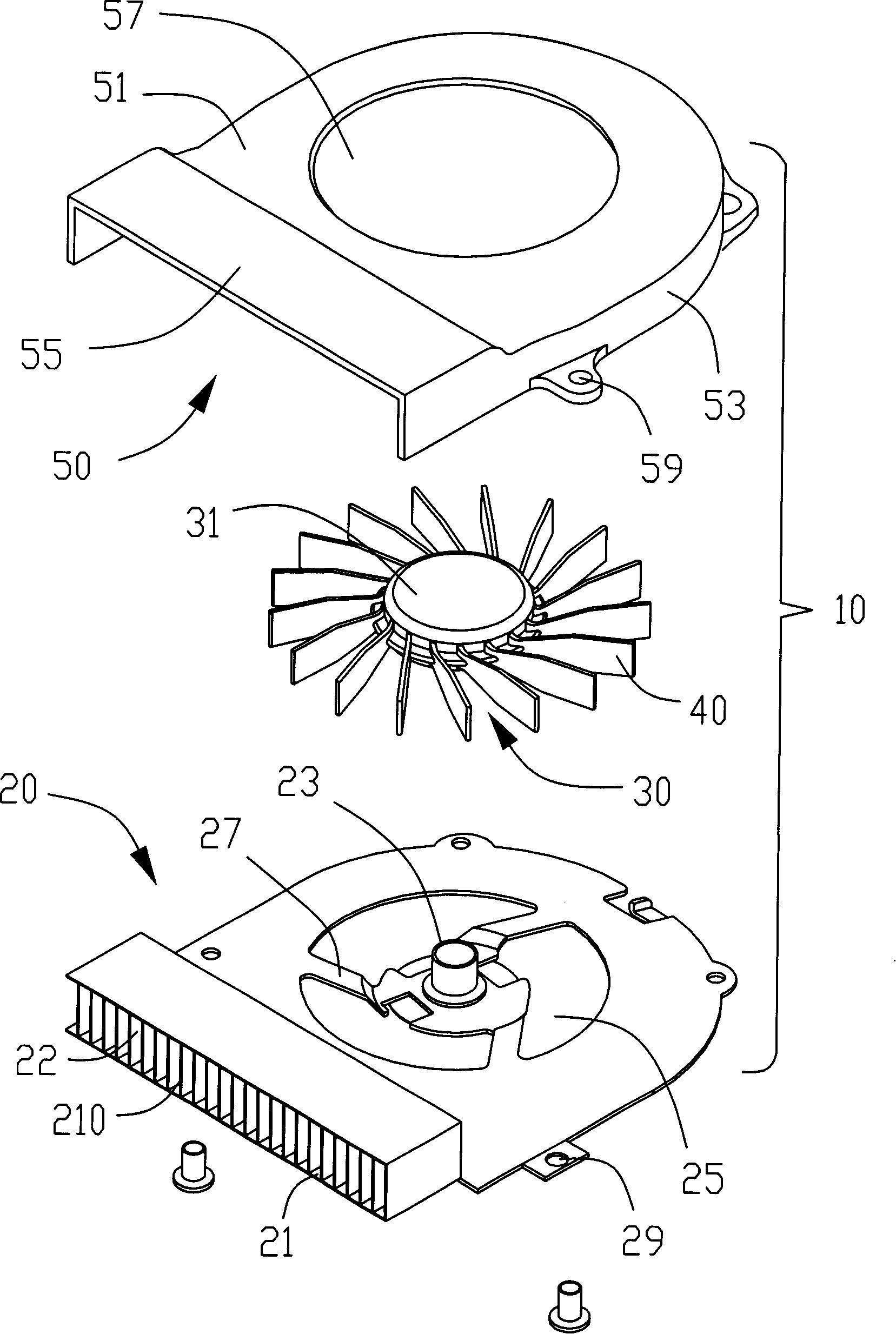

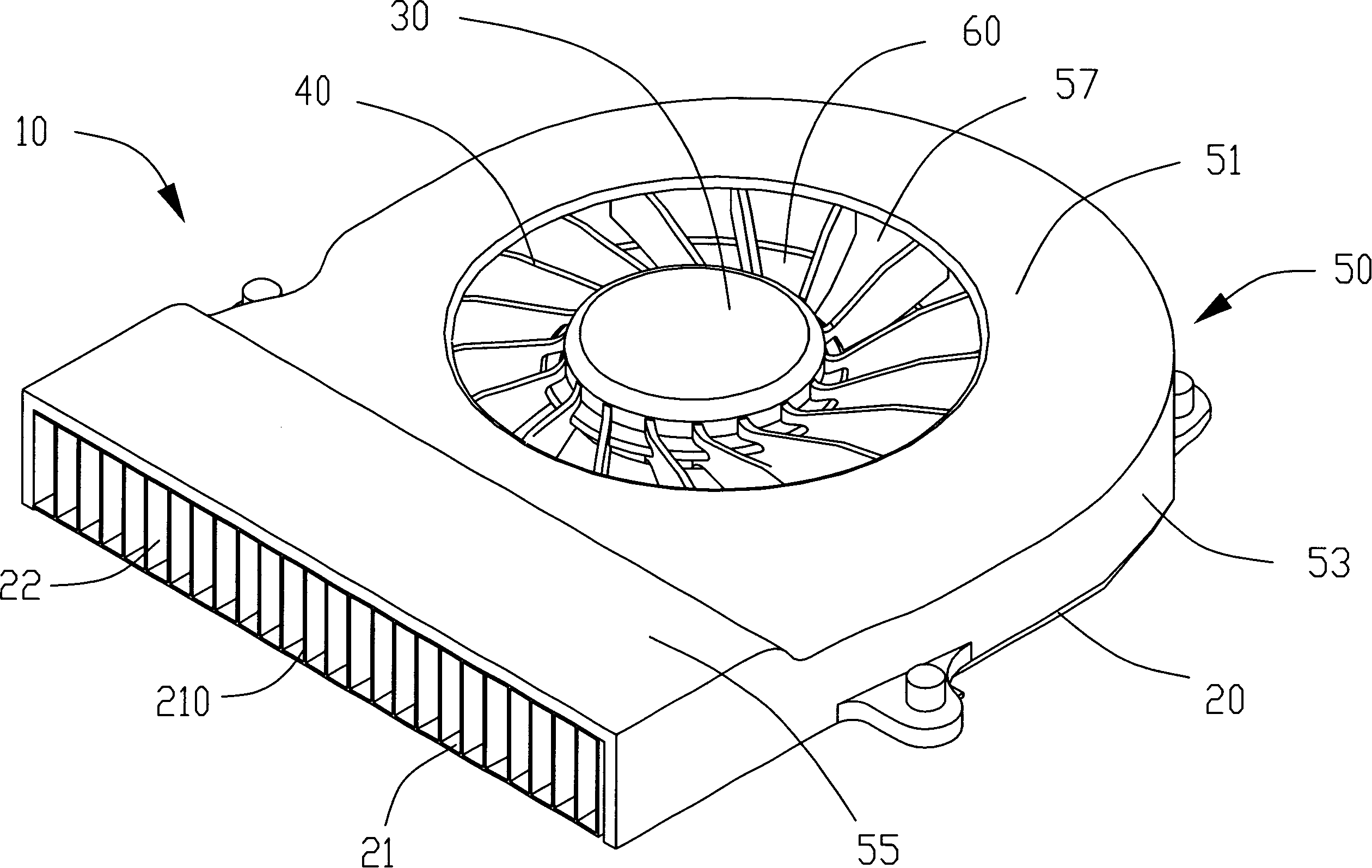

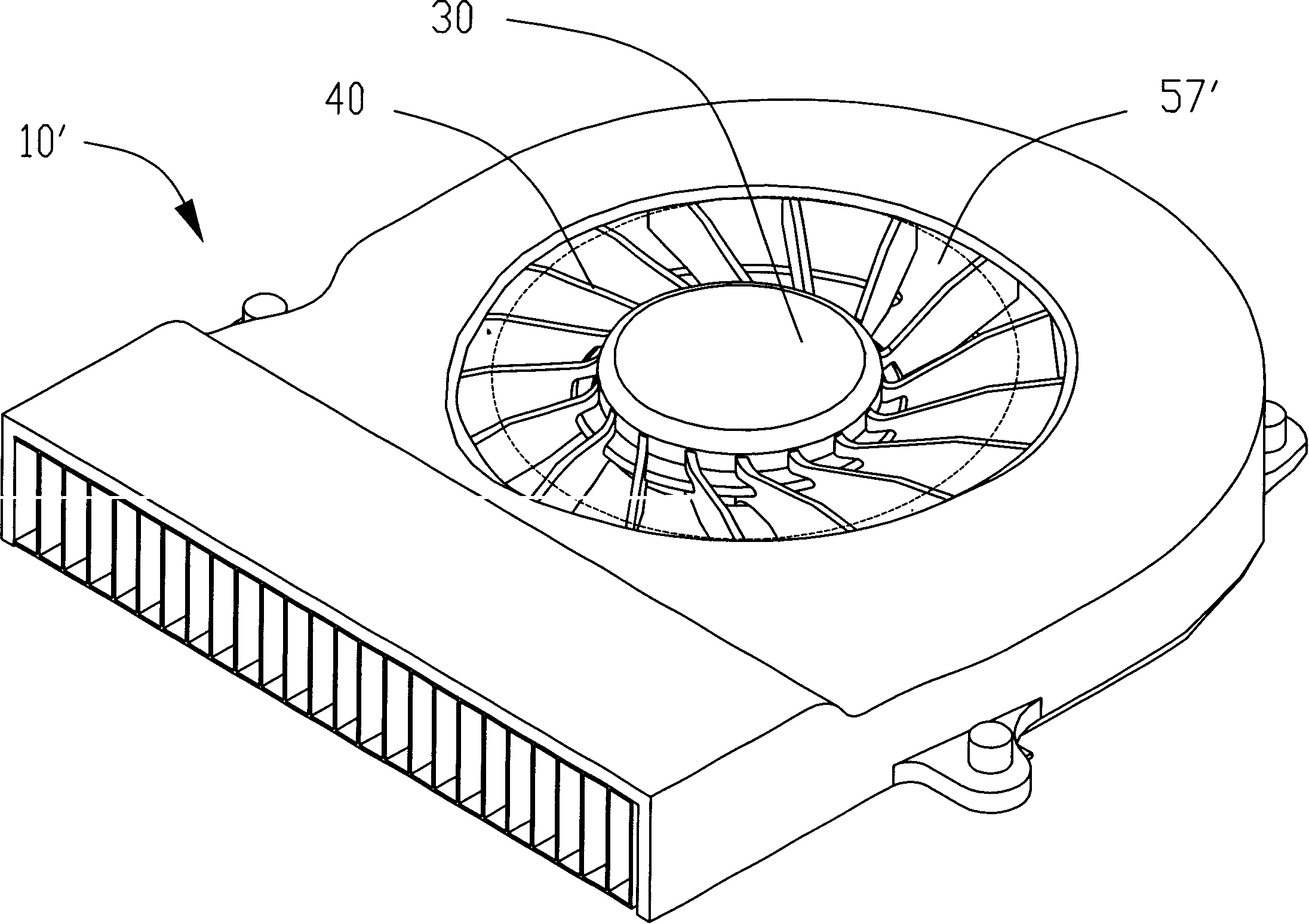

Heat radiation fan

InactiveCN1884846AImprove performanceReduced eddy current lossPump componentsDigital data processing detailsEngineeringRadiation

The invention relates to a radiation fan, which comprises a base, an upper cover, a motor and several leaves annularly arranged at the edge of motor, wherein said base and upper cover form one containing space to contain the motor and leaves; the upper cover has one wind inlet; the side end of radiation fan has wind outlet vertical to the wind inlet; each point of the edge of wind inlet and the central point of motor form different distances, to effectively reduce the airflow vortex loose and improve the fan property.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

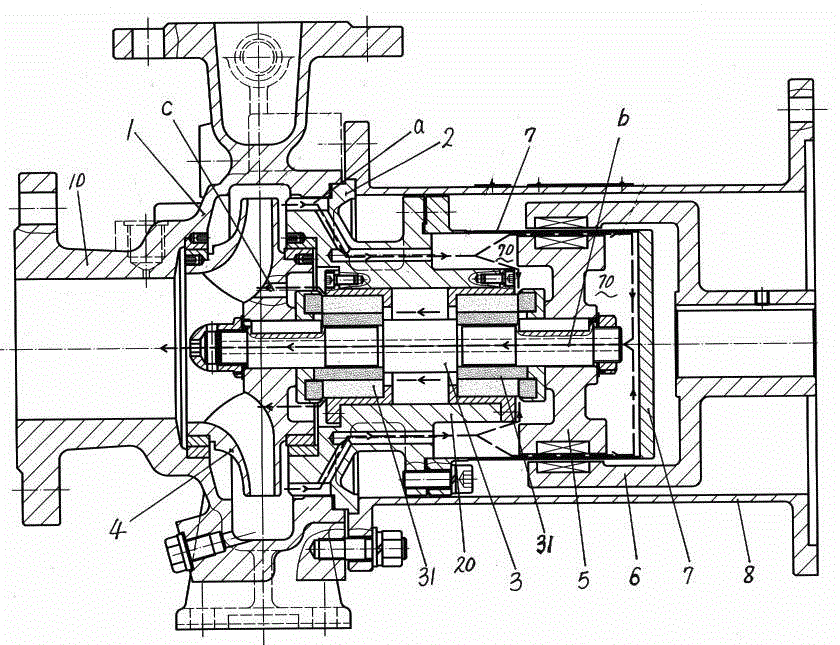

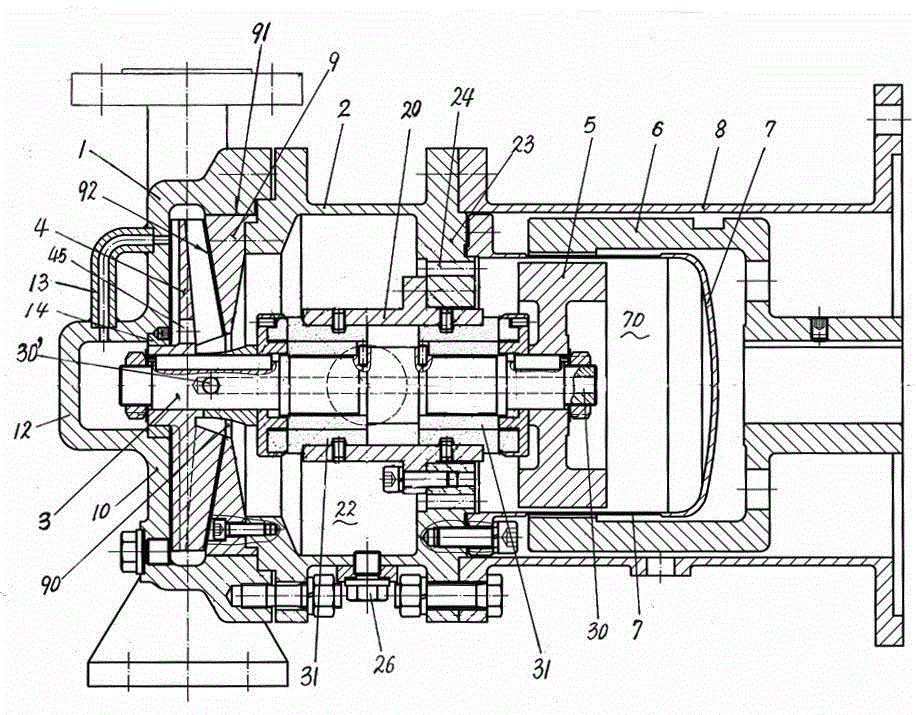

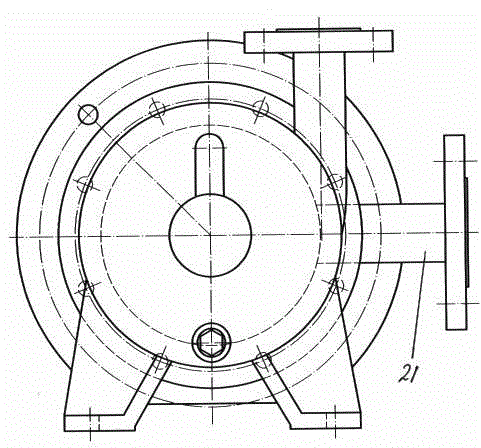

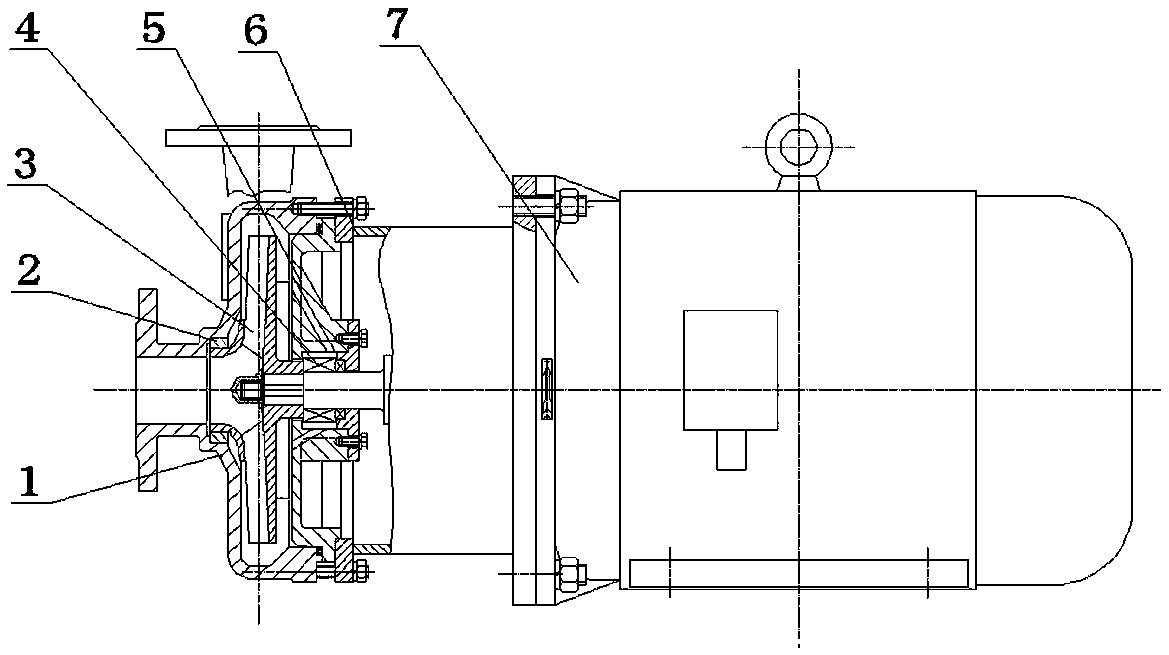

High pressure resistant magnetic pump

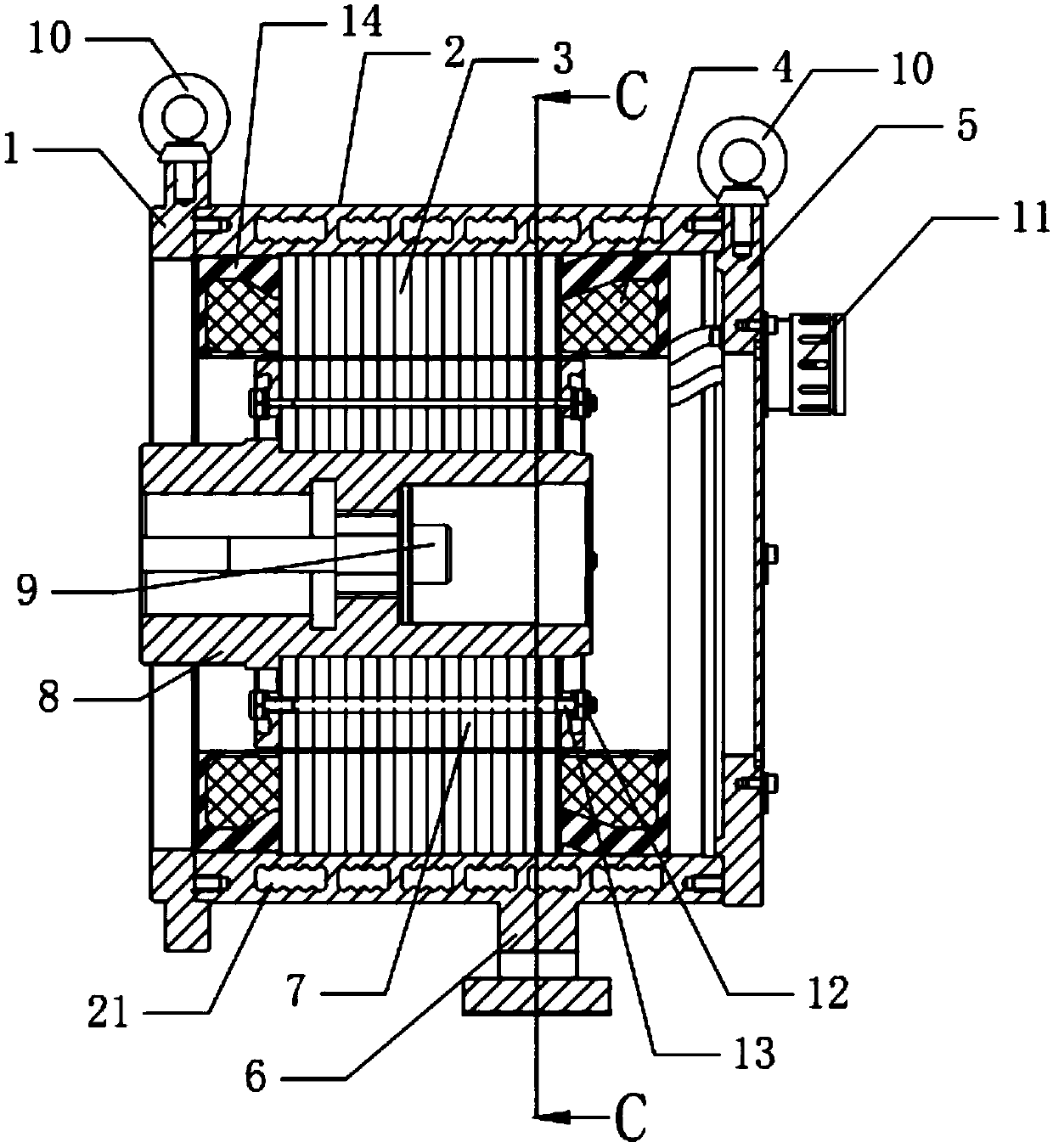

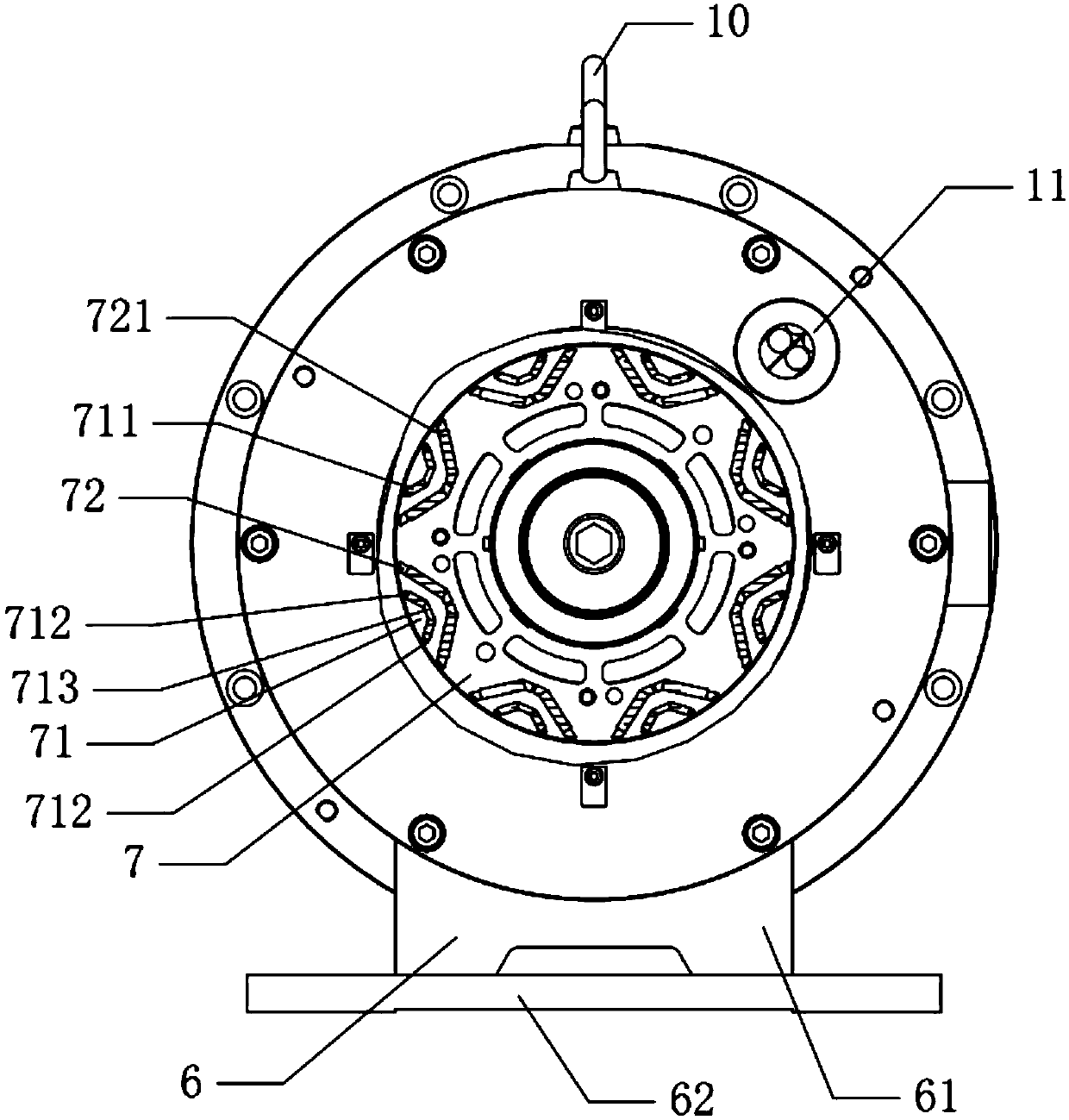

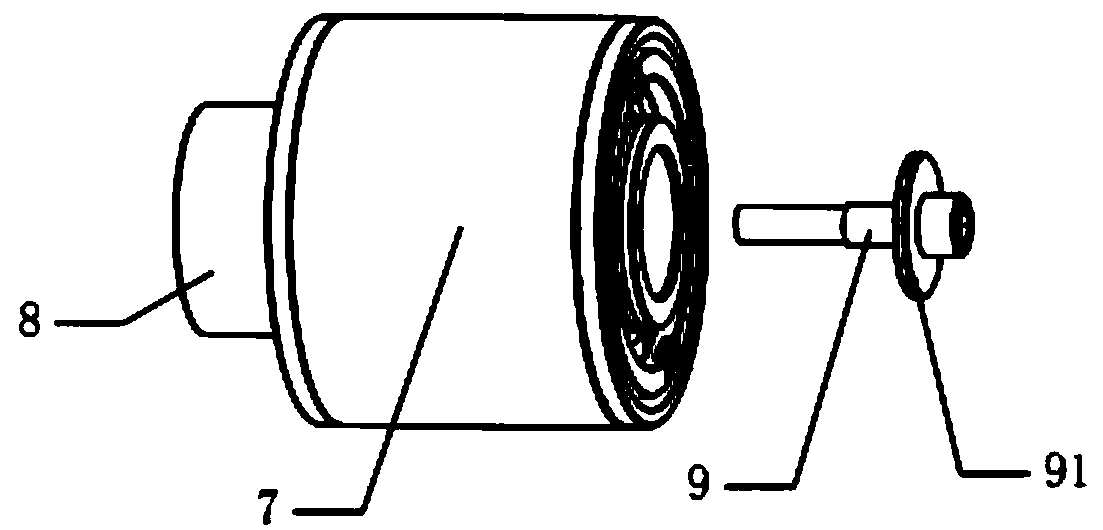

ActiveCN104806530AEasy to manufactureEasy to assembleSpecific fluid pumpsPump componentsImpellerDrive shaft

The invention discloses a high pressure resistant magnetic pump, which comprises a pump body (1), a pump cover (2), a pump shaft (3), an impeller (4), an internal magnetic rotor (5), an external magnetic rotor (6), an isolation sleeve (7), a connection frame (8), a drive shaft and a drive shaft bearing box; a spacing ring (9) is fixedly connected by a bolt through match with a spigot of the pump cover (2) in the pump body (1) so as to form the side wall of a pump cavity; an internal annular hole (90) of the spacing ring (9) forms a liquid inlet of the pump cavity; the pump cover (2) is radially provided with a liquid inlet pipe port (21); the pump cover (2) is provided with a drainage liquid inlet (24); the center of the pump shaft (3) is provided with a flow returning hole (30). Pressure borne by an inner cavity (70) of the isolation sleeve is equal to the inlet pressure of the pump, the pressure resistance of the pump is improved, a bearing device (31) of the pump shaft is totally positioned in a flowing liquid inlet medium environment, the cooling effect is good, the machining is convenient, the production cost is reduced and the service life is long.

Owner:DANDONG TOP PUMP

Thin type cigarette machine

ActiveCN109405026AReduce circumferential eddy current lossEasy to moveDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention discloses a thin type cigarette machine, which comprises a box body and a fan component, wherein a flow guide plate is arranged in the box body, an air inlet is arranged on the flow guide plate, at least part of the flow guide plate in an area surrounding the air inlet is a double-sided flow guide area, a lower surface and an upper surface of the double-sided flow guide area respectively form an air inlet flow guide surface and an air outlet flow guide surface, the air inlet flow guide surface and the air outlet flow guide surface extend upwards gradually in a direction towards the air inlet; the fan component is arranged in the box body and comprises a centrifugal wind wheel and a volute, wherein the volute is arranged above the flow guide plate, the centrifugal wind wheel is arranged in the volute, an air inlet end of the fan component is arranged towards the air inlet, and air flow blown out by an air outlet end of the fan component flows through the air outlet flow guide surface. By the adoption of the thin type cigarette machine, a circumferential vortex loss is reduced, flow is optimized, an air volume loss is reduced, and the noise and the smoking effect are improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

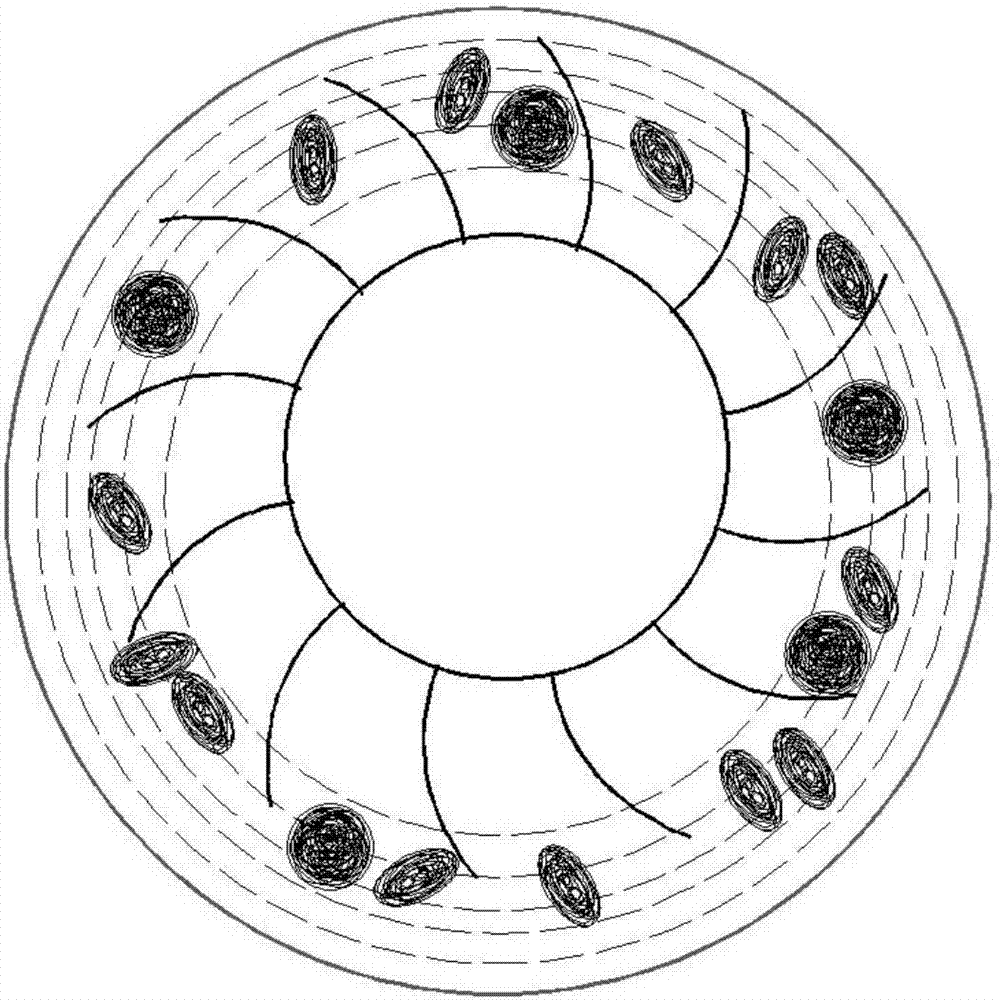

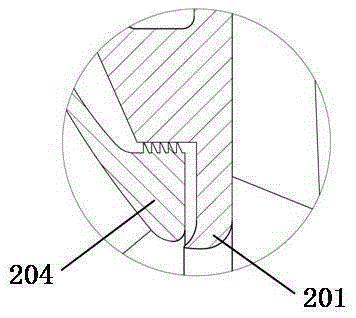

Sleeve magnetism-gathering magnetic circuit structure used for permanent magnetism eddy transmission apparatus

ActiveCN103618433AReduced eddy current lossSmall structure sizeDynamo-electric gearsPermanent magnet rotorTransmission technology

The invention provides a sleeve magnetism-gathering magnetic circuit structure used for a permanent magnetism eddy transmission apparatus, and belongs to the field of permanent magnetism transmission technologies. Compared with a sleeve permanent magnetism eddy transmission apparatus adopting a discrete magnetic circuit structure, a torque or the transmission power generated by permanent magnetism material per unit mass are bigger according to a sleeve permanent magnetism eddy transmission apparatus adopting the magnetic circuit structure provided by the invention. The magnetic circuit structure includes a permanent magnet rotor used as a first outer rotor and a vortex ring rotor used as a first inner rotor, each first permanent magnet set is composed of 2 to 5 magnets which tightly contact together, directions of the magnetizing magnetic polarities of magnets in the same first permanent magnet set are same, and directions of the magnetizing magnetic polarities of magnets of adjacent first permanent magnet sets are different. The magnetic circuit structure includes a vortex ring rotor used as a second outer rotor and a permanent magnet rotor used as a second inner rotor, each second permanent magnet set is composed of 2 to 5 magnets which tightly contact together, directions of magnetizing magnetic polarities of adjacent magnets in the same second permanent magnet set are same, and directions of the magnetizing magnetic polarities of adjacent second permanent magnet sets are different.

Owner:LIAOYANG TAIKE LEINUO SCI & TECH

Semiconductor device and manufacturing method thereof

InactiveCN101847610AReduced eddy current lossAvoid short circuitSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneEngineering

Owner:TERAMIKROS INC

A kind of preparation method of rare earth permanent magnet with high resistivity

ActiveCN106653271BOvercome the problem of not being able to significantly increase the resistivityReduced eddy current lossInductances/transformers/magnets manufactureMagnetic materialsCalcium silicateRare-earth element

The invention relates to a preparation method of a high-resistivity rare-earth permanent magnet. The method comprises the following steps that 1, an insulation sheet is added into R1-M-B magnetic powder, wherein R1 is one of or a compound of multiple rare earth elements, M is one of or a compound of multiple of Ti, V, Cr, Mn, Co, Ga, Cu, Si, Al, Zr, Nb, W and Mo, and the insulation sheet is one of or a compound of multiple of quartz, zirconia, aluminum oxide and calcium silicate; 2, a mold is filled with a mixture, obtained in the first step, of the magnetic powder and the insulation sheet, and orientation pressing is conducted; 3, a blank obtained in the second step is sintered, aging treatment is conducted, and the rare-earth permanent magnet is obtained. According to the permanent magnet obtained through the technology, on the premise that the integrity of the appearance of the magnet is guaranteed, and the problem that the electrical resistivity cannot be increased greatly through other methods is solved; the magnet is applied to the high frequency alternating electromagnetic field environment and a motor operating at a high speed, and eddy current loss in the motor can be greatly reduced.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Extractor hood

ActiveCN108980947AImprove work efficiencyReduce working noiseDomestic stoves or rangesLighting and heating apparatusFilter effectIndustrial engineering

The invention discloses an extractor hood. The extractor hood comprises a fan cover, a smoke collecting cover, a flow-splitting plate and a center flow guide plate. A fan cavity is limited by the fancover. The fan cavity is internally provided with a fan. The smoke collecting cover is positioned below the fan cover, and limits a smoke collecting cavity communicated with the fan cavity. The smokecollecting cavity is provided with an oil and smoke inlet for collecting oil and smoke. The flow-splitting plate is installed in the fan cavity so that the fan cavity is divided to at least two sub-cavities distributed along an air inlet direction of the fan. The fan is installed in one of the sub-cavities. The center flow guide plate is installed in the sub-cavity provided with the fan, and the center flow guide plate is positioned below the fan and the flow-splitting plate. According to the extractor hood, because the fan cavity is internally provided with the flow-splitting plate and the center flow guide plate, vortex loss in the fan cavity is reduced, working efficiency of the extractor hood is improved, the filtering effect to oil and smoke air flow is improved, and working noise ofthe extractor hood is reduced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Twisted diffusion cylinder and axial-flow fan applying same

InactiveCN112610530ABeneficial technical effectReduce flowPump componentsPumpsMechanical engineeringMechanics

The invention discloses a twisted diffusion cylinder and an axial-flow fan applying the same. The twisted diffusion cylinder comprises a cylinder body, wherein through ventilation holes are formed in the cylinder body in the axis direction, the two ends, in the axis direction, of the cylinder body are an air inlet end and an air outlet end, and from the air inlet end to the air outlet end in the axis direction, the sectional area of the inner wall surface of the cylinder body is gradually increased in a manner of being vertical to the axis, and the cylinder body is arranged in a mode of being twisted along a coaxial spiral line. The axial-flow fan comprises a wind wheel and the cylinder body, wherein the spiral direction of the spiral line is opposite to the rotating direction of the wind wheel. The twisted diffusion cylinder and the axial-flow fan applying the same have the following beneficial effects: on the premise of not changing the original size and installation matching sizes, reverse secondary flow is generated when airflow passes through the cylinder body to weaken eddy and disturb a boundary layer on the inner wall surface, the rectification effect is enhanced, tangential airflow flowing is reduced, the flowing speed of the axial airflow is increased, the effects of pressurization, efficiency increasing, noise reduction and resistance reduction are further achieved on the basis of an original diffusion cylinder, and through experimental calculation, the efficiency is increased by 2% or above, and the noise is reduced by 2 dB (A) or above.

Owner:FANS TECH ELECTRIC CO LTD

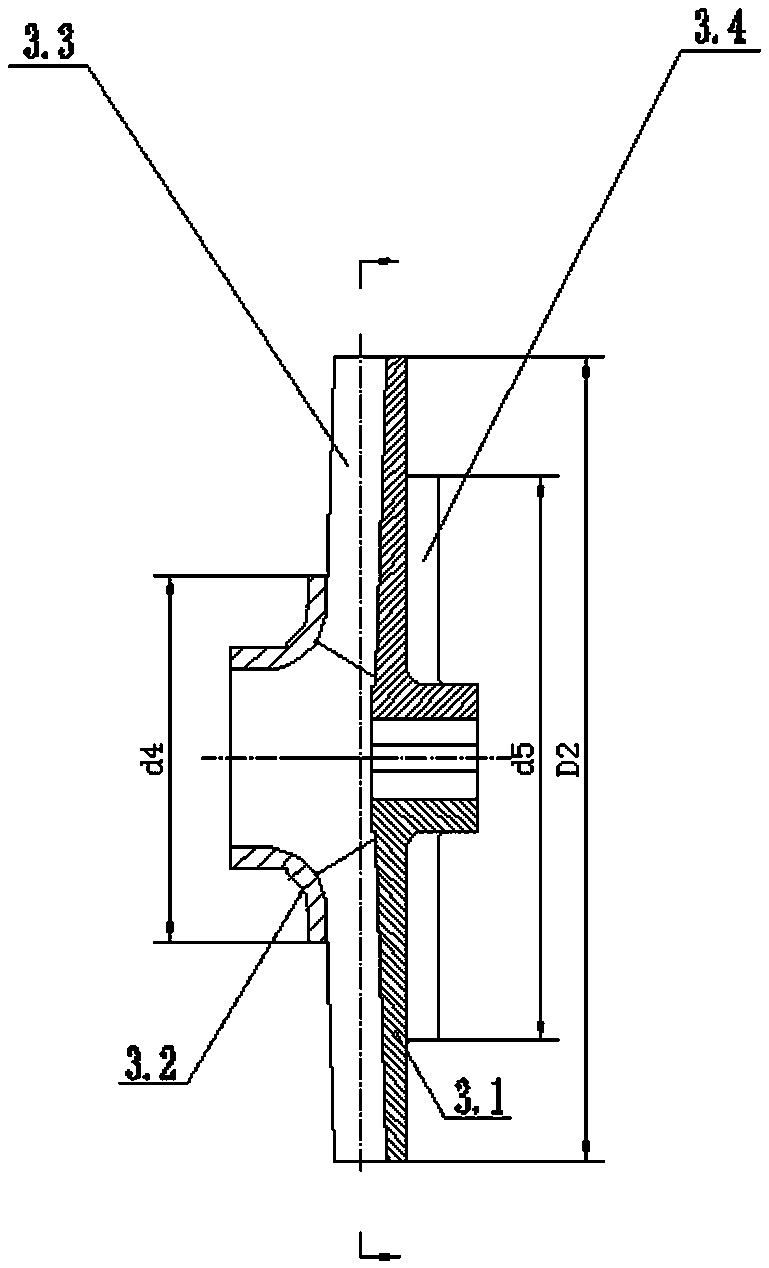

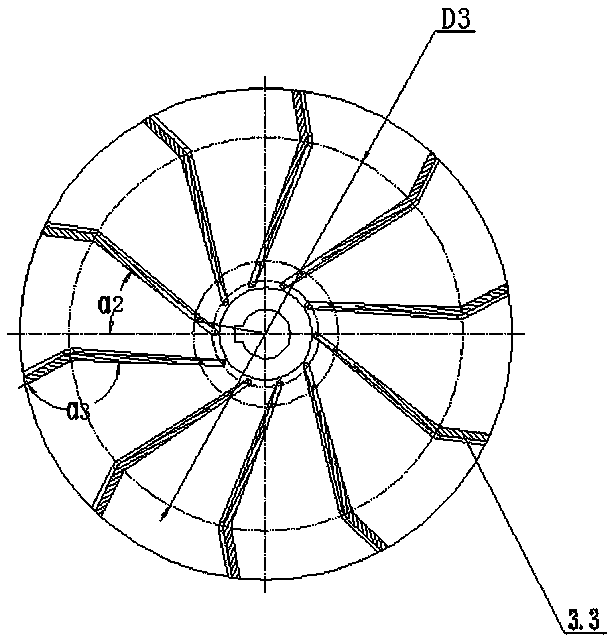

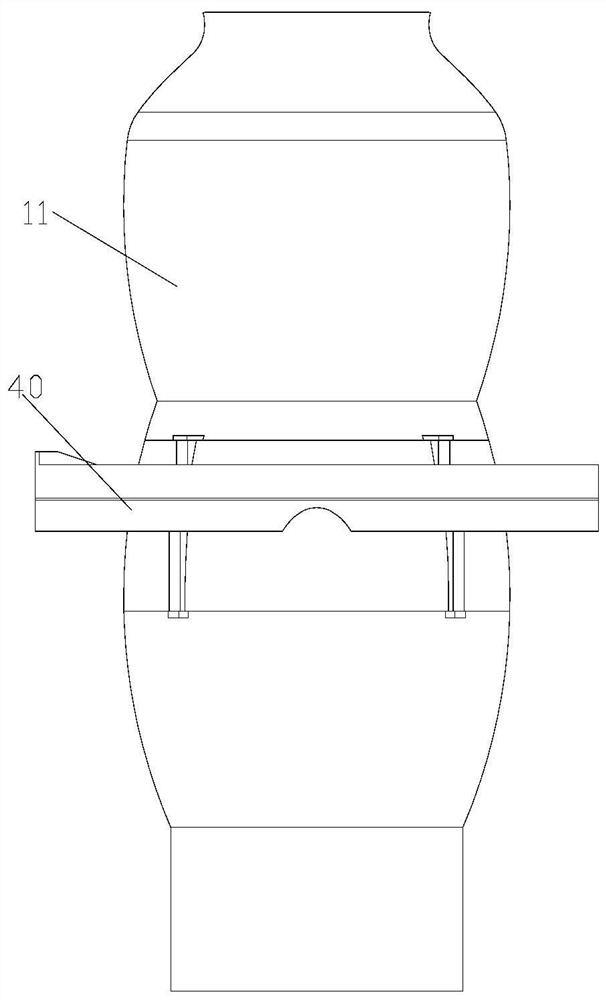

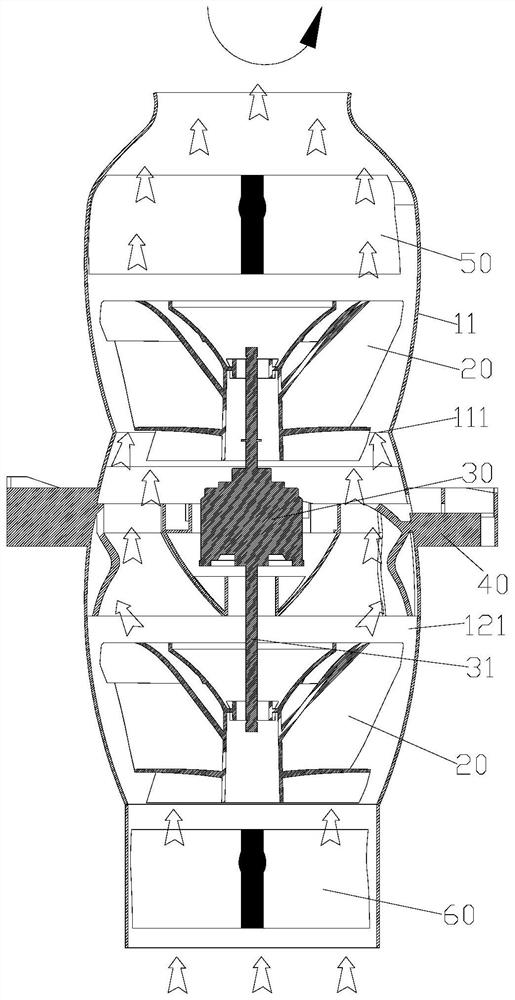

Constant-pressure vortex pump

InactiveCN110043476ASimple structureReduce manufacturing difficultyPump componentsPump installationsImpellerSemi open

The invention discloses a constant-pressure vortex pump. The constant-pressure vortex pump comprises a pump body, a sealing ring, an impeller, a mechanical seal, a pump cover, a bracket and a motor. The impeller is a semi-open type structural part with the diameter D2, 8-12 main blades evenly distributed on the front face of a rear cover plate and 8-12 auxiliary blades evenly distributed on the reverse side of the rear cover plate serve as a body, and in addition, layers of front cover plates are additionally arranged at the positions of inlets of all the main blades. The suction inlet ends ofthe front cover plates are in clearance fit with the sealing ring, the external diameters d4 of the front cover plates are equal to K1D2, and K1 ranges from 0.3 to 0.4. The main blades are obliquelyarranged relative to the axis in the same direction and anticlockwise folded at the positions of the diameters D3 by one bend uniformly, the auxiliary blades are half straight strip blocks, and all the auxiliary blades are evenly distributed in the d5 circumference and radially arranged. The front cover plates have the effects of improving and stabilizing the suction capacity of the inlets of themain blades and reducing internal leakage in the structure, thus, energy losses and noise in the constant-pressure vortex pump are reduced, the hydraulic efficiency of the pump can be improved, and meanwhile generation of camel curves under the small-flow working condition is avoided.

Owner:江苏振华海科装备科技股份有限公司

Air duct component and air conditioner

PendingCN112303012AOptimization directionImprove work efficiencyPump componentsLighting and heating apparatusEngineeringFan blade

The invention provides an air duct component and an air conditioner. The air duct component comprises an air duct body, fan blade assemblies, a mounting plate, a driving assembly, a first flow guide assembly and a second flow guide assembly, wherein the air duct body is provided with a circulation channel; the multiple fan blade assemblies are arranged in the circulation channel and are arranged at intervals in the axial direction of the circulation channel; the mounting plate is mounted in the circulation channel, the driving assembly is mounted on the mounting plate, the driving assembly isin driving connection with the fan blade assemblies, a receding channel is formed in the mounting plate, and a rectifying assembly is arranged in the receding channel; and the first flow guide assembly is arranged at the first end of the circulation channel, and the second flow guide assembly is arranged at the second end of the circulation channel. The air duct component can switch the air flow inlet direction and the air flow outlet direction, and meanwhile the first flow guide assembly, the rectifying assembly and the second flow guide assembly exist at the same time, so that the air duct component has the inlet pre-rotation and outlet rectification functions and the middle rectification function, an air flow trend channel is greatly optimized, and the working efficiency of the fan blade assemblies is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient direct connection type air compressor oil-cooling permanent magnet synchronous motor and pouring process thereof

InactiveCN107612257AImprove integrityImprove waterproof and moisture-proof performanceMagnetic circuit rotating partsSupports/enclosures/casingsConnection typeElectric machine

Disclosed is an efficient direct connection type air compressor oil-cooling permanent magnet synchronous motor. The efficient direct connection type air compressor oil-cooling permanent magnet synchronous motor comprises a front flange, a motor shell, a stator iron core, a coil, a back flange, a base, a rotor iron core, a rotary shaft and a rotor locking screw; the coil is wound around the statoriron core, and the coil is uniformly arranged around the stator iron core; the rotor iron core is arranged in the stator iron core in a sleeving manner; the rotary shaft is arranged in the rotor ironcore; the stator iron core, the rotor iron core and the rotary shaft adopt a concentric structure, wherein the rotor locking screw is also arranged in the rotary shaft; the rotary shaft extends from the front flange to be directly connected with an air compressor main shaft; the rotary shaft and the air compressor main shaft are tightly locked together through the rotor locking screw, and the aircompressor main shaft can be directly driven through the rotary shaft to rotate; and in addition, an epoxy pouring layer is arranged among the motor shell, the stator iron shell and the coil. By virtue of direct connection between the motor rotary shaft and the air compressor main shaft and by combination with dual-layered V-shaped magnetic steel groove and a cooling flowing channel with ribs, themotor efficiency can reach 97%.

Owner:SUZHOU DRANE ELECTRIC MOTORS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com