Moving-magnetic-type linear motor used for stirling cryocooler

A linear motor and moving magnet technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of small volume and specific thrust, high mass of the mover, and low reliability, etc., to reduce the quality of the mover and the specific thrust Increased thrust and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

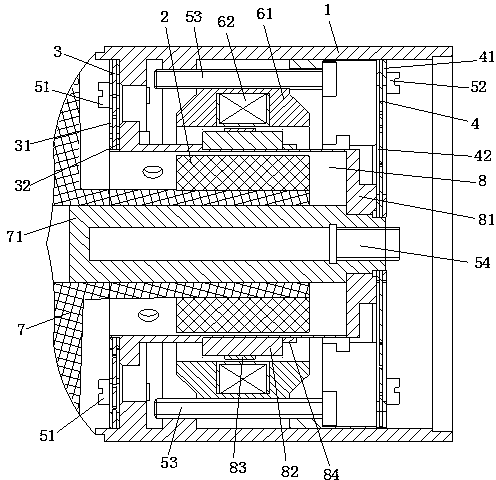

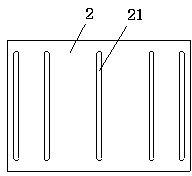

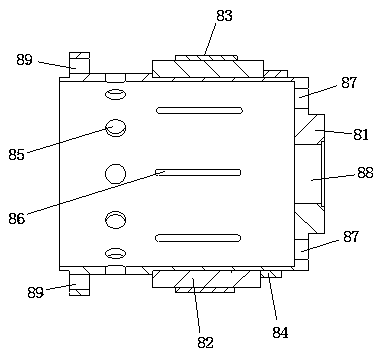

[0026] Such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 A moving magnet linear motor for a Stirling refrigerator is shown, which includes a casing 1, a mover is arranged inside the casing 1, an inner magnetic pole 2 is arranged inside the mover, an outer magnetic pole assembly is arranged outside the mover, and the mover The first and second diaphragm springs 3 and 4 are respectively provided at both ends of the rotor. The first diaphragm spring 3 is connected with the mover through the first screw 51, and the second diaphragm spring 4 is connected with the housing 1 through the second screw 52. The outer magnetic pole assembly includes an outer magnetic pole 61 and an enameled wire coil assembly embedded in the outer magnetic pole 61. The enameled wire coil assembly includes an enameled wire coil 62, a bobbin 63 and an insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com