Patents

Literature

108 results about "Stirling cryocooler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

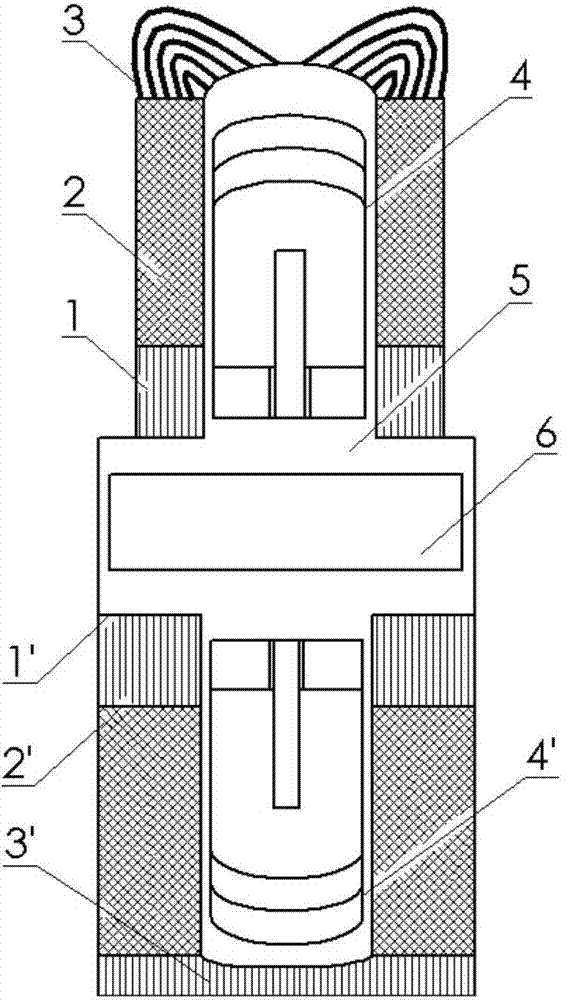

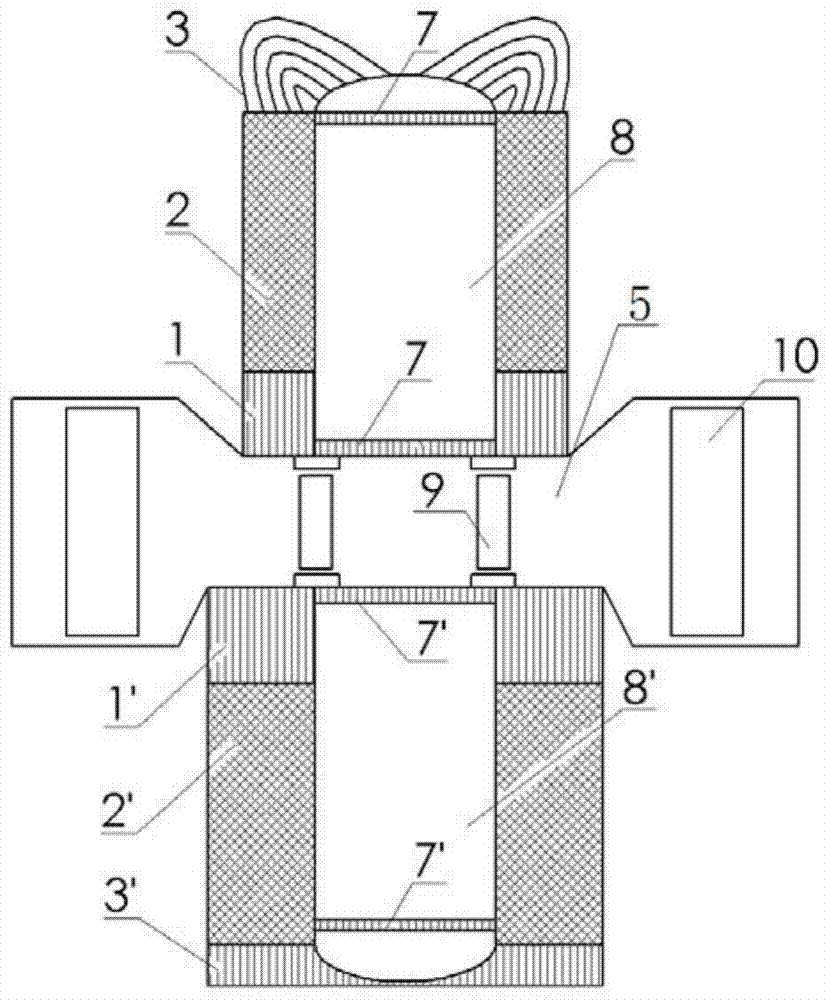

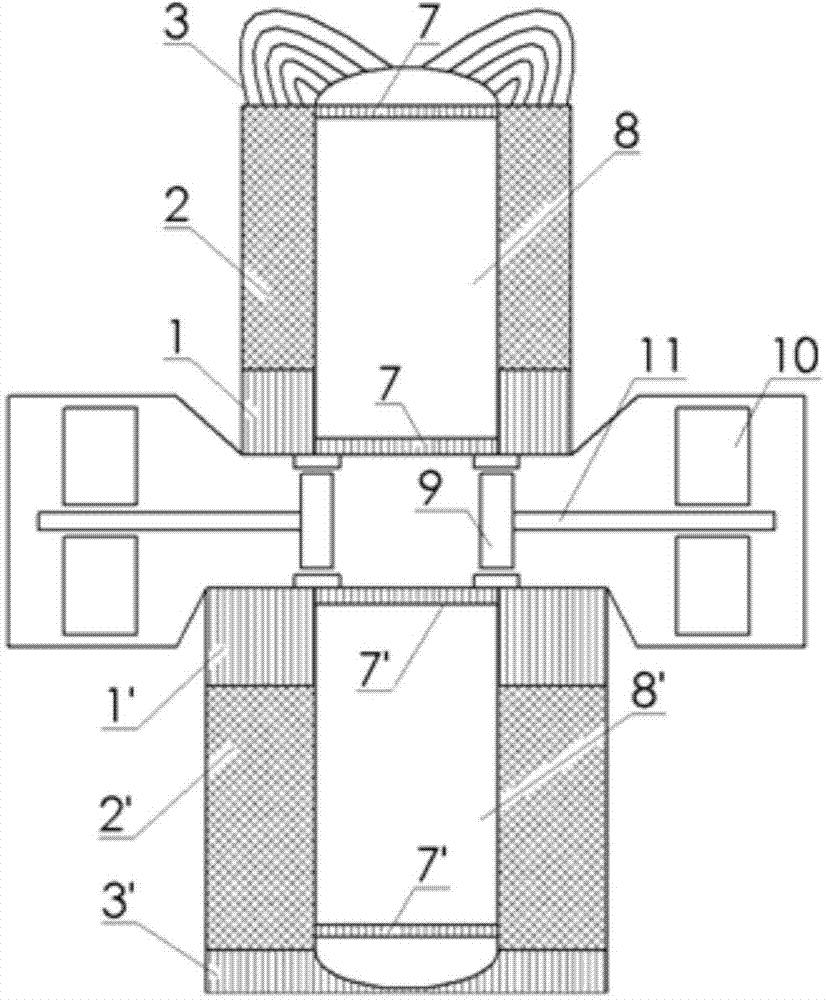

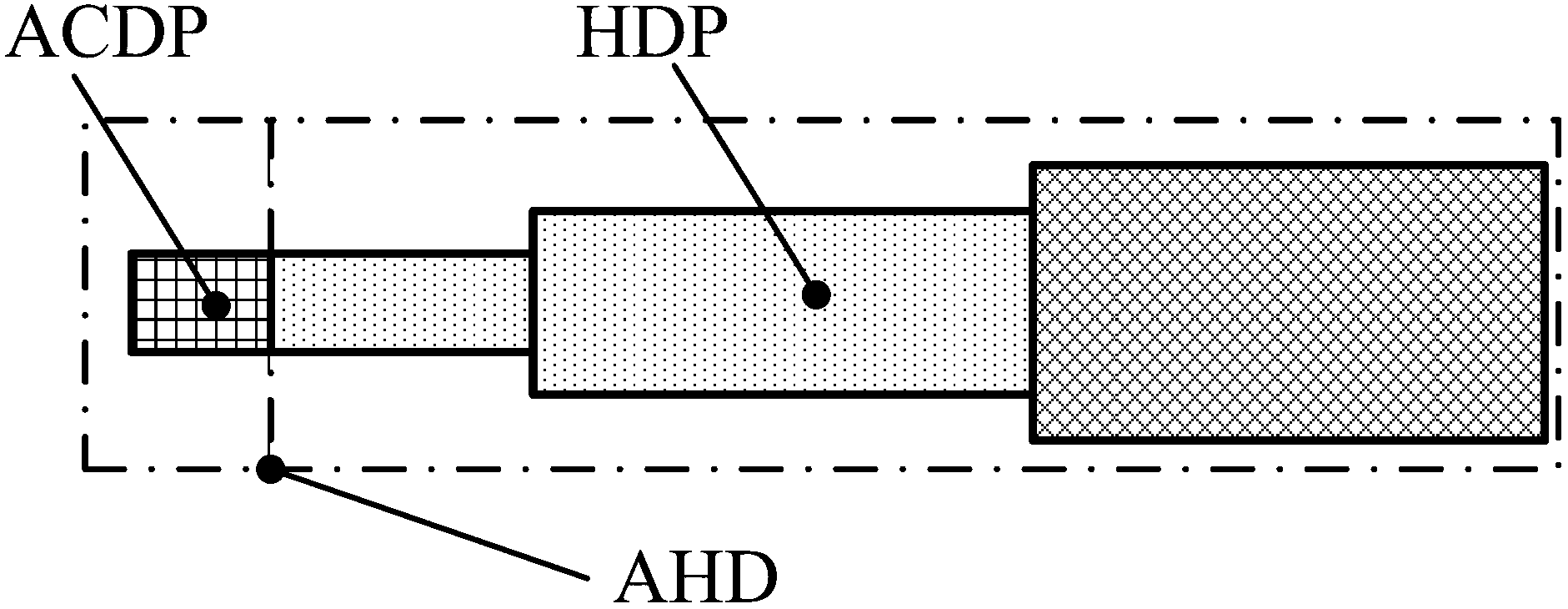

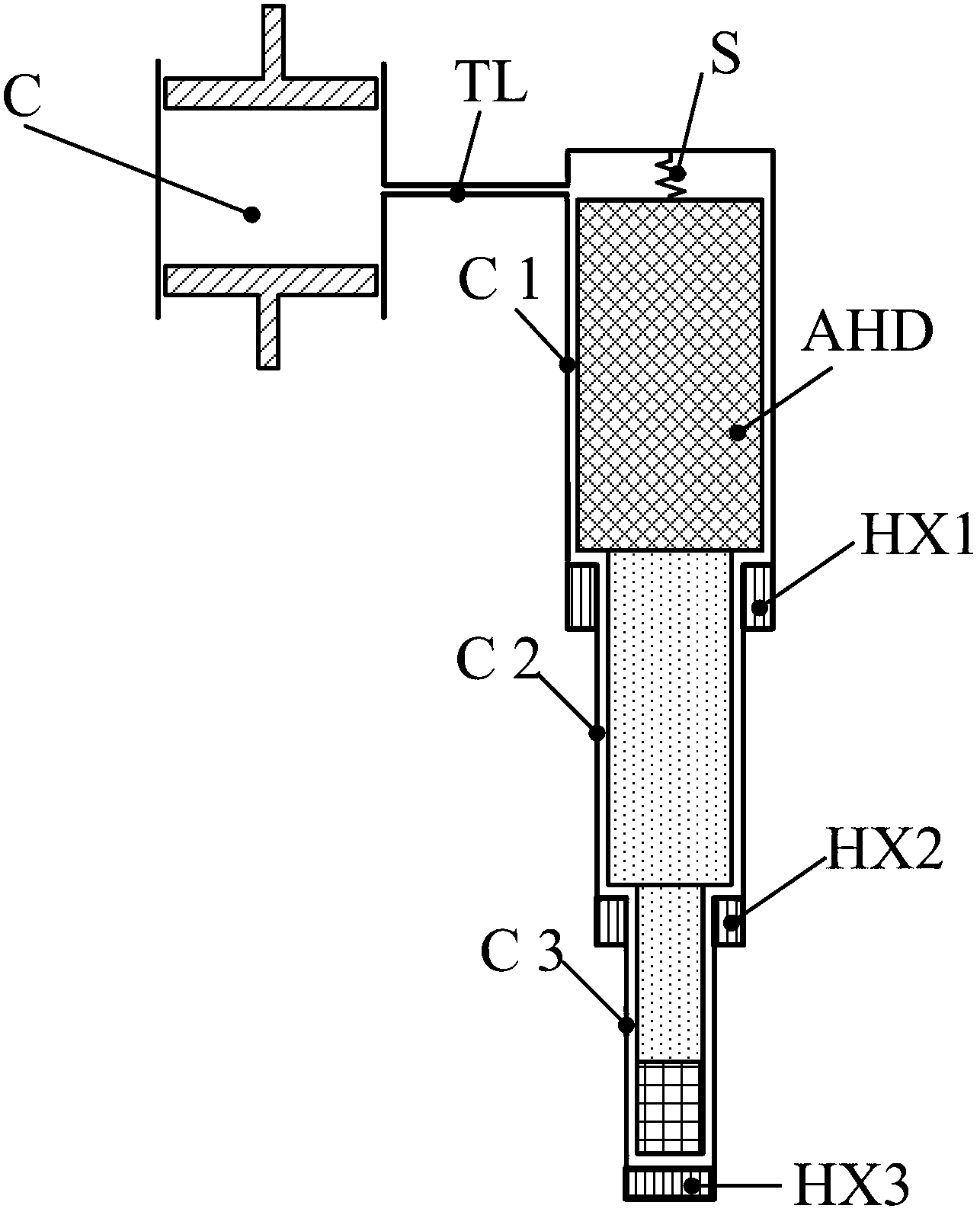

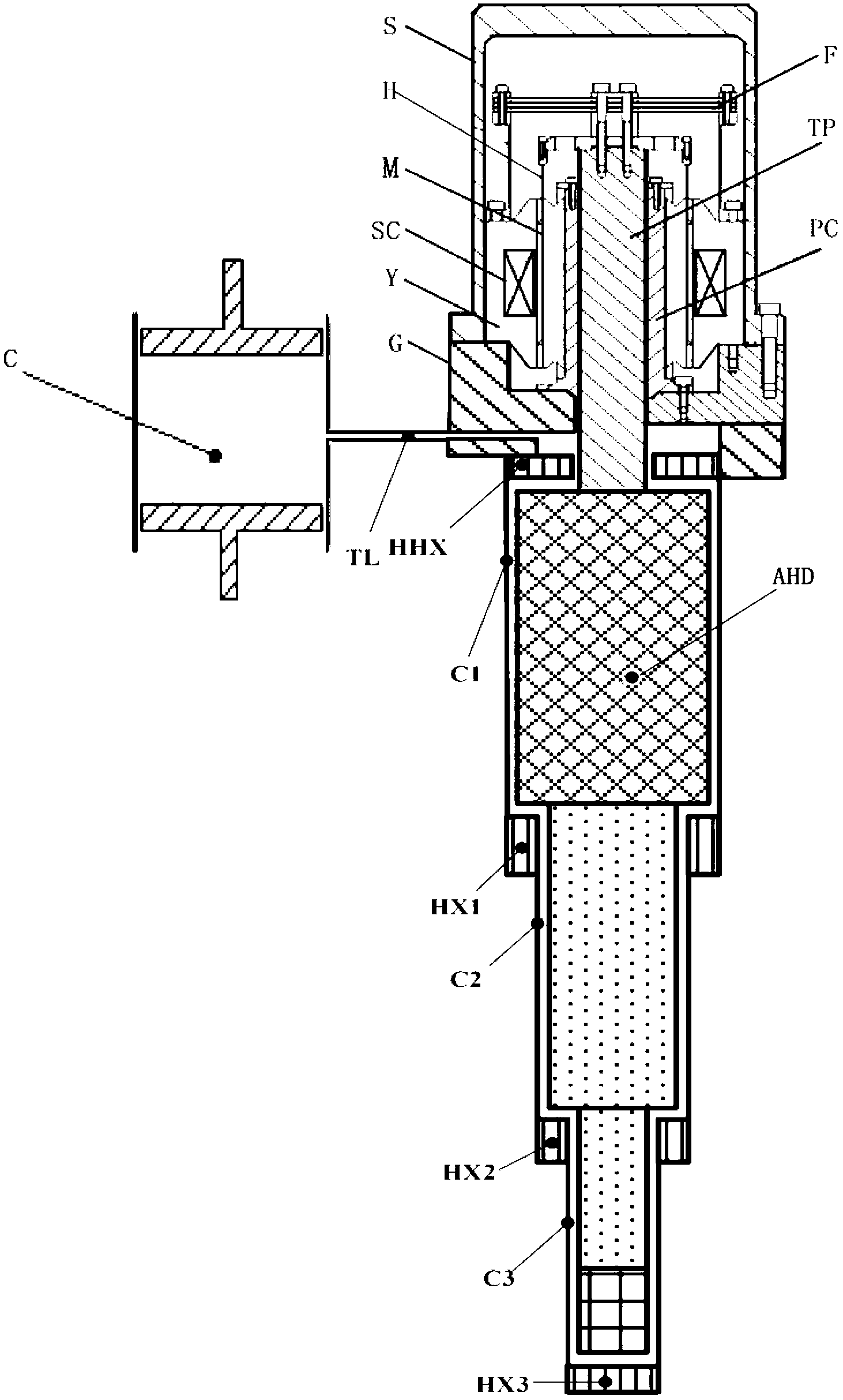

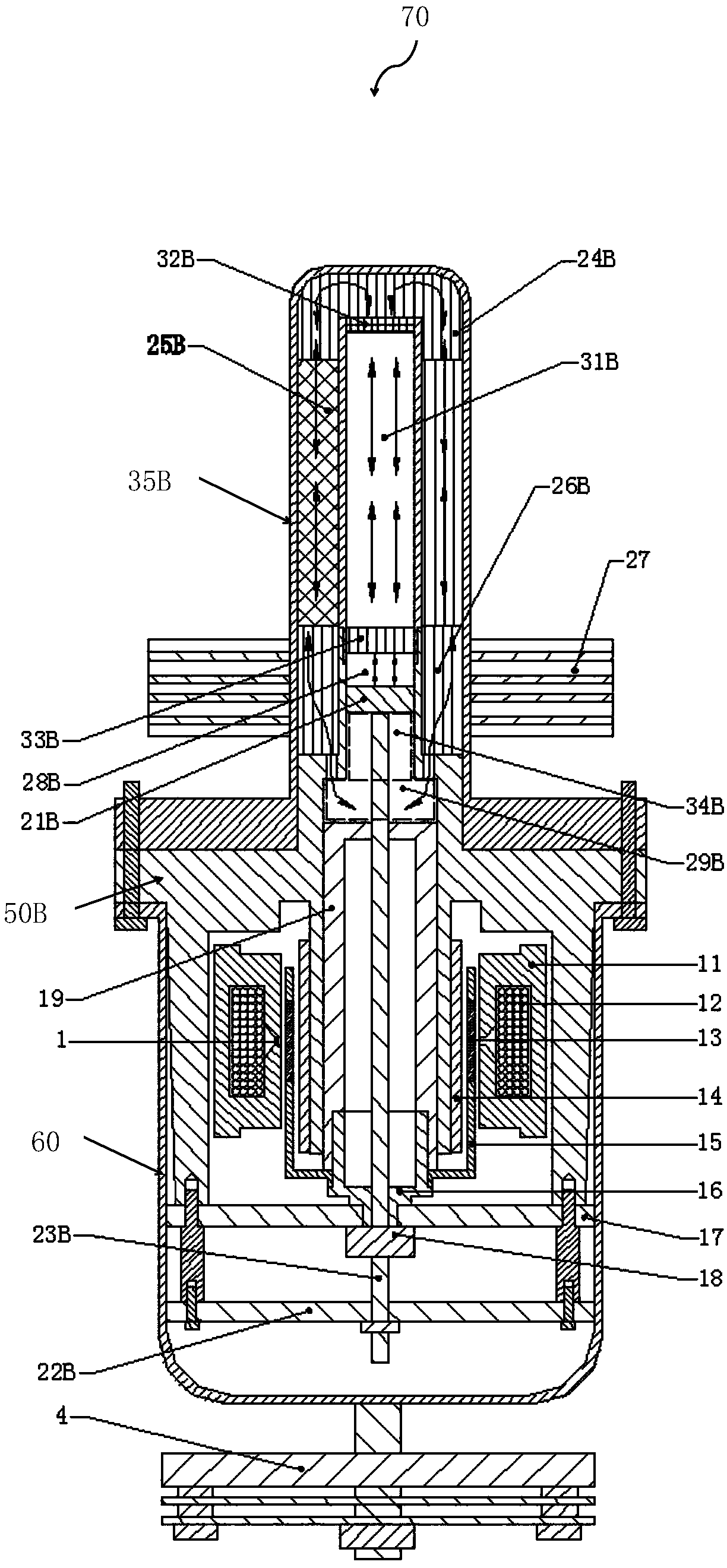

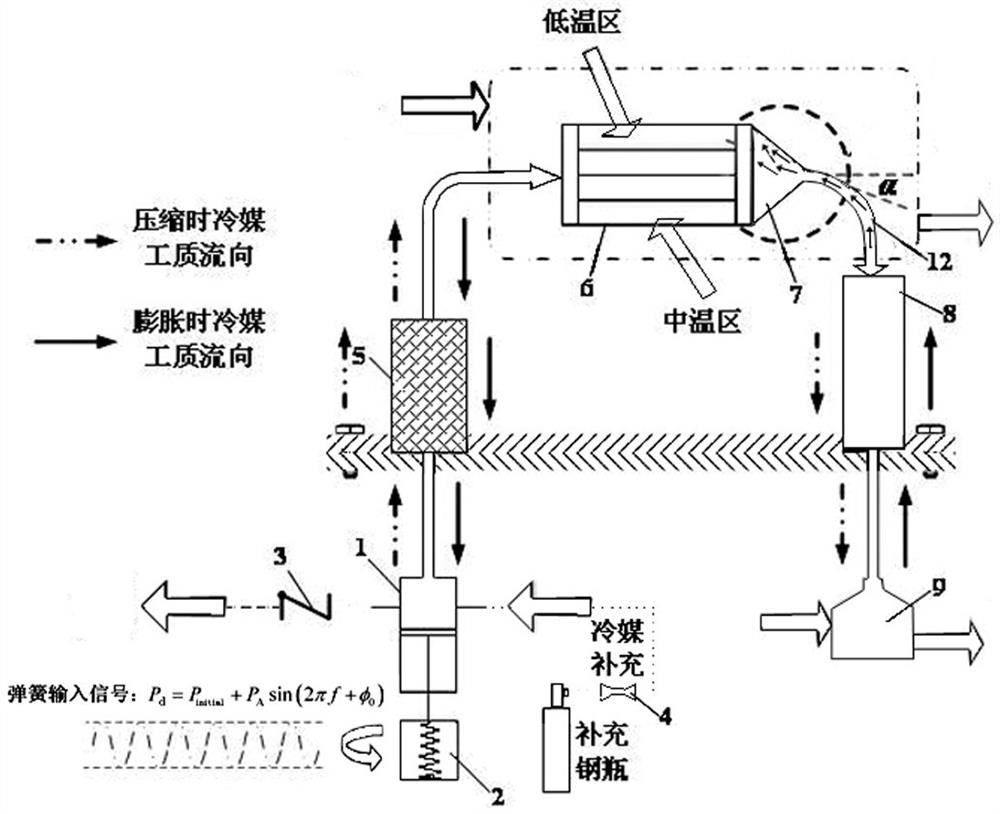

Thermally-driven stirling cryocooler

ActiveCN104848576AReduce design difficultyReduce processing difficultyCompression machinesHot gas positive displacement engine plantsPlate heat exchangerRoom temperature

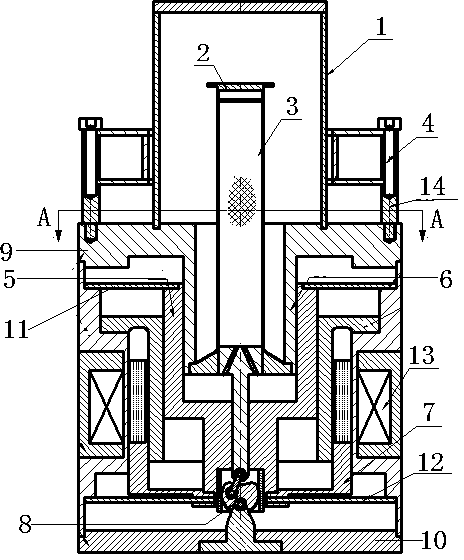

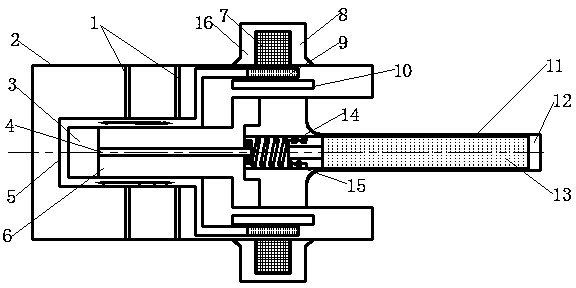

The invention relates to the field of a refrigerator, and discloses a thermally-driven stirling cryocooler. The thermally-driven stirling cryocooler comprises an engine, a refrigerator, a discharger and a harmonic oscillator; the engine comprises a hot end heat exchanger, a first heat accumulator and a first room temperature heat exchanger which are sequentially connected; the refrigerator comprises a second room temperature heat exchanger, a second heat accumulator and a cold end heat exchanger which are sequentially arranged, wherein the engine is internally provided with a first thermal buffering cavity, the refrigerator is internally provided with a second thermal buffering cavity, the upper end of the first thermal buffering cavity is connected with the hot end heat exchanger, and the lower end of the first thermal buffering cavity is connected with the first room temperature heat exchanger; the lower end of the second thermal buffering cavity is connected with the cold end heat exchanger, and the upper end of the second thermal buffering cavity is connected with the second room temperature heat exchanger; the engine and the refrigerator are relatively arranged up and down, a shared cavity is formed between the engine and the refrigerator, and the discharger and the harmonic oscillator are both arranged in the cavity in a contraposition way. The discharger provided by the invention can be operated at the room temperature end, the design and processing difficulty of the discharger can be reduced, and the vibration of the system can be reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

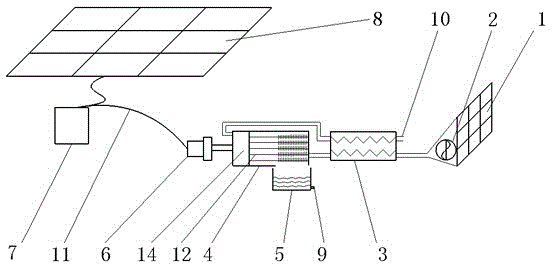

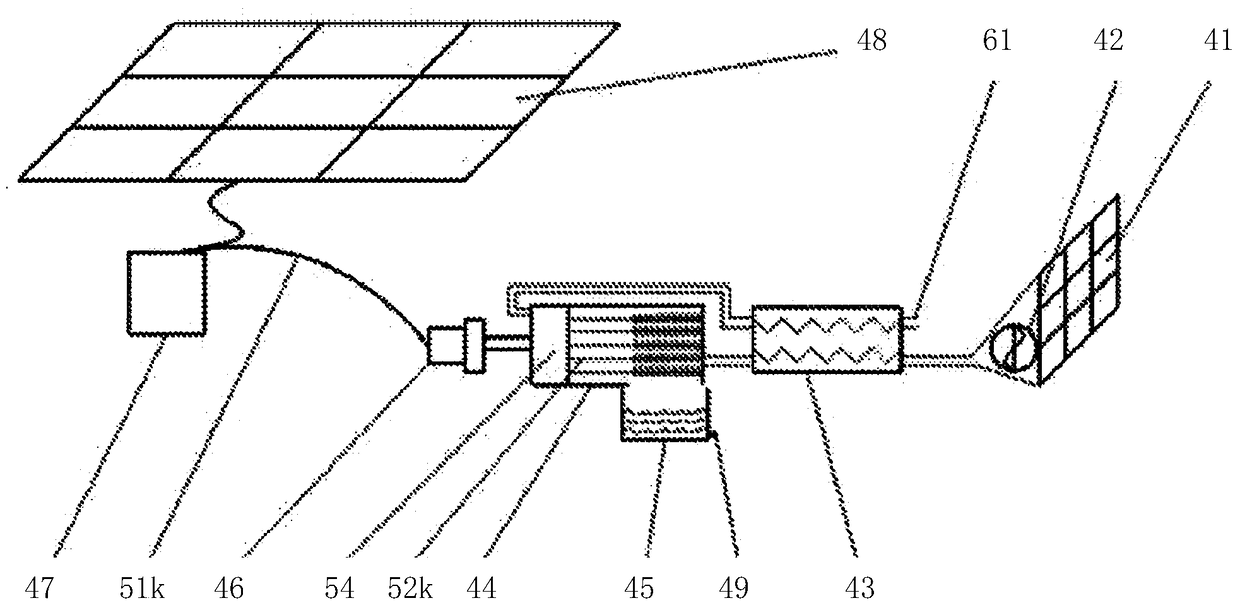

Movable solar air water taking system

The invention relates to a movable solar air water taking system. A solar cell supplies power to a draught fan and a Stirling cryocooler in daytime, and a storage battery supplies power to the draught fan and the Stirling cryocooler at night. The cold end of the Stirling cryocooler is connected with heat pipes in a water condenser, the heat pipes in the water condenser conduct cold and heat exchange with air collected and cooled by a heat regenerator, condensate water separated out by fins on the heat pipes condenses on the fins on the heat pipes and then flows into a water collector below the water condenser to be stored, cold air in the water condenser returns to the heat regenerator to cool air collected by the heat regenerator, and then the cooling cycle is formed. Adopted energy is completely provided by solar energy, sufficient solar energy resources exist in desert areas, and the water taking system is used for solving the water use problem during transportation in arid areas such as deserts. In combination with the Stirling cryocooler, the system is small in size, compact in structure, convenient to carry and high in refrigeration efficiency in low-temperature areas. The movable solar air water taking system has the advantages of being environmentally friendly, free of pollution and capable of continuously taking water in daytime and at night.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Double-mirror dual-optical path chilled-mirror dew-point hygrometer

InactiveCN106501313AReduce the volume of the whole machineAvoid duplicate purchasesMaterial moisture contentIndustrial gasEngineering

The invention relates to precision detection of an industrial gas dew point and concretely relates to a double-mirror dual-optical path chilled-mirror dew-point hygrometer. The double-mirror dual-optical path chilled-mirror dew-point hygrometer solves the problem that the traditional chilled-mirror dew-point hygrometer has harsh requirements on environmental working conditions such as an environment temperature, has a slow measurement speed and is not easy to carry because of large weight and volume of the whole hygrometer. The double-mirror dual-optical path chilled-mirror dew-point hygrometer uses two photoelectric measurement systems comprising two mirrors, two light sources and two optoelectronic receiver components, utilizes a temperature balance pressure plate and a measurement chamber to maintain temperature balance so that the equipment environment adaptability is improved, utilizes a special small Stirling cryocooler as a cold source which can quickly and accurately cool the object to 100 DEG C or less without any aid, so that the whole hygrometer volume and weight are greatly reduced, and directly utilizes the top surface of a refrigeration end of the Stirling cryocooler as a detection mirror surface so that the detection accuracy is improved.

Owner:CHANGZHOU HONGYUAN POWER TECH

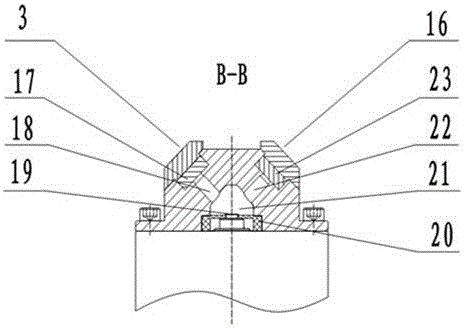

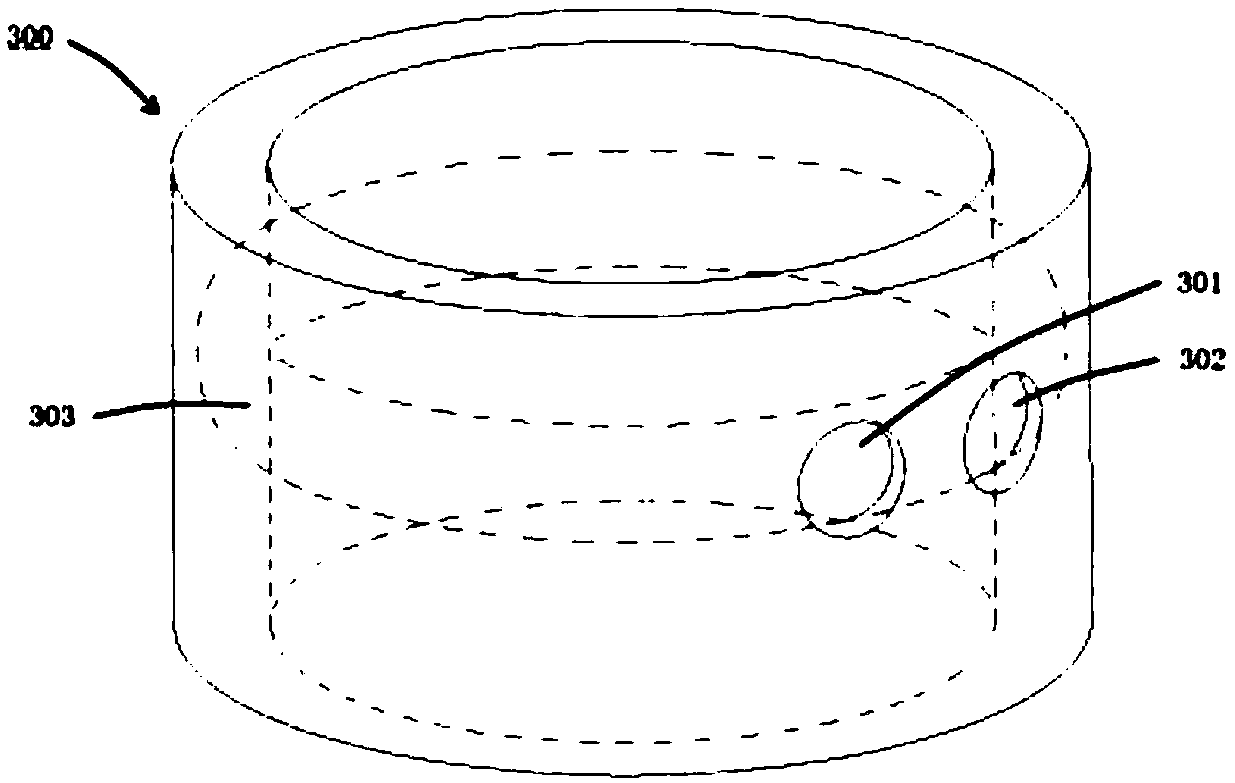

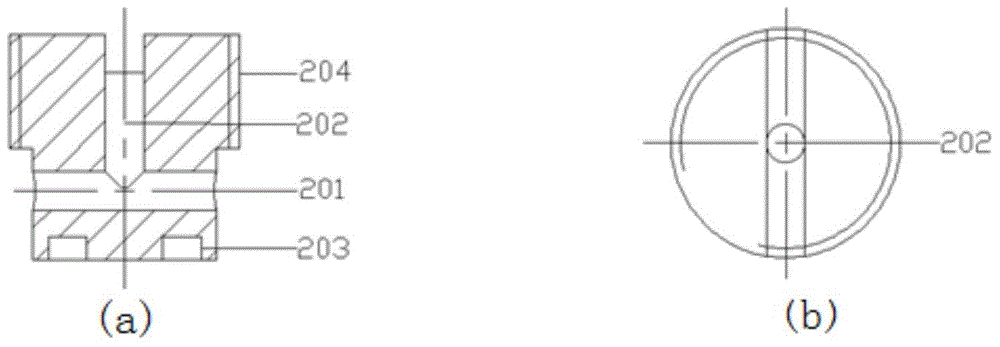

Profound hypothermia discharger adopting full carbon aerogel and stirling cryocooler

ActiveCN103216967AImprove stabilityImprove reliabilityCompression machinesProfound hypothermiaRefrigeration

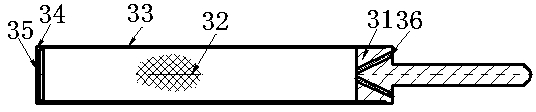

The invention discloses a profound hypothermia discharger adopting full carbon aerogel. The profound hypothermia discharger adopting the full carbon aerogel comprises a shell, a cold end and a hot end, an absorption layer is arranged on the cold end, and the absorption layer is composed of full carbon aerogel. A full carbon aerogel layer is arranged at the cold end of the profound hypothermia discharger, wherein one side of the full carbon aerogel layer is strong in absorption capability. Full carbon ultralight gel materials adsorbing helium have a high volumetric specific heat capacity within the temperature range of 10K and under 10K, and has a high thermal efficiency at the profound hypothermia under 10K. The invention further discloses a stirling cryocooler, the profound hypothermia discharge adopting the full carbon aerogel is applied to the stirling cryocooler to enable the stirling cryocooler to be good in stability and reliability in a deep low temperature zone, and high in refrigeration effect.

Owner:ZHEJIANG UNIV

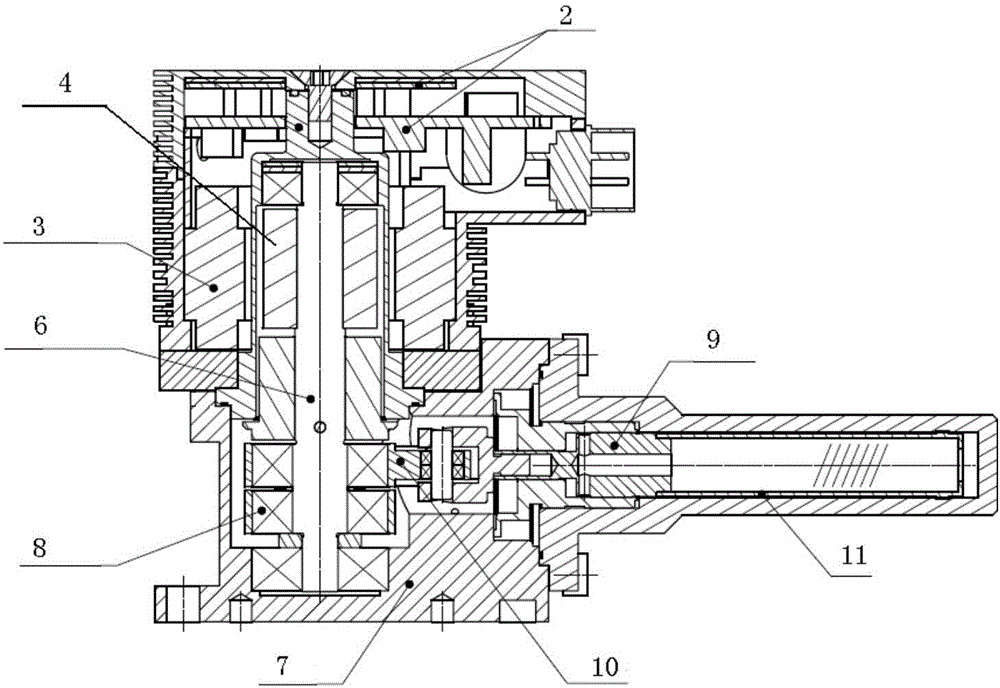

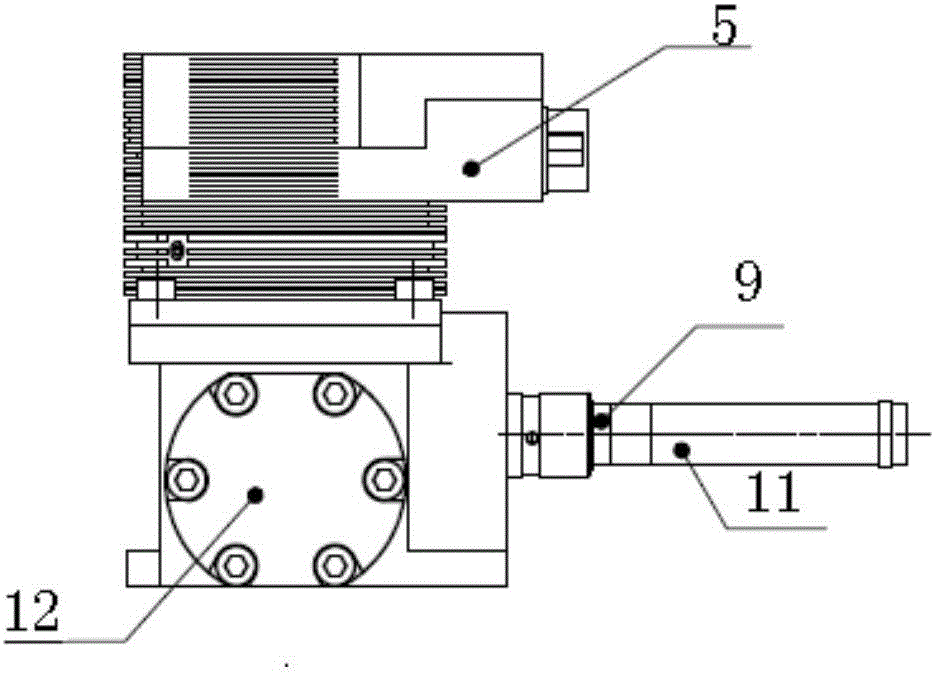

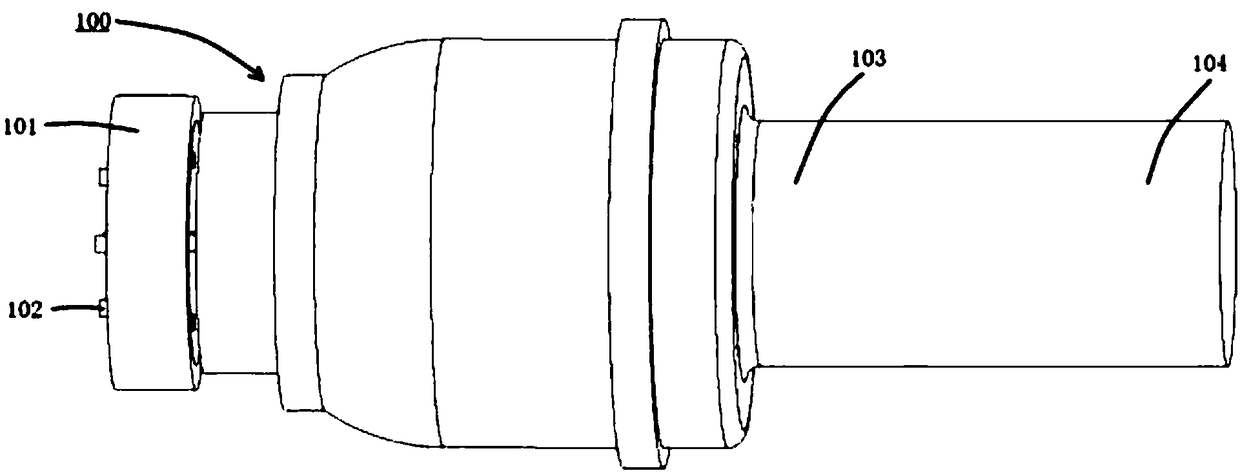

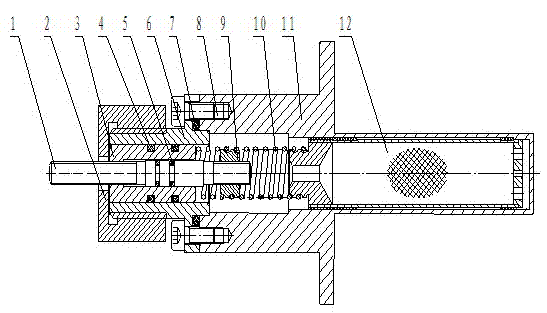

Linear integral stirling cryocooler

ActiveCN104048436AShorten the length of the machineReduce vibration displacementCompression machinesReciprocating motionPhase difference

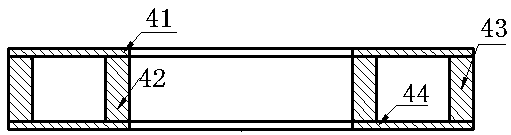

The invention relates to a linear integral stirling cryocooler. The stirling cryocooler comprises a Dewar, an expansion machine and a compressor. The outer side of the circumference of the Dewar is provided with a damper for reducing the vibration of a cold head. The expansion machine comprises an expansion cylinder and a displacer component. The compressor comprises a fixed piston, a movable cylinder, a linear motor and a phase regulation mechanism for regulating the movement phase difference between a displacer and the movable cylinder. The fixed piston is of a hollow structure, and the expansion machine is located in the fixed piston. The fixed piston is sleeved with the movable cylinder, a non-contact clearance sealed structure is arranged between the fixed piston and the movable cylinder, and a sealed cavity formed by the fixed piston and the movable cylinder is a compression cavity. The movable cylinder reciprocates along the axial direction of the linear motor under the driving of the linear motor. According to the technical scheme, by adopting the invention, the length of the integral linear integral stirling cryocooler is shortened, the vibration of the cold head is reduced, and the application of the linear stirling cryocooler to the gyro gimbal of a guided missile is facilitated.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

Cold platform of Stirling cryocooler

InactiveCN104807232AUniform temperature distributionReduce shockCompression machinesCold chainEngineering

The invention relates to a cold platform of a Stirling cryocooler. The cold platform comprises sealed vacuum space formed by a transition flange and a Dewar. An expansion machine is fixed on the transition flange, and a cold head of the expansion machine is disposed in the vacuum space and is connected with a cold plate through flexible cold chains, and a support unit connecting the cold plate with the transition flange is arranged between the cold plate and the transition flange. By means of the cold platform, the cold head and the lower plate surface of the cold plate are connected through the flexible cold chains, and accordingly, concentrated refrigerating and multi-point cooling effects are provided, and the cold plate temperature is distributed uniformly; meanwhile, vibration produced by the cold head is absorbed through the flexible cold chains, so that impact on the cold plate is reduced, and a vibration reduction purpose is provided.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

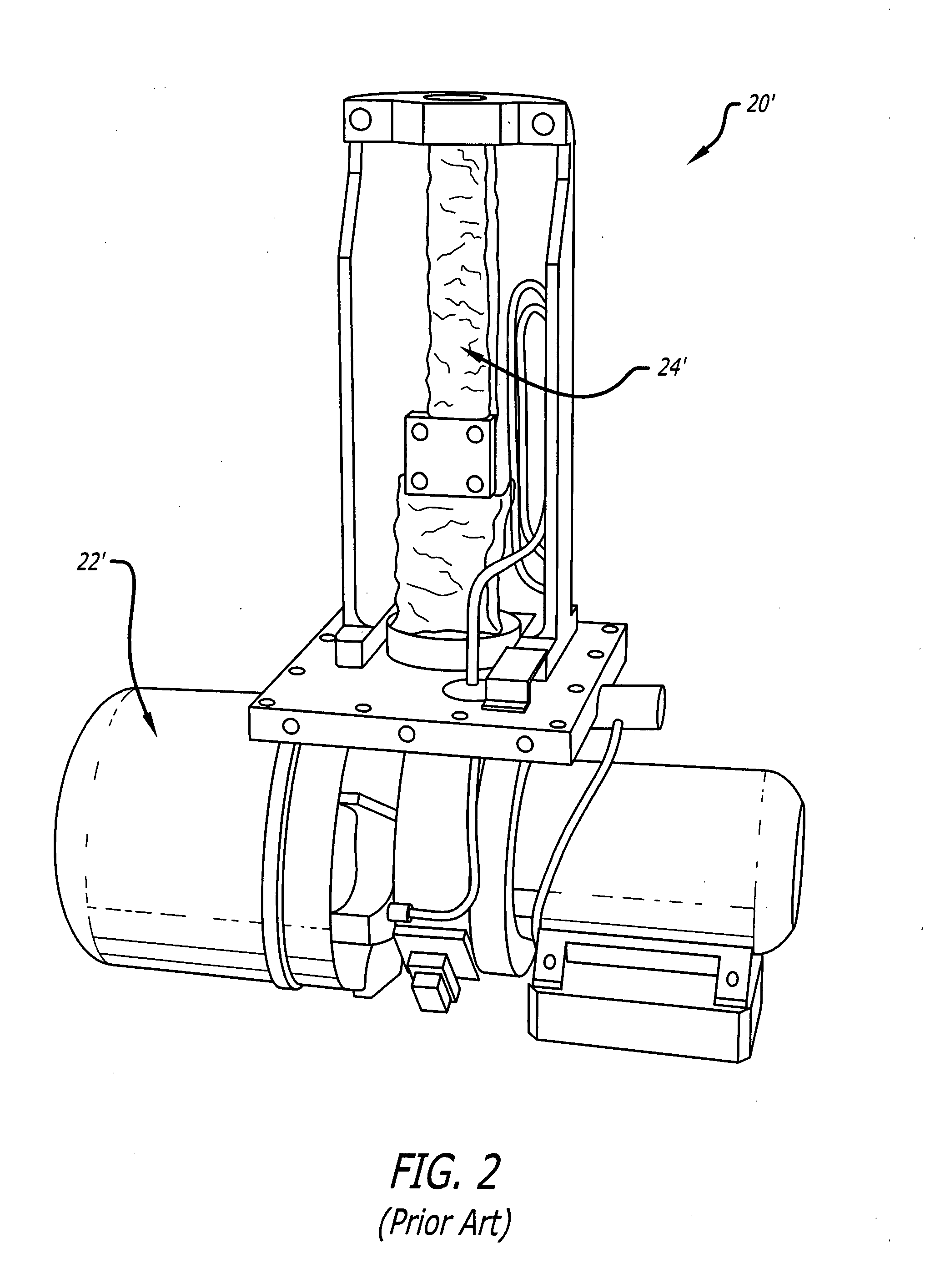

Stirling cycle cryogenic cooler with dual coil single magnetic circuit motor

ActiveUS20080282706A1Compression machinesMachines using electric/magnetic effectsDual coilElectric machine

A method and mechanism for eliminating one of the magnetic circuits in a conventional two motor Stirling cryocooler. The inventive cooler is a Stirling cycle cryogenic cooler with a magnetic circuit for generating a field of magnetic flux in two separate magnetic gaps; a first coil disposed in the flux field of one gap; and a second coil disposed in the flux field of the second gap. The second coil is mounted for independent movement relative to the first coil. In a specific embodiment, the first coil is a compressor coil and the second coil is a displacer coil. The coils are energized with first and second variable sources of electrical energy in response to signals from a controller.

Owner:RAYTHEON CO

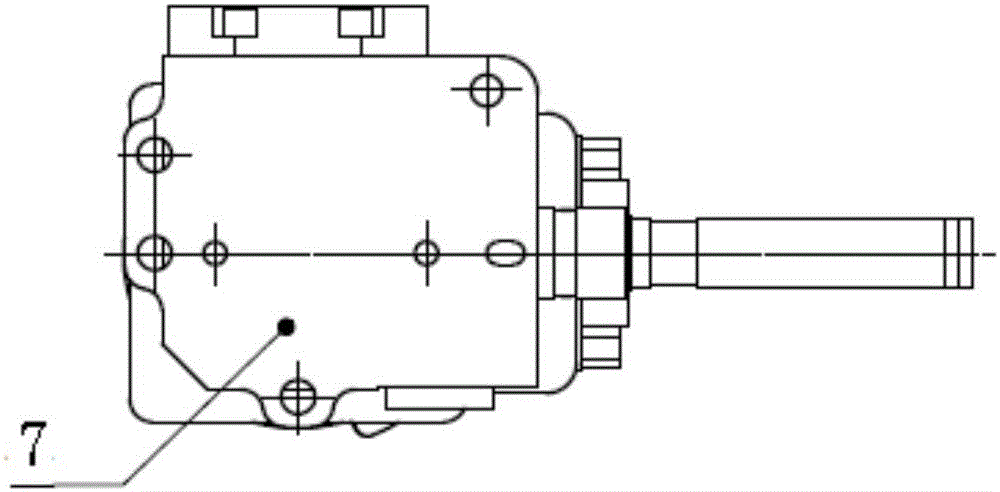

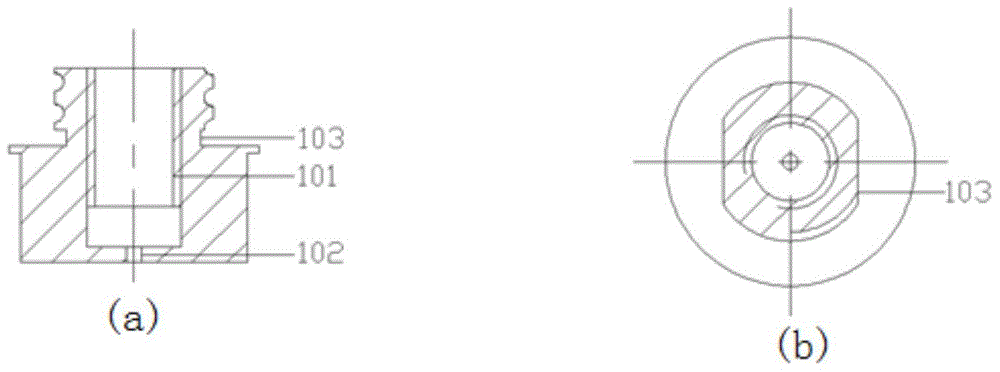

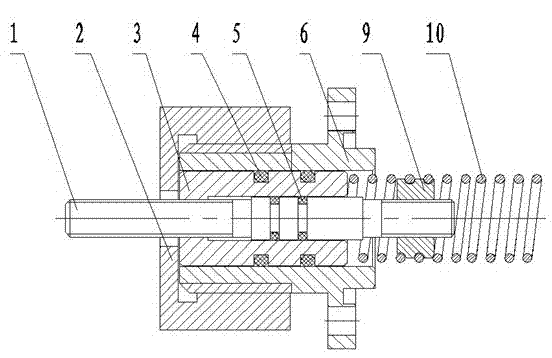

Moving-magnetic-type linear motor used for stirling cryocooler

ActiveCN103762816AEasy to installEasy to fixDynamo-electric machinesArchitectural engineeringMagnetic poles

The invention relates to a moving-magnetic-type linear motor used for a stirling cryocooler. An outer magnetic pole is of a split structure and is formed by splicing two half round magnetic poles, the outer magnetic pole is provided with an inner lead hole and an outer lead hole, the outer circumference of the outer magnetic pole is provided with a fixing hole, the inner circumference of the outer magnetic pole is provided with a notch groove for reducing loss of eddy currents, the inside of the outer magnetic pole is provided with a wiring groove for holding enameled wire coil assemblies, and the inner magnetic pole is attached to the outer diameter of a cylinder in an adhesive mode. The outer magnetic pole is formed by splicing the two half round magnetic poles and is easy to install and fix; meanwhile, due to the fact that the inner lead hole and the outer lead hole of the outer magnetic pole are matched with a wire outlet hole in a coil framework, motor wire leading is greatly facilitated, the outer circumference is provided with the fixing hole which can be used for firm positioning of the outer magnetic pole and weight reducing, the notch groove formed in the inner circumference can reduce the loss of the eddy currents, the inner magnetic pole is directly attached to the outer diameter of the cylinder in an adhesive mode, the mass of a motor is reduced, and accordingly the specific thrust of the motor is increased, and efficiency is improved.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

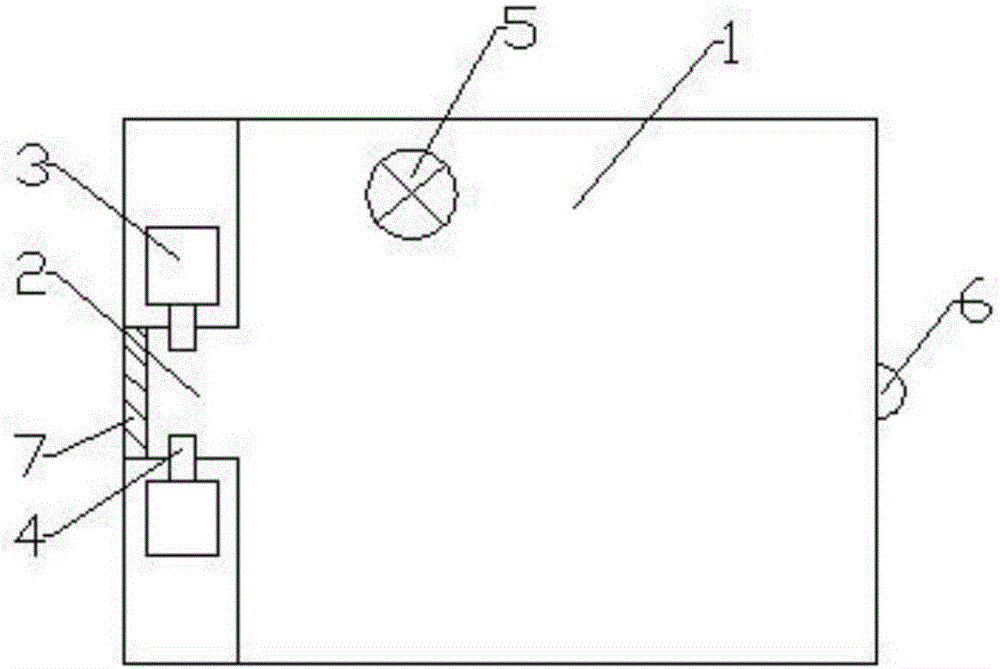

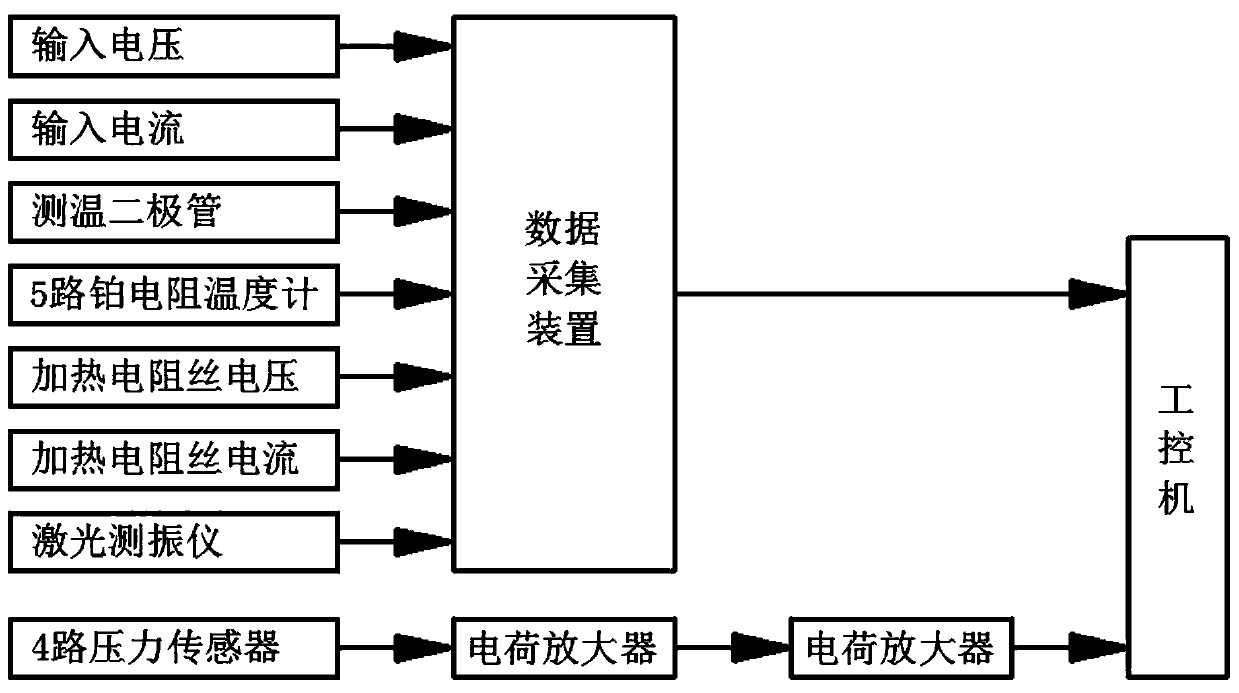

Driving and temperature controlling system and method for rotary split-type pneumatic Stirling cryocooler

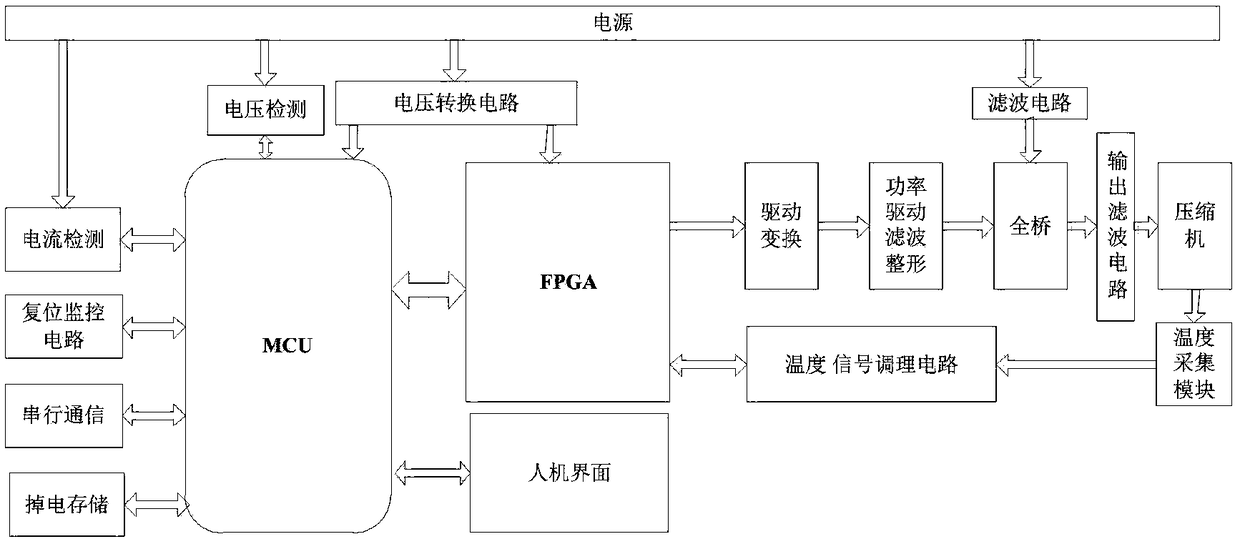

ActiveCN106288479AControlled coolingEfficient conversionCompression machinesRefrigeration safety arrangementBrushless motorsEngineering

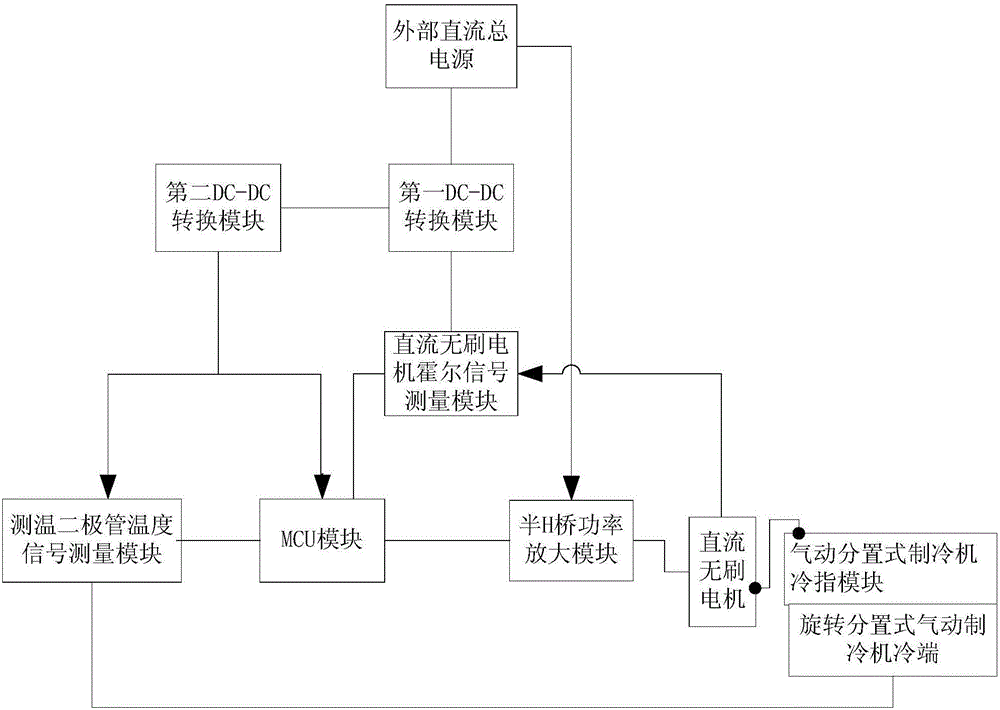

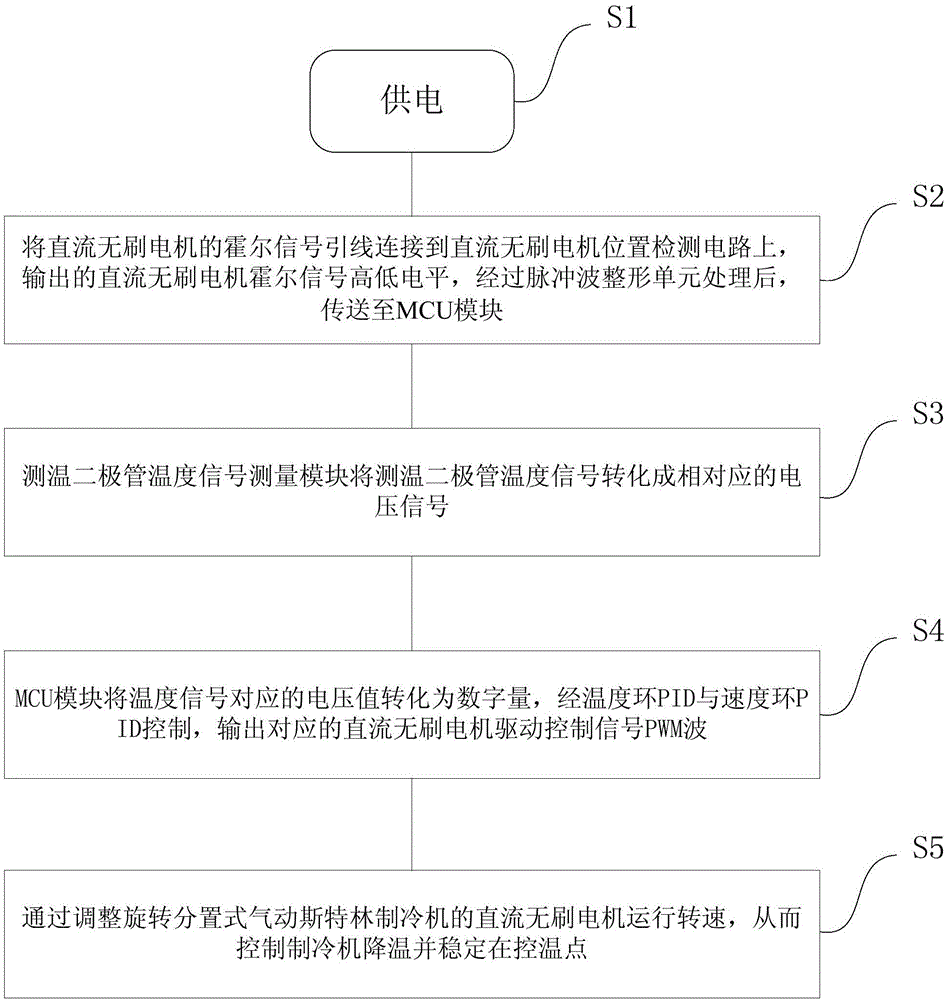

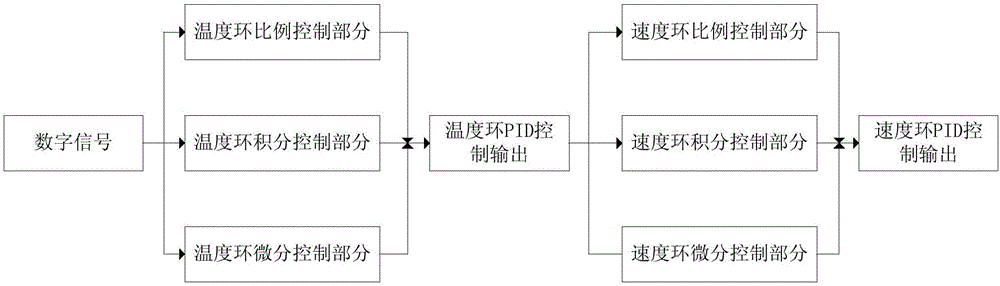

The invention relates to a driving and temperature controlling system and method for a rotary split-type pneumatic Stirling cryocooler. The system comprises an external direct-current main power, and further comprises a first DC-DC conversion module, a second DC-DC conversion module, a semi-H-bridge power amplification module and a direct-current brushless motor Hall signal detection module, wherein the first DC-DC conversion module and the semi-H-bridge power amplification module are separately connected with the external direct-current main power; the second DC-DC conversion module and the direct-current brushless motor Hall signal detection module are separately connected with the first DC-DC conversion module; the second DC-DC conversion module is further separately connected with a temperature-measurement diode temperature signal detection module and an MCU module; the MCU module is separately connected with the direct-current brushless motor Hall signal detection module, the temperature measurement diode temperature signal detection module and the semi-H-bridge power amplification module; the semi-H-bridge power amplification module is connected with the rotary split-type pneumatic Stirling cryocooler; and the rotary split-type pneumatic Stirling cryocooler is connected with the temperature measurement diode temperature signal detection module and the direct-current brushless motor Hall signal detection module.

Owner:WUHAN GAOXIN TECH

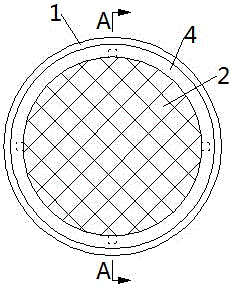

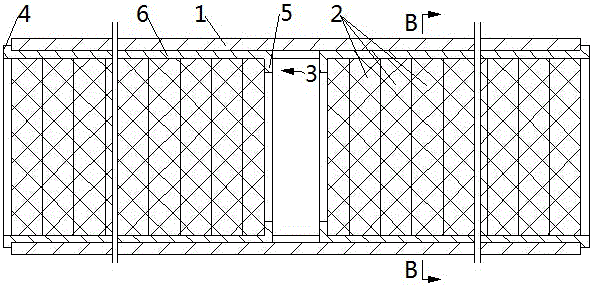

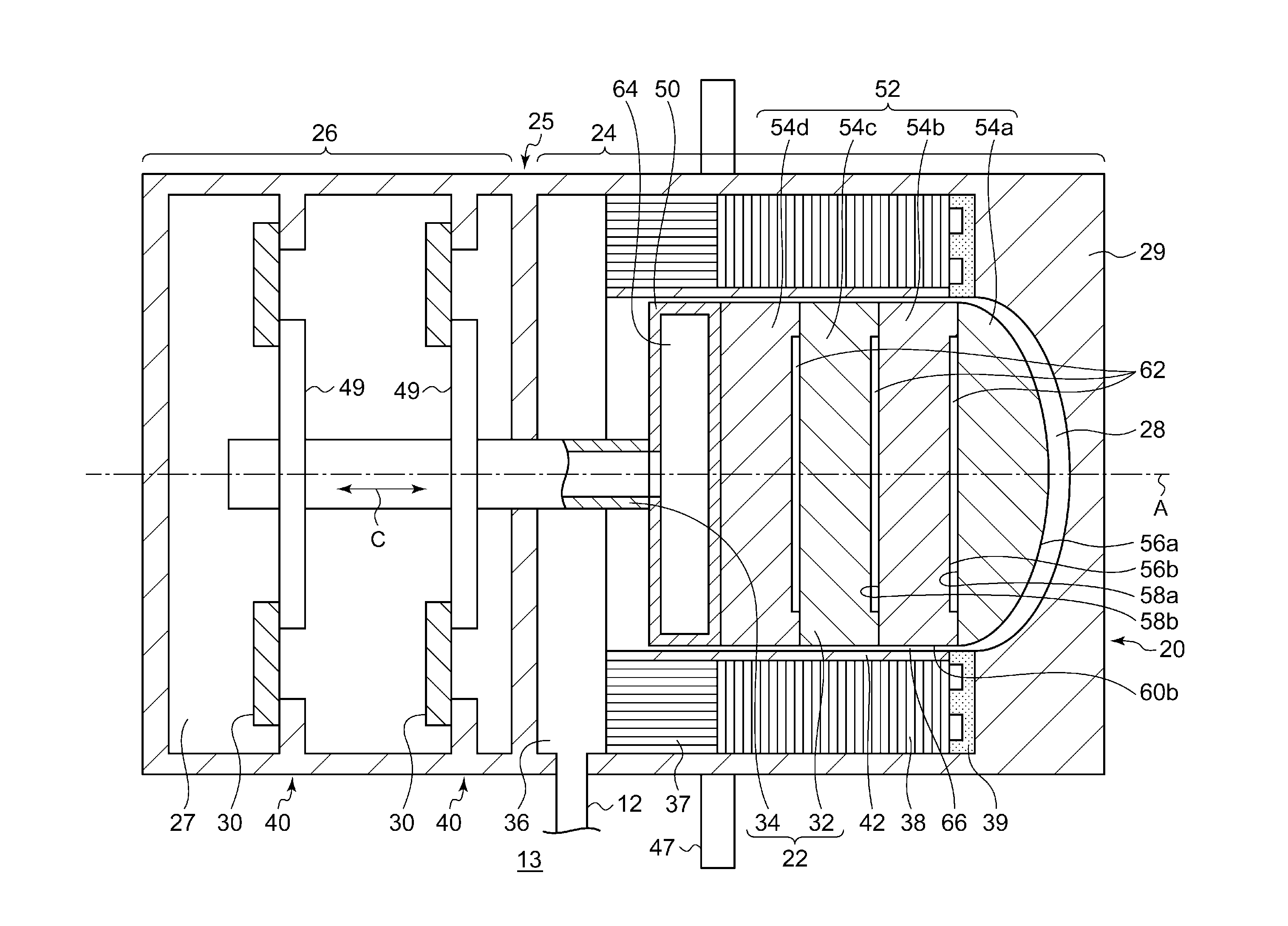

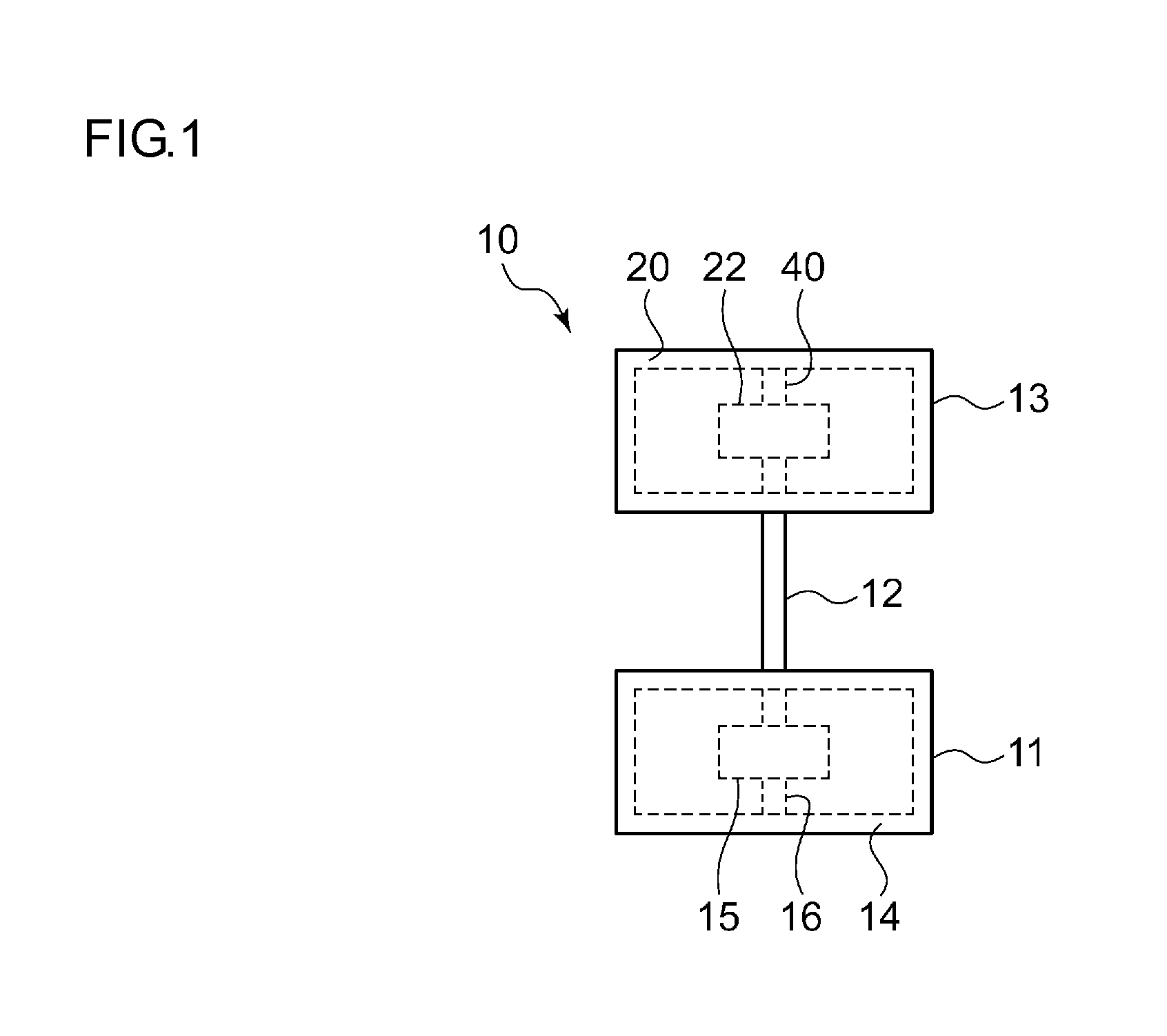

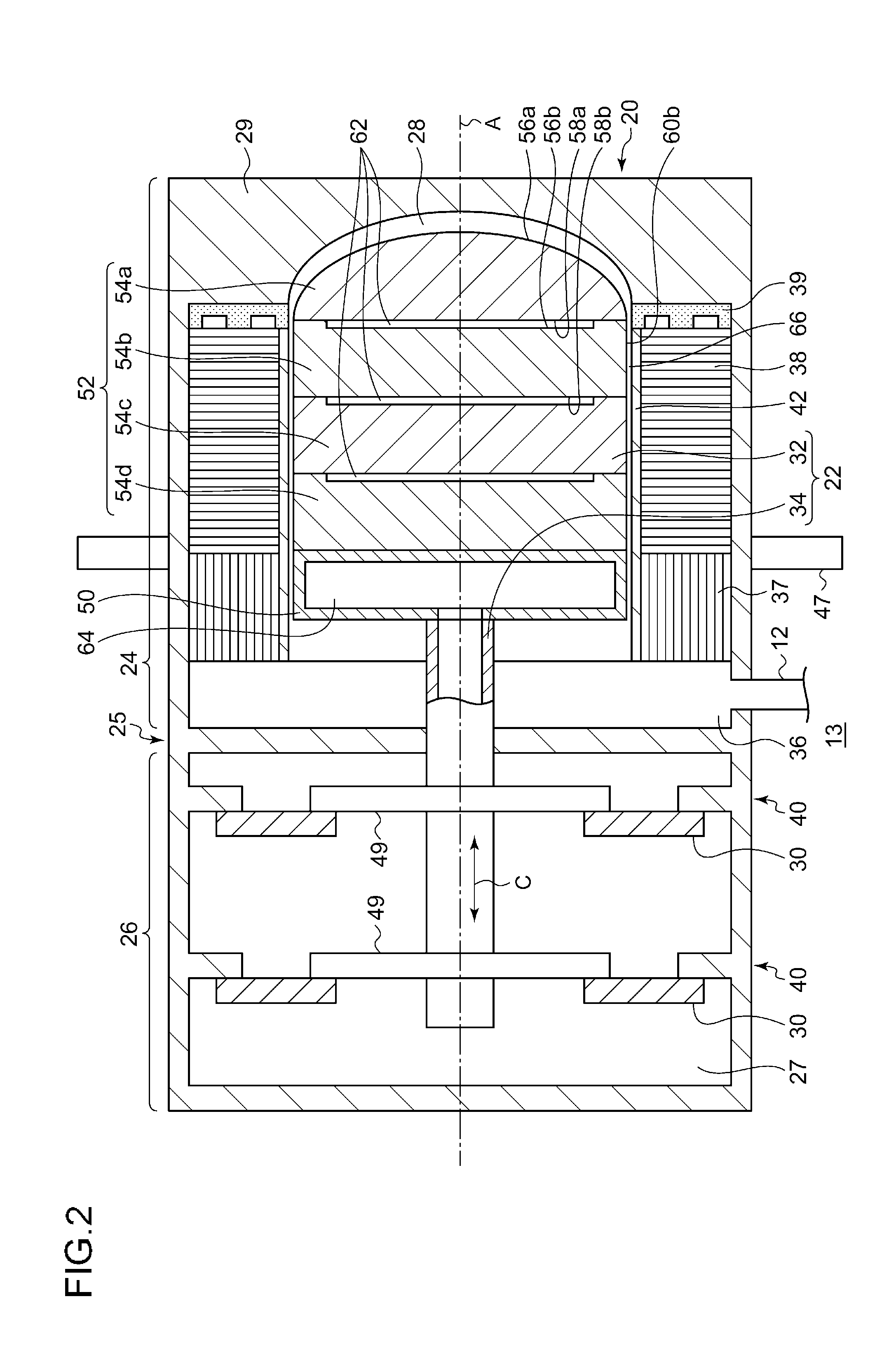

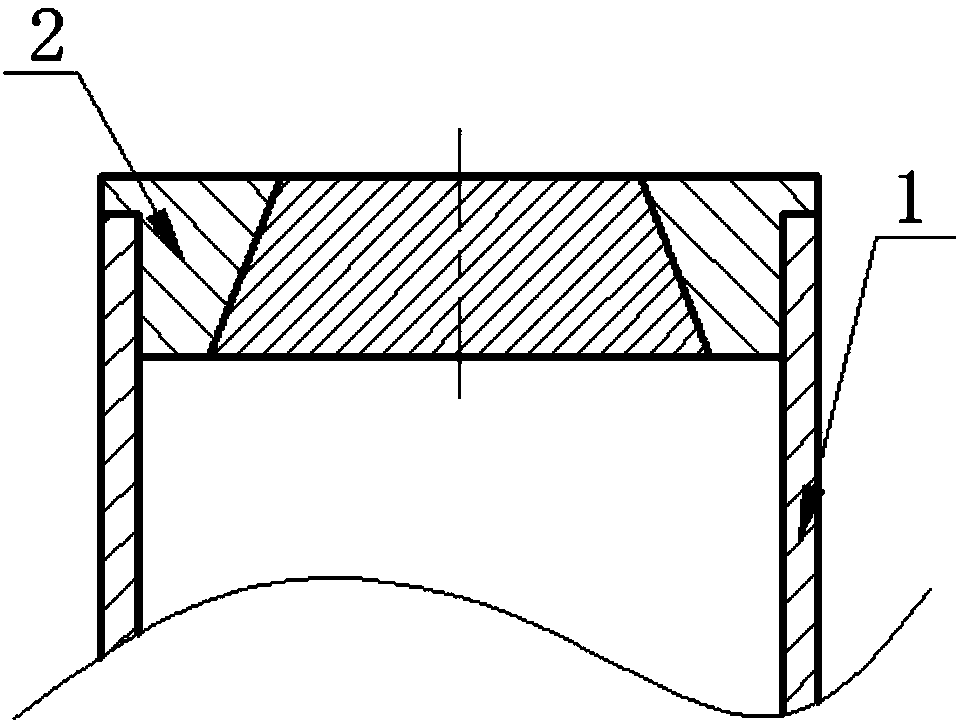

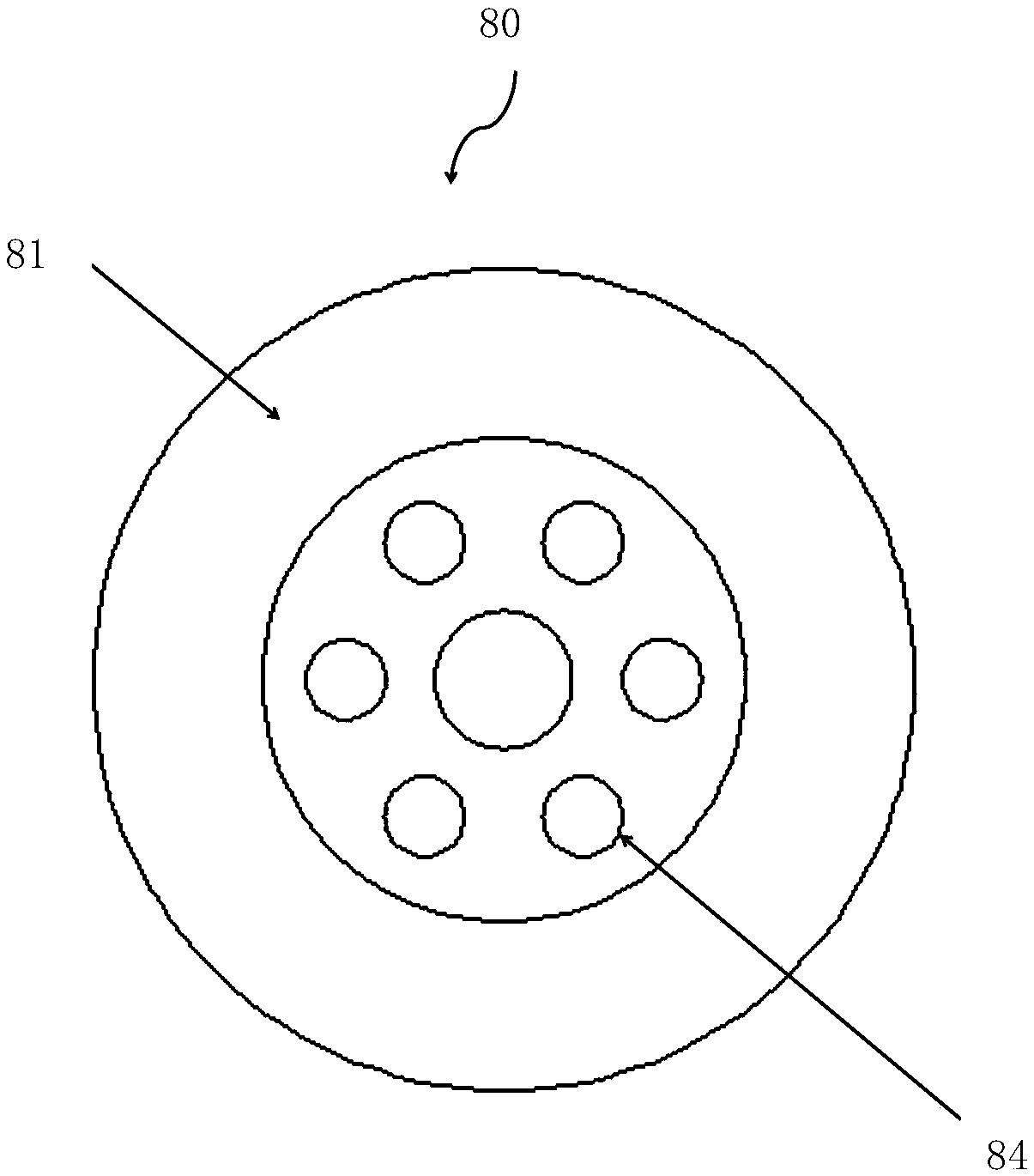

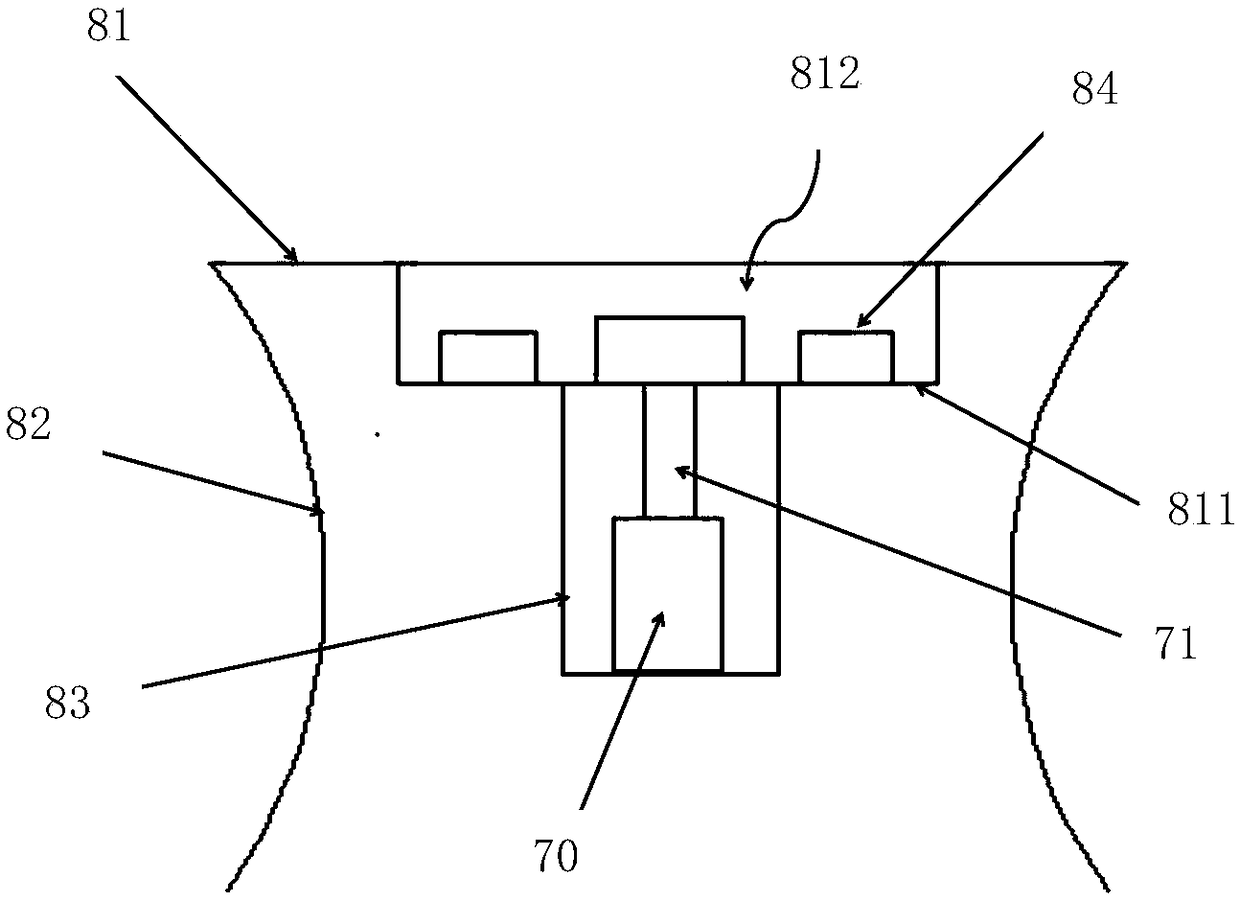

Regenerator and stirling cryocooler

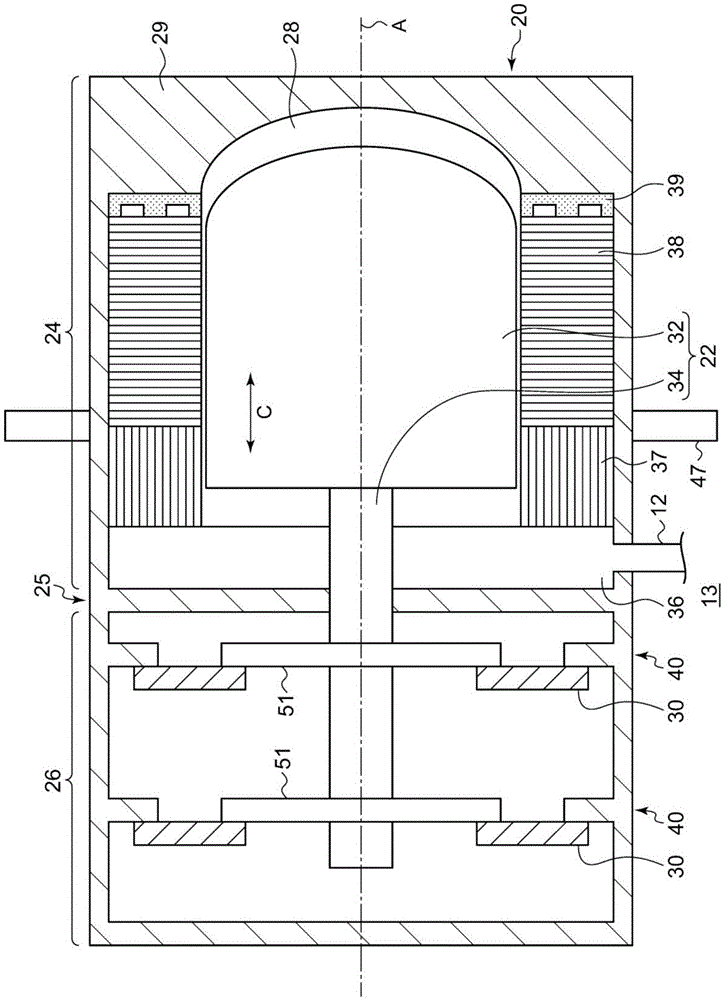

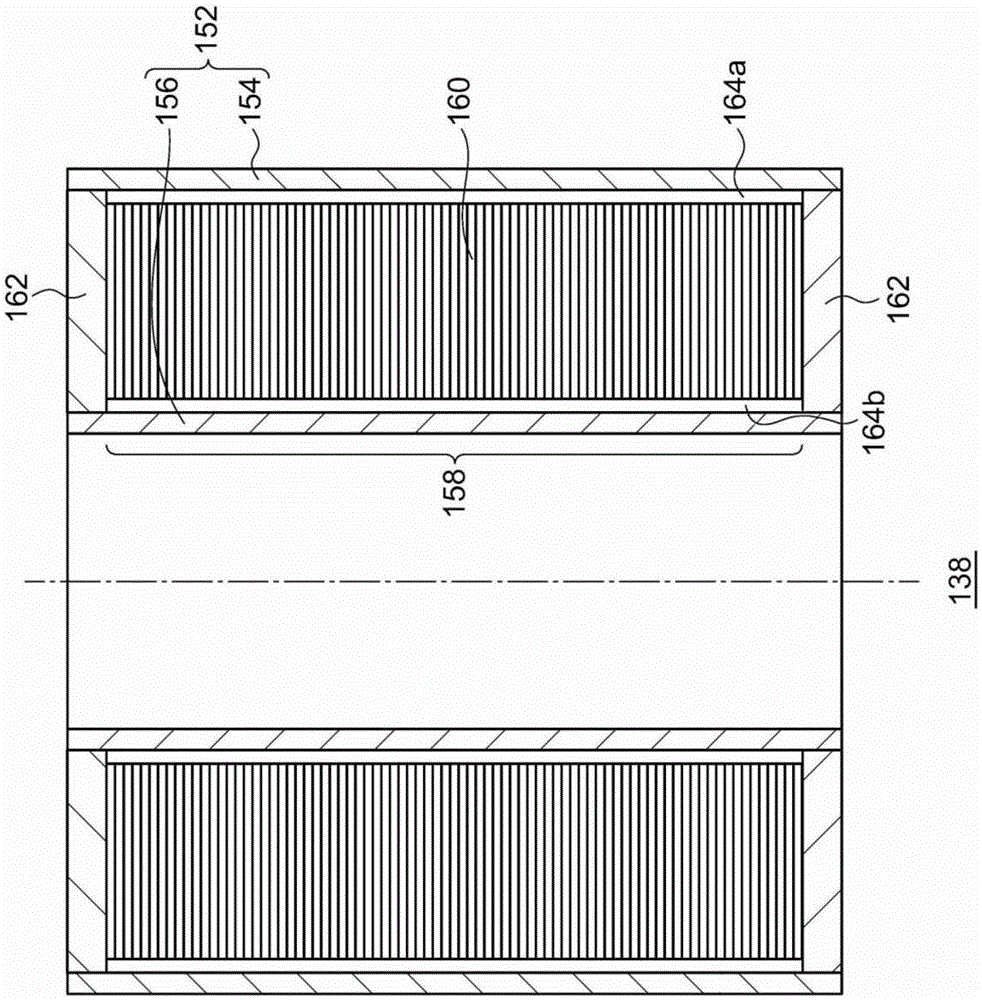

The invention provides a regenerator and a striling cryocooler, which can shrink a gap between a regenerator element and a container in the regenerator of an ultralow temperature refrigerating machine. A regenerator (38) includes an axially extending regenerator-element container (52), and a regenerator-element laminated structure (58) accommodated in the regenerator-element container (52). The regenerator-element laminated structure (58) comprises a plurality of regenerator-element members (60) axially stacked in layers, and each extending along a plane perpendicular to the axis of regenerator extension. Each of the plurality of regenerator-element members (6) comprises an outer rim portion (60 a) and / or an inner rim portion (60 b) extending in a direction not lying in said plane, such as to fill a gap between the regenerator-element container (52) and the regenerator-element laminated structure (58).

Owner:SUMITOMO HEAVY IND LTD

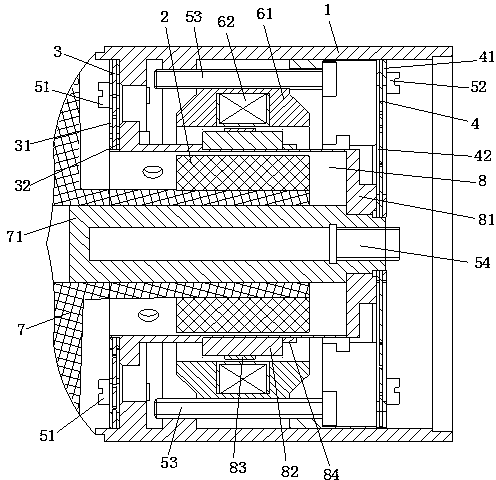

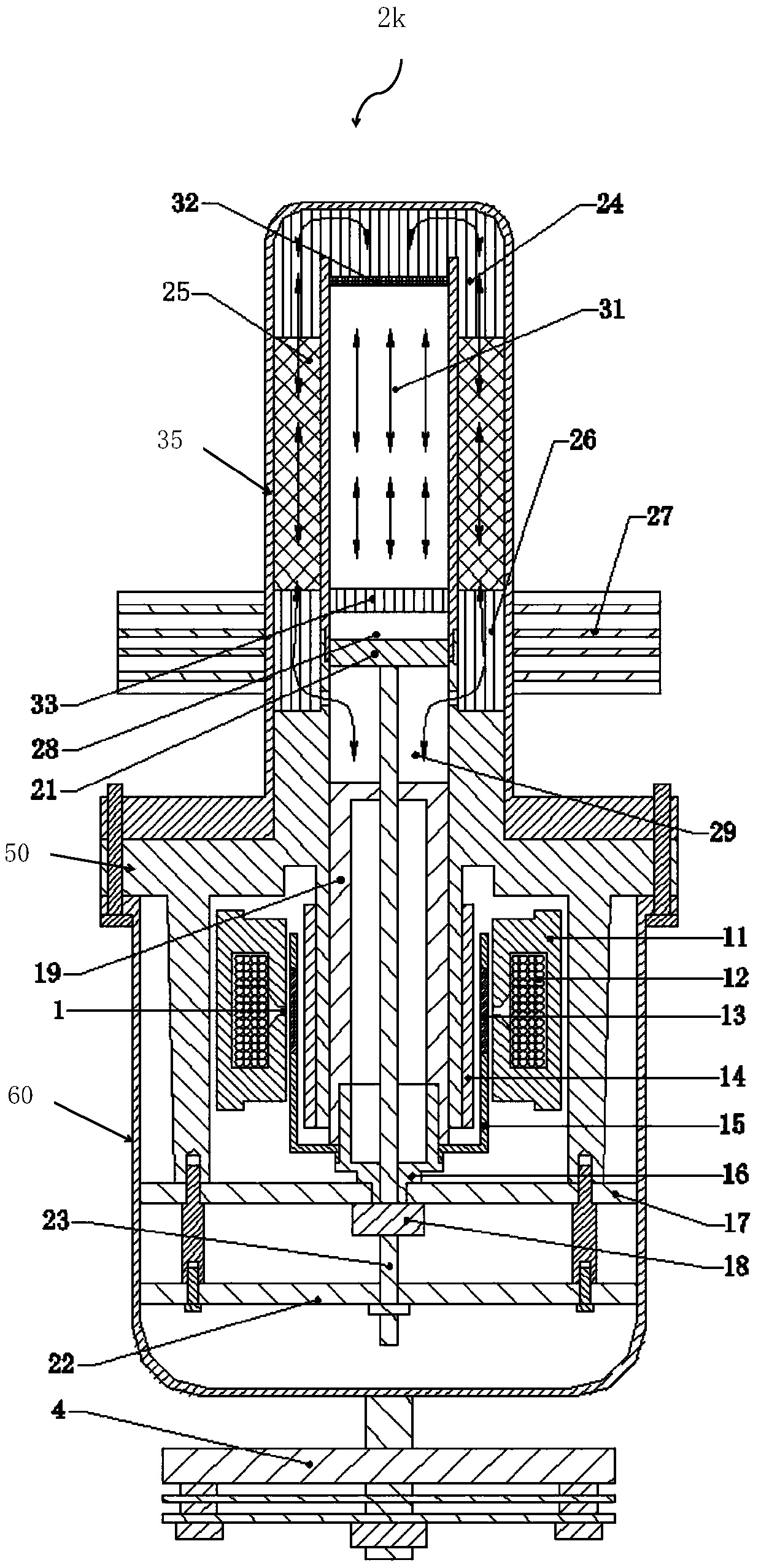

Rotary integrated stirling cryocooler

ActiveCN106679216AMiniaturizationAchieve large cooling capacityCompression machinesMiniaturizationCryocooler

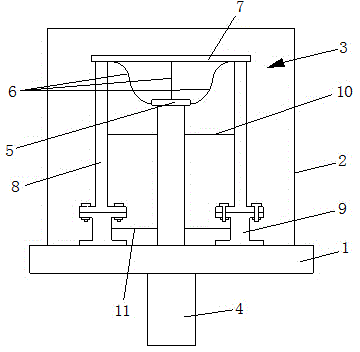

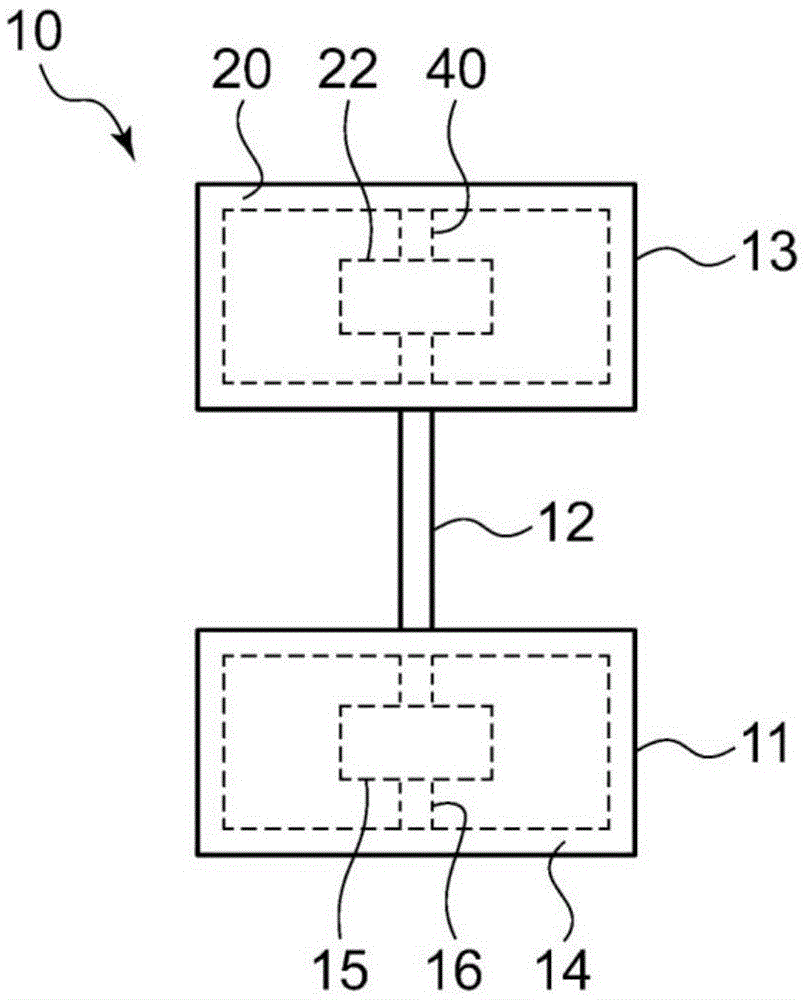

The invention discloses a rotary integrated stirling cryocooler. The rotary integrated stirling cryocooler comprises a motor stator component and a cryocooler body connected with the motor stator component. The motor stator component comprises a first shell, a motor driving controller and a motor stator, and the motor driving controller and the motor stator are located in the first shell. The cryocooler body comprises a second shell, a motor rotor and a cooling component, and the motor rotor and the cooling component are located in the second shell. When the motor stator component is connected with the cryocooler body, the motor rotor in the cryocooler body is inserted into the motor stator, wherein the motor stator and the motor rotor constitute a motor. According to the rotary integrated stirling cryocooler, miniaturization and high cooling capacity of the cryocooler are realized by integrating the motor driving controller in the shell through combination of the optimum structural design. The rotary integrated stirling cryocooler has the characteristics of being compact in structure, small in size, light in weight, low in power consumption and the like.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

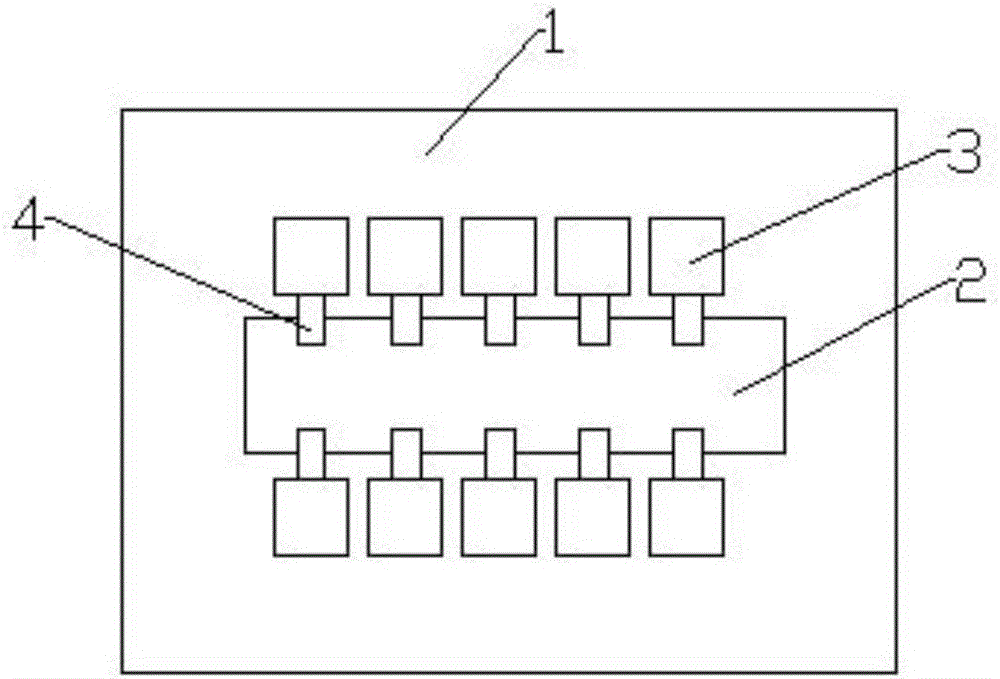

Cold-chain logistic container with Stirling cryocooler

InactiveCN105905468AGuaranteed low temperature drying effectImprove efficacyLarge containersTank wagonsCold chainWater vapor

The invention discloses a cold-chain logistic container with a Stirling cryocooler. The cold-chain logistic container comprises a container body, wherein an air vent is formed in the container body; each of two sides of the air vent is sequentially provided with at least one Stirling cryocooler; and the cold ends of the Stirling cryocoolers located at two sides of the air vent are opposite, and the cold end of each Stirling cryocooler is located in the air vent, so that air flowing into the container body through the air vent is subjected to cold end cooling treatment by the Stirling cryocooler. Due to the adoption of the technical scheme, the air flowing into the container body through the air vent can be subjected to cold end cooling treatment by the Stirling cryocooler, and water vapor is liquefied rather than entering the retainer body; and the efficiency of a Stirling motor is high so that the low-temperature drying effect of the air in the retainer body can be efficiently ensured in an energy-saving way.

Owner:CHINA STIRLING ENGINE MFG

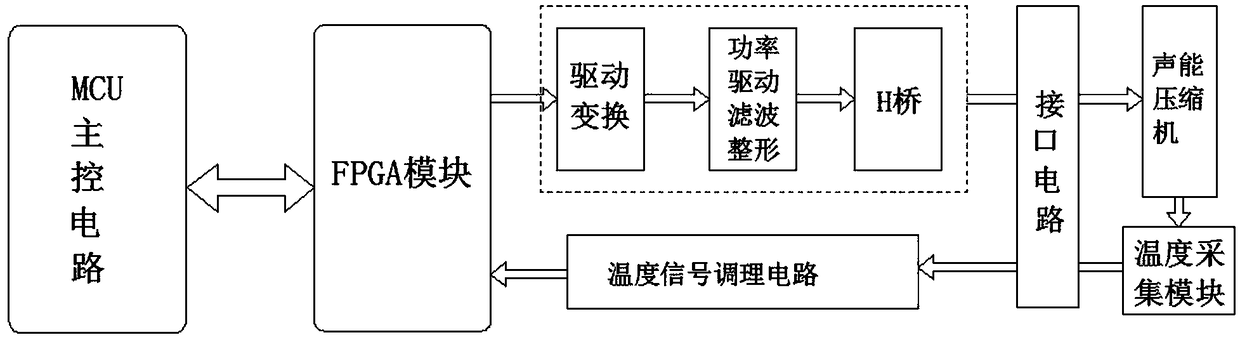

Precise temperature control driving circuit of Stirling cryocooler and control method

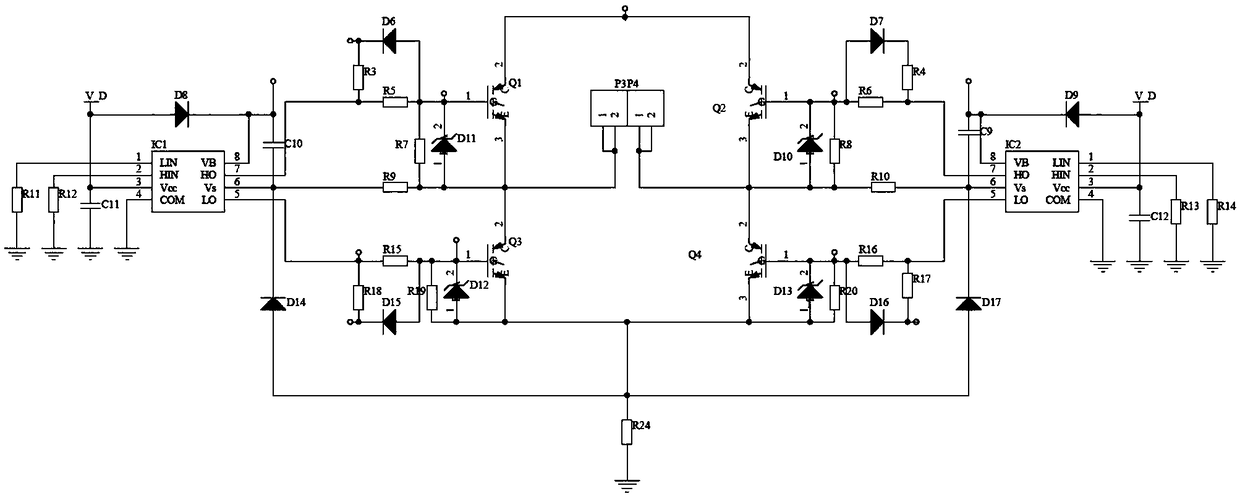

InactiveCN108981218AImprove adaptabilityReduce vibrationCompression machinesRefrigeration safety arrangementSignal processing circuitsFull bridge

The invention discloses a precise temperature control driving circuit of a Stirling cryocooler. The circuit comprises an MCU main control circuit body, an FPGA module and a full-bridge driving module.The MCU main control circuit body is used for being in real-time communication with a computer or a system platform; the FPGA module is used for conducting collection process of temperature data, implementation of a vague PID control algorithm and generation of SPWM waveforms; the full-bridge driving module is used for improving the driving capacity. The MCU main control circuit body is electrically connected with the FPGA module, the FPGA module is electrically connected with the full-bridge driving module, and the full-bridge driving module is electrically connected with an acoustic energycompressor and a temperature collection module through an interface circuit; the acoustic energy compressor is electrically connected with the temperature collection module, and the temperature collection module is connected with the FPGA module through a temperature signal processing circuit. According to the precise temperature control driving circuit, through common use of an FPGA and an MCU, the advantages of the FPGA and the MCU are achieved to the greatest degree, which is beneficial to more precise temperature control and parameter interaction.

Owner:方舟

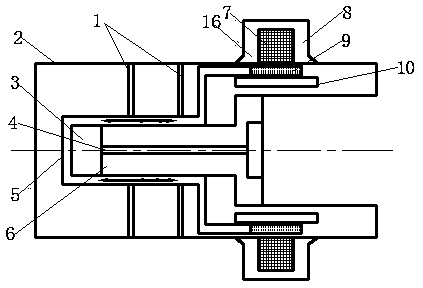

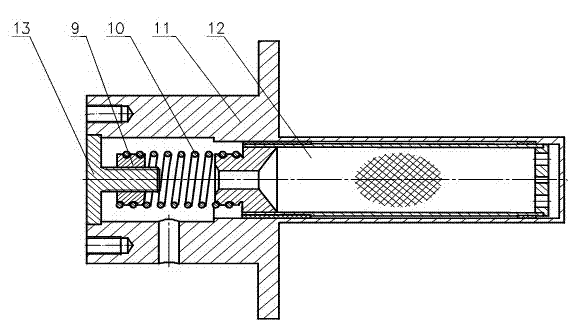

Embedded integral type Stirling cryocooler

ActiveCN104048437AShorten the length of the machineMeet the requirements of short and lightCompression machinesLinear compressorReciprocating motion

The invention relates to an embedded integral type Stirling cryocooler, comprising a linear compressor and an expander, wherein the linear compressor is dished, and the expander is embedded and mounted in the linear compressor; the linear compressor comprises a moving cylinder, a static piston and a linear motor, the moving cylinder reciprocates along the axial direction under the driving of the linear motor, and the static piston keeps static; the expander comprises a cold finger, a heat regenerator and a phase adjusting structure for adjusting the movement phases of the heat regenerator and the moving cylinder; a gas channel is formed between the linear compressor and the expander and is formed in the static piston. According to the technical scheme, the embedded integral type Stirling cryocooler is compact in structure, small in size, light in weight, and suitable for environments with strict requirements on the size and the weight of Stirling cryocoolers; the Stirling cryocooler has the characteristics of fewer components, convenience for installing, fixed process, productization and the like.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

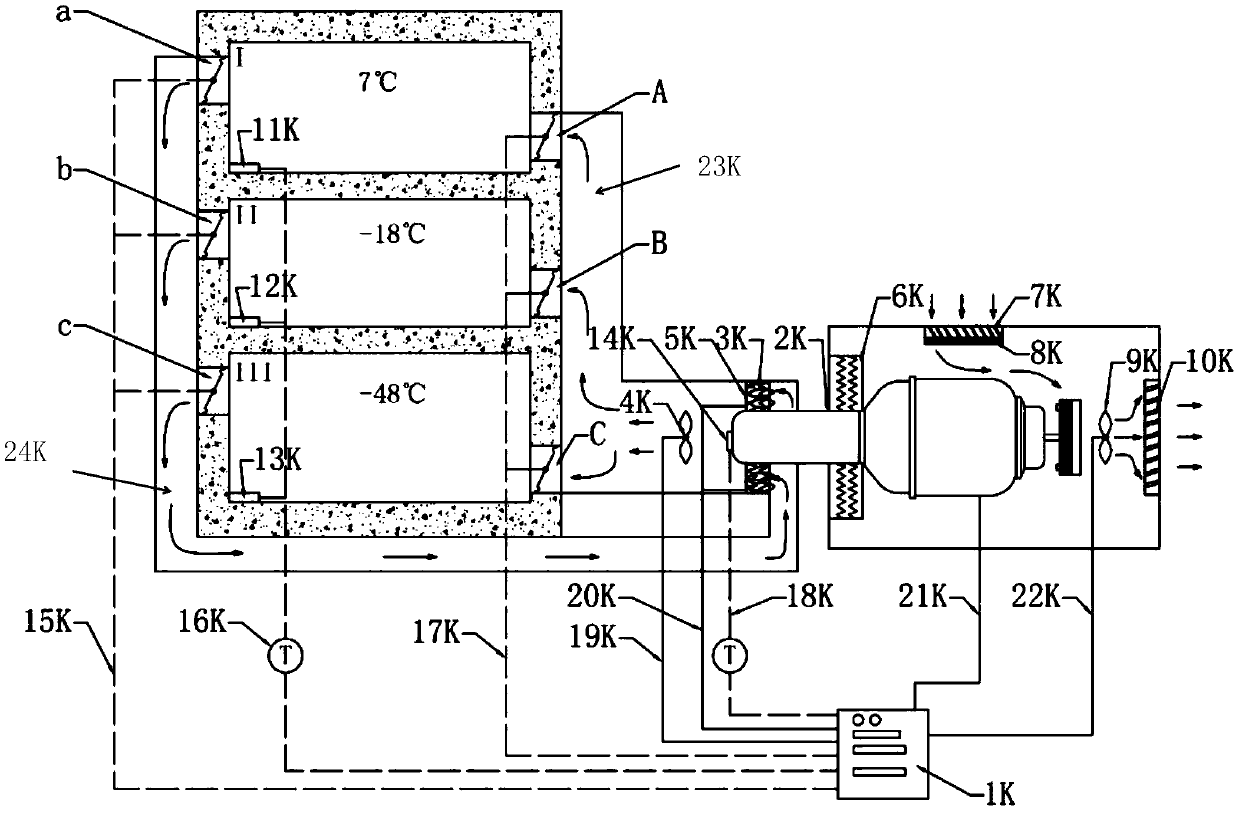

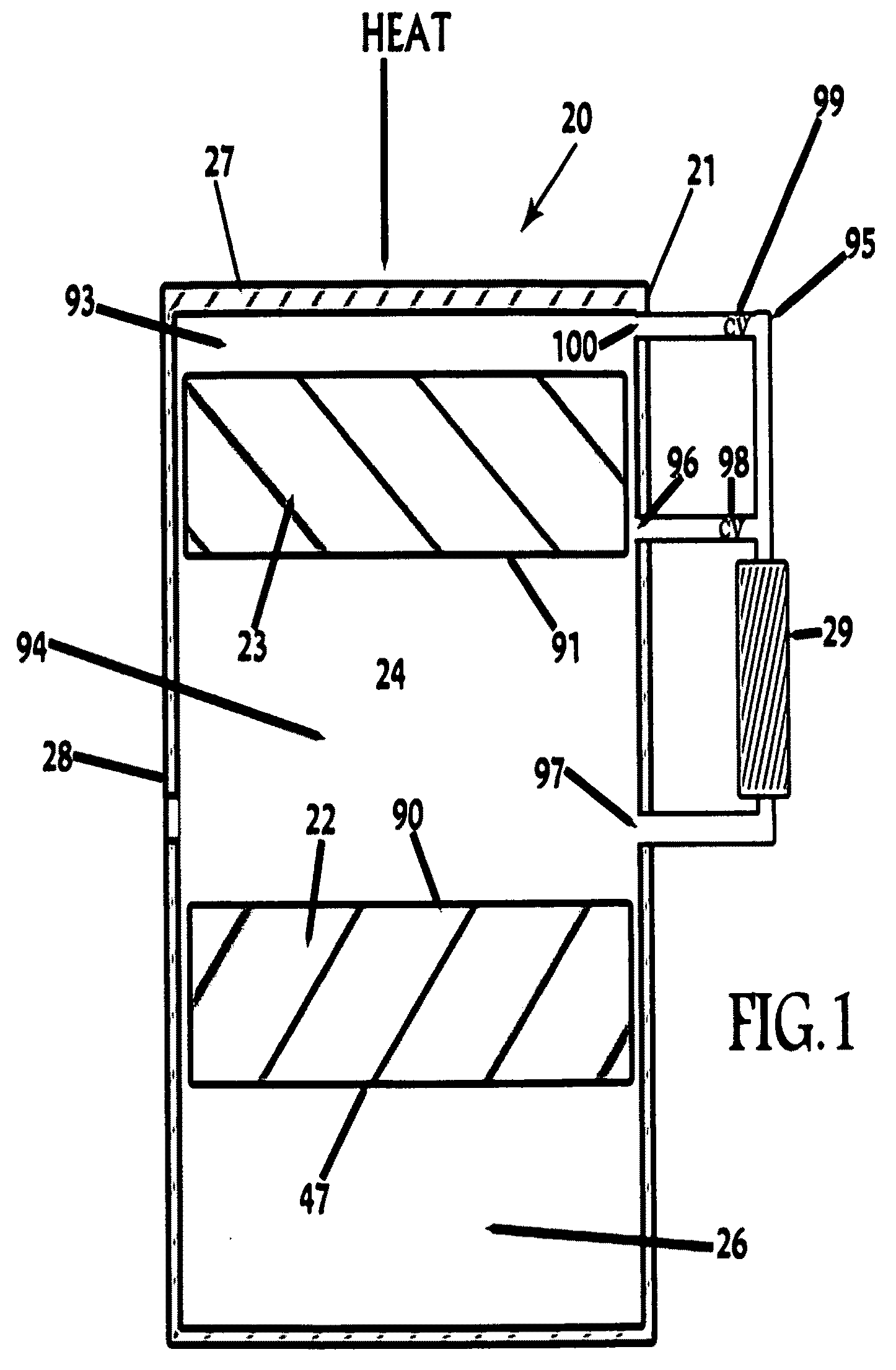

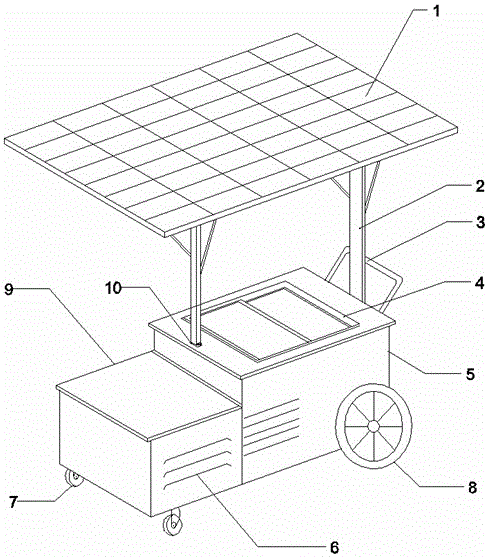

Multi-temperature-zone air-cooled refrigerator adopting Stirling cryocooler and temperature control method

ActiveCN108800713AControl refrigerationControl refrigeration temperatureLighting and heating apparatusDomestic refrigeratorsTemperature controlInlet valve

The invention relates to a multi-temperature-zone air-cooled refrigerator adopting a Stirling cryocooler and a temperature control method. The multi-temperature-zone air-cooled refrigerator comprisesa refrigerator body, a refrigerating portion and a control portion. The temperature control method of the multi-temperature-zone air-cooled refrigerator includes the following initial temperature control steps that firstly, the temperatures in three air compartments of the air-cooled refrigerator are all kept at the environment temperature, the pulse tube type free piston Stirling cryocooler operates at the maximum power, and air compartment air inlet valves and air compartment air return valves in the three air compartments all keep the maximum opening degrees at the moment; secondly, after the first air compartment reaches a first target temperature, the air compartment air inlet valve and the air compartment air return valve in the first air compartment are closed; thirdly, after the second air compartment reaches a second target temperature, the air compartment air inlet valve and the air compartment air return valve in the second air compartment are closed; fourthly, after the third air compartment reaches a third target temperature, the air compartment air inlet valve and the air compartment air return valve in the third air compartment are closed; fifthly, the cryocooler anda cold-side fan stop operating; and sixthly, an electric heating wire is started for defrosting.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

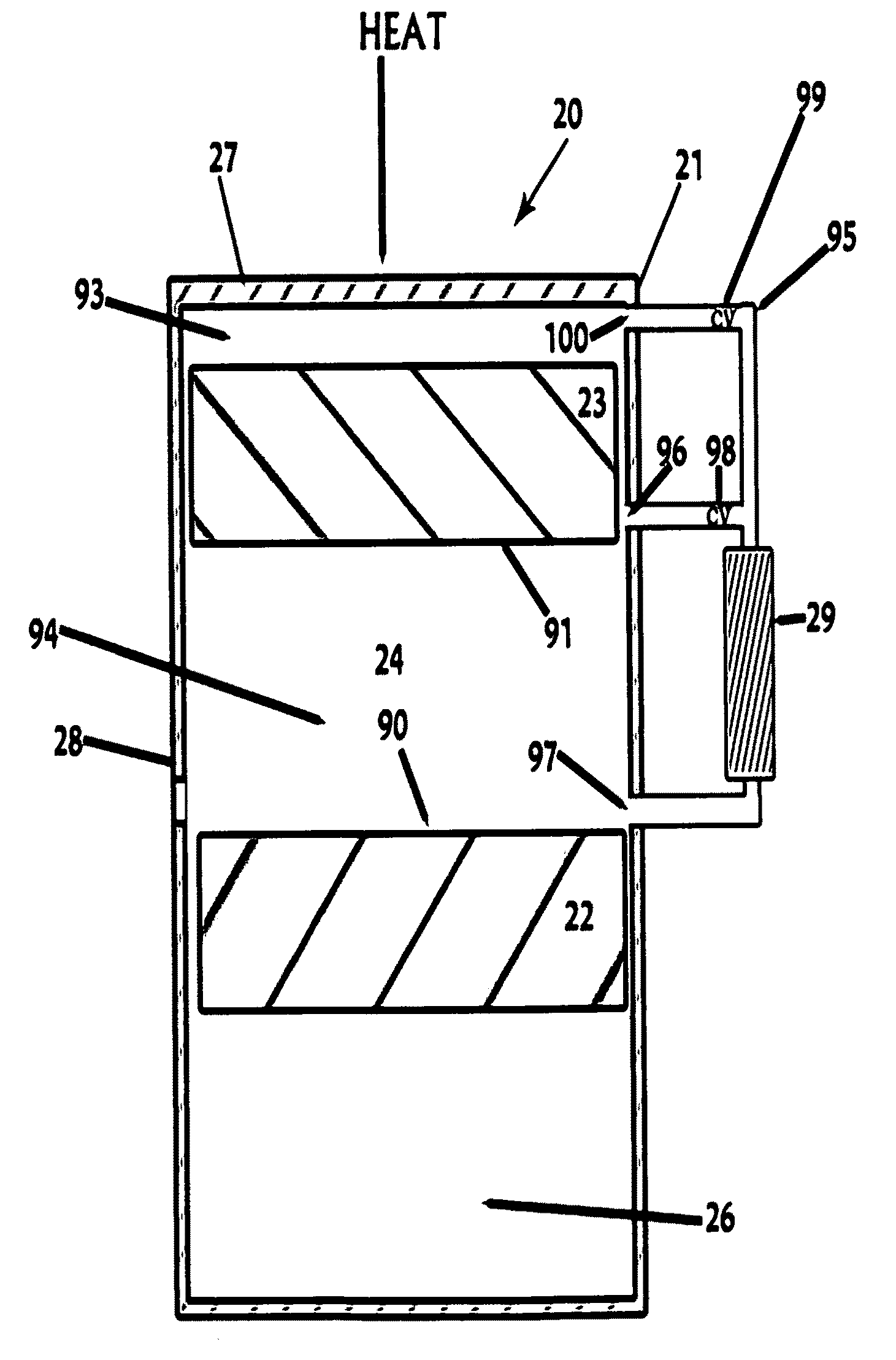

Multi-temperature-area refrigerator adopting vessel type free piston stirling cryocooler

ActiveCN108592481AControl refrigerationControl refrigeration temperatureDomestic refrigeratorsCompression machinesHeat conductingEvaporation

The invention discloses a multi-temperature-area refrigerator adopting a vessel type free piston stirling cryocooler. The multi-temperature-area refrigerator comprises a refrigerator body and a refrigerating system; the refrigerator body comprises a refrigerating chamber, a freezing chamber and a temperature change chamber; the refrigerating chamber is positioned at the upper half part of the refrigerator body; the freezing chamber and the temperature change chamber are positioned at the lower half part of the refrigerator; the refrigerating system consists of a compression throttling refrigerating system and a stirling cryocooler-heat pipe system; the stirling cryocooler-heat pipe system comprises the vessel type free piston stirling cryocooler, a cold end gravity heat pipe, a heat end gravity heat pipe, a cold conducting copper sleeve and a heat conducting copper sleeve; a condensation section pipeline of the heat end gravity heat pipe is upwards arranged on the inner side of the left wall surface of a refrigerator shell; an evaporation section pipeline of the cold end gravity heat pipe is downwards arranged on the back wall surface and the left and right wall surfaces in the temperature change chamber; a condensation section of the cold end gravity heat pipe is connected with a cold head of the vessel type free piston stirling cryocooler through the cold conducting copper sleeve; and an evaporation section of the heat end gravity heat pipe is connected with a heat end of the vessel type free piston stirling cryocooler through the heat conducting copper sleeve.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Vacuum sticking method for Stirling cryocooler piston and wear-resistant materials

The invention provides a vacuum sticking method for a Stirling cryocooler piston and wear-resistant materials. The vacuum sticking method comprises the steps that the piston, the wear-resistant materials and an adhesive are placed into a vacuum glove box, wherein the wear-resistant materials and the adhesive are placed at a heating area inside the vacuum glove box; the wear-resistant materials and the adhesive are heated for a period of time at the certain temperature; the adhesive evenly coats the outer circumferential face of the sticking end of the piston and the surface of an inner hole of the sticking end of the wear-resistant materials; the sticking end of the piston is rotationally screwed into the inner hole of the sticking end of the wear-resistant materials, so that the piston and the wear-resistant materials are stuck; the obtained stuck sample piece is placed at the heating area inside the vacuum glove box for solidification. According to the vacuum sticking method, the Stirling cryocooler piston and the wear-resistant materials are well stuck firmly, the long-term sticking stability of the piston and the wear-resistant materials is improved, and the service life of the Stirling cryocooler is prolonged.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

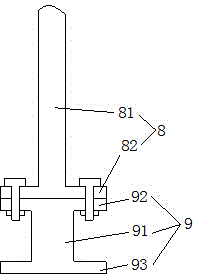

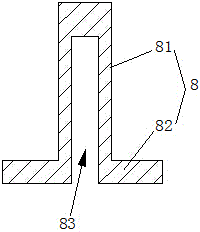

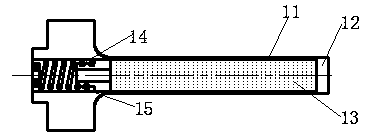

Hollow discharger for stirling cryocooler and vacuum air extraction device thereof

InactiveCN104534718AGuaranteed vacuumSimple and fast operationCompression machinesEngineeringStirling cryocooler

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

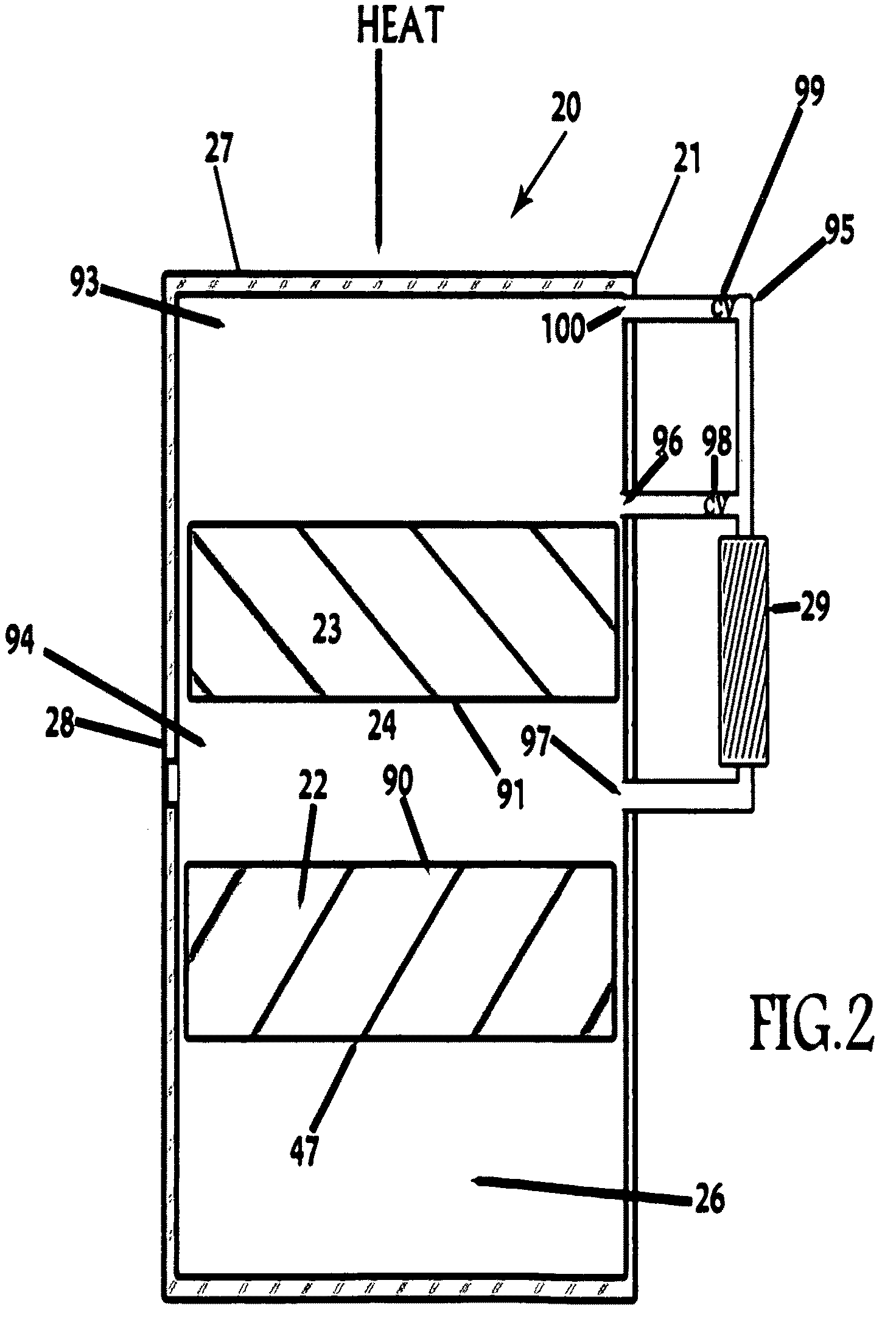

Method for increasing performance of a stirling or free-piston engine

InactiveUS20100064681A1Improve performanceMaximize forceClosed-cycle gas positive displacement engine plantFree-piston engineWorking fluid

A method for improving performance of a free-piston engine, also comprising various other engines such as Stirling Engines, Ericsson engines, Stirling cryocoolers and other external combustion or hot air engines. The improvement is the inclusion of a means, such as a valve or set of valves interposed in a passageway, to contain the working fluid (gas) in the hot or expansion work area so that increased work can occur; or the improvement is by means of piston blocking a port to the working gas passageway such that working gas is contained in the work space such that increased work can occur. The improvement reduces or ideally eliminates free flow of fluid until such time in the cycle where valve or port opens and allows the fluid to flow to the passageway from one space to the other.

Owner:NEXTWAVE SOLAR

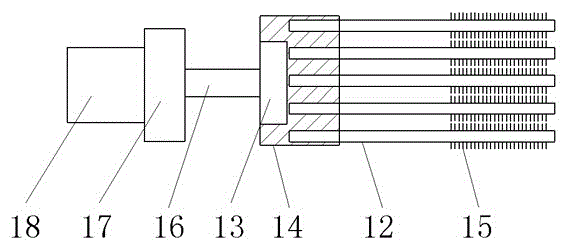

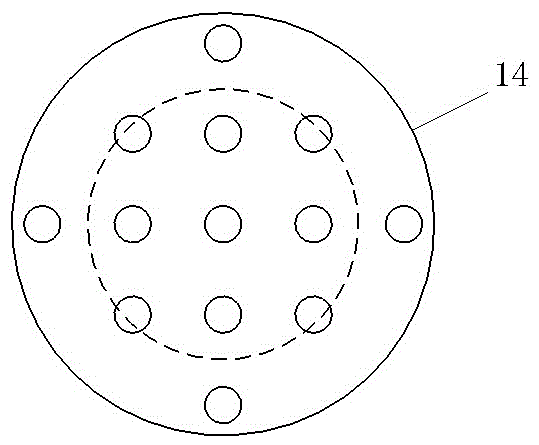

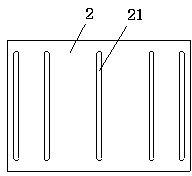

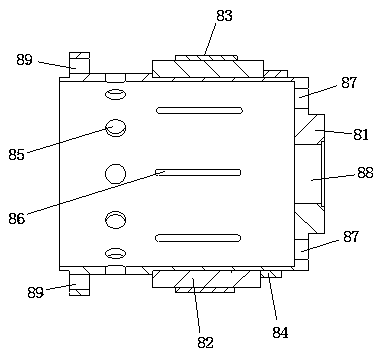

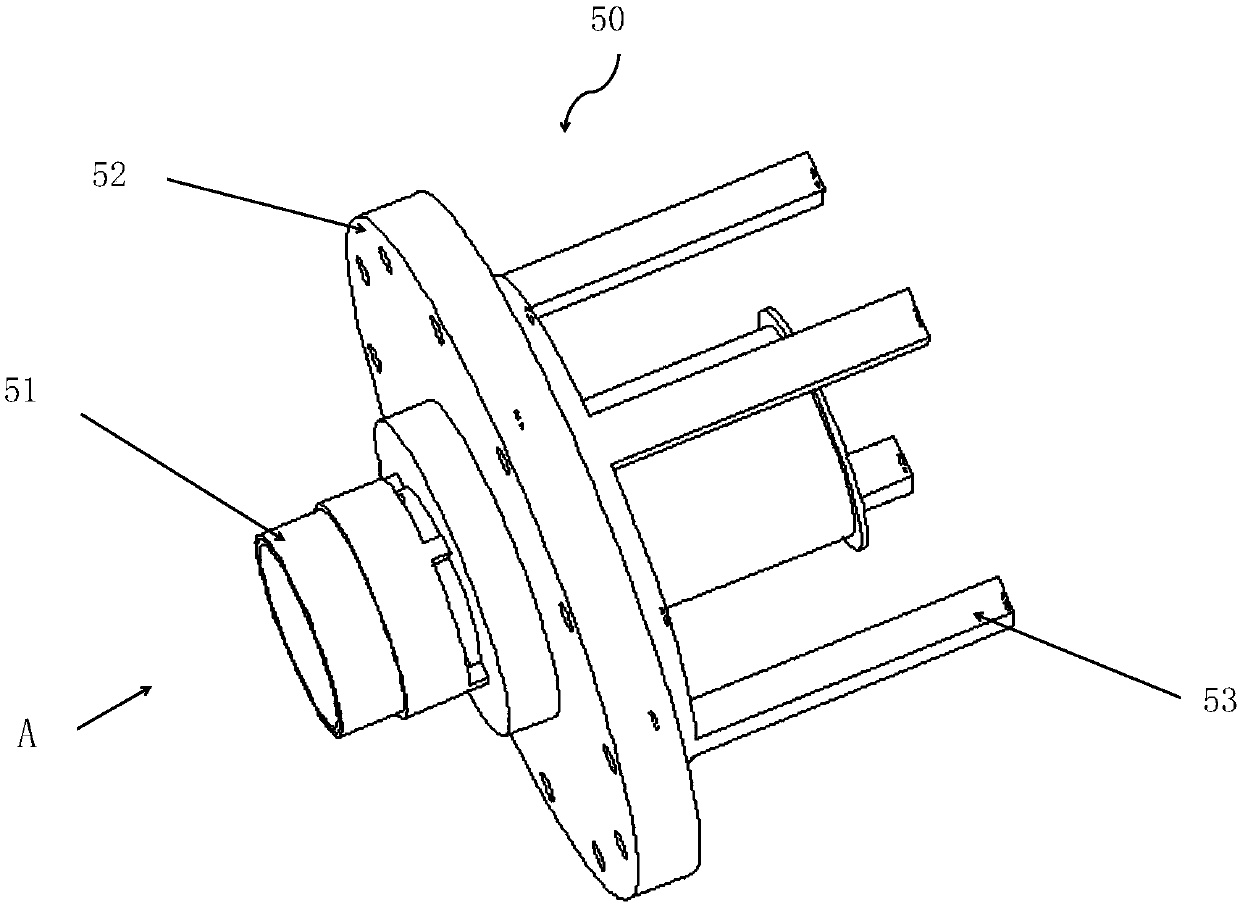

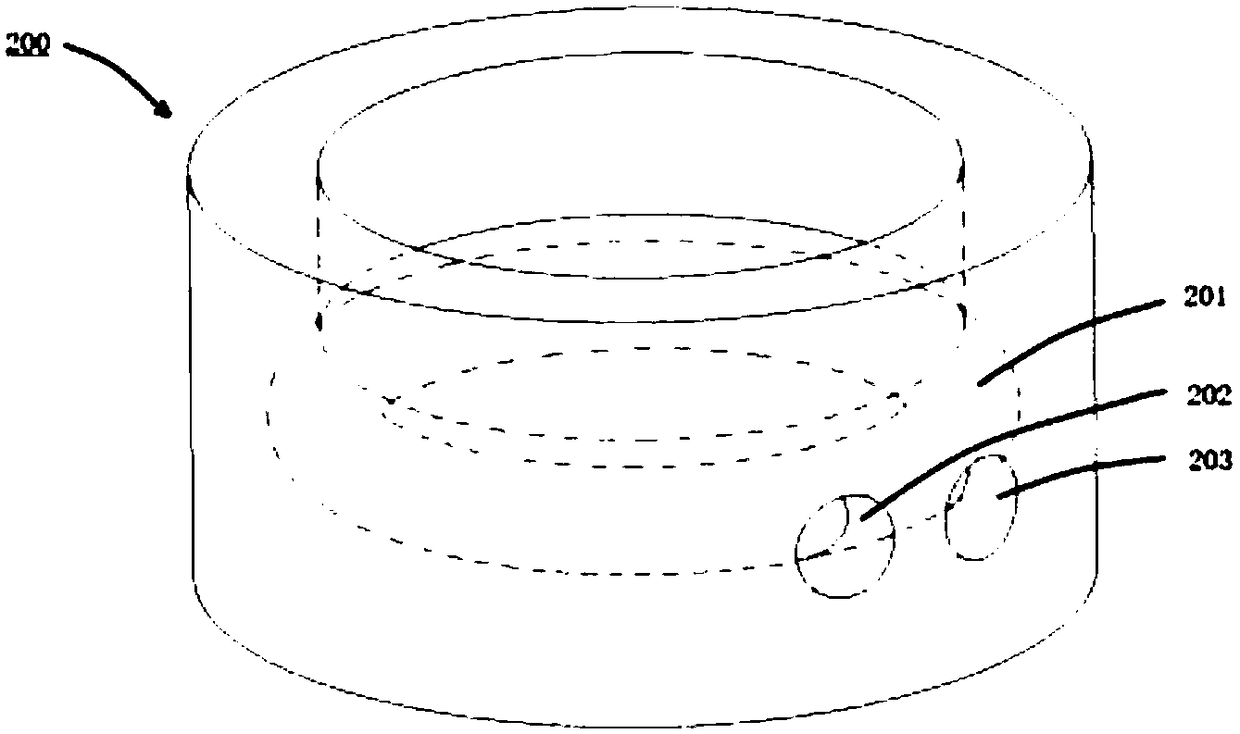

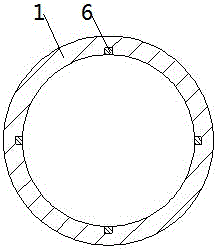

Heat regenerator of Stirling cryocooler and processing method of packing bodies for heat regenerator

ActiveCN106288540AHigh densityQuick disassemblyFurnace typesSuperheatersStirling cryocoolerMechanical engineering

The invention discloses a heat regenerator of a Stirling cryocooler and a processing method of packing bodies for the heat regenerator, and aims at providing a high-heat-exchange-efficiency heat regenerator of a Stirling cryocooler and a processing method of packing bodies for the heat regenerator. The heat regenerator comprises a cylinder, the packing bodies arranged in the cylinder in a packing mode, and two installation frames. Each installation frame comprises a first ring plate located at the end of the cylinder, a second ring plate located in the cylinder, and four guide bars connected with the end face of the first ring plate and the outer edge of the second ring plate and evenly distributed in the circumferential direction of the first ring plate, wherein the outer edge of the second ring plate is attached to the inner wall of the cylinder, the inner diameter of the first ring plate is equal to the outer diameter of the second ring plate, the outer diameter of the first ring plate is larger than the inner diameter of the cylinder, the inward wall surfaces of the guide bars are flush with the inner wall of the cylinder, and four guide grooves in sliding fit with the guide bars are evenly distributed in the inner wall of the cylinder. The second ring plates of the two installation frames are spaced by a certain distance. The packing bodies are formed by a plurality of stainless steel sintered nets or a plurality of pieces of stainless steel sintered felt and are arranged in the installation frames in a packing mode respectively.

Owner:KUNMING INST OF PHYSICS

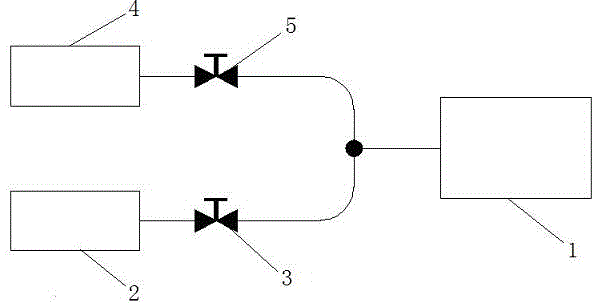

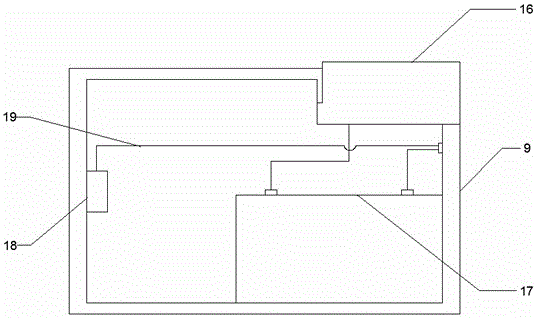

One-open and one-standby vacuum pump set

InactiveCN105570094AMeet the requirements of long-term continuous workPump installationsPositive-displacement liquid enginesEngineeringStirling cryocooler

The invention discloses a one-open and one-standby vacuum pump set, and relates to the technical field of low-temperature refrigeration. The one-open and one-standby vacuum pump set comprises a vacuum cavity, a vacuum pump set I, a vacuum valve I, a vacuum pump set II and a vacuum valve II; the vacuum pump set I is connected with the vacuum valve I; the vacuum pump set II is connected with the vacuum valve II; and the vacuum valve I is connected with the vacuum cavity after being connected with the vacuum valve II in parallel. The one-open and one-standby vacuum pump set satisfies long-time continuous working requirement of a stirling cryocooler by adopting one set to work and one set to standby use.

Owner:HEFEI LIQING ENVIRONMENTAL PROTECTION EQUIP

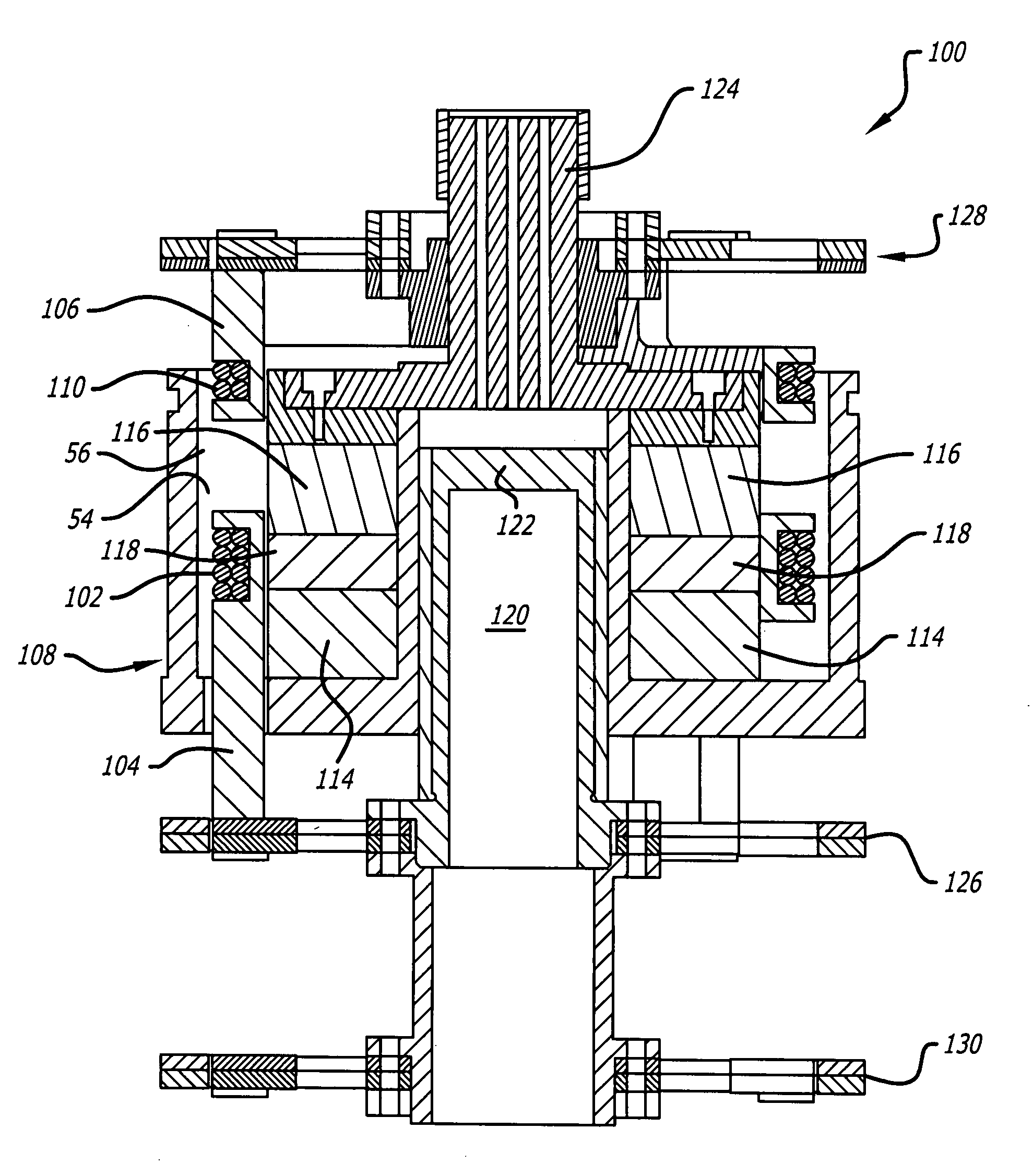

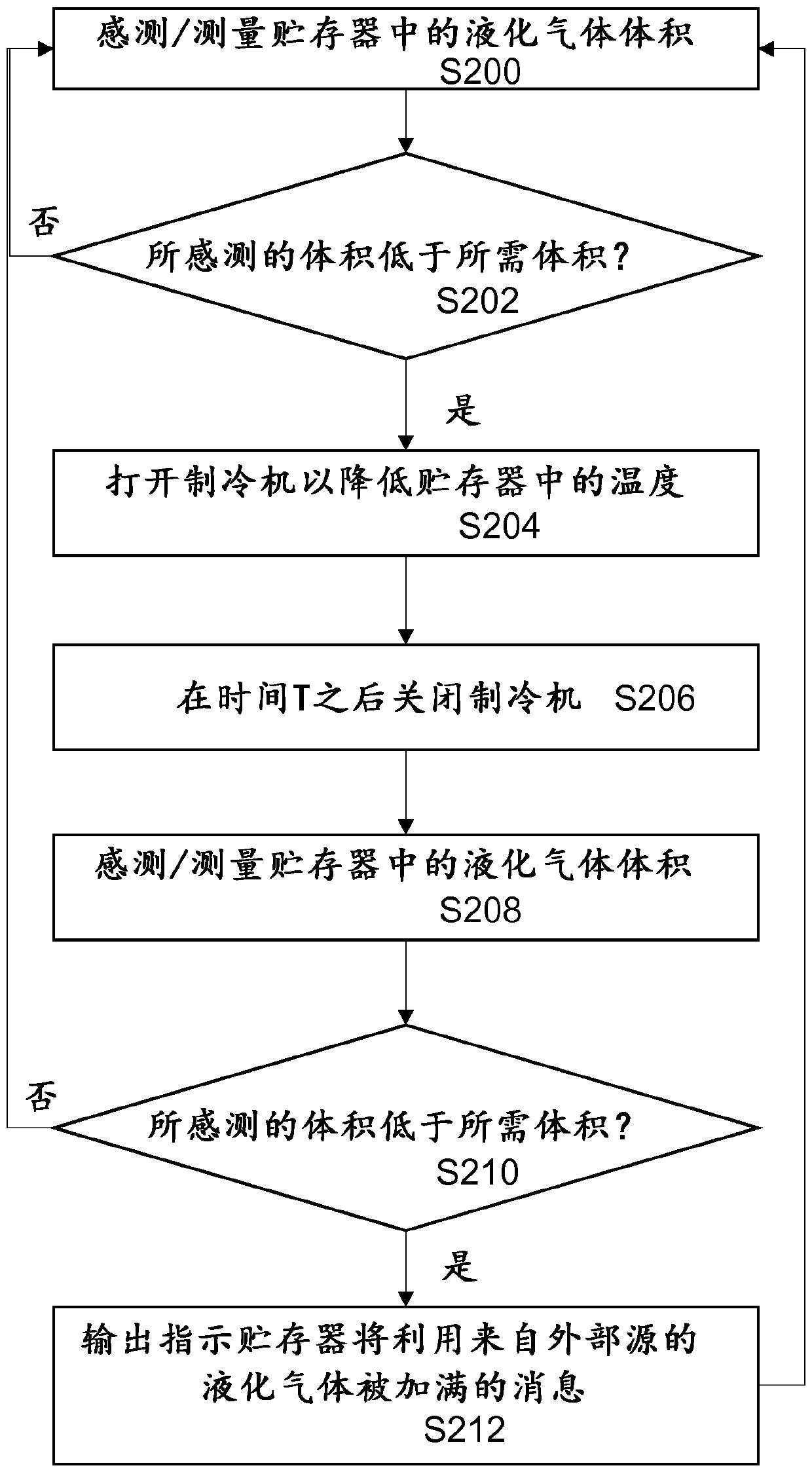

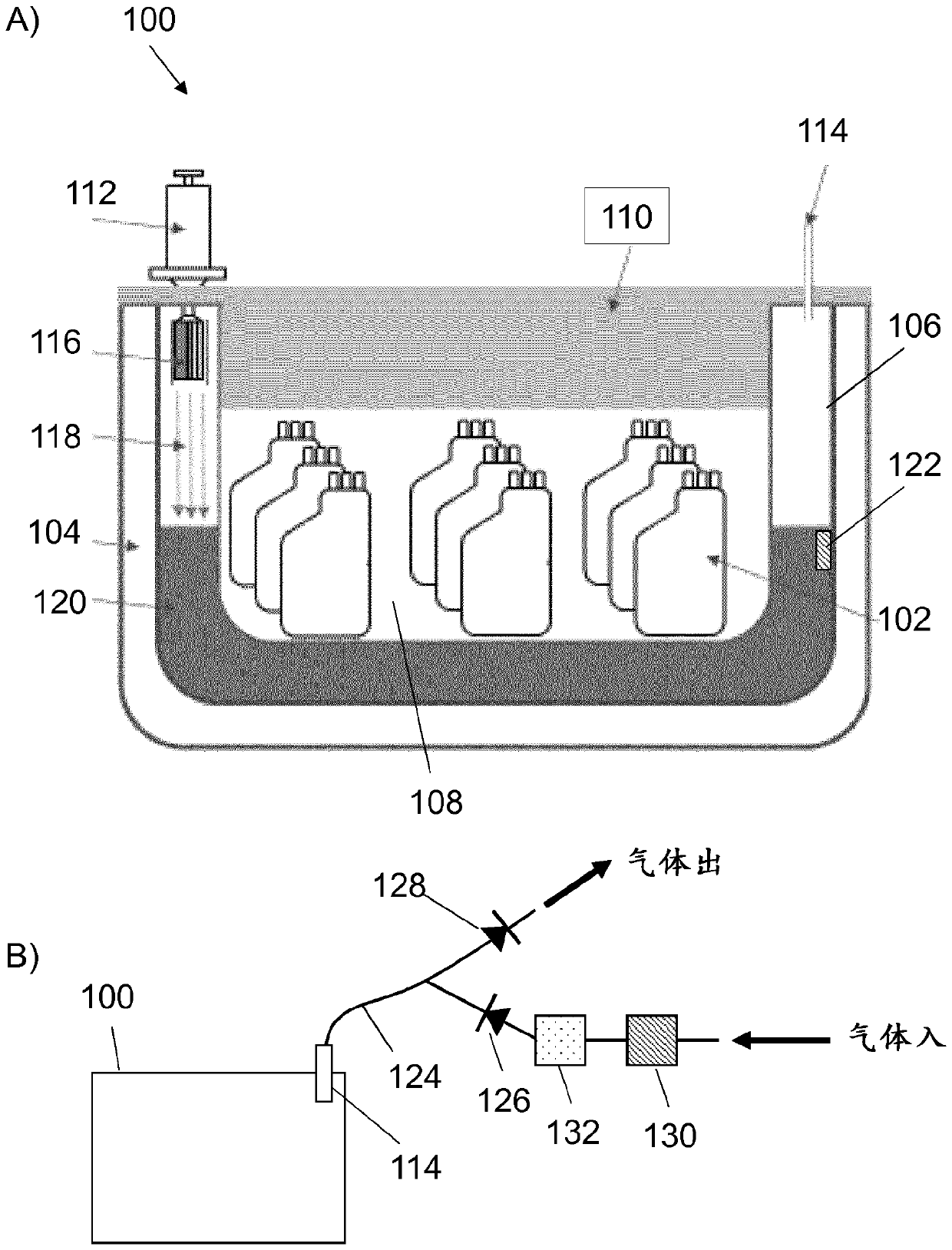

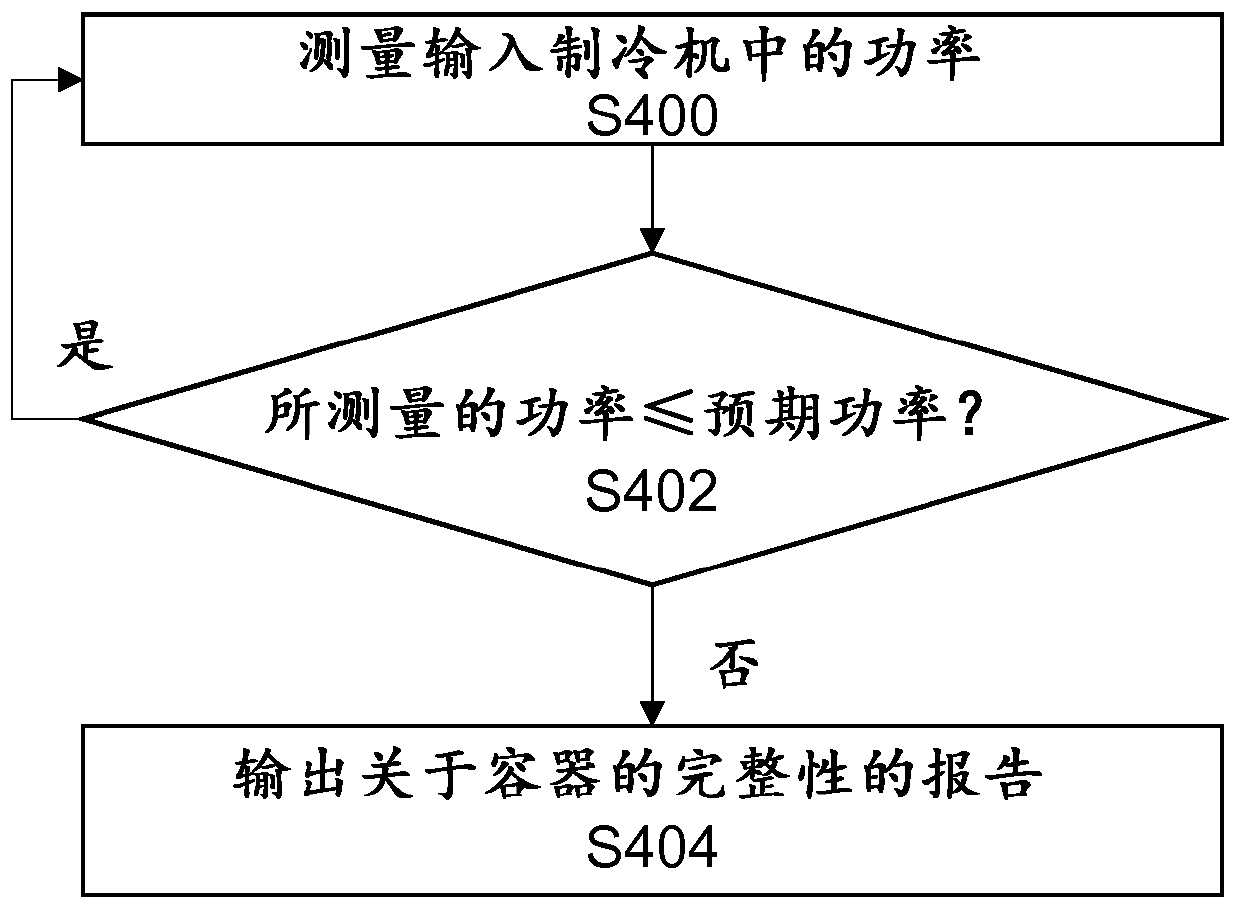

Container for cryopreserved samples

Disclosed are containers (100) for cryopreserved biological samples (102), which comprise an insulated housing comprising a cavity (108) for containing at least one cryopreserved biological sample; and a sealed reservoir (106) at least partly surrounding the cavity, the sealed reservoir comprising liquified gas (120) such as liqified air, the gas being kept largely liquified by means of a heat transfer engine (112) such as a Stirling cryocooler. A valve (114) may be provided to function as both a pressure relief valve and an inlet valve. The inlet valve may be coupled to a sensor (122) for sensing a volume of liquified gas within the sealed reservoir. The container may further comprise a heat exchanger (116) coupled to the heat engine and extending into the sealed reservoir.

Owner:ASYMPTOTE

Stirling cryocooler

A Stirling cryocooler includes a displacer having a displacer base portion disposed on a center axis and a displacer tip portion aligned along the center axis, extending from the displacer base portion to a working-gas expansion space, and a regenerator disposed surrounding the displacer tip portion such as to guide reciprocating travel of the displacer along the center axis. The displacer tip portion includes a plurality of platelike components arranged along the center axis, with each of the plurality of platelike components being furnished with a component side surface defining a portion of the outer surface of the displacer tip portion. The plurality of platelike components form working gas layers between pairs of adjoining components, and / or are formed of a synthetic resin material.

Owner:SUMITOMO HEAVY IND LTD

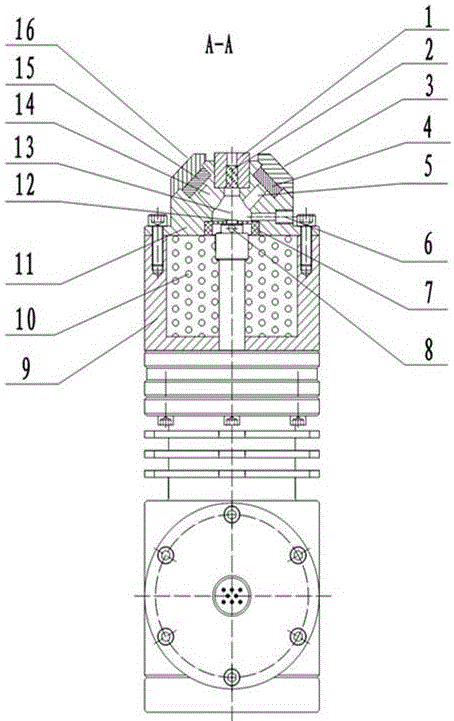

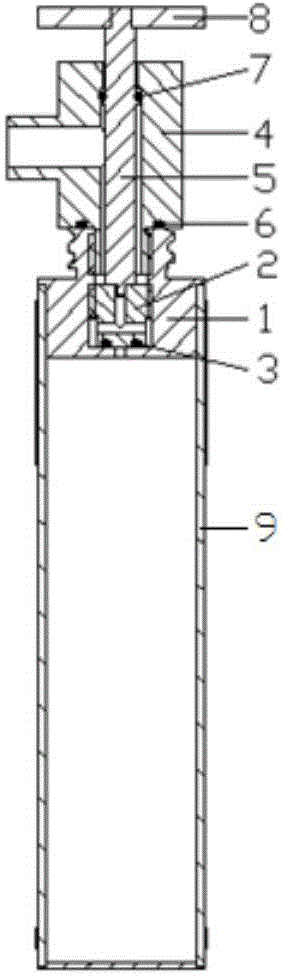

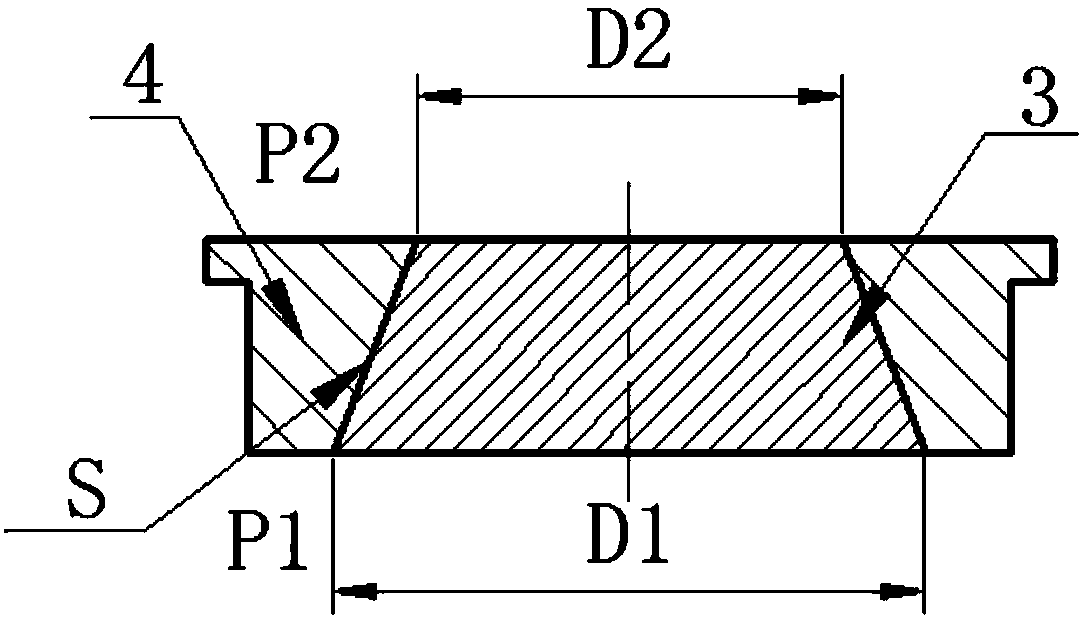

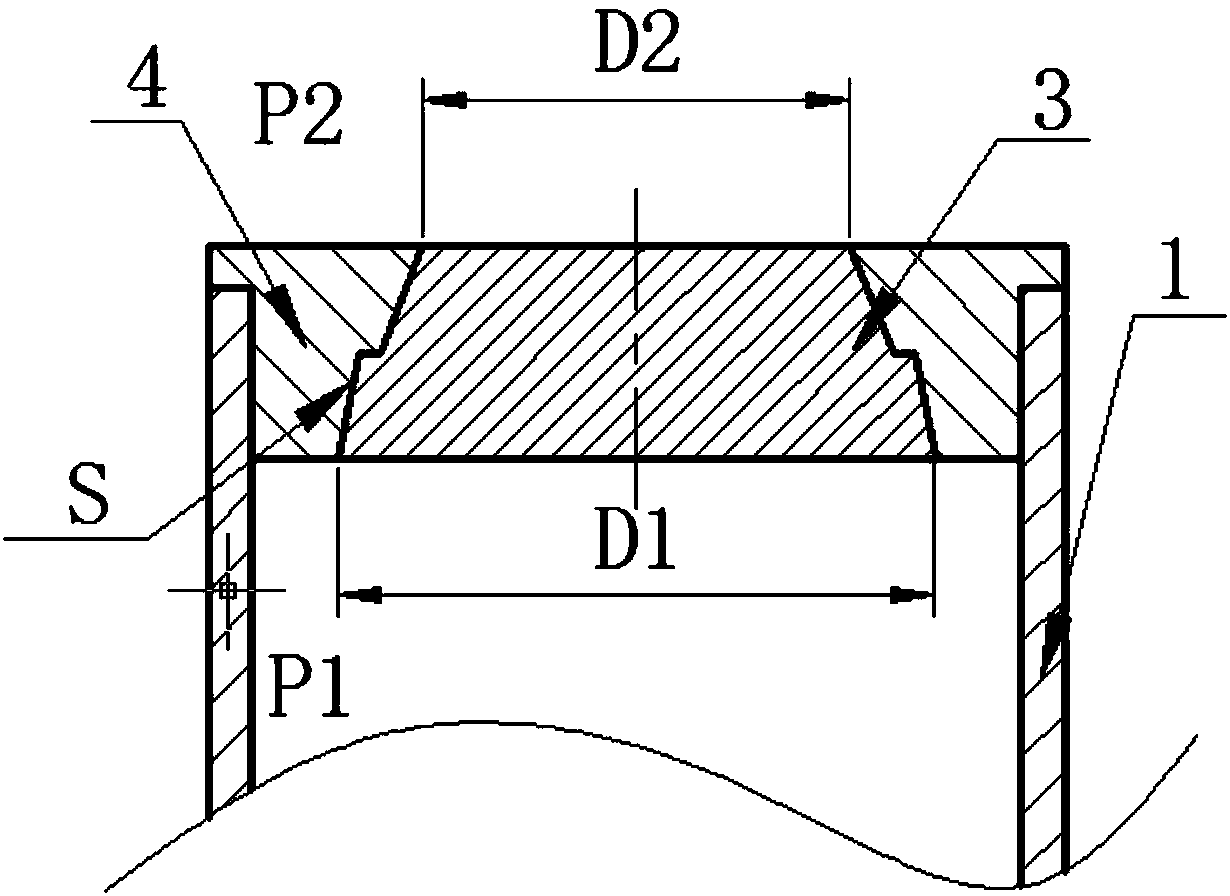

Cold finger cold plate structure of Stirling cryocooler

PendingCN108469129AGuaranteed geometric toleranceAchieving high geometric tolerance requirementsCompression machinesPosition toleranceEngineering

The invention relates to a cold finger cold plate structure of a Stirling cryocooler. The cold finger cold plate structure comprises an air cylinder and a cold plate structure, wherein the cold platestructure is embedded into an opening in the end part of the air cylinder; the cold plate structure comprises a base body and a conduction plate which are coaxially arranged, and the conduction plateis connected in the middle of the base body in an embedded mode; let the pressure on the air cylinder side of the cold plate structure be P1 and the pressure on the other side be P2, let the diameterof the air cylinder side of the conduction plate be D1 and the diameter of the other side of the conduction plate be D2, and if P1 is greater than P2, D1 is greater than D2; and let the side surface of the conduction plate be an S surface, and the S surface is one conical surface, a plurality of stepped conical surfaces or a plurality of stepped cylindrical surfaces. According to the technical scheme of the cold finger cold plate structure, under the condition that manufacturing is not carried out any more after the cold plate structure and the air cylinder base body are welded, the influenceof welding on the form and position tolerance of the air cylinder base body can be greatly reduced, and the requirement for high form and position tolerance of the air cylinder base body can be met. The cold finger cold plate structure has the advantage that the form and position tolerance of a cold finger air cylinder structure can be guaranteed, and meanwhile, the cold loss can be reduced to themaximum degree.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

Refrigeration table adopting acoustic energy refrigerator

InactiveCN108402687ASolve the problem of sound power recoveryReduce manufacturing difficultyCompression machinesServing tablesAcoustic energyCooling effect

A refrigeration table adopting an acoustic energy refrigerator comprises a table body and the acoustic energy refrigerator, wherein the table body is provided with table legs and a table top, the table top is horizontally arranged, and a cavity with a concave horizontal bottom surface is arranged in the center of the table top; the bottom surface is made of metal, the acoustic energy refrigeratoris a pulse free-piston stirling cryocooler, and the pulse free-piston stirling cryocooler is provided with a cold end; the cold end is in contact with the bottom surface of the cavity, which is used for cooling the bottom surface. The pulse free-piston stirling cryocooler used by the refrigeration table has the advantages that the size is small, the structure is compact, the carrying is convenient, and the refrigerating efficiency is high. The refrigeration table is high in cooling speed, the cooling effect is good, the temperature is easy to control, and the accuracy of controlling the temperature is higher.

Owner:杨厚成

On-line regulation device of expansion machine of split type stirling cryocooler

InactiveCN103175357APlay a limiting roleGuaranteed air tightnessStructural/machines measurementRefrigeration safety arrangementCryocoolerStirling cryocooler

The invention discloses an on-line regulation device of an expansion machine of a split type stirling cryocooler. The on-line regulation device comprises a regulating stem, wherein one end of the regulating stem can be connected with a spring fixing seat of the expansion machine, a self-sealing seat is installed on the periphery of the regulating stem, an outer fixing seat is installed on the periphery of the self-sealing seat, and the outer fixing seat is provided with a bolt hole which is used for being connected with an air cylinder of the expansion machine; and the other end of the regulating stem is stretched out of the end portion of the outer fixing seat and the end portion of the self-sealing seat to form a stretched regulating portion. The on-line regulation device can achieve on-line parameter regulation during testing processes of the cryocooler, can improve debugging efficiency, shortens the development cycle of the stirling cryocooler, and is simple in structure, convenient to operate and low in manufacturing cost.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

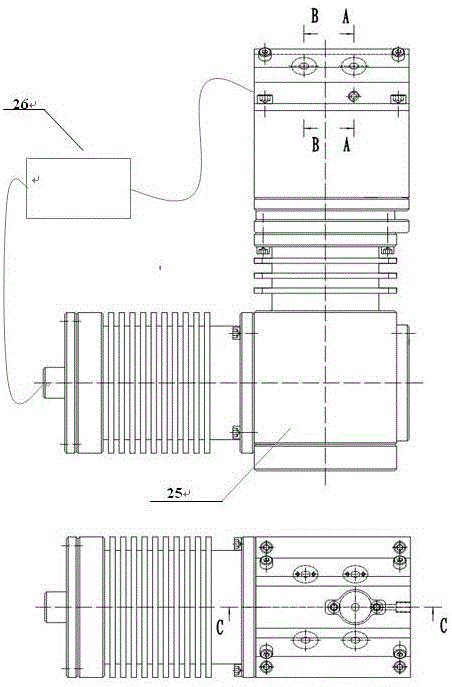

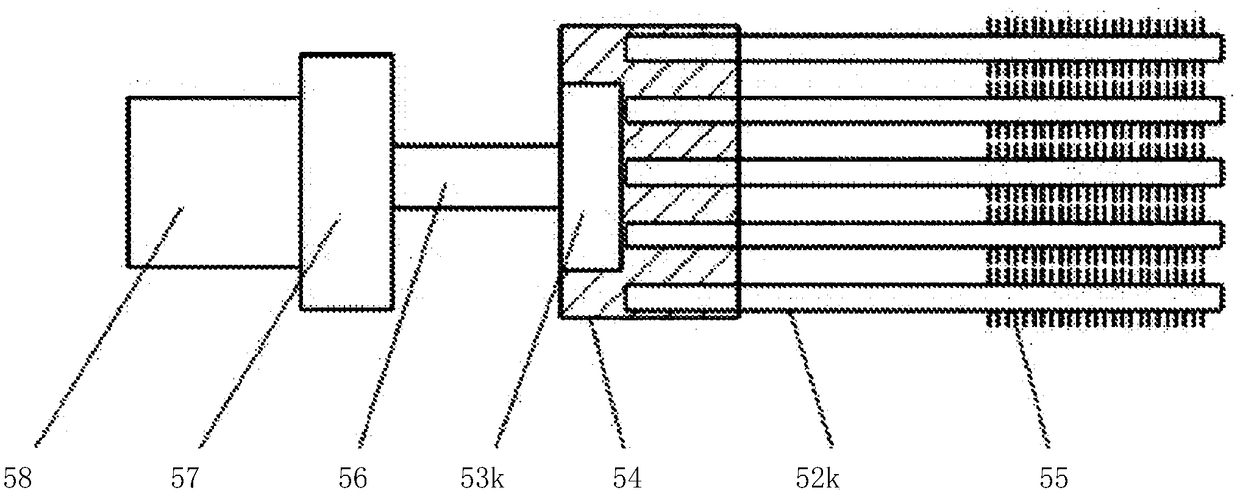

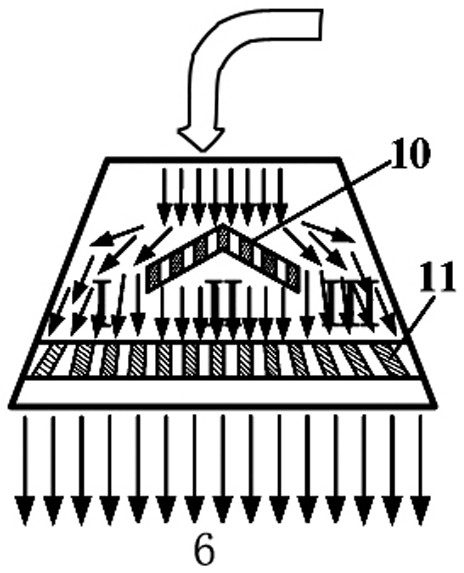

Solar energy air water obtaining device

ActiveCN108797702ASolve the problem of sound power recoveryReduce manufacturing difficultyDrinking water installationEngineeringRecuperator

The invention discloses a solar energy air water obtaining device which comprises an air water obtaining part and a pulse pipe type free piston Stirling cryocooler with a cold end heat exchanger. Theair water obtaining part comprises a fan, a heat regenerator, a water condenser, a copper plate, a heat pipe, a water collector, a solar cell and a storage battery; the fan is connected with the heatregenerator through a pipeline, the heat regenerator is connected with the water condenser through a pipeline for cooling air, multiple heat pipes are distributed inside the water condenser, the coldends of the heat pipes are connected with a cold end heat exchanger through the copper plate, dense fins are distributed at the hot ends of the heat pipe, cooling air flowing through the heat regenerator and the hot ends of the heat pipes are subjected to cold-heat exchange, the water collector is arranged below the water condenser and used for collecting condensate water separated from the fins,the solar battery and the storage battery are connected for supplying power to the fan and the Stirling cryocooler, and the pulse pipe type free piston Stirling cryocooler comprises a linear motor, acompression unit, an expansion machine unit and a rack.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

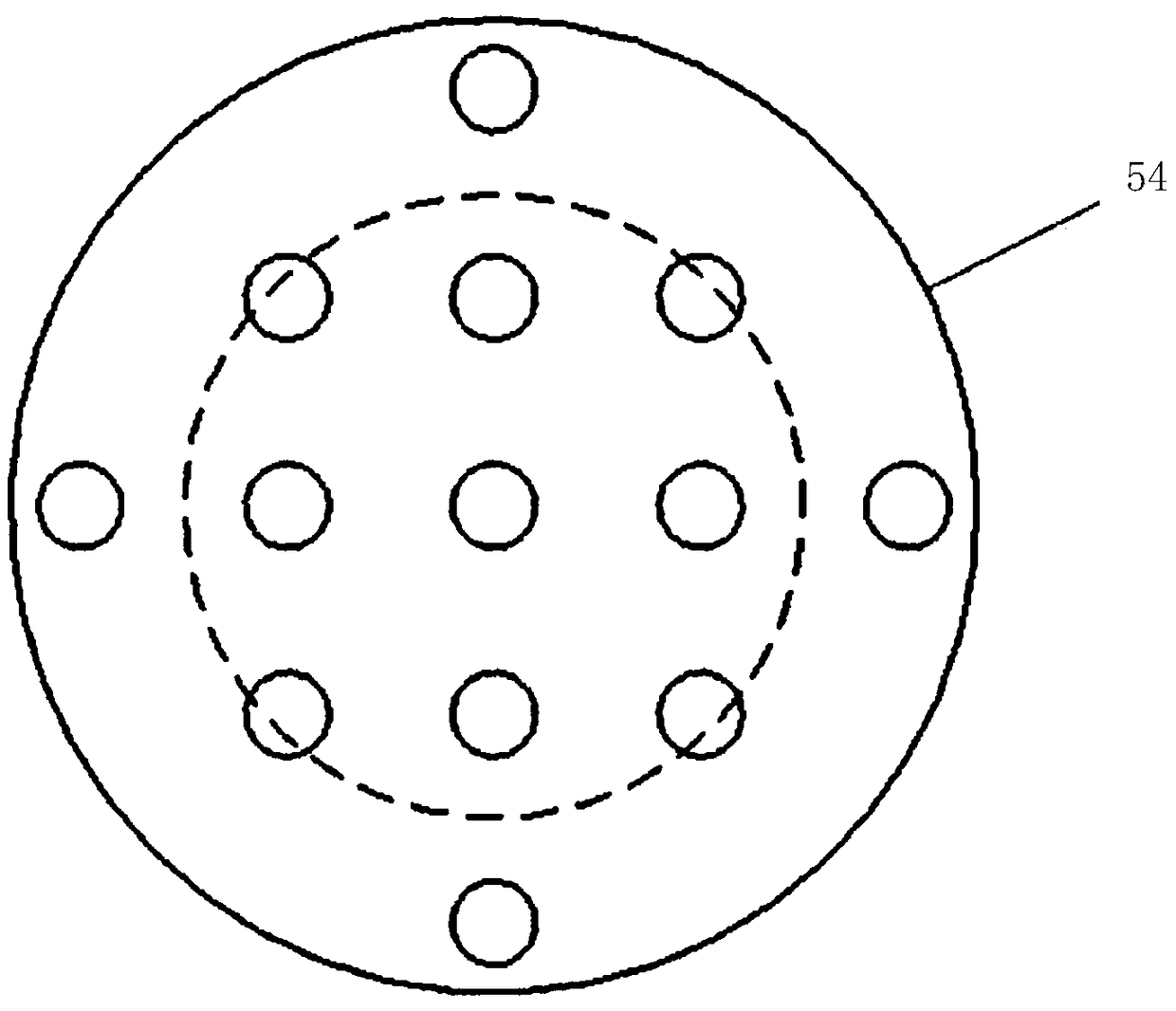

Stirling cryocooler capable of improving cooling efficiency

PendingCN112781264AIncrease heat exchange rateImprove cooling efficiencyCompression machinesEngineeringStirling cryocooler

The invention discloses a Stirling cryocooler capable of improving cooling efficiency. The Stirling cryocooler comprises an input signal spring, a piston air cylinder, a heat regenerator, a regenerator, a low-temperature pulse tube and a high-temperature heat exchanger, wherein the input signal spring inputs periodic sine pressure fluctuation to a system, acts on refrigerant gas through the piston air cylinder, an outlet of the piston air cylinder is connected to an inlet of the heat regenerator. The heat regenerator is mainly used for cooling out pressure gas of the piston air cylinder, an outlet of the heat regenerator is connected to an inlet of the regenerator, and the regenerator is used as a system cooling capacity output window and used for transmitting cooling capacity to cooled gas. According to the Stirling cryocooler, based on the uniform distribution performance of the refrigerant gas, refrigerant gas space distribution parts are arranged in a connecting structure of a refrigerant gas outlet and the regenerator, so that the refrigerant gas entering the interior of the regenerator is uniformly distributed inside the regenerator, the heat exchange rate between the refrigerant gas and a cooled medium is improved, and the overall refrigerating efficiency of the refrigerator is improved.

Owner:HANGZHOU HANGYANG

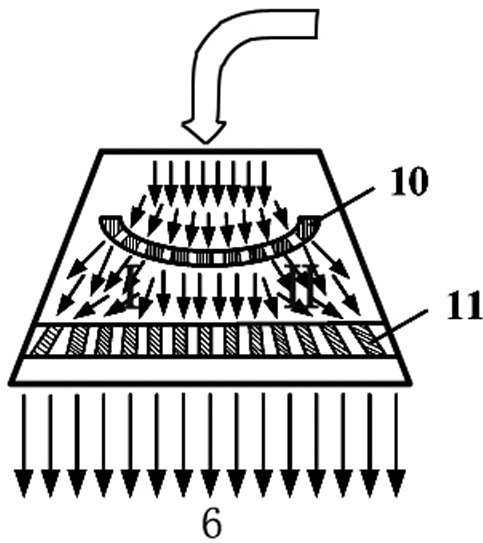

Solar cold drink mobile vehicle

InactiveCN106052246AFully absorbedAvoid pitfalls that require power connectionPhotovoltaic supportsSolar heating energySolar powerSolar cell

The invention relates to a solar cold drink mobile vehicle. The solar cold drink mobile vehicle comprises a solar cell panel and a vehicle body, wherein the vehicle body comprises an electric control chamber and a refrigerating chamber; a storage battery, a photovoltaic controller and an adaptor are mounted in the electric control chamber; a stirling cryocooler, a gravity assisted heat pipe and a cold cabinet are mounted in the refrigerating chamber; the stirling cryocooler is connected with the gravity assisted heat pipe; the solar cell panel, which is connected with the storage battery through the photovoltaic controller, is mounted on the upper surface of the vehicle body through a supporting frame; the stirling cryocooler is connected with the storage battery through a conductor or connected with a power supply through the adaptor. According to the solar cold drink mobile vehicle, the stirling cryocooler is combined with the cold drink mobile vehicle, helium is used as a working medium, and the whole cycling is free of phase change, so that the solar cold drink mobile vehicle has the advantages of being high in efficiency, free of refrigerator pollution, environmentally friendly, and energy saving; the solar energy is utilized to generate power to be used as the electricity energy of the stirling cryocooler, and the electricity energy can be stored into the storage battery through a solar power generation system, so that the limitation from a field power supply can be avoided, and the cold drink mobile vehicle can move conveniently.

Owner:陕西仙童科技有限公司

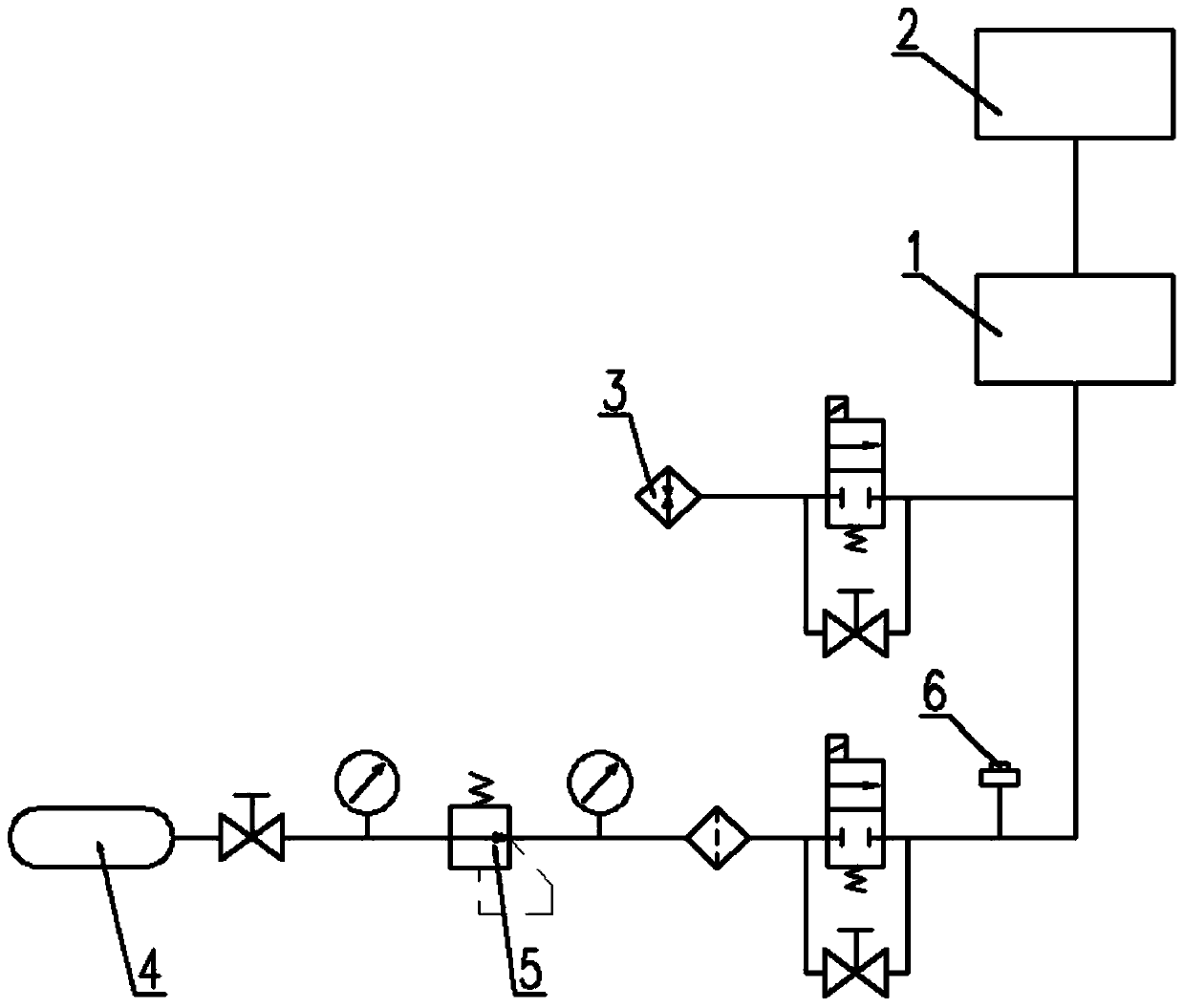

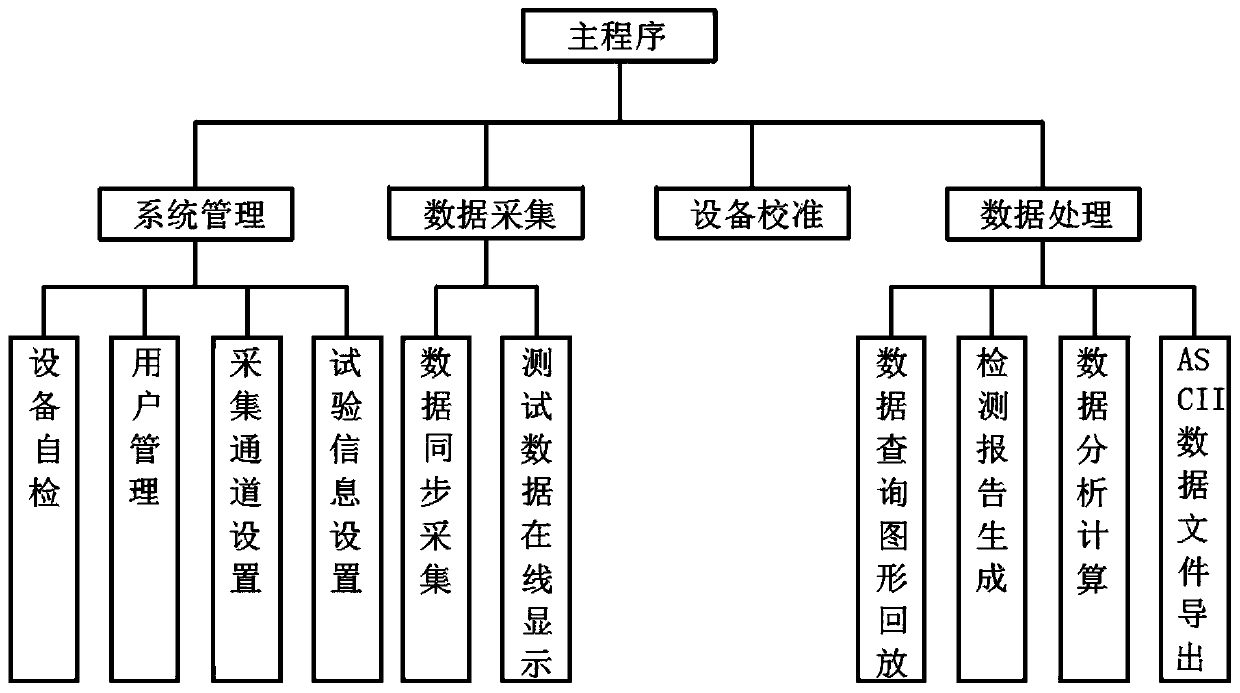

Split-stirling cryocooler air inflation and performance test bed

PendingCN110595813AReal-time acquisitionRealize analysisDetection of fluid at leakage pointCompression machinesEconomic benefitsProduct engineering

The invention relates to a split-stirling cryocooler air inflation and performance test bed, comprising a vacuumizing device used for vacuumizing a cryocooler, a helium gas injection device used for injecting a helium gas into the cryocooler, a helium mass spectrometer leak detector used for detecting leak of the cryocooler and a test system used for testing cooling performance of the cryocooler,wherein the cryocooler, the vacuumizing device, the helium gas injection device and the helium mass spectrometer leak detector are connected with the test system. The test bed provided by the invention solves many problems appearing in a manual operation process and is integrated with later data processing and report generation. The test bed provided by the invention is high in automation degree and high in reliability and can achieve unattended operation, so that research and development time is greatly shortened and product engineering application level is improved, and the test bed is innovative, is a leading technology in China, has a wide use space and can produe relatively high economic benefit.

Owner:CAMA LUOYANG GAS SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com