Cold finger cold plate structure of Stirling cryocooler

A refrigerator and cold plate technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve problems such as difficulties, poor weld formation, and change of weld crystallization conditions, so as to reduce the impact, reduce the loss of cooling capacity, The effect of guaranteeing geometric tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

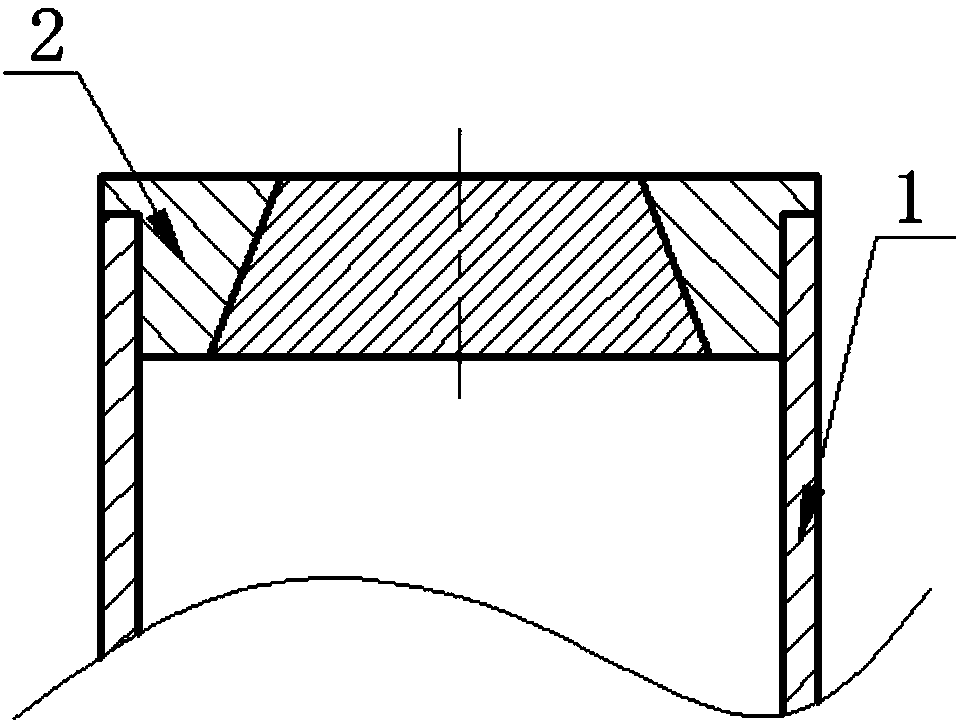

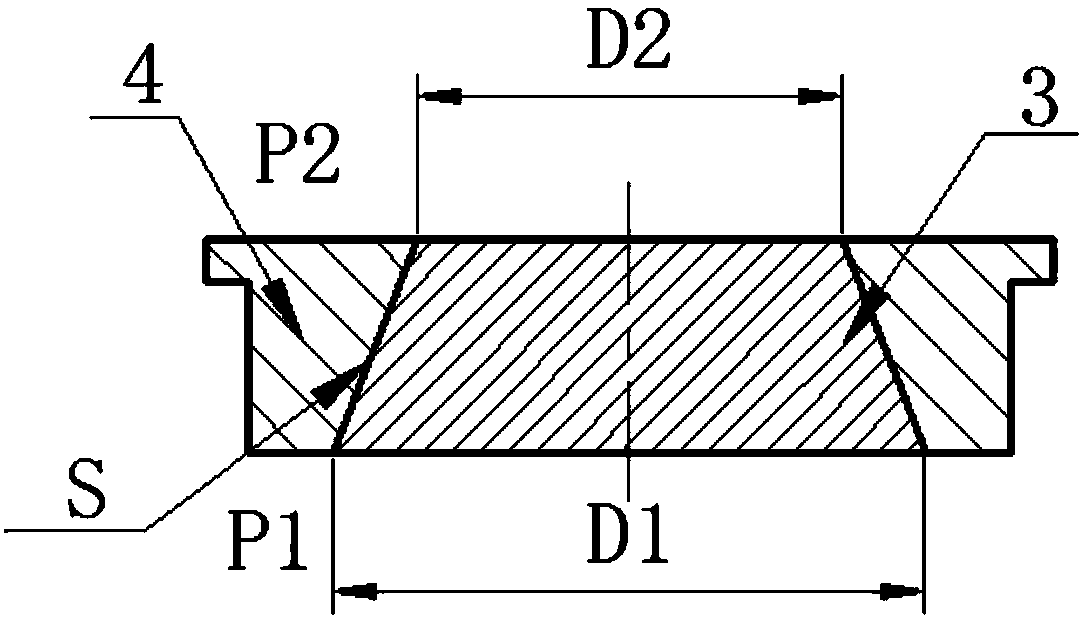

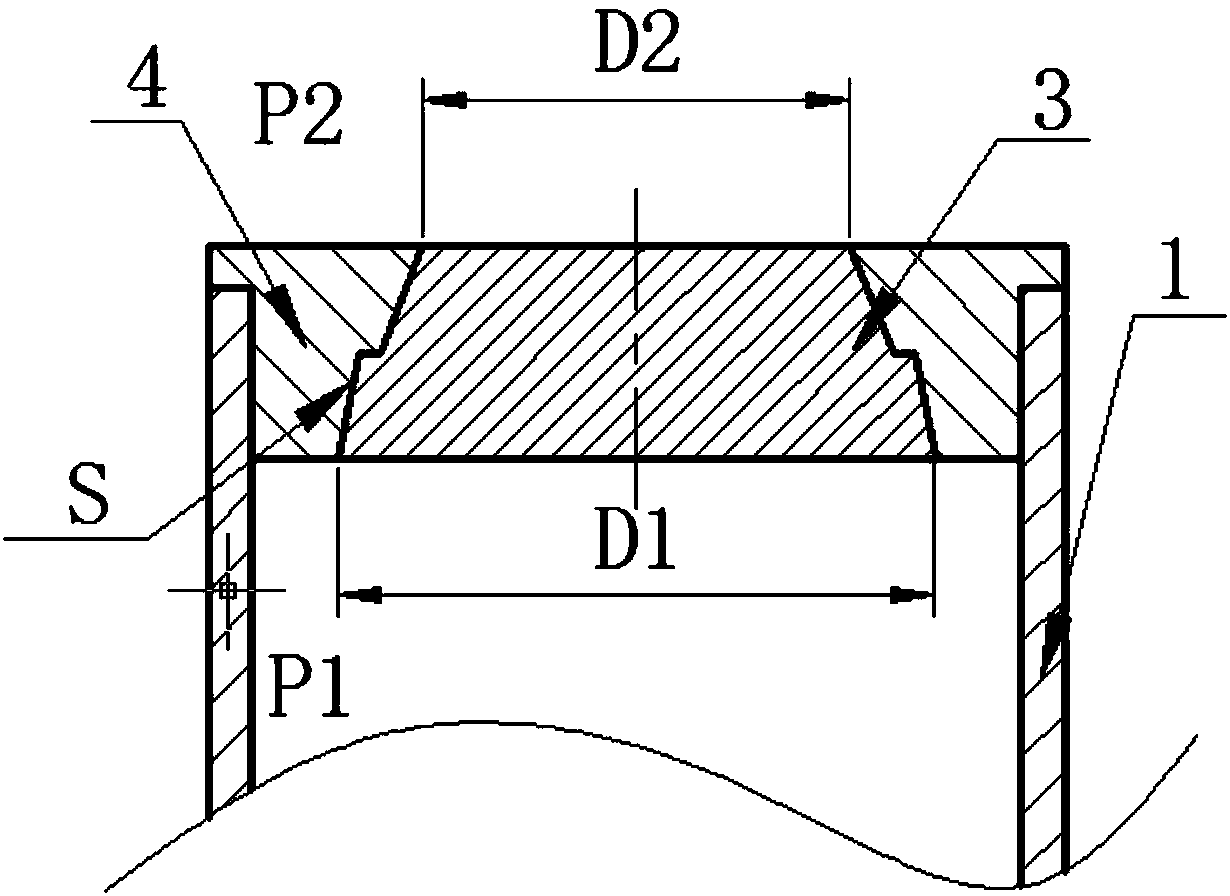

[0019] like Figure 1-Figure 2 A Stirling refrigerator cold finger cold plate structure shown includes a cylinder 1 and a cold plate structure 2 embedded and welded at the opening of the end of the cylinder 1 . The cold plate structure 2 includes a coaxial base 4 and a conduction plate 3 , and the conduction plate 3 is embedded and welded in the middle of the base 4 . After the conduction plate 3 and the base body 4 are welded, they are processed and repaired to form the cold plate structure 2 . The cold plate structure 2 is welded to the cylinder 1. Let the pressure on the cylinder side of the cold plate structure be P1, and the pressure on the other side be P2; let the diameter of the conduction plate cylinder side be D1, and the diameter of the other side be D2; if P1>P2, then D1>D2. Let the side of the conduction plate be the S surface, and the S surface be a conical surface.

[0020] In the actual design, there is a pressure difference between the two ends of the cold ...

Embodiment 2

[0024] like image 3 As shown, the side surface of the conduction plate is assumed to be an S surface, and the S surface is composed of a plurality of stepped cone surfaces. Others are the same as embodiment one.

Embodiment 3

[0026] like Figure 4 As shown, the side surface of the conduction plate is assumed to be an S surface, and the S surface is composed of a plurality of stepped cylindrical surfaces. Others are the same as embodiment one.

[0027] Design principle of the present invention is:

[0028] The Stirling refrigerator is used to cool the detector assembly after generating cold energy. The generated cold energy is on the P1 side (inside the cold plate structure), and the cold energy is used on the P2 side (outside the cold plate structure). The use of high-conductivity materials can maximize the use of cold energy, but the hardness and strength of high-conductivity materials cannot meet the requirements of cylinders for materials. Therefore, while utilizing the cold capacity to the greatest extent, the cylinder and the cold plate structure cannot be selected from the same material. In the present invention, the same material is used for the welding of the cold plate structure and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com