Digital controlled lathe for processing engine crank shaft connecting rod

A technology of crankshaft connecting rods and CNC lathes, applied in the field of CNC lathes, which can solve the problem that the shape tolerance and axial distance of a single connecting rod cannot be guaranteed, restrict the processing quality and production efficiency of crankshaft connecting rods, and the consistency gap between multiple connecting rods, etc. problems, to avoid quality accidents and personal injuries, shorten processing time, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

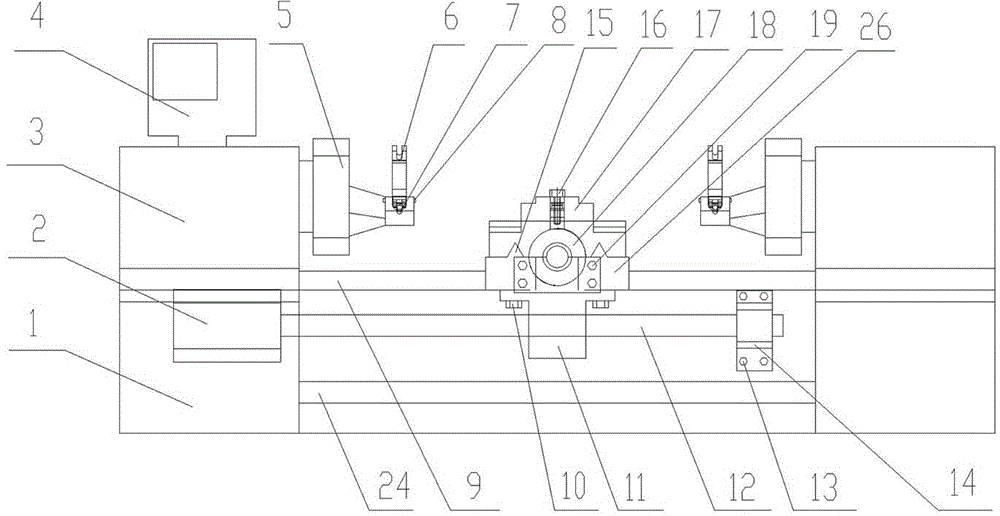

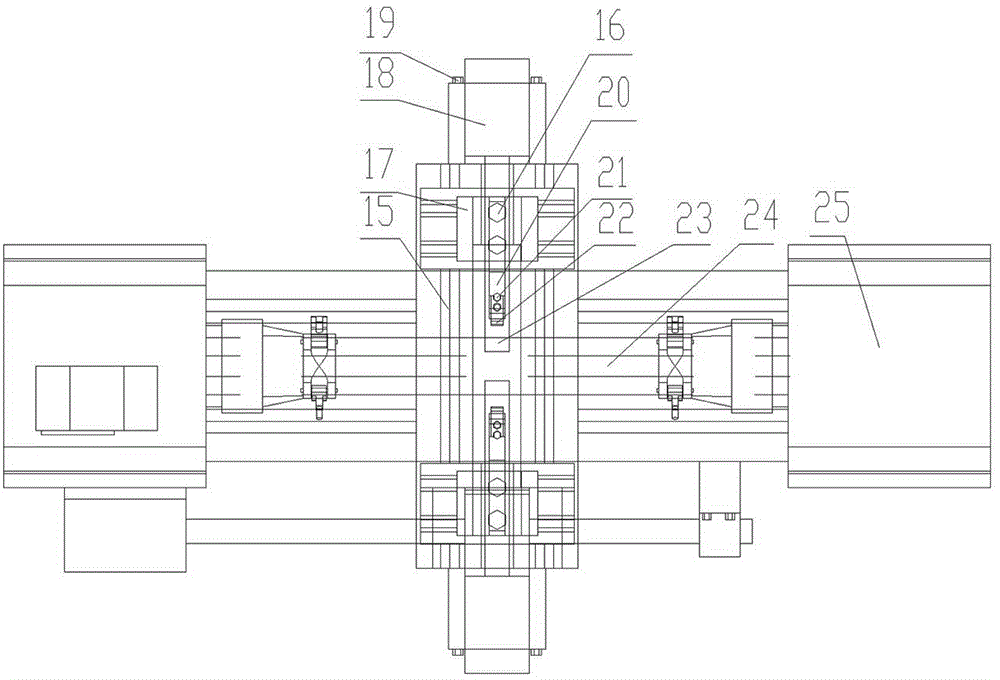

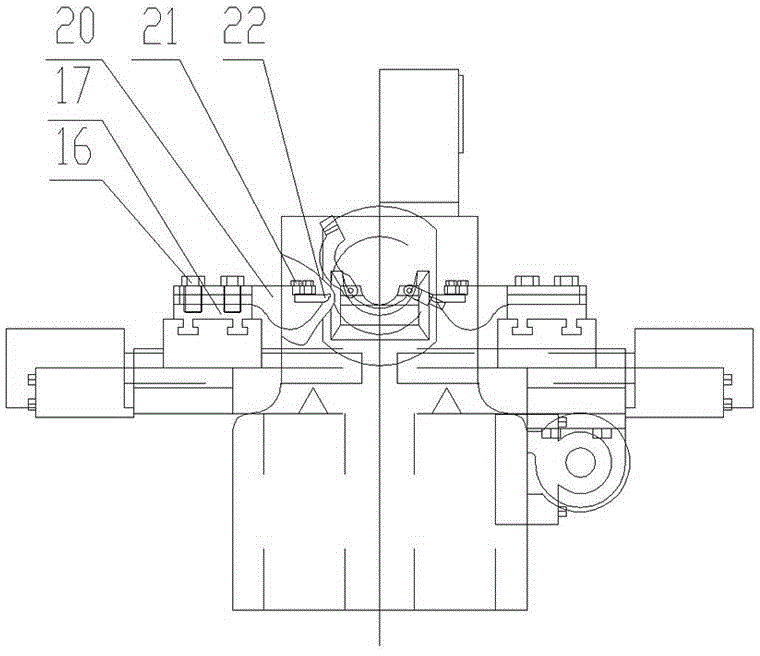

[0015] A numerically controlled lathe for processing engine crankshaft connecting rods, mainly comprising a base 1, a front rotating body 3, a rear rotating body 25, a first servo motor 2, a first lead screw 12, a turning bed surface guide rail 9, and a second servo motor 18 and the second lead screw 23, such as figure 1 , figure 2 , image 3 shown. The base 1 is provided with a front rotating body 3 , a rear rotating body 25 , a turning bed surface guide rail 9 and a first servo motor 2 . The first servo motor 2 is fixed on the lower left side of the turning bed guide rail 9, and the front rotating body 3 and the rear rotating body 25 are respectively installed on the left and right sides near the end of the turning bed guiding rail 9, and the front part rotates Body 3 is connected with rear rotating body 25 through transmission shaft 24 . The turning bed surface guide rail 9 is provided with a turning bed surface 26 that can move left and right along the turning bed sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com