Clamp for finish-turning inner and outer circles of open circular ring work piece and finish-turning method by the use of clamp

An open ring and workpiece technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problem of relatively high dimensional accuracy and geometric tolerance requirements, the sealing ring cannot directly clamp the parts, and the processing deformation control is difficult. Large and other problems, to achieve the effect of convenient manufacture and use, stable clamping, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

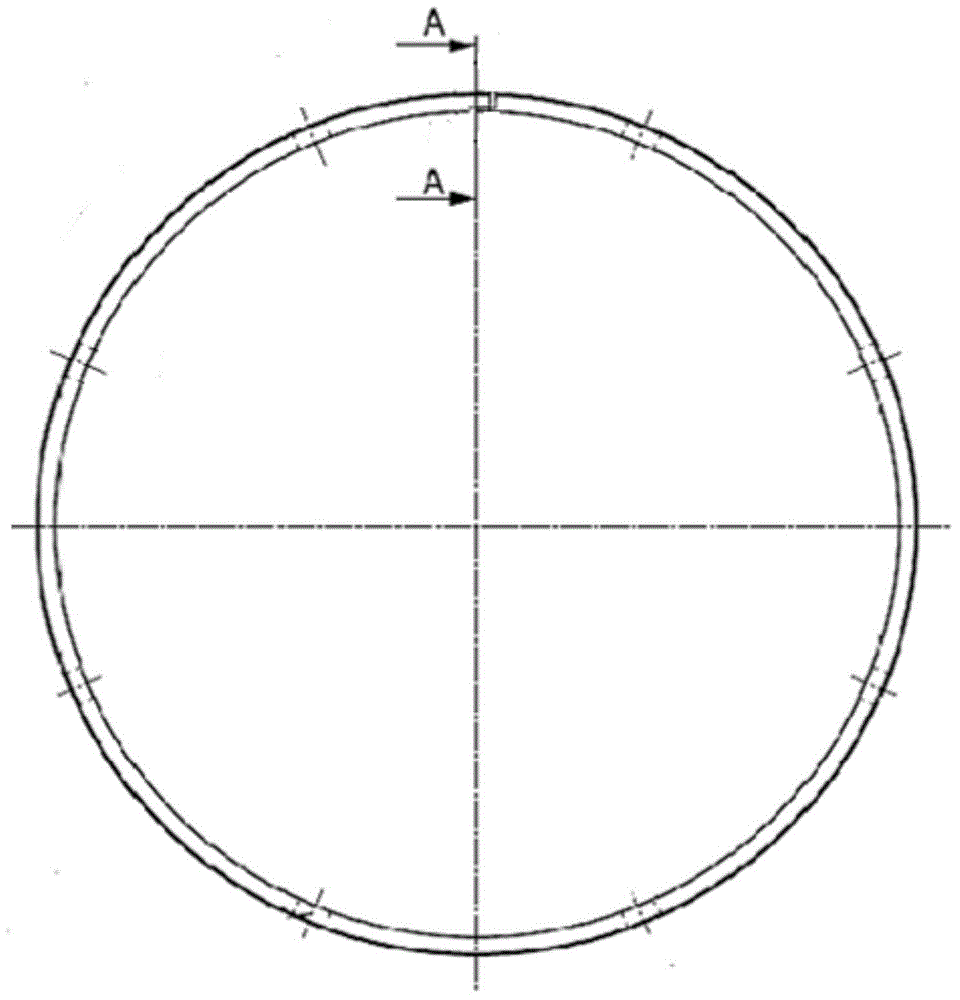

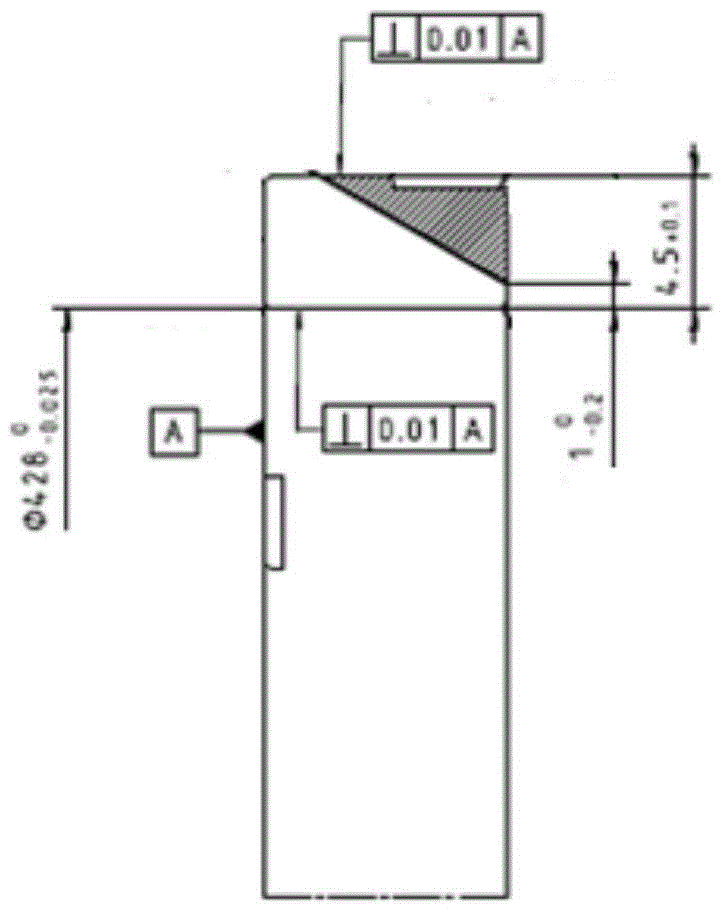

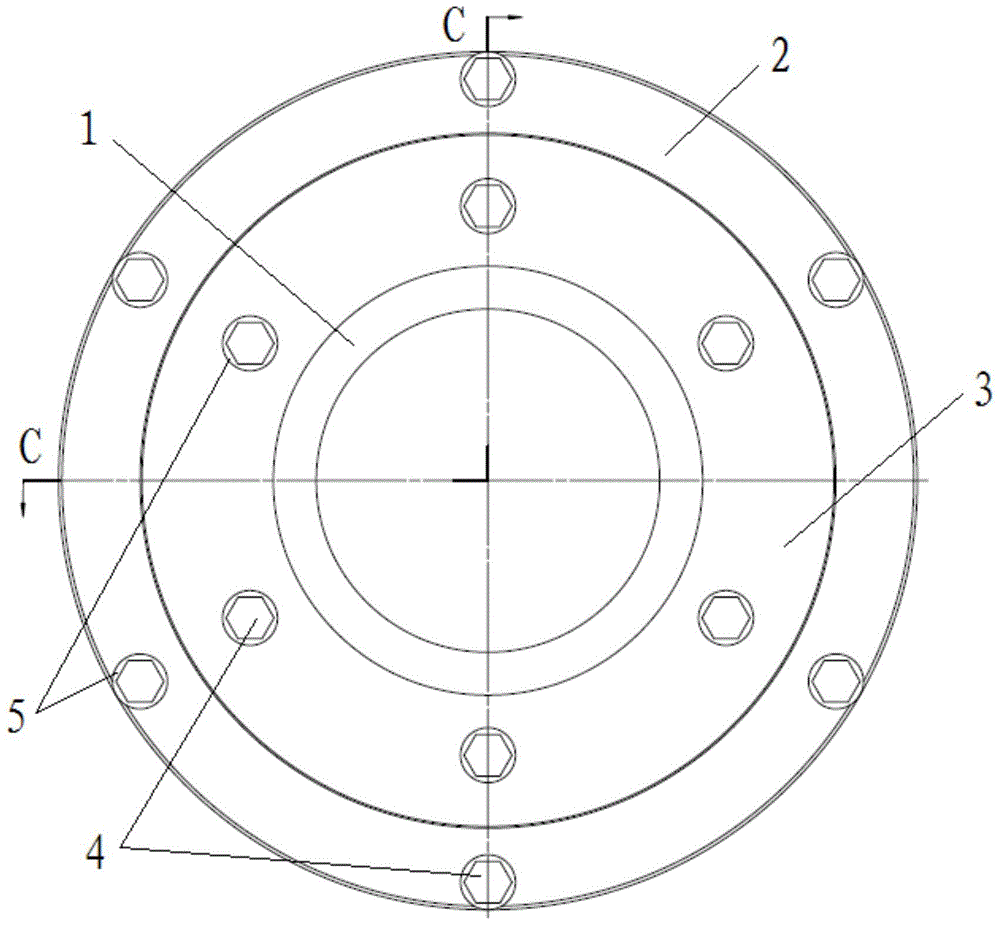

[0049] image 3 , 4 It schematically shows the state diagram of the fixture for the inner and outer circles of the finish turning open ring workpiece of the present invention when the outer pressure ring is installed after the outer circle of the open ring workpiece is turned. The fixture for the inner and outer circles of the open ring workpiece in finishing turning includes a clamp body 1 , an inner pressure ring 2 and an outer pressure ring 3 .

[0050] see also Figure 5 , the clamp body 1 is used for fixed connection with the rotating shaft of the lathe (not shown in the figure), and its end face opposite to the rotating shaft of the lathe has a first positioning end face 11 perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com