Linear integral stirling cryocooler

An integral, refrigerator technology, used in refrigerators, refrigeration and liquefaction, compressors, etc., can solve problems such as short length, and achieve the effect of reducing vibration displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

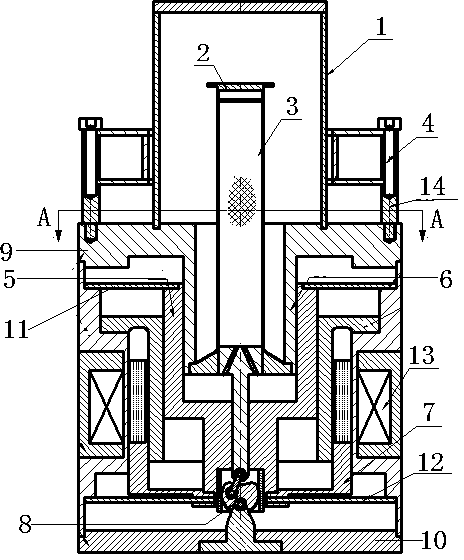

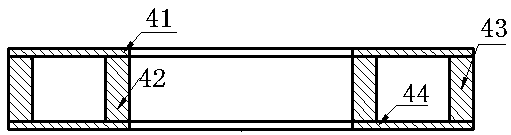

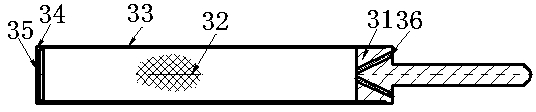

[0028] Such as figure 1 A linear integral Stirling refrigerator is shown, including a Dewar 1, an expander and a compressor. The outer side of the Dewar 1 is provided with a shock absorber 4 for reducing the vibration of the cold head. The expander includes an expansion cylinder 2 and an ejector assembly 3. The compressor includes a fixed piston 6, a moving cylinder 5, a linear motor, and a phase adjustment mechanism 8 for adjusting the phase difference between the ejector and the moving cylinder. The fixed piston 6 has a hollow structure, and the expander is located inside the fixed piston 6. The fixed piston 6 is sleeved in the moving cylinder 5, the non-contact gap sealing structure is formed between the fixed piston 6 and the moving cylinder 5, and the sealed cavity composed of the fixed piston 6 and the moving cylinder 5 is compressed Cavity. The moving cylinder 5 reciprocates along its axial direction driven by a linear motor. The outer side of the fixed piston 6 is f...

Embodiment 2

[0036] Such as Figure 7 with Figure 8 As shown, the mover assembly 7 is composed of a mover skeleton 72 and a mover winding 73. The stator assembly 13 is composed of a stator frame 15, magnetic poles 17 and stator permanent magnets 18.

[0037] Others are the same as in Example 1.

[0038] During operation, the fixed piston 6 is fixed and the movable cylinder 5 is driven by the linear motor moving subassembly 7 to reciprocate along its axial direction. In the present invention, the expander is placed inside the fixed piston 6, which shortens the overall length of the linear integral Stirling refrigerator; and by arranging the shock absorber 4 outside the Dewar 1, the vibration displacement at the cold head can be reduced, It is conducive to the application of the linear Stirling refrigerator on the gyro frame of the missile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com