Material piling and taking machine

A reclaimer and material stacking technology, which is applied in the field of stacker reclaimers, can solve the problems of large excavation of the reclaimer conveying channel, high height of the reclaimer hopper, large span of the belt conveyor and the entry trestle, etc. Achieve the effect of reducing construction cost and construction period, reducing the diameter and height, and saving the amount of civil engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

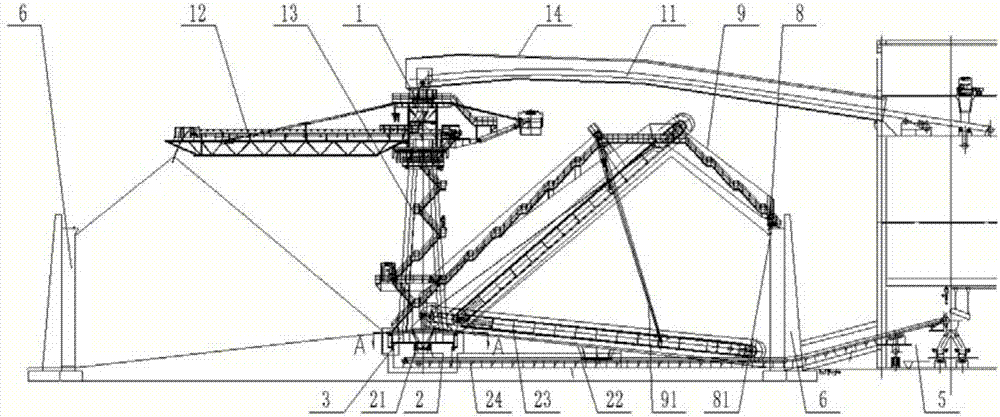

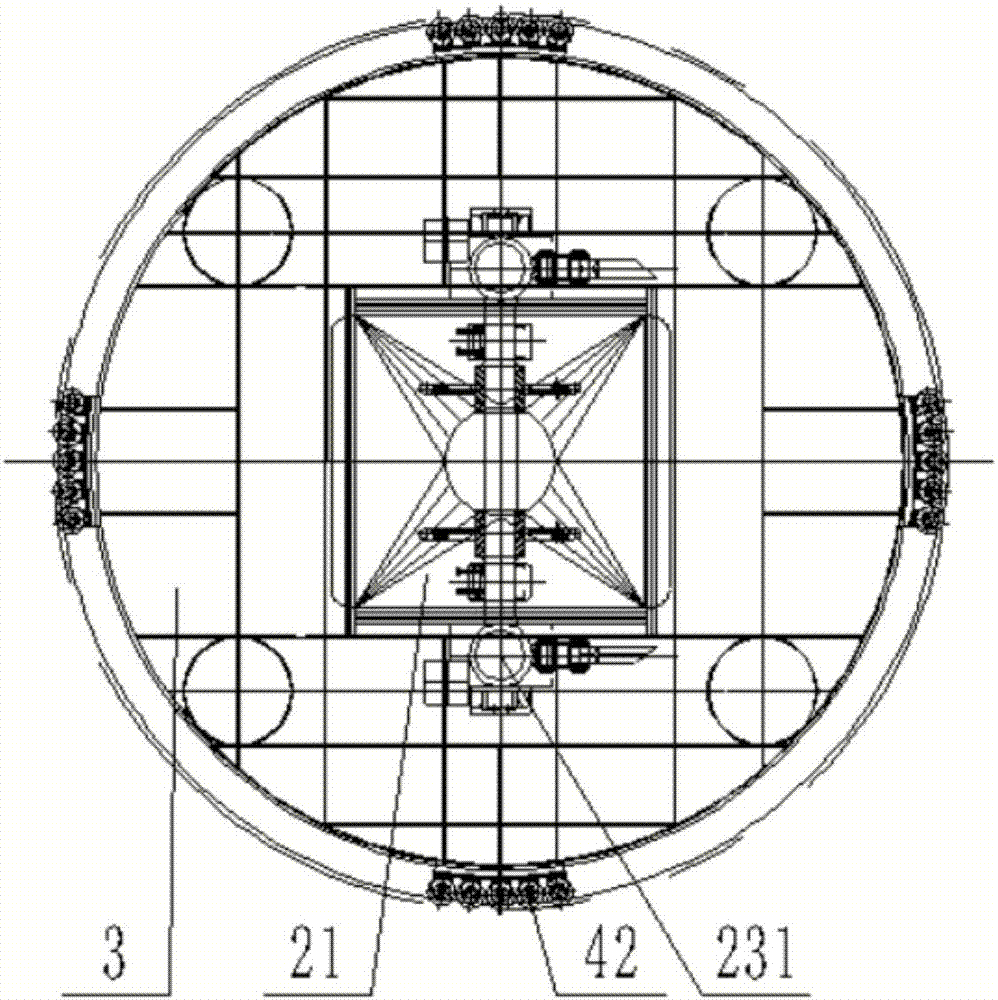

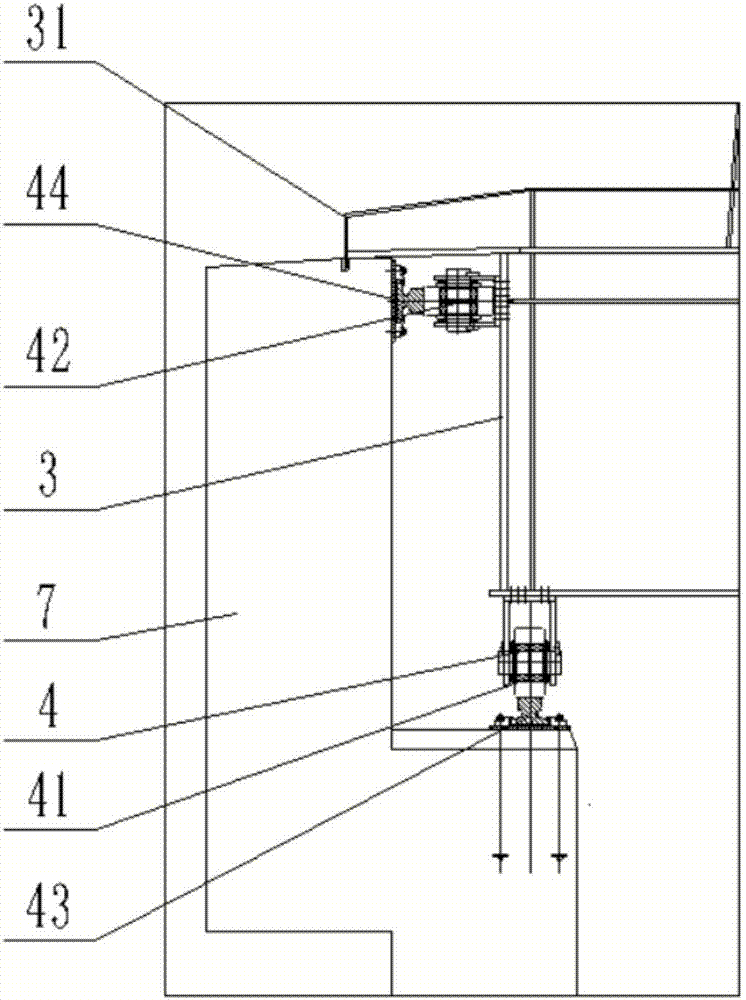

[0027] like figure 1 As shown, the stacker-reclaimer in this embodiment includes a stacker assembly 1 and a reclaimer assembly 2, the reclaimer assembly 2 is arranged below the stacker assembly 1, and the reclaimer assembly 2 includes a reclaimer hopper 21 and a reclaimer conveyor 22 , the reclaiming conveyor 22 is arranged below the reclaiming hopper 21. In this embodiment, the outer periphery of the reclaiming hopper 21 is provided with a rotary platform 3. The rotary platform 3 is light in weight and has a stable center of gravity, and the stacking assembly 1 is supported on the rotary platform 3. superior. In the present invention, a rotary platform 3 is arranged on the outer circumference of the reclaiming hopper 21, so that the stacking assembly 1 is suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com