Thermally-driven stirling cryocooler

A refrigerator and heat-driven technology, applied in refrigerators, hot gas variable displacement engine devices, refrigeration and liquefaction, etc., can solve problems such as difficult design and processing, system vibration, unfavorable practical application, etc., to reduce design and processing Difficulty, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

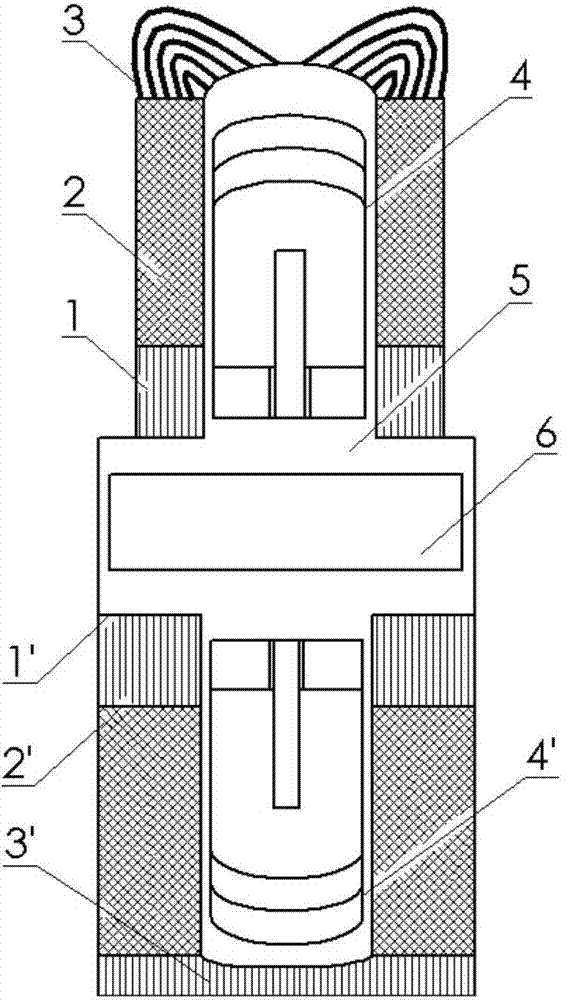

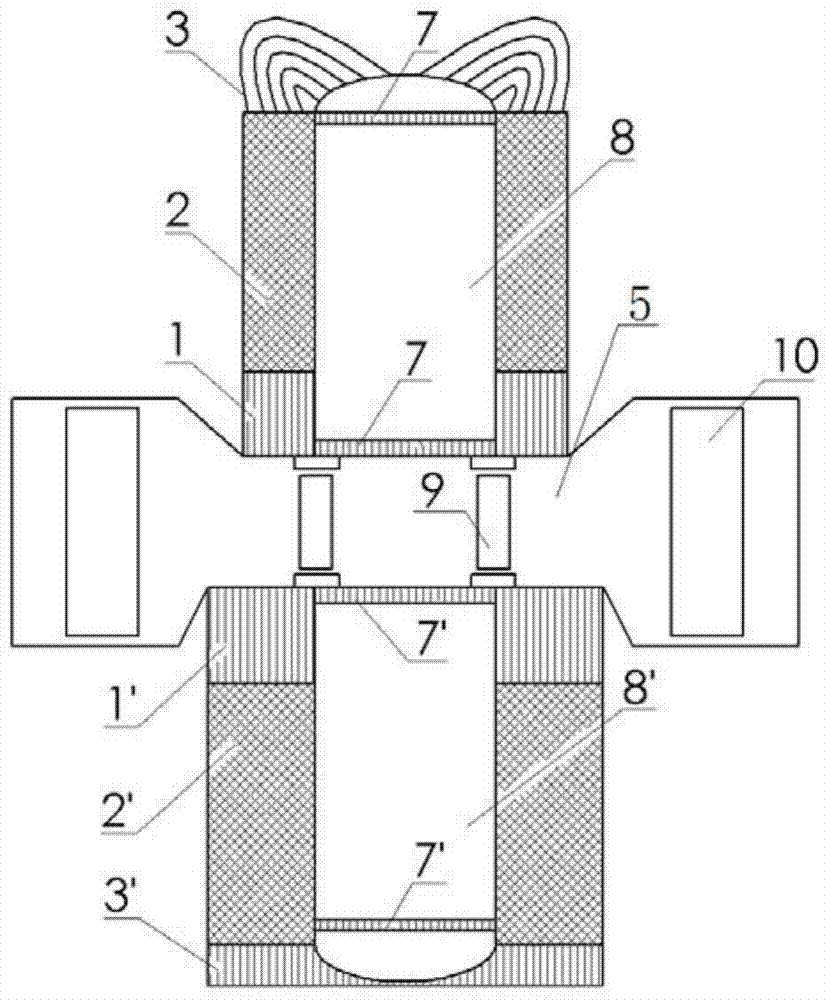

Embodiment 1

[0030] Such as figure 2 As shown, a heat-driven Stirling refrigerator provided by the present invention includes a motor, a refrigerator, an ejector and a vibrator, and the motor includes a hot end heat exchanger 3 connected sequentially from top to bottom, a first circuit The heat exchanger 2 and the first room temperature heat exchanger 1, the refrigerator includes a second room temperature heat exchanger 1', a second heat regenerator 2' and a cold end heat exchanger 3' connected in sequence from top to bottom, so The engine is provided with a first heat buffer chamber 8, the refrigerator is provided with a second heat buffer chamber 8', and the upper end of the first heat buffer chamber 8 is connected to the hot end heat exchanger 3 , the lower end of which is connected to the first room temperature heat exchanger 1 for transitioning the high temperature state at the end of the hot end heat exchanger 3 to room temperature; the lower end of the second thermal buffer chamber...

Embodiment 2

[0035] Such as Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the resonator 6 can be replaced by a linear motor, and the cavity 5 is respectively provided with a linear motor on the outside of the two first piston bodies 9, so The linear motor includes a stator 12, a mover 13 and a piston 14, the stator 12 is fixedly connected to the inner wall of the cavity 5, the piston 14 is arranged at the opposite end of the mover 13 to the first piston body 9, and the mover 13 is used to drive the piston 14 to reciprocate along the stator 12. The mover 13 and the piston 14 can be used as the harmonic oscillator 6; In this embodiment, the system can output electric energy and cooling energy to the outside at the same time, which is of great practical value in occasions where electric power is scarce.

Embodiment 3

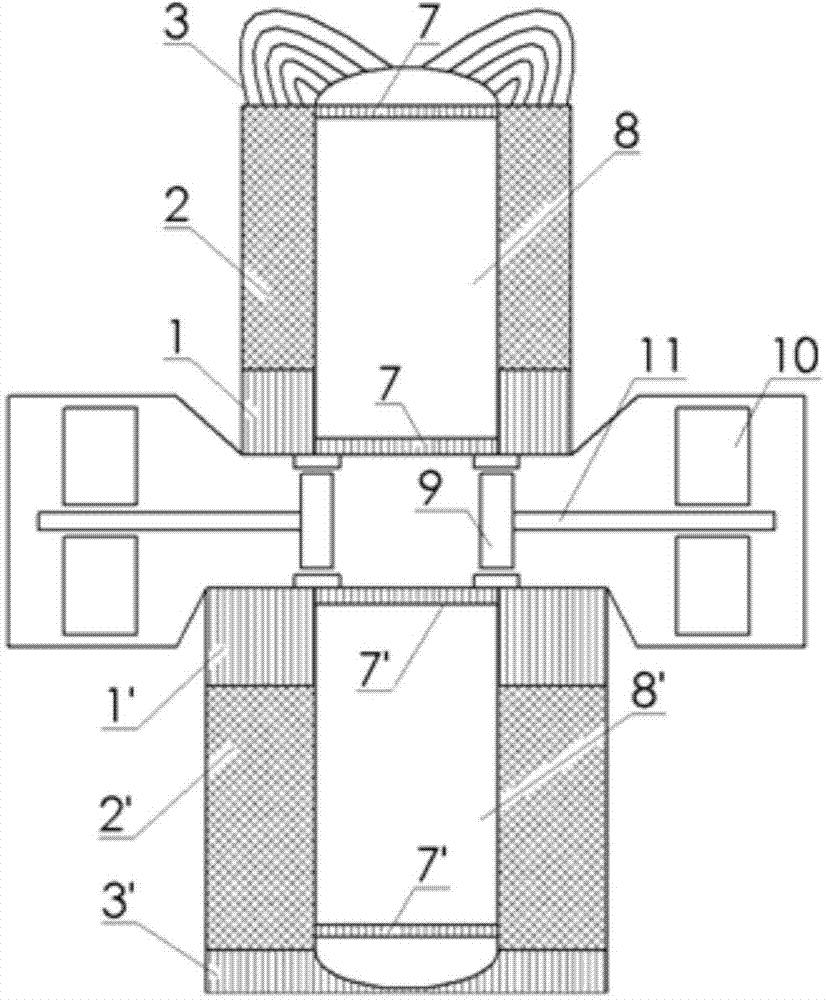

[0037] Such as image 3 As shown, the difference between the third embodiment and the first and second embodiments is that the opposite end of the first piston body 9 to the second piston body 10 or the piston 14 can be horizontally connected with a connecting rod 11, and the second piston body 10 or piston 14 are provided with the central through hole that passes described connecting rod 11, and connecting rod 11 passes central through hole, and like this, the area of first piston body 9 and second piston body 10 or piston 14 two ends is different, has This helps to reduce the stiffness of the spring required to support the reciprocating movement of the second piston body 10 or piston 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com