Patents

Literature

182 results about "Helium mass spectrometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A helium mass spectrometer is an instrument commonly used to detect and locate small leaks. It was initially developed in the Manhattan Project during World War II to find extremely small leaks in the gas diffusion process of uranium enrichment plants. It typically uses a vacuum chamber in which a sealed container filled with helium is placed. Helium leaks out of the container, and the rate of the leak is detected by a mass spectrometer.

Method and device for detecting leakage of shell type heat exchanger

InactiveCN101408466AImprove detection accuracyImprove detection efficiencyFluid-tightness measurement using fluid/vacuumPlate heat exchangerShell and tube heat exchanger

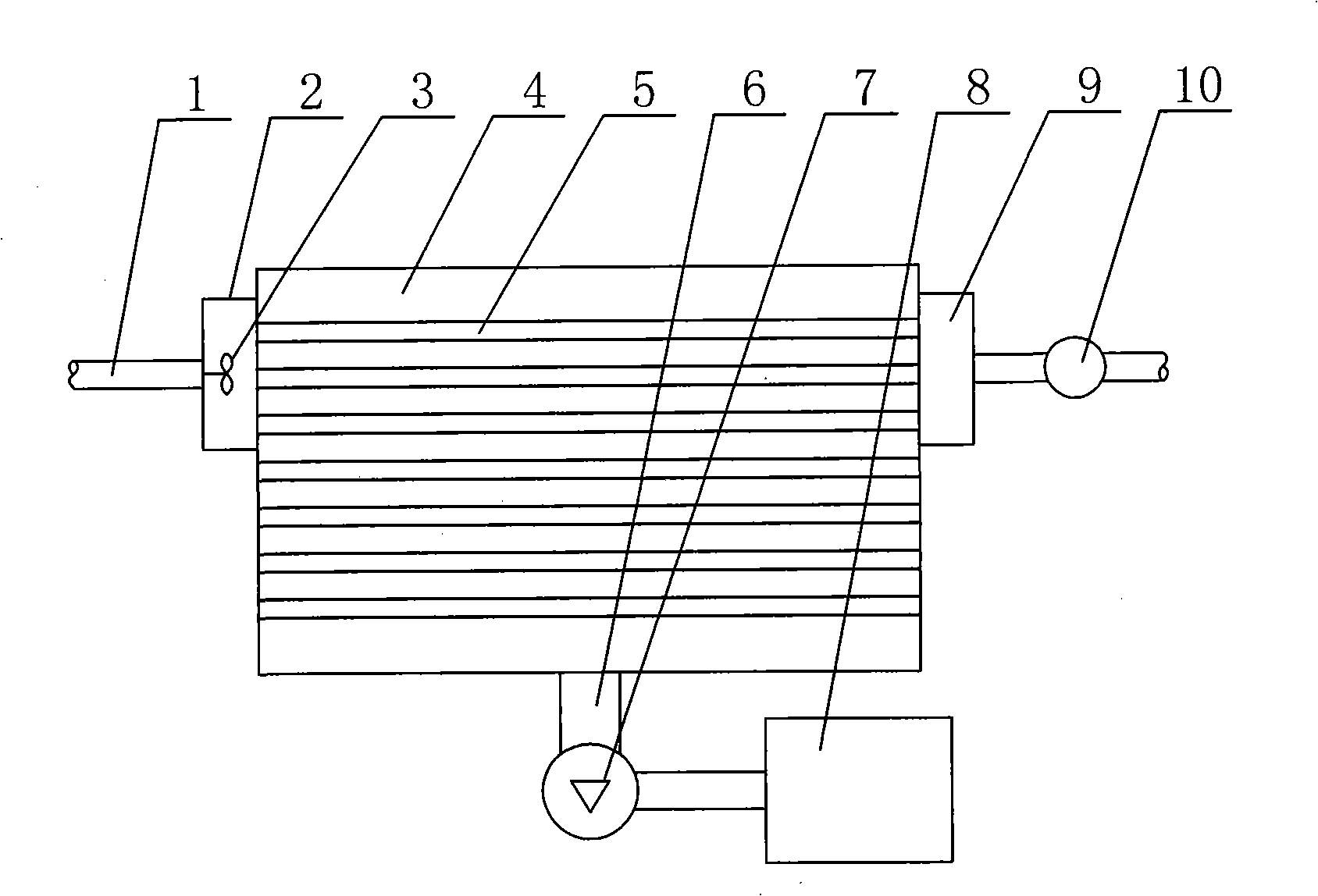

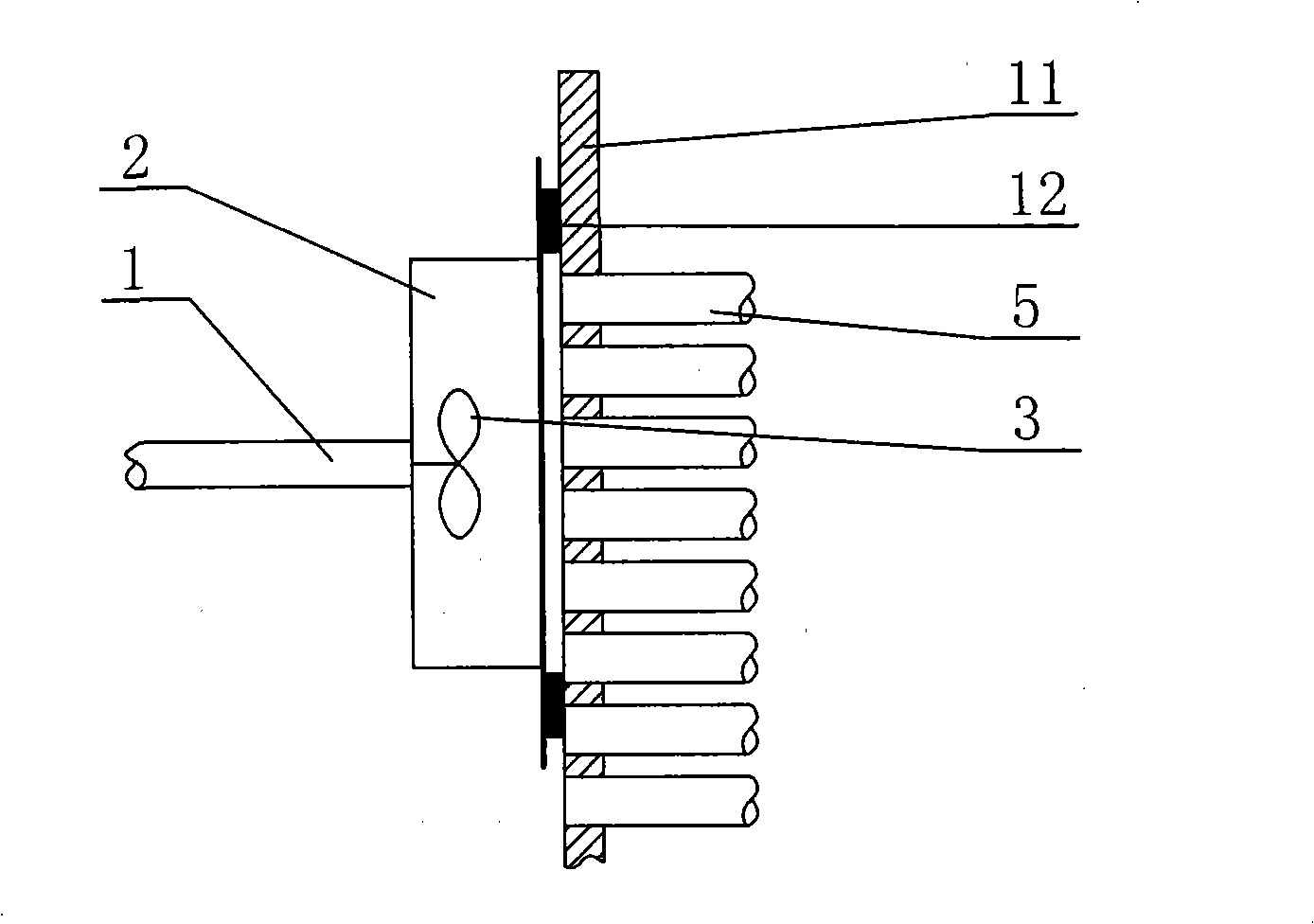

The invention relates to a detection method and a device thereof, in particular to a leak detection method for a shell-and-tube heat exchanger and a device thereof. The detection device comprises a helium mass spectrometer leak detector and a vacuum pump, and is characterized in that an air inlet tube is arranged on an air intake hood which is hermetically connected with one end of the shell-and-tube heat exchanger, an exhaust hood is hermetically arranged on the other end of the shell-and-tube heat exchanger and is equipped with an exhaust tube on the exhaust hood, a vacuum pump clearance tube is arranged on the outer shell of the shell-and-tube heat exchanger, and an air inlet of the helium mass spectrometer leak detector is communicated with the outlet of the vacuum pump. The detection device can lock the leak situations of all the detected shells and tubes in the air intake hood and the exhaust hood which are respectively arranged on the shell-and-tube heat exchanger at one time, and can accurately determine the leaking shells and tubes by replacing hoods of different specifications, thus greatly enhancing the detection efficiency and lightening the labor intensity. Meanwhile, the helium mass spectrometer leak detector is used, thus enhancing the detection precision of the device and eliminates the external interference.

Owner:宁夏电力科技教育工程院

Device and method for detecting whole satellite leak rate of satellite

ActiveCN102721515ASolve the problem of leak rate accuracyShorten the leak detection cycleDetection of fluid at leakage pointData acquisitionEngineering

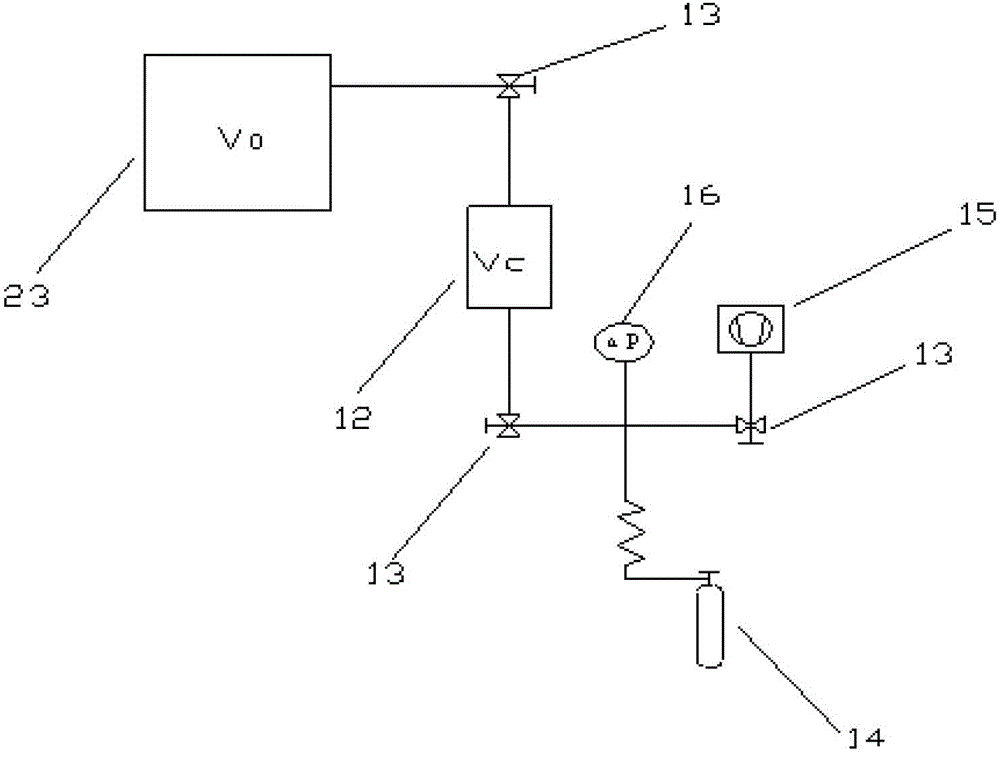

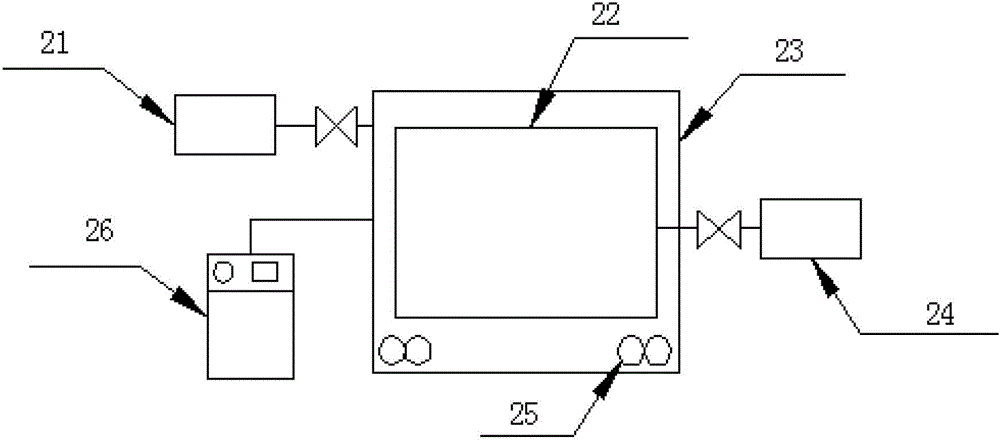

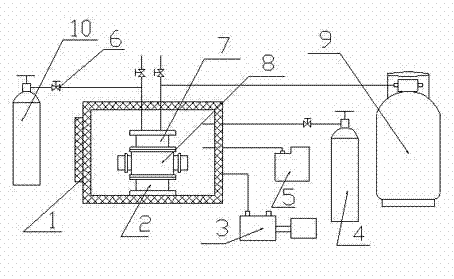

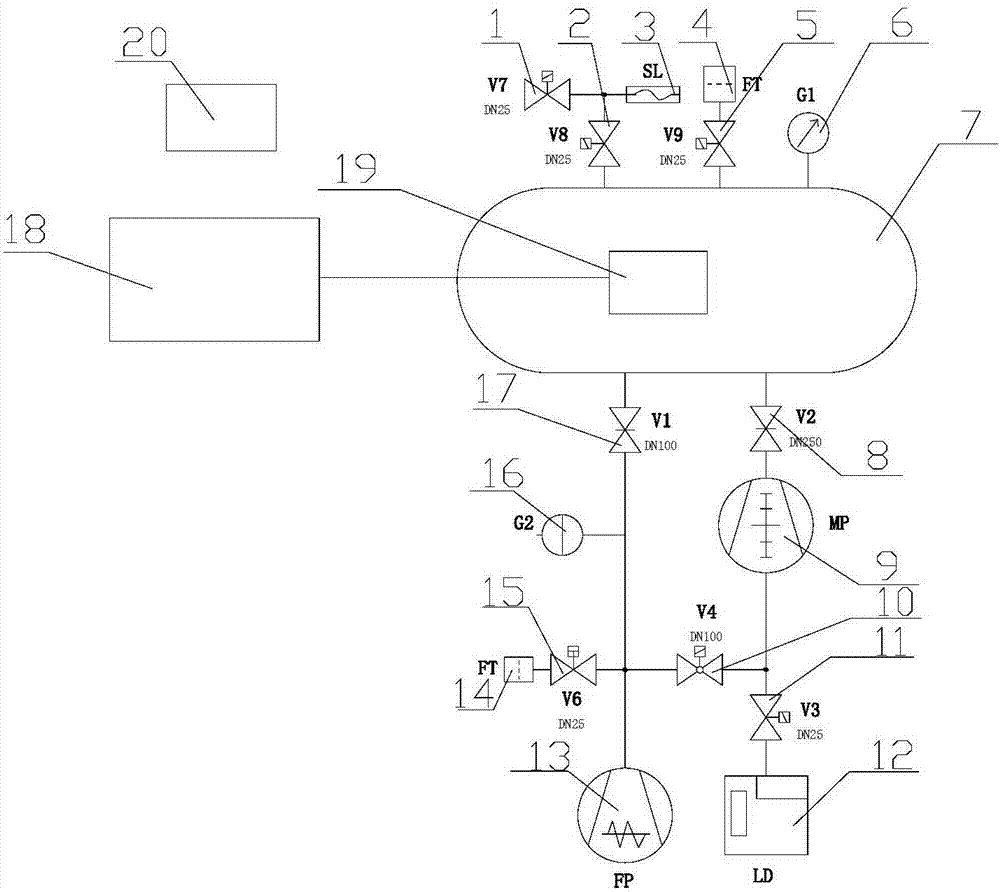

The invention discloses a device and a method for detecting a whole satellite leak rate of a satellite. The device comprises a leak-detecting gas collection tank, a calibration device, a gas charging and discharging device, a circulating fan and a helium mass spectrometer leak detector, wherein the satellite is arranged inside the leak-detecting gas collection tank; the leak-detecting gas collection tank is respectively connected with the calibration device and the gas charging and discharging device through manual fine-tuning vacuum valves; the helium mass spectrometer leak detector is connected to the leak-detecting gas collection tank; and the circulating fan is arranged in the leak-detecting gas collection tank. The whole satellite leak rate of the satellite can be acquired through calibration, residual helium clearing, accumulating data acquisition and data processing. By the device and the method, the whole satellite leak rate of the satellite can be obtained, the requirement of satellite in-orbit operation reliability on the whole satellite leak rate is met, and the advantages of improving the reliability of detecting data, shortening the time for detecting the satellite leak rate, reducing test cost and the like are acquired.

Owner:SHANGHAI YUDA IND

Cavity product airtightness detection table and detection method

ActiveCN105890849ASatisfy the sealing test requirementsImprove leak detection efficiencyDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention provides a cavity product airtightness detection table and a detection method. The cavity product airtightness detection table comprises a helium source, a helium mass spectrometer leak detector and a sealing device, wherein a hollow cavity for mounting a to-be-detected product is formed in the sealing device; the hollow cavity is divided by the to-be-detected product into a first sealing cavity and a second sealing cavity independent of each other; the first sealing cavity is communicated with an inner cavity of the to-be-detected product; the to-be-detected product is positioned in the second sealing cavity; the helium source is communicated with the first sealing cavity through an intake duct; and the helium mass spectrometer leak detector is communicated with the second sealing cavity through an exhaust duct. In the invention, the helium is introduced into the first sealing cavity through the helium source; and based on the characteristics of small molecular weight and excellent penetrability of the helium, the gas in the second sealing cavity is subjected to exhaust detection by the helium mass spectrometer leak detector to obtain a leakage rate detection result of the to-be-detected product, the airtightness detection accuracy is high, and the detection result is accurate and reliable.

Owner:MIANYANG FULIN PRECISION MACHINING

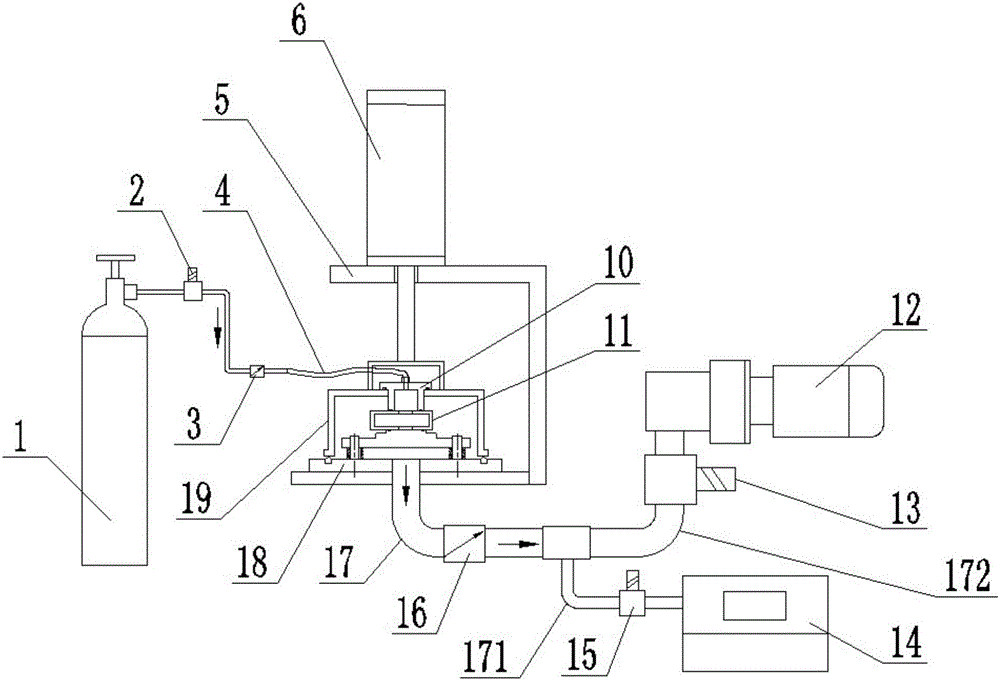

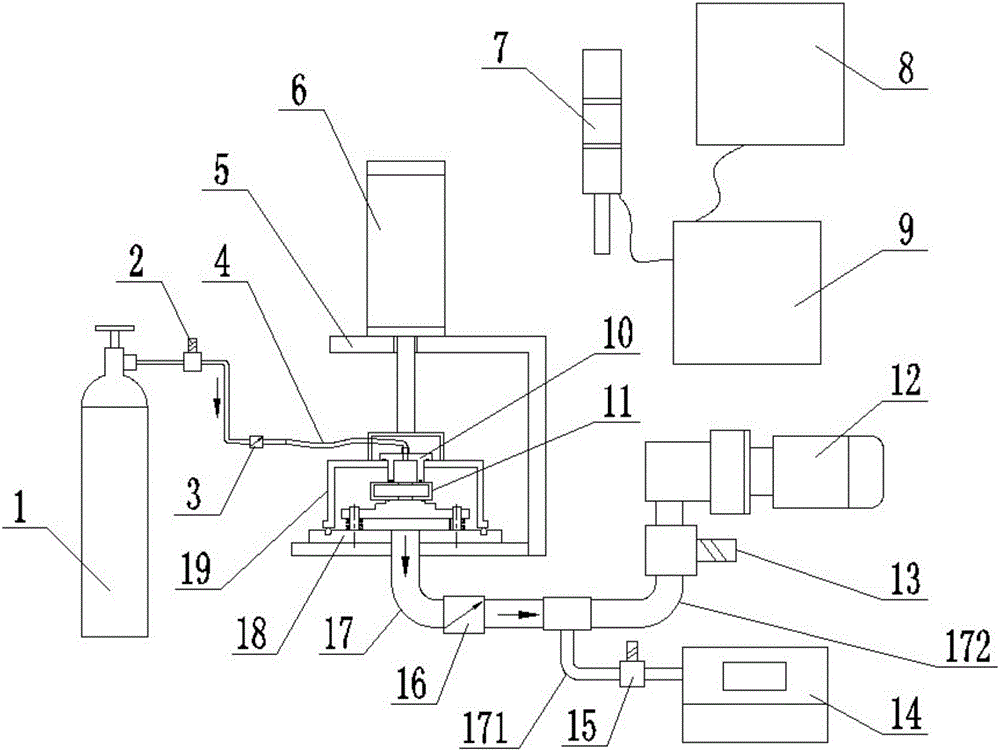

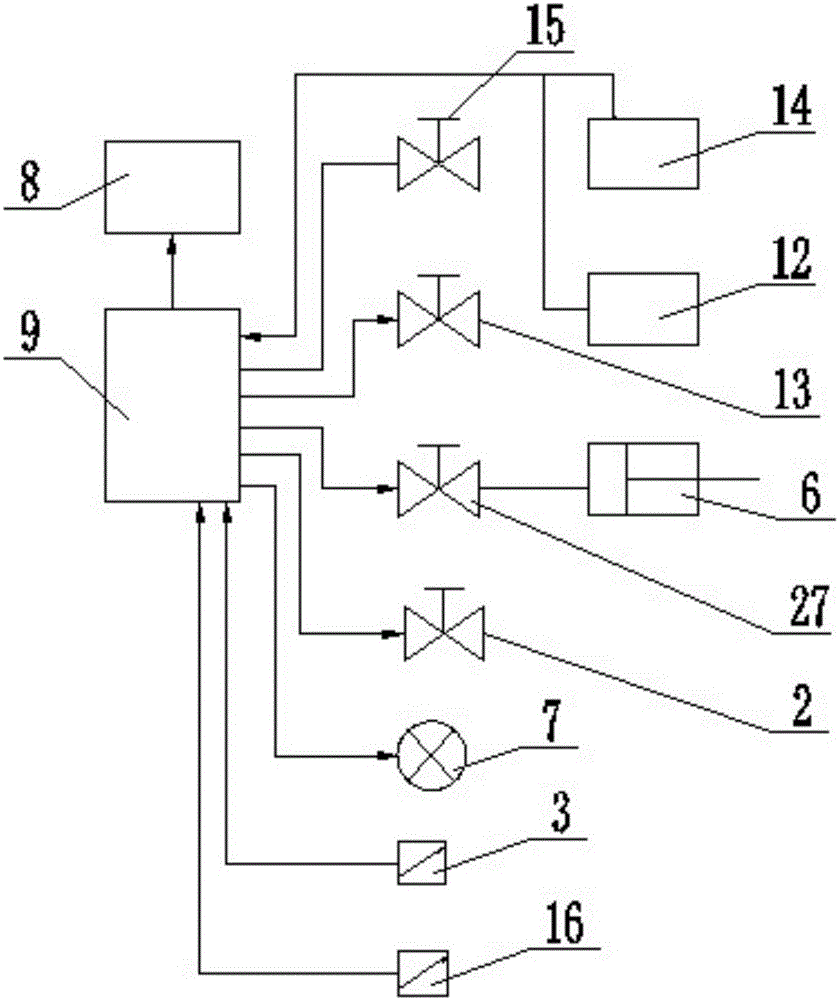

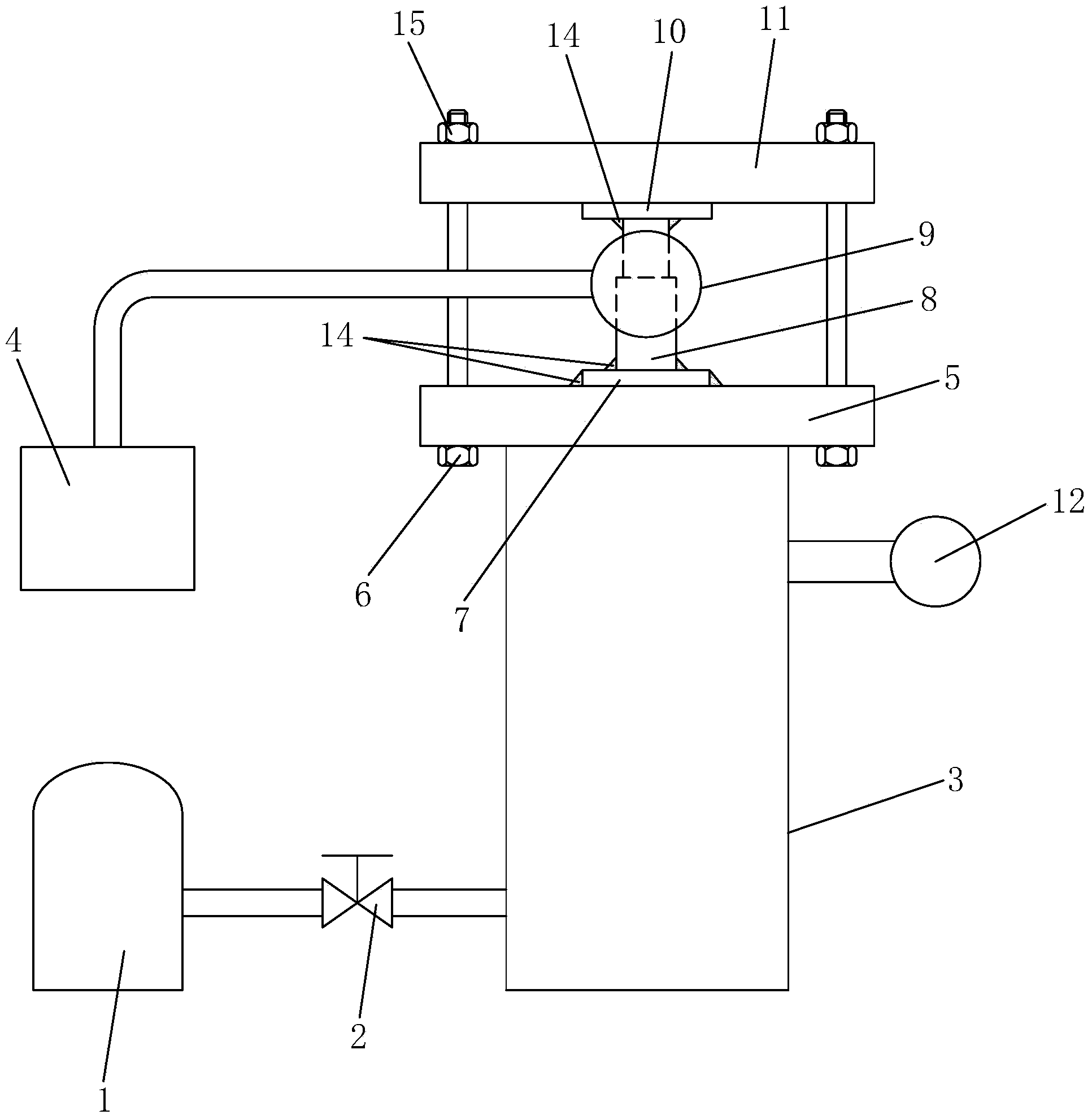

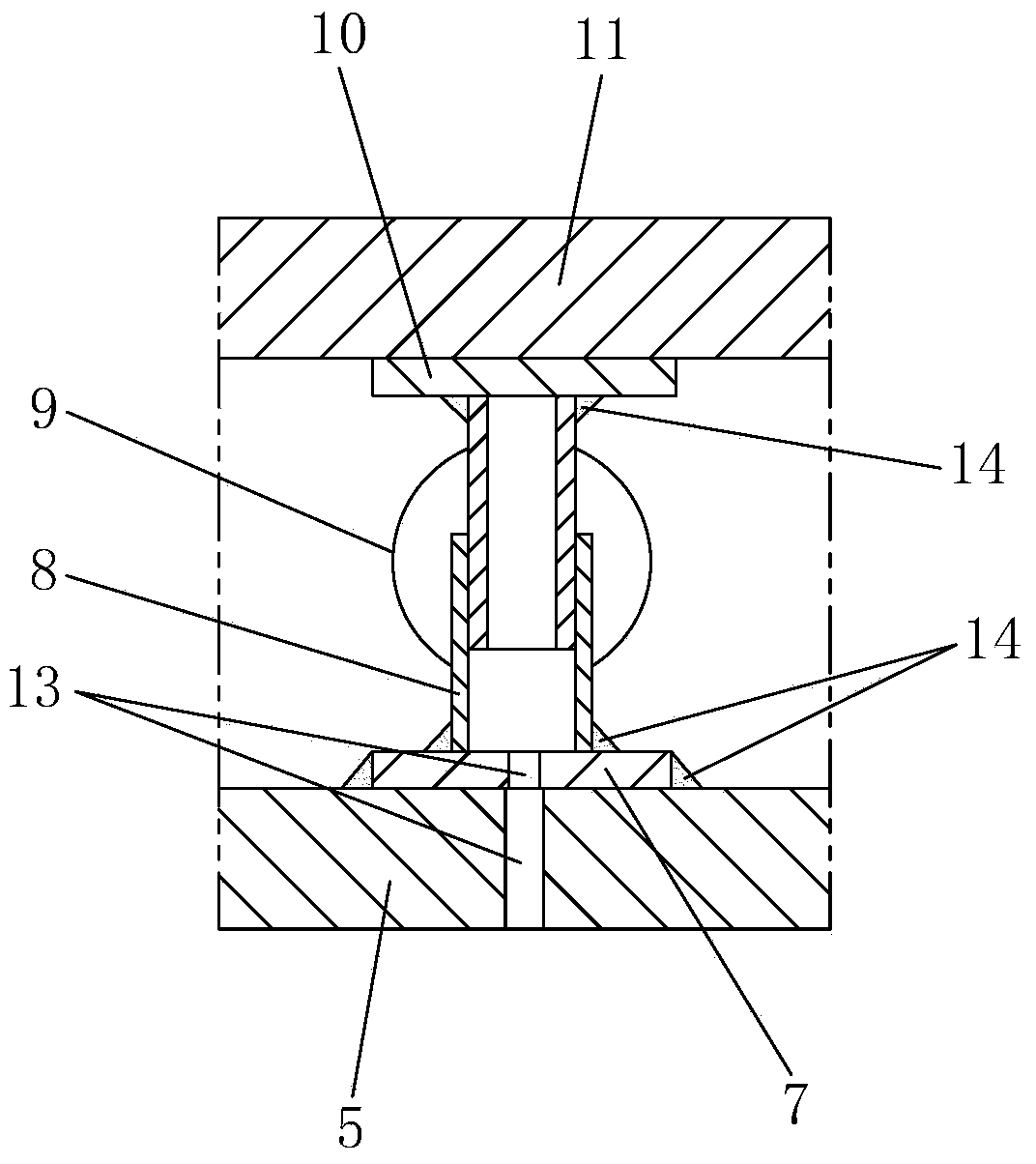

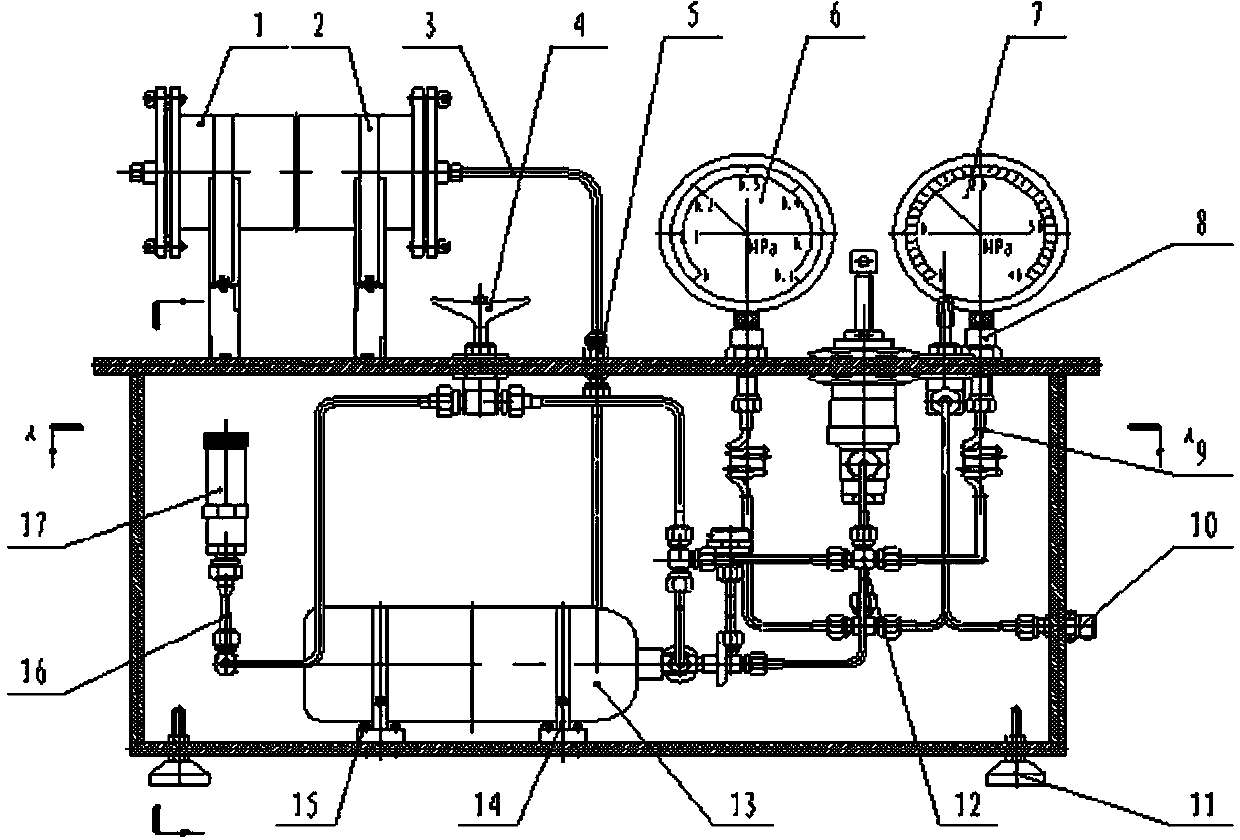

Accumulator ultralow-temperature leak test device and method

ActiveCN104713684AUltra-low temperature leak detection is convenientDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention provides an accumulator ultralow-temperature leak test device and method. The device is mainly composed of a vacuum leak test box for containing an accumulator, a liquid nitrogen low-temperature dewar flask connected with the vacuum leak test box through a pipe with a stop valve, a helium cylinder, a nitrogen cylinder, a vacuum pump, a compressed air source, a pressure gauge located in the vacuum leak test box, a temperature sensor, a sealing tool for vertically sealing the accumulator, a glove operation connector located on a box body and the like. The sealing tool is provided with three holes, namely a liquid nitrogen injection opening, a liquid nitrogen discharge opening and a helium injection opening, and the three holes are connected into the external liquid nitrogen low-temperature dewar flask, a safety discharge region and the helium cylinder through inside-outside connection pipes of the vacuum leak test box respectively. Furthermore, the vacuum leak test box is further provided with a helium mass spectrometer access opening, one end of the helium mass spectrometer access opening is connected with an external helium mass spectrometer, and the other end of the helium mass spectrometer access opening is located in a suction cavity in the helium mass spectrometer. By means of the accumulator ultralow-temperature leak test device, ultralow-temperature leak test can be conducted on the accumulator conveniently.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

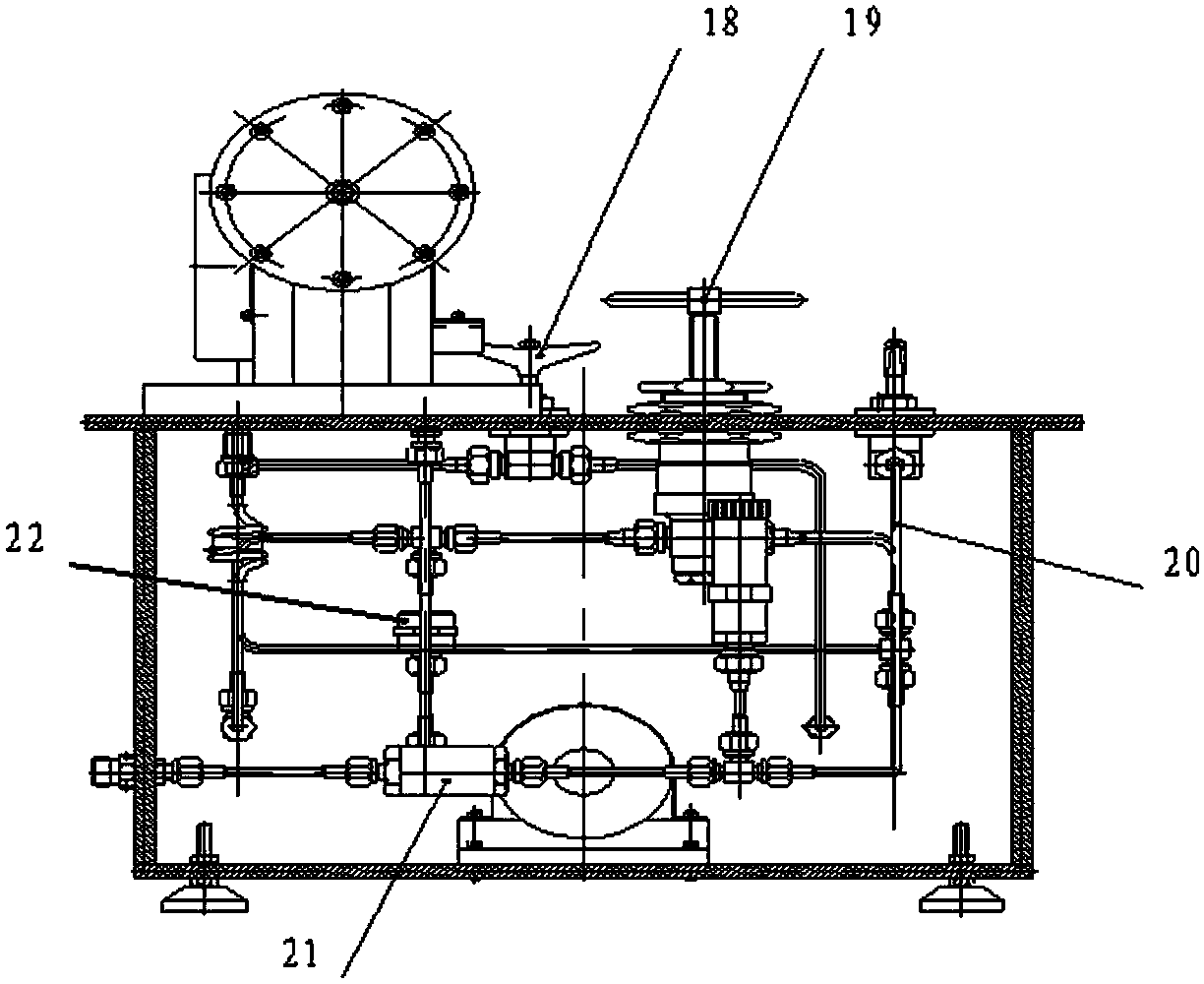

High-temperature and high-pressure helium leak quantitative detecting device and high-temperature and high-pressure helium leak quantitative detecting method

InactiveCN109163857AIngenious designRealize accurate quantitative detectionDetection of fluid at leakage pointEngineeringHigh pressure

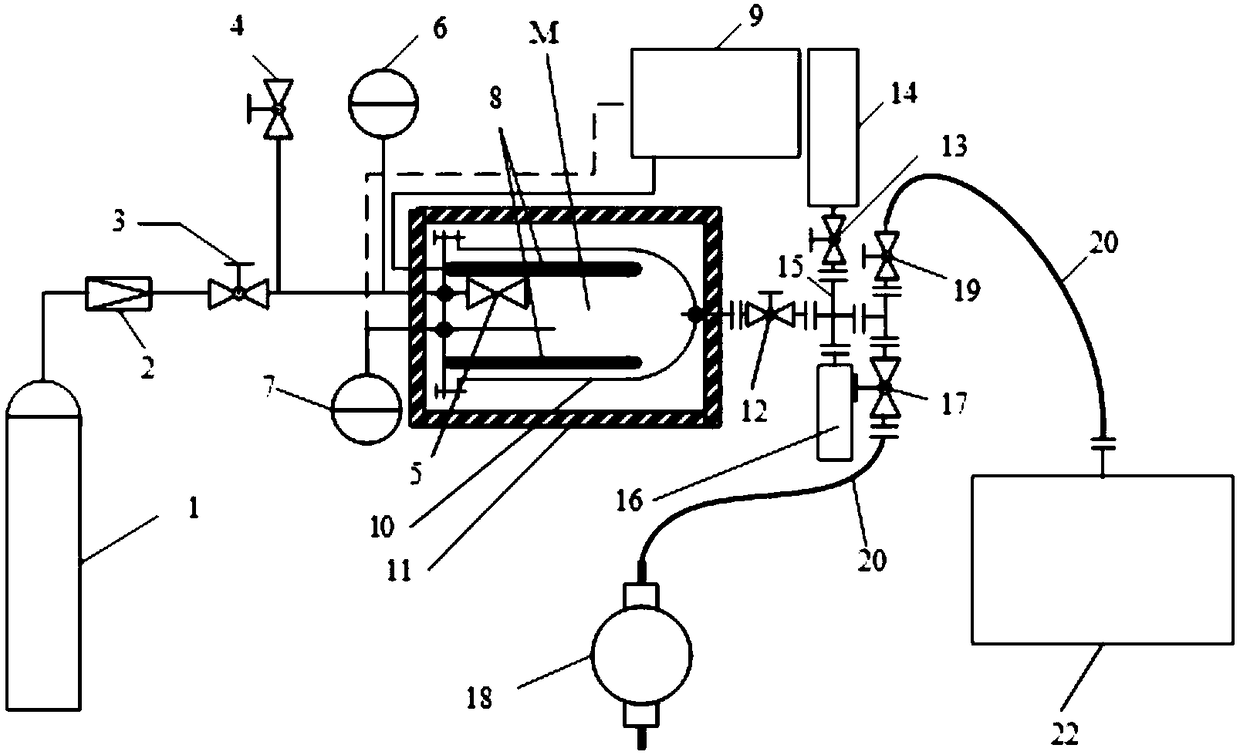

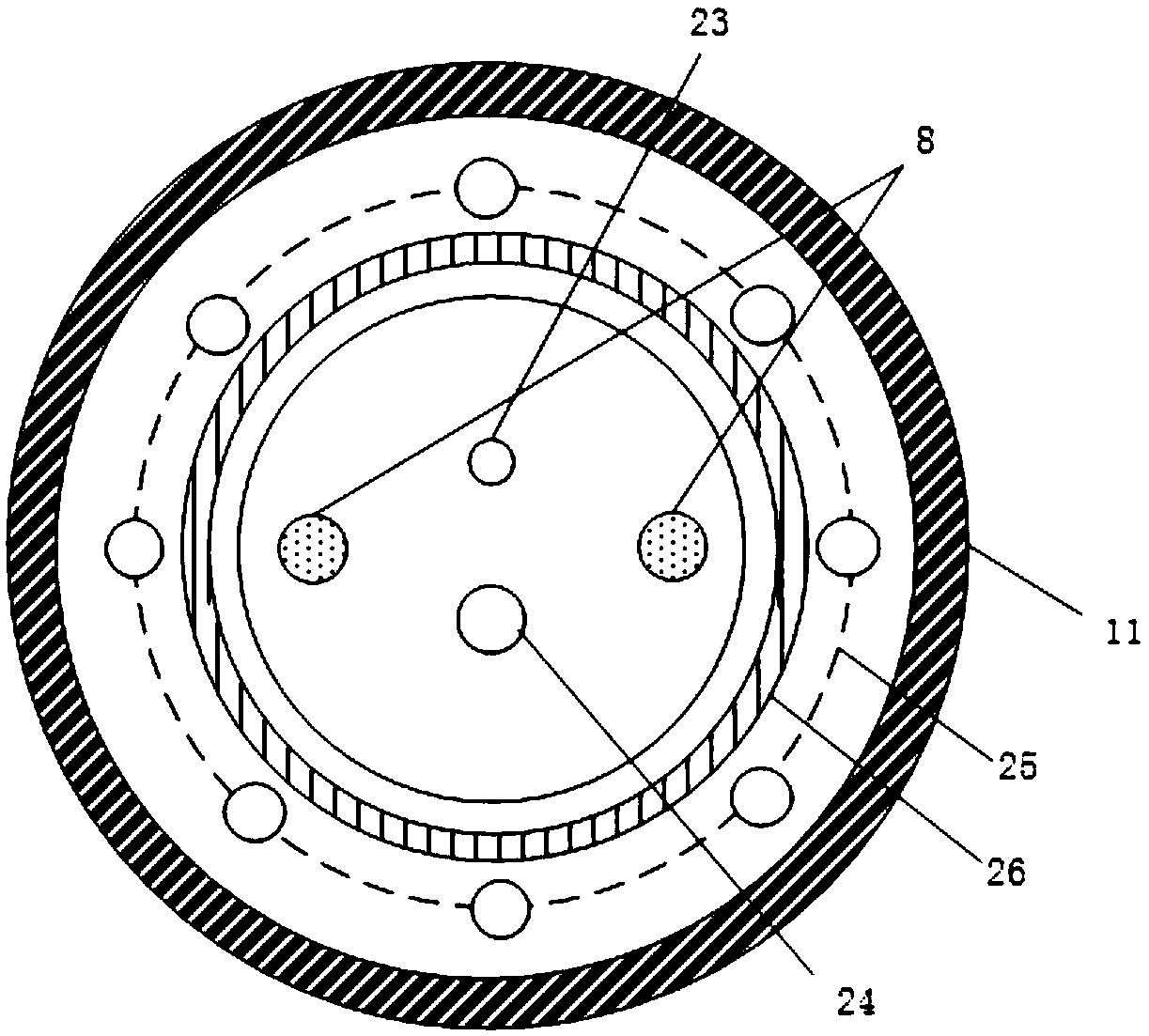

The invention discloses a helium leak quantitative detecting device, comprising the following components: a sealing cavity (M), wherein an electric heating rod (8), a thermocouple (7), a helium filling pipe (23), and sealing equipment (5) to be detected are provided in the sealing cavity (M); the helium filling pipe (23) is connected to a helium source (1) outside the sealing cavity (M), and is internally connected to the sealing equipment (5) to be detected; and a vacuum pump (18) and a helium mass spectrometer leak detector (22) are in communication with the sealing cavity (M) through a vacuum tube (20). The invention also discloses a helium leak quantitative detecting method using the detecting device. The invention can accurately and quantitatively detect the helium leakage rate of thesealing equipment to be detected under high temperature and high pressure.

Owner:TSINGHUA UNIV

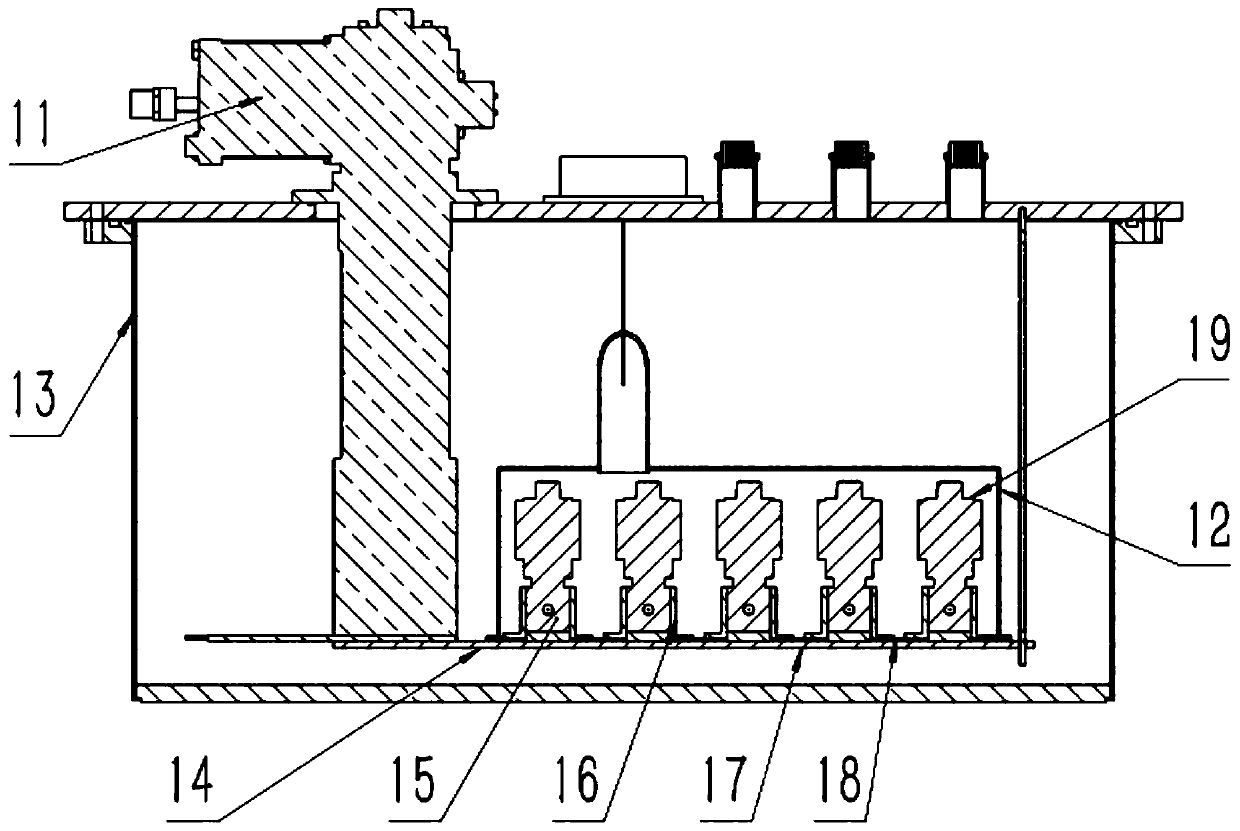

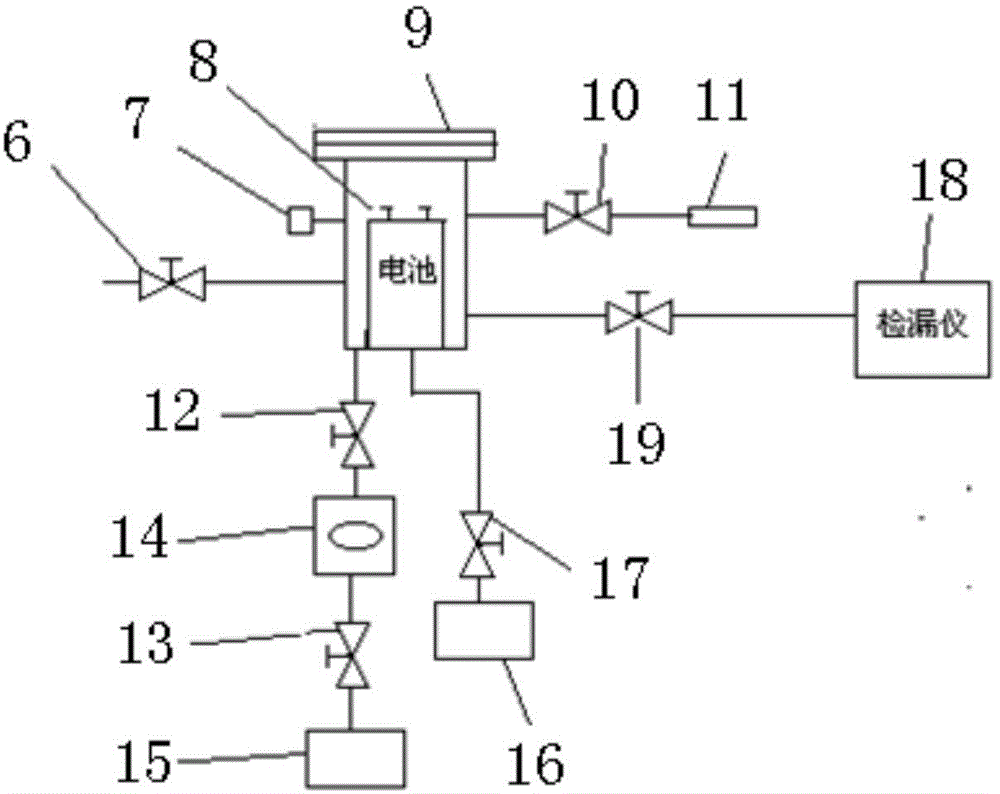

Apparatus and method for detecting sealing performance of battery system cabinet

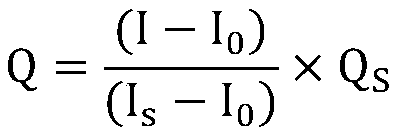

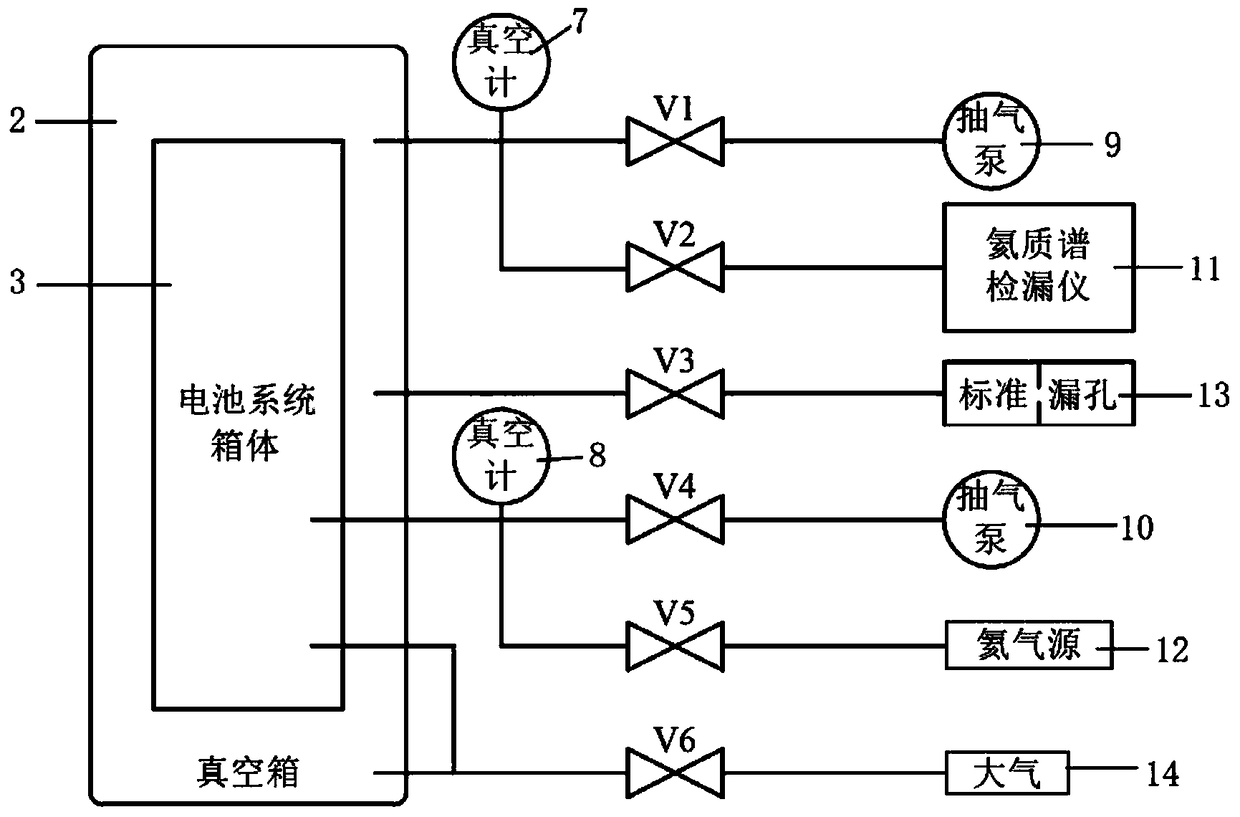

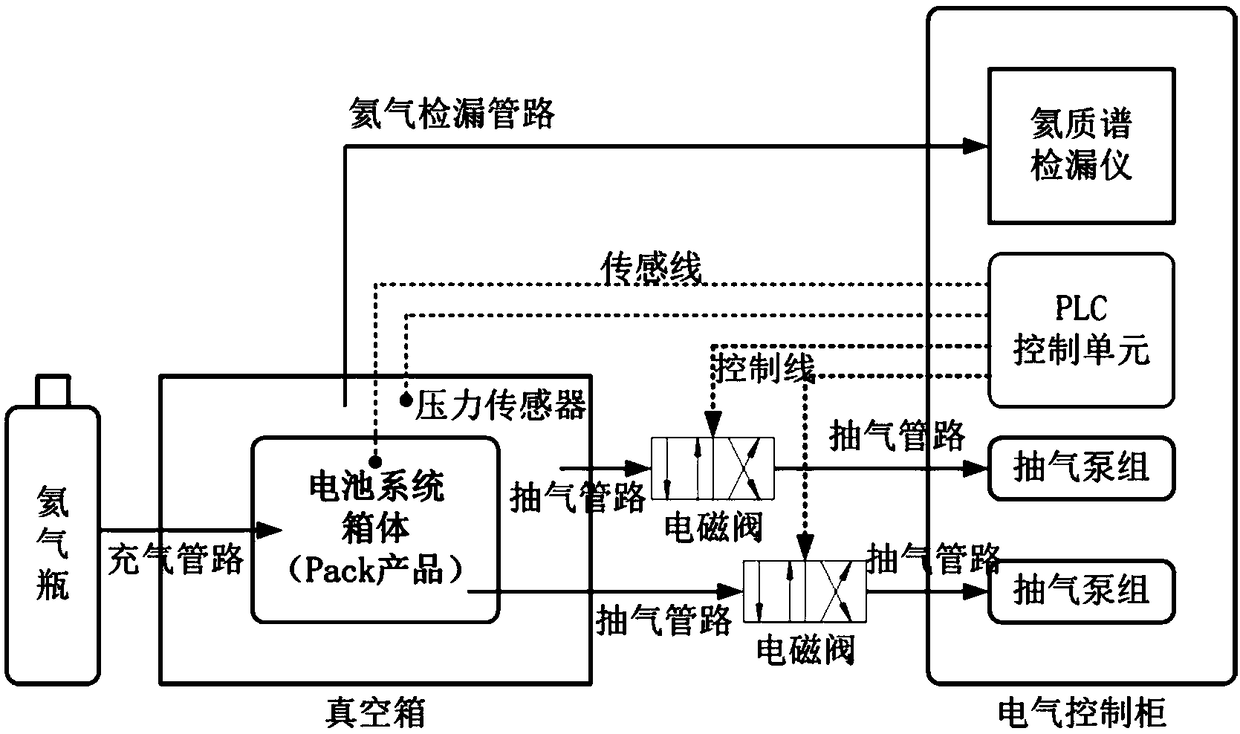

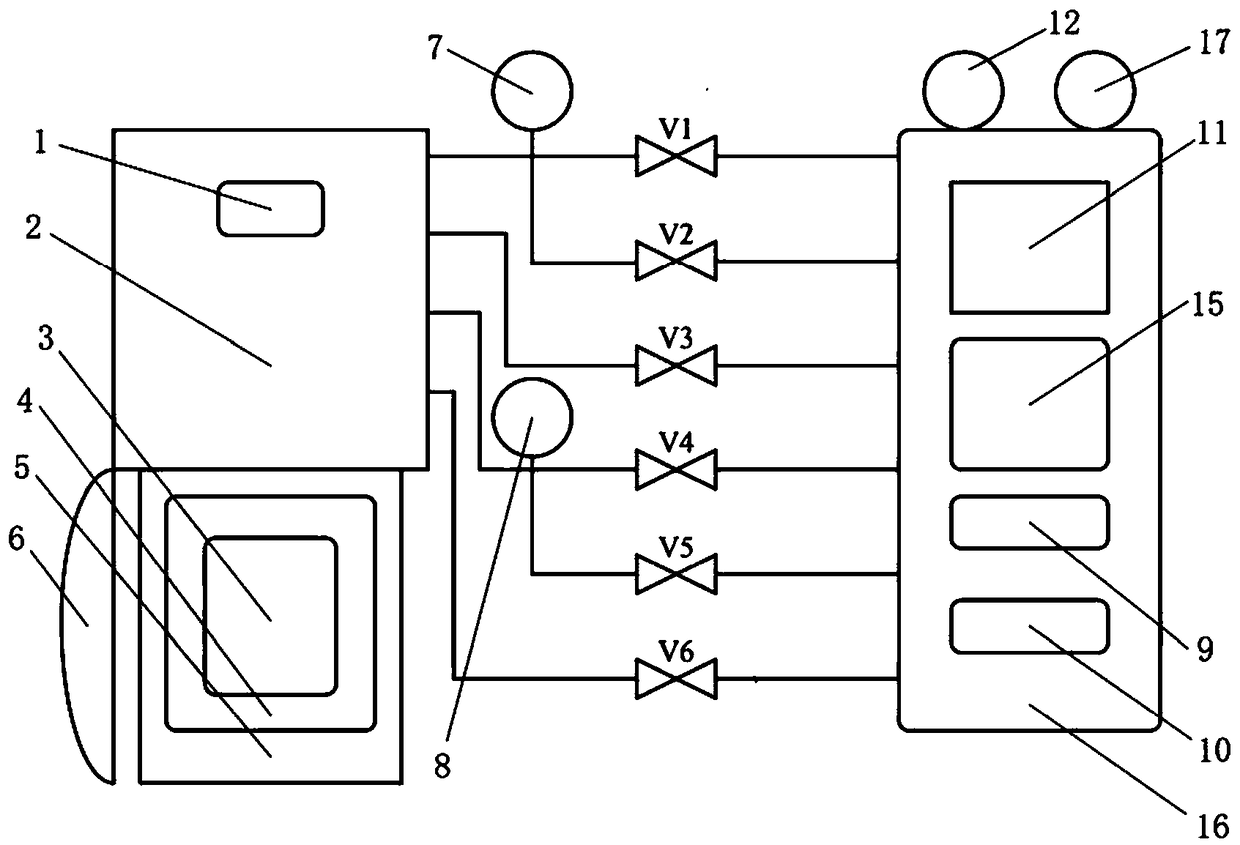

PendingCN109357819AEliminate misjudgmentGuaranteed calibration leak detection quantification accuracyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectrical batterySolenoid valve

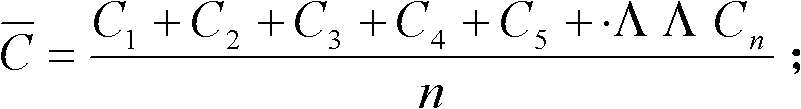

The invention discloses an apparatus and a method for detecting the sealing performance of a battery system box, comprising: a vacuum box, a helium mass spectrometer leak detector, two sets of suctionpumps, and a helium source. The battery system cabinet is arranged in the vacuum box during testing. The helium mass spectrometer leak detector is connected to the vacuum box through the leak detection pipeline. One of the two sets of suction pumps is connected to the vacuum box through the suction line, and the other set is connected to the battery system box through the suction line. The battery system cabinet is connected to the external helium source through the supply line. The battery system cabinet and the vacuum box are respectively connected to the atmosphere through a bleed valve and a relief valve. Pressure sensors are respectively arranged outside the vacuum box and the battery system box. The two pressure sensors are respectively connected to the PLC control unit. The vacuumbox is connected to a standard leak, which is used to calibrate the device. Each pipeline is provided with a solenoid valve, and each solenoid valve is controlled by a PLC control unit. The device cansafely and efficiently detect the sealing performance of the battery system cabinet, and the test accuracy is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Leak detecting method in production of large and medium-sized automobile air conditioner

InactiveCN103175662ARealize online detectionImprove continuityDetection of fluid at leakage pointProduction lineThermodynamics

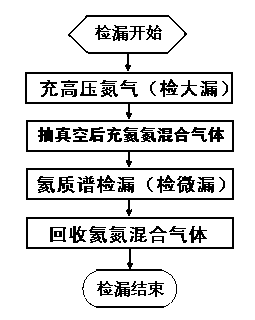

The invention relates to a leak detecting method in production of large and medium-sized automobile air conditioners. The leak detecting method comprises the following steps of: (1) filling high-pressure nitrogen, filling nitrogen into the pipe systems of large and medium-sized automobile air conditioner parts by using a filled helium recovery device so as to enable the gas pressure inside the pipe systems to achieve 2400-2600 kilopascals and enable the pressure holding time to be more than 6 seconds, and detecting large leak; (2) vacuumizing, and then filling helium and nitrogen mixed gas at the gas pressure of 750-850 kilopascals; (3) carrying out helium mass spectrometer leak detection, and carrying out helium mass spectrometer microleak detection on the parts by using a helium mass spectrometer leak detector; and (4) recovering the helium and nitrogen mixed gas, recovering the helium and nitrogen mixed gas inside the pipe systems of the parts by utilizing the filled helium recovery device so as to finish leak detection. According to the leak detecting method disclosed by the invention, overcomes the defect that the pressure needs to be maintained for 8-12 hours in the traditional leak detection by firstly filling the high-pressure nitrogen for the large leak detection of the large and medium-sized automobile air conditioner parts and then filling the helium and nitrogen mixed gas for the microleak detection of the large and medium-sized automobile air conditioner parts, the on-line detection of a production line can be realized, good production continuity is achieved, the leak detection effect is enhanced outstandingly, the product quality is ensured, and the production efficiency is greatly improved.

Owner:XIAMEN SONGZHI AUTOMOBILE AIR CONDITIONER

Method for detecting leak of lithium ion storage battery before liquid injection and sealing

ActiveCN102426082AReduce manufacturing costImprove reliabilityDetection of fluid at leakage pointLithiumEngineering

The invention relates to a method for detecting the leak of a lithium ion storage battery before liquid injection and sealing. The method comprises the following steps that: one end of a connecting cavity is connected to a quickly-locking flange of a helium mass-spectrometer leak detector, and the other end of the connecting cavity is connected to a liquid injection opening of the battery in a sealing manner before the liquid injection and the sealing; and the helium mass-spectrometer leak detector vacuums the inside of the battery through the liquid injection opening of the battery to detect large leak and small leak of the battery until the battery is completely positioned in a qualified sealing state. In the method, the helium mass-spectrometer leak detector vacuums the inside of the battery before the liquid injection and the sealing of the battery, so that the large leak can be detected; when the large leak of the battery occurs, only the shell is replaced, and a battery cell part with high cost can be continuously used, so that the manufacturing cost of the battery is reduced; a welding part outside the battery is aligned by a helium spray gun for point leak detection; leak rate data automatically occurs on the helium mass-spectrometer leak detector, so that whether the small leak exists at a detected position of the battery is easy to detect; and the small leak is subjected to secondary welding through a laser welding machine, so that the reliability of the battery is improved, and the waste caused by discarded batteries is reduced.

Owner:TIANJIN SPACE POWER TECH CO LTD

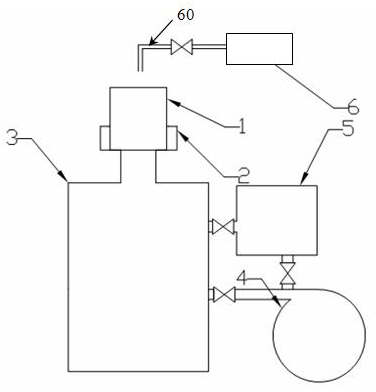

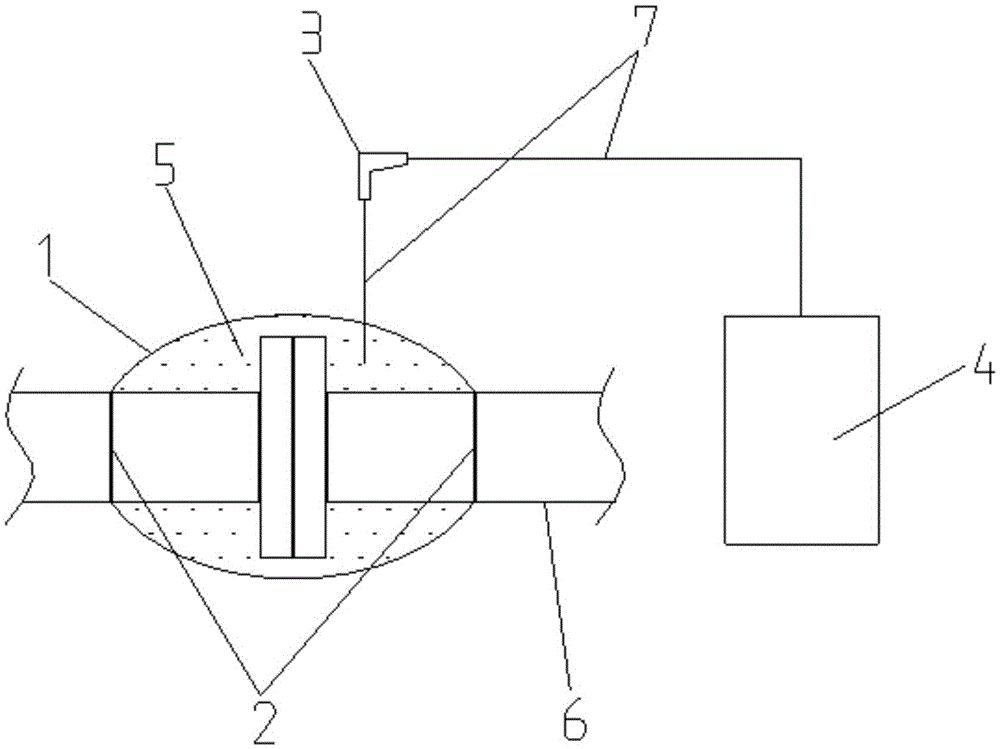

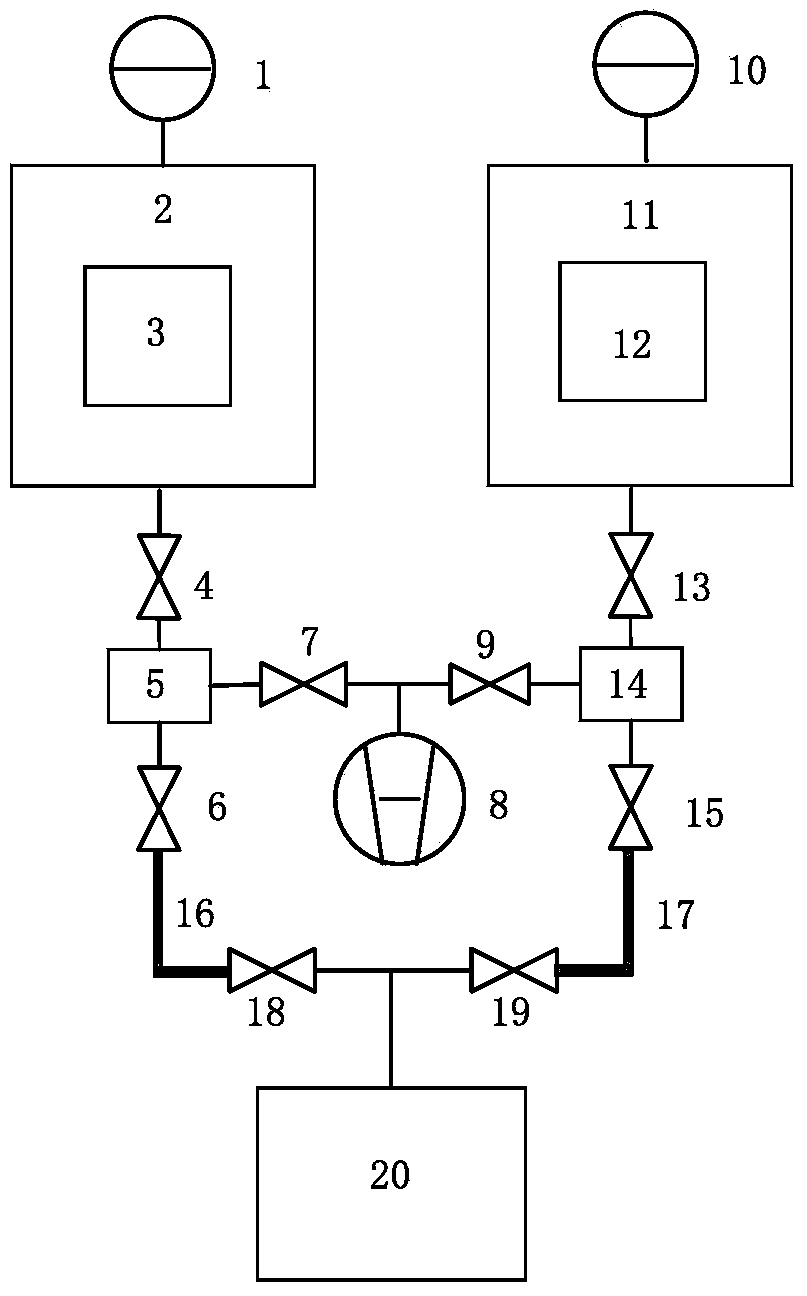

Leak-detecting device of super capacitor

InactiveCN102095557ASatisfy the sealing test requirementsImprove detection efficiencyDetection of fluid at leakage pointSupercapacitorEngineering

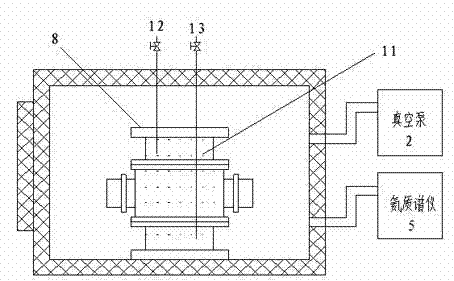

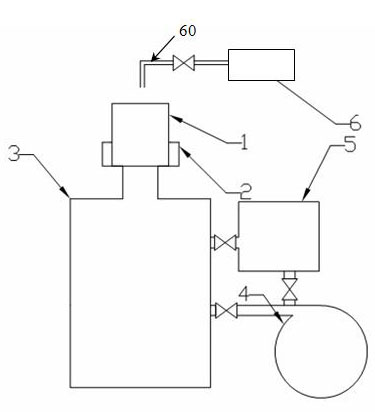

The invention discloses a leak-detecting device of a super capacitor, comprising a leak-detecting cavity (3), wherein the top opening of the leak-detecting cavity (3) is communicated with a super capacitor (1); the upper end and the lower end of the right side wall of the leak detection cavity (3) are respectively communicated with a helium mass spectrometer (5) and a vacuum pump (4); an air blow pipe (60) is arranged above the super capacitor (1); and the air blow pipe (60) is communicated with a helium source (6). The leak detection device of a super capacitor, which is disclosed by the invention, has the advantages of higher measuring precision and wider measuring range and is favourable for improving detection efficiency for the super capacitor, the tightness detection requirements of the super capacitor can be satisfied, the whole production efficiency of the super capacitor is improved so as to lower production cost, and the leak detection device has a significant production practice meaning.

Owner:TIANJIN LISHEN BATTERY

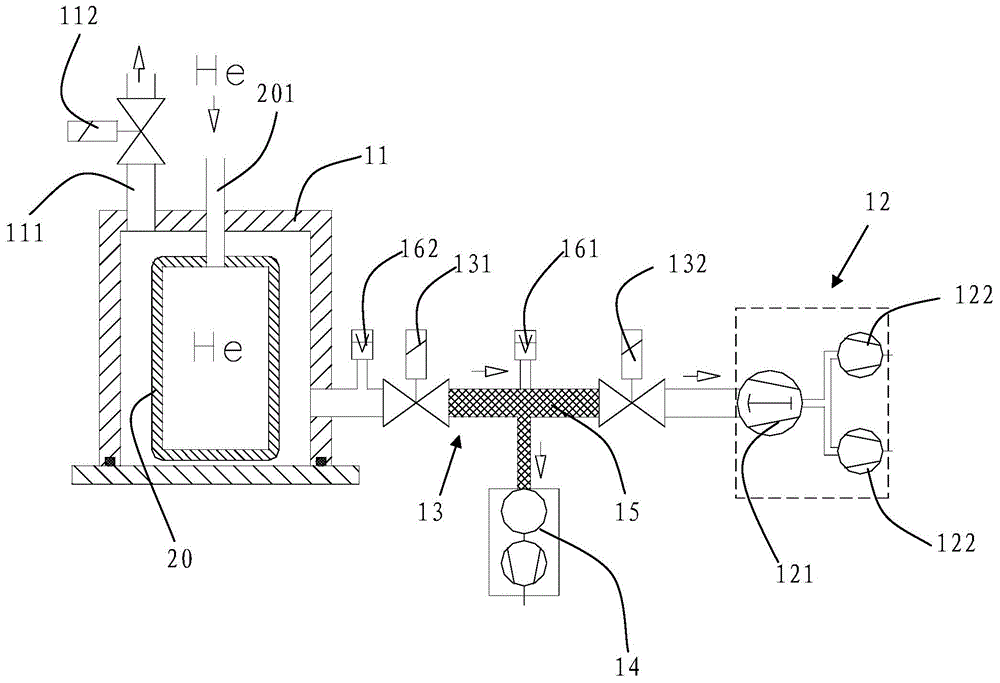

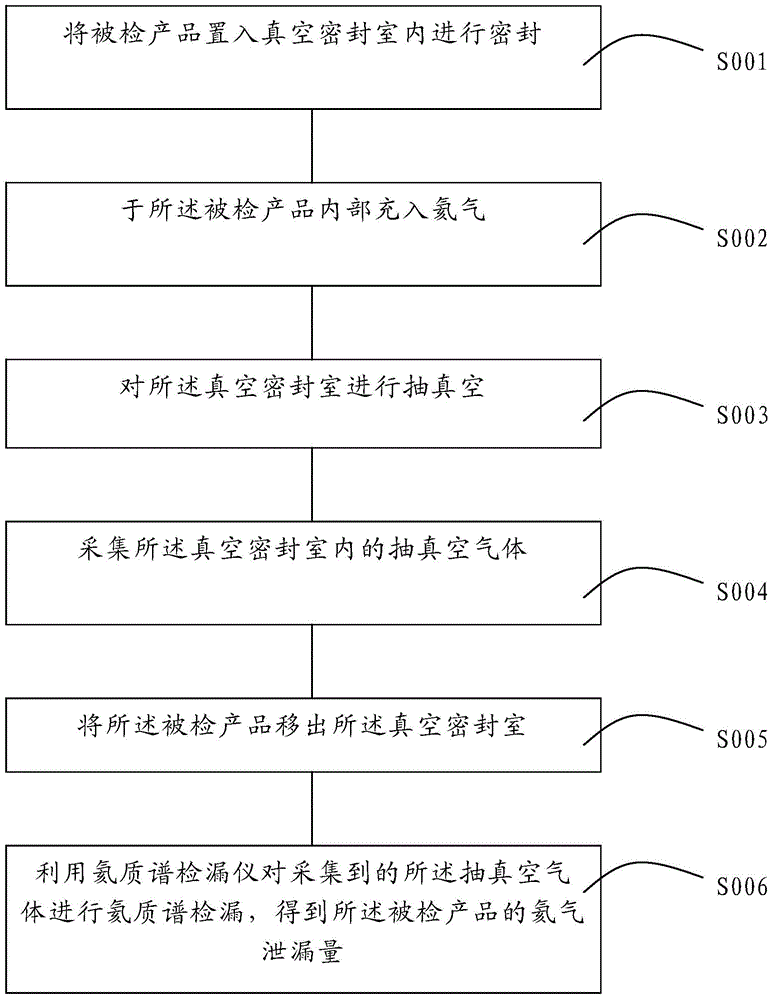

Method and device for interception sampling type helium mass spectrometer leak detection

InactiveCN104568337AHigh detection sensitivityIncrease productivityDetection of fluid at leakage pointEngineeringMass spectrometry

The invention discloses a method and a device for interception sampling type helium mass spectrometer leak detection. The method includes: putting a detected product in a vacuum hermetic chamber; filling helium into the detected product; vacuumizing the vacuum hermetic chamber; collecting vacuumizing gas in the vacuum hermetic chamber; removing the detected product out of the vacuum hermetic chamber; adopting a helium mass spectrometer leak detector for helium mass spectrometer leak detection of the acquired vacuumizing gas. A first shutoff valve and a second shutoff valve are mounted on a vacuumizing pipeline to form an interception section on the vacuumizing pipeline between the first shutoff valve and the second shutoff valve, when the vacuum hermetic chamber reaches a detection vacuum degree, the vacuumizing gas in the vacuum hermetic chamber is intercepted and collected in the interception section by closing the first shutoff valve and the second shutoff valve, and the sampled vacuumizing gas is subjected to leak detection after the detected product is taken away. Since the detected product is separated from a detection system during leak detection, production efficiency is improved, and high-speed online detection on a production line is realized.

Owner:SHANGHAI SIZE AUTOMATION EQUIP

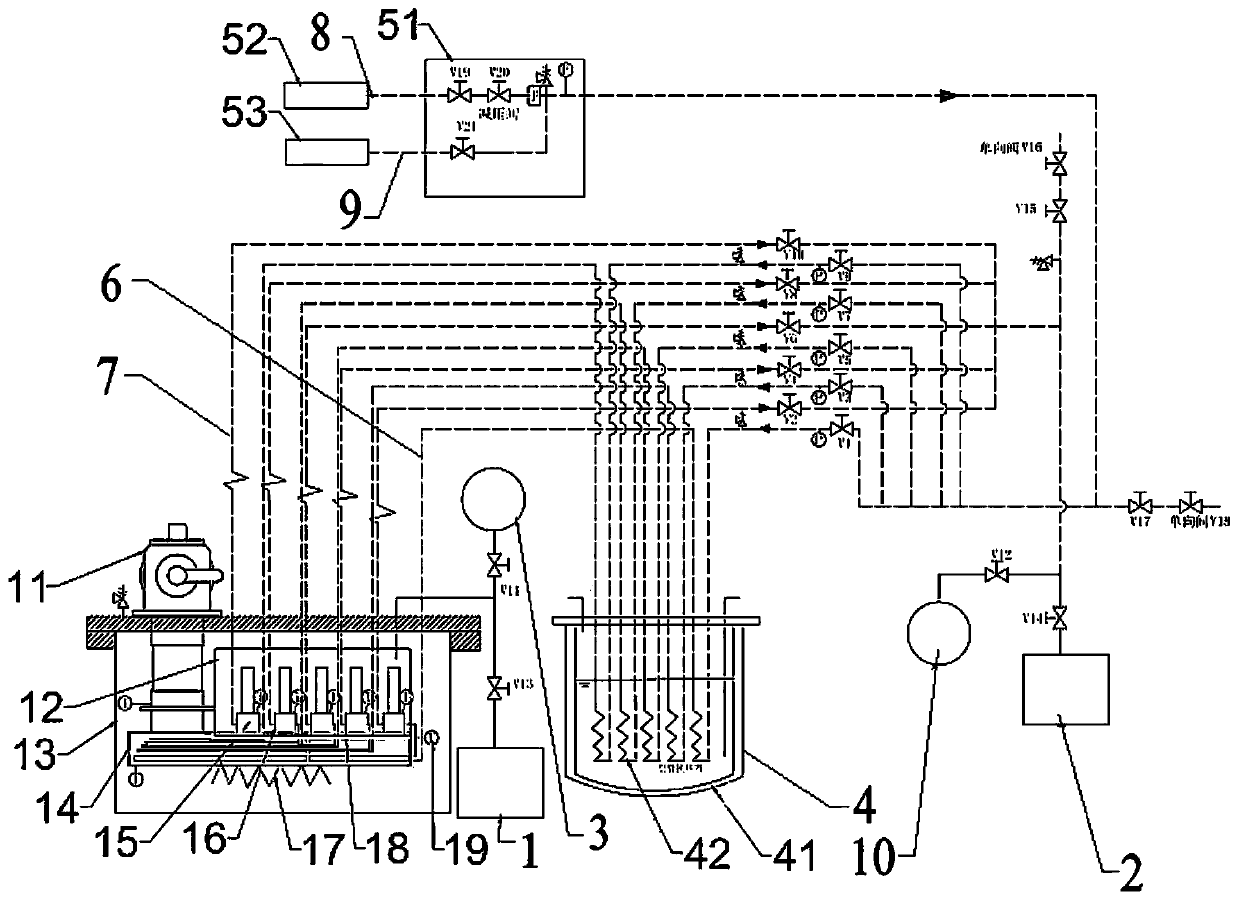

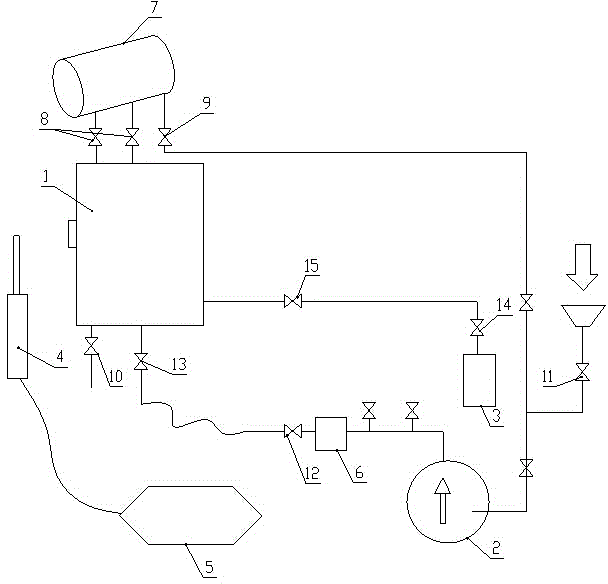

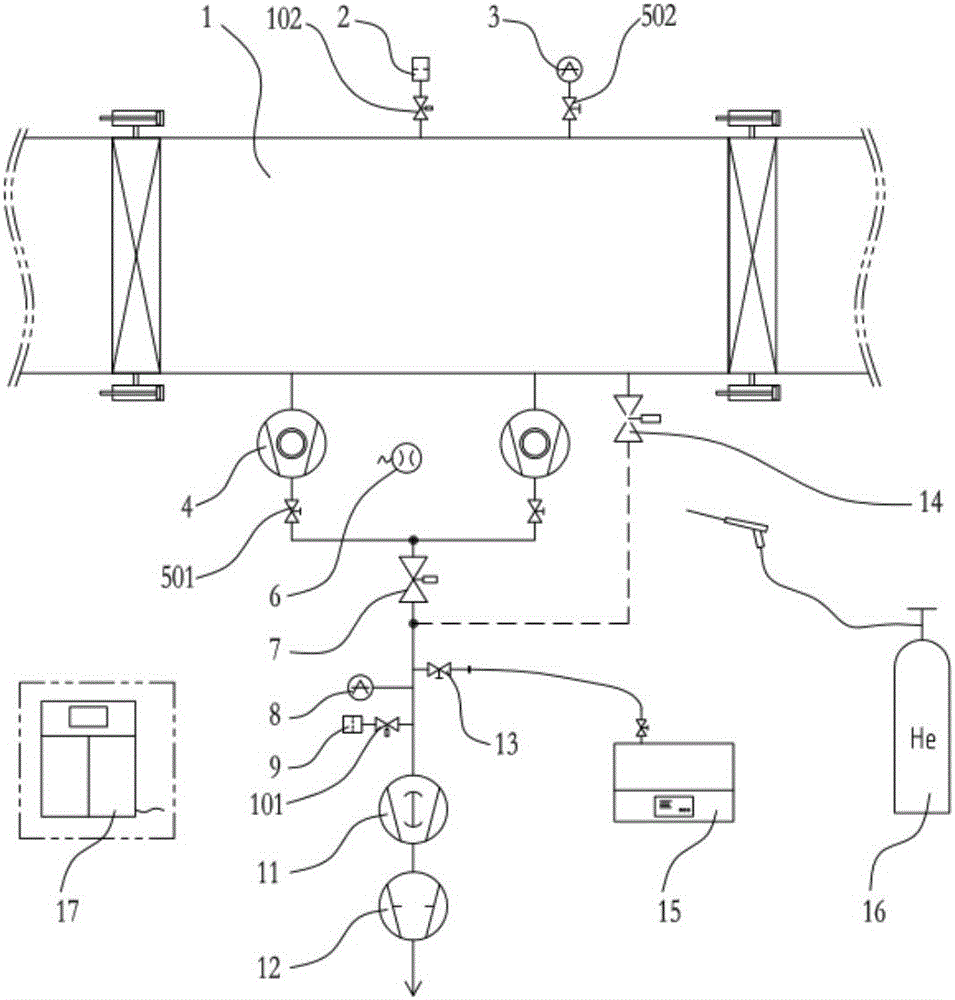

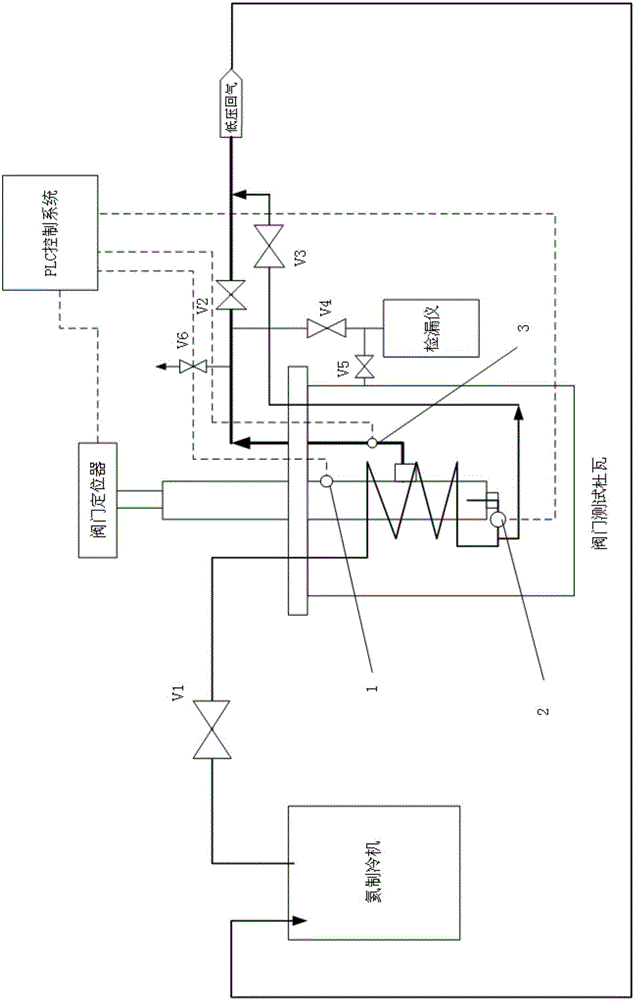

Low-temperature leak detection system and leak detection method of valve

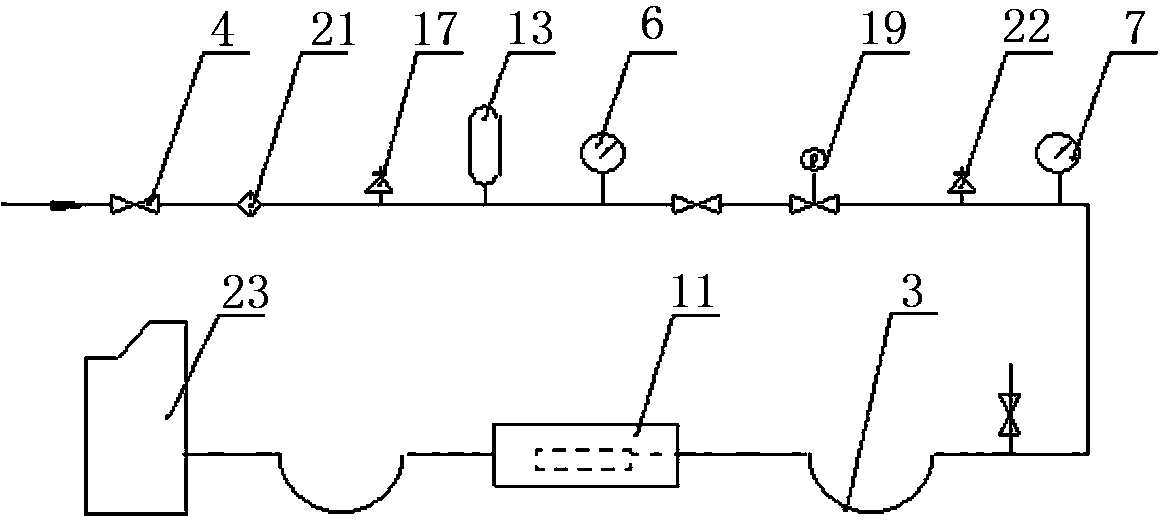

PendingCN110082046AImprove securityImprove reliabilityDetection of fluid at leakage pointNuclear energy generationMass spectrometryEngineering

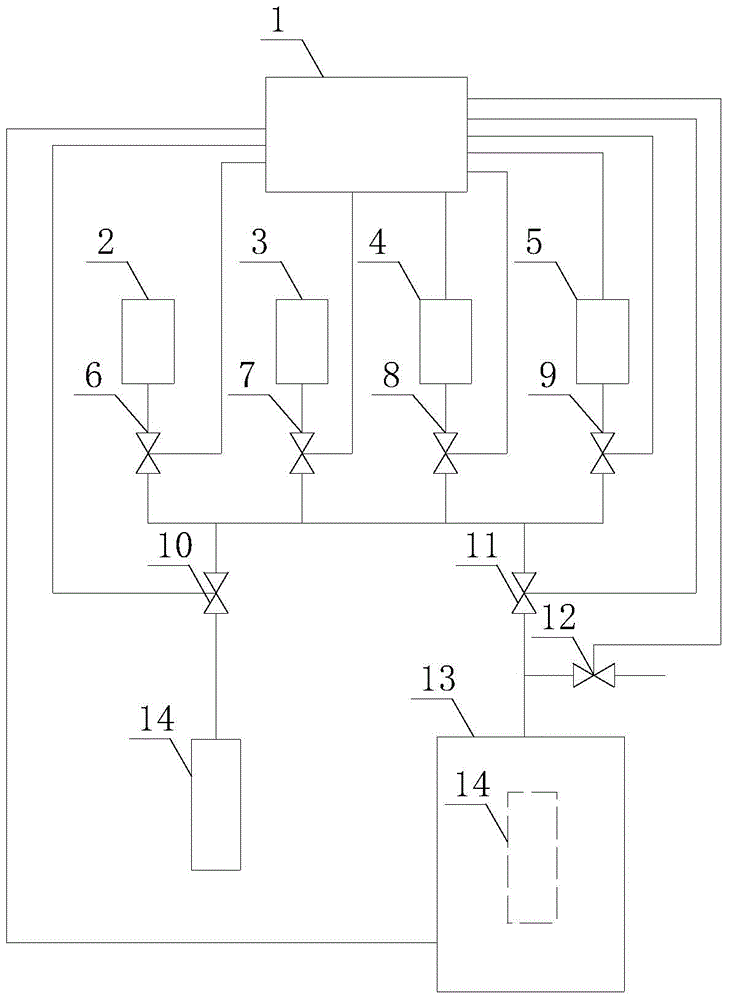

The invention relates to the technical field of low-temperature leak detection testing of valves, in particular to a low-temperature leak detection system and leak detection method of a valve. The system comprises a gas supply and distribution device, a refrigeration device, a first helium mass spectrometer leak detector, a second helium mass spectrometer leak detector, a plurality of gas inlet pipelines, a plurality of gas outlet pipelines and a vacuum detection platform, wherein the gas supply and distribution device is communicated with the vacuum detection platform through the gas inlet pipelines, the first helium mass spectrometer leak detector is communicated with the vacuum detection platform through the gas outlet pipelines, each pair of gas inlet pipeline and gas outlet pipeline is respectively connected to two ends of the corresponding valve to be detected, and valves are respectively arranged on the first helium mass spectrometer leak detector, the second helium mass spectrometer leak detector, the gas inlet pipelines and the gas outlet pipelines. According to the invention, the refrigeration device is used as a cold source, so that the safety and the reliability of thetest are improved, the labor cost and the test cost are reduced, the temperature of a sample is accurate and controllable, a plurality of valves to be tested can be detected in one test, and the testperiod is short.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

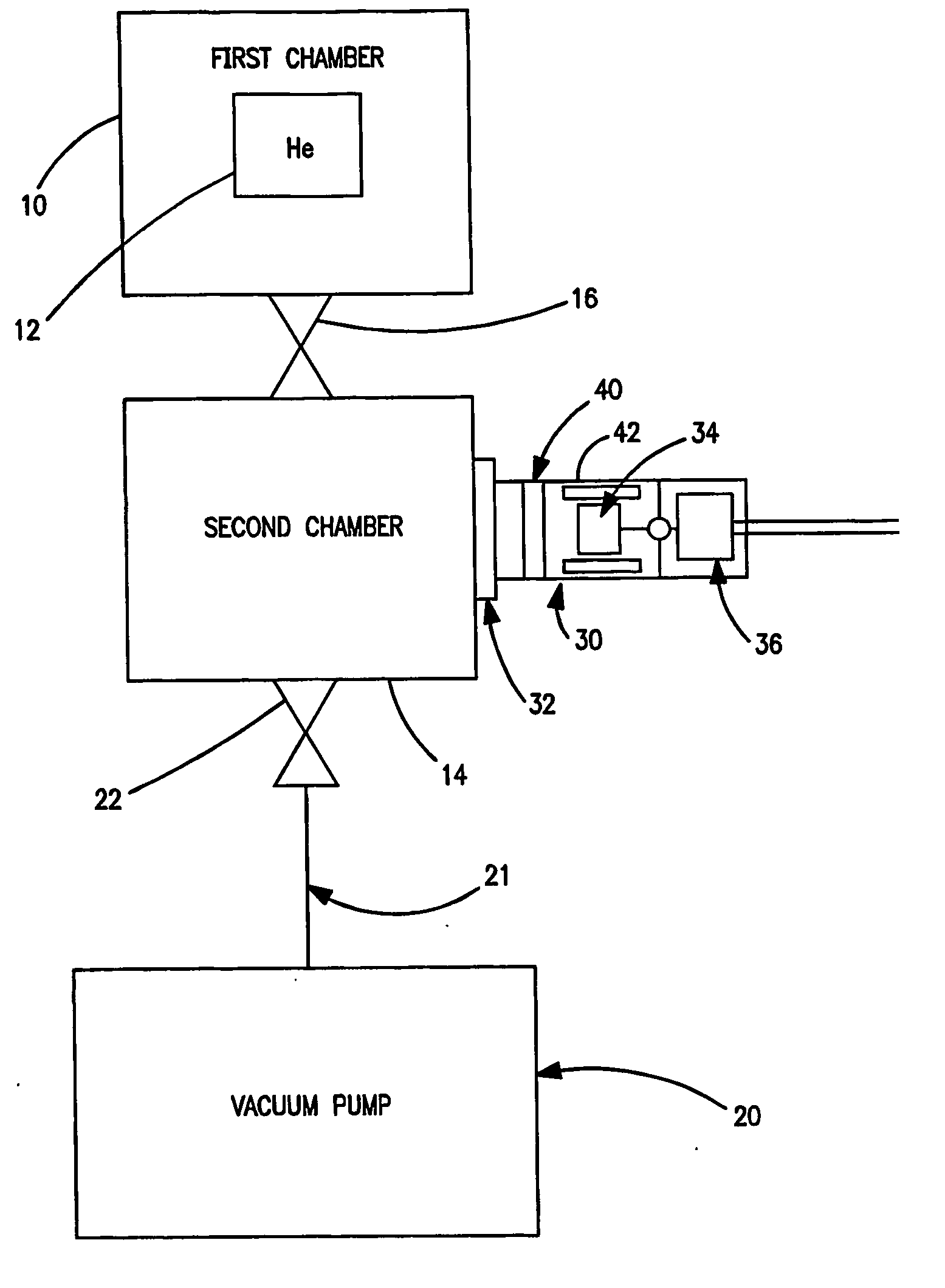

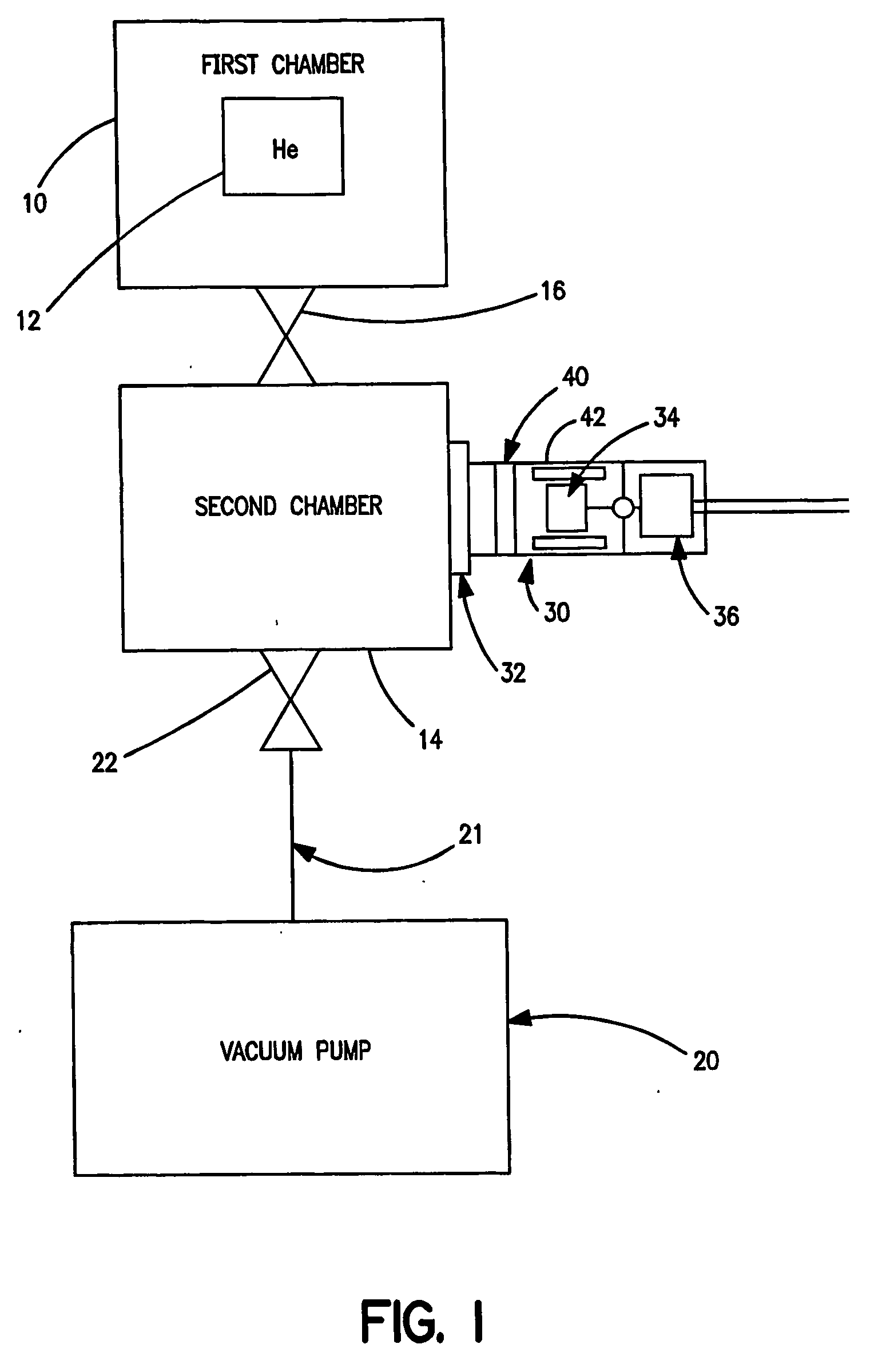

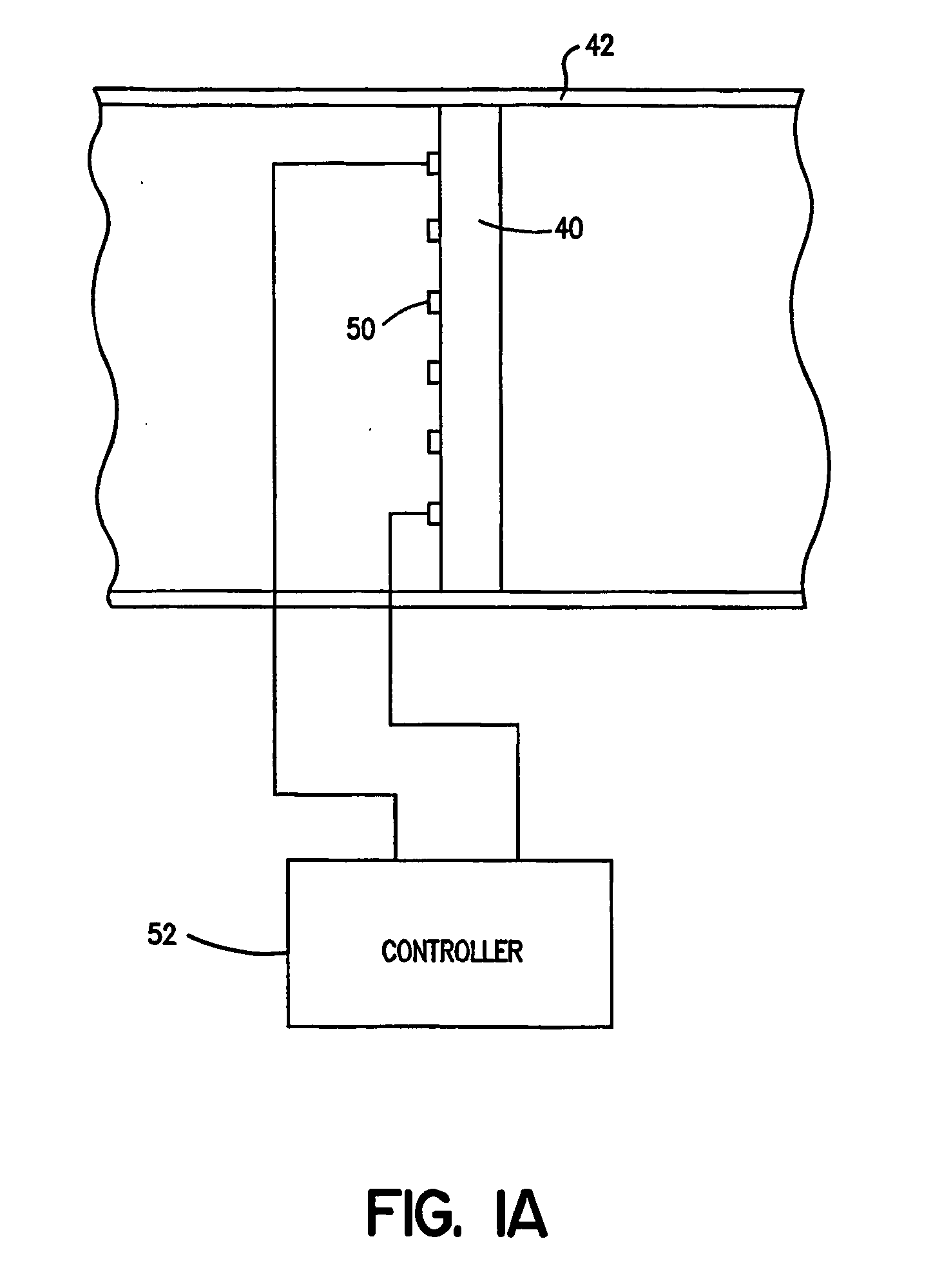

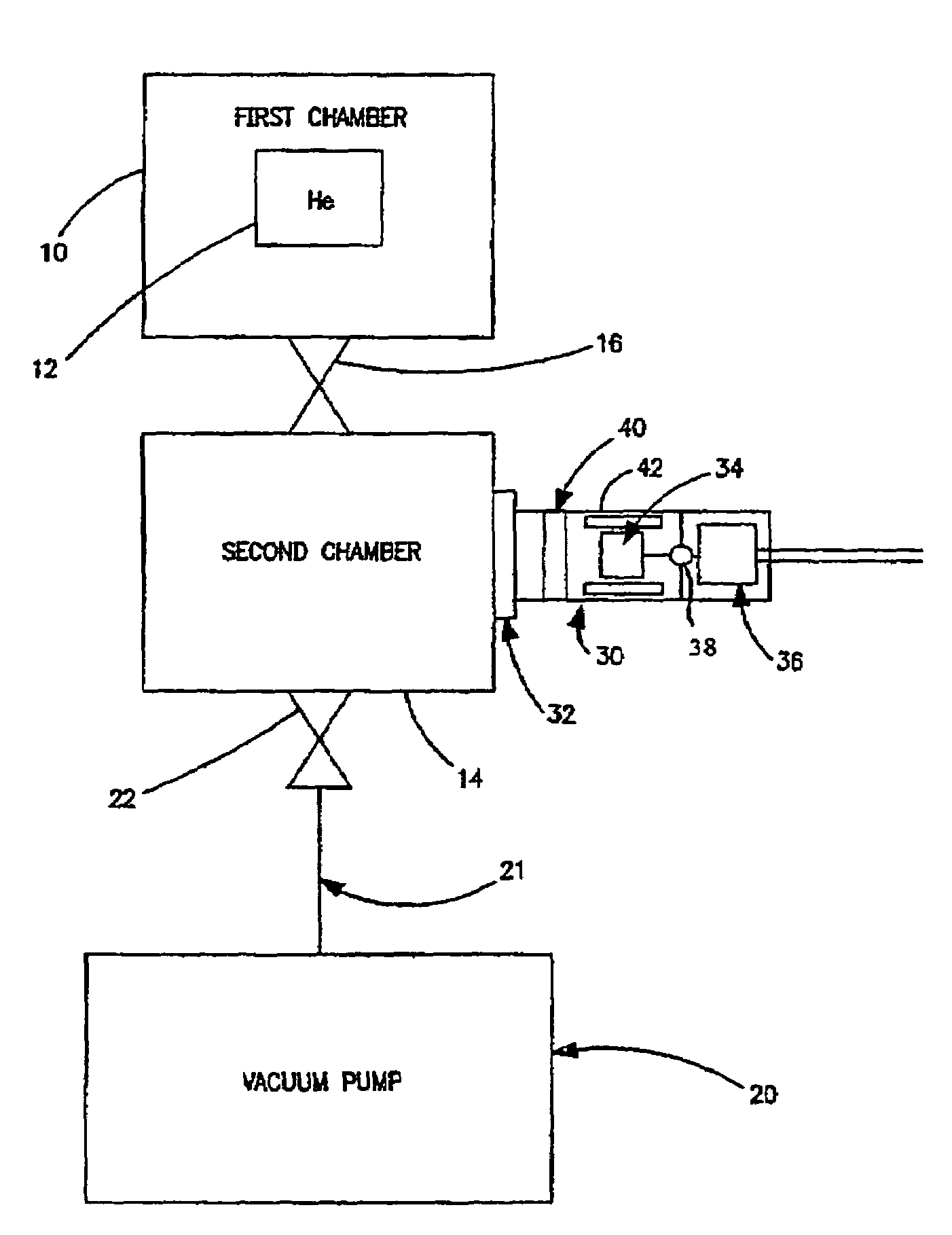

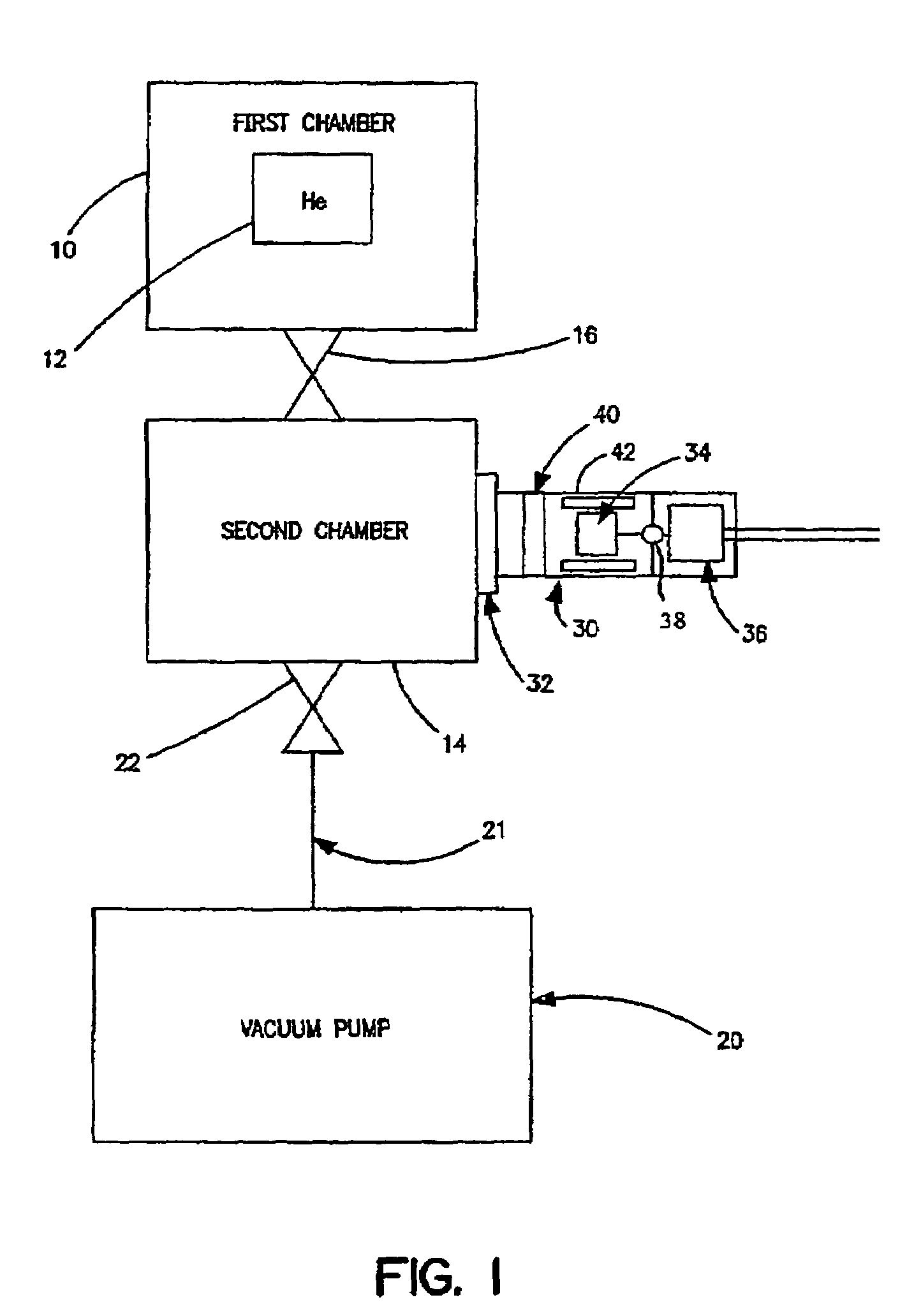

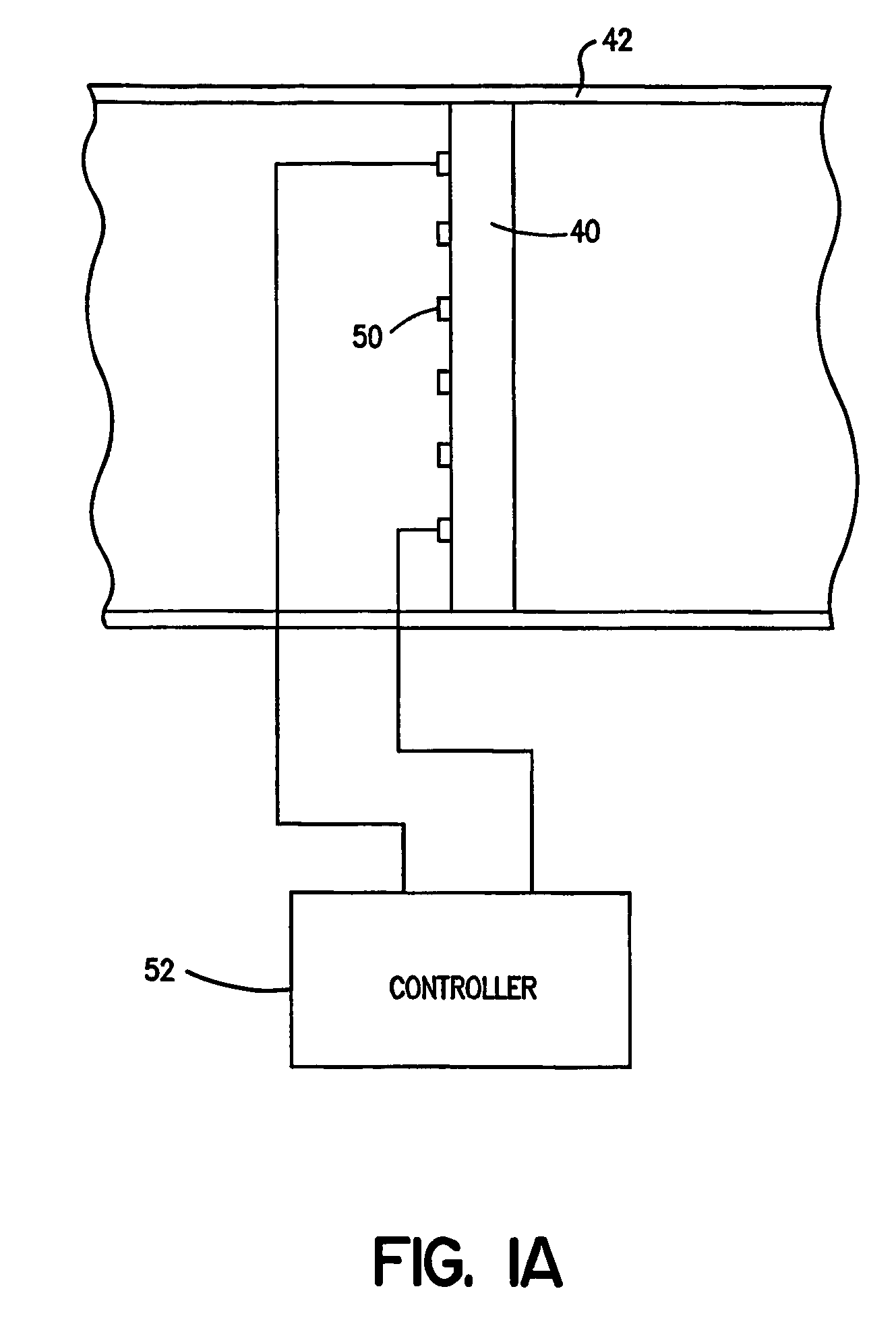

Methods and apparatus for detection of large leaks in sealed articles

Methods and apparatus are provided for detection of large leaks in scaled articles. Apparatus for leak detection includes a first sealable chamber configured to receive a test piece containing a trace gas, a second sealable chamber, a first valve coupled between the first and second chambers, a leak detector having a test port, a trace gas permeable member coupled between the second chamber and the test port of the leak detector, a vacuum pump having an inlet, and a second valve coupled between the second chamber and the inlet of the vacuum pump. The permeable member may be quartz, which is permeable to helium when heated. The leak detector may be an ion pump or a helium mass spectrometer leak detector.

Owner:AGILENT TECH INC

Vacuum leak detection automatic system with adjustable sensitivity

ActiveCN107543661AIncrease usageImprove convenienceDetection of fluid at leakage pointComputer control systemEngineering

The invention discloses a vacuum leak detection automatic system with adjustable sensitivity. The automatic system herein includes a vacuum acquisition and measurement unit and a leak detection unit.The vacuum acquisition and measurement unit includes a vacuum chamber, a molecular pump, a screw pump, a vacuum meter, a pneumatic gate valve, a controllable butterfly pump, an electromagnetic valve and a filter. The leak detection unit includes a helium mass spectrometer leak detector, a standard leak hole, an inflation and deflation device and a computer control system. The computer control system controls the molecular pump, the screw pump, the helium mass spectrometer leak detector and respective valve through a PLC program. According to the invention, by means of the computer control system, the system herein increases the easiness and accuracy in operating a test instrument, effectively increases the processing capability of test data, and saves time and cost spent in the test.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

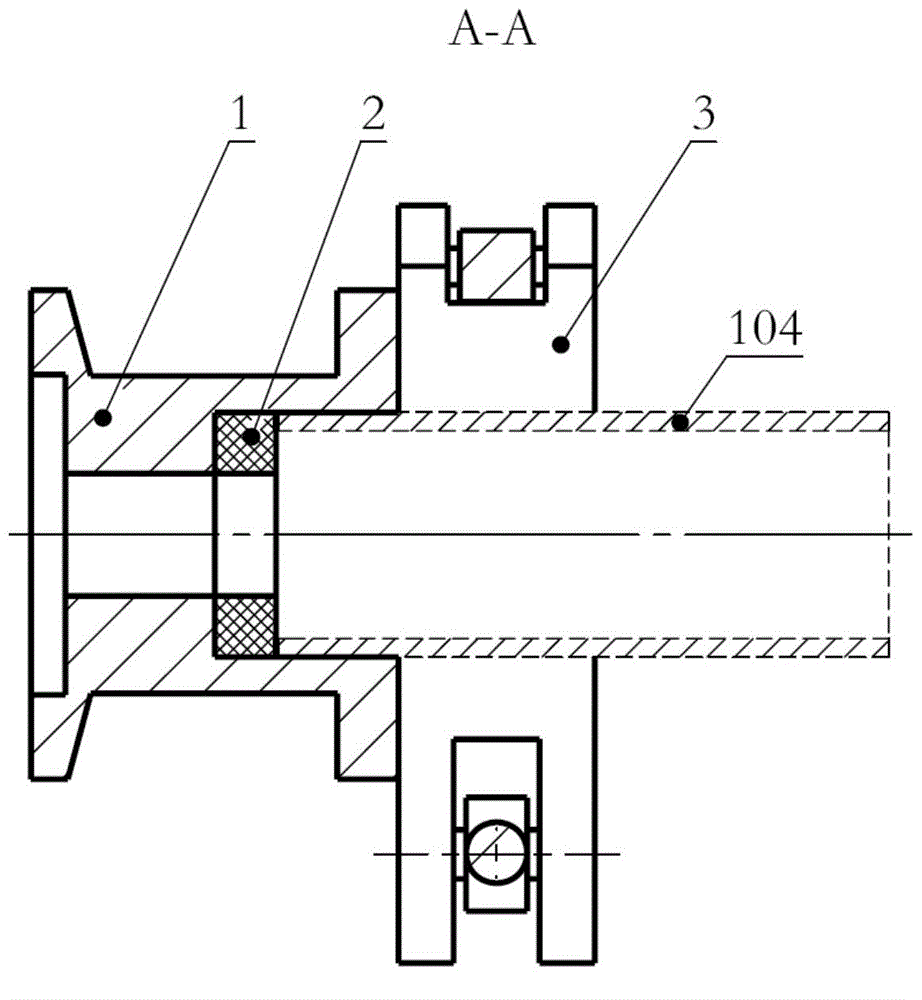

Rapid connection device of straight pipe helium mass spectrometer leak detection

InactiveCN103604569AImprove leak detection efficiencyQuick connectionDetection of fluid at leakage pointStraight tubeEngineering

The invention relates to a rapid connection device of straight pipe helium mass spectrometer leak detection. The device comprises a pipeline connecting piece, a sealing rubber washer, a snap ring assembly, a bolt and a flat washer. One end of the pipeline connecting piece is a vacuum-standard quick-release connector connection disk and the other end is a snap ring installation disk. The connection snap ring assembly comprises a movable semi-ring and a fixed semi-ring. The two semi-rings are connected together through a semi-ring joint hinge. The fixed semi-ring is connected to and fixed on the pipeline connecting piece through the bolt and the movable semi-ring can rotate about the semi-ring joint hinge. By using the apparatus, a vacuum system connection interface does not need to be welded on the pipeline; rapid connection of a smooth straight tube and a vacuum-standard quick-release connector can be conveniently and rapidly realized without changing and processing tubing; leak detection preparation time is shortened and tubing leak detection efficiency is increased.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

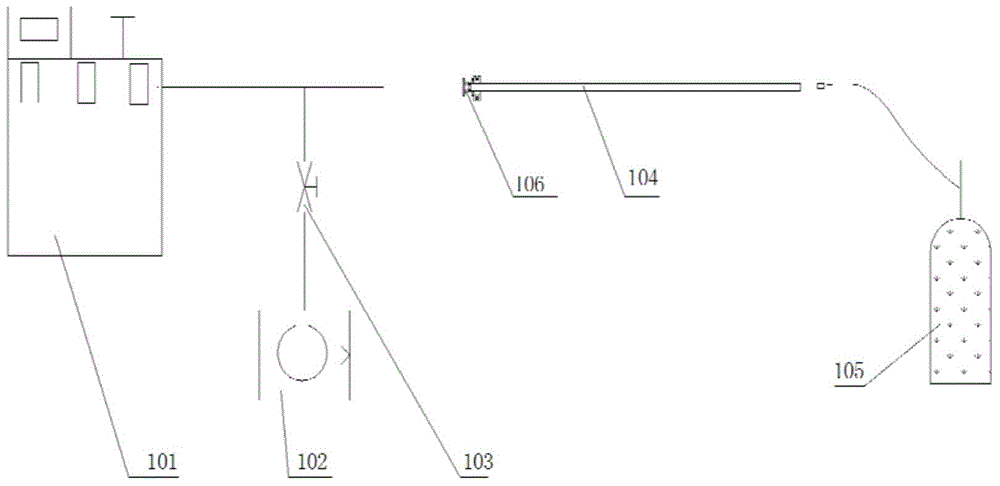

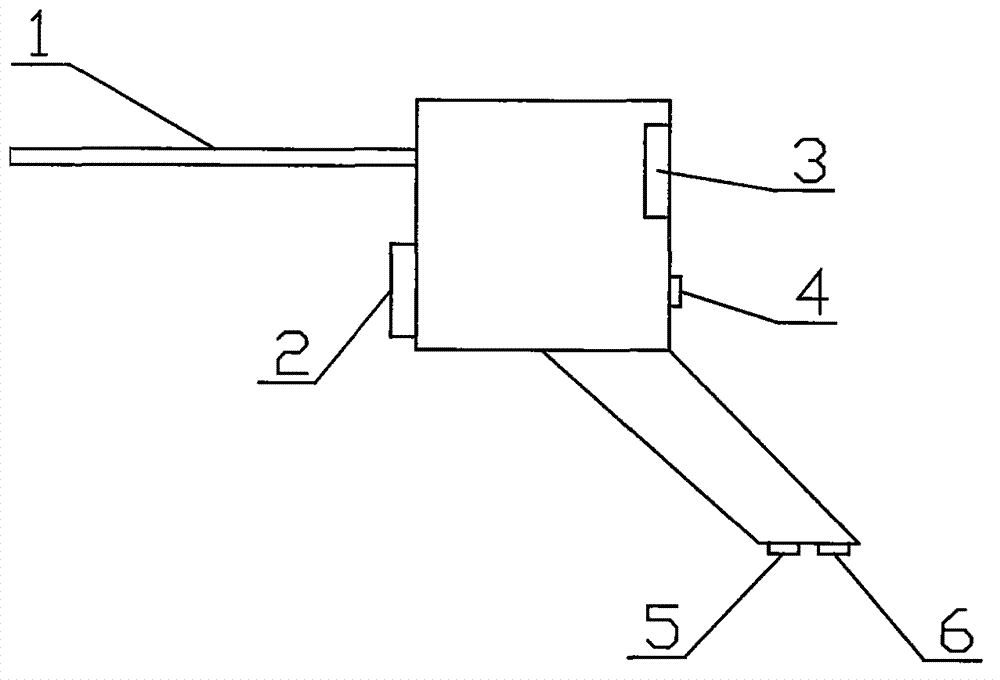

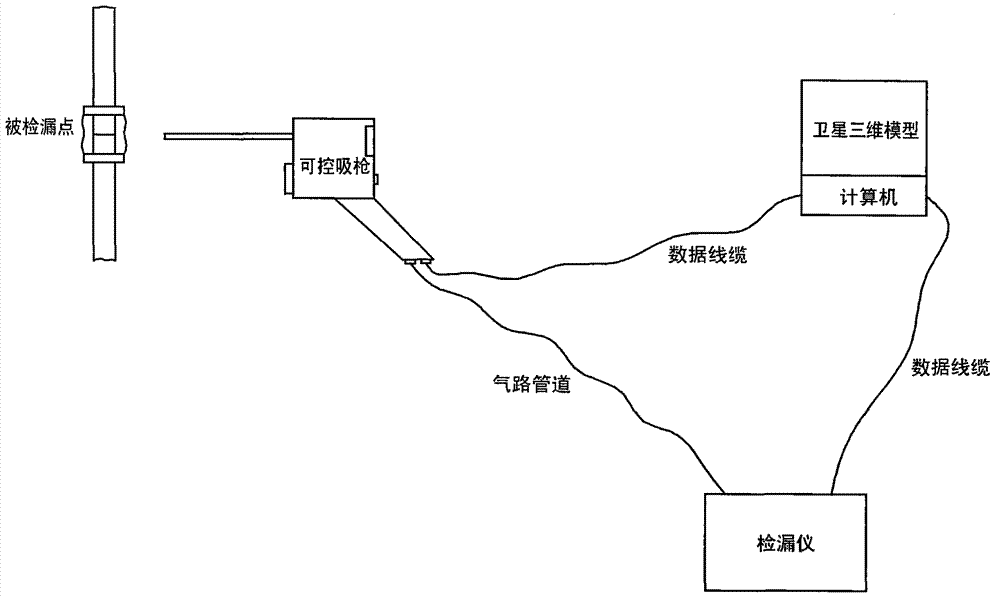

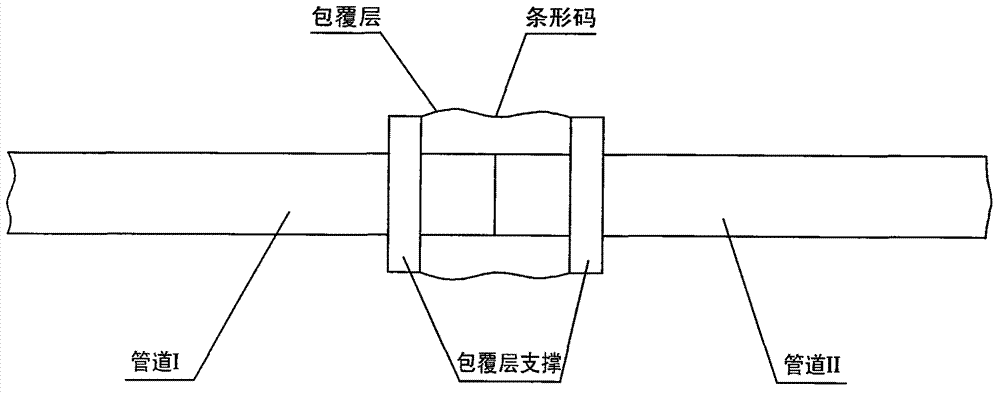

Controllable suction gun, as well as leak detection system and leak detection method adopting same

ActiveCN102759433AReduce labor intensityRealize visualizationDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention discloses a spacecraft-used controllable suction gun with the automatic identification and guidance functions, as well as a leak detection system and a leak detection method both used for leak detection through adopting the suction gun. The system is finally endowed with the automatic identification and guidance functions through the manner that a weld joint is recognized through a bar code covered on a coating layer of a to-be-detected weld joint, and the leak detection system for leak detection of weld joints comprises the controllable suction gun, a helium mass spectrometer leak detector, a computer and a satellite three dimensional model stored in the computer. Compared with the conventional leak detection system, the leak detection system with the automatic identification and guidance functions, provided by the invention, realizes the automatic identification of to-be-detected weld joints, and can guide an operator to detect all the weld joints one by one as per the preset leak detection order.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Method for calibrating helium mass spectrometer leak detector

ActiveCN102494852AReduce measurement uncertaintyAvoid small leak rate rangesDetection of fluid at leakage pointHelium mass spectrometerPhysics

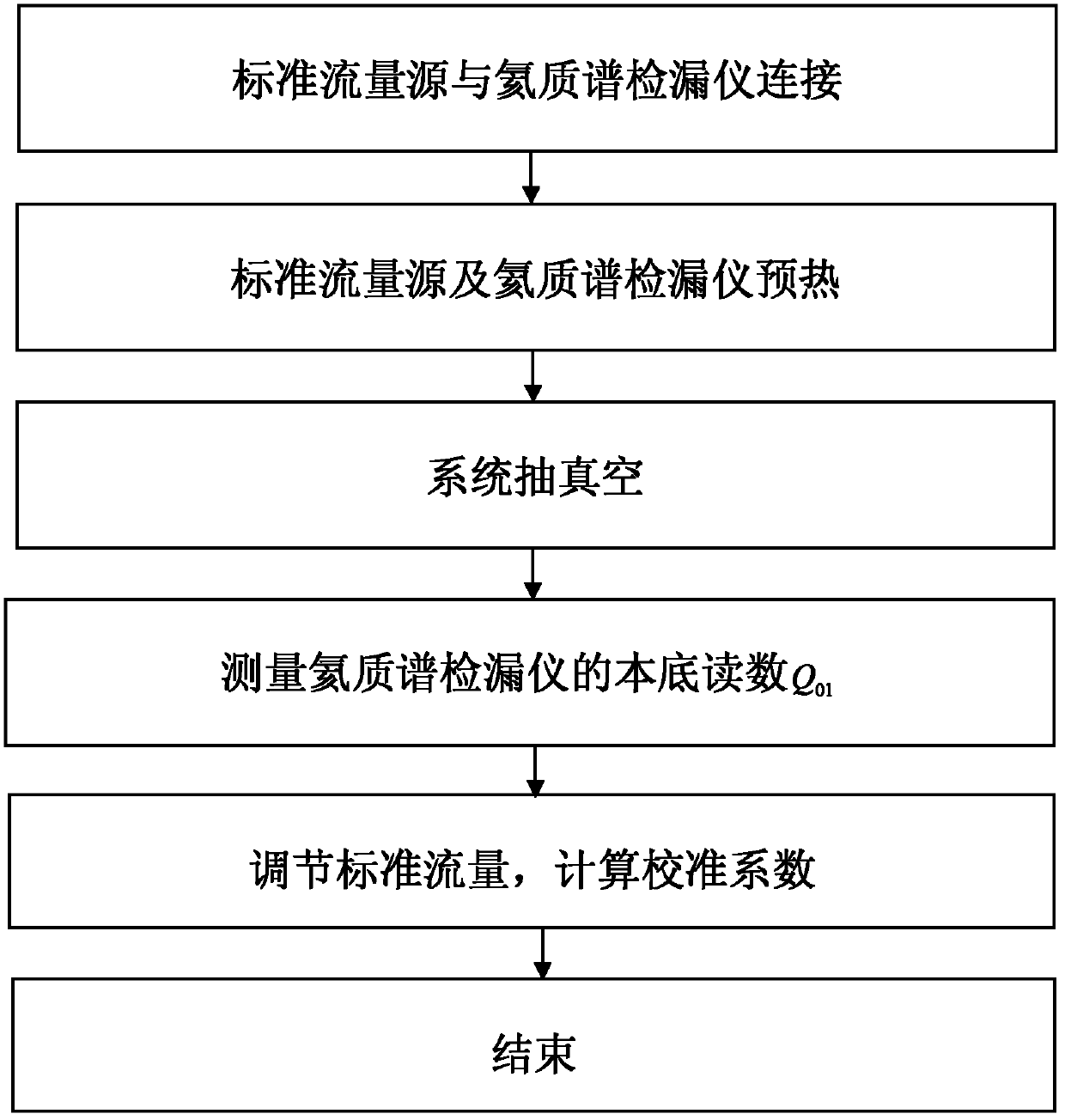

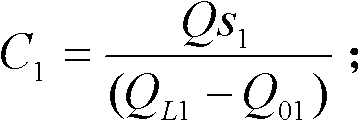

The invention discloses a method for calibrating a helium mass spectrometer leak detector, belonging to the technical field of vacuum metering. The method comprises the following steps of: 1, connecting a standard flow source with the helium mass spectrometer leak detector; 2, pre-heating the standard flow source with the helium mass spectrometer leak detector; 3, vacuumizing a system; 4, measuring a background reading Q01 of the helium mass spectrometer leak detector; 5, adjusting a standard flow and calculating a calibration factor C1 of the helium mass spectrometer leak detector; 6, continuously adjusting the flow supplied by the standard flow source to sequentially increase the standard flow; and repeating the steps 4 and 5 to obtain the calibration factors C2, C3, C4, C5, C6, C7, C8...of the helium mass spectrometer leak detector with different standard flows; and 7, calculating an average calibration factor C`0 of the helium mass spectrometer leak detector. According to the method provided by the invention, the helium mass spectrometer leak detector can be calibrated in a wide measurement range, so that the calibration accuracy is improved, the calibration process is simple and feasible, the measurement time period is short and the measurement uncertainty is small.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Nickel-cadmium battery helium mass spectrometer leak rate test method

InactiveCN105784288AImprove reliabilityEasy to operateDetection of fluid at leakage pointNickel cadmiumEngineering

The invention relates to a nickel-cadmium battery helium mass spectrometer leak rate test method, and belongs to the technical field of nickel-cadmium batteries. The nickel-cadmium battery helium mass spectrometer leak rate test method is characterized in that the helium mass spectrometer leak rate test is adopted. During the test process, after a nickel-cadmium battery cell is sealed, the nickel-cadmium battery cell, qualified for chemical leak detection test, is placed in a closed tank. After that, the helium gas is filled into the closed tank. When the pressure inside the closed tank is constant, the timing is started. After that, the closed tank is placed in a detection chamber of a system. When the vacuum degree inside the detection chamber reaches the specified requirement, a check valve is opened. By means of a helium mass spectrometer leak detector, the overall leak rate of the nickel-cadmium battery cell is quantitatively detected. The nickel-cadmium battery helium mass spectrometer leak rate test method is simple in operation, convenient in test, accurate in data, high in test level and high in reliability. Therefore, the nickel-cadmium battery can be effectively and quantitatively detected.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

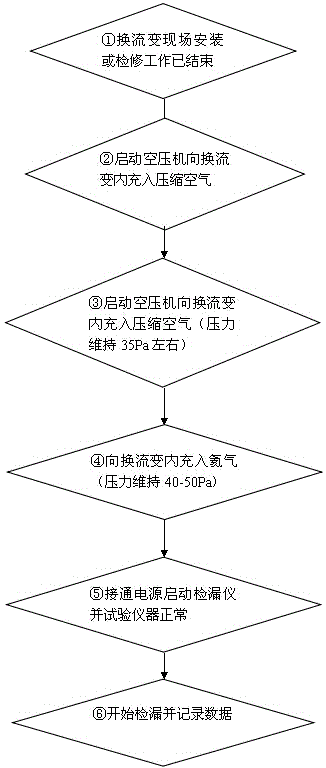

Rapid leakage detecting method suitable for extra-high voltage converter transformers

ActiveCN104132786ASolve the rapid detectionHigh precisionDetection of fluid at leakage pointTransformerEngineering

Provided is a rapid leakage detecting method suitable for extra-high voltage converter transformers. According to the method, a rapid leakage detecting device is used for detection and comprises a converter transformer used as equipment to be detected, an air compressor used as inflating equipment, a helium gas bottle, a helium mass spectrometer leak detector and a suction gun. A compressed air tank is arranged between the converter transformer and the air compressor, the helium gas bottle is connected with the converter transformer through a pipeline, and the suction gun is connected with the helium mass spectrometer leak detector through a pipeline. The method achieves rapid detection of leakage points of the extra-high voltage converter and is especially suitable for the extra-high voltage converter transformers and also suitable for other large-volume oil-filled transformers.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +3

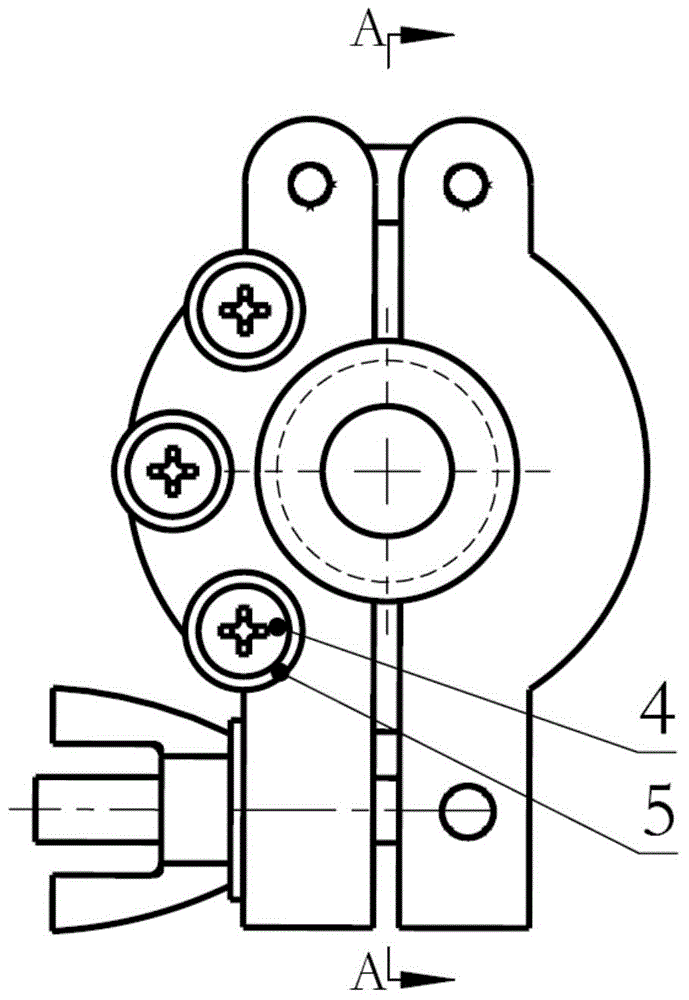

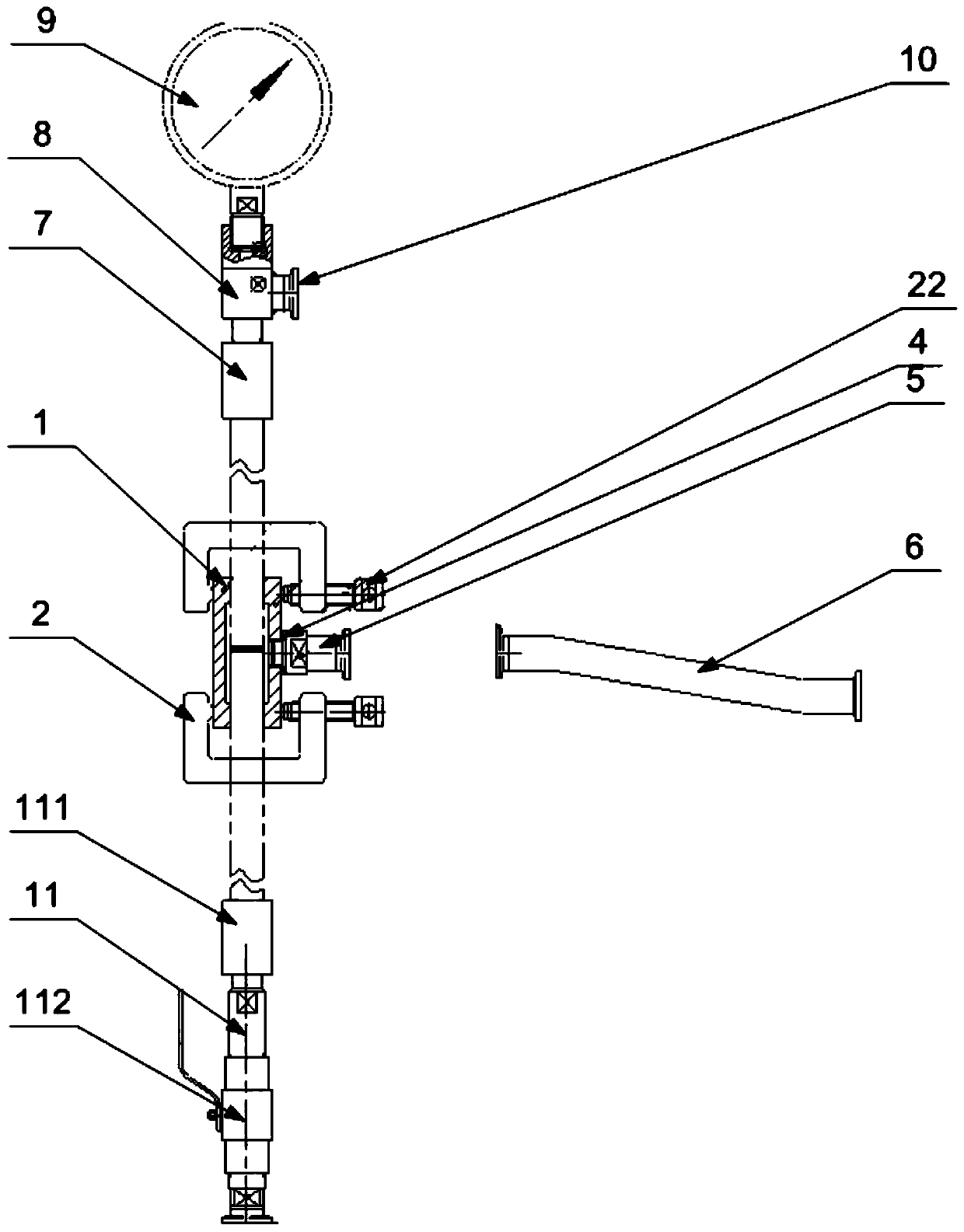

Helium mass spectrometer leak detection device for pipe-to-pipe butt welding line and leak detection method

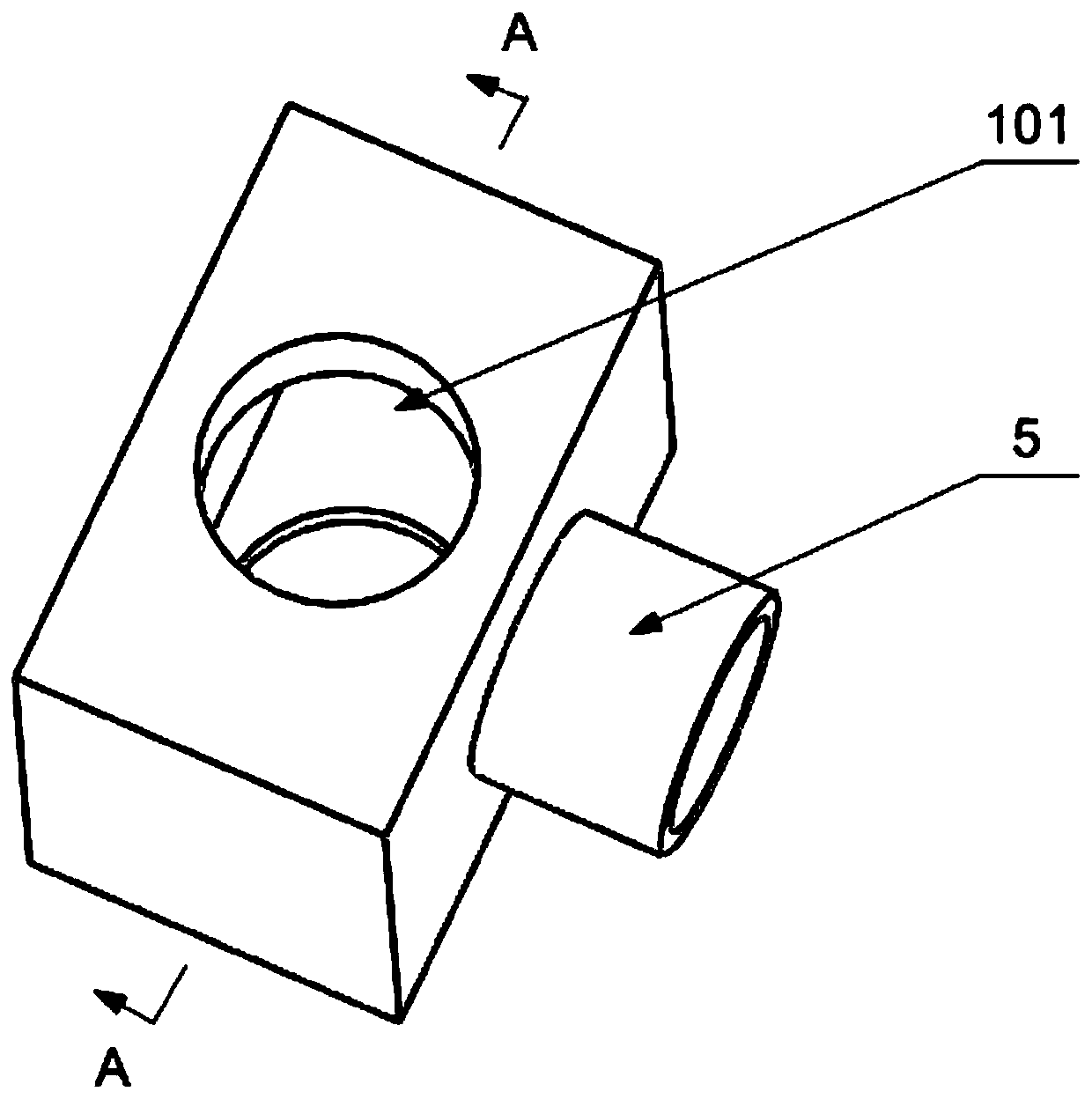

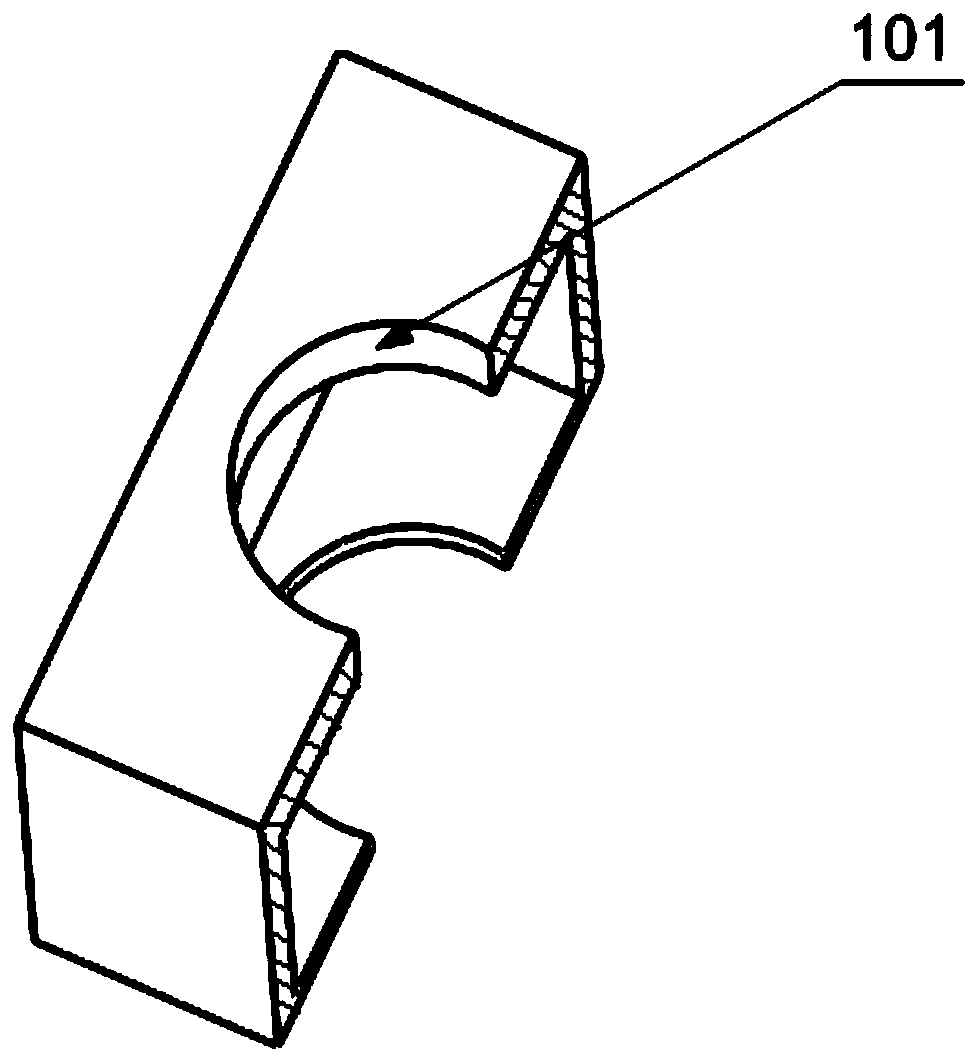

InactiveCN110595698AImprove leak detection efficiencyLow costDetection of fluid at leakage pointInterior spaceBody joints

The invention discloses a helium mass spectrometer leak detection device for a pipe-to-pipe butt welding line. The device comprises a box body (1), a box body joint (5) and a helium mass spectrometer,wherein a through hole (101) is formed in the box body (1), the box body joint (5) is arranged on the box body (1) and is connected with the helium mass spectrometer, and the through hole is formed on the box body joint (5) so that the helium mass spectrometer communicates with the inner space of the box body (1). The helium mass spectrometer leak detection device for the pipe-to-pipe butt welding line has the advantages of being free from damaging pipes and welding lines, high in leak detection efficiency, low in cost, easy in manufacturing, high in reliability, and capable of determining leak point positions and the like.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

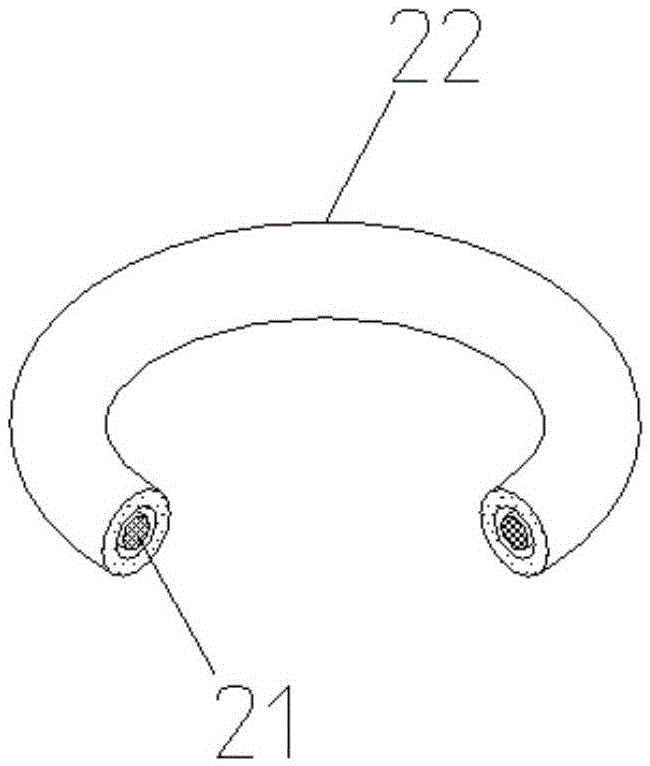

Simply-coated accumulative air tightness detection device and method

InactiveCN105486466ANo intermittent phenomenonPlay a sealing roleDetection of fluid at leakage pointHelium mass spectrometerAir tightness

The invention provides a simply-coated accumulative air tightness detection device. The device comprises a seal membrane, lute, an adapting piece, a helium mass spectrometer leak detector and a helium source, wherein the lute is a formed lute part and comprises a forming ring and an outer mold, the forming ring is an annular structure made of an elastic material, and the forming ring is wrapped in the outer mold made of vacuum lute in a sleeved and adhesive mode. The invention further provides a method for detecting the air tightness of a workpiece to be detected by means of the device. The formed lute part is adopted to replace bulk lute to seal the seal membrane and the edge of the detection area of the workpiece to be detected. Compared with bulk lute, the formed lute part has the remarkable advantages that by the adoption of the structure that the forming ring is wrapped in the outer mold, no leakage point can be generated, and excellent sealing performance is guaranteed; after leakage detection is finished, the formed lute part can be peeled off together with the seal membrane, time and labor are saved, repeated use can be realized, and then cost is reduced.

Owner:BOYI TIANJIN PNEUMATIC TECH INST

Pipe joint leakage detector

ActiveCN104075855ASimple structureReasonable designDetection of fluid at leakage pointBuffer tankMass spectrometry

The invention discloses a pipe joint leakage detector which comprises a helium tank, a stop valve, a buffer tank, a collecting gas bag and a helium mass spectrometer leak detector, wherein an outlet of the helium tank is connected with one end of the stop valve, and the other end of the stop valve is connected with an inlet of the buffer tank; a pressure meter is connected onto the buffer tank; a pipe joint connecting mechanism is arranged at the top of the buffer tank and comprises a connecting flange, a pressing plate, a first gasket and a second gasket; the connecting flange is fixed at the top of the buffer tank; the pressing plate is arranged above the connecting flange; the second gasket is arranged on the lower end surface of the pressing plate; the first gasket is arranged on the upper end surface of the connecting flange; a pipe joint is arranged between the first gasket and the second gasket; through holes are formed in centers of the connecting flange and the first gasket; the pressing plate is fixedly connected with the connecting flange through fastening pieces; the collecting gas bag is arranged outside the possible leaking part of the pipe joint in a sleeving manner; and a suction gun of the helium mass spectrometer leak detector is communicated with the collecting gas bag. The pipe joint leakage detector can detect leakage of the pipe joint and has high detection sensitivity, accuracy and efficiency.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

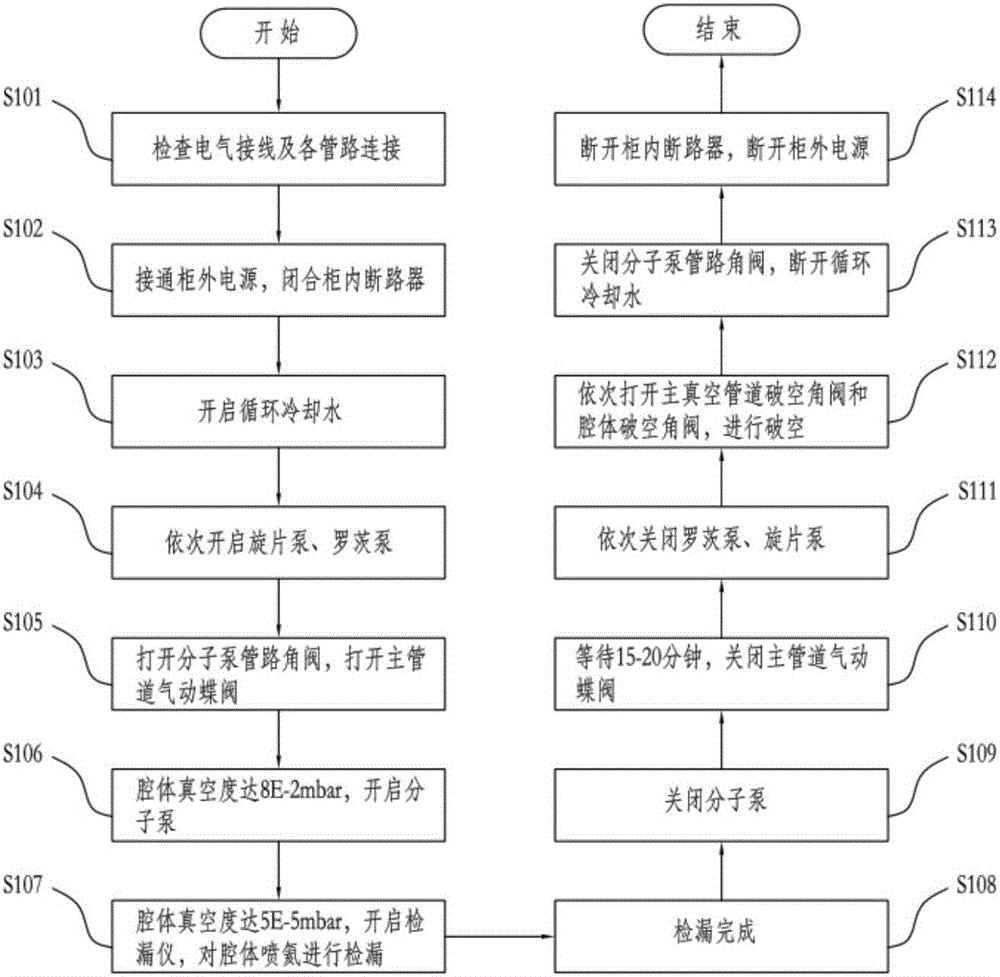

Vacuum coating cavity leak detection system and leak detection method

ActiveCN106802218APrecise positioningHigh leak detection sensitivityDetection of fluid at leakage pointAutomatic controlEngineering

The invention provides a vacuum coating cavity leak detection system and leak detection method. The system comprises a detected vacuum cavity, a leak detection apparatus, and an electric control system, the lower side of the detected vacuum cavity is connected with the leak detection apparatus, the electric control system is connected with and controls the leak detection apparatus, a sidewall of the detected vacuum cavity is provided with a vacuum breaking device I and a vacuum detection element I, the leak detection apparatus comprises high vacuum pumps, a backing pump set I, a backing pump set II, a vacuum detection element, a vacuum breaking apparatus, a helium mass spectrometer leak detector, and a helium-jetting system, the high vacuum pumps are directly arranged at the sidewall of the detected vacuum cavity through flanges, and the backing pump set I and the backing pump set II are connected in series through a vacuum pipeline and then are connected with the high vacuum pumps in series through a high vacuum butterfly valve I. According to the system and method, an automatic control system is employed, and an electrical component has the one-touch operation function; the sensitivity of leak detection is high, and leakage hole positions can be accurately located, and the size of leakage points can be judged in a quantitative manner; besides, the structure is simple, and the operation is easy.

Owner:TRIUMPH HEAVY IND

Leakage detecting method for sealing structure part

InactiveCN102564709AEasy to useLow leak detection rateDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention relates to a leakage detecting method for a sealing structure part, which comprises the following steps: 1) connecting a part to be detected into a helium mass spectrometer leak detector; 2) vacuumizing the part to be detected and the helium mass spectrometer leak detector; 3) blowing helium to the part to be detected; and 4) carrying out sealing detection to the part to be detected according to the indication situation of an output meter of the helium mass spectrometer leak detector. In the invention, the leakage detecting method for the sealing structure part, which can directly reflect the omission factor, is accurate to detect the leakage, simplifies the leakage detecting process and is convenient to use, is provided.

Owner:AVIC NO 631 RES INST

Positive pressure leakage hole calibration device and method based on static accumulation attenuation comparison method

ActiveCN104236813AAvoid compromising accuracyReduce measurement uncertaintyDetection of fluid at leakage pointUltrasound attenuationPositive pressure

The invention provides a positive pressure leakage hole calibration device and method based on a static accumulation attenuation comparison method. By means of the device and method, calibration on positive pressure leakage holes can be achieved; in addition, the calibration range is wide, and calibration on a plurality of kinds of leak indication gas is achieved. The device is mainly composed of a gas exhaust system, a helium mass spectrometer leak detector and two sampling systems; each sampling system comprises a pressure meter, a gas collecting room, a first stop valve, a second stop valve, a third stop valve, a sampling room and a capillary tube. The connected relations include that each pressure meter is connected with the corresponding gas collecting room, each gas collecting room is connected with a gas inlet of the corresponding sampling room through the corresponding first stop valve, a gas outlet of each sampling room is sequentially connected with the helium mass spectrometer leak detector through the corresponding second stop valve, the corresponding capillary tube and the corresponding third stop valve. The gas exhaust system is mainly composed of a gas exhaust pump, a stop valve A and a stop valve B. The gas exhaust pump is connected with the sampling room of one sampling system through the stop valve A, and connected with the sampling room of the other sampling system through the stop valve B.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Low-temperature valve property testing device

InactiveCN106768687AAutomate operationImprove work efficiencyDetection of fluid at leakage pointCold testBottle

The invention discloses a low-temperature valve property testing device. The low-temperature valve property testing device comprises a Dewar bottle, wherein a low-temperature liquid delivery tube is wound on a valve rod of a low-temperature valve to be tested from top to bottom; the low-temperature liquid delivery tube is divided into two channels before entering a valve inlet; one channel is directly connected with an output pipe opening of an upper sealing flange and returns to a low-pressure air return pipeline of a refrigerator; a stop valve is mounted on an outlet of the pipeline; the other channel is connected with a low-temperature valve inlet, is connected with another output pipe opening of the upper sealing flange via a low-temperature valve outlet, and returns to the low-pressure air return pipeline of the refrigerator through the stop valve; meanwhile, the pipeline is connected with a helium mass spectrometer leak detector via a flange through a stop valve; and low-temperature thermometers are respectively mounted on the valve rod of the valve to be tested, the valve inlet and the valve outlet. The whole low-temperature testing system is operated automatically, the working efficiency is improved, repeatability and accuracy of operation are high, meanwhile, online storage and history viewing of data are realized, and data analysis and operation optimization are facilitated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

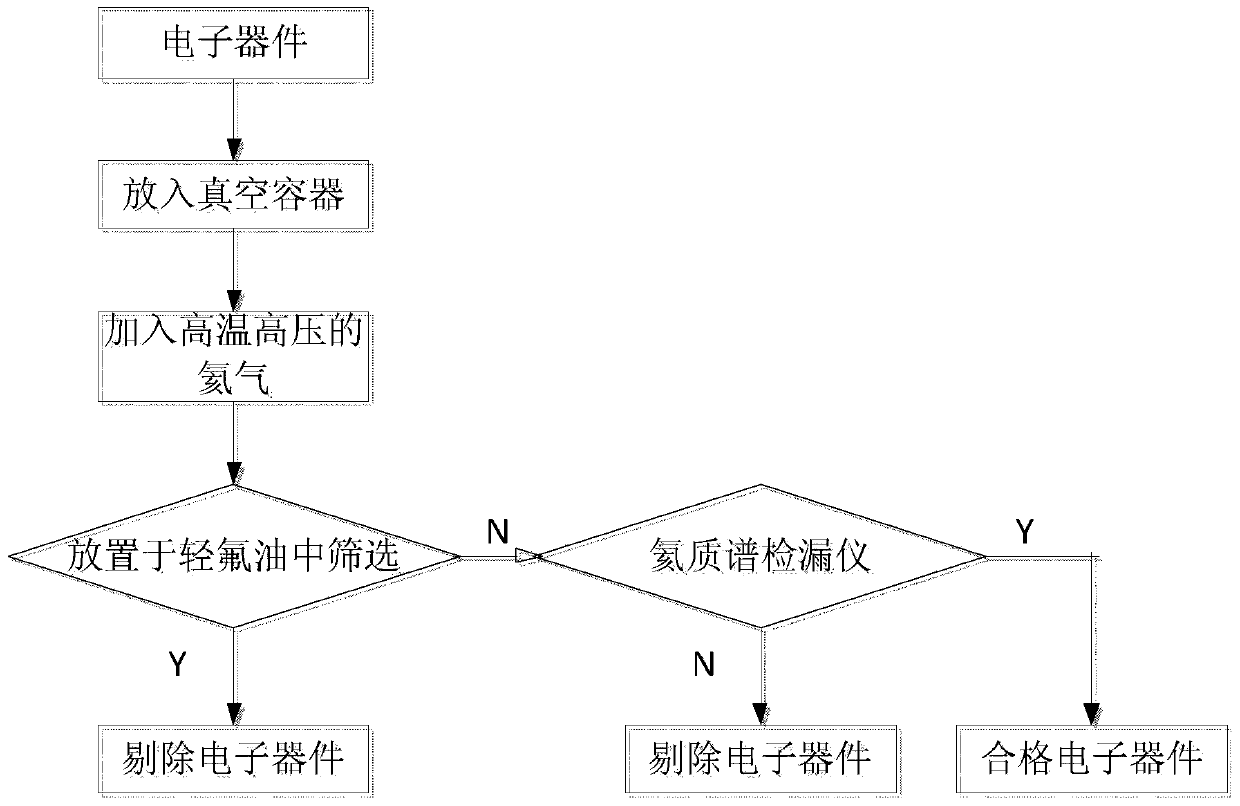

Leak detection method of electronic device

InactiveCN103557995AImprove leak detection efficiencyNo purification requiredDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention relates to the technical field of electronic circuits, in particular to a leak detection method of an electronic device. The method includes the following steps that the electronic device to be detected is placed into a pressurizing container, and after the container is vacuumized, pressurizing is carried out on the electronic device through high-pressure tracer gas helium with the purity of 99.999%; after pressurizing is finished, the electronic device is directly soaked in light fluorocarbon oil, and judgment is carried out by observing whether the electronic device bubbles; the detected electronic device which is qualified in bubbling is placed into a vacuum container, and leakage rate testing and judging are carried out by means of a helium mass spectrometer vacuum leak detection method. By means of the leak detection method, on the situation that original equipment is used, leak detection efficiency is improved, purifying is not needed, new defects are avoided, and meanwhile leak detection cost is saved.

Owner:桂林机床电器有限公司

Methods and apparatus for detection of large leaks in sealed articles

Owner:AGILENT TECH INC

Lightning arrester sealing test device and method

InactiveCN104458151ARealize leak detectionImprove detection accuracyDetection of fluid at leakage pointNitrogenEngineering

Owner:CHINA XD ELECTRIC CO LTD

Leak detection test bed

InactiveCN104006930ALeakage data is accurateVersatileDetection of fluid at leakage pointGas cylinderMass spectrometry

The invention relates to an internal-pressurized and external-vacuum leak detection test bed. An air inflation pipeline in the test bed is communicated with an air storage bottle through a filter, a high pressure safety valve and a stop valve. The air storage bottle is communicated with a cavity of a detected assembly through a reducing valve and a low-pressure safety valve. The detected assembly is arranged in a vacuum working room which is connected with a helium mass spectrometer leak detector. The air inflation pipeline is connected with a pressure gauge. The leak detection test bed has the advantages of being accurate in leak detection data, multifunctional, stable in performance, convenient to operate and control, capable of achieving energy conservation and environment protection, safe, reliable and the like. The leak detection test bed and the helium mass spectrometer leak detector are connected to form an internal-pressurized and external-vacuum leak detection system.

Owner:SHENYANG AEROSPACE XINGUANG GRP

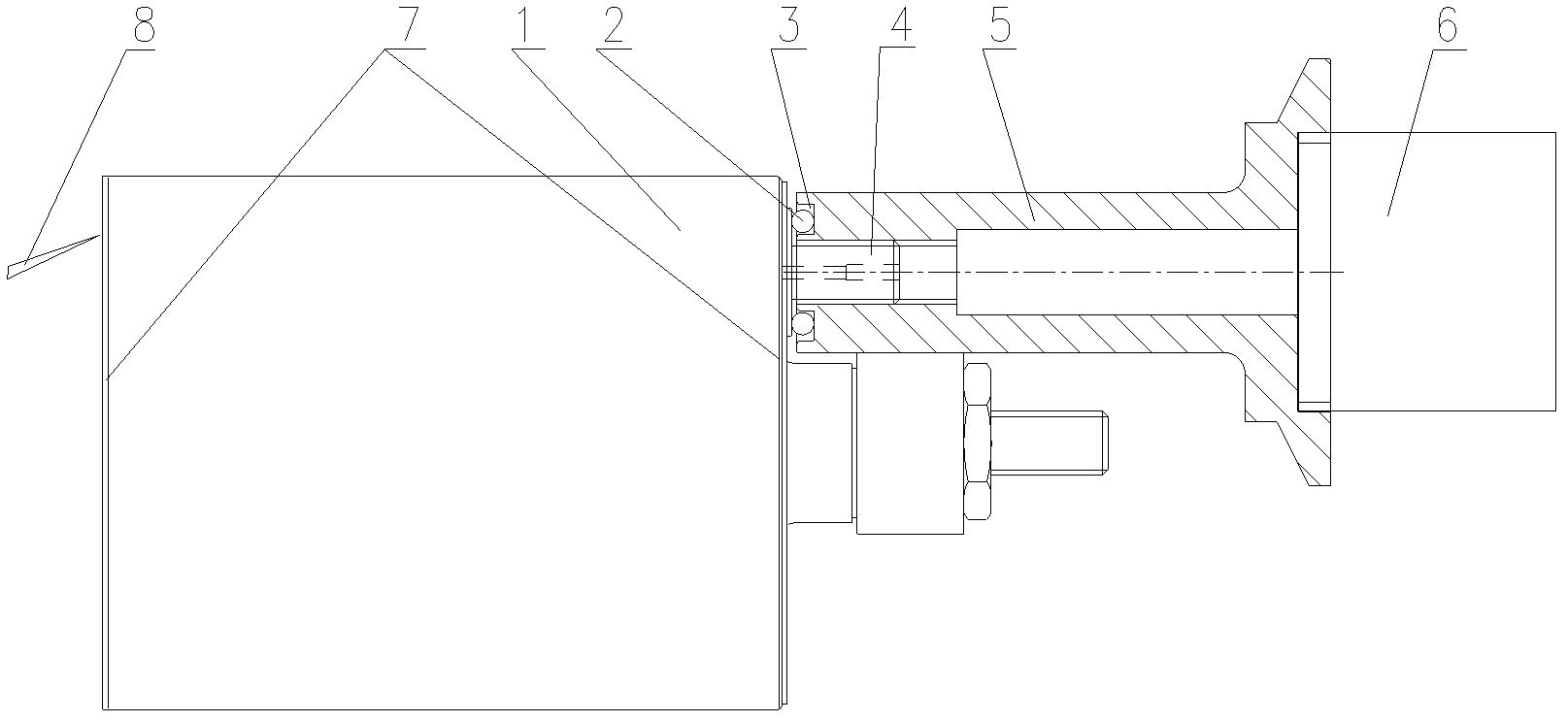

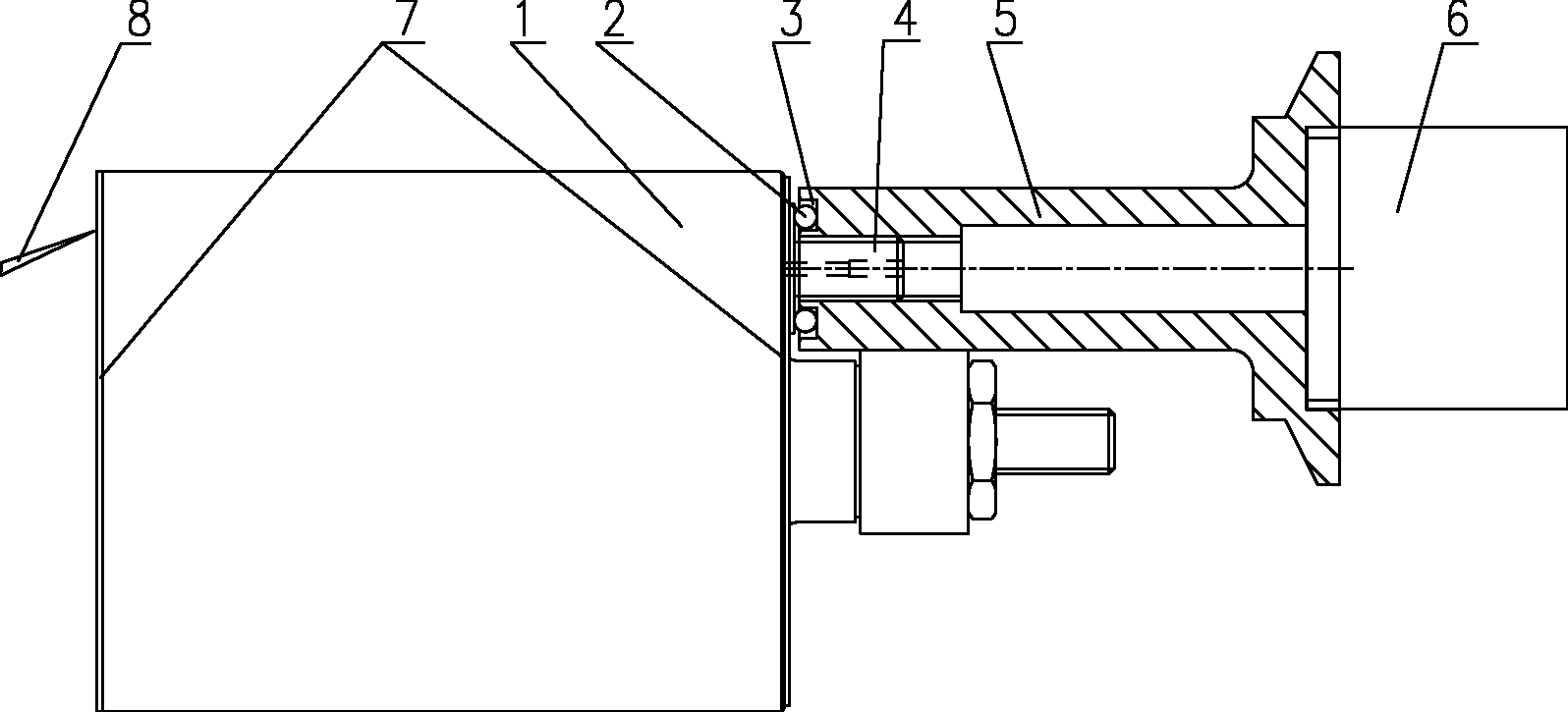

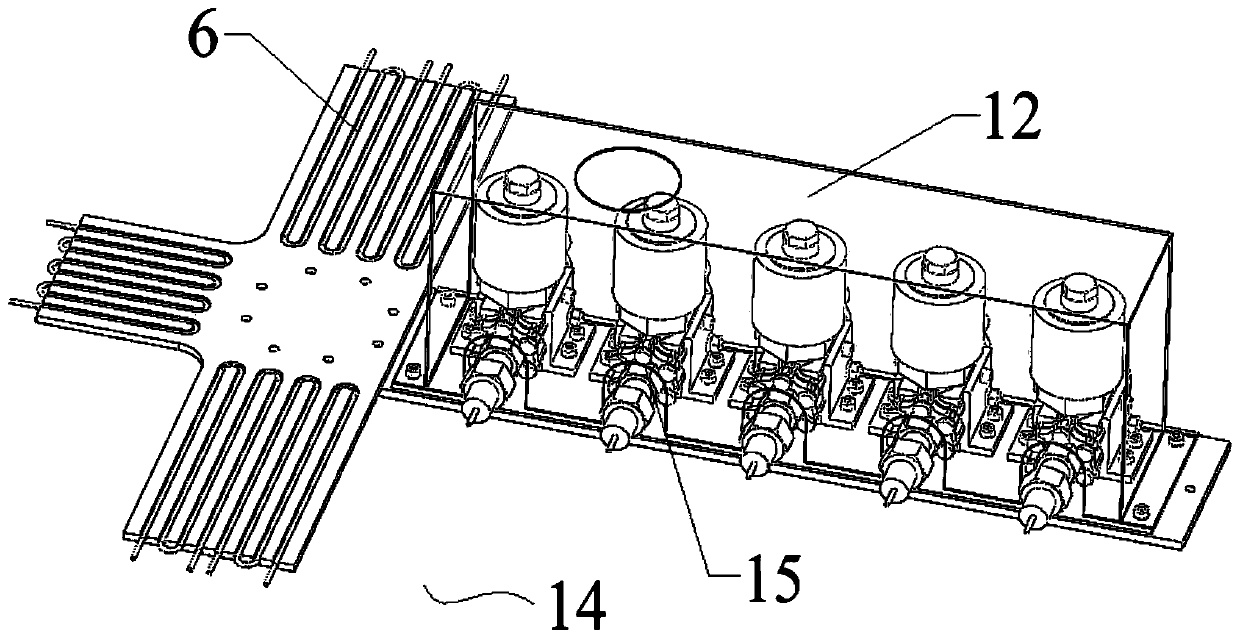

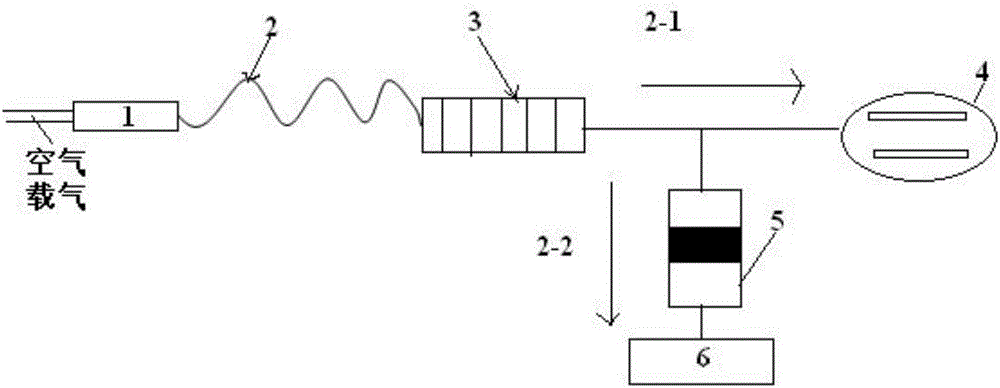

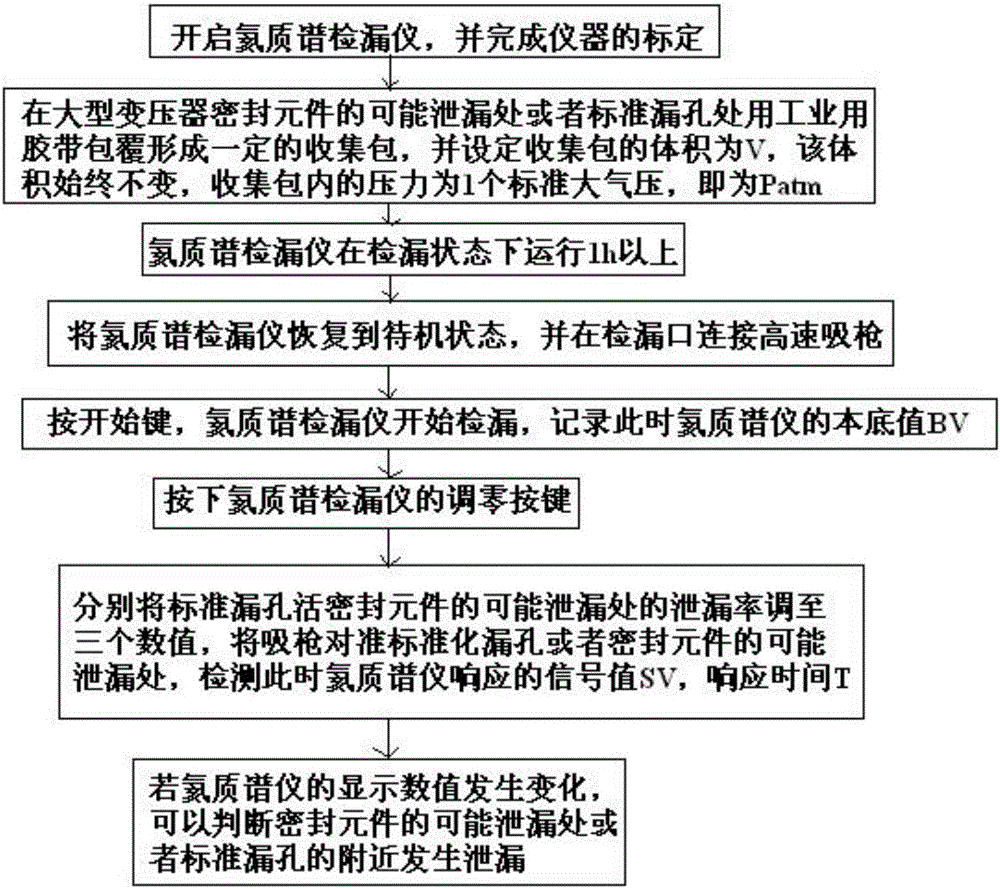

High speed suction gun leak detection device and detection method for large transformer sealing element

The invention provides a high speed suction gun leak detection device for a large transformer sealing element. The device is characterized by including a high speed suction gun (1), a sampling pipe (2), a filter (3), a high-power suction pump (4), a helium separator (5) and a helium mass spectrometer (6). The air carrier gas enters from a probe of the high speed suction gun (1), passes through a first branch (2-1) of the sampling pipe (2), and is pumped out by the high-power suction pump (4). The helium leaked from a leak in the detected large transformer sealing element enters the probe of the high speed suction gun (1), then passes through a second branch (2-2) of the sampling pipe (2) with the high speed air carrier gas provided by the high-power suction pump (4), enters a mass spectrum chamber of the helium mass spectrometer (6) through the helium separator (5) to be analyzed. Finally, a response leak rate signal is given. A high speed suction gun leak detection method for the large transformer sealing element is further provided.

Owner:南京扬子动力工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com