Low-temperature valve property testing device

A testing device and valve technology, which can be used in measuring devices, fluid tightness testing, and machine/structural component testing. The effect of analysis and operational optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

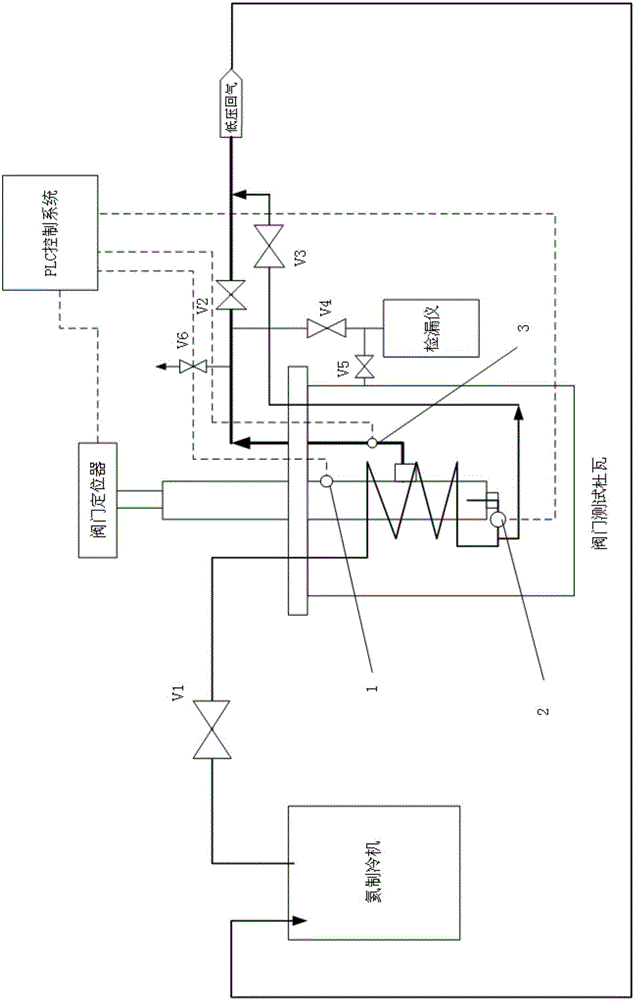

[0018] See attached picture.

[0019] A low-temperature valve performance testing device has a low-temperature test Dewar, the low-temperature test Dewar has a sealing flange, the valve to be tested is installed on the flange, and a low-temperature input nozzle and two output nozzles are opened on the flange at the same time. And the aviation plug, the aviation plug is used to weld the signal line of the thermometer. The cryogenic infusion tube is connected to the helium refrigerator, and a shut-off valve and a safety valve are installed on the cryogenic infusion tube. Inside the test Dewar, the low-temperature infusion tube is coiled on the valve stem from top to bottom, and it is divided into two paths before entering the valve inlet. Install a stop valve on the outlet. The other line is connected to the inlet of the low-temperature valve, and the outlet of the low-temperature valve is connected to the other output pipe port of the upper sealing flange, and then returns to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com