Lightning arrester sealing test device and method

A sealing test and arrester technology, applied in the field of arrester testing, can solve the problems that the test results are easily interfered by external factors, the detection accuracy and detection efficiency are low, and the leak detection of the arrester cannot be sealed, so as to achieve high detection accuracy and detection efficiency, and realize storage. and leak rate, realize the effect of calculation analysis

Inactive Publication Date: 2015-03-25

CHINA XD ELECTRIC CO LTD

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The sealing test of the arrester adopts the partial injection leak detection on the sealing surface, and the overall seal leak detection of the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

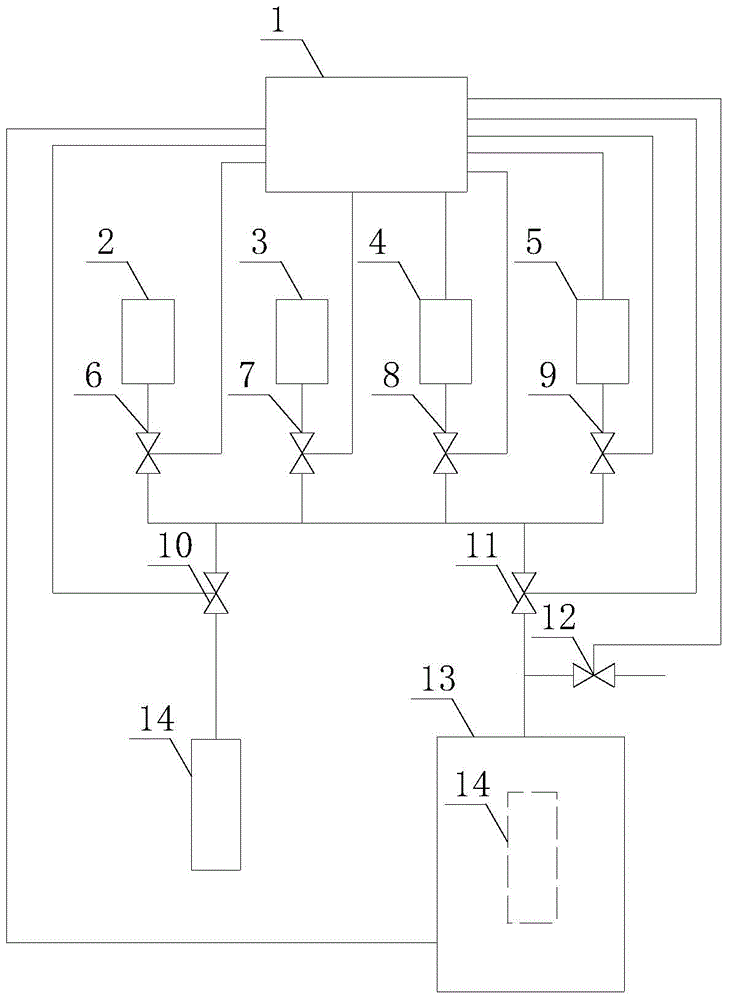

The invention discloses a lightning arrester sealing test device and method. A vacuum box is connected with a helium mass spectrometer through a first vacuum box valve and a helium mass spectrometer valve and is connected with a return pump through the first vacuum box valve and a return pump valve. By means of a measurement control unit, vacuumizing and helium and nitrogen mixture gas filling are carried out on a test object, and the vacuum box, the first vacuum box valve, the return pump valve, the return pump, the helium mass spectrometer valve, the helium mass spectrometer and a second vacuum box valve are controlled to vacuumize and detect the vacuum box. Parameters of helium in the vacuum box detected by the helium mass spectrometer are collected into the measurement control unit to be analyzed, calculated and stored to obtain the leak rate value of the test object. According to the lightning arrester sealing test device and method, whole seal and leakage detection of a lightning arrester are achieved, the detection precision and efficiency are improved, helium mass spectrometer detection value storage and leak rate calculation and analysis are achieved, and powerful testing data and guarantee are provided for reliable running of the lightning arrester.

Description

technical field [0001] The invention belongs to the technical field of lightning arrester testing, in particular to a lightning arrester sealing test device and a testing method. Background technique [0002] Arrester is an important protective device in power system, and has been widely used in power system. The sealing characteristics of arrester determine the reliable operation of arrester. According to statistics, more than 50% of arrester failures are caused by arrester sealing. The measurement and research on the sealing performance of arrester is very important. The sealing test of the arrester uses local spraying of the sealing surface for leak detection, which cannot be used for overall seal leak detection of the arrester. The detection accuracy and efficiency are low, and the test results are easily interfered by external factors. Contents of the invention [0003] The object of the present invention is to solve the above problems, and provide a lightning arrest...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/20

Inventor 何计谋苗发金祝嘉喜李小社

Owner CHINA XD ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com