Electromechanical valve sealing performance detection equipment and method suitable for intelligent manufacturing of Internet of Things

A technology of tightness detection and intelligent manufacturing, which is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, and testing of machine/structural components, etc. It can solve problems such as incompatibility of electromechanical valve production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

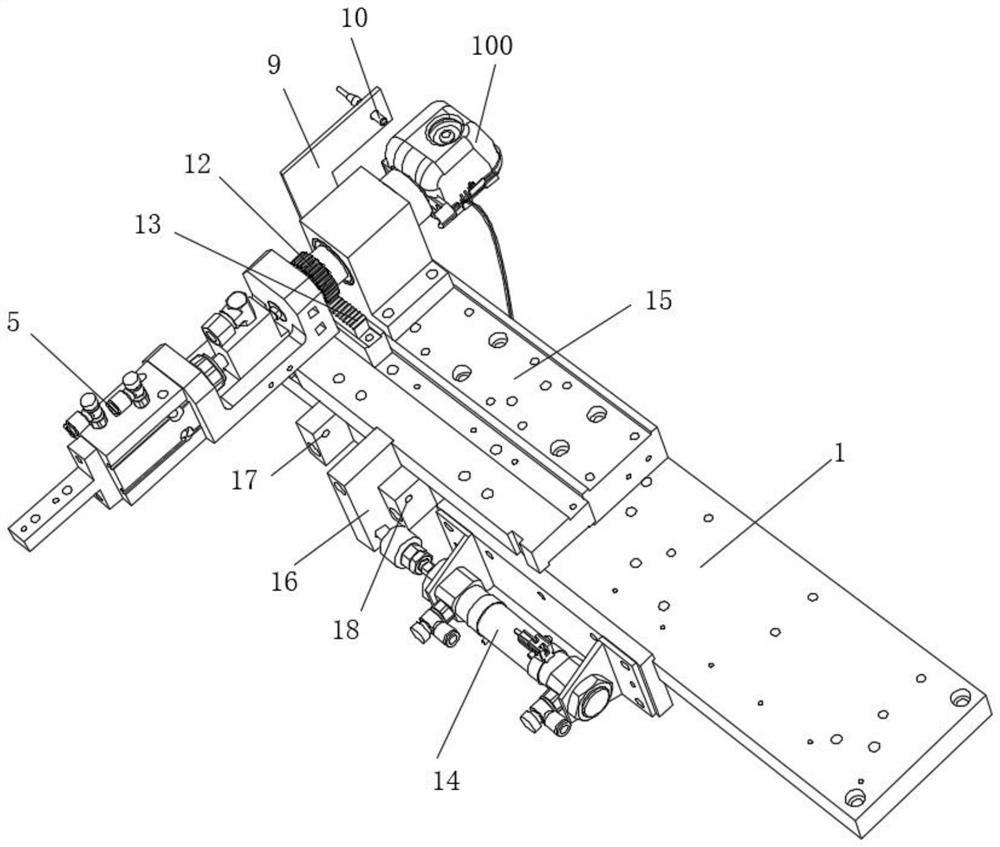

[0065] A leak detection device for an electromechanical valve 100 includes a mounting base plate 1, a blocking assembly and an air pressure detection assembly.

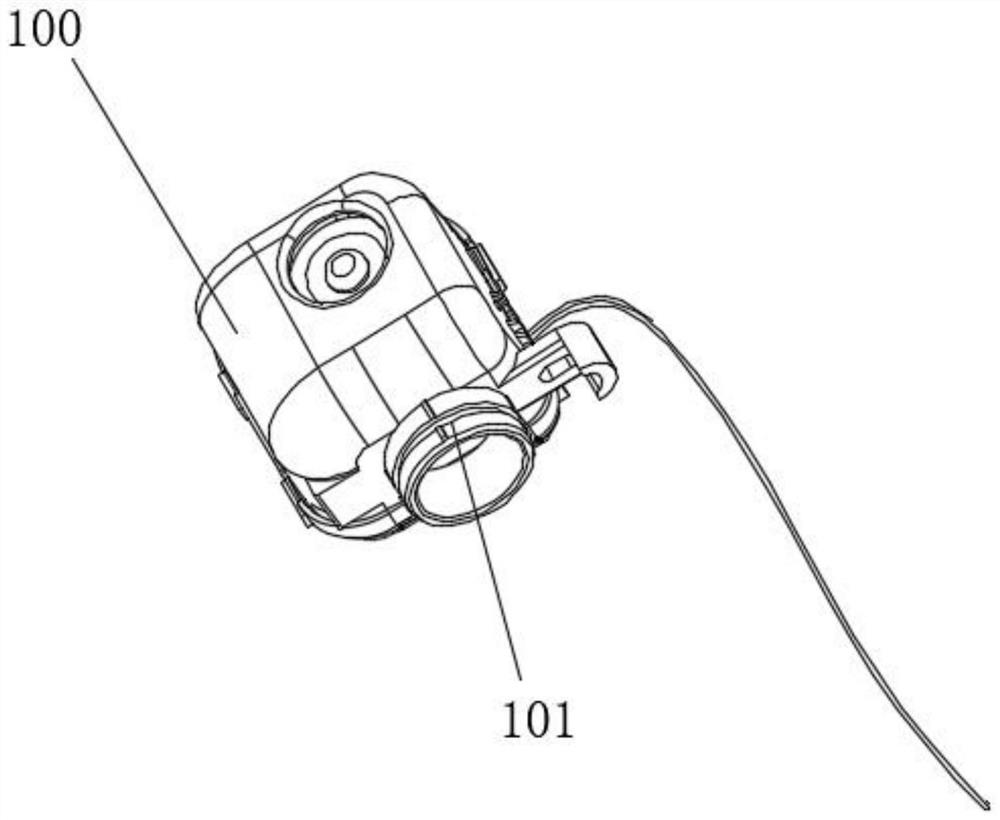

[0066] The installation substrate 1 has a detection position for placing the electromechanical valve 100 to be detected. The detection position is only for positioning the position of the plugging assembly, that is, after the electromechanical valve 100 is moved to the detection position, it is convenient for the plugging assembly to move out of the electromechanical valve 100. Gas port 101 is blocked.

[0067] The blocking component is arranged on the installation substrate 1, and the air outlet 101 of the electromechanical valve 100 located at the detection position is blocked, and an inflation channel is arranged inside the blocking component;

[0068] The air port of the air pressure detection component is connected to the air charging channel. The air pressure detection component includes an air pump and a pressu...

Embodiment 2

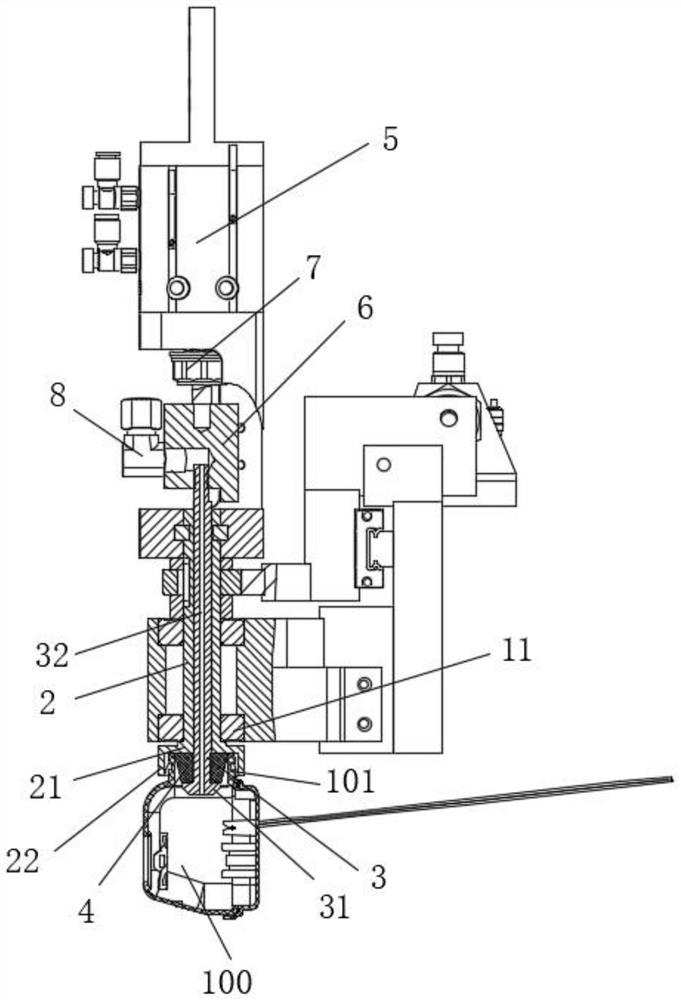

[0071] In the above embodiments, the air outlet 101 needs to be blocked by a plugging component. At present, manual plugging is mostly used. This embodiment provides an automatic sealing structure. The plugging component includes a hollow shaft 2 and a hollow tie rod 3 And rubber sealing ring 4;

[0072] The hollow shaft 2 has a first end and a second end, which is a straight cylindrical structure. The hollow shaft 2 is provided with a first axial through hole inside. The hollow shaft 2 is connected to the mounting substrate 1, and the central axis of the hollow shaft 2 is The central axis of the air outlet 101 coincides, and the first end of the hollow shaft 2 is provided with a first protrusion 21;

[0073] The first protrusion 21 can be a ring coaxial with the hollow shaft 2 .

[0074] The hollow tie rod 3 has a first end and a second end, which is a straight cylindrical structure. The inside of the hollow tie rod 3 is provided with an axial second through hole 32. The hol...

Embodiment 3

[0083] Because the diameter of the air outlet 101 of the electromechanical valve 100 is small, the diameter of the hollow tie rod 3 should not be too large. If the hollow tie rod 3 is directly connected to the moving end of the first linear moving assembly 5, it may cause a connection with the air pump. The structure is unstable, so the blocking assembly in this embodiment also includes a connecting block 6 .

[0084] For the convenience of description, several faces of the connecting block 6 are respectively named as the first end face, the second end face and the side (the side can be a plurality of straight faces and / or curved faces, and can also be a cylindrical face), and the position is limited: The first end face of the connection block 6 is arranged parallel to the second end face of the connection block 6, and the side surface of the connection block 6 is vertically arranged with the first end face of the connection block 6;

[0085] The second end of the hollow tie r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com