Air tightness detection device for battery bottom support

A technology for air tightness detection and battery bottom, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, which can solve the problem that the air leakage of the blind rivet nut on the battery bottom support cannot be detected. and other problems, to achieve the effect of intuitive and clear leak detection and air tightness detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

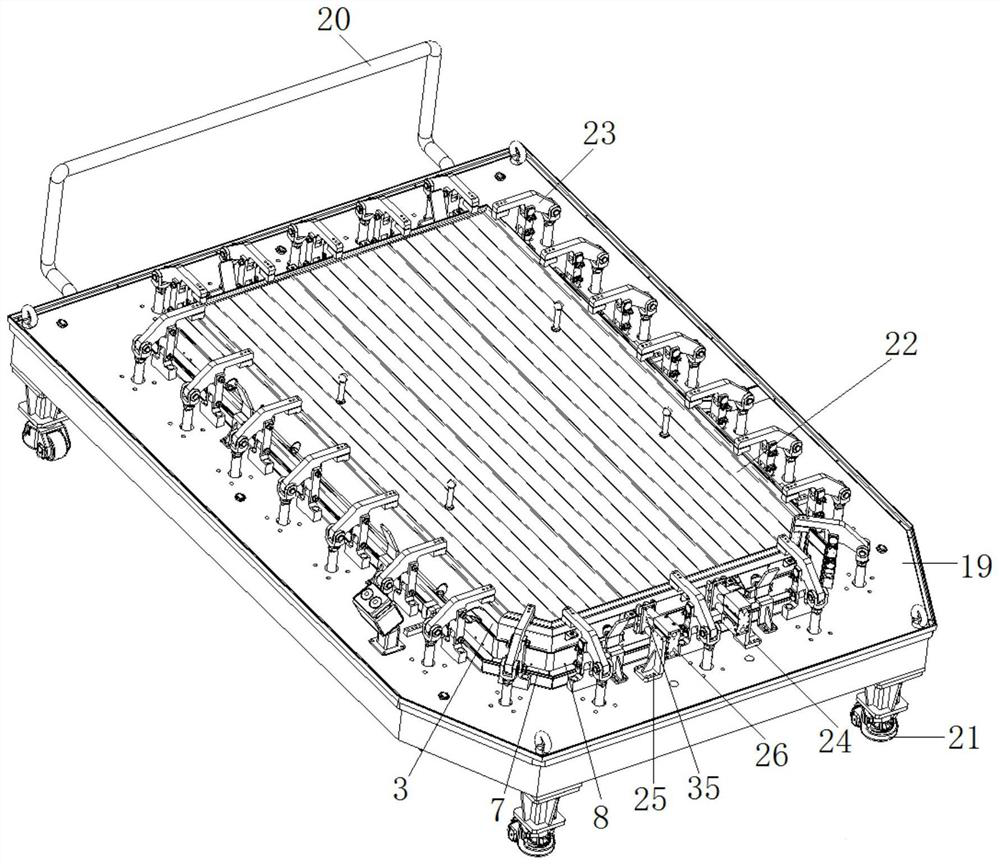

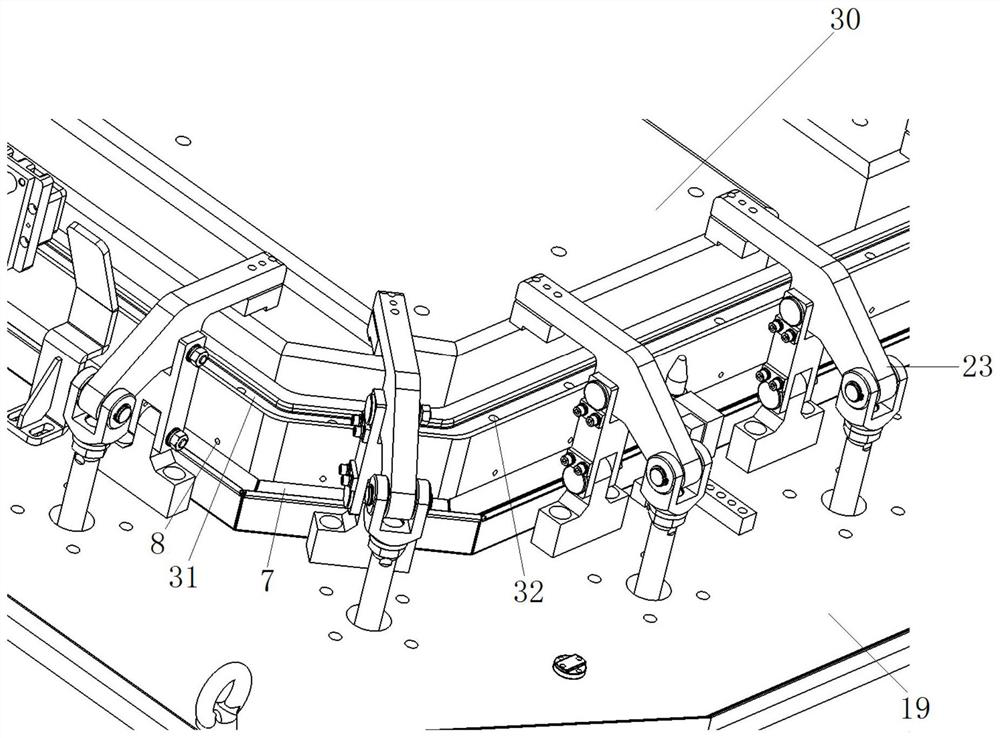

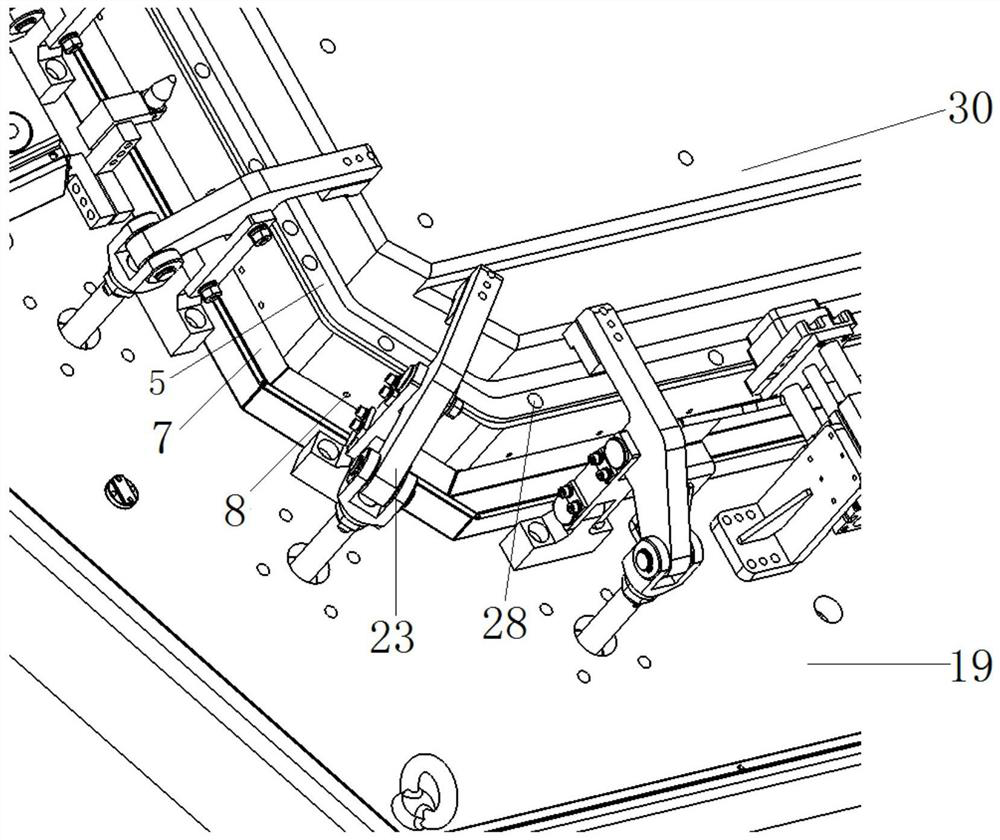

[0018] Such as Figure 1-8 As shown, the airtightness detection device of the battery bottom bracket of the present invention includes a battery bottom bracket cavity detection area 30 and a blind rivet nut detection area 31; wherein, a plurality of detection holes 32 are provided on the blind rivet nut detection area 31. The detection holes 32 on the rivet nut detection area 31 are provided in one-to-one correspondence with the rivet nuts 4 on the peripheral beam 3 of the battery bottom support; The air hole 8 and the air hole 8 communicate with the water tank 7 on the periphery of the rivet nut detection area 31; the rivet nut detection area 31 is also laid with a sealing ring 5, and the sealing ring 5 is provided with a through hole 28 at the corresponding position of each detection hole 32 The peripheral beam 3 of the battery bottom support is pressed on the sealing ring 5 of the blind rivet nut detection area 31 , and each blind rivet nut 4 on the peripheral beam 3 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com