Photoelectric instrument air tightness detector

A photoelectric instrument and air-tightness technology, which is applied in the direction of liquid-tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems of detection result errors, etc., to prevent mold and solve air-tightness the effectiveness of the robustness detection challenge, ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

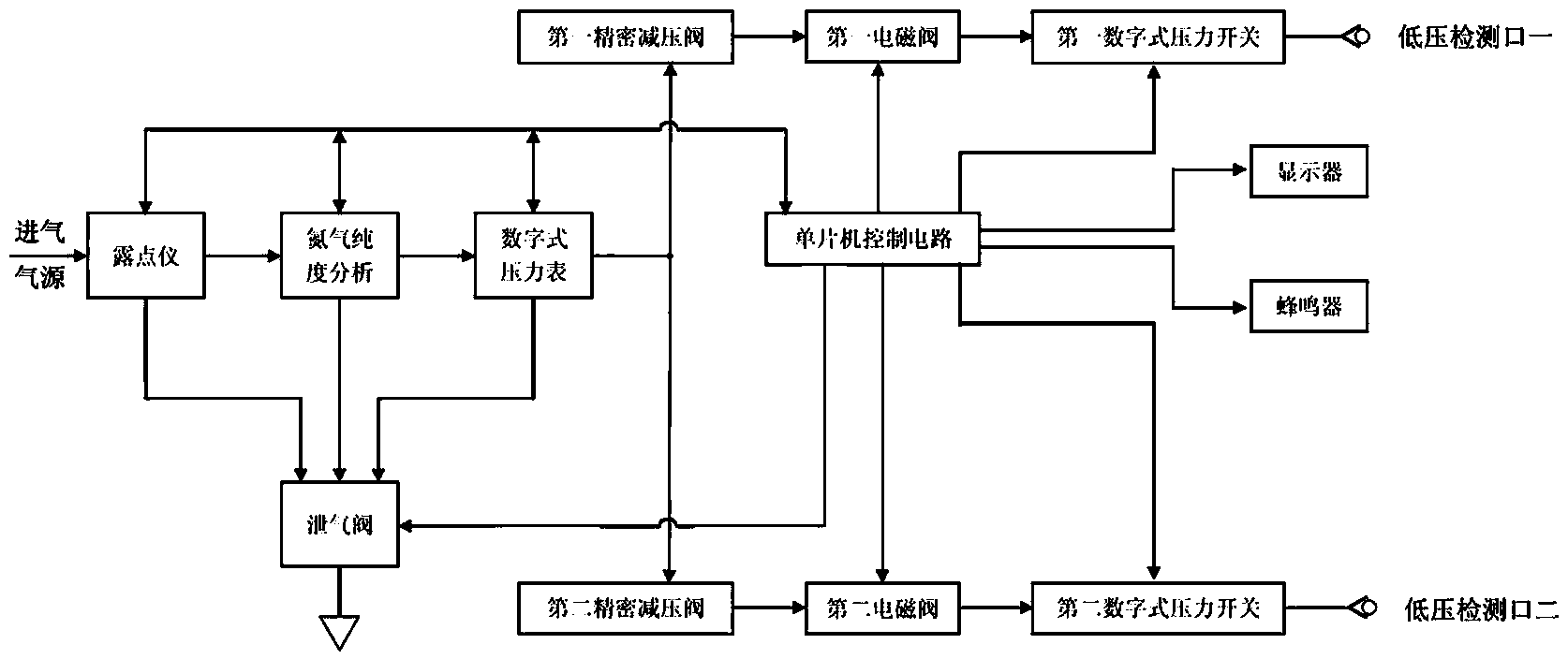

[0026] Such as figure 1 As shown, the present invention is composed of a dew point meter, a nitrogen purity analyzer and a digital pressure gauge connected in series to form a nitrogen online quality analysis module to detect whether the nitrogen quality input into the photoelectric instrument under test meets the specified technical index requirements; the dew point meter , Nitrogen purity analyzer and digital pressure gauge are respectively connected with the vent valve, when the unqualified gas source is detected, under the control of the single-chip microcomputer control circuit, the corresponding gas source will be released in time.

[0027] Connected to the output end of the nitrogen online quality analysis module are two gas charging channels, each of which is equipped with a precision pressure reducing valve to decompress the 200kPa input gas source to two different low pressures; in each gas charging channel It is also connected with a composite on-off valve composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com