A performance analysis test system and method for pipe plugging robot slips and rubber cartridges

A test system and plugging performance technology, applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve the problems of high cost, inability to achieve universality, and few test systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

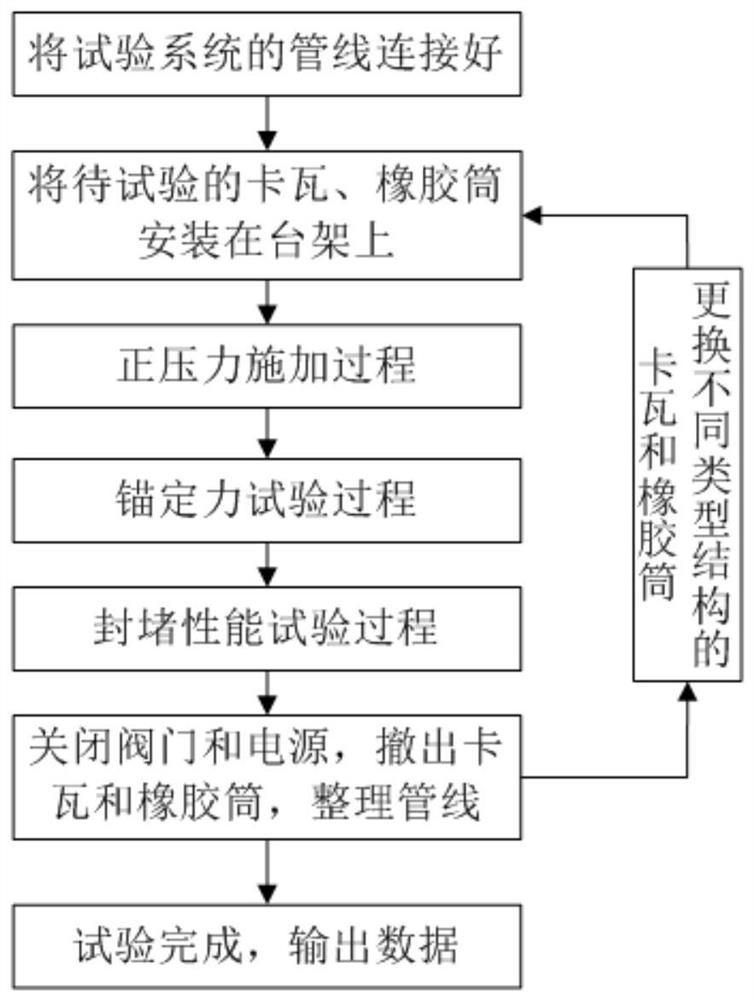

[0047] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. In the description of the present invention, it should be understood that the use of "I", "II" and "III" Words such as to define components are only for the convenience of distinguishing the above-mentioned components. If there is no other statement, the above-mentioned words have no special meaning, so they should not be construed as limiting the protection scope of the present invention.

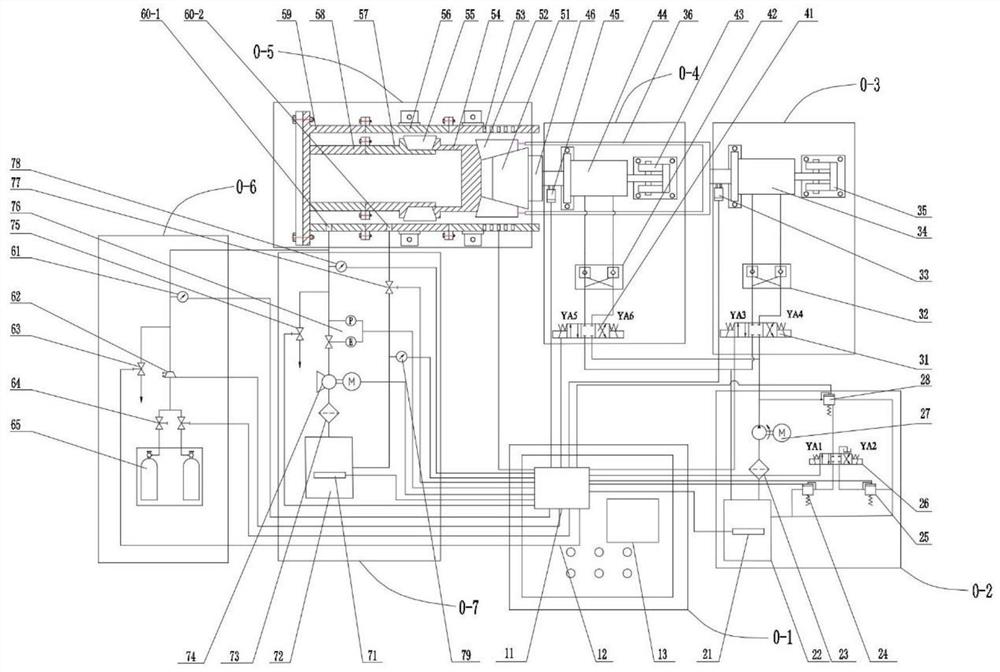

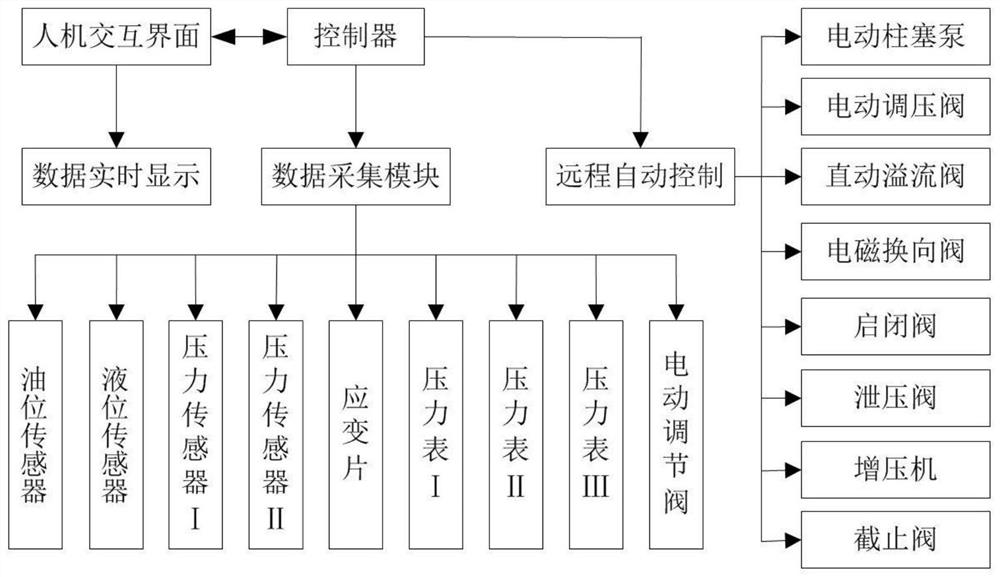

[0048] Such as figure 1 , figure 2 As shown, a pipeline plugging robot slips and rubber cartridge performance analysis test system, including: electrical signal control module (0-1), three-stage pressure regulation module (0-2), anchoring force test module (0- 3), positive pressure output module (0-4), anchor plugging performance test module (0-5), gas path simulation module (0-6) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com