Positive pressure leakage hole calibration device and method based on static accumulation attenuation comparison method

A positive pressure leak and calibration device technology, applied in the field of measurement, can solve the problems of low calibration efficiency, narrow calibration range of constant pressure method, and high requirements for researchers and operators, so as to reduce measurement uncertainty and simple calibration method Ease of operation and the effect of extending the calibration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

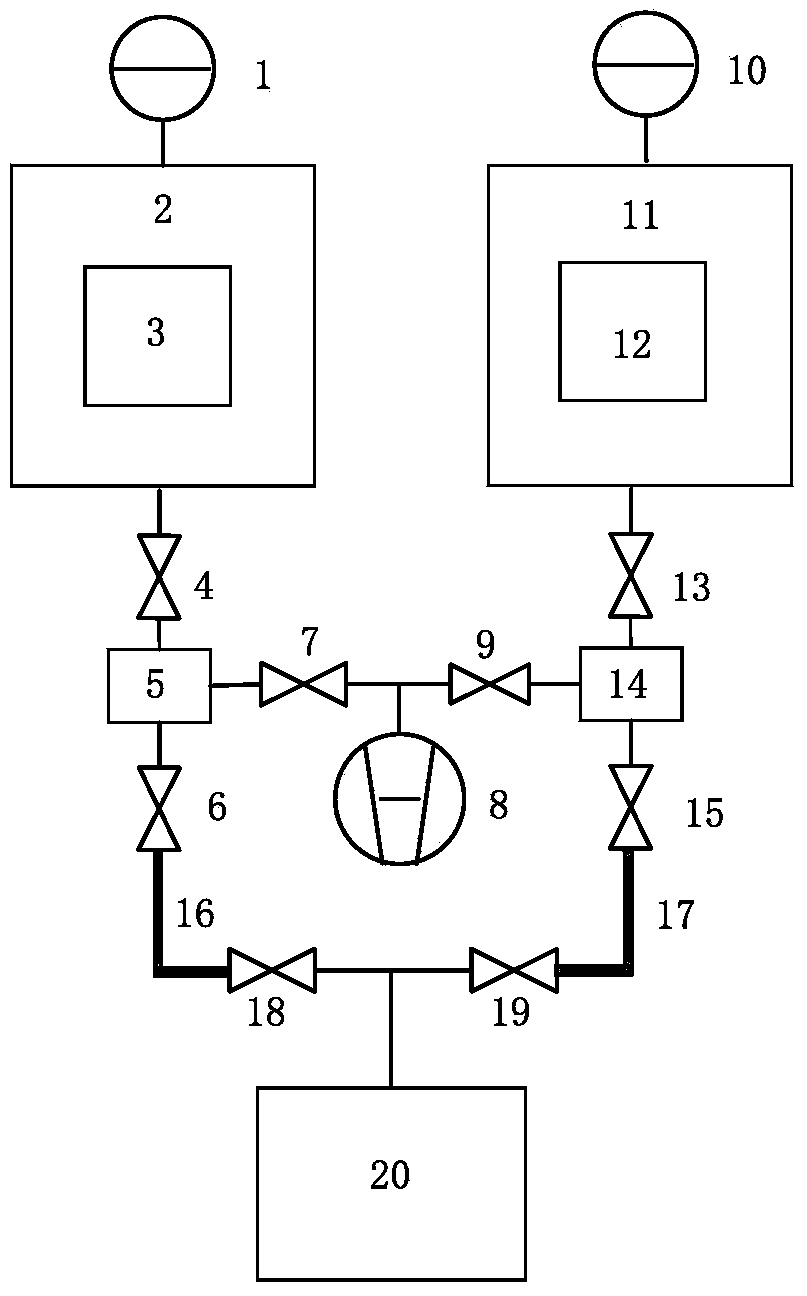

[0030] Such as figure 1 As shown, a positive pressure leak calibration device based on the static cumulative attenuation comparison method designed by the present invention is mainly composed of an air extraction system, a mass spectrometer leak detector 20 and two sets of sampling systems; wherein

[0031] The two sets of sampling systems are identical. The sampling system includes pressure gauges 1 and 10, gas collection chambers 2 and 11, shut-off valves I4 and 13, shut-off valves II6 and 15, shut-off valves III18 and 19, sampling chambers 5 and 14 and capillary tubes 16, 17; the connection relationship is: the pressure gauges 1, 10 are connected to the gas collection chambers 2, 11, the gas collection chambers 2, 11 are connected to the air inlets of the sampling chambers 5, 14 through the stop valves I4, 13, and the sampling chambers 5, 14 are connected to each other. The gas outlet is connected to the helium mass spectrometer leak detector 20 through stop valves II6, 15,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com