Capillary rheometer and method for measuring rheological properties of polymer materials

A capillary rheometer and polymer material technology, which is applied in the measurement of DC flow characteristics, can solve the problems of high price of the instrument, difference in tightness, and low measurement accuracy of the capillary rheometer, and achieves reasonable processing technology, comparability and The effect of increased credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below.

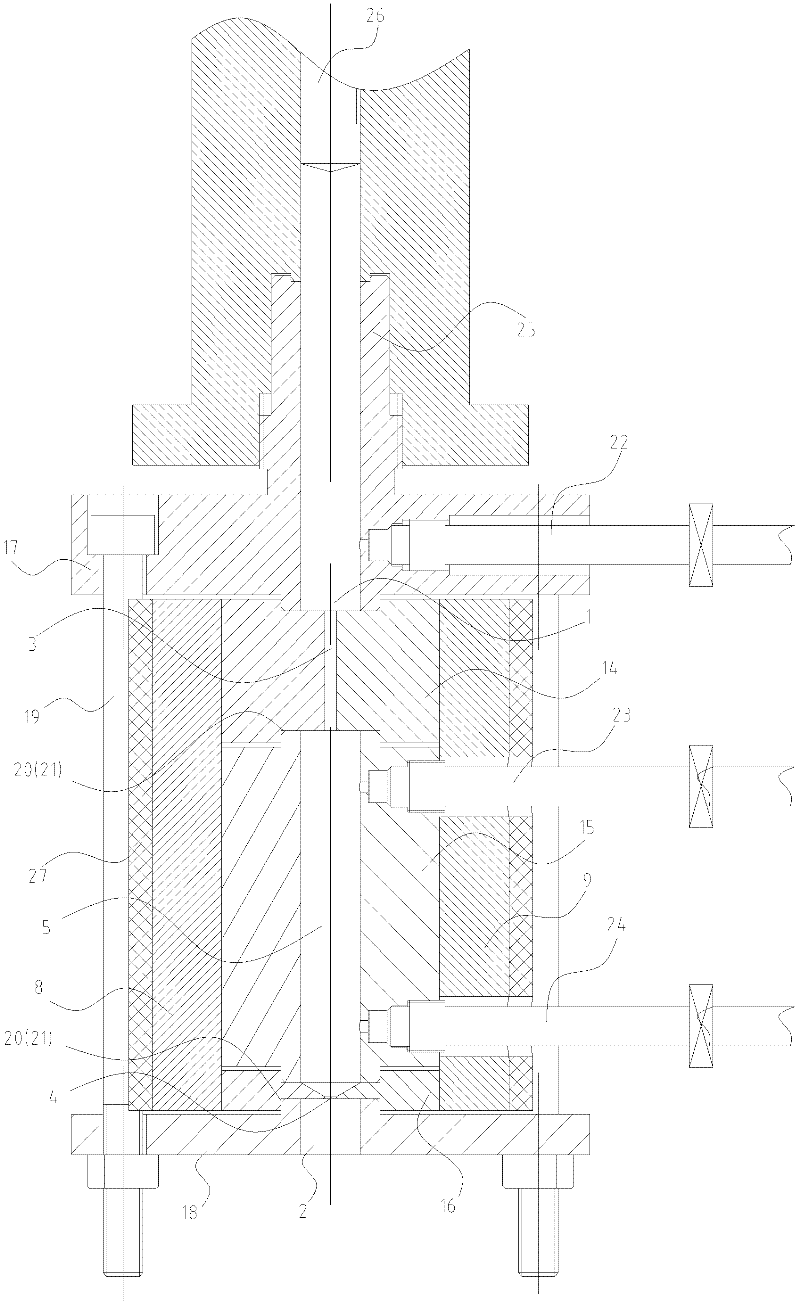

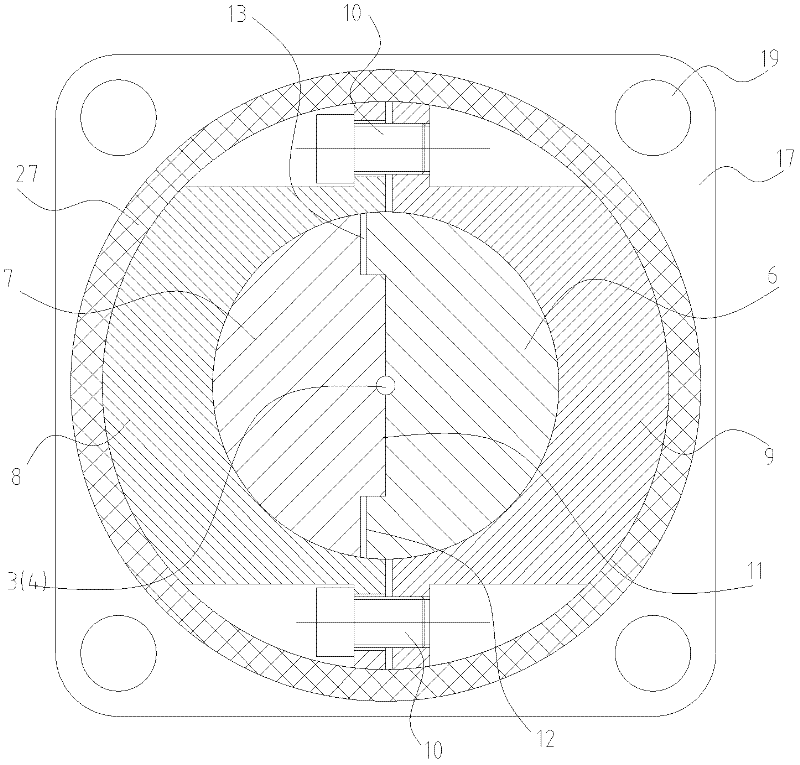

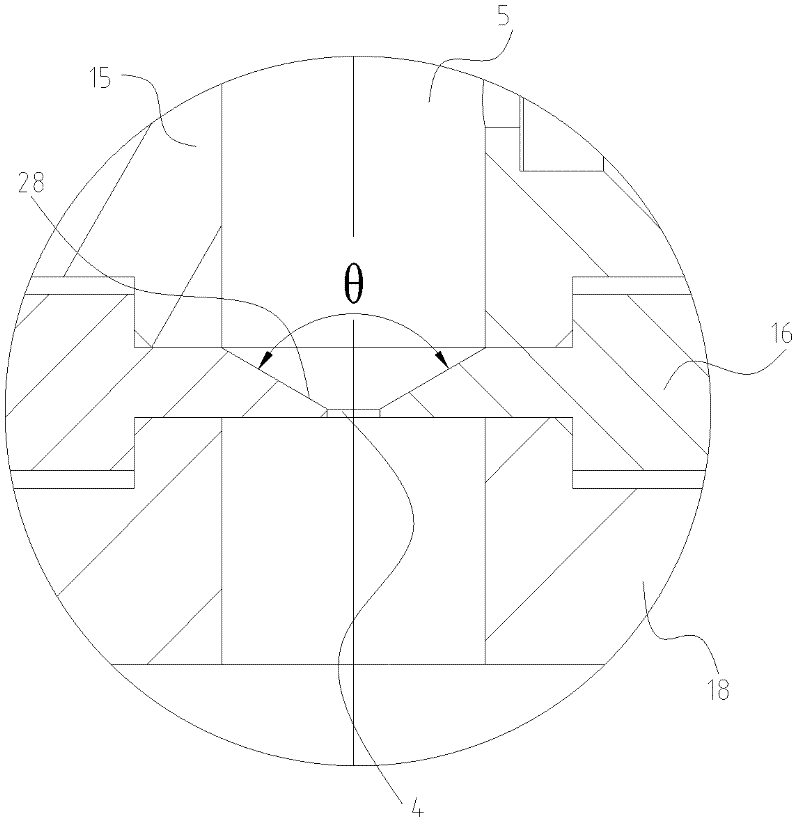

[0036] Such as Figure 1 to Figure 3 As shown, a capillary rheometer includes a barrel, a feed port 1 is provided at the front end of the barrel, a discharge port 2 is provided at the rear end of the barrel, and a first capillary channel 3 is arranged in the barrel , the material passing pipeline 5 and the second capillary pipeline 4, the feed inlet 1 communicates with the discharge port 2 through the first capillary pipeline 3, the material passing pipeline 5, and the second capillary pipeline 4 successively, and the cross-sectional area of the material passing pipeline 5 is greater than The cross-sectional area of the first capillary 3 and the second capillary 4.

[0037]Wherein, the material cylinder includes a first half cylinder 6 and a second half cylinder 7, and the opposite surfaces of the first half cylinder 6 and the second half cylinder 7 are respectively provided with a first half...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com