Leak detection method of electronic device

An electronic device and leak detection technology, which is applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems that affect the final result, missed judgment, and misjudgment of leak detection. Achieve the effects of no need for purification treatment, improve efficiency, and save leak detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

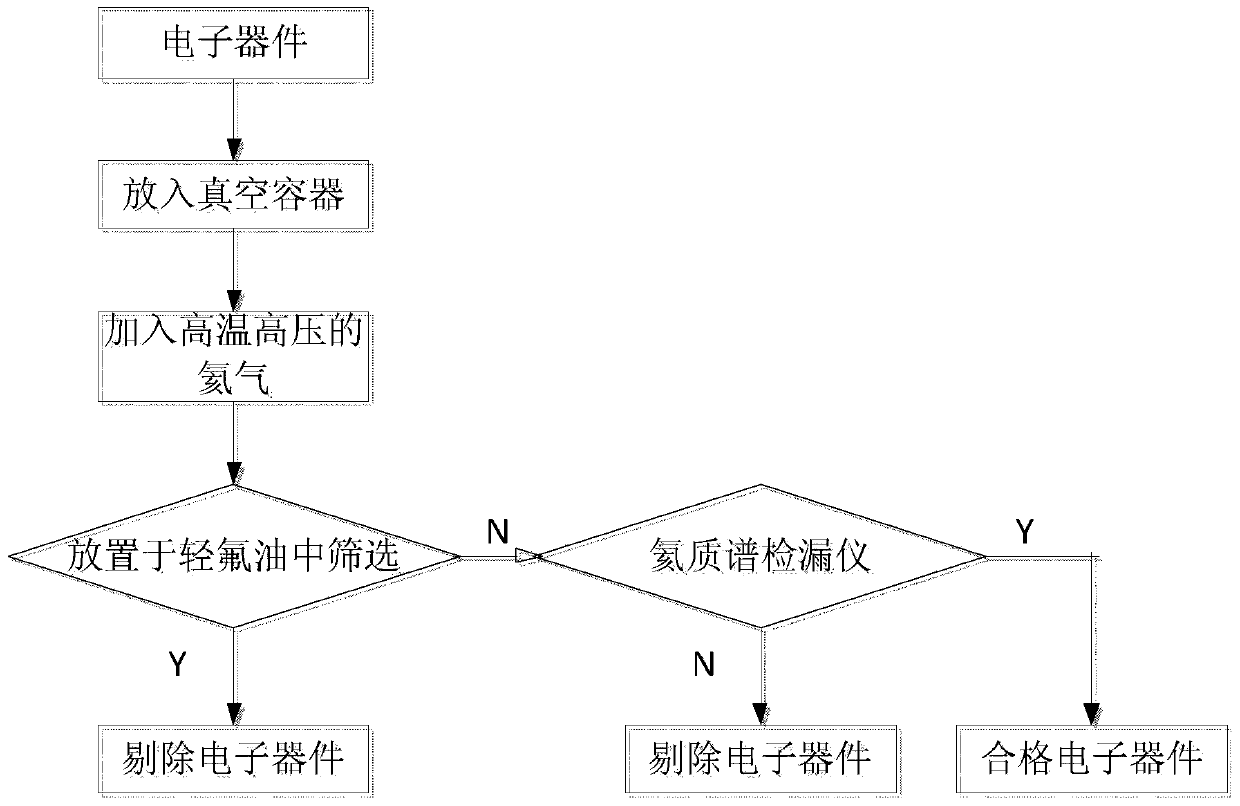

[0022] Such as figure 1 Shown is a flow chart of a leak detection method for an electronic device according to the present invention, and the steps are as follows:

[0023] Step 1: Put the tested electronic device into a pressurized container, and after the container is evacuated, pressurize the device with 99.999% high-pressure tracer gas helium, and the helium gas is pressed into the device through the leak hole on the device lumen;

[0024] Step 2: After the pressure treatment is completed, immerse the electronic device directly in light fluorine oil, and judge by observing whether the device is bubbling;

[0025] Step 3: Put the tested electronic device that has passed the bubbling into the vacuum container, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com