Patents

Literature

30results about How to "Good vacuum tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

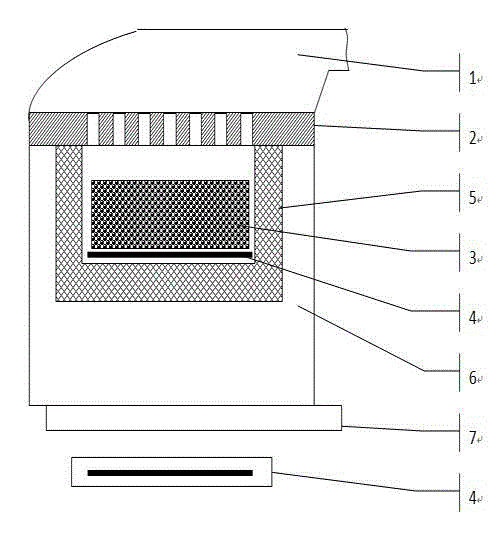

Domical microwave plasma chemical vapor deposition diamond film device

ActiveCN103668127AGood vacuum tightnessAid in depositionElectric discharge tubesChemical vapor deposition coatingResonant cavityPhysical chemistry

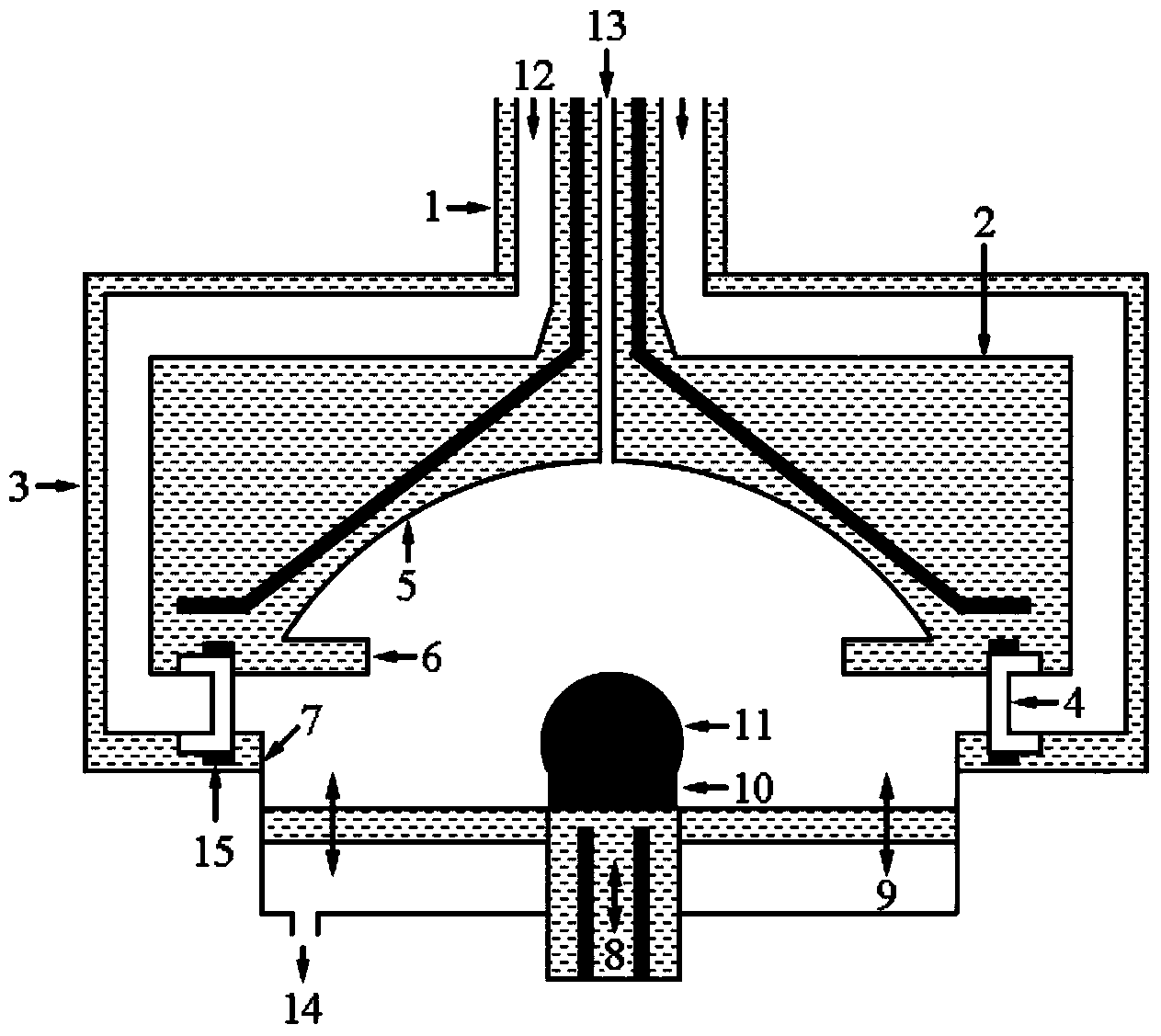

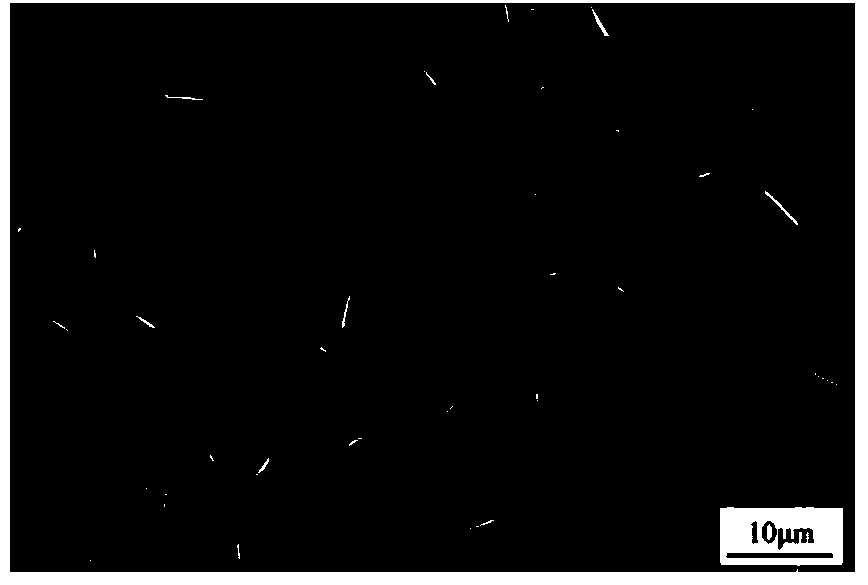

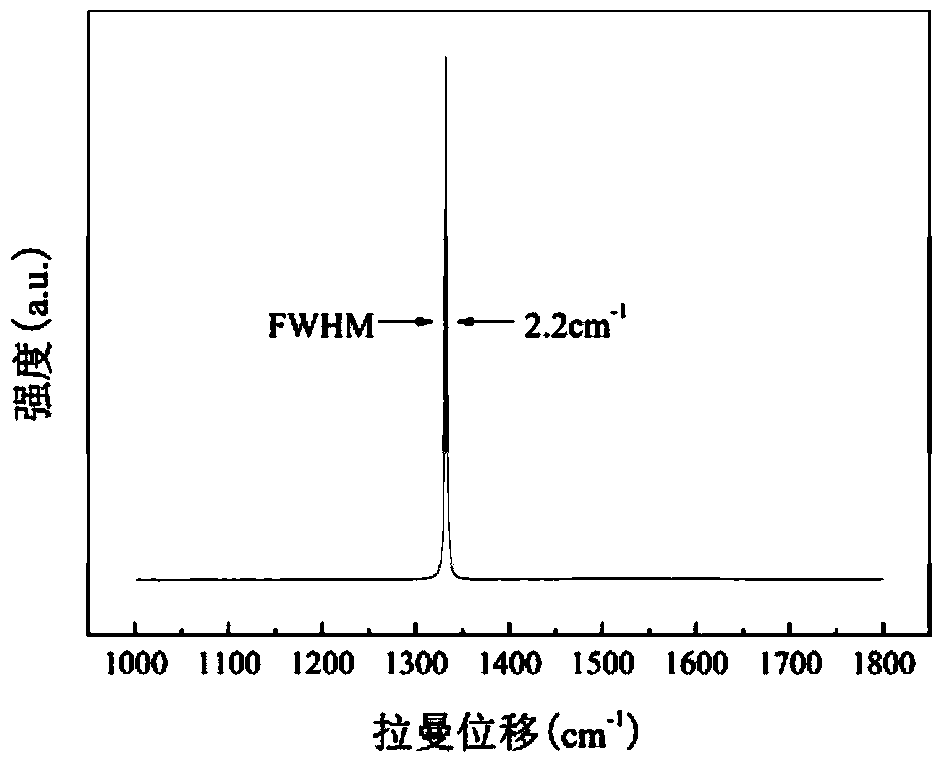

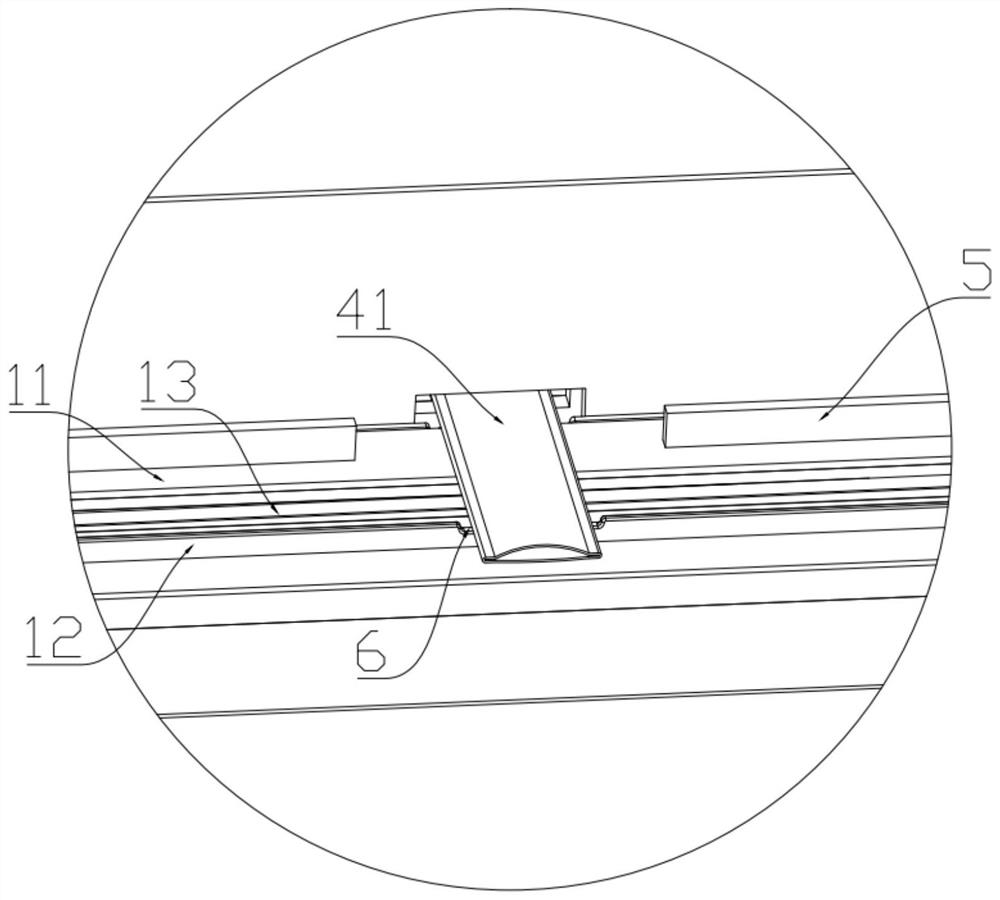

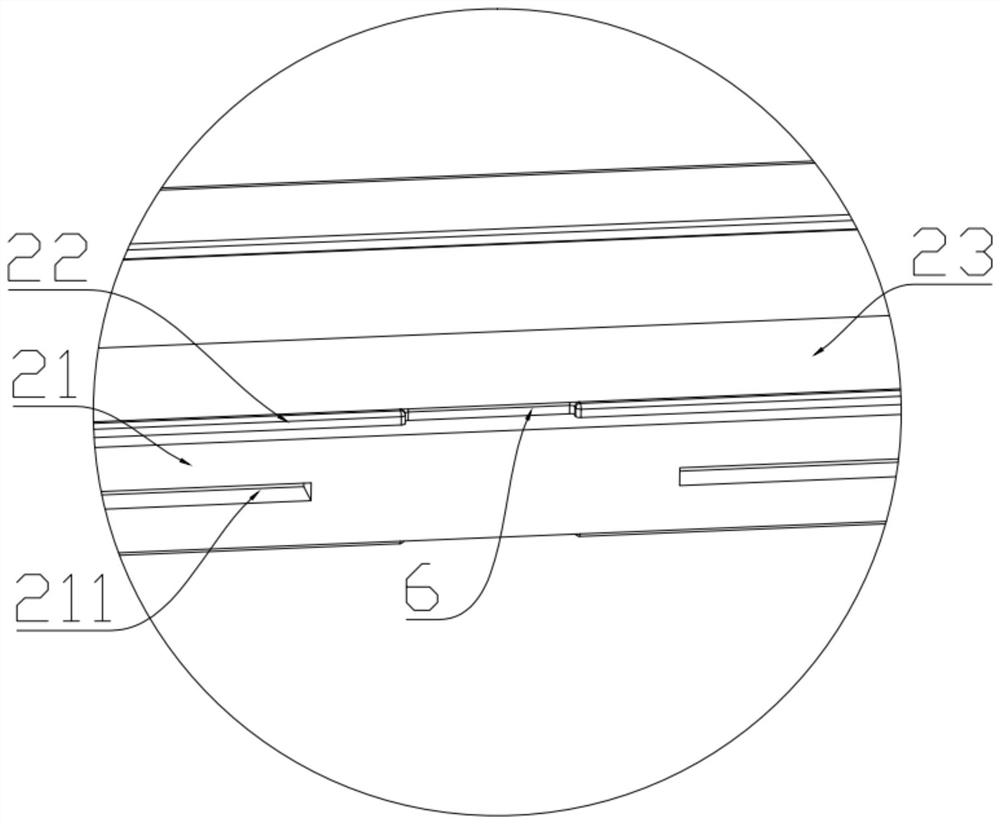

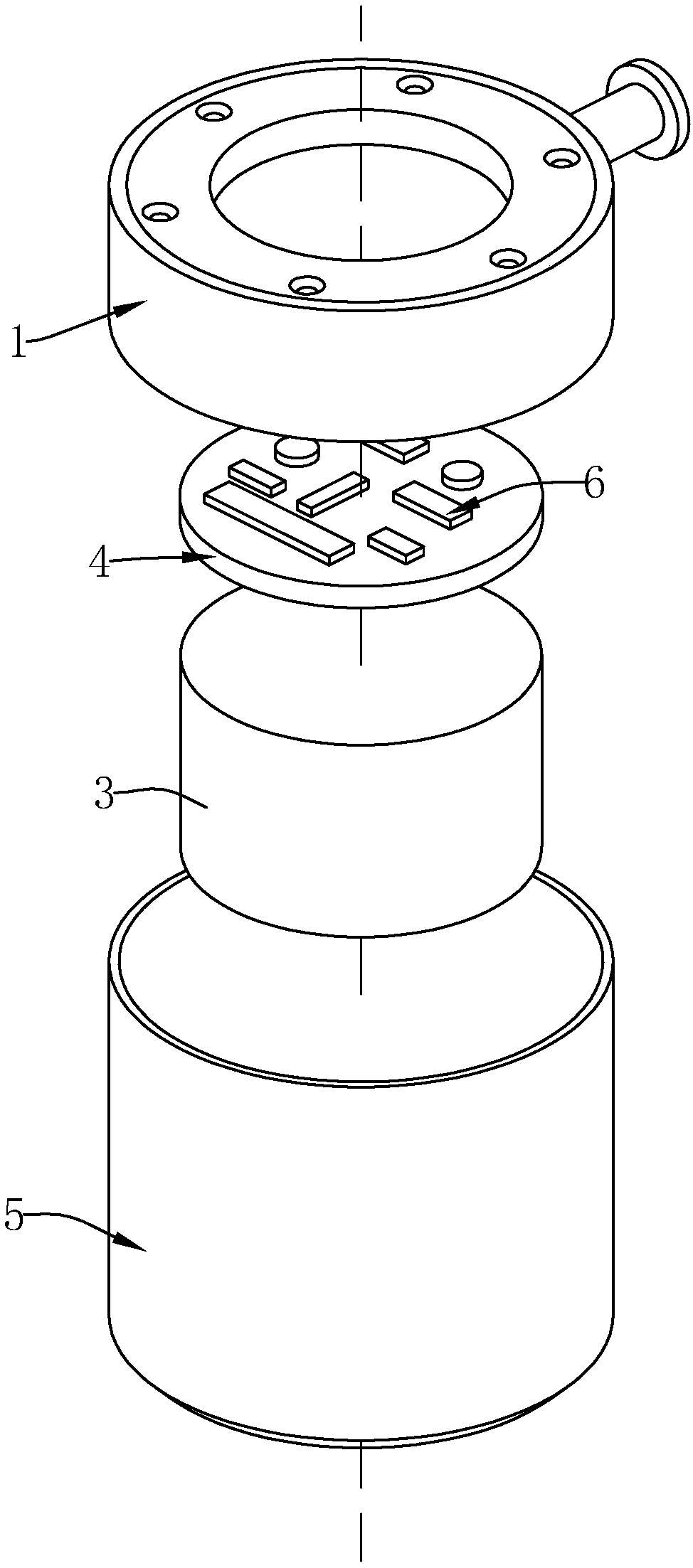

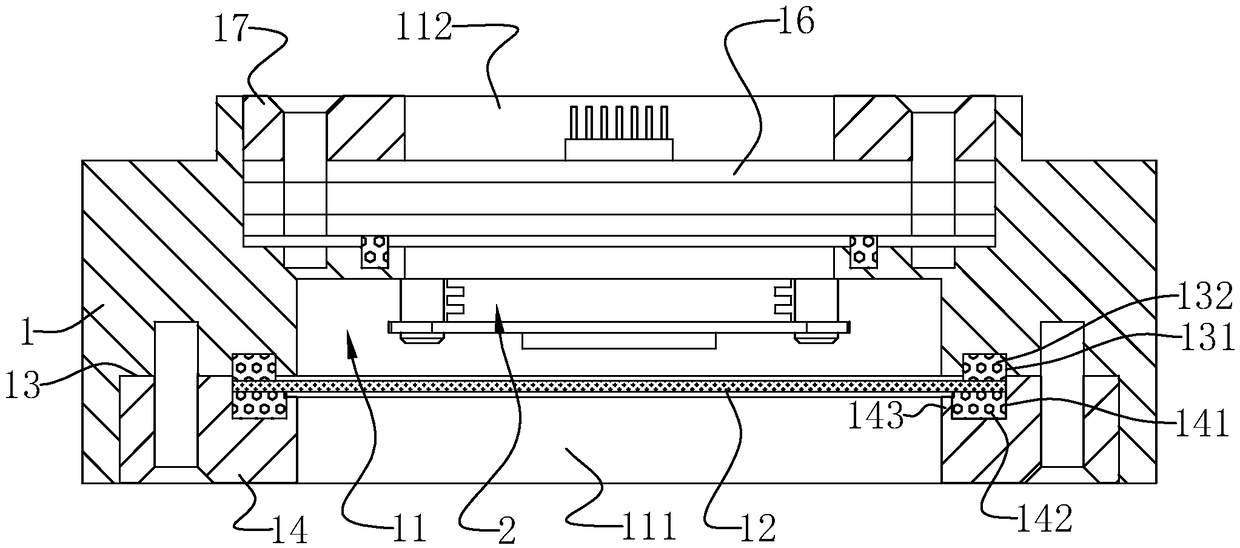

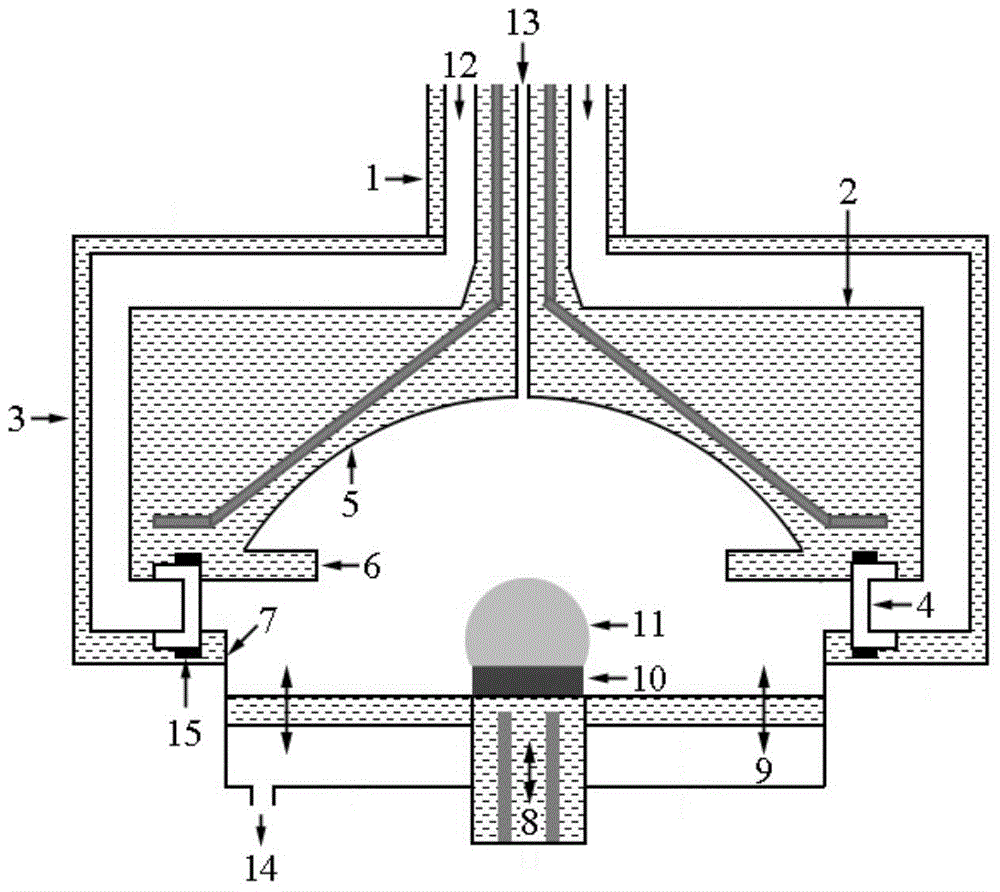

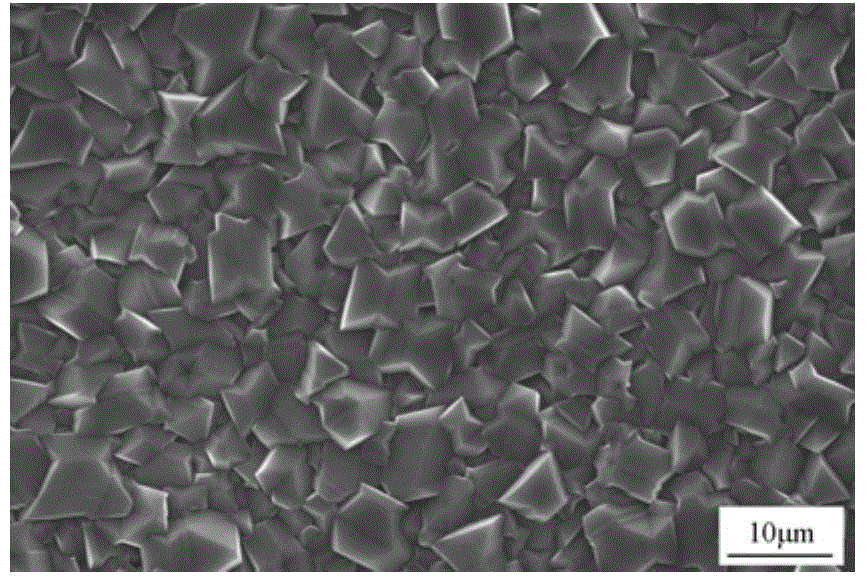

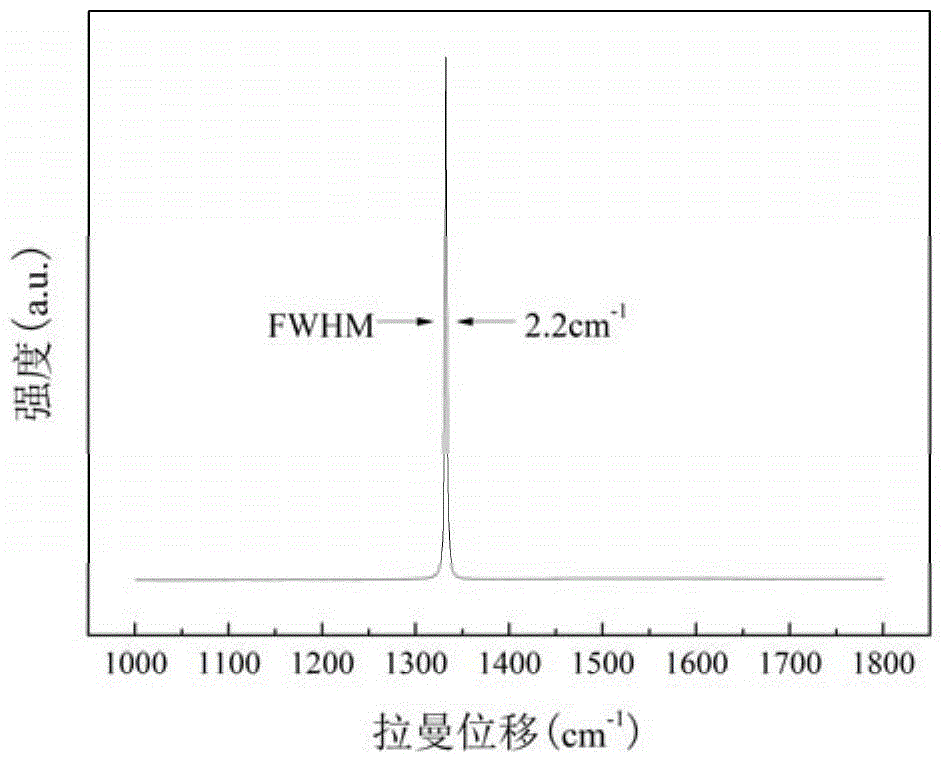

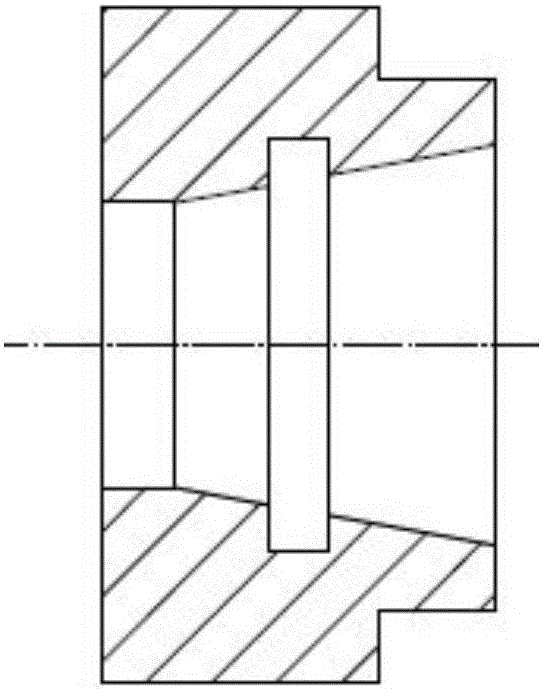

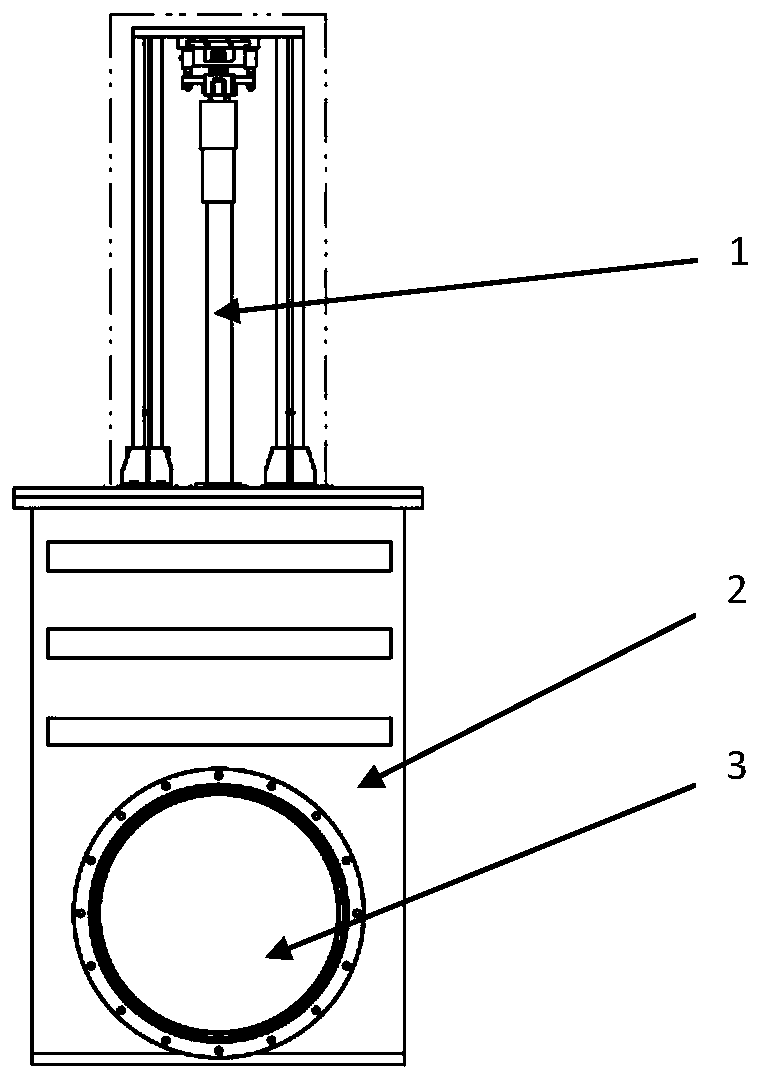

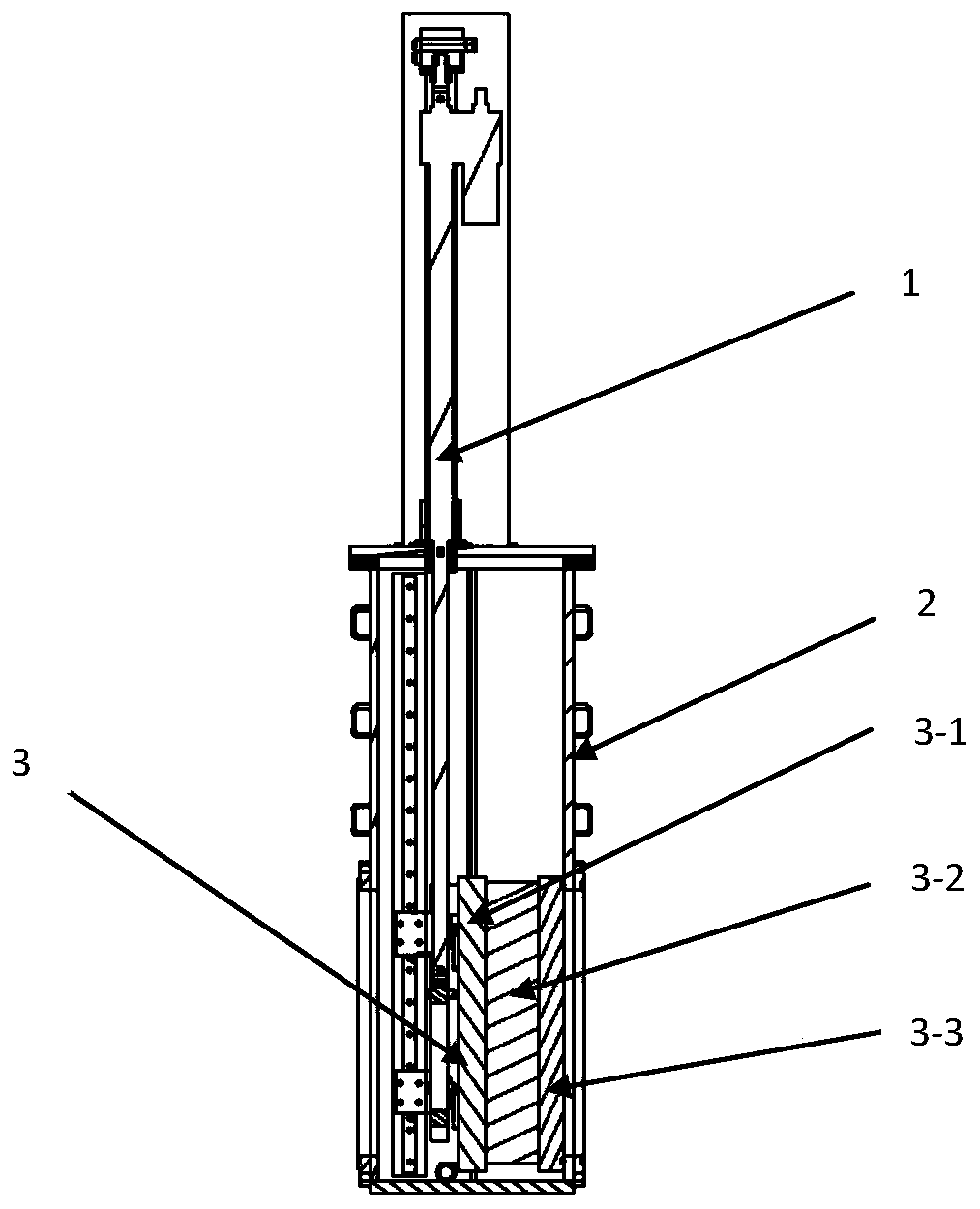

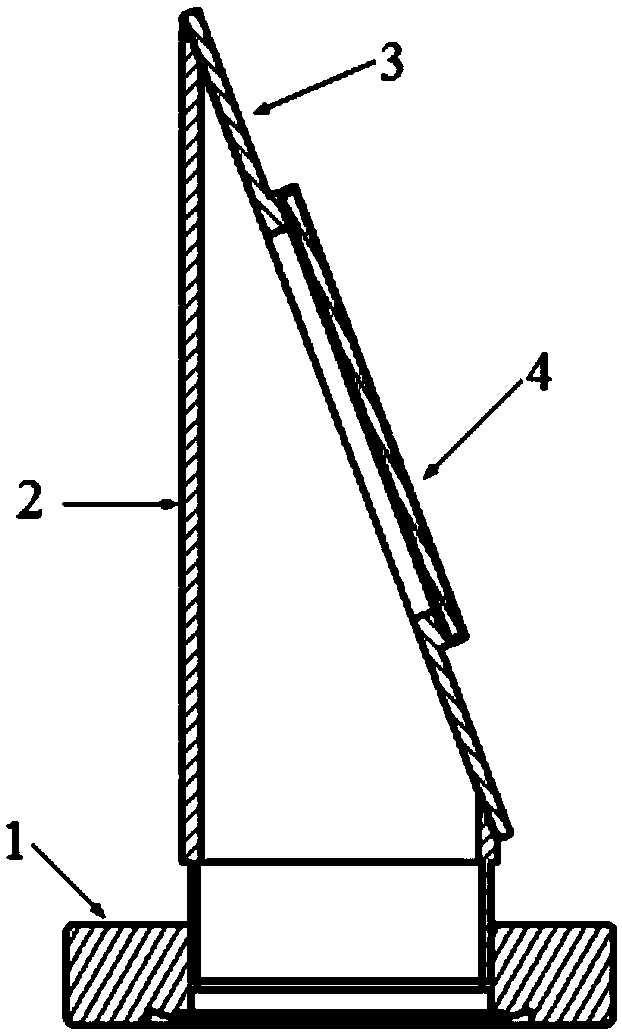

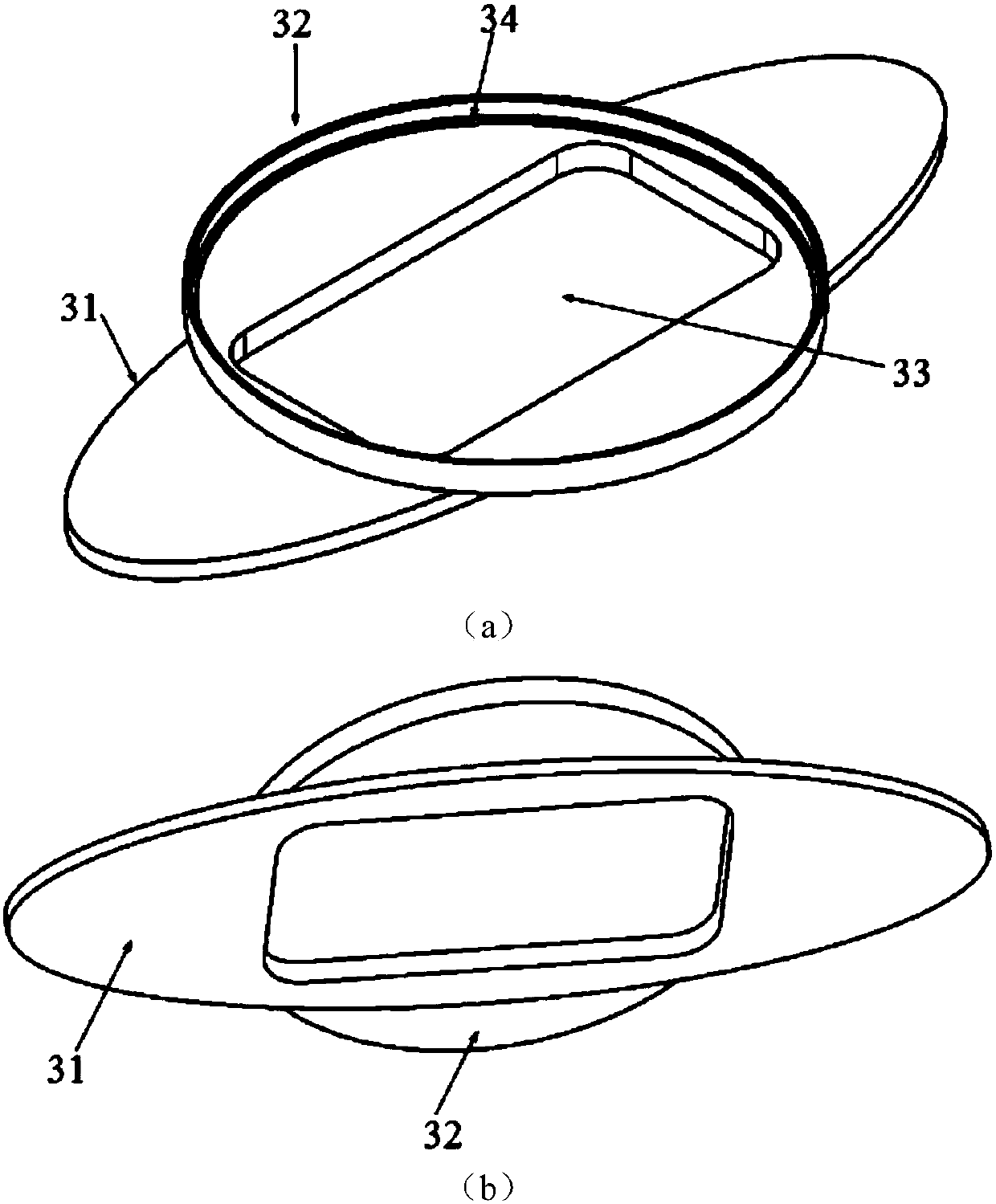

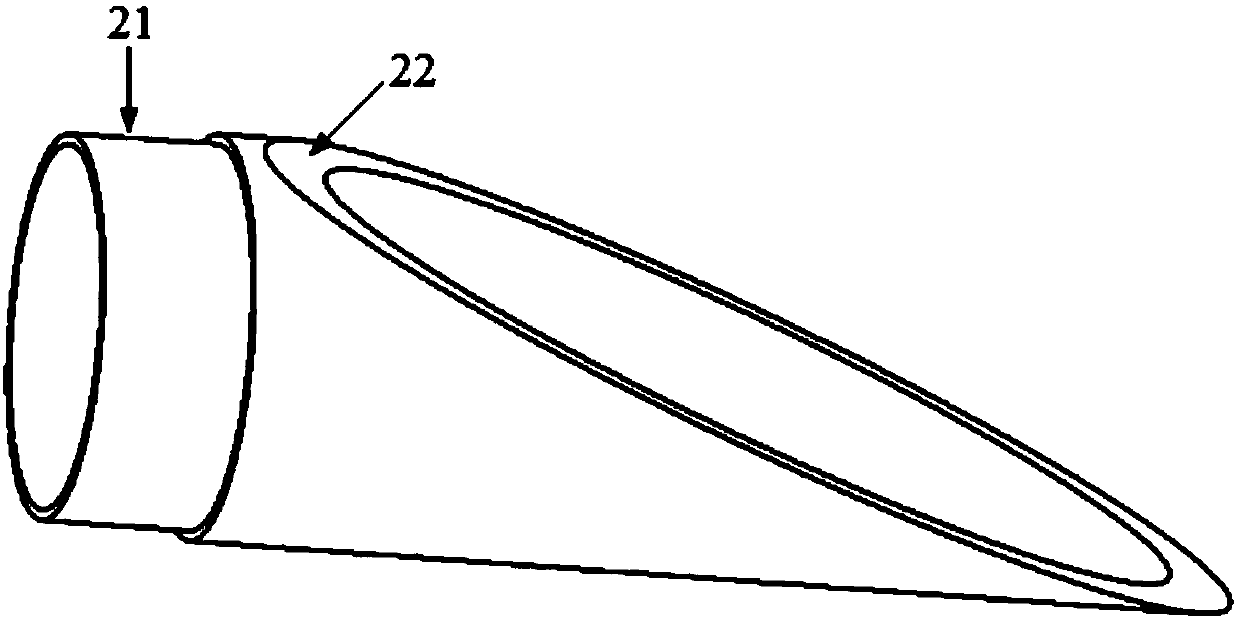

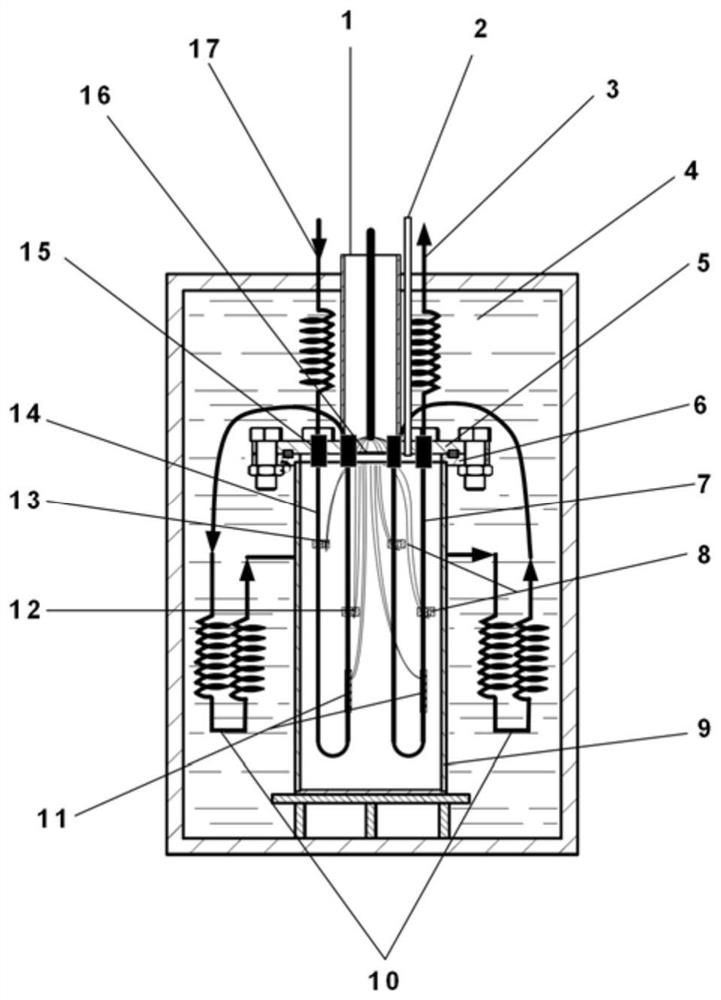

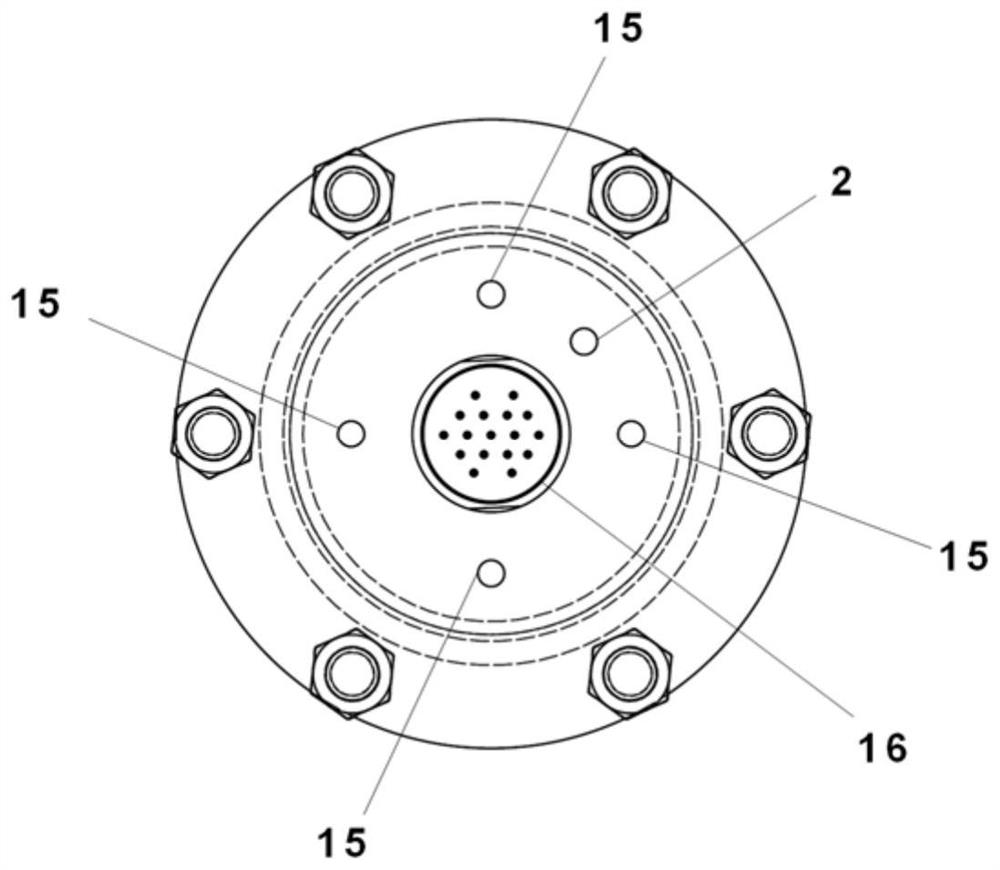

The invention relates to a domical microwave plasma chemical vapor deposition diamond film device which is suitable for quick preparation of a high-quality diamond film in the presence of high-power microwave input. A resonant cavity main body is composed of a domical reflecting body, a metal sheet reflecting body, a quartz ring window, a cylindrical reflecting body and a deposition platform, wherein the metal sheet reflecting body can block spreading of microwave to the top of the resonant cavity, so that more microwave can be accumulated above a substrate; the deposition platform is divided into a central deposition platform and a marginal deposition platform, and the independent vertical moving functions of the central deposition platform and the marginal deposition platform are beneficial to realize quick optimization of a plasma state; and the quartz ring window is hidden in a slit formed by the wall of the resonant cavity, thus avoiding etching of plasma and being beneficial to improve the vacuum performance of the resonant cavity. Besides, the favorable design of a water cooling system ensures the high-power operating safety of the equipment. So many advantages are combined, so that the domical microwave plasma chemical vapor deposition device has a capability of depositing a high-quality diamond film at high speed under a high power level.

Owner:HEBEI PLASMA DIAMOND TECH

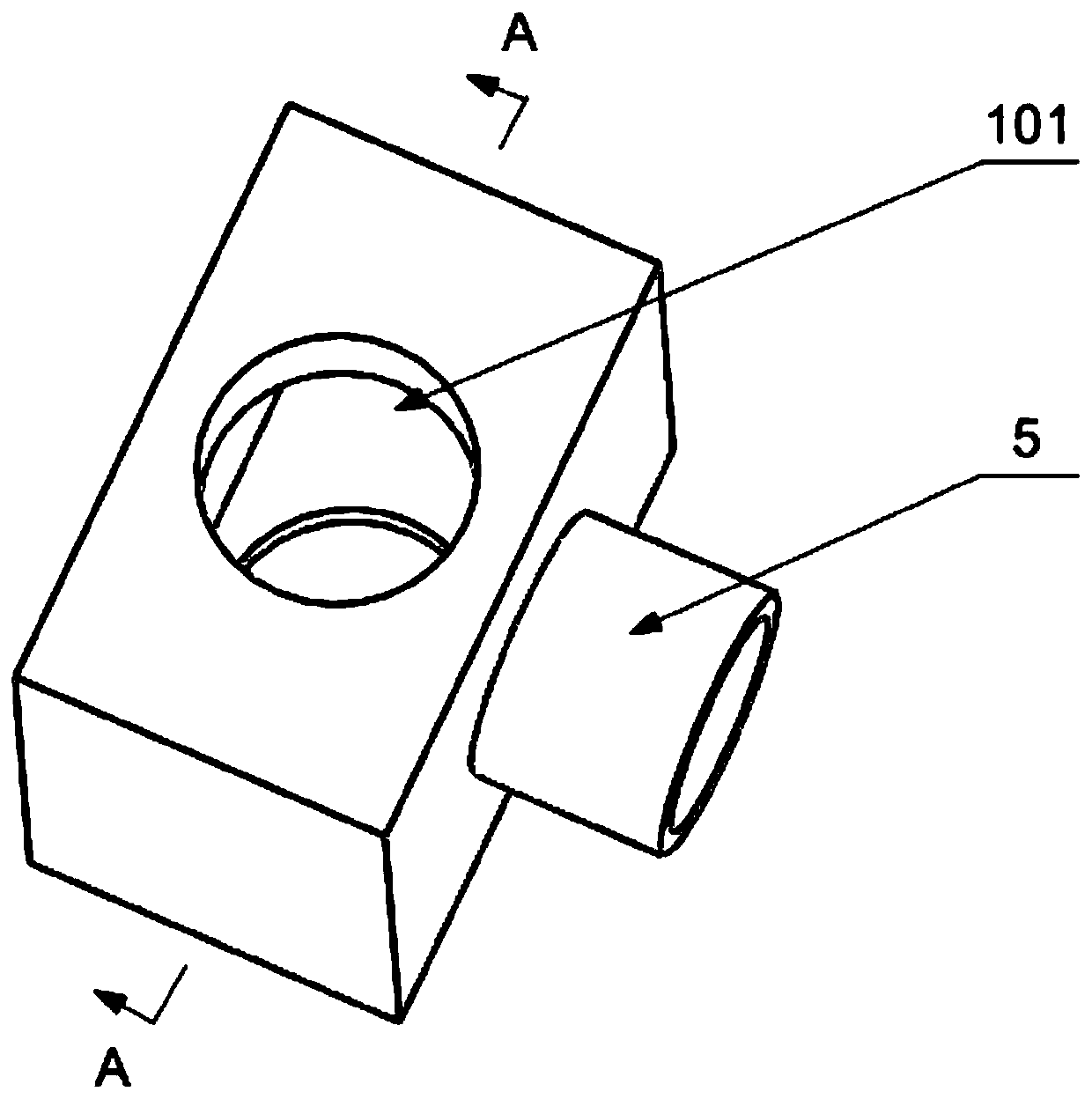

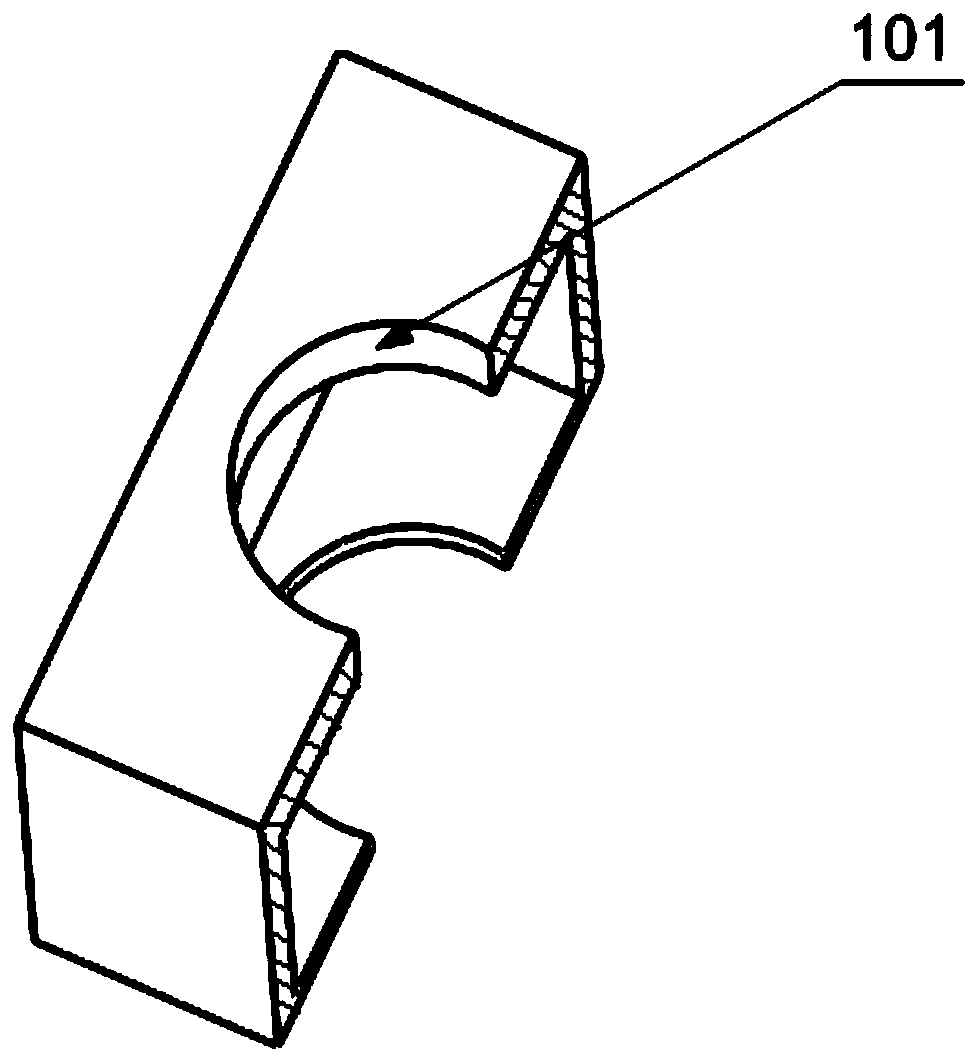

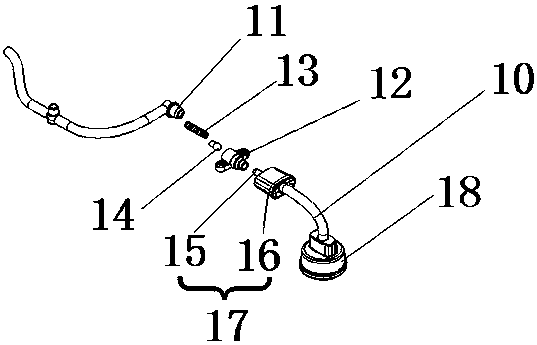

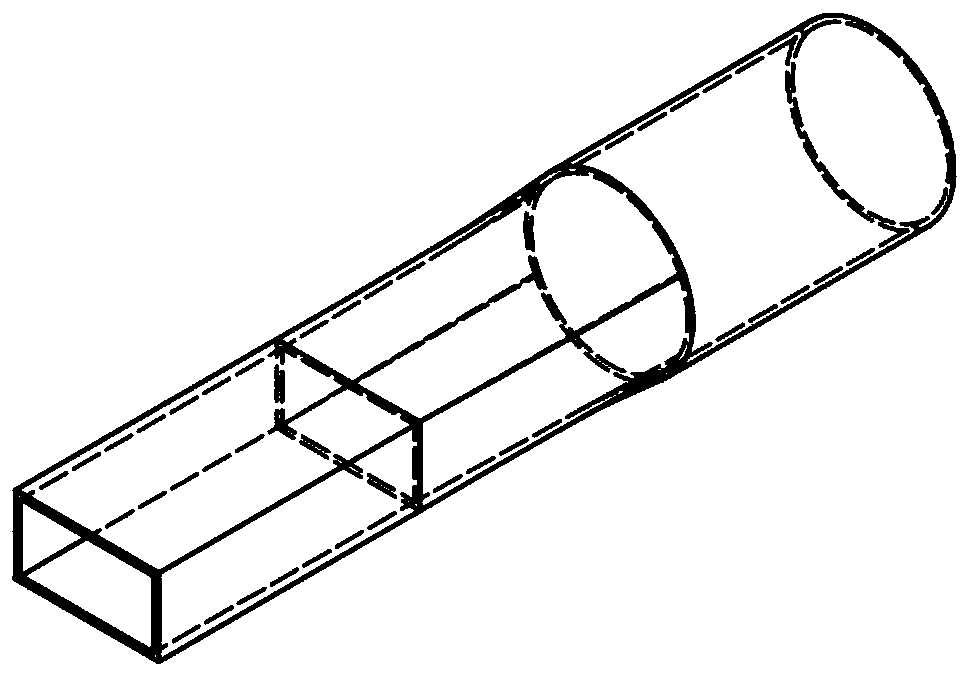

Helium mass spectrometer leak detection device for pipe-to-pipe butt welding line and leak detection method

InactiveCN110595698AImprove leak detection efficiencyLow costDetection of fluid at leakage pointInterior spaceBody joints

The invention discloses a helium mass spectrometer leak detection device for a pipe-to-pipe butt welding line. The device comprises a box body (1), a box body joint (5) and a helium mass spectrometer,wherein a through hole (101) is formed in the box body (1), the box body joint (5) is arranged on the box body (1) and is connected with the helium mass spectrometer, and the through hole is formed on the box body joint (5) so that the helium mass spectrometer communicates with the inner space of the box body (1). The helium mass spectrometer leak detection device for the pipe-to-pipe butt welding line has the advantages of being free from damaging pipes and welding lines, high in leak detection efficiency, low in cost, easy in manufacturing, high in reliability, and capable of determining leak point positions and the like.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

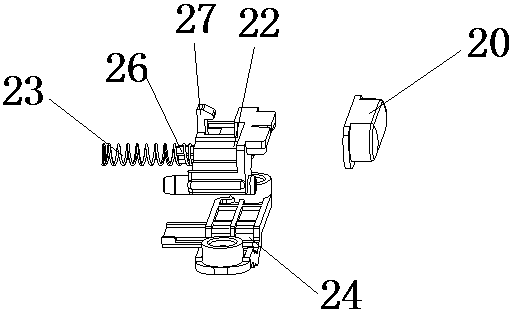

Caliper disc brake vacuum leakproofness test device

InactiveCN103776598ARush in for easy controlMaintain pressure difference between inside and outsideMeasurement of fluid loss/gain rateGas compressorAir compressor

The invention discloses a caliper disc brake vacuum leakproofness test device comprising a sealed body. A sealed cavity for accommodating a caliper disc brake is arranged in the sealed body. A fixation device for arranging the caliper disc brake is arranged in the sealed cavity. An air compressor is further comprised. The air compressor is connected with a pipeline on / off device. The pipeline on / off device is connected with a ventilation pipeline. The ventilation pipeline is connected to the sealed cavity. An air pressure gauge for testing the pressure in the caliper disc brake is further arranged outside the sealed body. The test end of the air pressure gauge is extended into the sealed body. The caliper disc brake vacuum leakproofness test device of the invention has the following advantages the device has advantages of simple manufacture, convenient operation and reliable test result can be realized, and can be used to realize caliper disc brake process 100% vacuum leakproofness tests.

Owner:RIZHAO BEIYE BRAKE PUMP

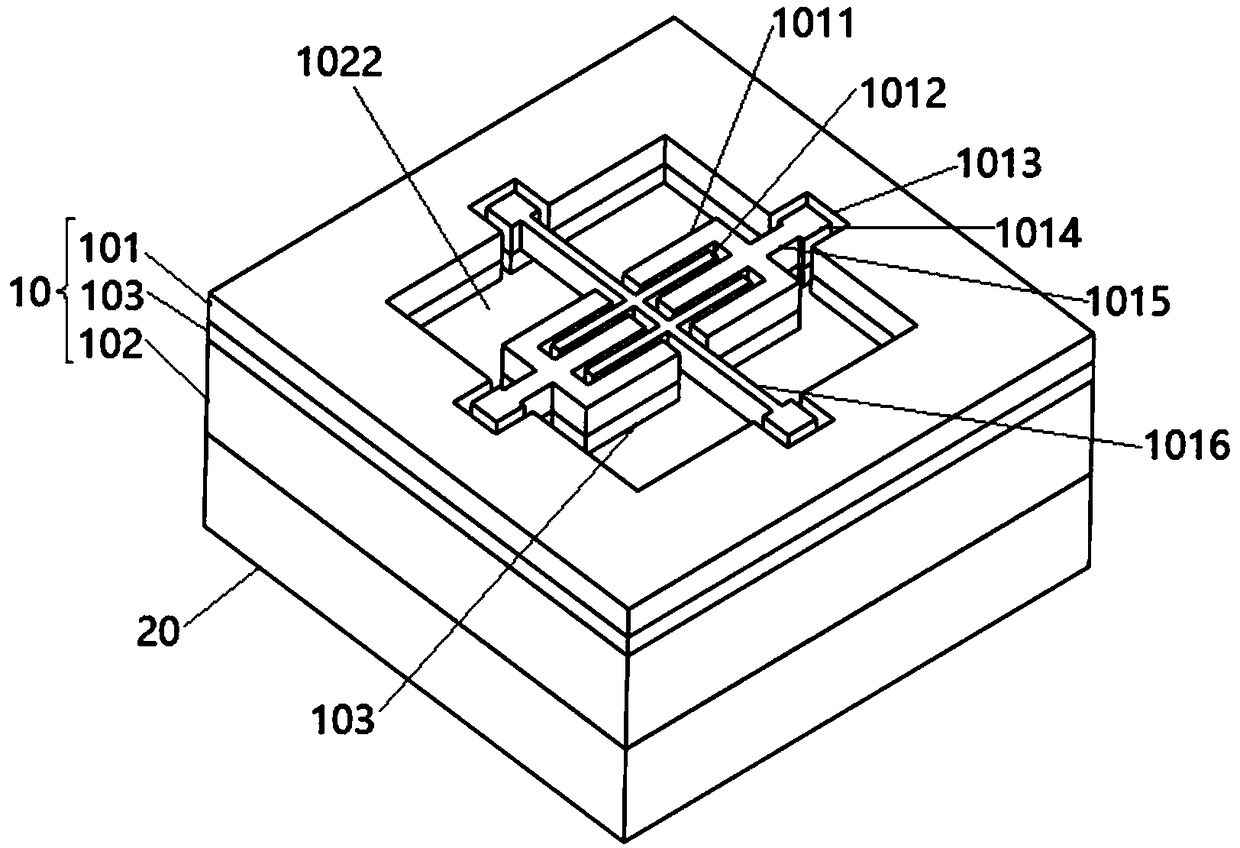

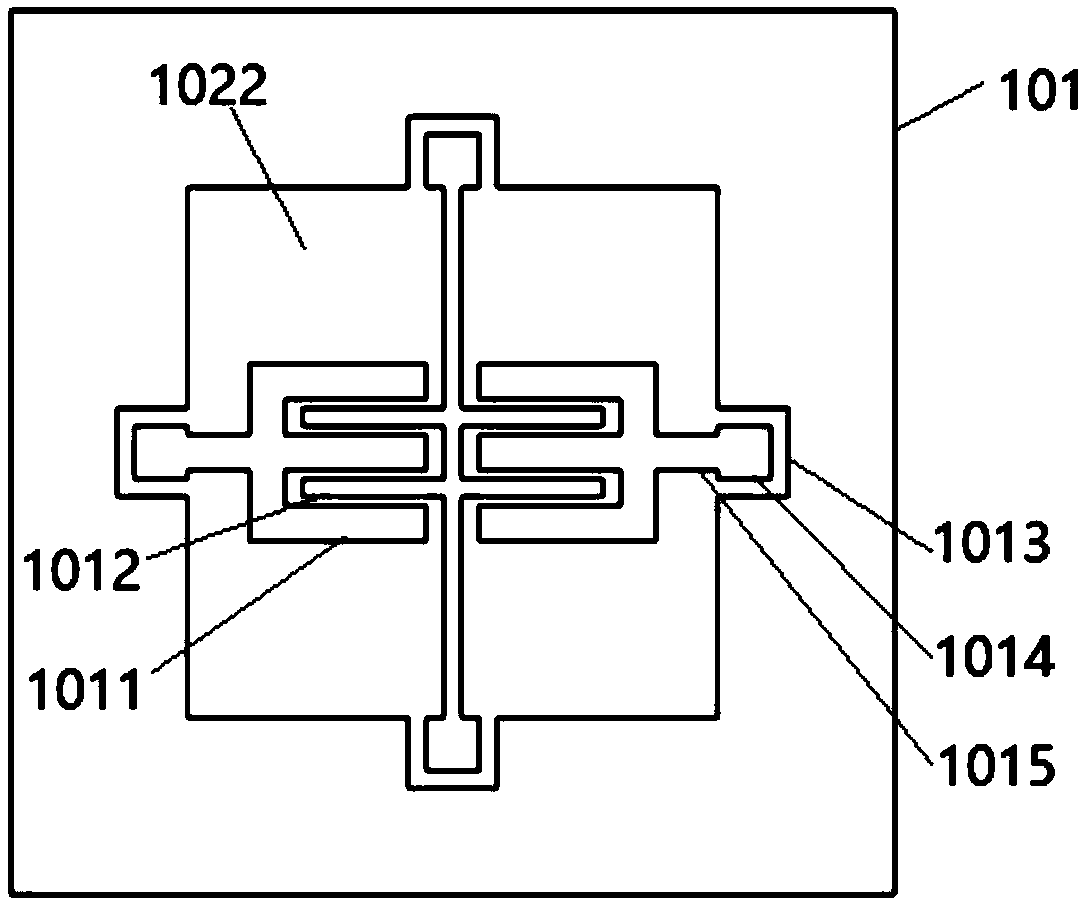

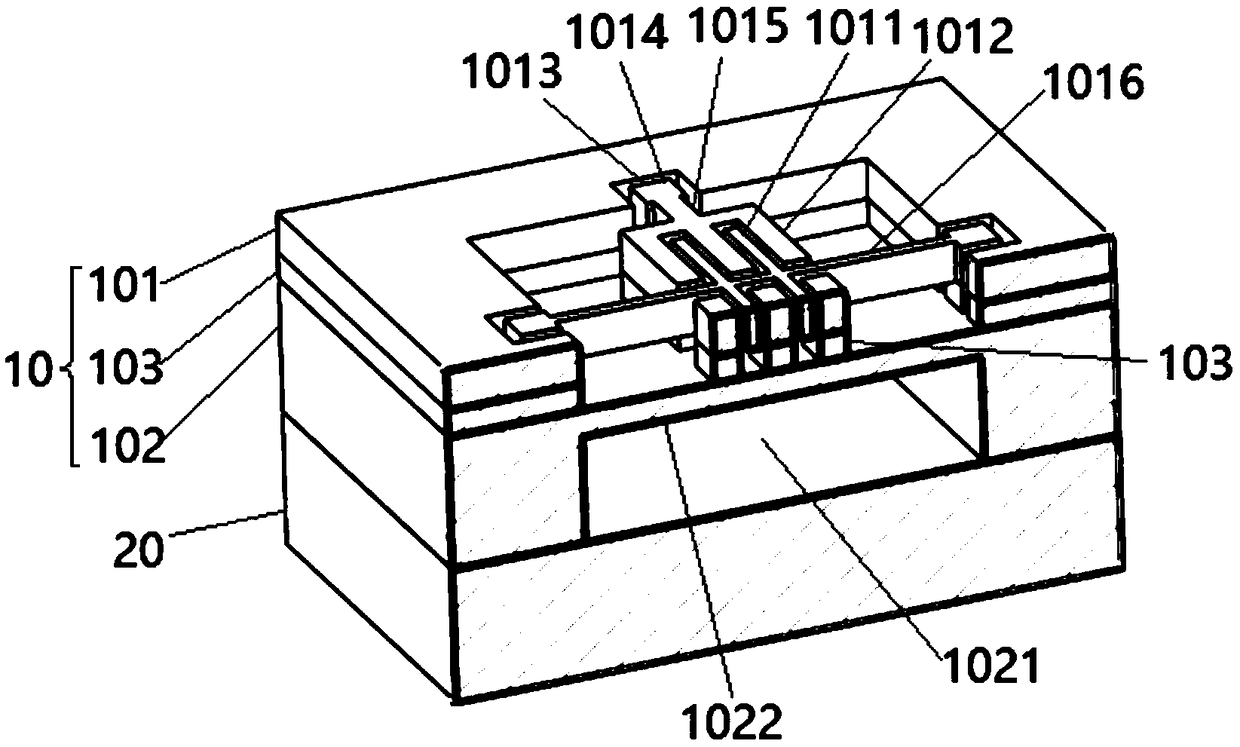

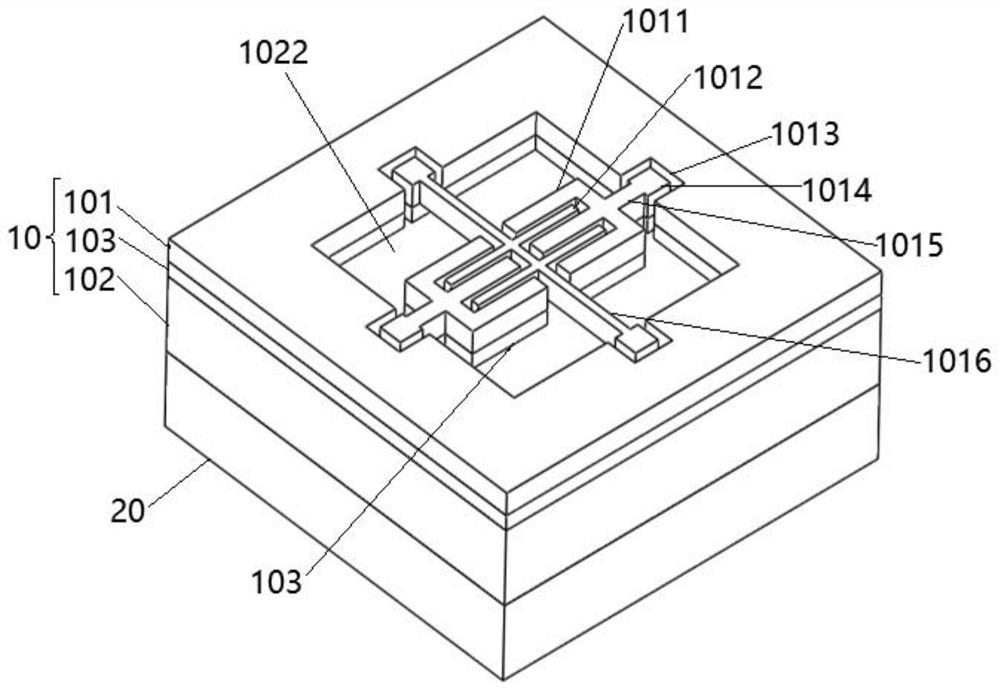

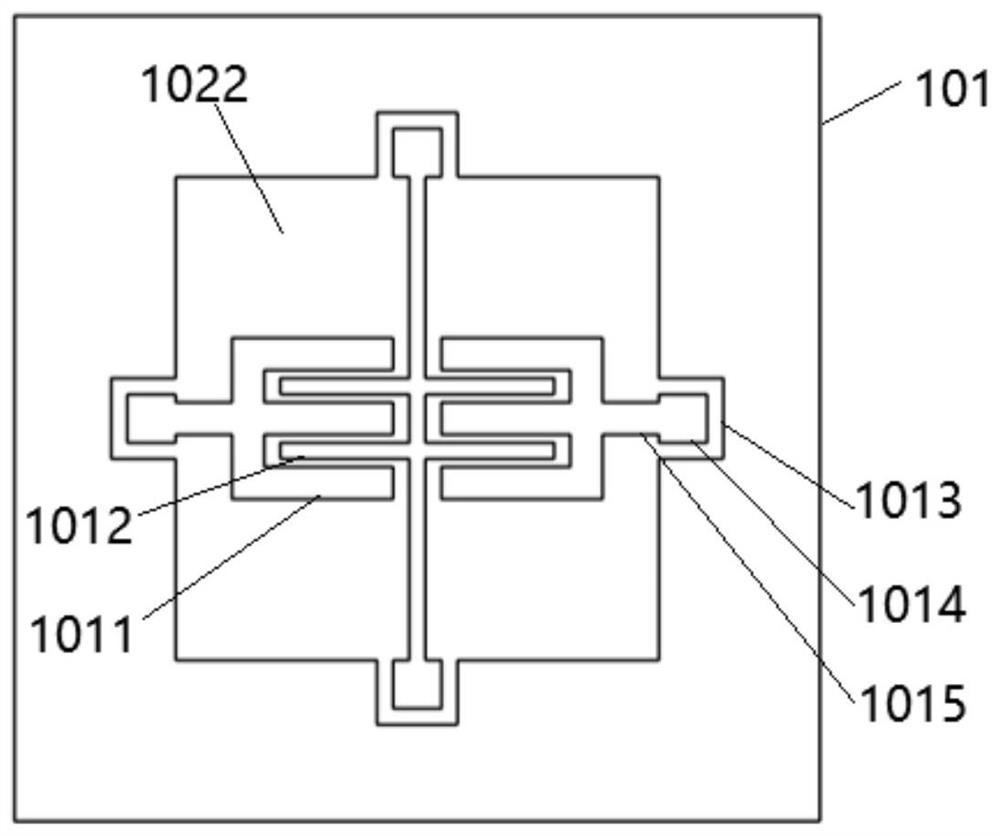

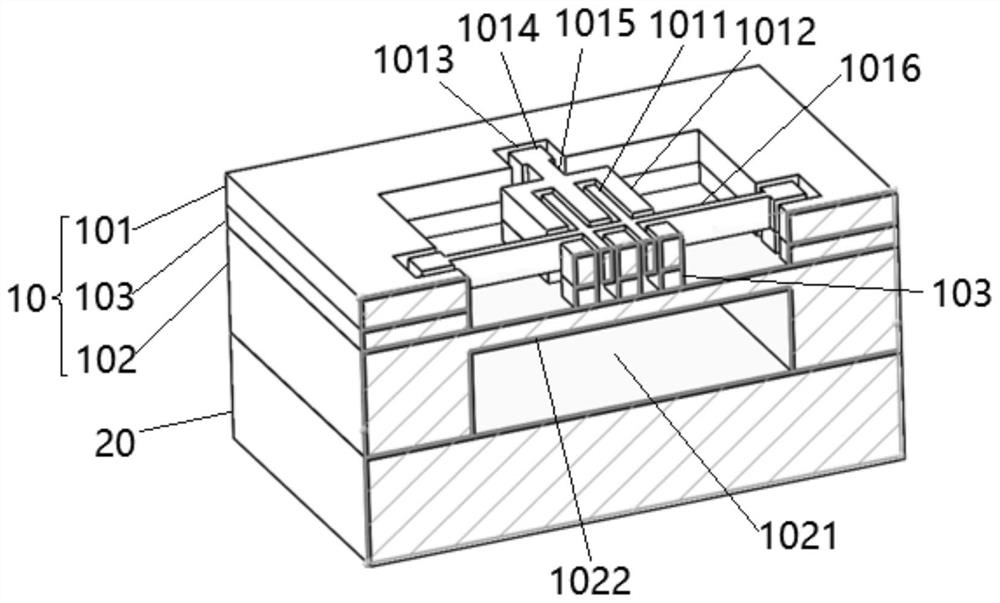

Capacitive pressure sensor, preparation method thereof, and pressure measure device

ActiveCN109231156AAvoid elicitingChange capacitance valueTelevision system detailsImpedence networksCapacitive pressure sensorInsulation layer

Disclosed is a capacitive pressure sensor, applicable to the field of sensors. The capacitive pressure sensor includes a substrate and a cover plate. The substrate includes a top layer, a bottom layerand an insulation layer, the lower surface of the bottom layer is provided with a groove, a lid groove, so that the groove forms a vacuum cavity, and a varistor film is formed on the groove bottom ofthe groove, wherein the top layer is provided with a movable interdigital capacitor and a fixed interdigital capacitor which are staggered and arranged at an equal distance from each other, the movable interdigital capacitor is bonded to the varistor film through an insulating layer positioned directly below the movable interdigital capacitor, and the insulating layer directly below the fixed interdigital capacitor is suspended between the bottom layer and the fixed interdigital capacitor. The embodiment of the invention also discloses a preparation method of a capacitive pressure sensor anda pressure measuring device. When the varistor film is deformed, the area of the movable interdigital capacitance relative to the fixed interdigital capacitance can be changed, thereby changing the capacitance value, and exhibiting a good linear output. At the same time, the vacuum sealing property is good, and the lead-out of the electrode in the vacuum cavity can be avoided.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

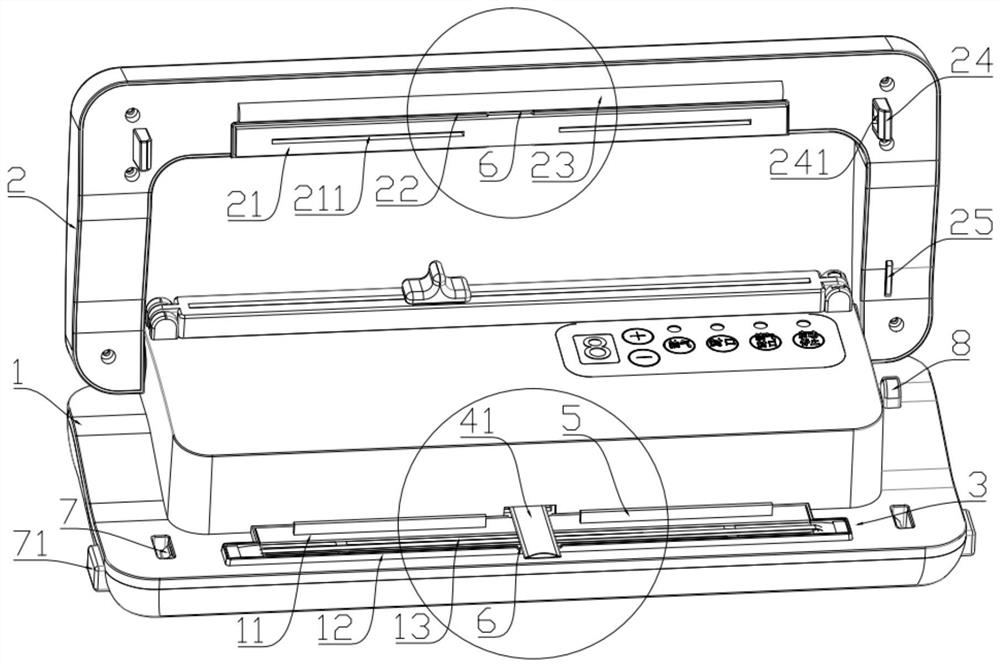

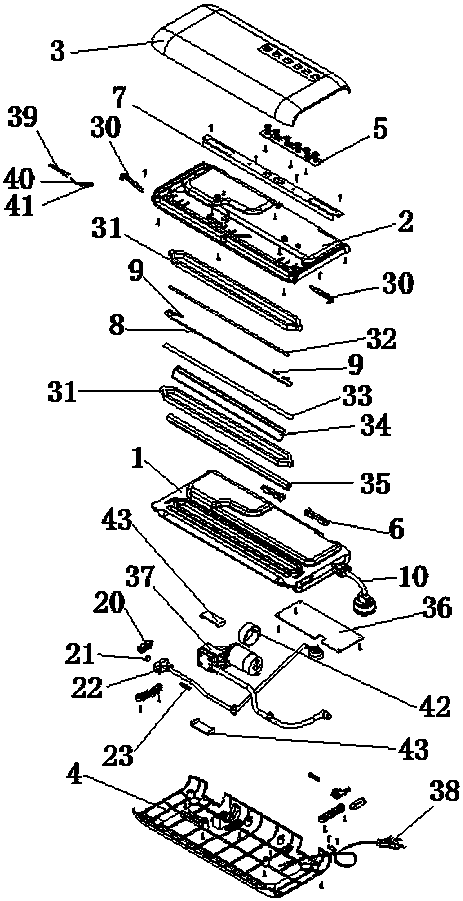

Vacuum sealing machine

PendingCN111674619APrecise pumpingGood vacuum sealing effectPackaging by pressurising/gasifyingWrapper twisting/gatheringPhysicsEngineering

The invention belongs to the technical field of packaging equipment, and particularly relates to a vacuum sealing machine. The vacuum sealing machine comprises a shell and a sealing cover connected tothe shell and capable of turning over relative to the shell, wherein a processing space allowing a packaging bag to stretch in is defined between the shell and the sealing cover, an exhaust assemblyis arranged in the shell, and an exhaust pipe capable of extending out of the shell and entering the processing space is arranged in the exhaust assembly; and a heating strip is arranged on the position, in the processing space, of the shell, a lower sealing strip is arranged on the position, in the processing space, of the shell, the lower sealing strip is located at the front end of the heatingstrip, the exhaust pipe passes through the upper end of the lower sealing strip when extending out of the shell, and an upper sealing strip aligned with the lower sealing strip is arranged on the position, in the processing space, of the lower end of the sealing cover. The vacuum sealing machine can carry out vacuum sealing treatment on any packaging bag.

Owner:WENZHOU HAIZHOU PACKAGING MACHINERY CO LTD

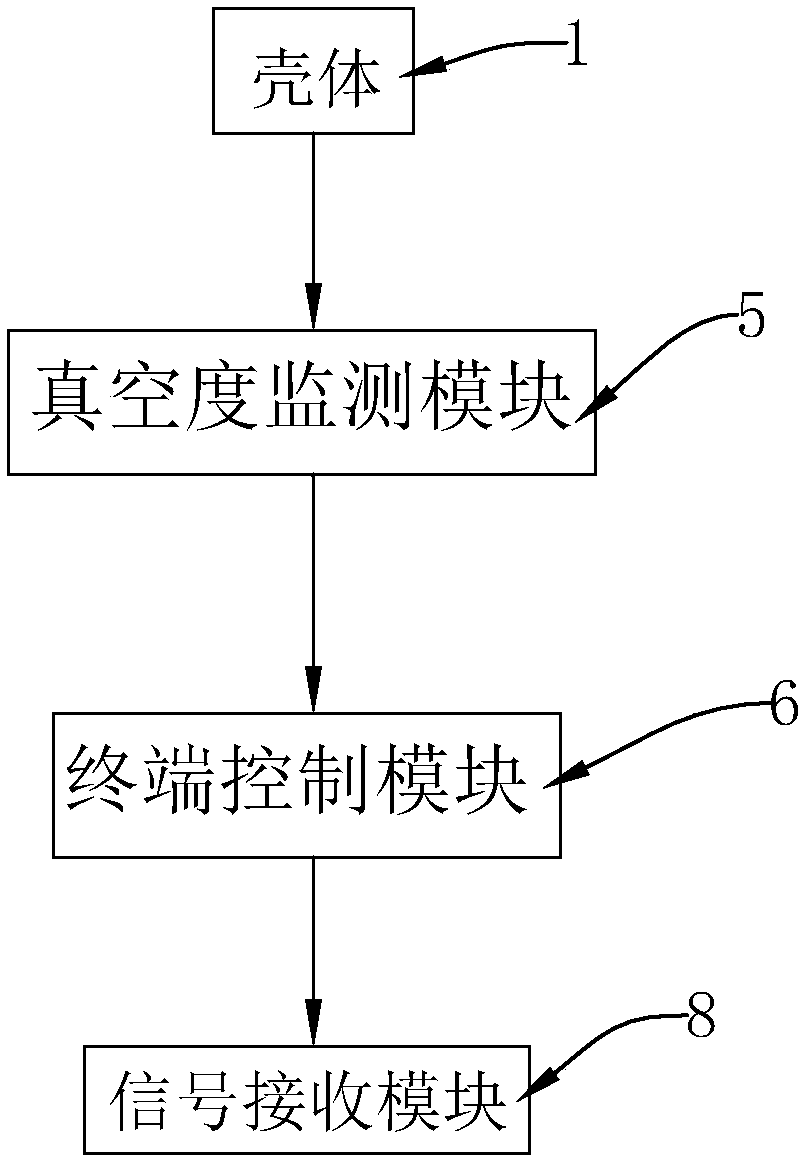

Camera image conversion system for vacuum packaged image sensor chip

PendingCN108391042AClear imagingGood effectTelevision system detailsColor television detailsImage sensorData processing

The invention discloses a camera image conversion system of a vacuum packaged image sensor chip. According to the technical scheme, the camera image conversion system of the vacuum package image sensor chip comprises a housing, an image conversion module, a power module for supplying power to the image conversion module and a data processing module for processing signals of the image conversion module, wherein the image conversion module, the power module and the data processing module are arranged in the housing; a sealed cavity is formed in the housing, and a vacuum degree monitoring moduleis disposed in the sealed cavity; a terminal control module is disposed on the outer side of the sealed cavity and connected to the vacuum degree monitoring module. The vacuum degree in the sealed cavity can be monitored in real time, vacuum degree signals can be sent in real time, and changes of the vacuum degree in the sealed cavity can be known more accurately and timely.

Owner:LIGHT SPEED VISION BEIJING

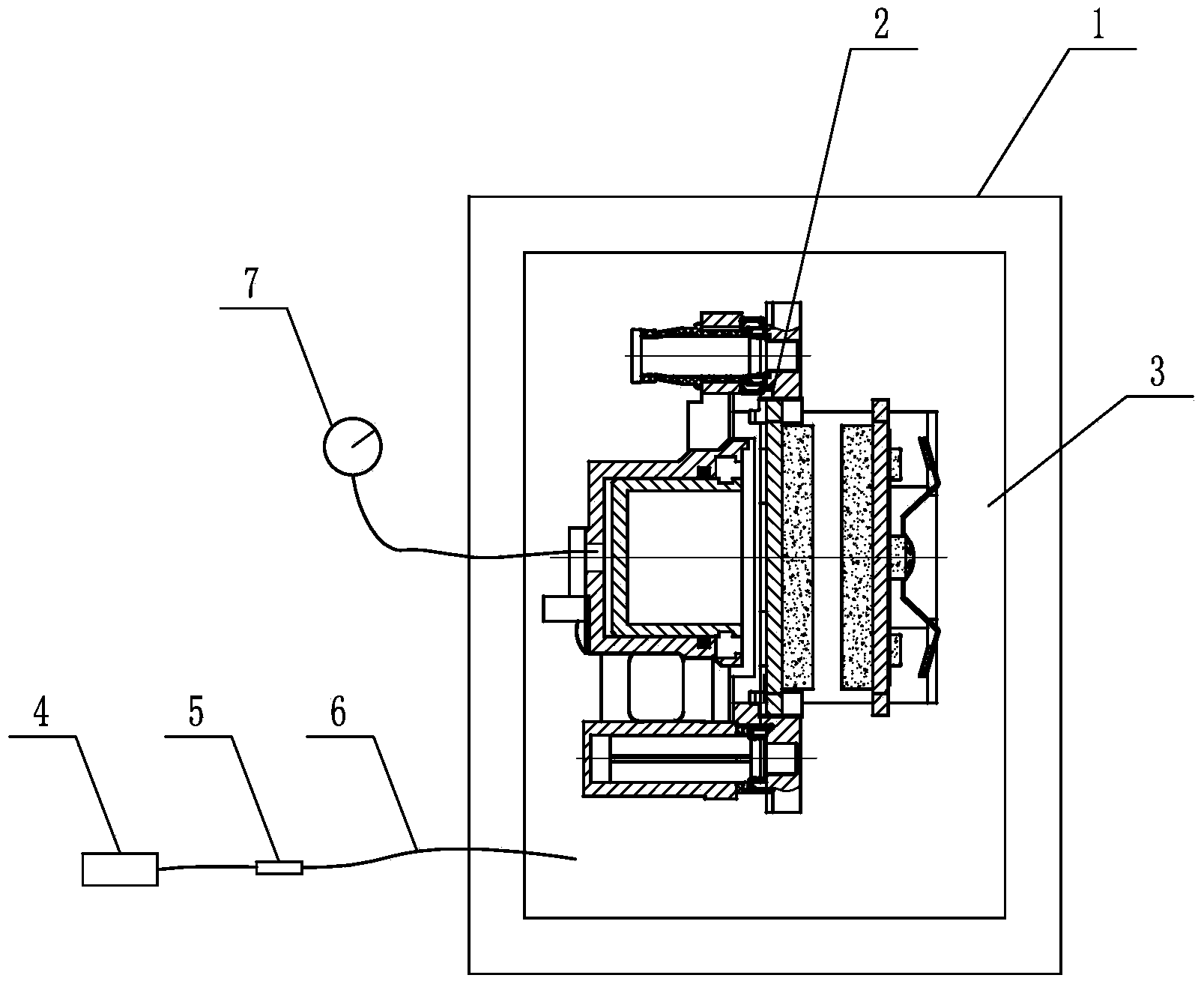

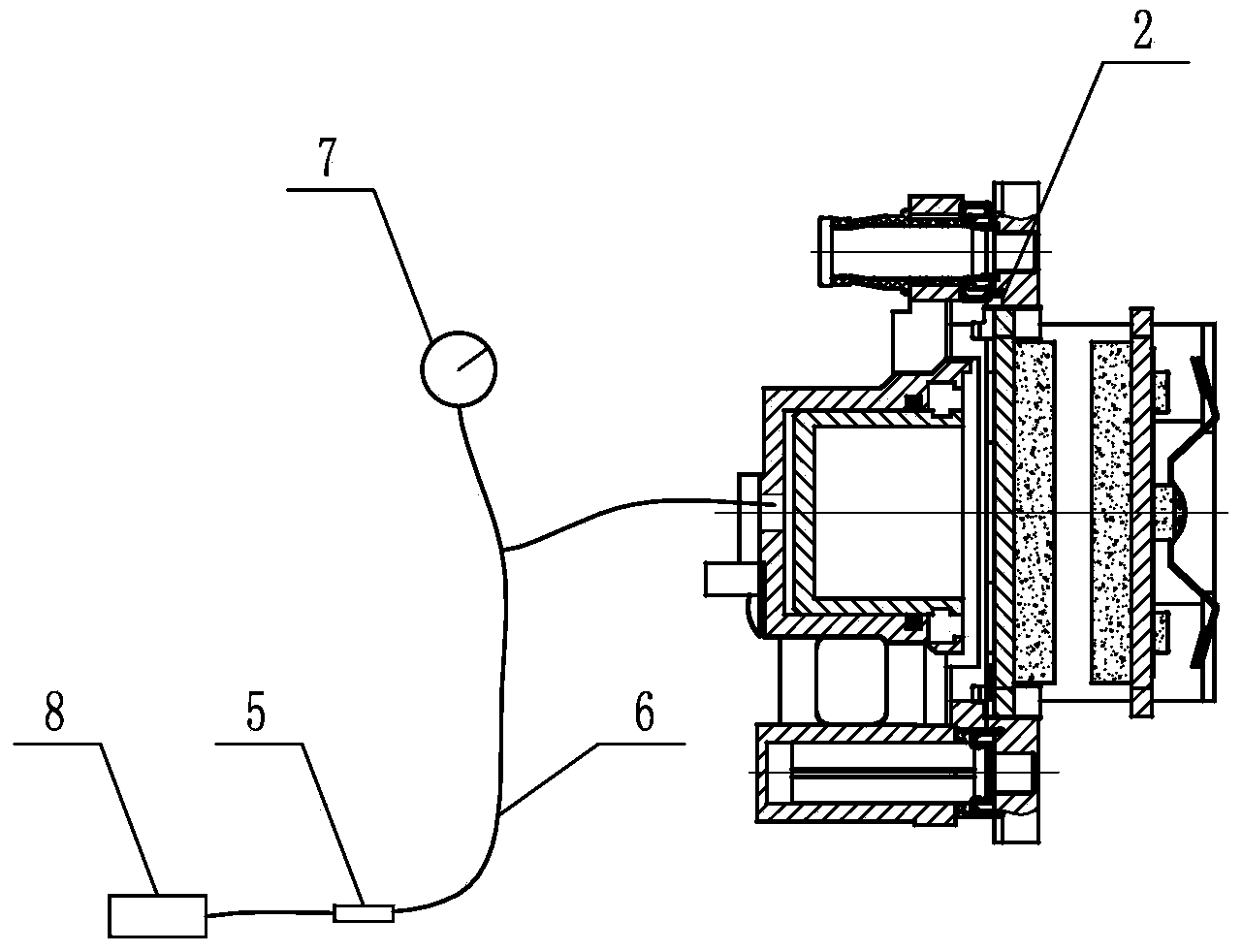

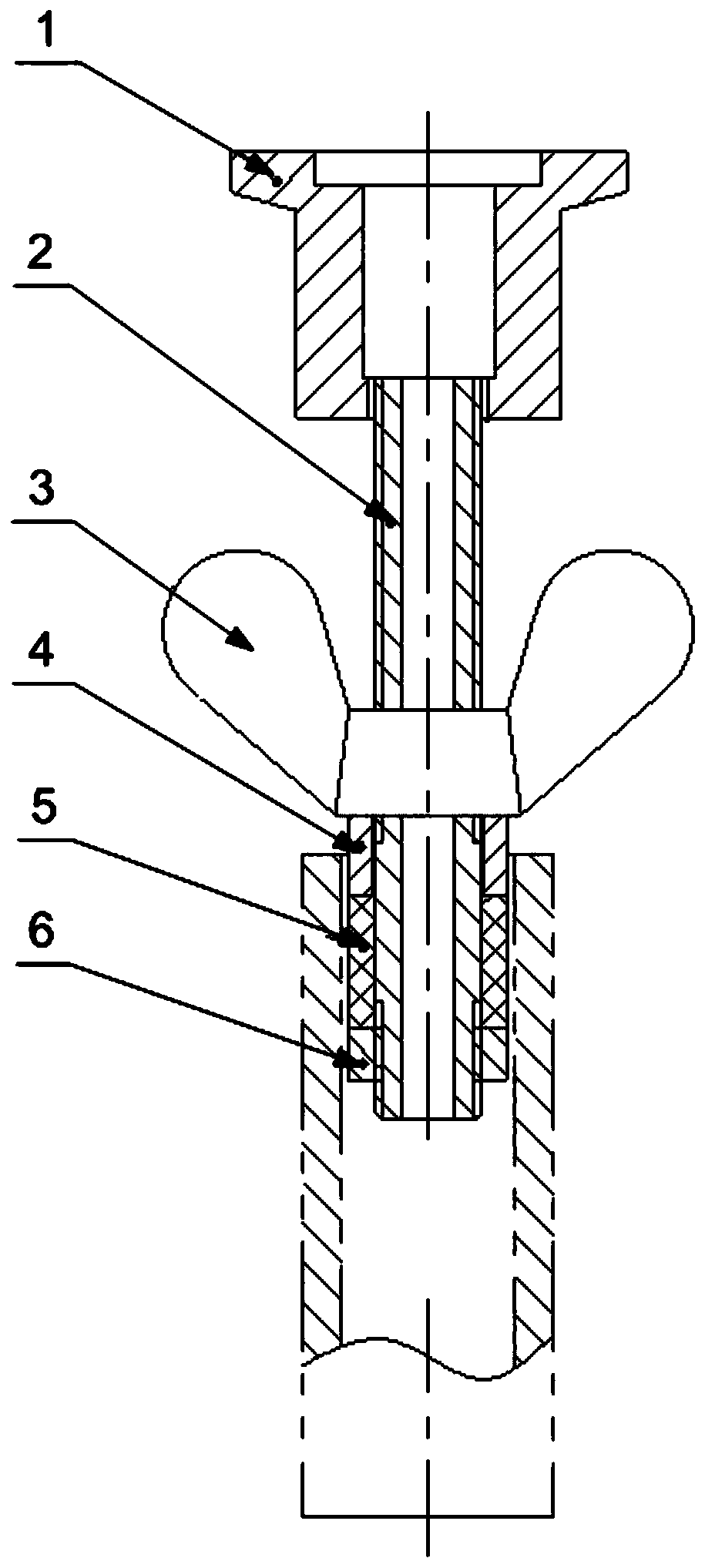

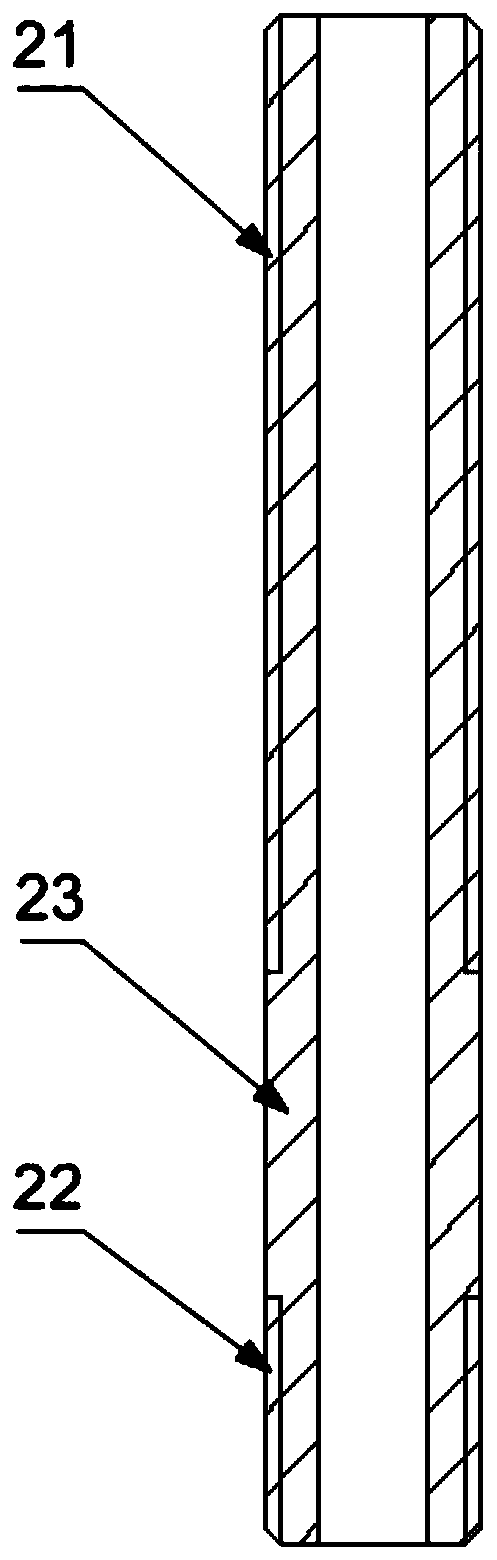

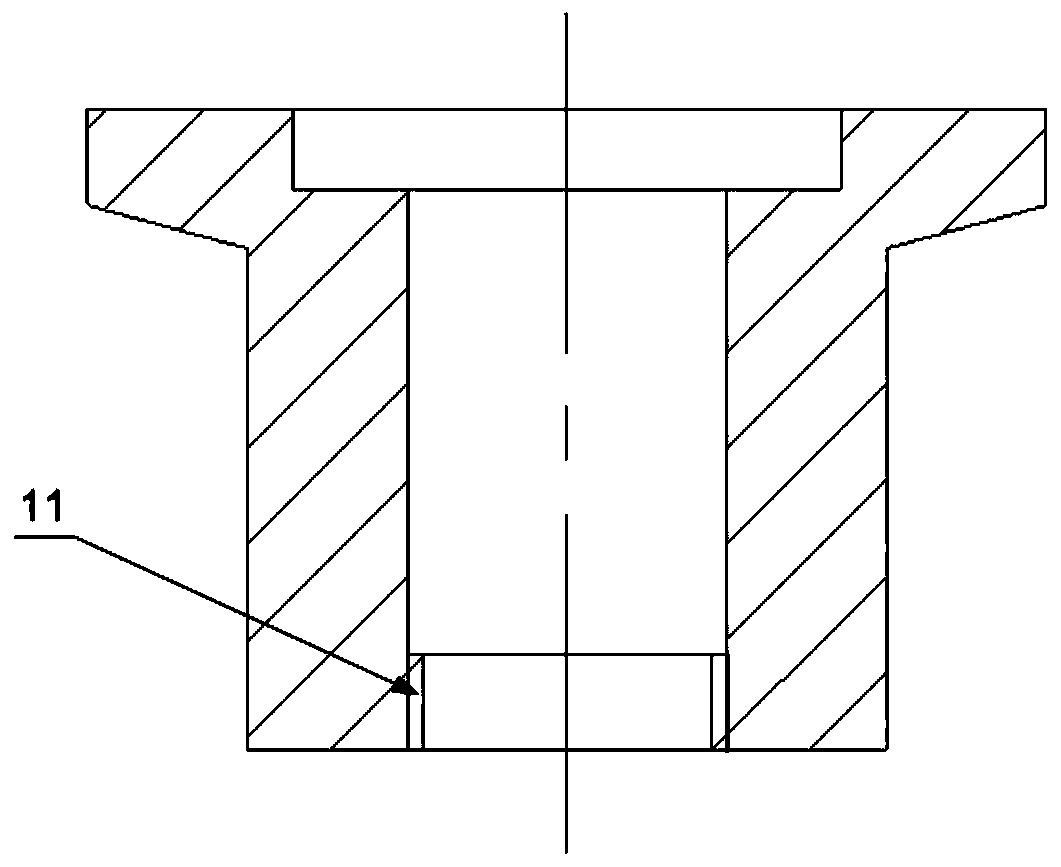

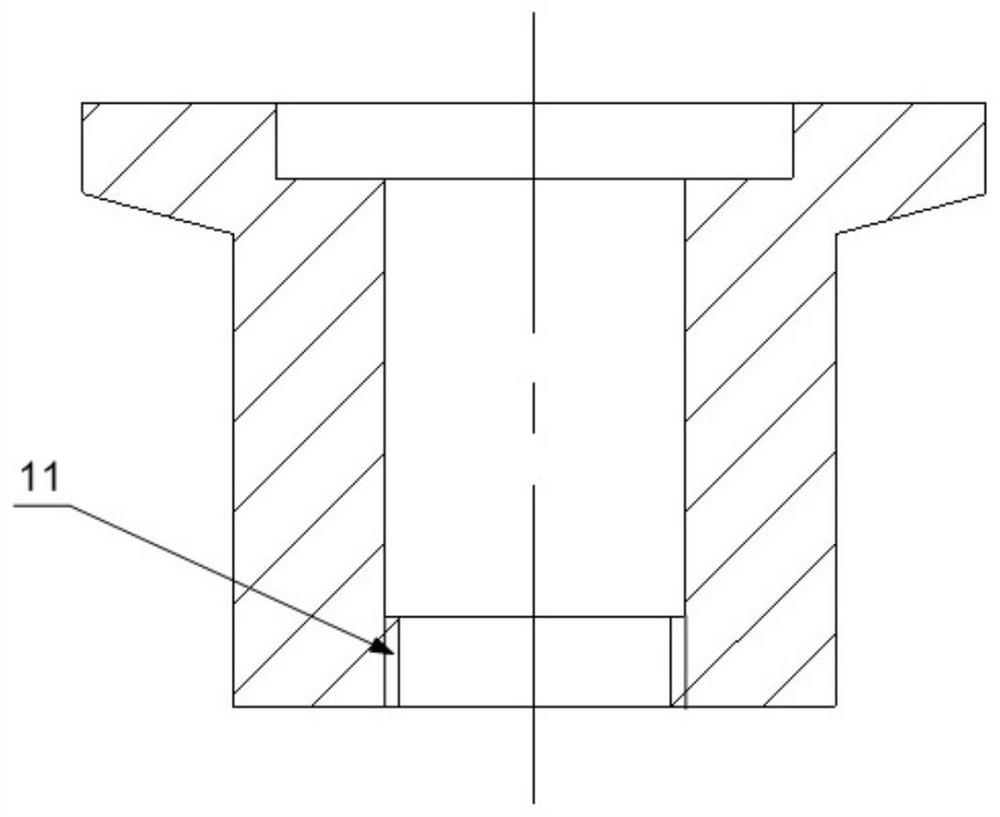

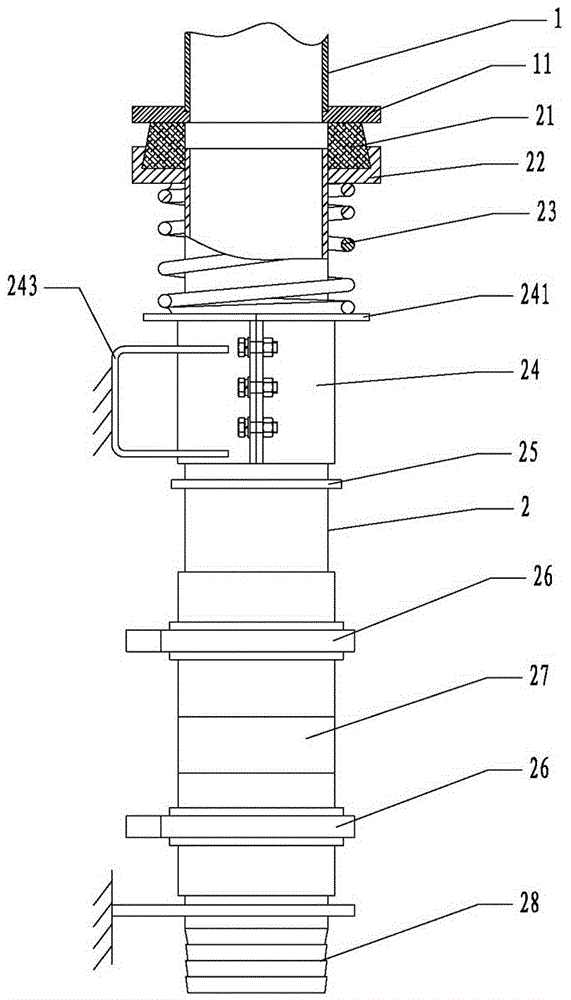

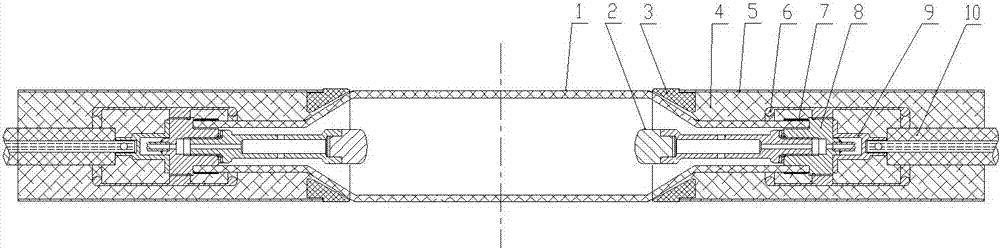

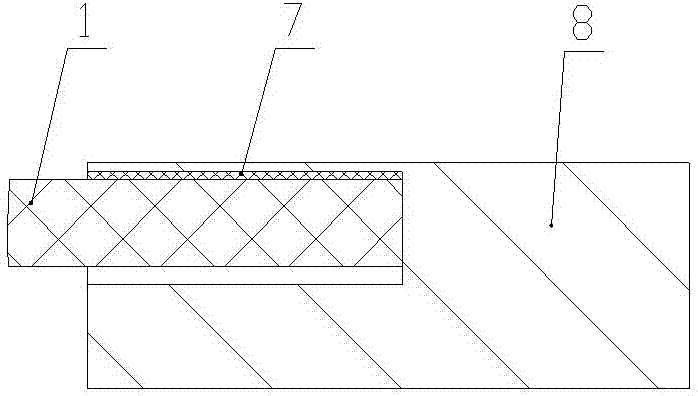

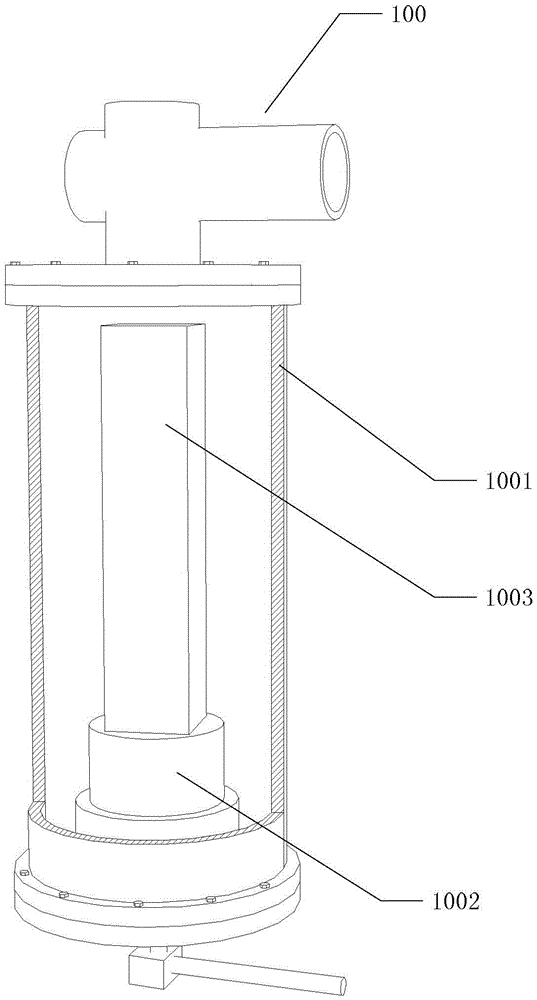

Tube helium mass spectrometer leak detection apparatus and method

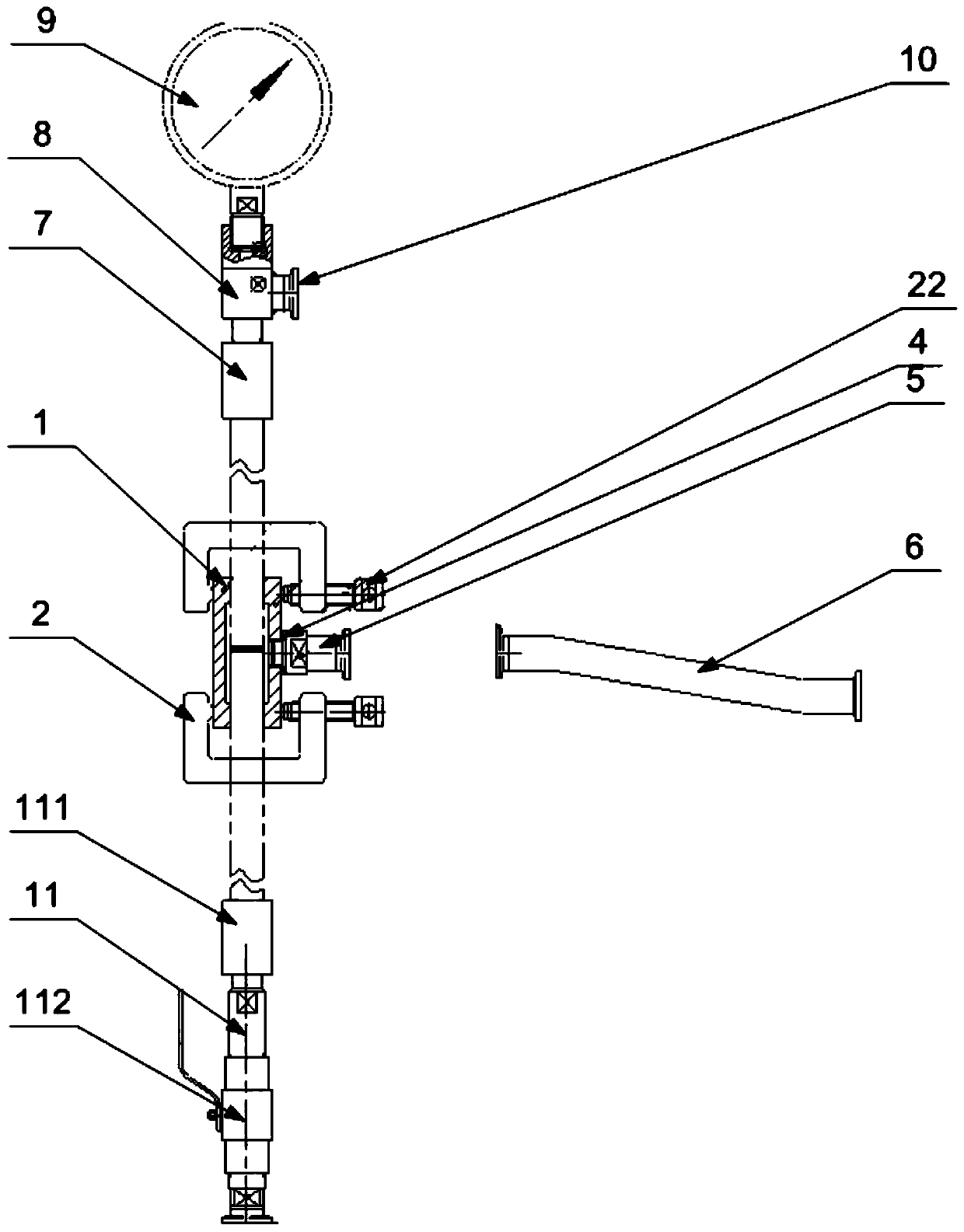

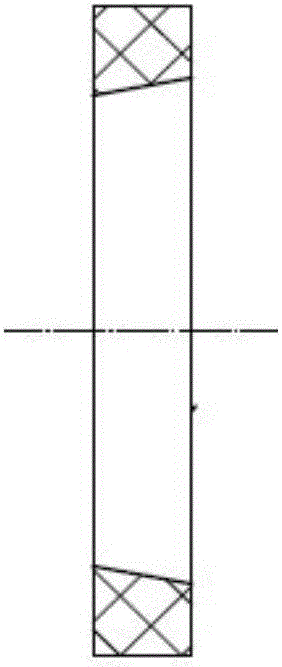

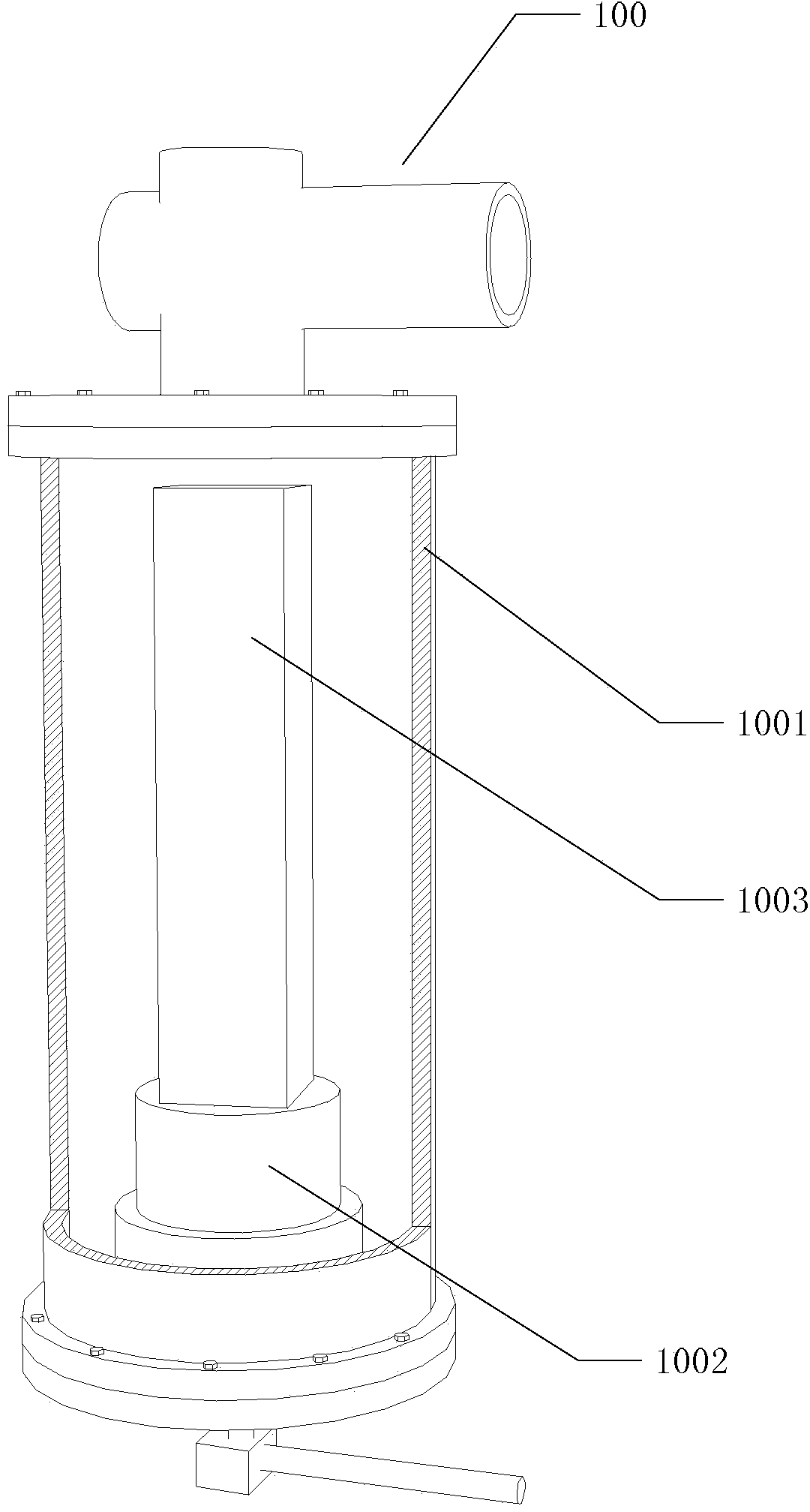

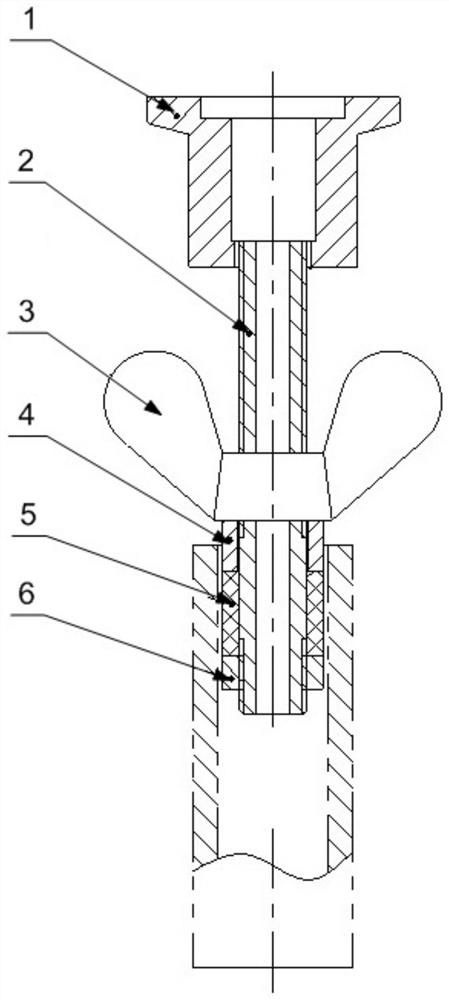

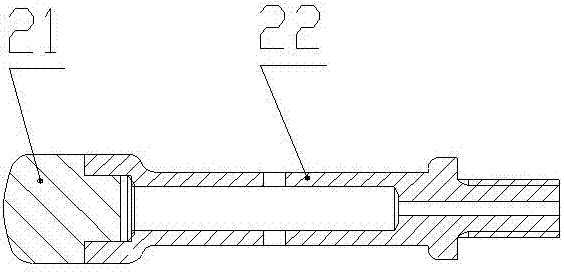

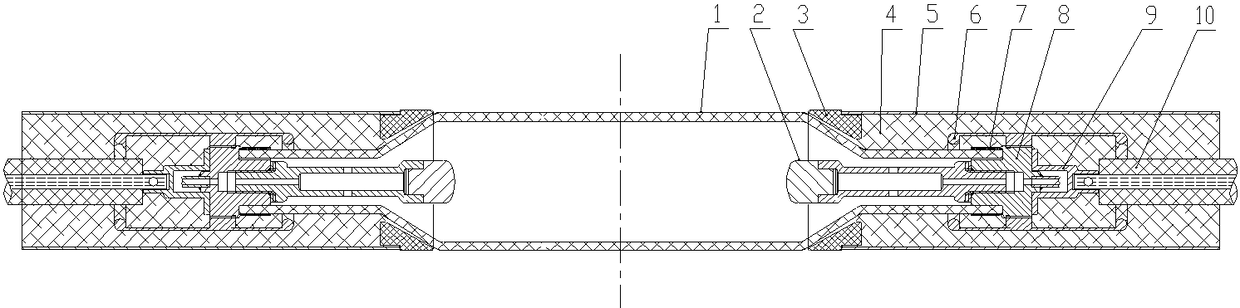

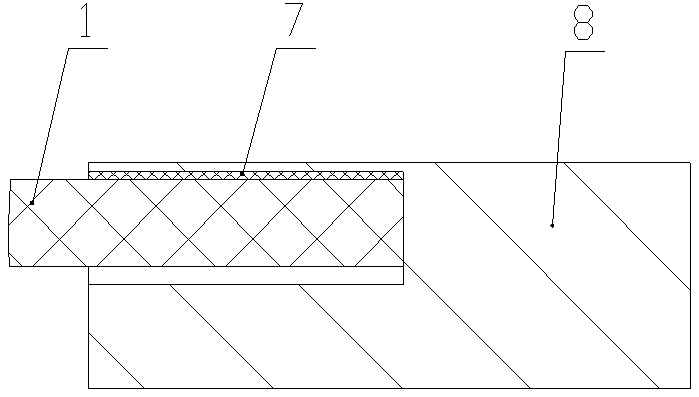

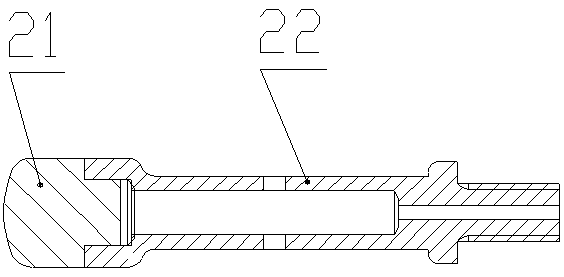

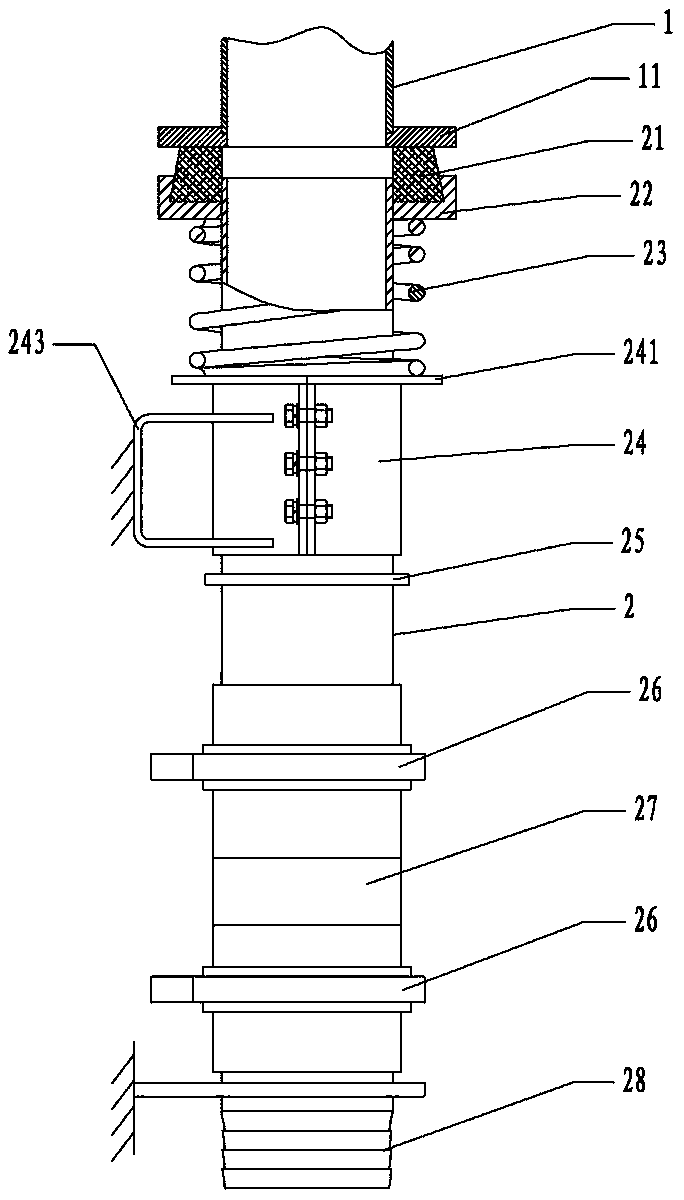

ActiveCN110595699AEasy to manufactureGood vacuum tightnessDetection of fluid at leakage pointMass spectrometryEngineering

The present invention discloses a tube helium mass spectrometer leak detection apparatus. The tube helium mass spectrometer leak detection apparatus comprises s a vacuum joint (1), a mandrel (2), a pressing member (3), a gasket (5), a support member (6), and a helium mass spectrometer. The mandrel (2) is a hollow tubular structure; the vacuum joint (1) is arranged at the top of the mandrel (2); the pressing member (3), the gasket (5) and the support member(6) sleeve on the mandrel (2); the support member (6) is detachably fixed on the mandrel (2); and the pressing member (3) can move axially along the mandrel (2), so that the gasket ( 5) can expand radially along the mandrel (2) under the action of the pressing member (3) and the support member (6). The tube helium mass spectrometer leak detection apparatus provided by the present invention has multiple advantages such as easy manufacture, a simple operation, high reliability, high leak detection efficiency, a low cost, reusability, and the like.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

A dome-type microwave plasma chemical vapor deposition diamond film device

ActiveCN103668127BDeposition high speedImprove qualityElectric discharge tubesChemical vapor deposition coatingResonant cavityThin metal

A dome-type microwave plasma chemical vapor deposition diamond film device , suitable for rapid preparation of high-quality diamond films under high-power microwave input. The main body of the resonant cavity is composed of a dome reflector, a metal sheet reflector, a quartz ring window, a cylindrical reflector and a deposition platform. The reflector of the thin metal plate can block the propagation of the microwave to the top of the resonant cavity, so that the microwave can be more concentrated on the substrate. The deposition platform is divided into two parts, the central deposition platform and the edge deposition platform. The independent up and down movement functions of the two parts are conducive to the rapid optimization of the plasma state. The quartz ring window is hidden between the slits formed by the walls of the resonant cavity, which can avoid plasma etching and improve the vacuum performance of the resonant cavity. In addition, good water cooling system design ensures the safety of equipment running under high power. The combination of many advantages makes the dome-type microwave plasma chemical vapor deposition device capable of depositing high-quality diamond films at high speeds at high power levels.

Owner:HEBEI PLASMA DIAMOND TECH

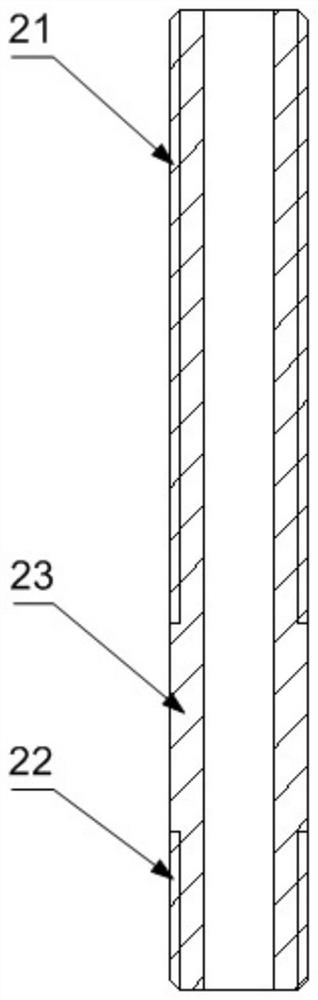

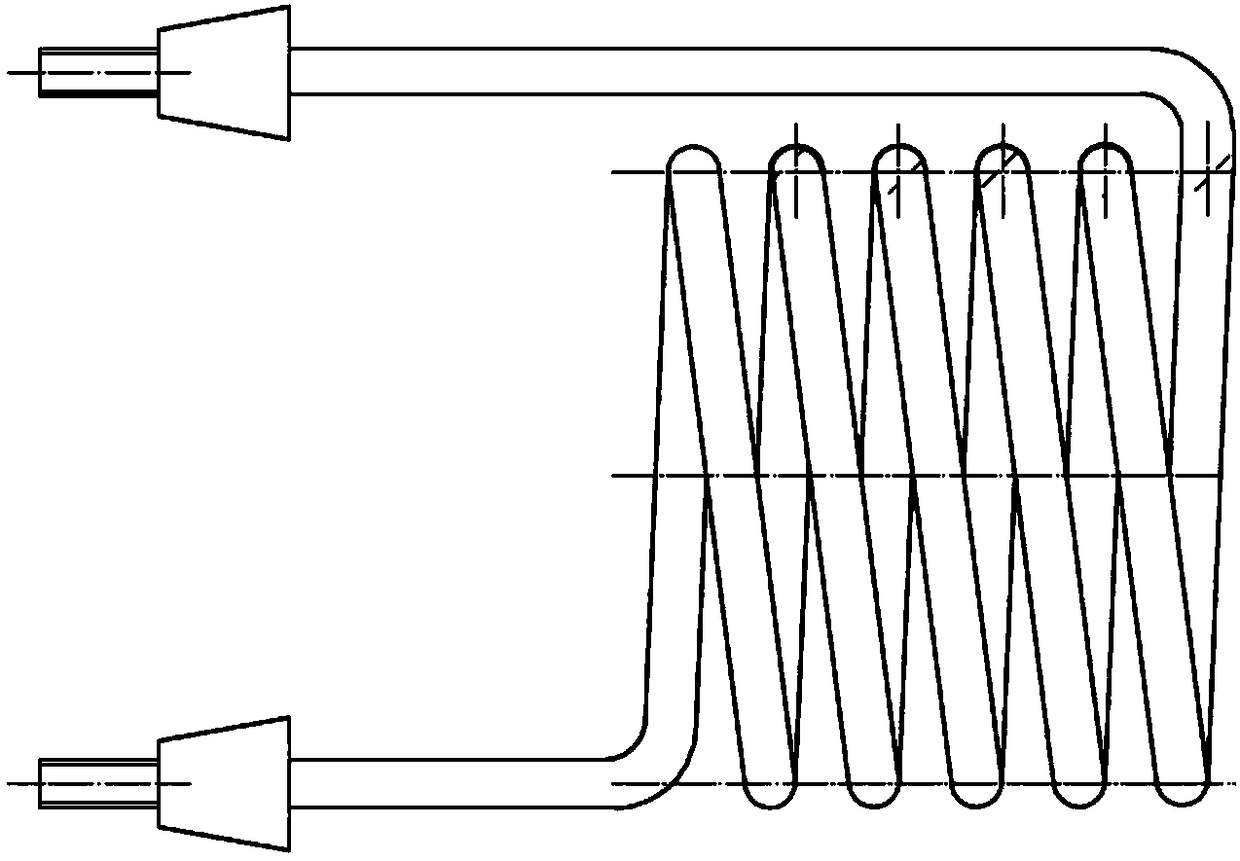

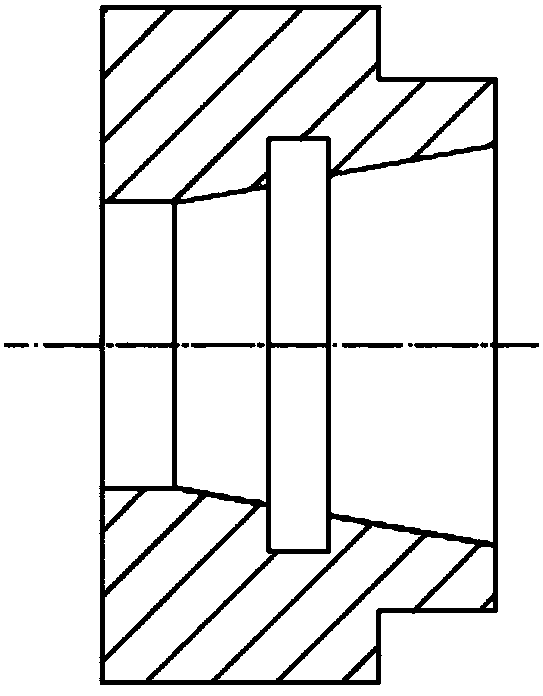

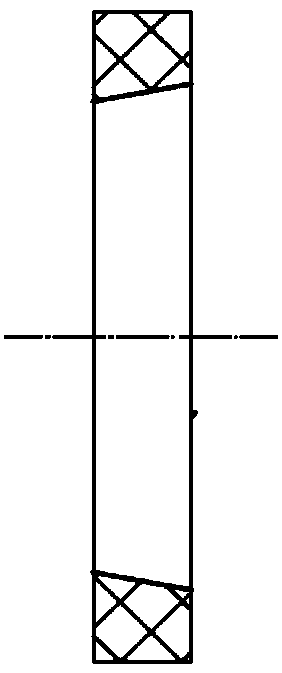

Vacuum sealing joint for low-temperature tubular heating tube

InactiveCN105909791ASolve the technical requirements that cannot ensure the vacuum sealing of the furnaceSimple structureEngine sealsEngineeringHeating furnace

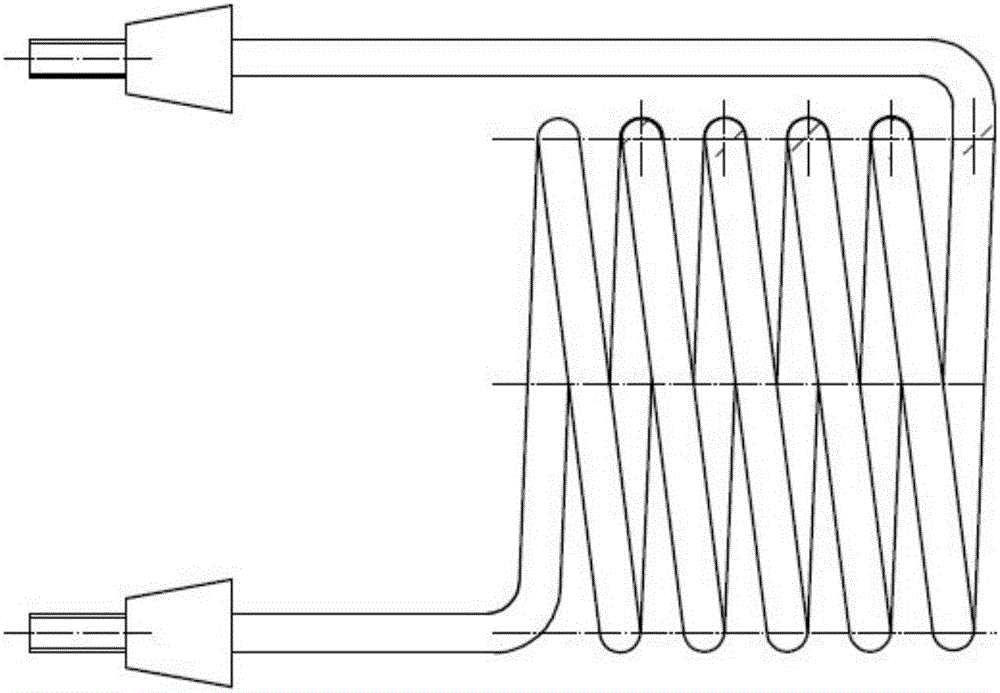

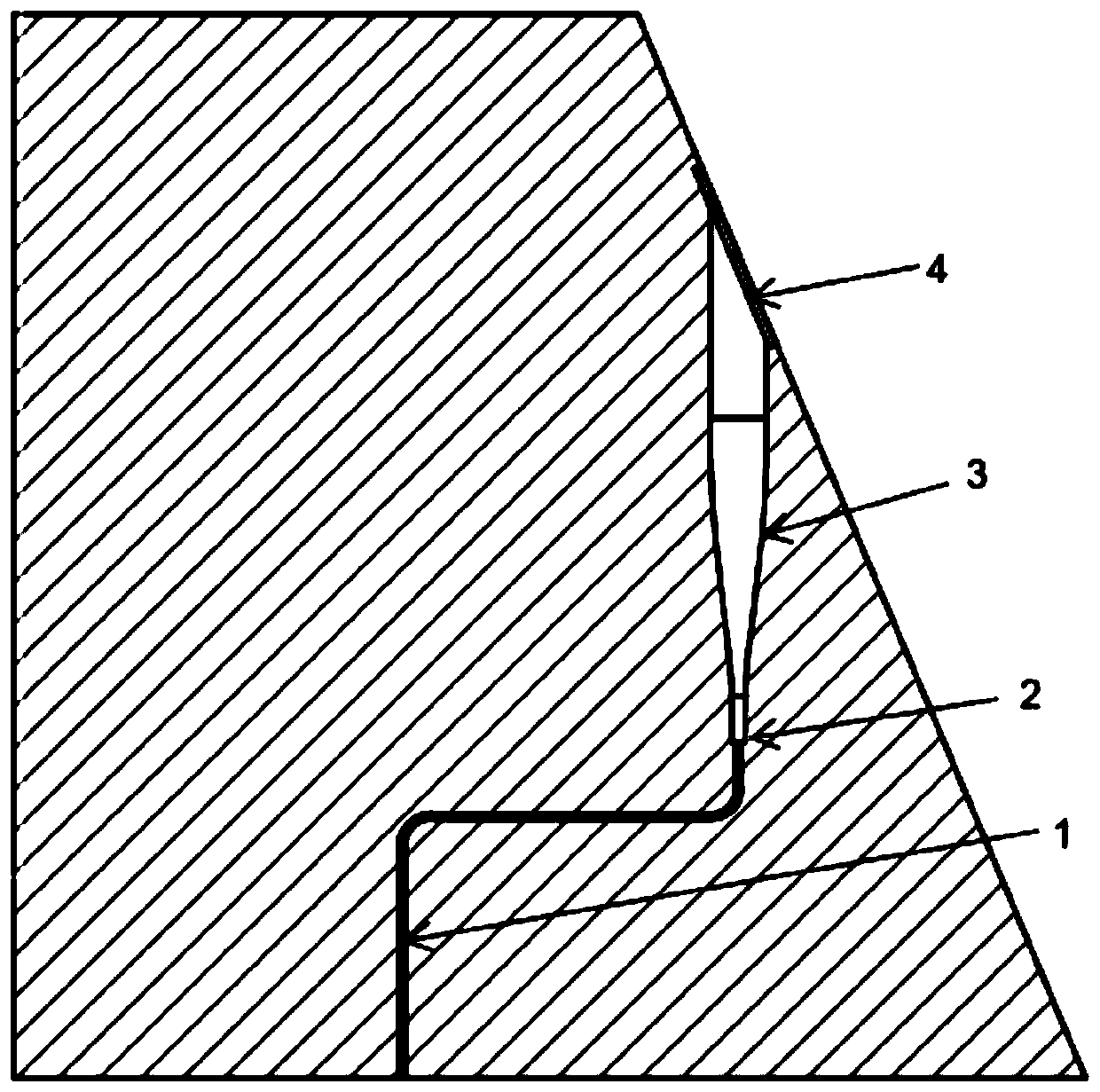

The invention relates to a vacuum sealing joint for a low-temperature tubular heating tube. The vacuum sealing joint comprises a tubular spiral heating tube, a vacuum joint, a sealing ring and compression nuts, wherein the vacuum joint is fixedly connected into an installation hole of a vacuum furnace wall; conducting ends of the tubular spiral heating tube are inserted in the vacuum joint; the vacuum joint is provided with inner conical holes, and in fit connection with outer conical tables on the tubular spiral heating tube through the inner conical holes; the sealing ring is arranged between the inner conical holes and the outer conical tables; and the tubular spiral heating tube is locked and fixed, and the sealing ring is compressed on the conducting ends of the tubular spiral heating tube through the compression nuts, so as to achieve a vacuum sealing effect. The joint enables a heating component of a vacuum furnace to be directly supplied with power of 220 V instead of being supplied with power by configuring voltage dropping equipment, thus configuration of a small vacuum furnace is simplified, and the equipment cost is reduced. Moreover, a reliable sealing structure is provided for producing the small vacuum heating furnace by virtue of the heating component for vacuum heating, and a technical support is provided for producing the small vacuum heating furnace by widely using the tubular heating tube.

Owner:SHANGHAI HENGTUO HYDRAULIC CONTROL TECH

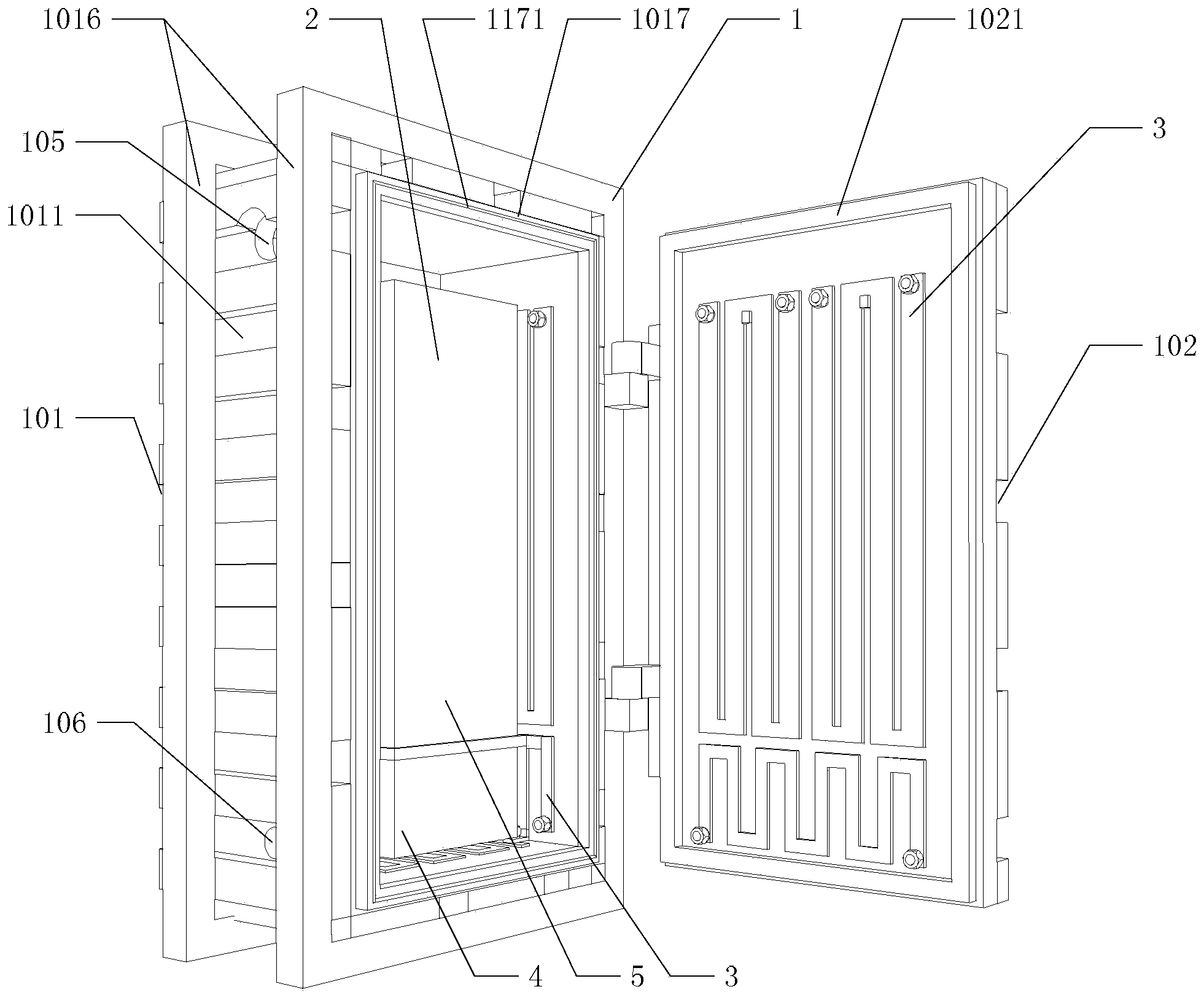

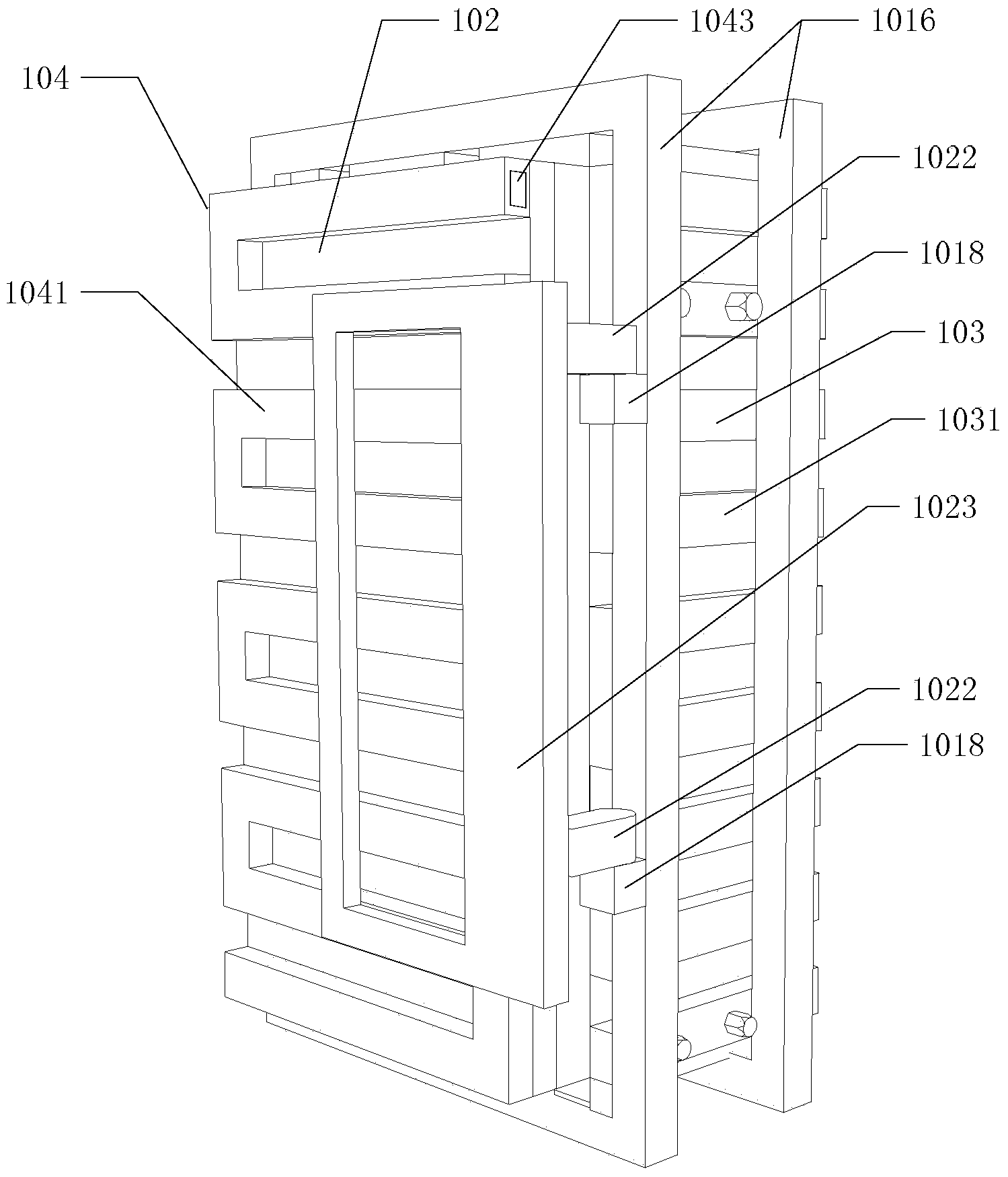

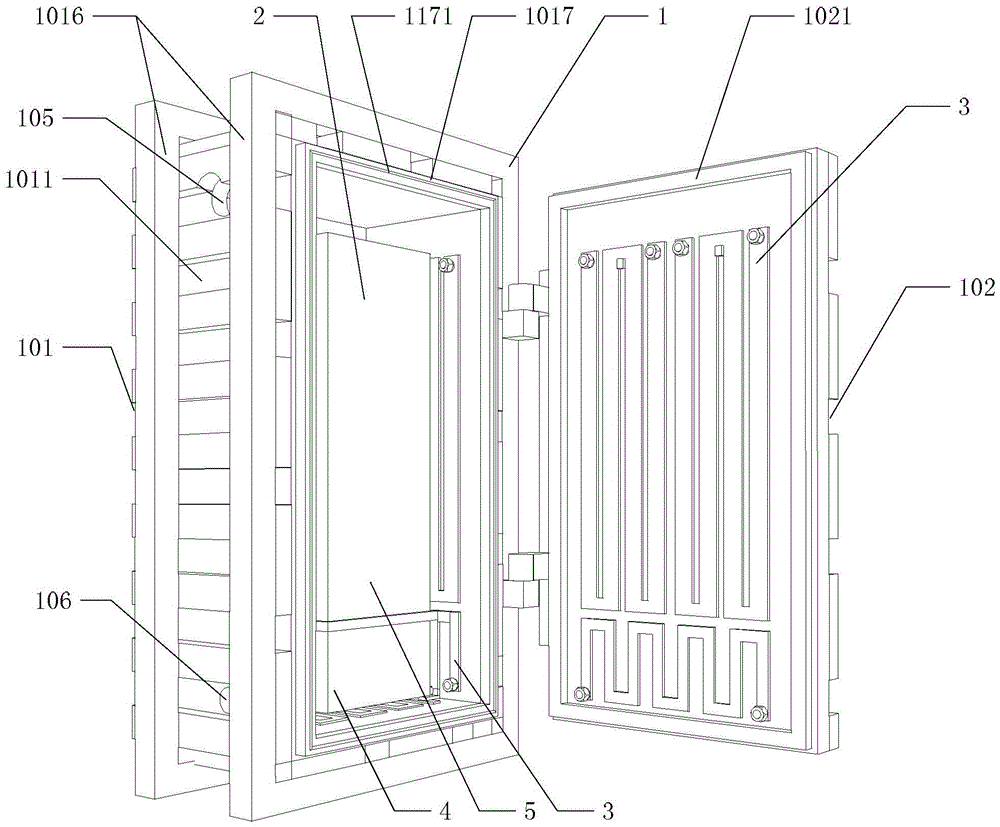

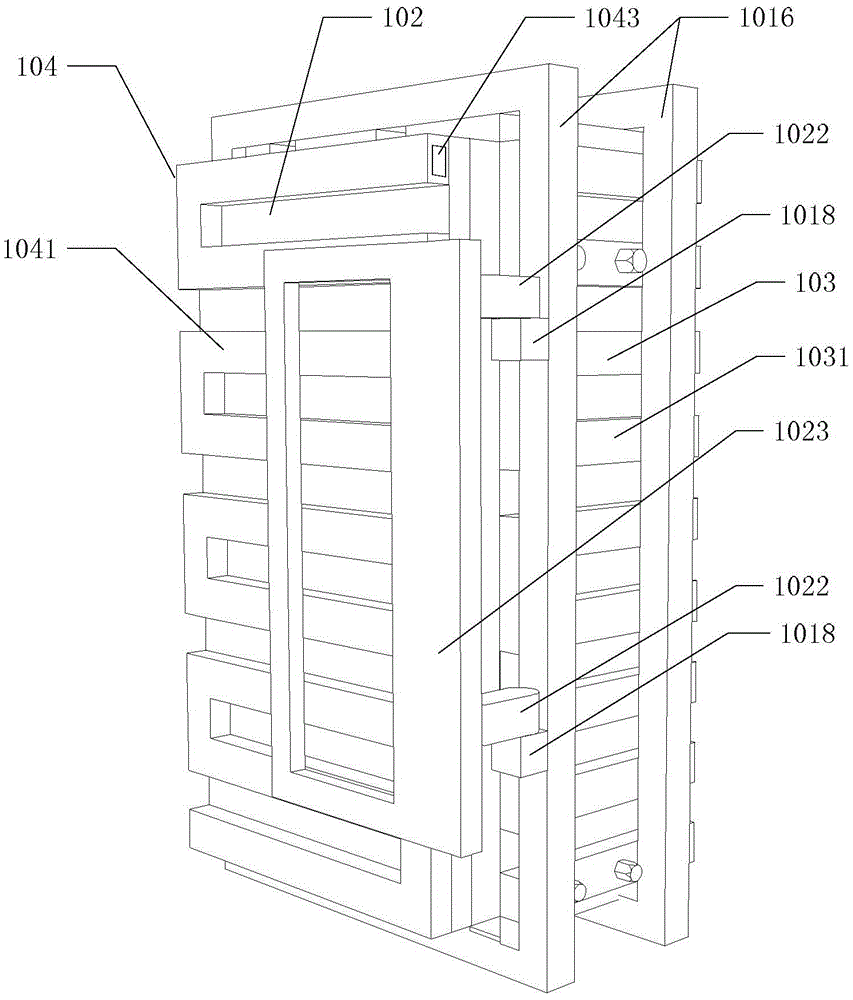

Chemical vapor deposition equipment

ActiveCN103757605AMeet industrial scale productionRealize industrial scale productionChemical vapor deposition coatingGas phaseEngineering

The invention relates to chemical vapor deposition equipment which comprises a shell, a reaction system, and a heating element positioned between the shell and the reaction system, wherein the reaction system is arranged in the shell, and comprises a raw material supply device and a reaction room; the heating element is arranged on the inner wall of the shell on the outer sides of the raw material supply device and the reaction room. The chemical vapor deposition equipment is characterized in that the shell comprises a shell main body and a door; an inner cavity is formed by surrounding of the shell main body and the door, and is a cuboid; the door can be opened or close one surface of the inner cavity. The chemical vapor deposition equipment, provided by the invention, can prepare materials with huge size, and realizes the preparation of the materials with huge size under the premise of possibly decreasing the volume; the single-surface door opening design enables the daily mounting and disassembly of internal components to be directly operated simply on the ground level; the control and use of a reaction furnace can be realized by less manpower; the chemical vapor deposition equipment satisfies the industrial large-scale production of preparing the materials with huge size by the CVD (Chemical Vapor Deposition) technology, improves the productivity, and reduces the production cost.

Owner:SINOMA SYNTHETIC CRYSTALS (SHANDONG) CO LTD

Double-purpose vacuum sealing machine

PendingCN109229523AEasy to useEasy to open and closePackaging by pressurising/gasifyingWrapper twisting/gatheringAir pumpPulp and paper industry

The invention discloses a double-purpose vacuum sealing machine. The machine comprises a bottom cover, a face cover and an air pump, an upper vacuum cavity is formed in the lower portion of the face cover, and a lower vacuum cavity is formed in the upper portion of the bottom cover; the upper vacuum cavity and the lower vacuum cavity form a vacuum cavity for extracting air, and the vacuum cavity is communicated with the air pump through an air pipe. The machine further comprises an external air extraction device which is communicated with the vacuum cavity, and the other end of the external air extraction device is provided with an external connection device which is cooperatively connected with the external air extraction device to be used for being connected with a vacuumizing container.The double-purpose vacuum sealing machine can be used for vacuumizing an internal vacuum cavity and can also vacuumize the outside through the external device, the vacuum sealing performance is good,and the machine is safe to use and convenient to open and close.

Owner:浙江圣光电器有限公司

Vacuum gate valve with neutron shielding function

InactiveCN111561576AWith neutron shielding functionIncrease conductanceOperating means/releasing devices for valvesSlide valveEthylene-propylene-diene-monomerEngineering

The invention relates to a vacuum gate valve with a neutron shielding function. The vacuum gate valve comprises a driving mechanism, a valve shell and a valve plate, and is characterized in that the valve plate comprises an outer valve plate made of 0Cr18Ni9 stainless steel, a shielding plate made of lead boron polyethylene and an inner valve plate made of 0Cr18Ni9 stainless steel; an annular sealing groove is formed in the side, close to the valve shell, of the outer valve plate, and an ethylene propylene diene monomer vacuum sealing ring is embedded into the annular sealing groove and used for achieving vacuum sealing between the outer valve plate and the valve shell. According to the vacuum gate valve with the neutron shielding function, the problem that an existing conventional vacuumgate valve cannot shield neutron radiation is solved, the vacuum gate valve can be applied to the environment with neutron radiation, and the two functional requirements of vacuum sealing and neutronradiation shielding are met. The vacuum gate valve with the neutron shielding function has the advantages of being large in conductance, good in vacuum sealing performance, convenient to arrange a vacuum system, high in reliability and the like.

Owner:北京利方达真空技术有限责任公司

A terahertz traveling wave tube ultra-broadband quasi-light output system and its preparation method

ActiveCN109545639BAvoid bandwidthReduces the possibility of crackingTravelling-wave tubesTransit-tube coupling devicesUltra-widebandCoupling

The invention discloses a terahertz traveling wave tube ultra-wideband quasi-light output system and a manufacturing method thereof. A Gaussian horn is used to convert a waveguide mode into a Gaussianmode, to realize long-distance low-loss transmission and high-efficiency coupling of free space. A Brewster output window is used to overcomes a characteristic of a traditional box-type output windowof low bandwidth, and vacuum sealing is realized, and broadband output is ensured. A traditional system device processing mode is abandoned, and the system integrally processes molding, thereby greatly reducing transmission loss caused by flange connection gap and structural irregularity caused by welding. a processing loading table is used in the system, and a groove of a window piece is processed on the loading table. In welding, force of the window piece is uniform, and possibility of cracking of the window piece caused by force is greatly reduced, and transmission loss caused by deformation of the window piece due to force is reduced. The system can realize ultra-wideband output of electromagnetic waves in a terahertz band and has good vacuum sealing performance.

Owner:PEKING UNIV

Capacitive pressure sensor, manufacturing method thereof, and pressure measuring device

ActiveCN109231156BAvoid elicitingChange capacitance valueTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCapacitive pressure sensorInterdigital capacitor

The invention discloses a capacitive pressure sensor, which is suitable for the sensor field. It includes a substrate and a cover plate. The substrate includes a top layer, a bottom layer and an insulating layer. So that the groove forms a vacuum cavity, and the bottom of the groove forms a pressure-sensitive film, and the top layer is provided with a movable interdigital capacitor and a fixed interdigital capacitor, which are arranged staggered and equidistant from each other, and the movable interdigital capacitor passes through. The insulating layer directly under it is attached to the pressure-sensitive film, and the insulating layer directly under the fixed interdigital capacitor is suspended between the bottom layer and the fixed interdigital capacitor. The embodiment of the present invention also discloses a preparation method and a pressure measurement device of a capacitive pressure sensor. When the pressure-sensitive film is deformed by force, the facing area between the movable interdigital capacitor and the fixed interdigital capacitor can be adjusted. It has good linear output, and at the same time, the vacuum tightness is good, which can avoid the extraction of electrodes in the vacuum cavity.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

An ultra-broadband terahertz Brewster vacuum window and its preparation method

ActiveCN106154396BRealize ultra-wideband transmissionUniform stress distributionMountingsOptical light guidesStress distributionUltra-wideband

The invention discloses an ultra-wideband terahertz Brewster vacuum window and a production method thereof. The ultra-wideband terahertz Brewster vacuum window adopts a window plate supporting frame, wherein the window plate supporting frame comprises an elliptical bottom surface and a circular groove; through the elliptical bottom surface, an elliptical section of a cylindrical waveguide is welded, and through the circular groove, a circular window plate is welded, so that electromagnetic wave is propagated from the cylindrical waveguide to the circular window plate; during welding of the circular window plate, stress distribution is relatively uniform, and when the circular window plate is welded with the window plate supporting frame, the influence of stress can be reduced to avoid cracking; a rectangular through hole is formed in the window plate supporting frame, and the influence of the stress can be reduced when a passing condition of the wave is met, so that welding success rate is greatly increased; the structures are connected in a welding manner so as to meet a sealing vacuum requirement; the thickness of the circular window plate meets a requirement that reflected wave and the re-refracted wave are counteracted with each other, so that the transmission efficiency is improved; the ultra-wideband terahertz Brewster vacuum window can achieve ultra-wideband transmission of the electromagnetic wave within a terahertz wave band, has good vacuum sealing performance, and has the advantages of easy production and low price.

Owner:PEKING UNIV

Pipe helium mass spectrometer leak detection device and method

ActiveCN110595699BEasy to manufactureGood vacuum tightnessDetection of fluid at leakage pointMass Spectrometry-Mass SpectrometryEngineering

The invention discloses a helium mass spectrometer leak detection device for pipe materials, which comprises a vacuum joint (1), a mandrel (2), a lower pressure piece (3), a sealing gasket (5), a support piece (6) and a helium mass spectrometer detector. The mandrel (2) is a hollow tubular structure, and a vacuum joint (1) is provided on the top of the mandrel (2), and the pressing member (3), the gasket (5) and the supporting member (6) are set Set on the mandrel (2), the support (6) is detachably fixed on the mandrel (2), and the pressing member (3) can move axially along the mandrel (2), so that the gasket ( 5) It can radially expand along the mandrel (2) under the extrusion action of the pressing member (3) and the supporting member (6). The pipe material helium mass spectrometer leak detection device of the present invention has many advantages such as easy manufacture, simple operation, high reliability, high leak detection efficiency, low cost, and reusability.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

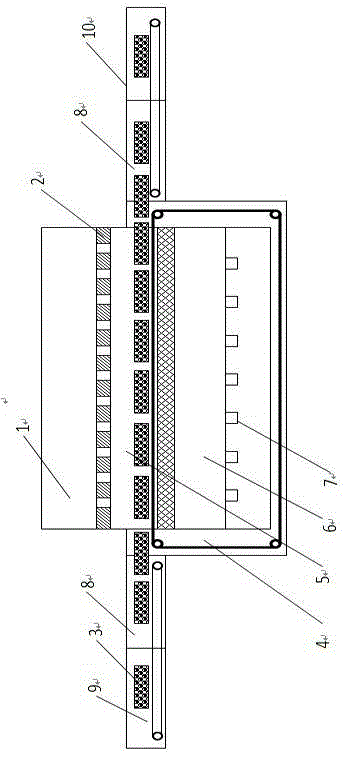

Microwave continuous freeze-drying device

InactiveCN102226635BUniform microwave fieldAvoid glow dischargeDrying using combination processesDrying solid materials with heatMicrowaveFreeze-drying

A continuous microwave freeze-drying devices comprises a vacuum water-trapping system (1), a microwave shield plate (2), a microwave bin (6) and a freeze-drying bin (5) located in the microwave bin (6), wherein the treeze-drying bin (5) comprises an upper bin opening, a left bin wall, a right bin wall and a bottom bin wall, and the left, right and bottom bin walls are all made from nonmetal wave transmitting materials, such as polyrfluortetrethylene, polyethylene, polypropylene or quartz glass. The device solves the technical problem of freeze-drying failure caused by glow discharge of microwave under freeze-drying environment.

Owner:SICHUAN HOPE MICROWAVE SCI & TECH

A kind of lead-free solder for quartz glass sealing

ActiveCN109822257BImprove vacuum sealing performanceSimple sealing processWelding/cutting media/materialsSoldering mediaTitanium coatingSoldering

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Cryogenic Tubular Heating Tube Vacuum Seal Fittings

InactiveCN105909791BSolve the technical requirements that cannot ensure the vacuum sealing of the furnaceSimple structureEngine sealsEngineeringHeating furnace

The invention relates to a vacuum sealing joint for a low-temperature tubular heating tube. The vacuum sealing joint comprises a tubular spiral heating tube, a vacuum joint, a sealing ring and compression nuts, wherein the vacuum joint is fixedly connected into an installation hole of a vacuum furnace wall; conducting ends of the tubular spiral heating tube are inserted in the vacuum joint; the vacuum joint is provided with inner conical holes, and in fit connection with outer conical tables on the tubular spiral heating tube through the inner conical holes; the sealing ring is arranged between the inner conical holes and the outer conical tables; and the tubular spiral heating tube is locked and fixed, and the sealing ring is compressed on the conducting ends of the tubular spiral heating tube through the compression nuts, so as to achieve a vacuum sealing effect. The joint enables a heating component of a vacuum furnace to be directly supplied with power of 220 V instead of being supplied with power by configuring voltage dropping equipment, thus configuration of a small vacuum furnace is simplified, and the equipment cost is reduced. Moreover, a reliable sealing structure is provided for producing the small vacuum heating furnace by virtue of the heating component for vacuum heating, and a technical support is provided for producing the small vacuum heating furnace by widely using the tubular heating tube.

Owner:SHANGHAI HENGTUO HYDRAULIC CONTROL TECH

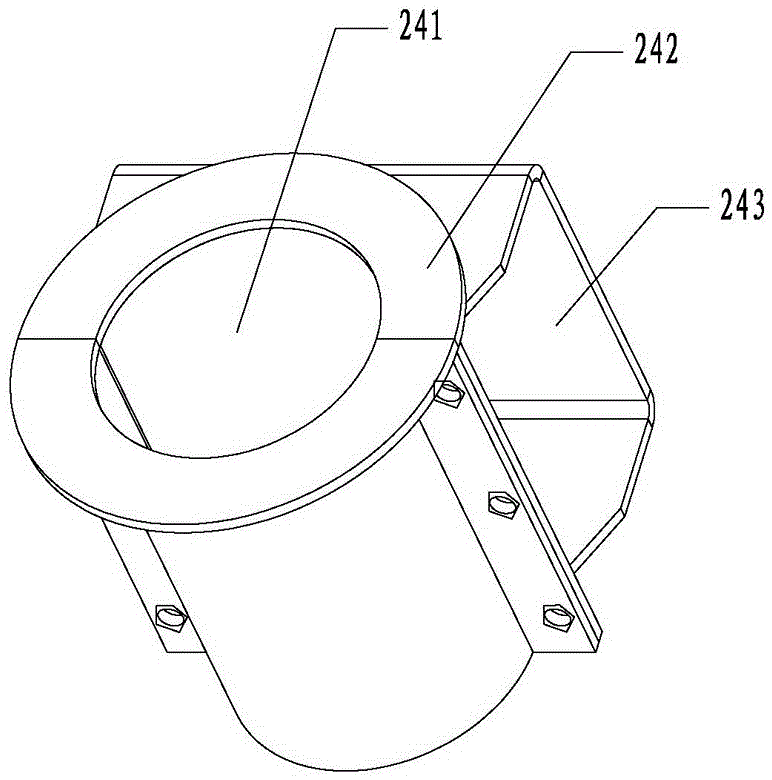

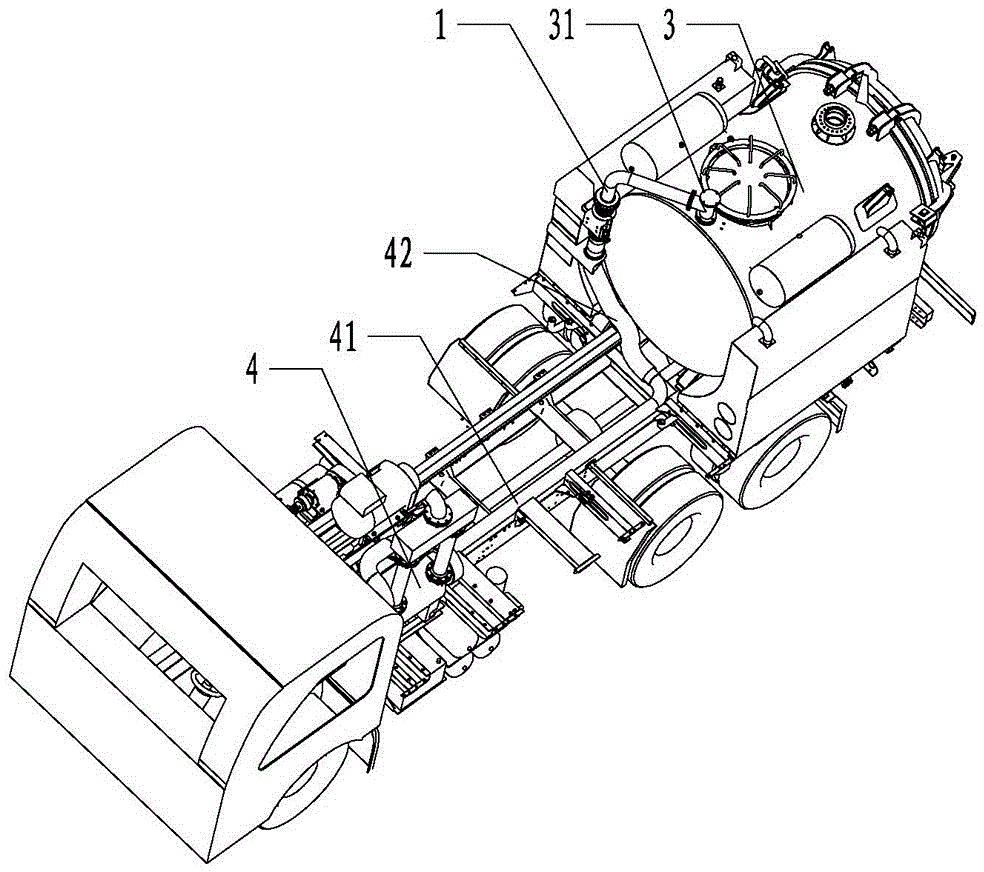

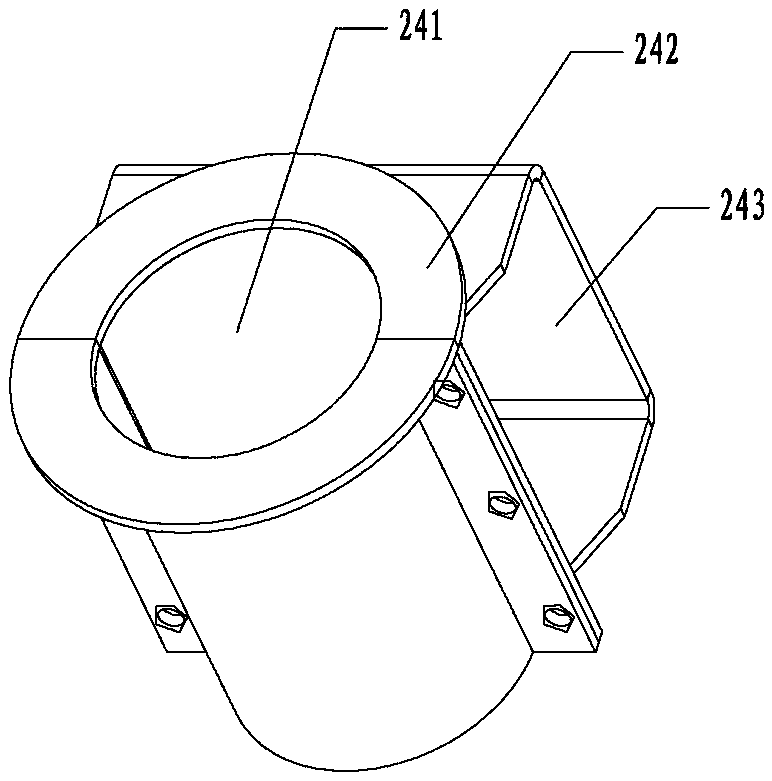

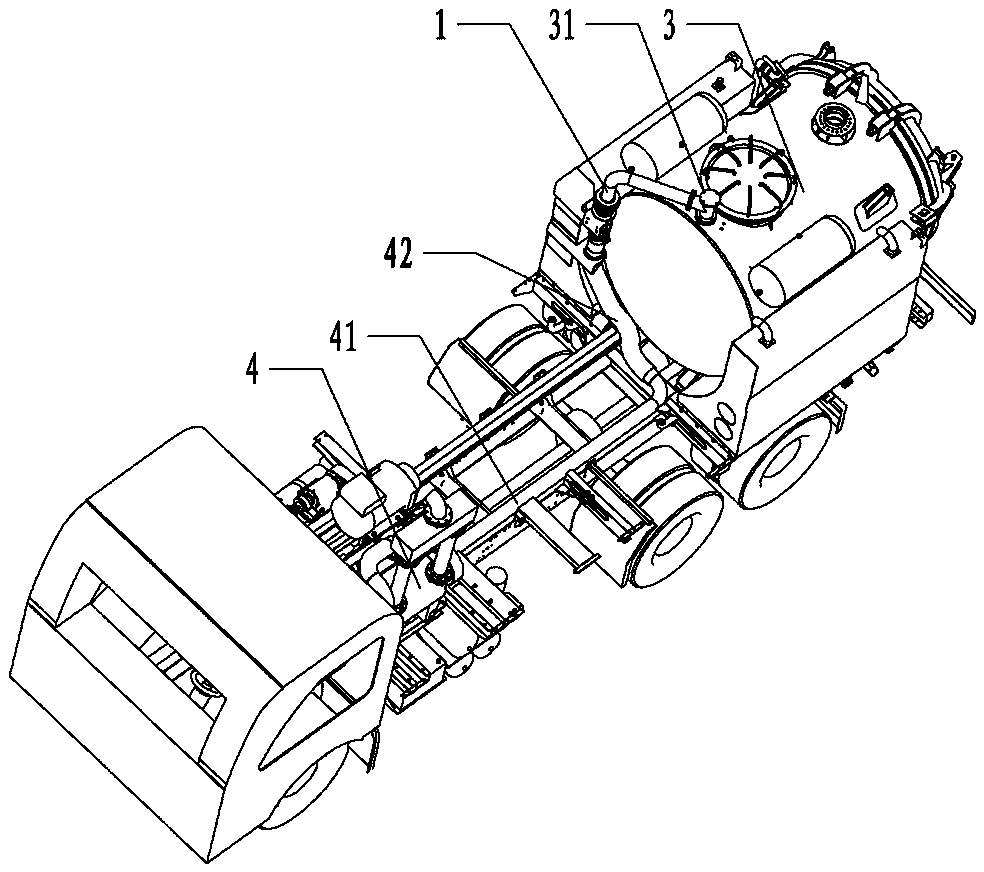

Automatic compensation type vacuum tube connecting device and dredging machinery with connecting device

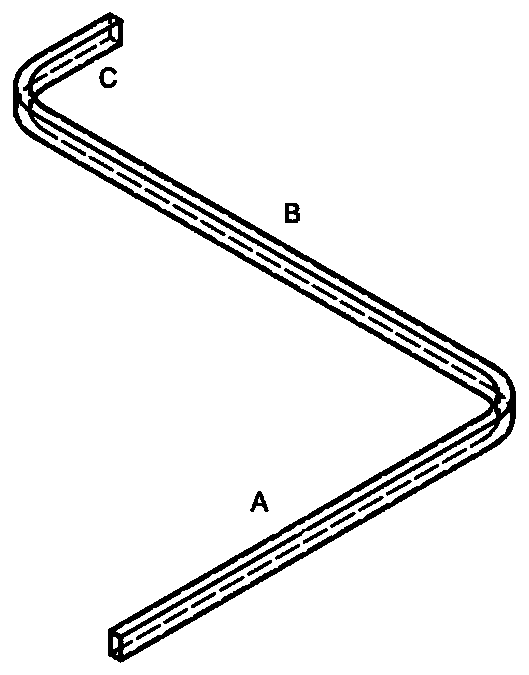

ActiveCN105805472AReduce weightIncrease carrying capacityPipeline expansion-compensationAdjustable jointsEngineeringSewage

The invention relates to an automatic compensation type vacuum tube connecting device and a dredging machinery with the connecting device. The connecting device is characterized by comprising a dynamic connecting pipe and a static connecting pipe; an annular flange is arranged in a port of a connecting end of the dynamic connecting pipe with the static connecting pipe; a sealing rubber, a concave ring, a spring and a circular pipe guide base coat a connecting end of the static connecting pipe with the dynamic connecting pipe from top to bottom in sequence; the top of the sealing rubber is butted against the annular flange, and the bottom is arranged in the concave ring; and the spring is butted against between the bottom of the concave ring and the top of the circular pipe guide base. The vacuum pipe connecting device consisting of the dynamic connecting pipe and the static connecting pipe can be connected and preferably sealed in the dirt sucking operation, can be released when unloading a sewage tank, and can eliminate errors generated in the manufacturing process and higher pressure stress generated in the joint process of the dynamic connecting pipe and the static connecting pipe.

Owner:厦门威迪思汽车设计服务有限公司

Pulse xenon lamp and sealing method of the same

InactiveCN106898539AImprove automationEasy to achieve productivityGas discharge lamp detailsCold cathode manufactureCouplingEngineering

The invention discloses a pulse xenon lamp and a sealing method of the same. The pulse xenon lamp and the sealing method of the same are characterized in that two ends in a quartz tube in a xenon lamp are respectively provided with an electrode I and an electrode II along a transverse central axis; the electrode I and the electrode II are bilaterally symmetrical with a longitudinal central axis of the quartz tube; the tail of the electrode I at the right end of the longitudinal central axis of the quartz tube is fixedly connected with an electrode cap, a patchplug and a cable wire along the transverse central axis successively; the structure of the left end of the longitudinal central axis of the quartz tube is the same as the structure of the right end of the longitudinal central axis of the quartz tube; the electrode cap sleeves the outside of the port of the quartz tube, and active solders are filled between the electrode cap and the port of the quartz tube, and are heated to more than 600DEG C in a vacuum environment being less than 5*10-3Pa; and when the active solders are fused and are fully reacted with quartz glass, direct non-coupling sealing of the electrode cap and the quartz tube is completed. The sealing method of the pulse xenon lamp is easy to realize automation and large scale production of xenon lamp sealing, is simple and stable in the sealing process, is high in the vacuum sealing performance of the sealing area, and is high in structural intensity. The xenon lamp can bear large current, and the service life and working reliability of the xenon lamp are significantly improved.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

A pulsed xenon lamp and its sealing method

InactiveCN106898539BImprove automationGood vacuum tightnessGas discharge lamp detailsCold cathode manufactureCouplingEngineering

The invention discloses a pulse xenon lamp and a sealing method of the same. The pulse xenon lamp and the sealing method of the same are characterized in that two ends in a quartz tube in a xenon lamp are respectively provided with an electrode I and an electrode II along a transverse central axis; the electrode I and the electrode II are bilaterally symmetrical with a longitudinal central axis of the quartz tube; the tail of the electrode I at the right end of the longitudinal central axis of the quartz tube is fixedly connected with an electrode cap, a patchplug and a cable wire along the transverse central axis successively; the structure of the left end of the longitudinal central axis of the quartz tube is the same as the structure of the right end of the longitudinal central axis of the quartz tube; the electrode cap sleeves the outside of the port of the quartz tube, and active solders are filled between the electrode cap and the port of the quartz tube, and are heated to more than 600DEG C in a vacuum environment being less than 5*10-3Pa; and when the active solders are fused and are fully reacted with quartz glass, direct non-coupling sealing of the electrode cap and the quartz tube is completed. The sealing method of the pulse xenon lamp is easy to realize automation and large scale production of xenon lamp sealing, is simple and stable in the sealing process, is high in the vacuum sealing performance of the sealing area, and is high in structural intensity. The xenon lamp can bear large current, and the service life and working reliability of the xenon lamp are significantly improved.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

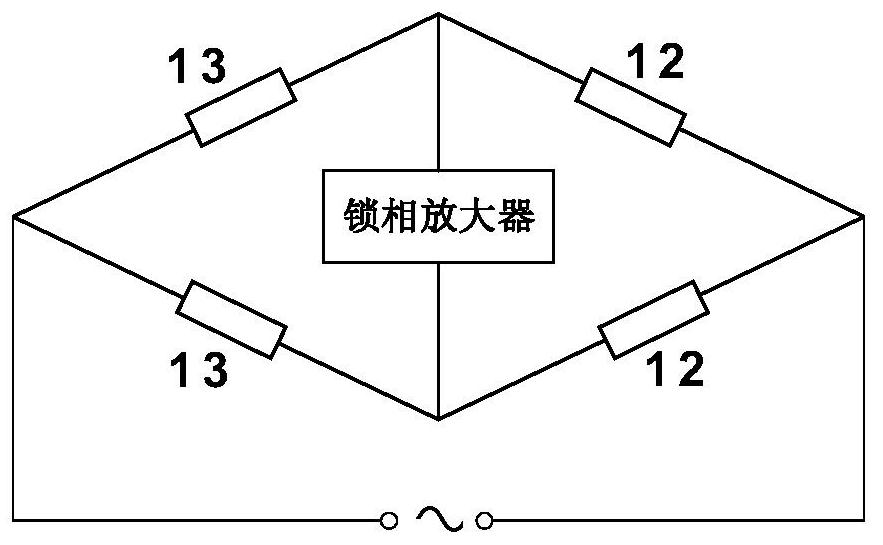

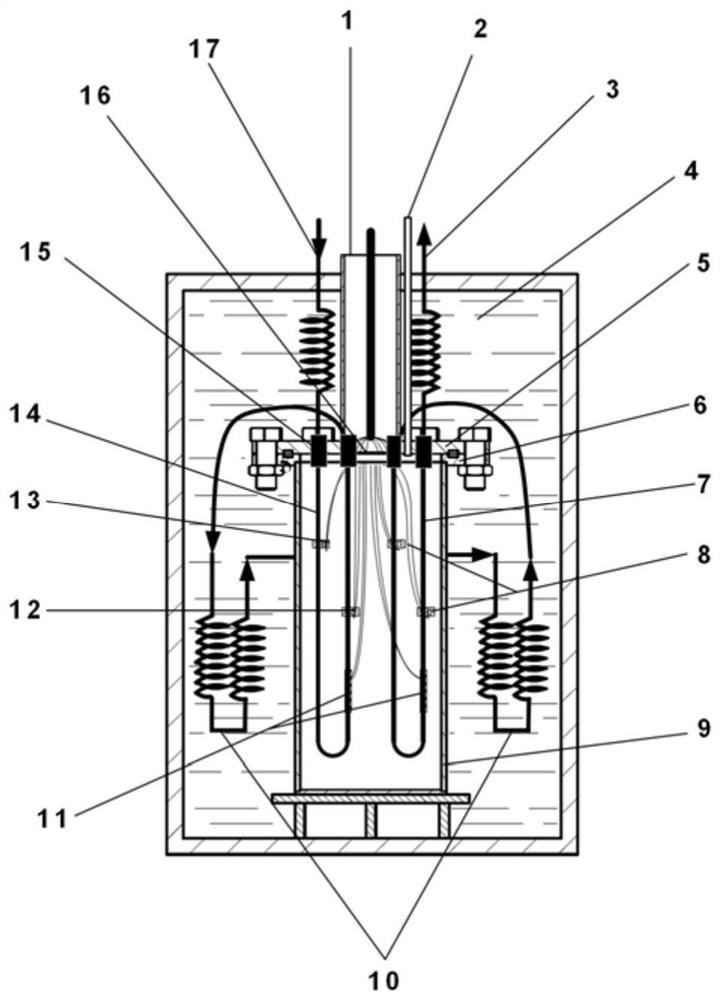

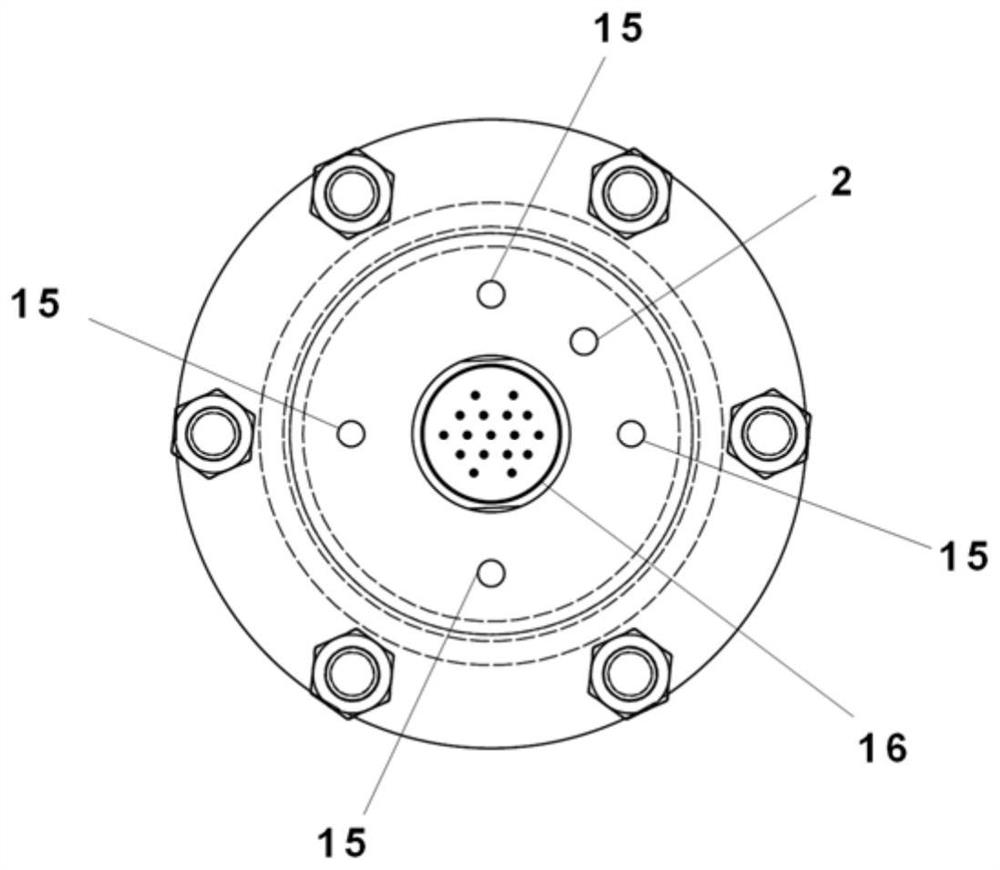

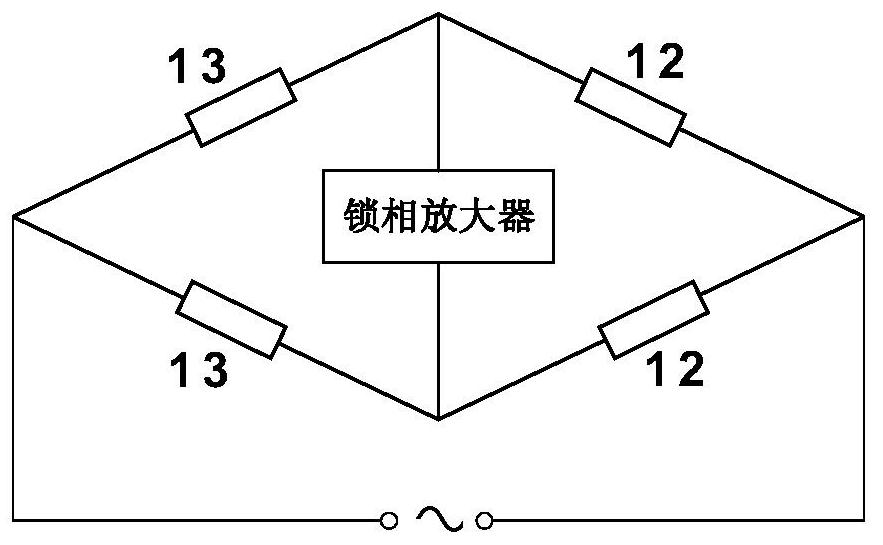

Device and method for measuring specific heat capacity by dual-flow method

ActiveCN112748145BElimination temperatureHigh precisionMaterial heat developmentSpecific heat investigationMeasurement deviceEngineering

A device and method for measuring specific heat capacity by a double-flow method, including a calorimeter part and a heating control part; the calorimeter part includes a vacuum chamber, the top of the vacuum chamber is provided with a lower flange and an upper flange end cover matched with the lower flange , the upper flange end cover is provided with a vacuum pipe; the inside of the vacuum chamber is provided with a second U-shaped tube and a first U-shaped tube with the same structure, and the upper ends of the second U-shaped tube and the first U-shaped tube are connected to the two-way The lower end is connected, the second U-shaped tube and the first U-shaped tube are wound with a heating wire, and the two ends of the heating wire are respectively provided with through holes for the first temperature sensor and the second temperature sensor; the heating control part is located outside the calorimeter , the heating control part is connected with the heating wire. The invention can accurately measure the specific heat capacity of the liquid, the device has good stability, and the measurable temperature and pressure range is wide. It can be used for the specific heat measurement of dilute electrolyte solutions and organic matter in industry and scientific research, and can also be used in energy and power related fields. The teaching of course experiments.

Owner:XI AN JIAOTONG UNIV

A kind of sn-ti-ag ternary alloy solder for quartz glass sealing

ActiveCN109986233BImprove vacuum sealing performanceSimple sealing processWelding/cutting media/materialsSoldering mediaTitanium coatingPhysical chemistry

The invention discloses a Sn-Ti-Ag ternary alloy solder for quartz glass sealing. The matrix of the ternary alloy solder is tin, the weight percent components of Ti and Ag introduced are Ti: 0.1%-1.6%, Ag: 0.1%-2.0%, and the atomic percent components of O introduced are 0.05%-3.9% %, the mass percentage of impurities in the ternary alloy solder is less than or equal to 0.1%. The welding temperature range of the ternary alloy solder is 650℃~800℃, and the welding vacuum degree is less than or equal to 5×10 ‑3 Pa. The ternary alloy solder does not need flux in the quartz glass sealing process, simplifies the quartz glass sealing process, and improves the vacuum sealing reliability of the quartz glass sealing. The ternary alloy solder can be widely used not only in quartz glass sealing, but also in silica glass, which has a softening temperature of not lower than 800 °C and is made of SiO 2 The mutual welding of glass, titanium, oxygen-free copper and metal with titanium coating on the surface as the main component is especially suitable for the preparation of pulsed xenon lamps, which can significantly improve the service life and working reliability of pulsed xenon lamps.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Lead-free solder for sealing quartz glass

ActiveCN109822257ASimple sealing processImprove vacuum sealing performanceWelding/cutting media/materialsSoldering mediaTitaniumPrimary component

The invention discloses lead-free solder for sealing quartz glass. A matrix of the lead-free solder is tin, and the atomic percent of introduced Ti and O is a follows: 0.2-6% of Ti and 0.05-5.9% of O.The atom ratio of Ti and O is greater than 1, and the mass percent of impurities in the lead-free solder is smaller than or equal to 0.1%. The welding temperature range of the lead-free solder is 600-800 DEG C, and the welding vacuum degree is smaller than or equal to 5*10<-3>Pa. In a quartz glass sealing process, scaling powder is not needed for the lead-free solder for sealing quartz glass, sothat the quartz glass sealing process is simplified and the vacuum sealing reliability of quartz glass sealing is improved. The lead-free solder can be widely applied to quartz glass sealing and can be also applied to welding quartz glass, glass, the softening temperature of which is not lower than 800 DEG C, taking SiO2 as a primary component, a titanium material, metals with titanium plating onthe surface and the like. The lead-free solder is in particular suitable for preparing a pulse xenon lamp, so that the service life of the pulse xenon lamp can be prolonged obviously and the working reliability of the pulse xenon lamp can be improved obviously.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

An automatic compensation type vacuum pipe connection device and dredging machine with the connection device

ActiveCN105805472BReduce weightIncrease carrying capacityPipeline expansion-compensationAdjustable jointsEngineeringSewage

Owner:厦门威迪思汽车设计服务有限公司

Sn-Ti-Cu ternary alloy welding flux used for sealing of quartz glass

ActiveCN109986232ASimple sealing processImprove vacuum sealing performanceWelding/cutting media/materialsSoldering mediaTernary alloyTitanium

The invention discloses Sn-Ti-Cu ternary alloy welding flux used for sealing of quartz glass. The matrix of the Sn-Ti-Cu ternary alloy welding flux is tin; the weight percentage of introduced Ti and Cu are 0.1%-2.0% of Ti and 0.1%-1.0% of Cu; the atomic percentage of introduced O is 0.05%-4.9%; and the mass percentage of impurities in the ternary alloy welding flux is smaller than or equal to 0.1%. the welding temperature range of the ternary alloy welding flux is 650 DEG C to 800 DEG C; and the welding vacuum degree is smaller than or equal to 5 multiplied by 10<-3> Pa. The ternary alloy welding flux has the advantages that no scaling powder is needed during the quartz glass sealing process; the quartz glass sealing technique is simplified; the vacuum sealing reliability of quartz glass sealing is improved; the ternary alloy welding flux can be widely applied to quartz glass sealing, and can also be applied to mutual welding of quartz glass, glass which has softening temperature above800 DEG C and takes SiO2 as the main component, a titanium material, oxygen-free copper, metal of which the surface is provided with a titanium cladding layer and the like; the ternary alloy weldingflux is especially applicable to manufacturing pulse xenon lamps; the service lives of the pulse xenon lamps can be prolonged; and the reliability of the pulse xenon lamps is obviously improved.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Device and method for measuring specific heat capacity through double-flow method

ActiveCN112748145AElimination temperatureEliminates the effects of fluctuations in flow ratesMaterial heat developmentSpecific heat investigationPumping vacuumCalorimeter

The invention discloses a device and a method for measuring a specific heat capacity through a double-flow method. The device comprises a calorimeter component and a heating control component. The calorimeter component comprises a vacuum cavity, a lower flange and an upper flange end cover matched with the lower flange are arranged at the top of the vacuum cavity, and a vacuumizing pipeline is arranged on the upper flange end cover; a second U-shaped pipe and a first U-shaped pipe which are the same in structure are arranged in the vacuum cavity, the upper ends of the second U-shaped pipe and the first U-shaped pipe are both connected with the lower end of a two-way pipe, heating wires are wound on the outer sides of the second U-shaped pipe and the first U-shaped pipe, and through holes of a first temperature sensor and a second temperature sensor are formed in the two ends of the heating wires respectively; and the heating control component is positioned outside the calorimeter and is connected with the heating wire. The device can accurately measure the specific heat capacity of a liquid, is good in stability and wide in measurable temperature and pressure range, can be used for specific heat measurement of dilute electrolyte solutions and organic matters in industry and scientific research, and can also be used for teaching of course experiments of energy and power related professions.

Owner:XI AN JIAOTONG UNIV

A kind of sn-ti-cu ternary alloy solder for quartz glass sealing

ActiveCN109986232BImprove vacuum sealing performanceSimple sealing processWelding/cutting media/materialsSoldering mediaTitanium coatingPhysical chemistry

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

A chemical vapor deposition device

ActiveCN103757605BMeet industrial scale productionRealize industrial scale productionChemical vapor deposition coatingGas phaseProcess engineering

Owner:SINOMA SYNTHETIC CRYSTALS (SHANDONG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com