Patents

Literature

45results about How to "Improve vacuum sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

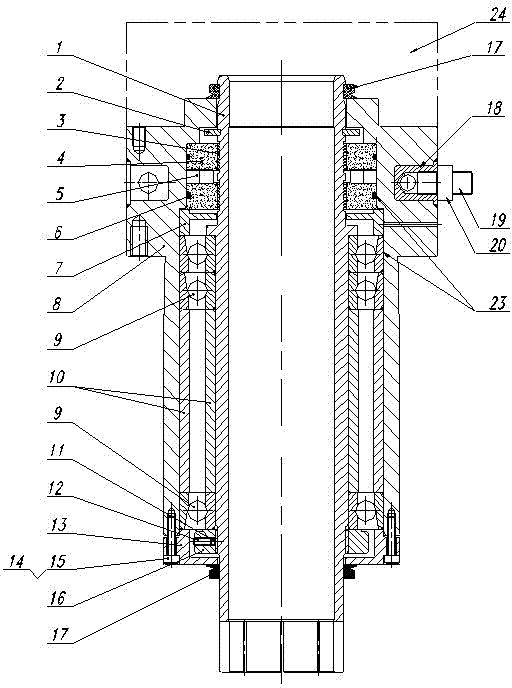

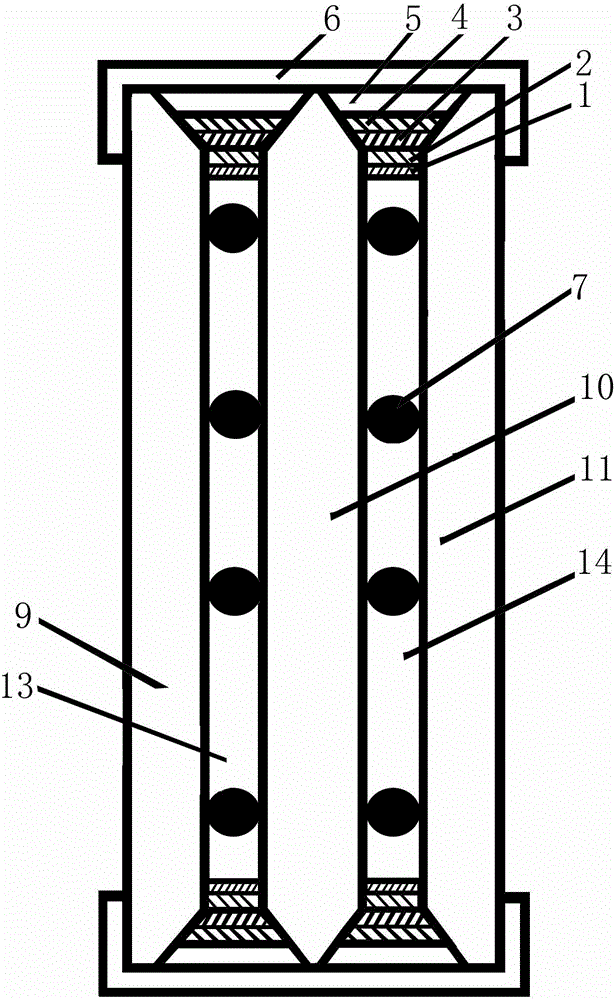

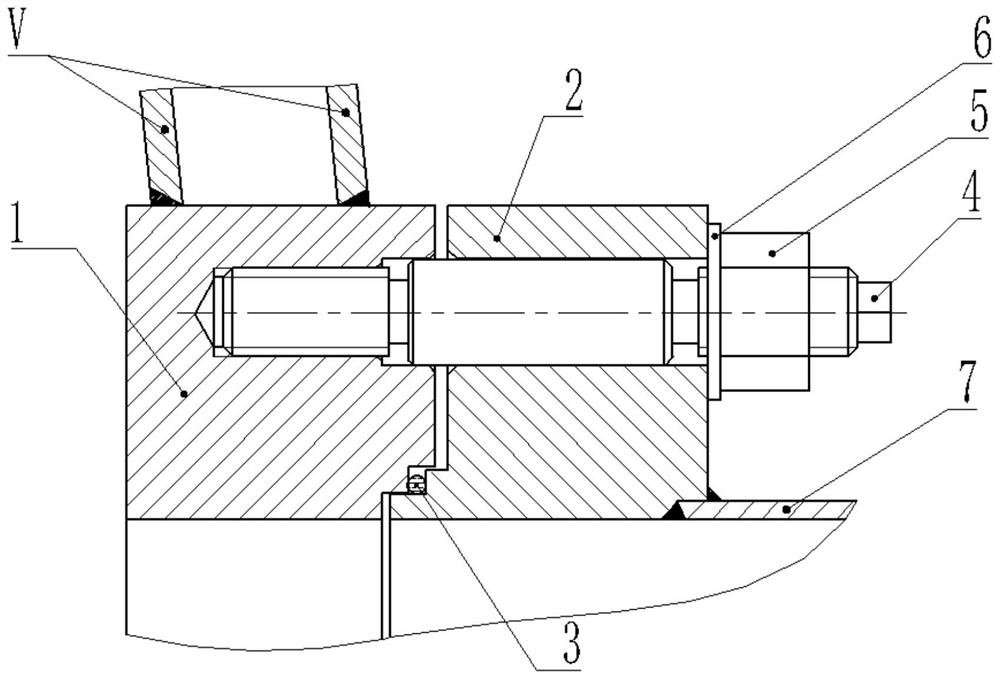

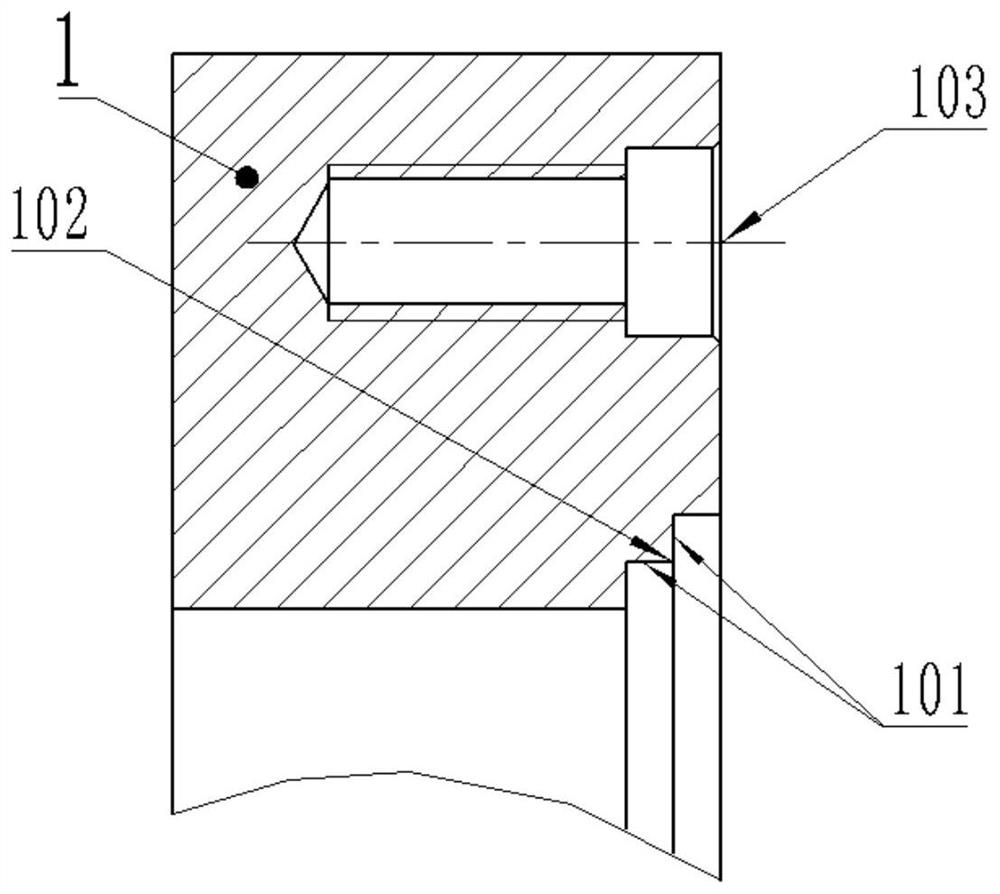

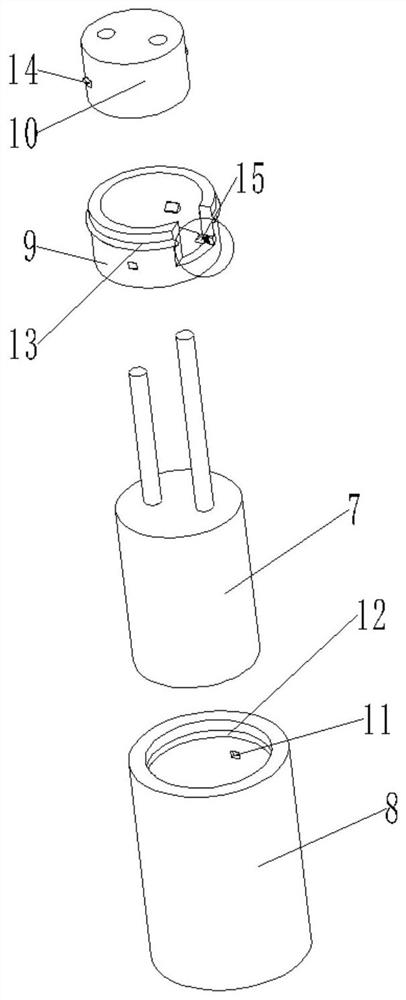

Sealing device for transmission input shafts in vacuum environment and using method of sealing device

InactiveCN102927283AReduce heat damageImprove the magnetic effectEngine sealsBall bearingMagnetic poles

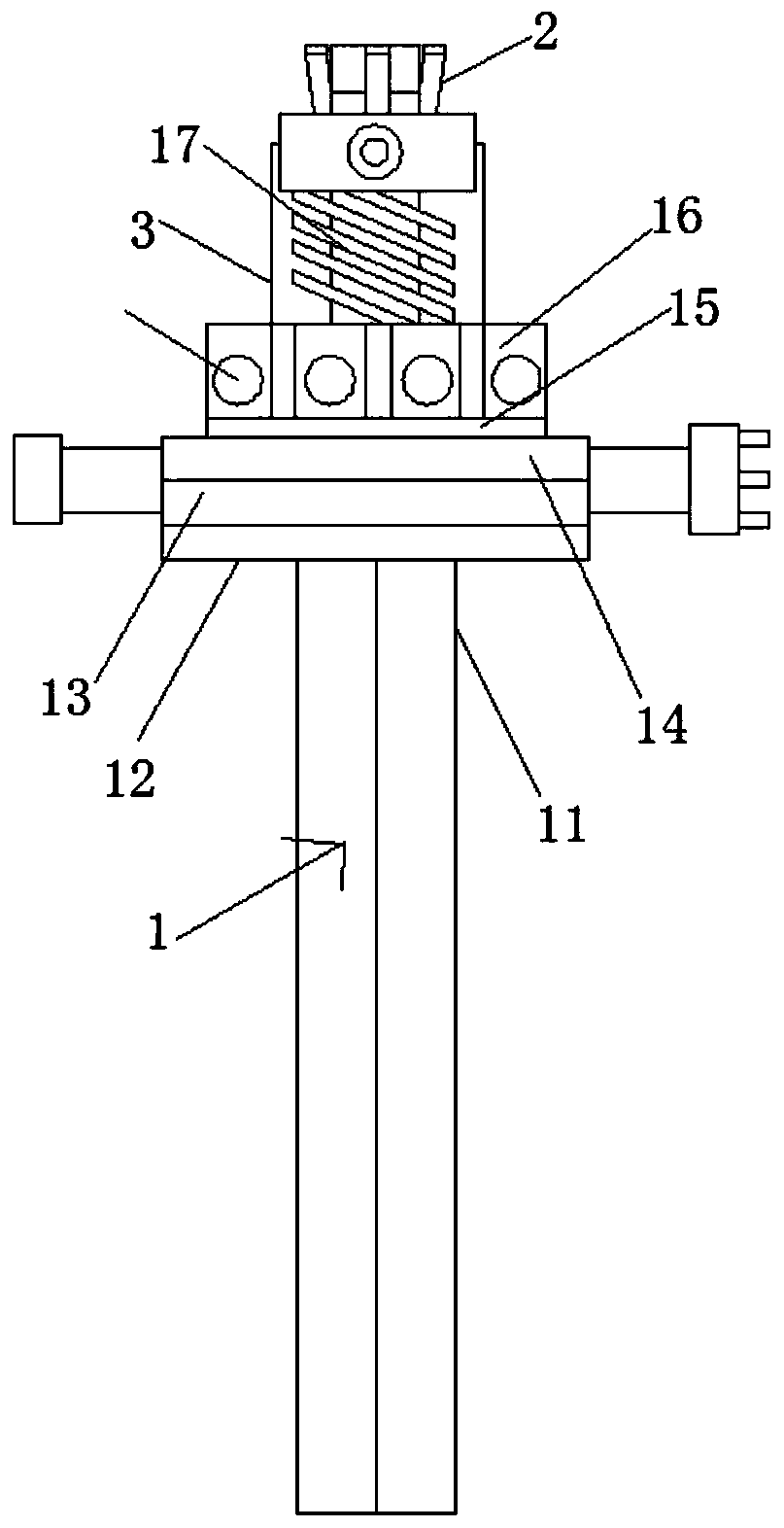

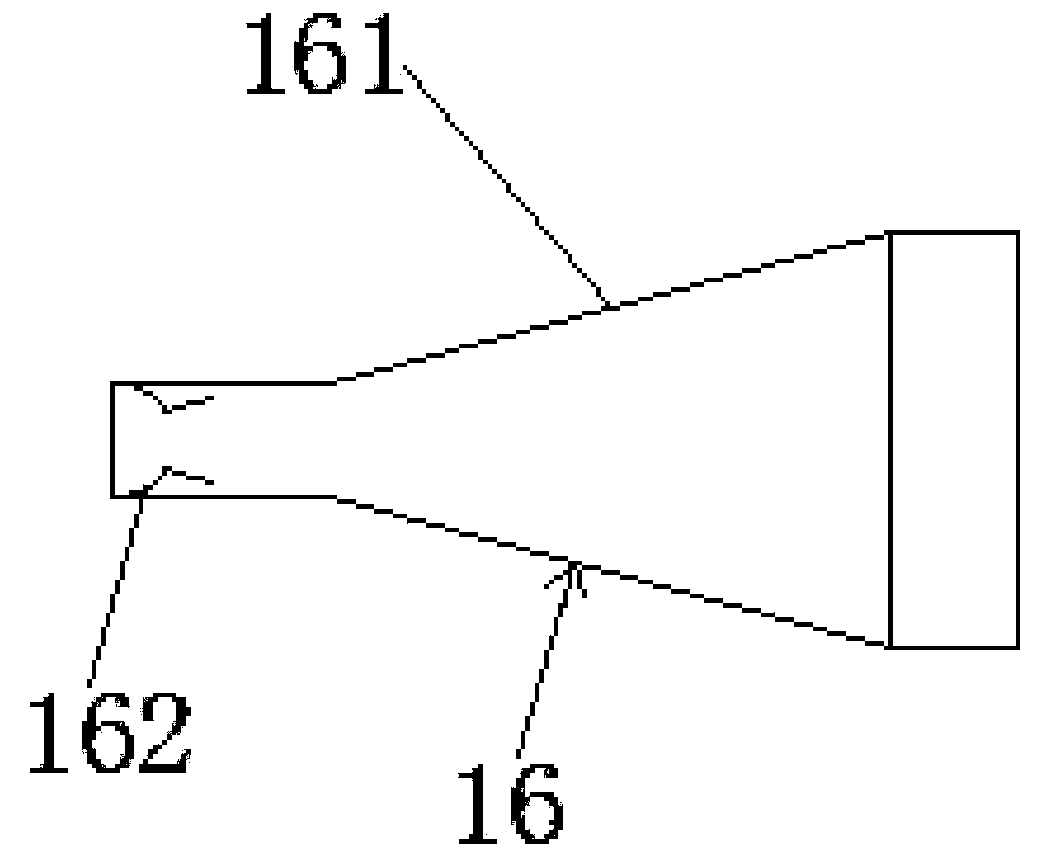

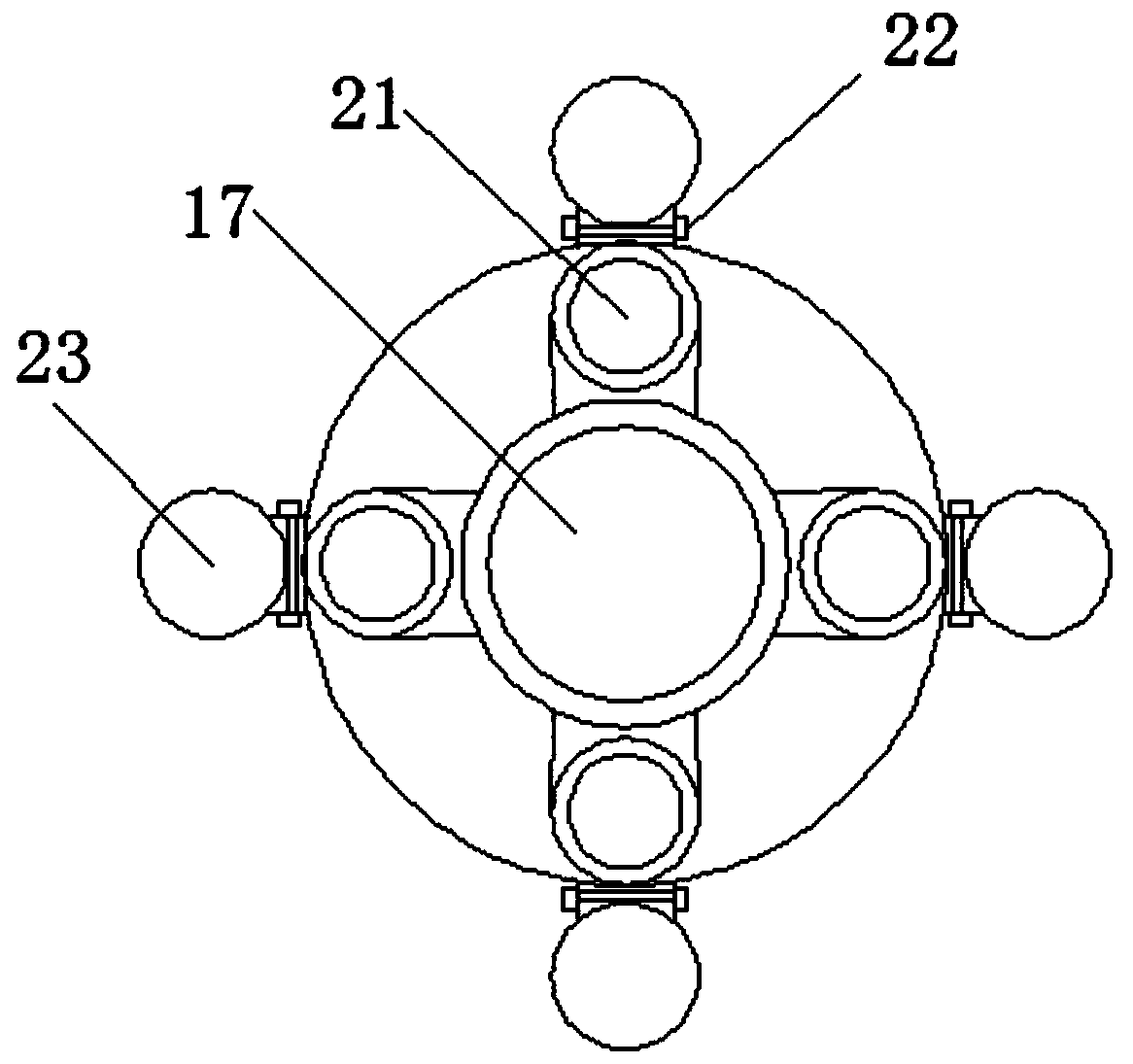

The invention discloses a sealing device for transmission input shafts in a vacuum environment and a using method of the sealing device. The sealing device comprises a transmission input shaft, elastic shaft check rings, magnetic liquids, magnetic poles, magnets, O-shaped rings, special-made gaskets, outer casings, angular contact ball bearings, pairing ferrules, locking blocks, set screws with flat points, end caps, hexagon socket head cap screws, glue, lock nuts, V-shaped oil seals, a four-way connection block, a water outlet connector, a water inlet connector, a water delaying baffle block, outer water channel ferrule pieces and oil, wherein an oil seal limiting groove, check ring shaft grooves, magnetic liquid chambers, shaft shoulders, locking threads and equal division shaft kerfs are arranged on the transmission input shaft. According to the sealing device, novel magnetic fluid materials are applied for vacuum seal, a water cooling system is applied for cooling, by means of the sealing device, thermal damage is reduced in thermal field environments, magnetic effects of magnetism work pieces are improved, the vacuum sealing performance is good, and the sealing device can be used in vacuum sealing devices with higher vacuum requirements.

Owner:浙大新剑(上海)智能技术有限公司 +1

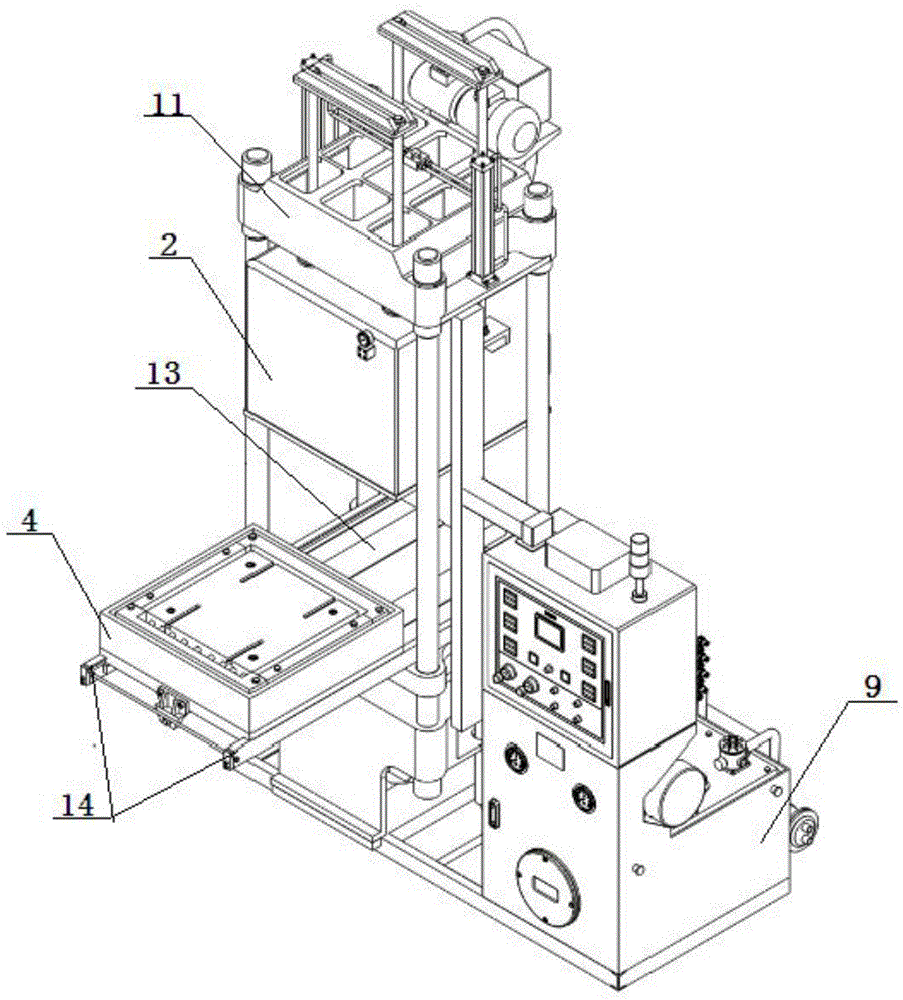

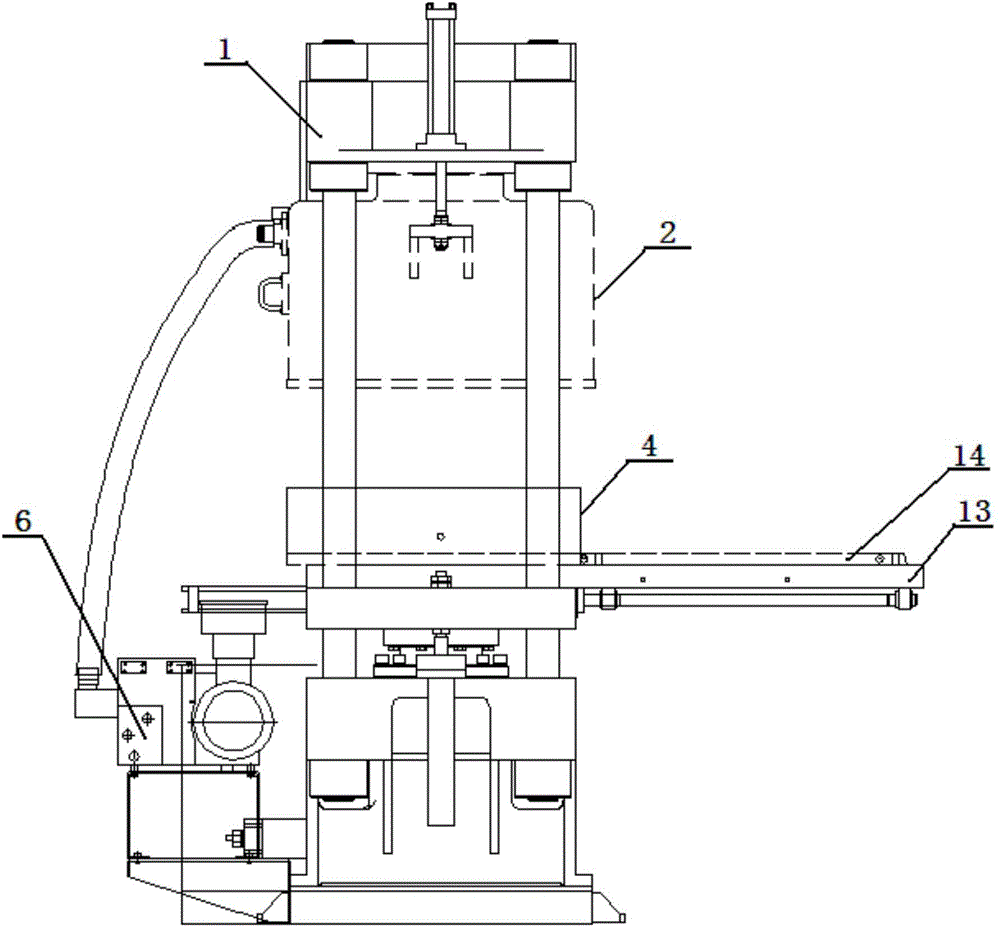

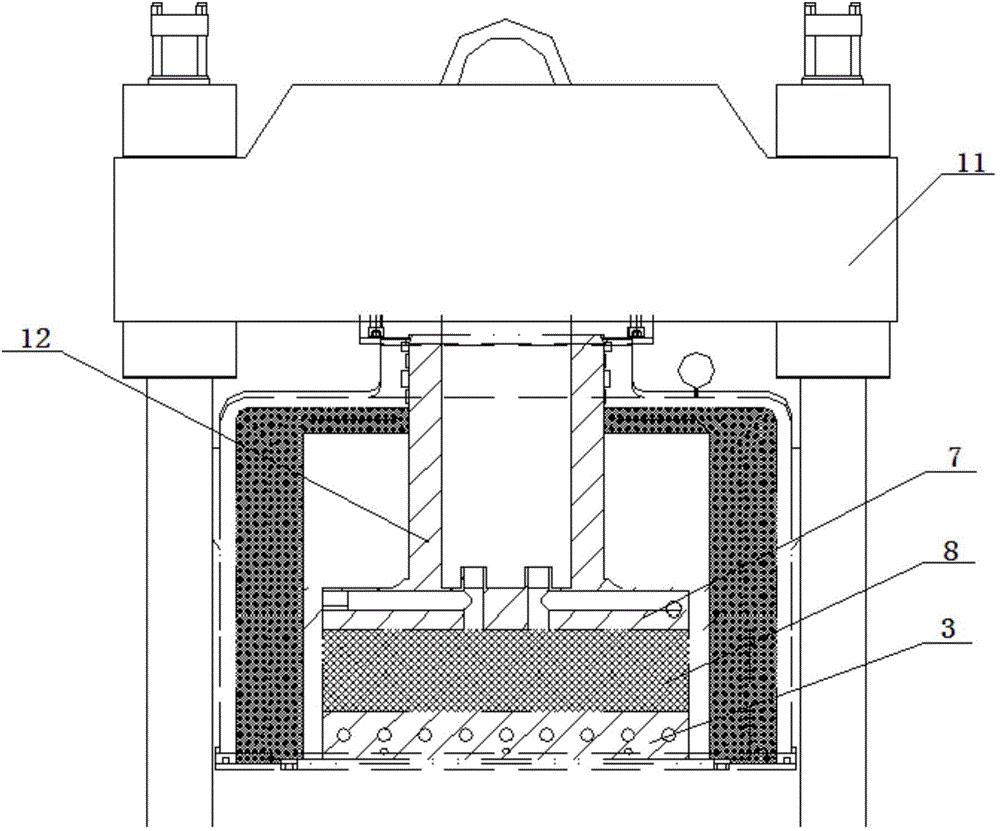

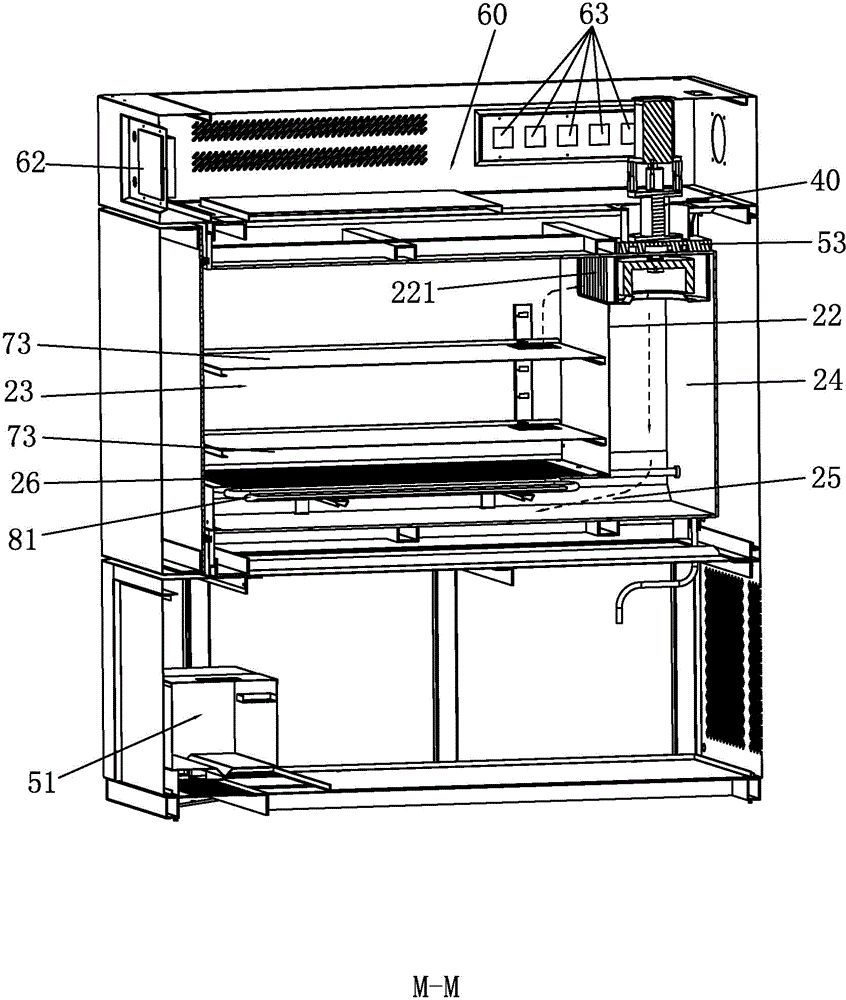

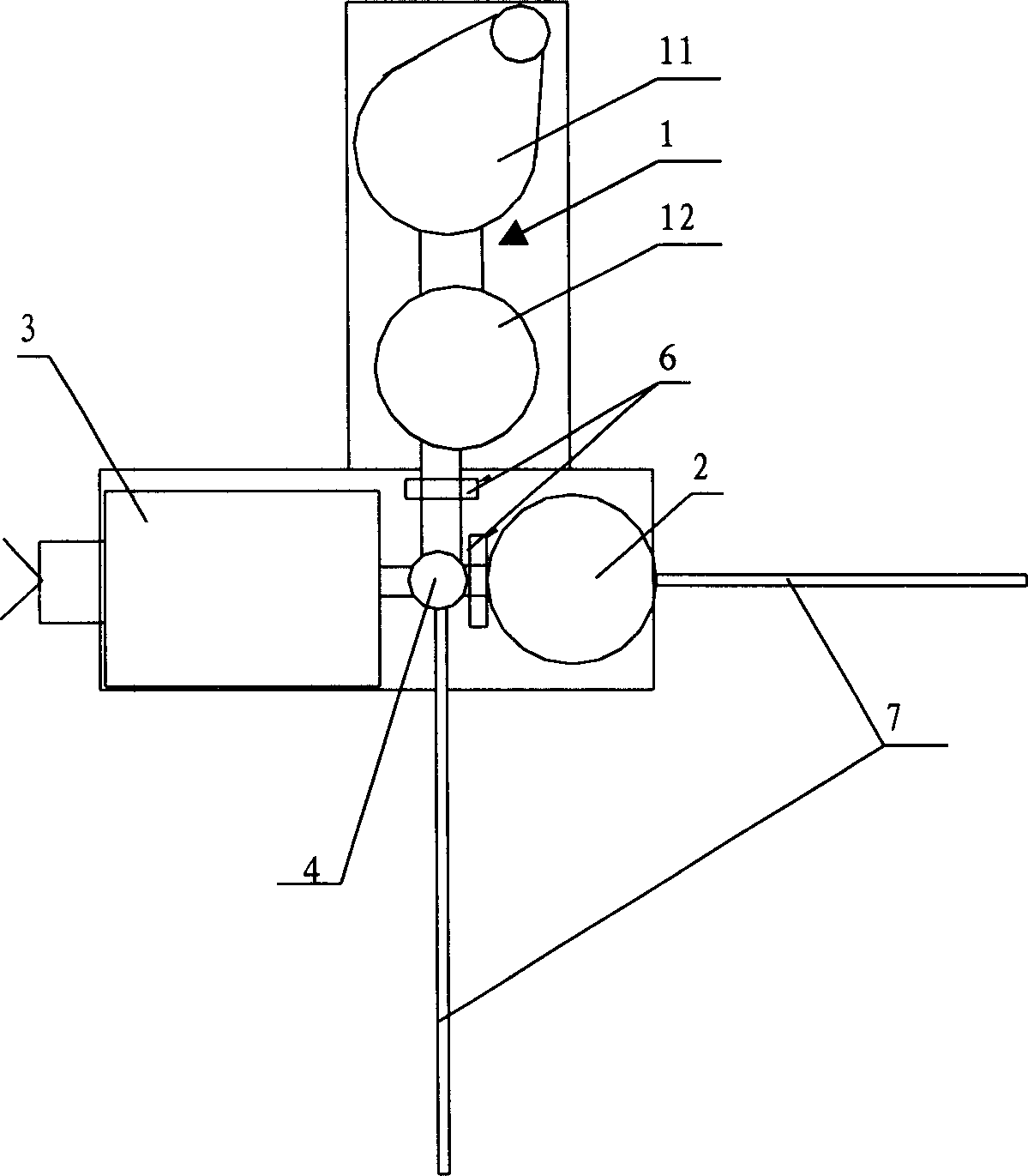

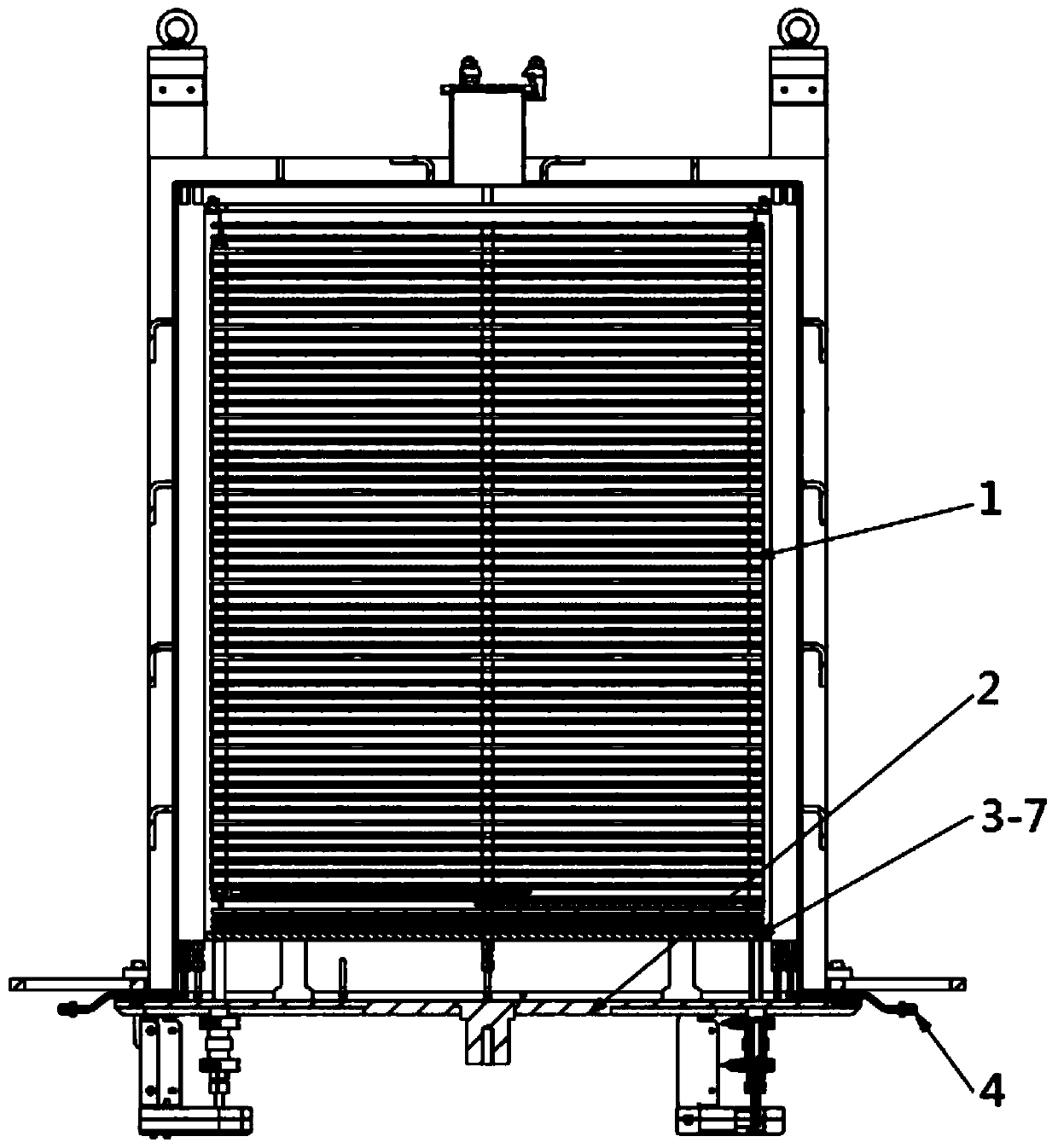

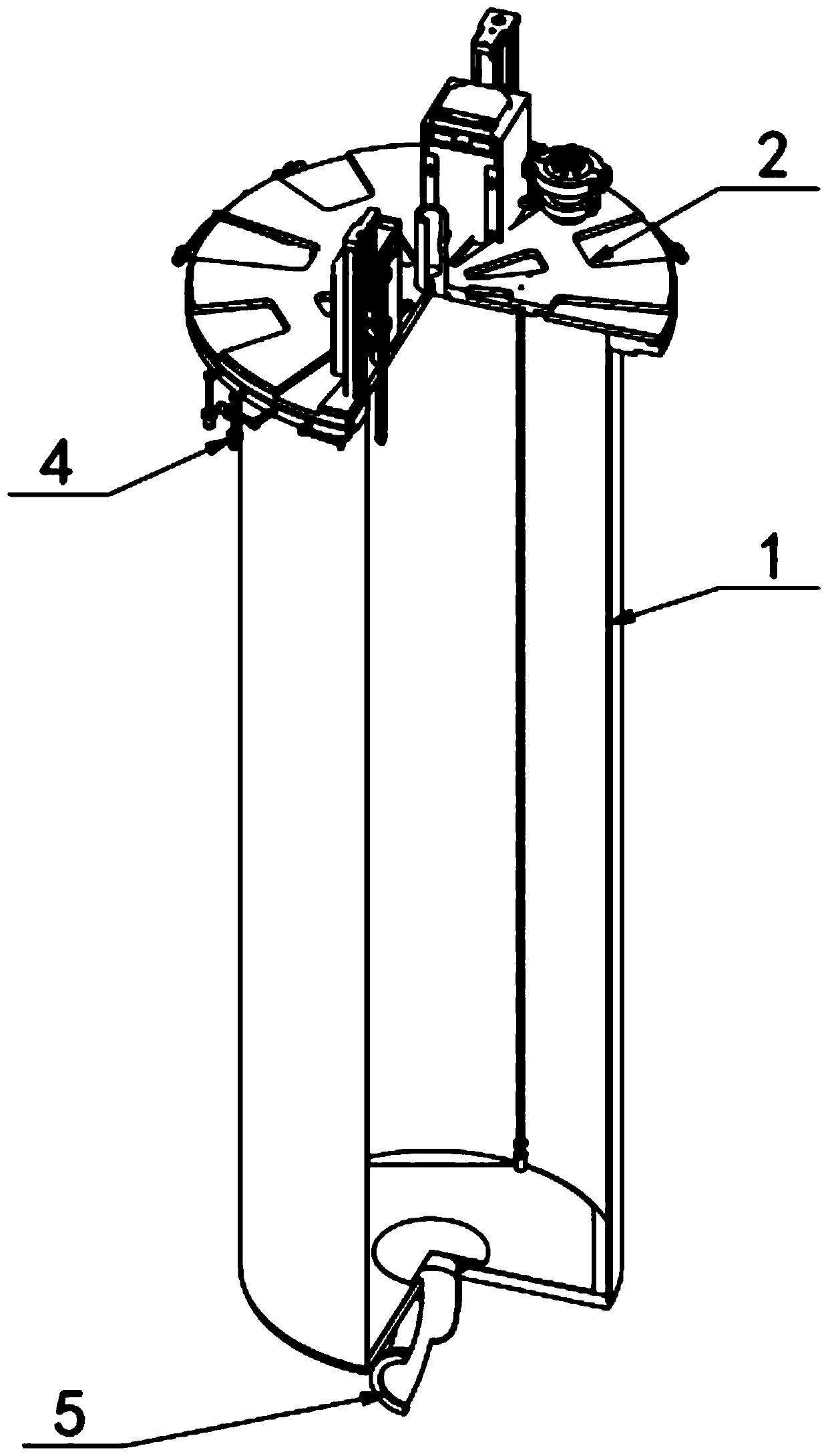

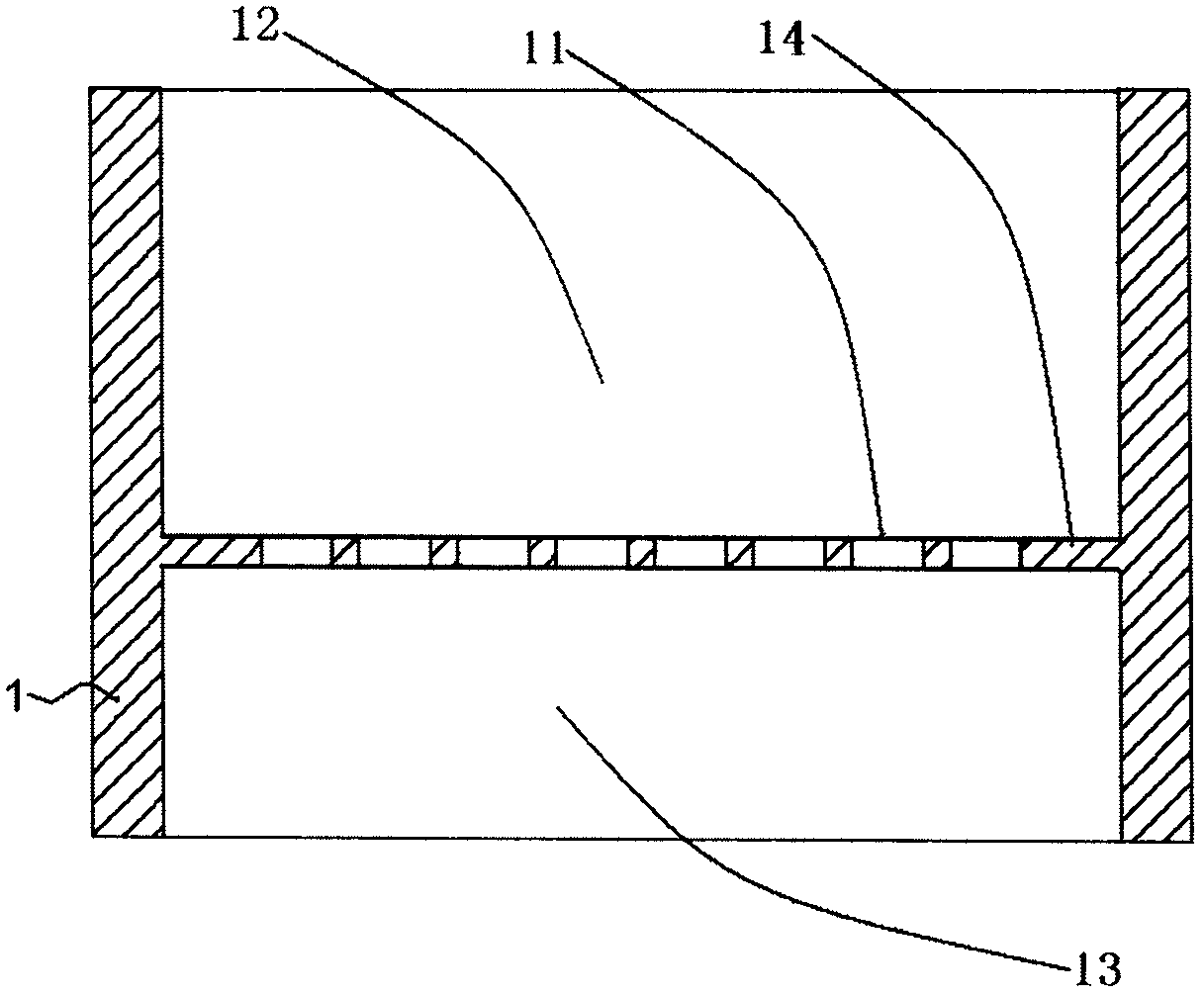

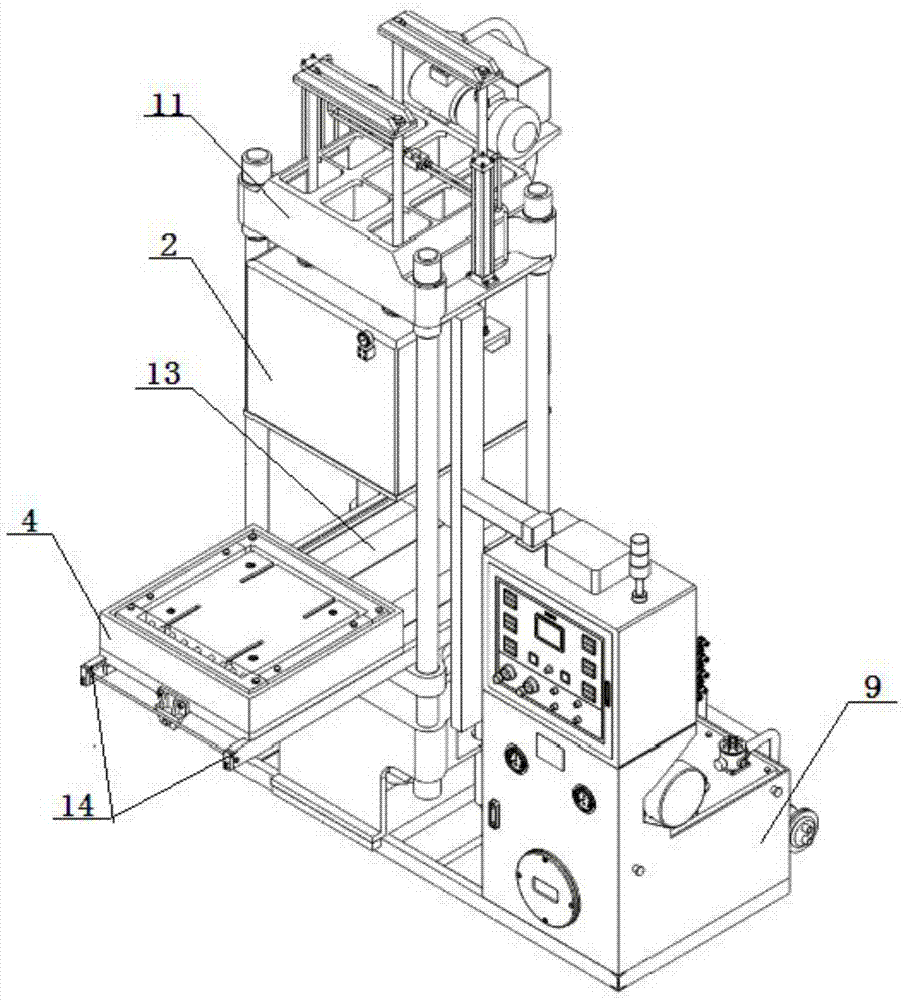

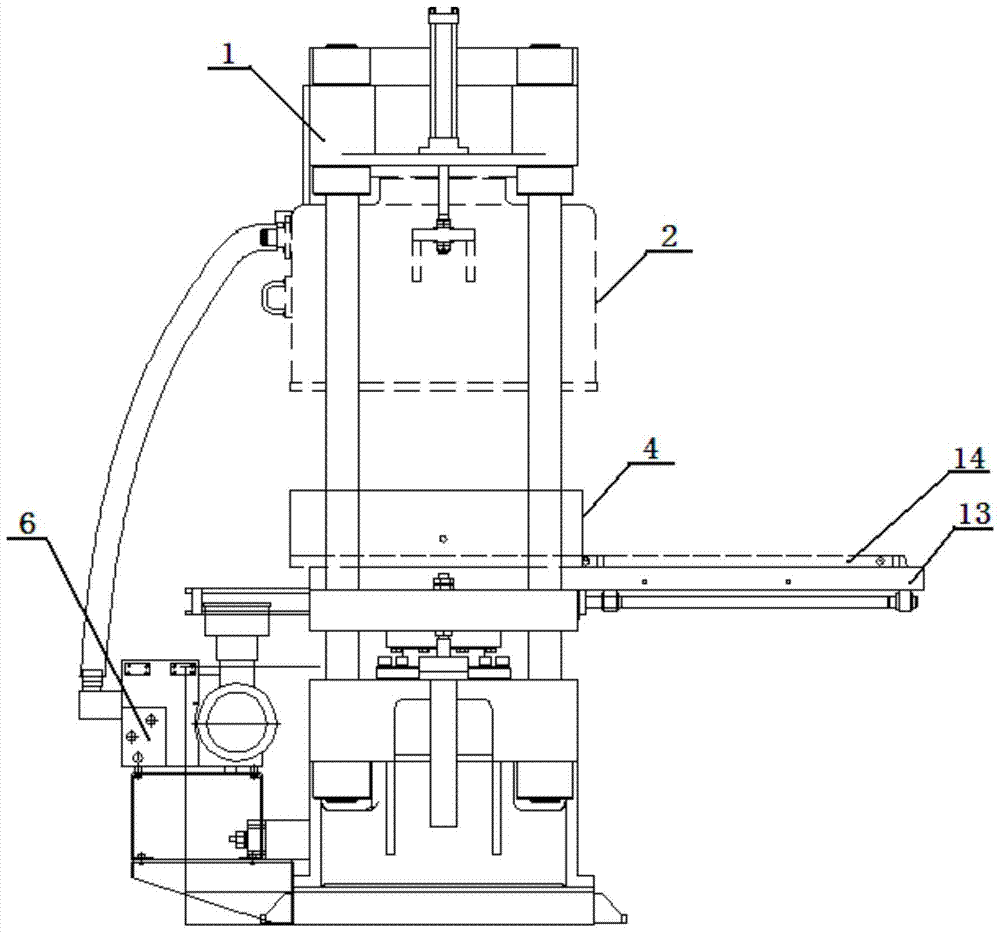

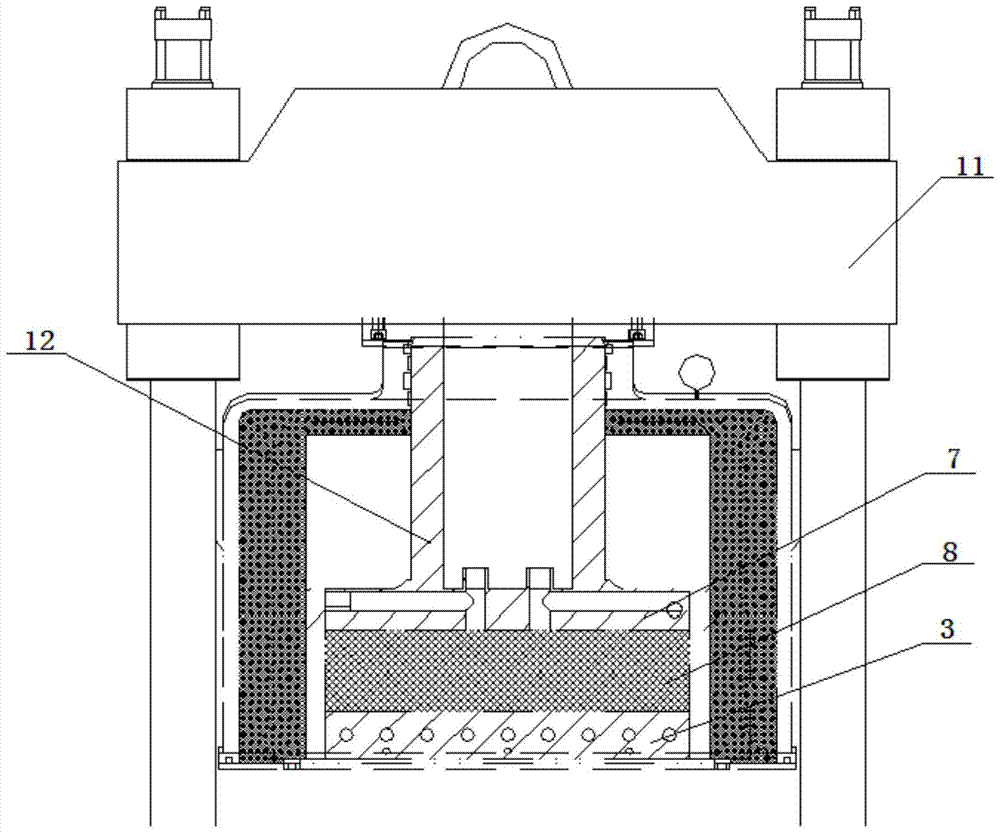

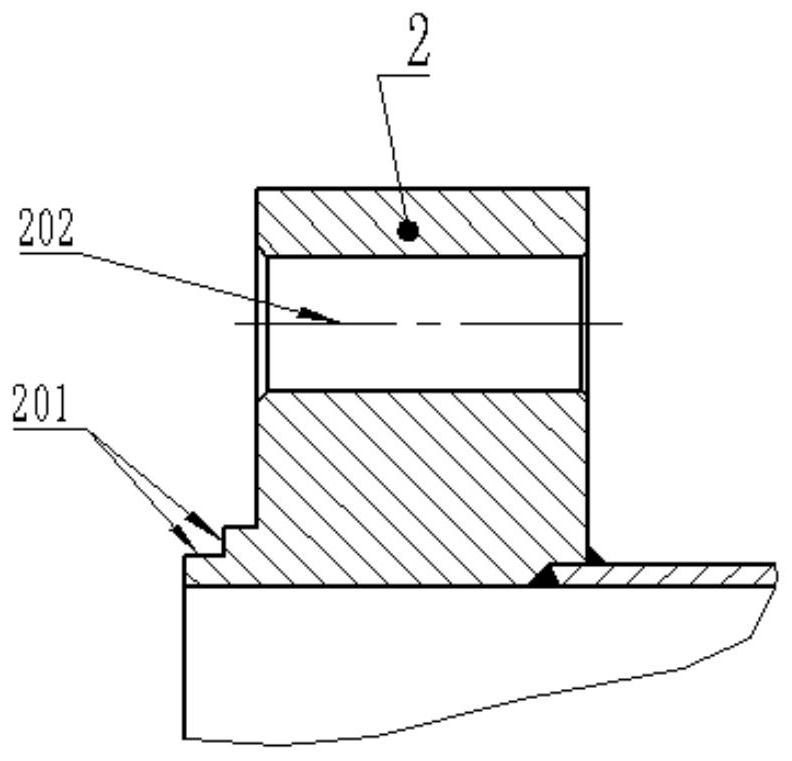

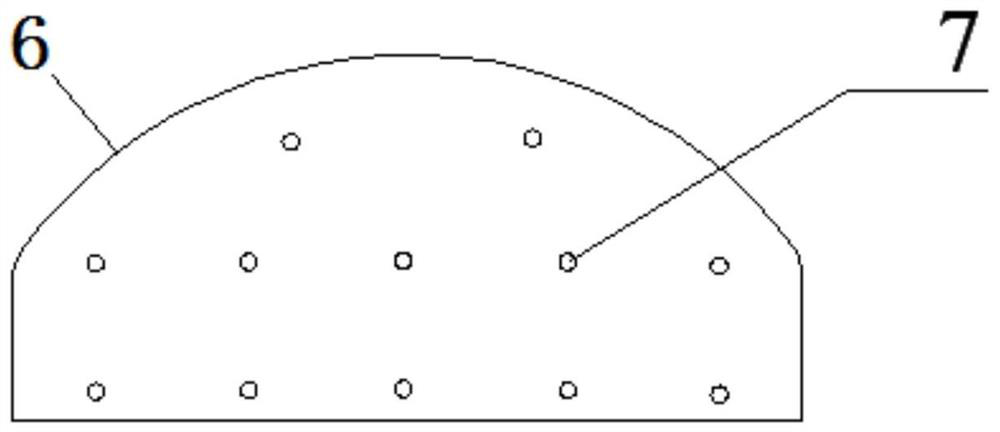

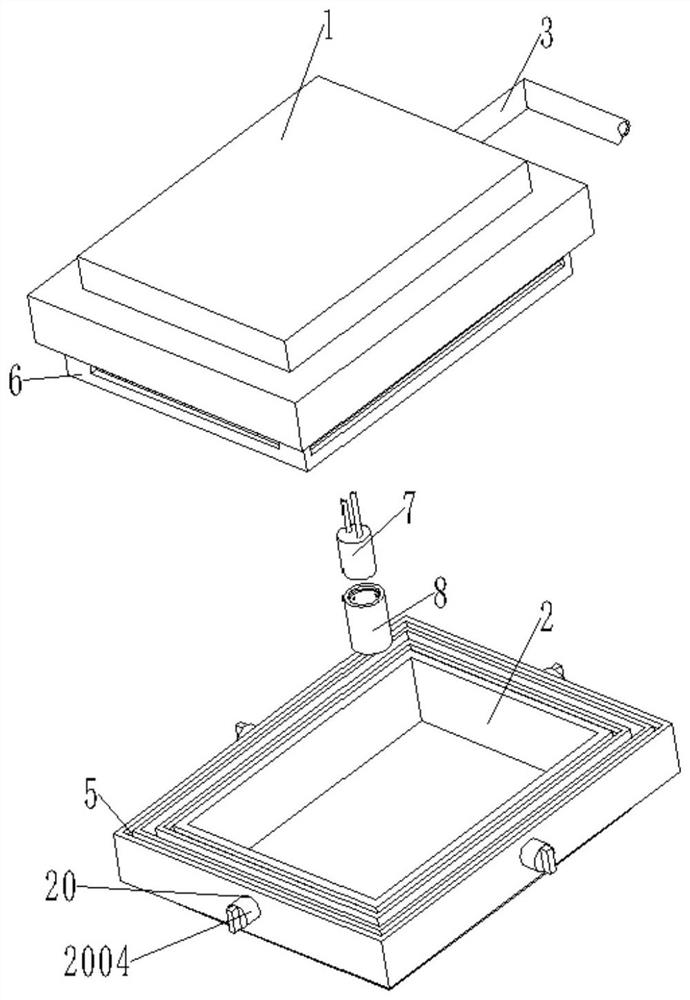

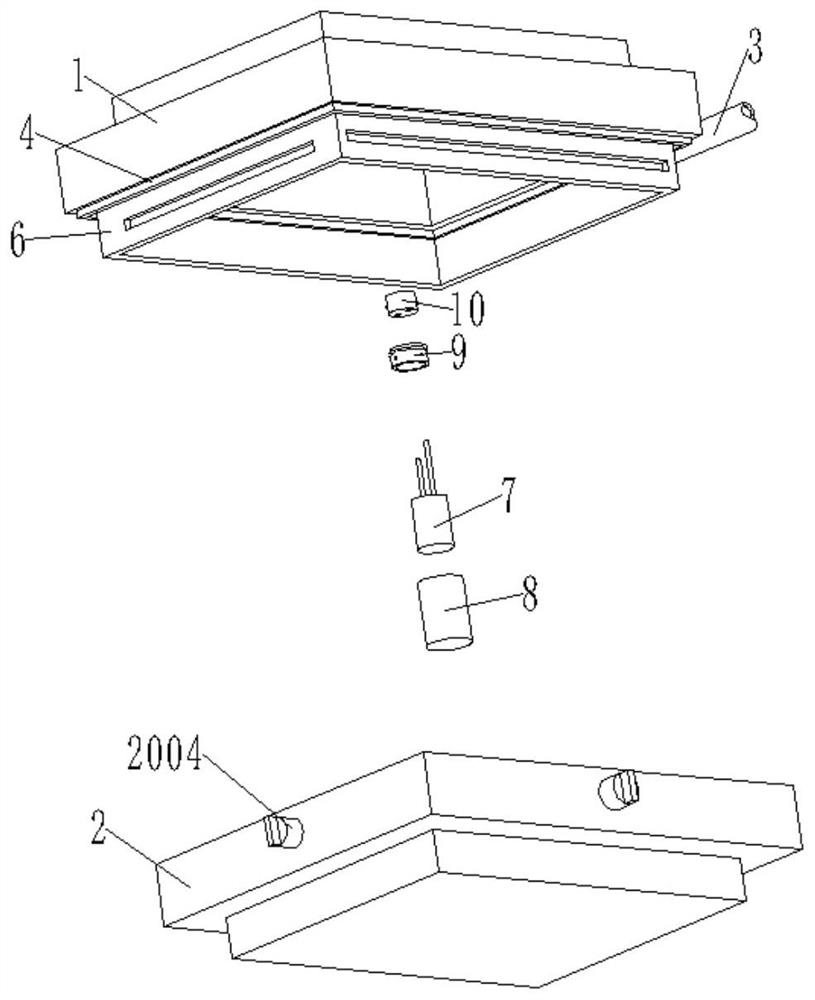

Vacuum high-temperature hot pressing molding machine

The invention discloses a vacuum high-temperature hot pressing molding machine. The vacuum high-temperature hot pressing molding machine comprises a rack (1) for wholly supporting a molding machine, an upper heat-preservation cold-state vacuum cover (2), a lower heat-preservation cold-state vacuum cover (4) corresponding to the upper heat-preservation cold-state vacuum cover (2), and a vacuumizing device (6) connected with the upper heat-preservation cold-state vacuum cover (2) or the lower heat-preservation cold-state vacuum cover (4), wherein the upper heat-preservation cold-state vacuum cover (2) can move up and down and is internally provided with an upper heating plate (3); the lower heat-preservation cold-state vacuum cover (4) can move front and back and up and down; and the lower heat-preservation cold-state vacuum cover (4) is internally provided with a lower heating plate (5) corresponding to the upper heating plate (3). The vacuum high-temperature hot pressing molding machine is simple in structure, reasonable in design, convenient to use, good in vacuum sealing effect, high in molding temperature, good in molding effect and low in heat dissipation.

Owner:大连天能装备制造有限公司

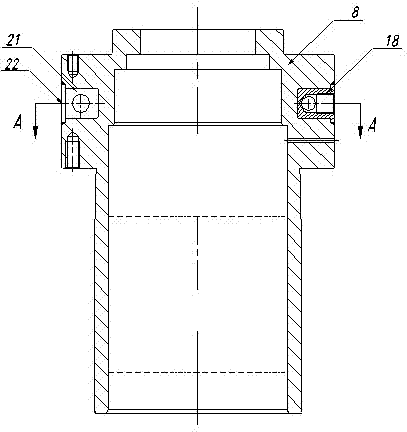

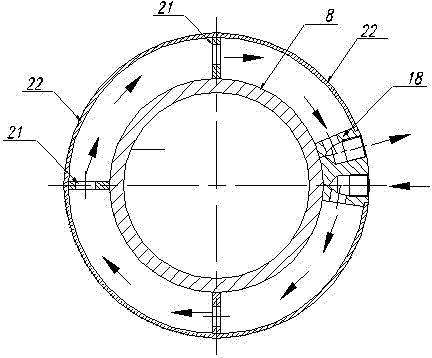

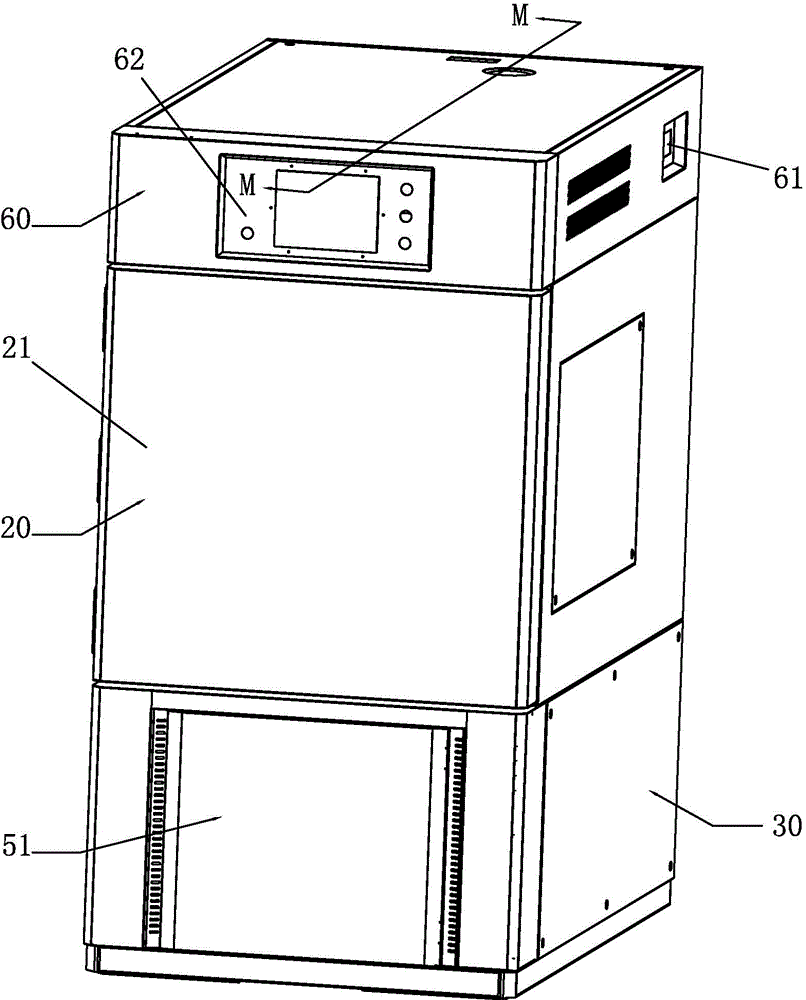

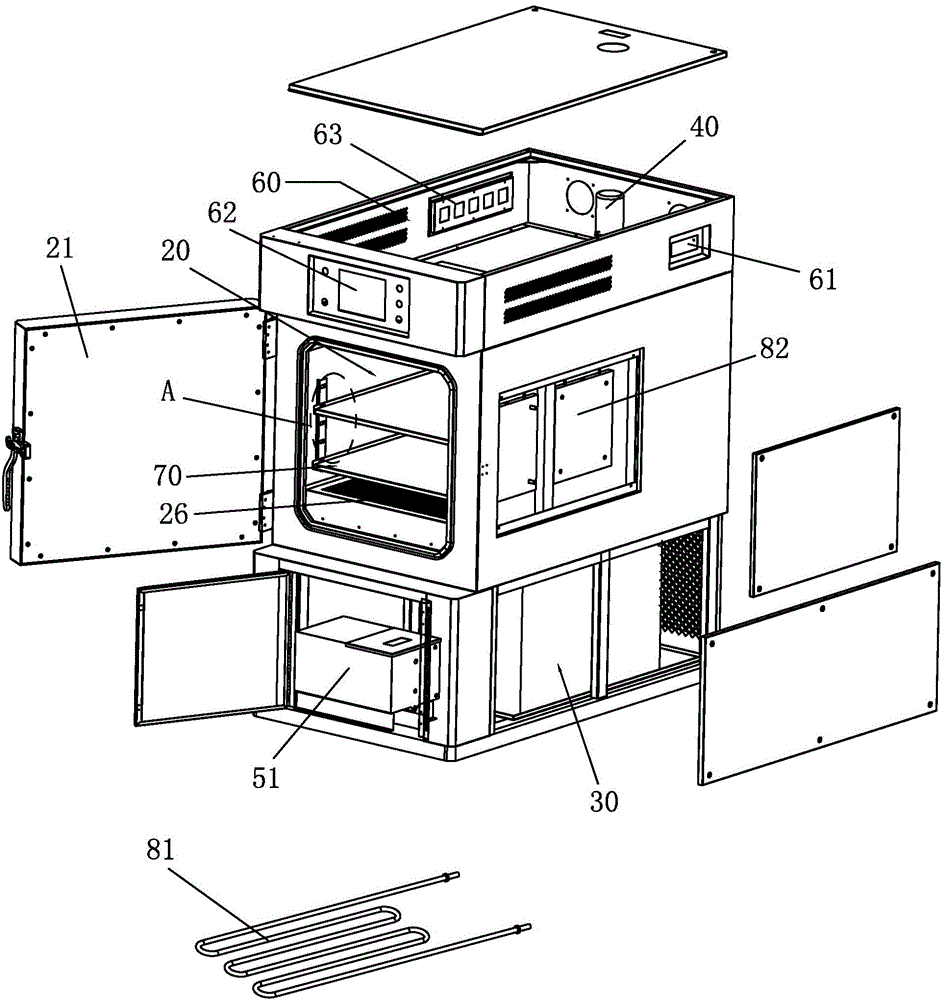

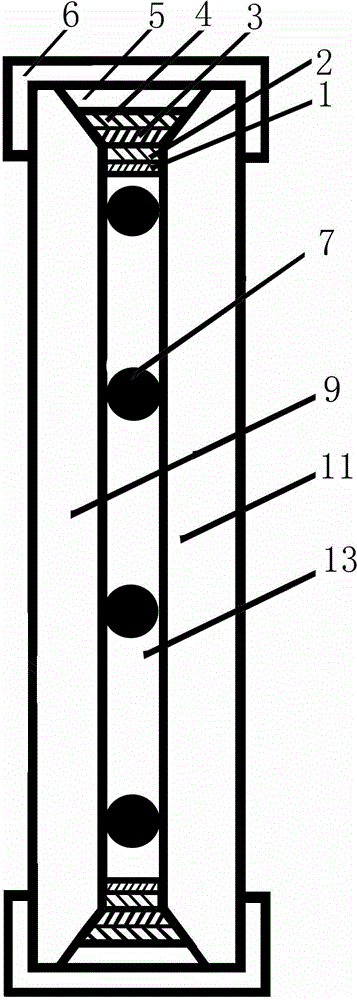

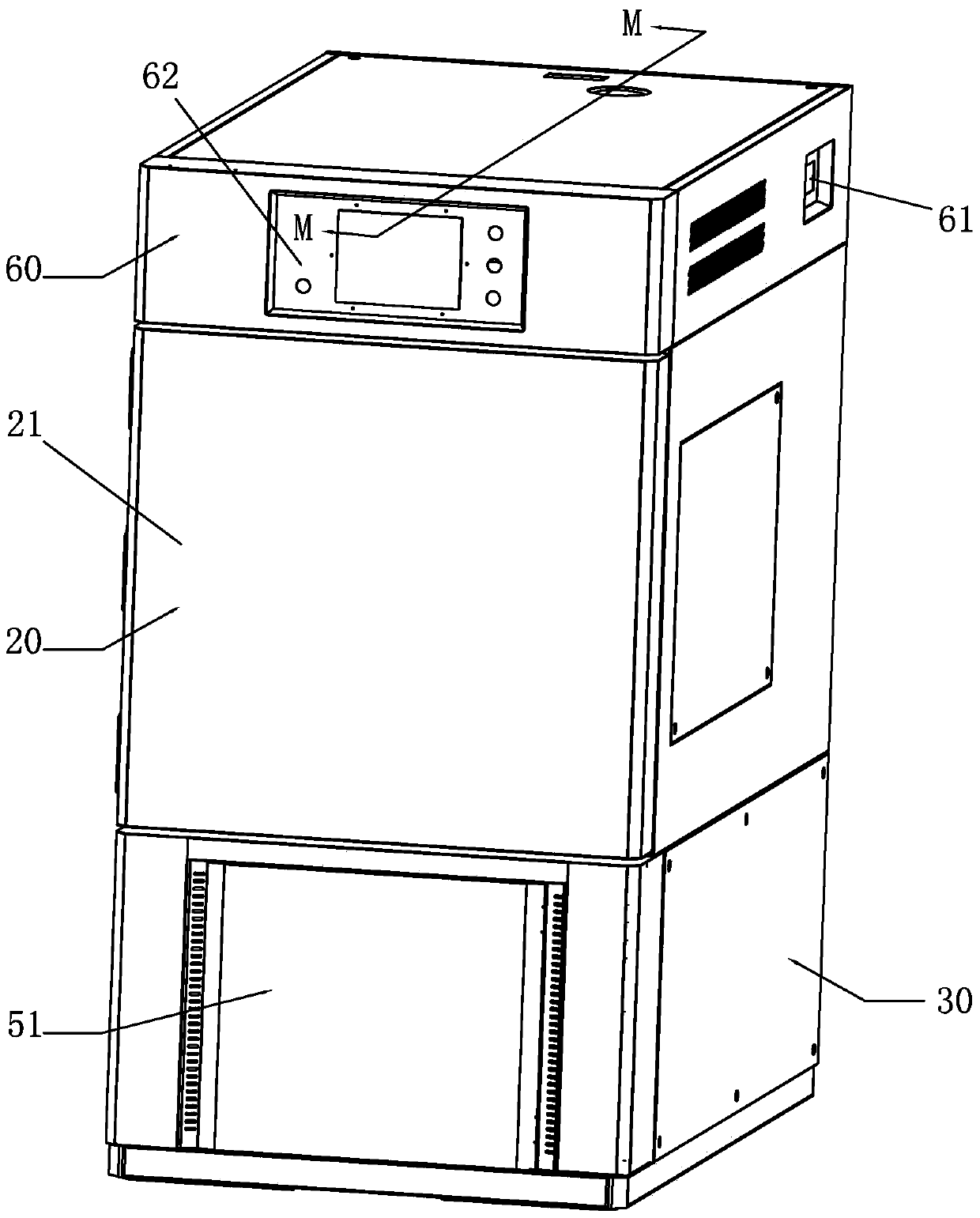

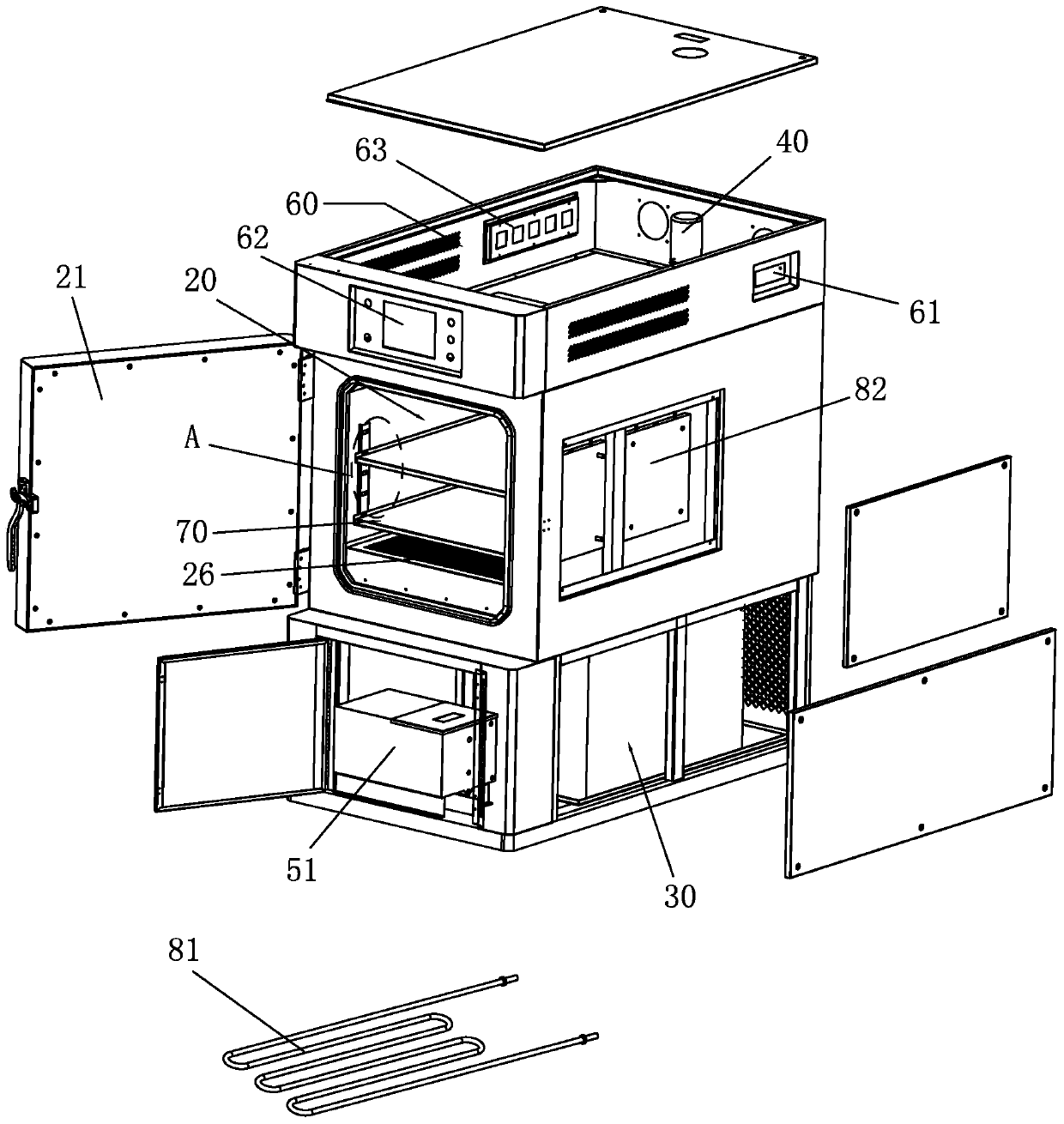

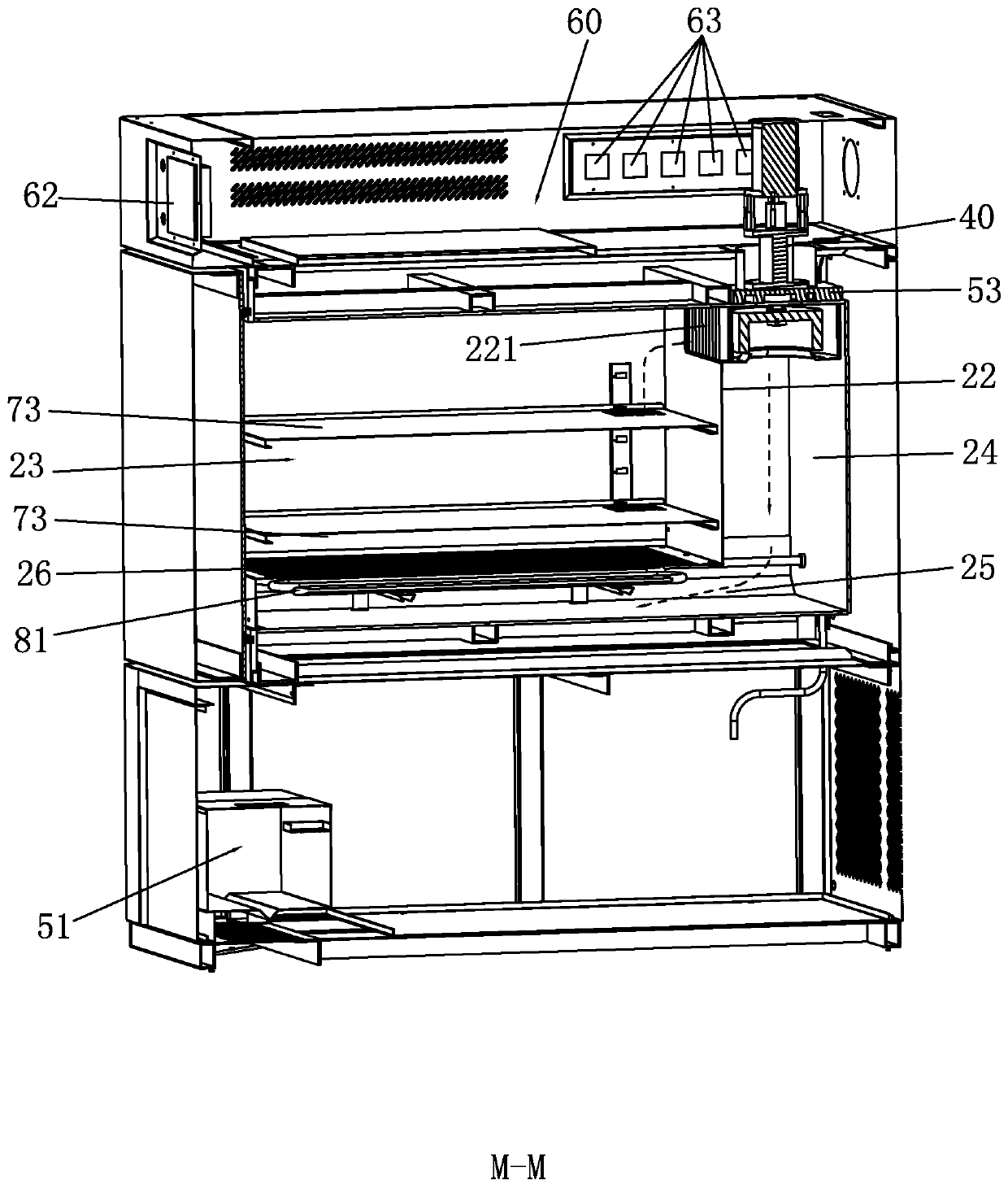

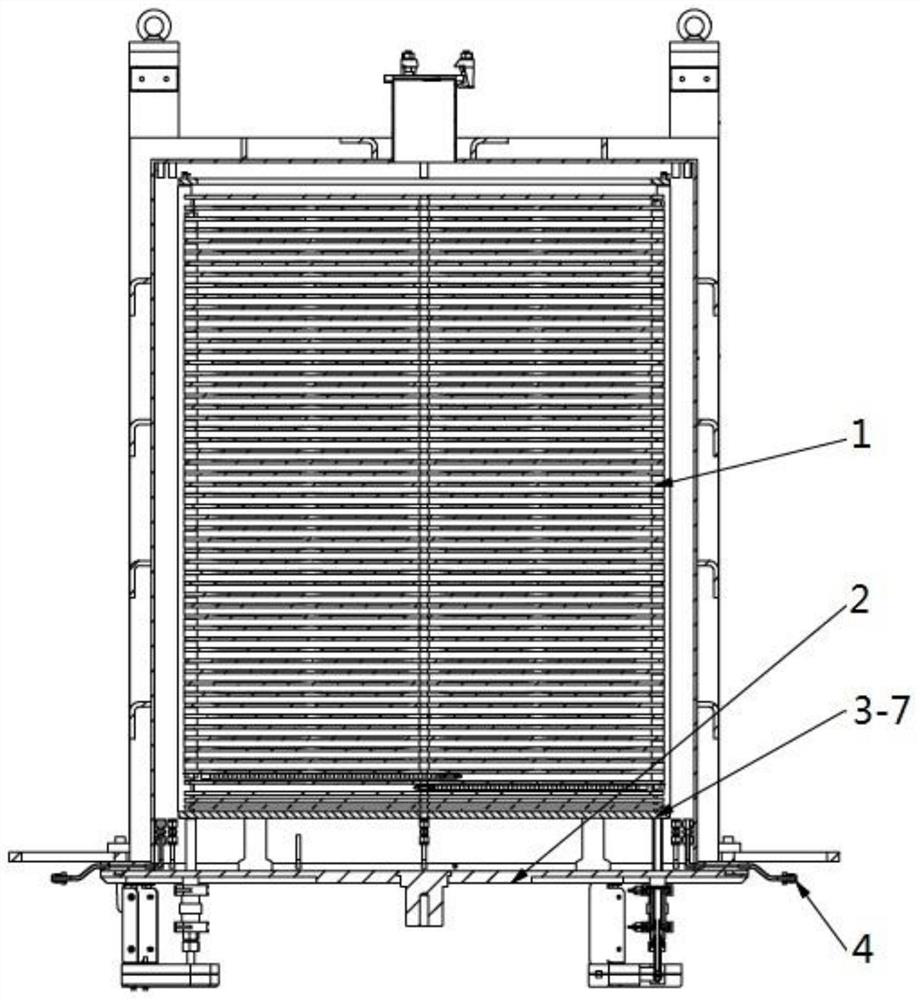

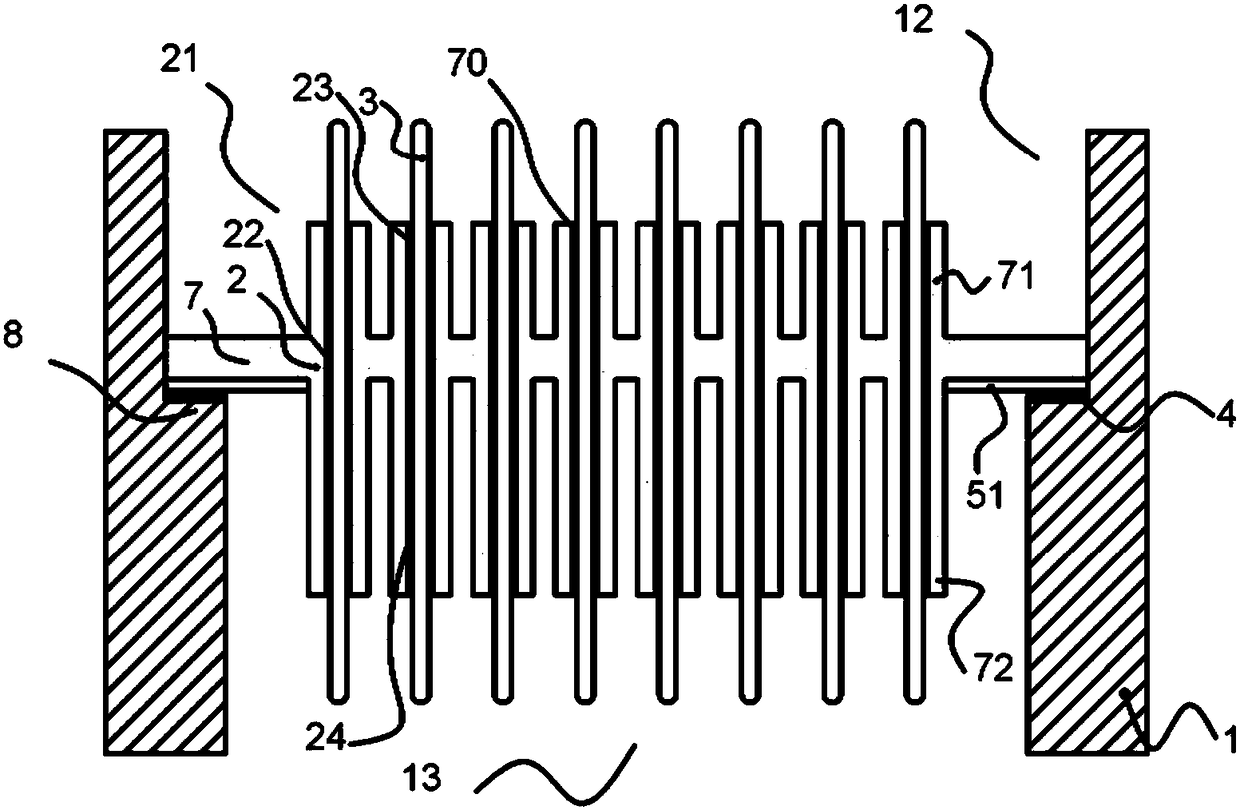

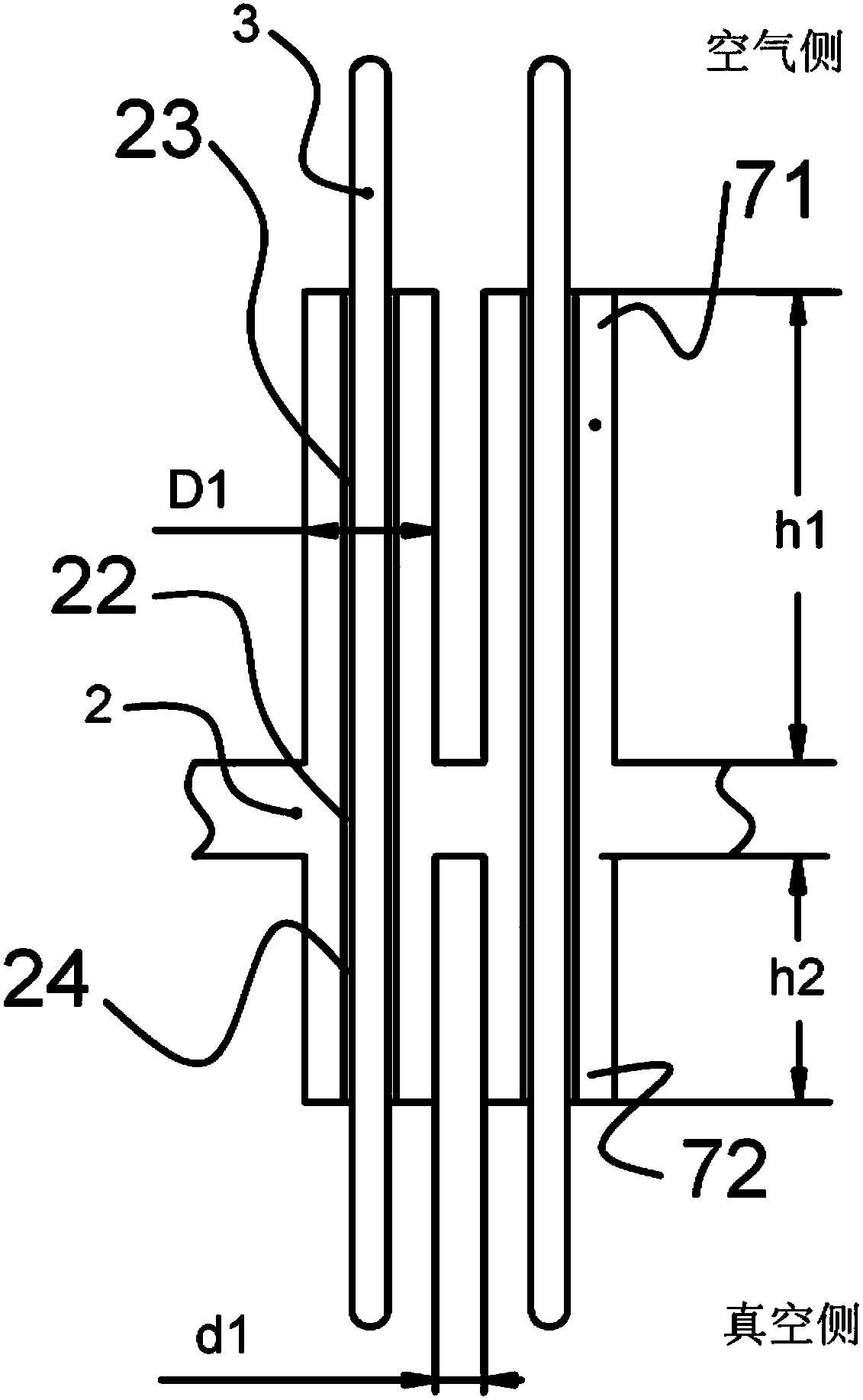

Novel vacuum drying oven

ActiveCN104864685AGood temperature distributionImprove vacuum sealing performanceDrying gas arrangementsDrying chambers/containersCooling downWaste management

The invention discloses a novel vacuum drying oven. The novel vacuum drying oven comprises an oven body, a drying chamber, a hot air circulation system and a vacuum unit, wherein a vertical partition is arranged in the drying chamber and divides the drying chamber into a storage cavity and an air outlet cavity; heating tubes are distributed at the inner bottom of the storage cavity; heating plates are arranged on two side walls of the storage cavity; the hot air circulation system comprises a magnetic fluid circulating fan mounted on the top wall of the air outlet cavity; the rotating shaft of the fan penetrates the top wall; the air outlet part of the fan is located in the air outlet cavity; an air inlet is formed in the vertical partition and corresponds to the air outlet part; the storage cavity and the air outlet cavity are communicated through the air inlet. Therefore, the interior of the drying chamber is designed into a unique air duct structure, and through cooperation of the magnetic fluid circulating fan, air is uniformly circulated, and the temperature distribution uniformity in the drying chamber is extremely good; a cooling water path for cooling down a magnetic fluid can cool down the magnetic fluid in real time, so that the vacuum leakproofness, the service performance and the safety performance of the drying oven are better.

Owner:广东科明环境仪器工业有限公司

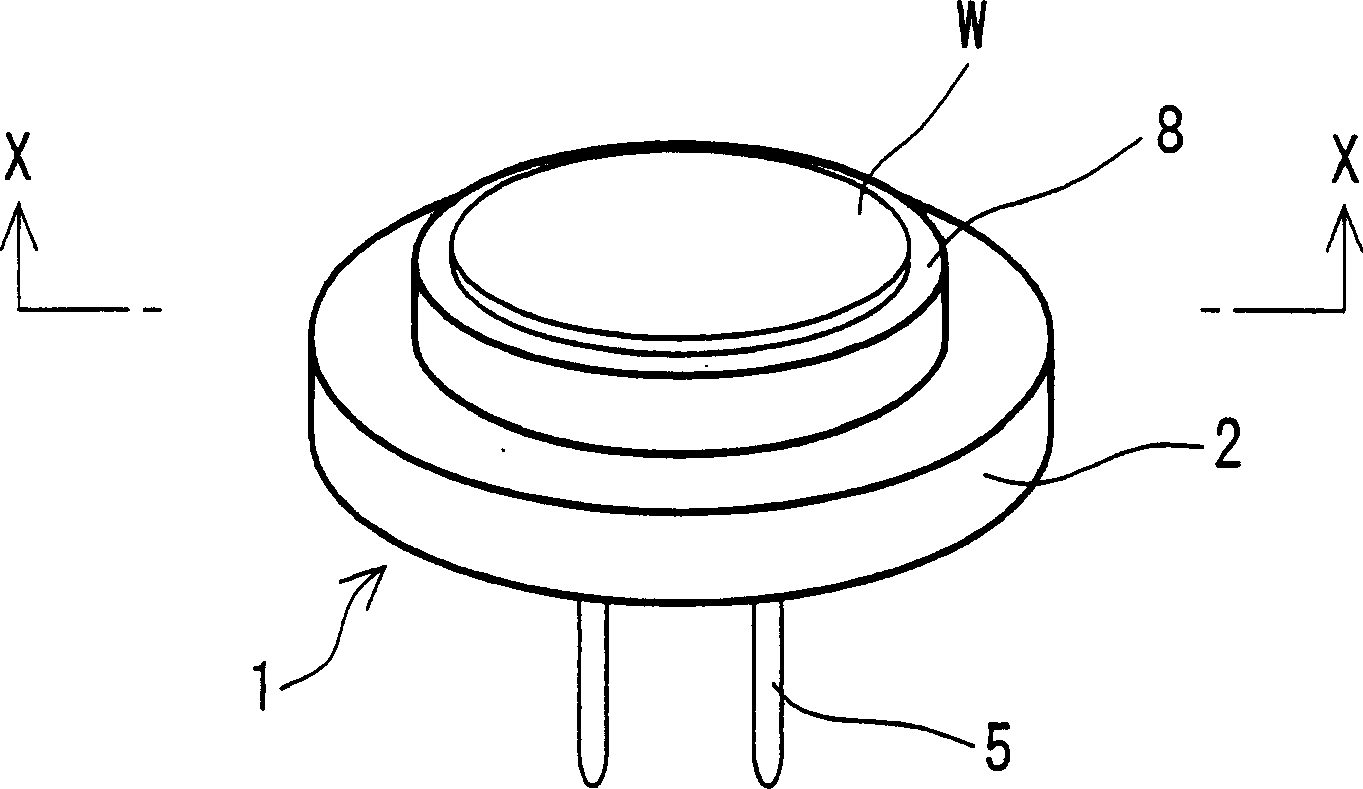

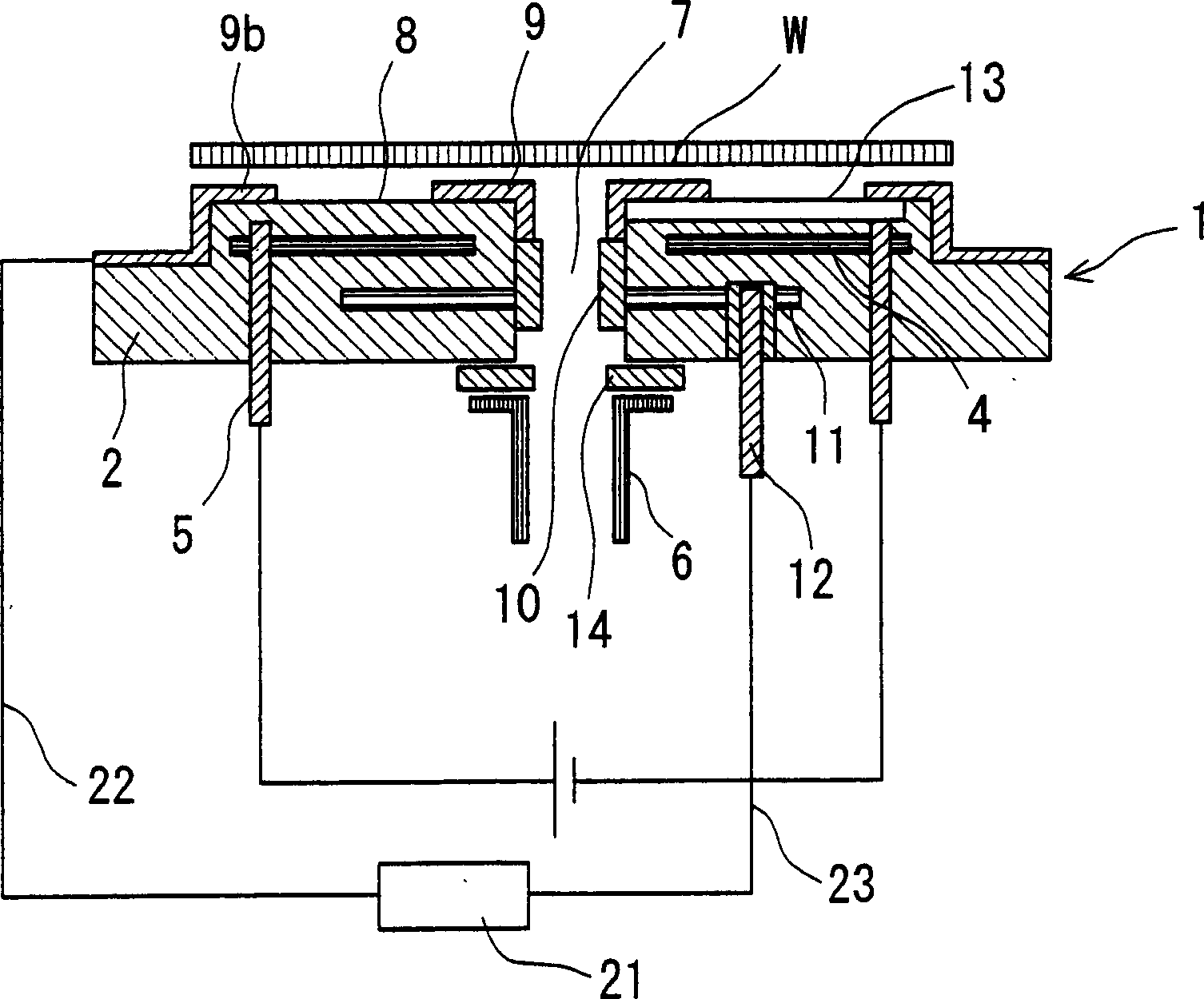

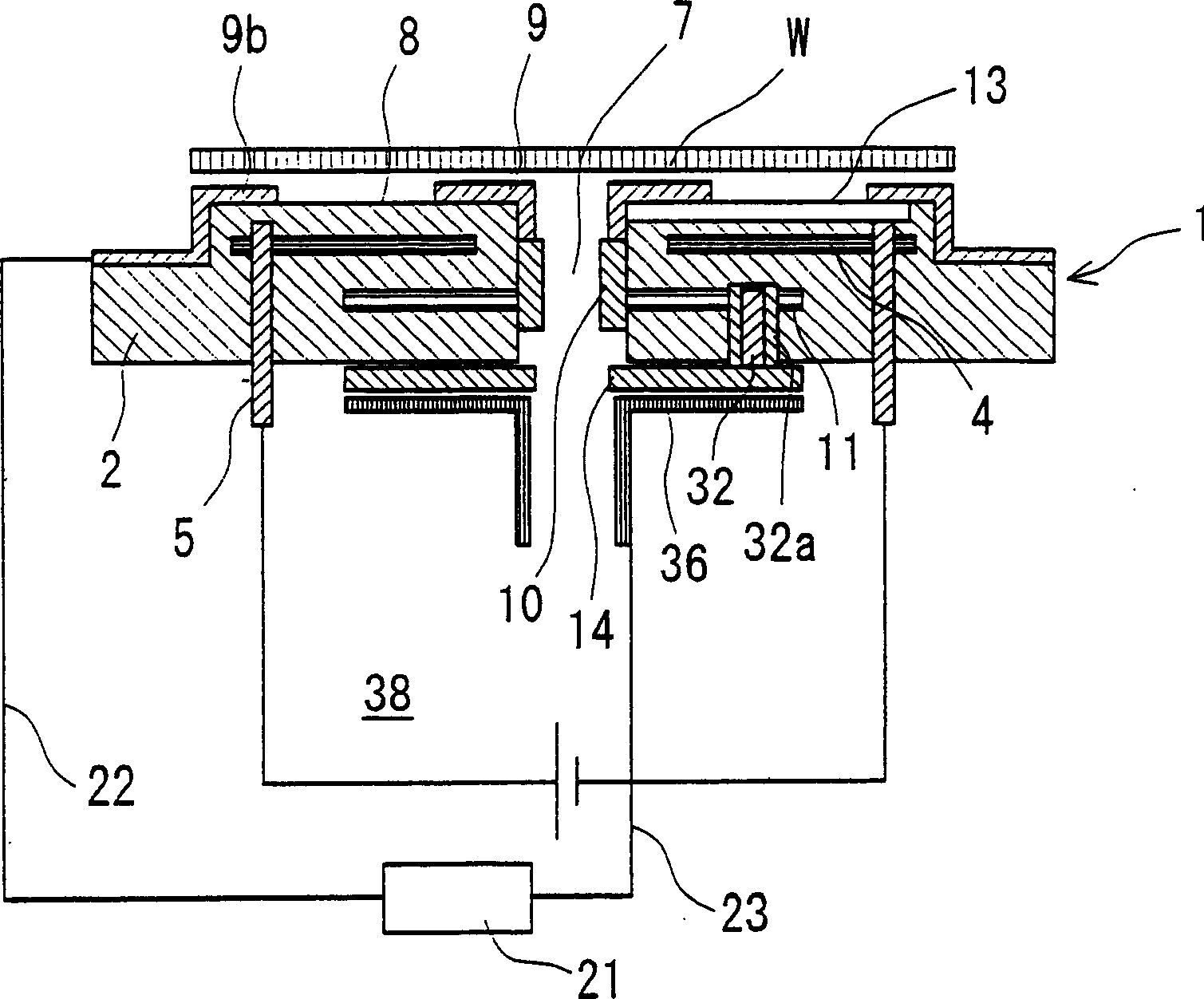

Wafer support member and semiconductor manufacturing system using the same

InactiveCN1779940AImprove reliabilityImprove vacuum sealing performanceSemiconductor/solid-state device manufacturingElectrical connectionSemiconductor

The present invention provides a simple and practical wafer support member that enables highly reliable electrical connection between a conductive layer formed on a placement surface and a power supply terminal on the atmosphere side while maintaining vacuum sealing. This wafer support member includes: a plate-shaped ceramic body having one main surface as a placement surface on which a wafer is placed, and a through hole penetrating from the one main surface to the other main surface; and a ceramic body provided on the placement surface. a conductive layer; a connecting conductive layer connected to the conductive layer and provided on the inner surface of the through hole; and a buried conductive layer connected to the connecting conductive layer and embedded in the plate-shaped ceramic body; and having one end and another One end is connected to the buried conductive layer in the vicinity of the one end, and the other end protrudes from the other main surface of the ceramic body, and is provided at a position away from the through hole of the plate-shaped ceramic body.

Owner:KYOCERA CORP

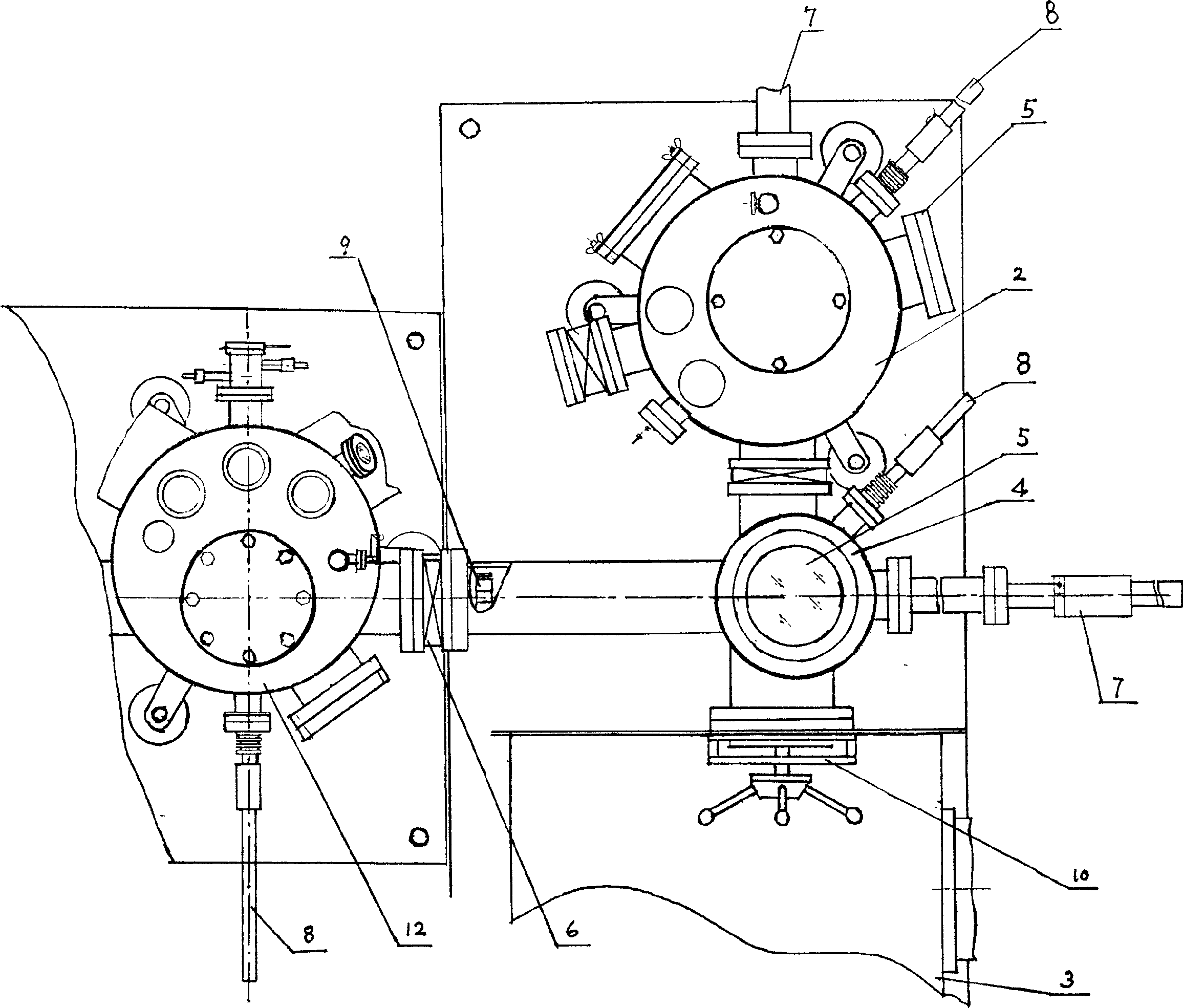

Gas-phase deposition coating and vacuum heat-treatment on-line combined composite coating equipment

InactiveCN1428455AImprove cleanlinessSolve pollutionVacuum evaporation coatingSputtering coatingGas phaseManipulator

The present invention relates to a gas-phase deposition film-plating and vacuum heat treatment on-line combined composite deposition equipment, including deposition chamber, heat treatment chamber, glove box and transition chamber. The transition chamber is made into a stainless steel cylindrical structure, and is set between the deposition chamber, heat treatment chamber and glove box and is connected with the deposition chamber, heat treatment chamber and glove box by means of stainless steel pipeline, and on the stainless steel pipeline a stainless steel high vacuum insertion plate valve is set. Said transition chamber also is equipped with upper cover with observation window, and its side wall is equipped with a transfer bar and a robot, its heat treatment chamber also is equipped with an observation window.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

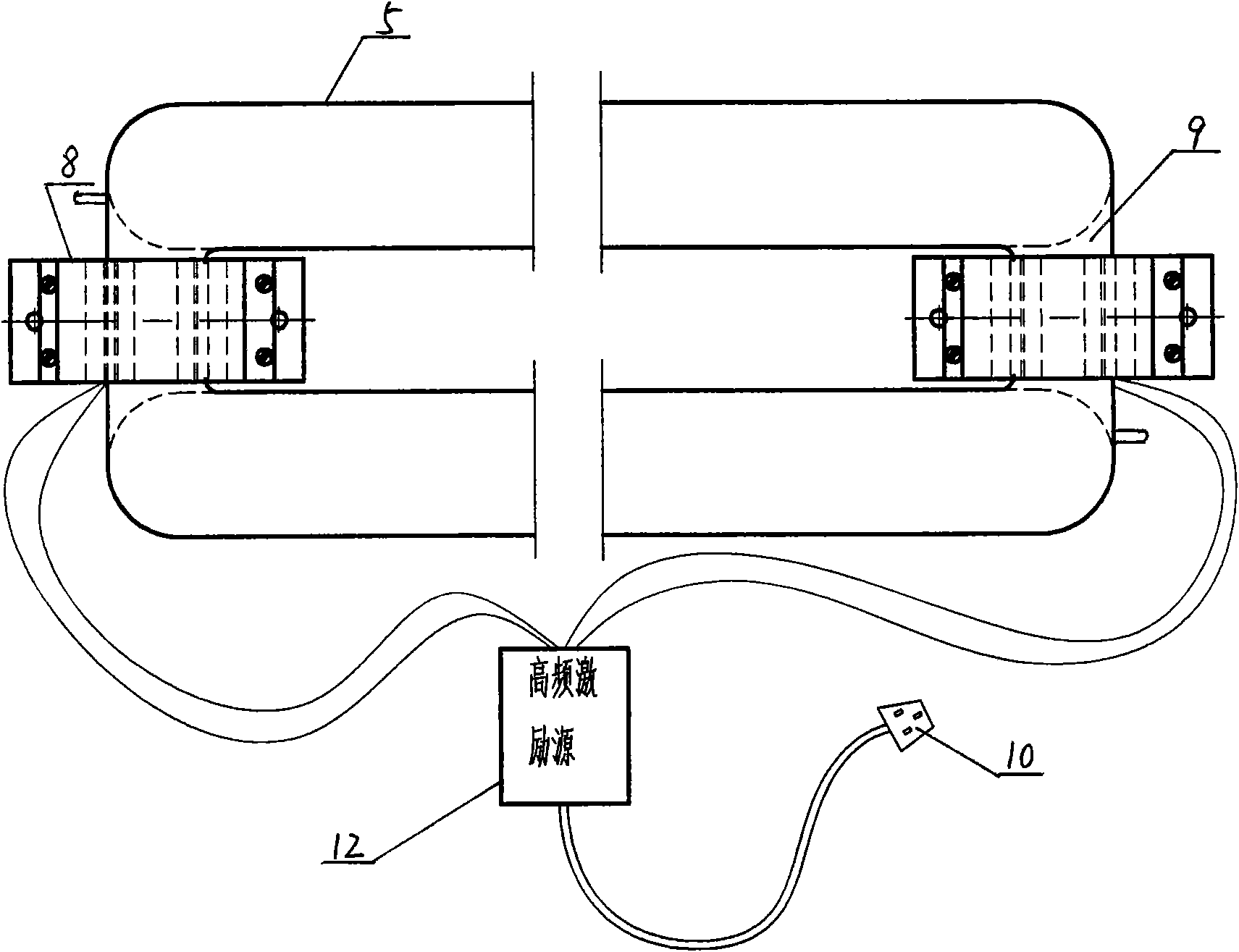

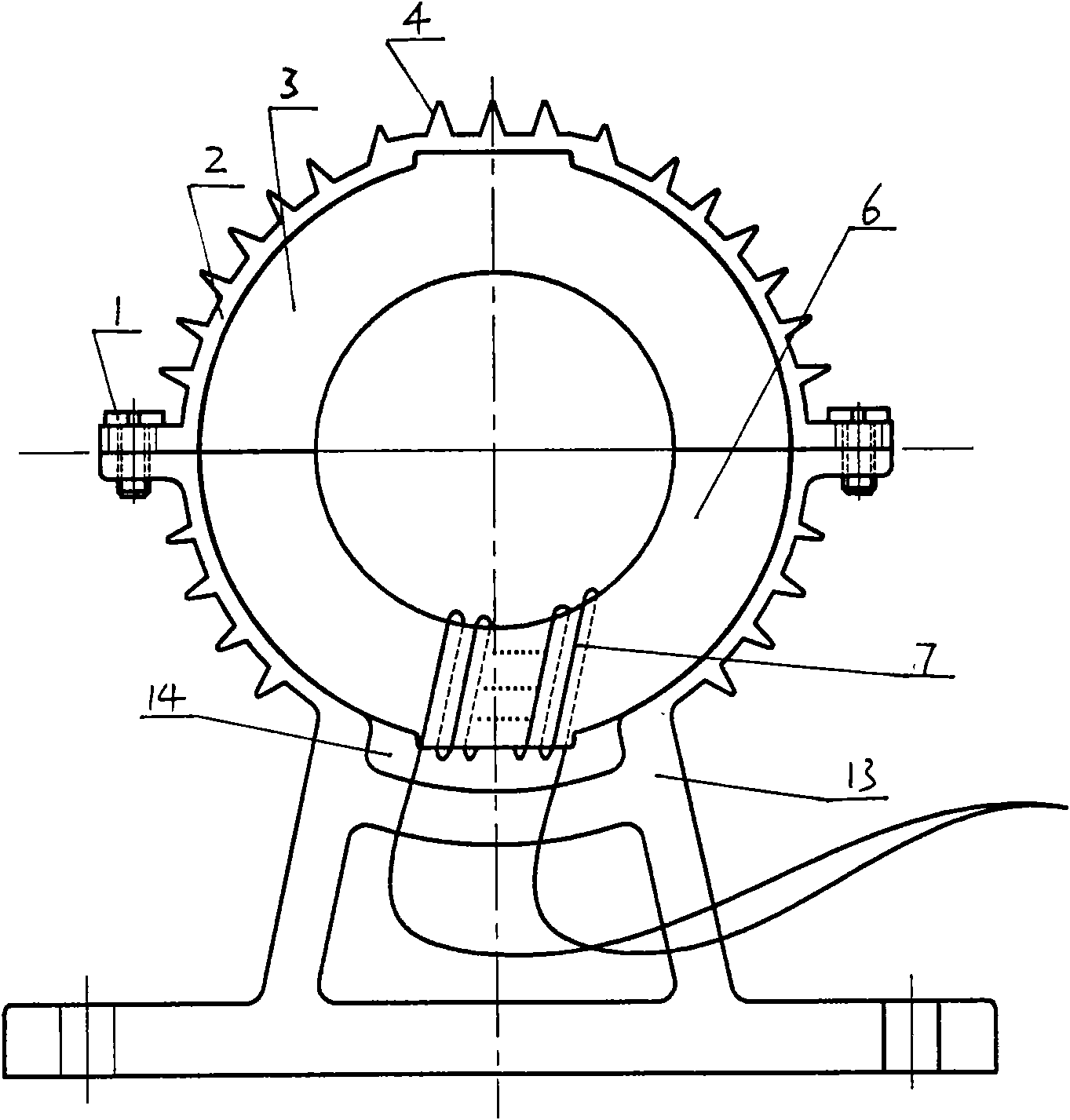

Electrodeless ultraviolet germicidal lamp

InactiveCN101620979AImprove efficiencyIncrease UV intensityGas discharge lamp detailsRadiationEngineeringProcessing cost

The invention discloses an electrodeless ultraviolet germicidal lamp which comprises a frame-shaped lamp tube, two power couplers and a high-frequency excitation source; a heat radiator comprises a base and a top cover and the upper end of the base is combined together with the top cover to form a complete circle; a magnetic ring comprises an upper semicycle and a lower semicycle which can be combined into a complete circle; the magnetic ring is arranged in the heat radiator and fixed through buckles on the base and the top cover of the heat radiator; a coil is wound at the bottom of the lower semi-circular magnetic ring, and the number of turns of the coil is set according to the demand of output powder; output ends of the high-frequency excitation source are respectively connected at the both ends of the coil, input ends of the high-frequency excitation source are connected with a power supply; blind pipes at the both ends of the lamp tube are loaded with amalgam, the lamp tube is filled with inert gas and the two short sides of the lamp tube are clipped in the upper semi-circular magnetic ring and the lower semi-circular magnetic ring of the power couplers. The invention solves the contradiction which cannot be solved by the electrode ultraviolet germicidal lamp and has the advantages of high efficiency, high power, wide power range, long service life, instant start, environmental-protection, wide applicable temperature range, simple manufacturing process, lower processing cost, and the like.

Owner:涿州迅利达创新科技发展有限公司

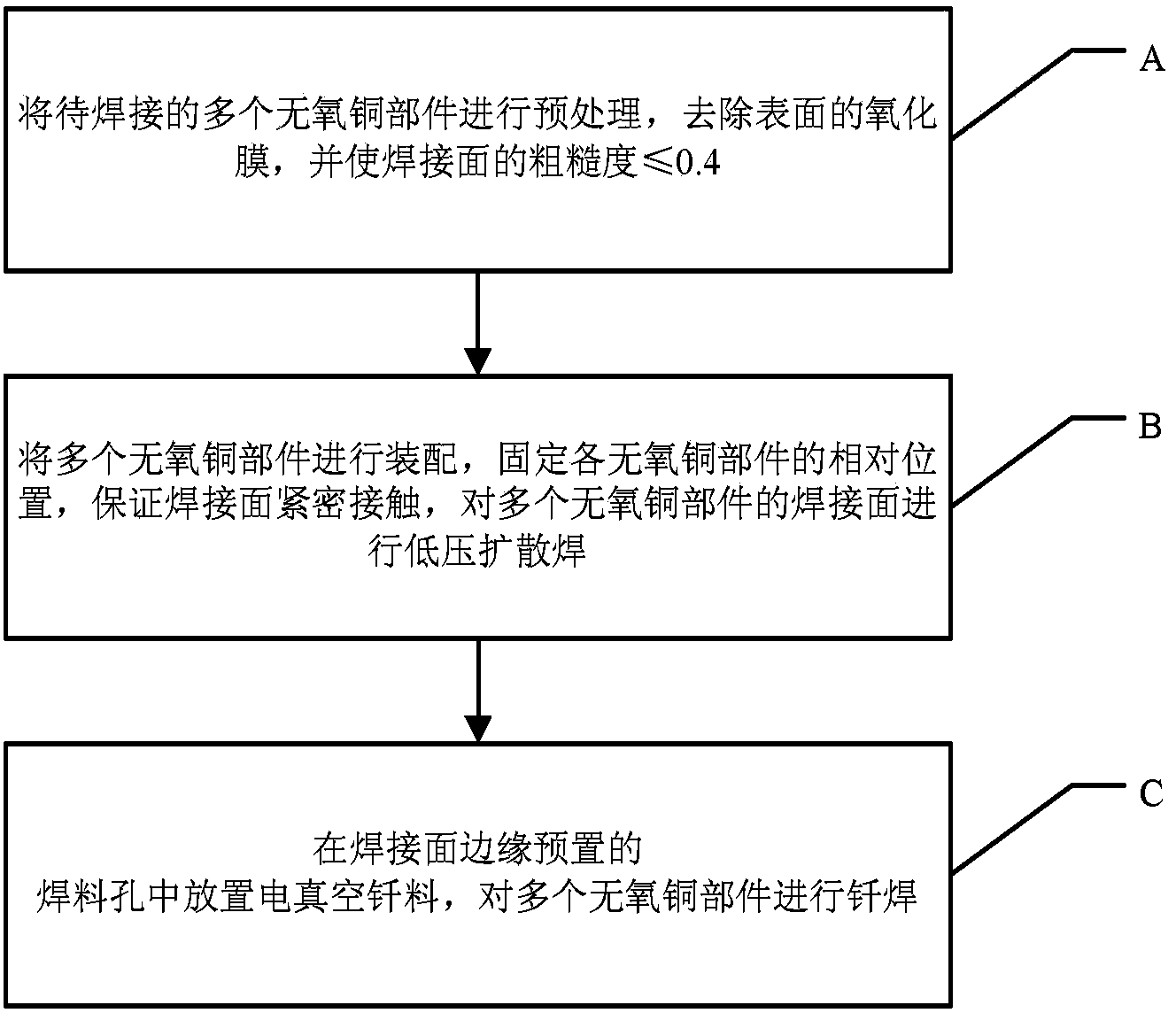

Oxygen-free copper composite welding method

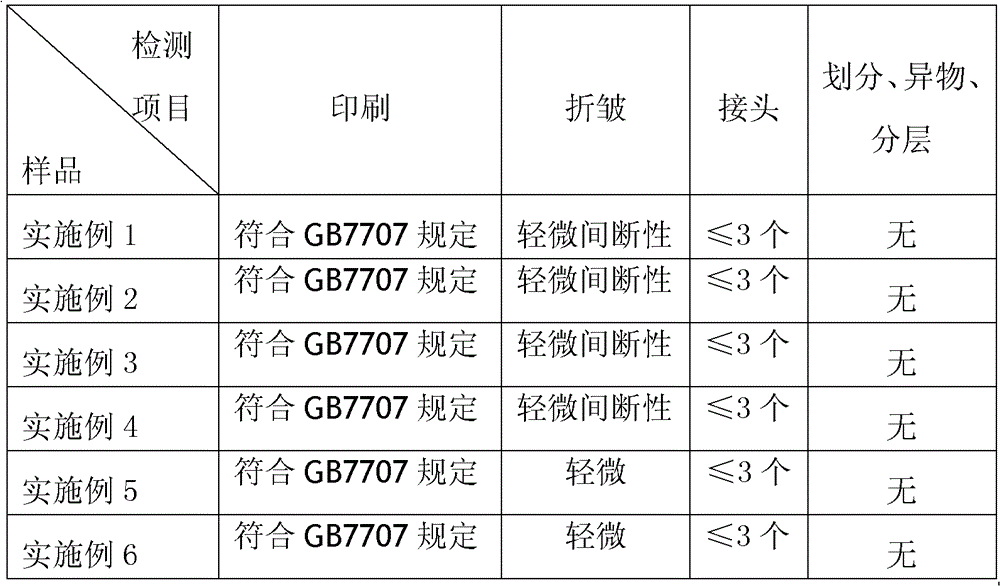

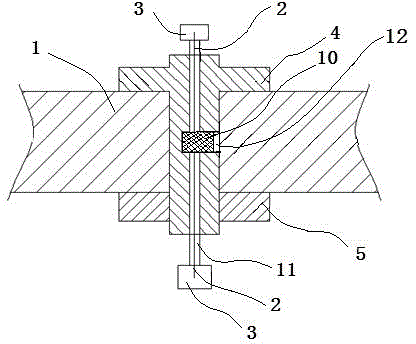

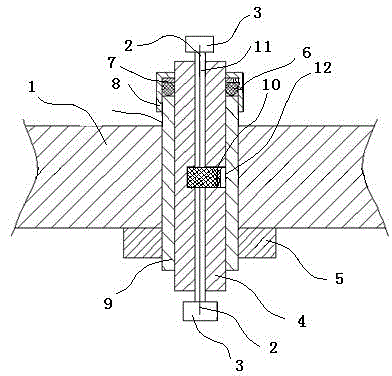

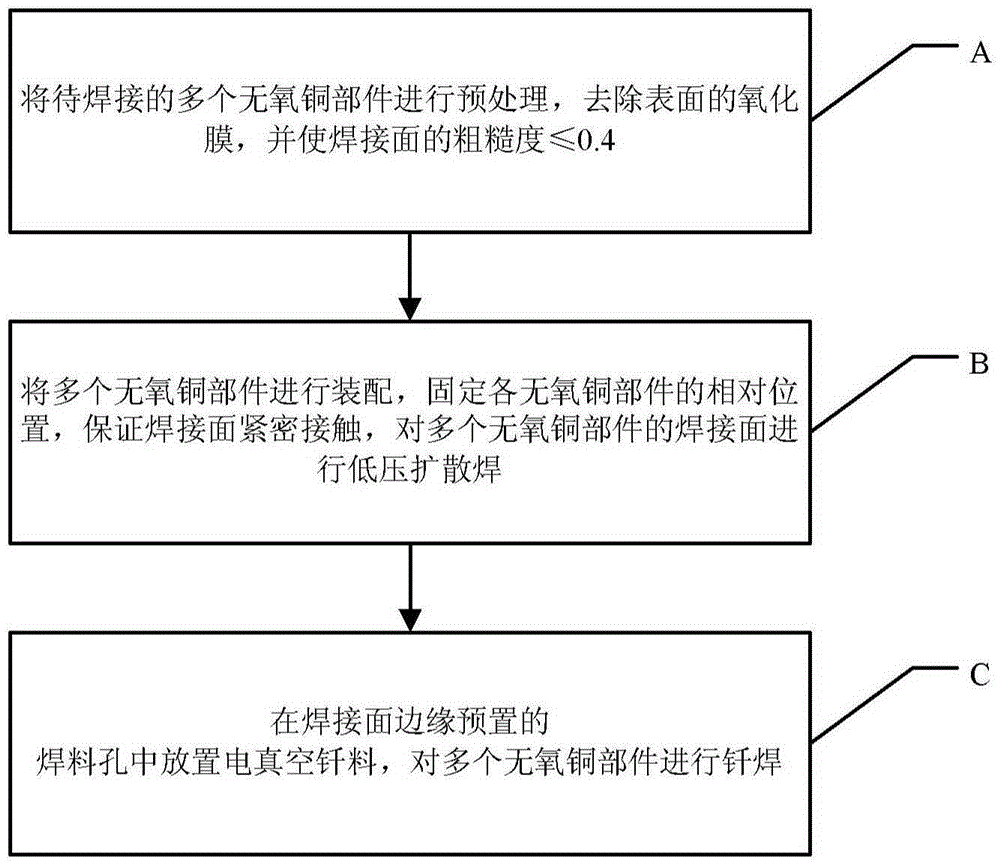

ActiveCN103817451ATightly boundImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesOxideBase metal

The invention provides an oxygen-free copper composite welding method by combining low pressure diffusion welding with brazing compound welding. The oxygen-free copper composite welding method comprises the steps: step A, preprocessing multiple oxygen-free copper parts to be welded to remove the oxide film on the surfaces of the oxygen-free copper parts; step B, assembling the multiple oxygen-free copper parts, fixing the relative position of each oxygen-free copper part to ensure close contact of welding faces, and carrying out low pressure diffusion welding on the welding faces of the oxygen-free copper parts; step C, placing electric vacuum brazing filler metal in the welding holes preset in the edges of the welding faces and brazing the multiple oxygen-free copper parts. A composite welding head formed through the oxygen-free copper composite welding method is bonded tightly, the precision of welding is high, the vacuum leakproofness is good, and the joint tensile strength is 200-300 MPa, being close to or even higher than the oxygen-free copper base metal strength.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

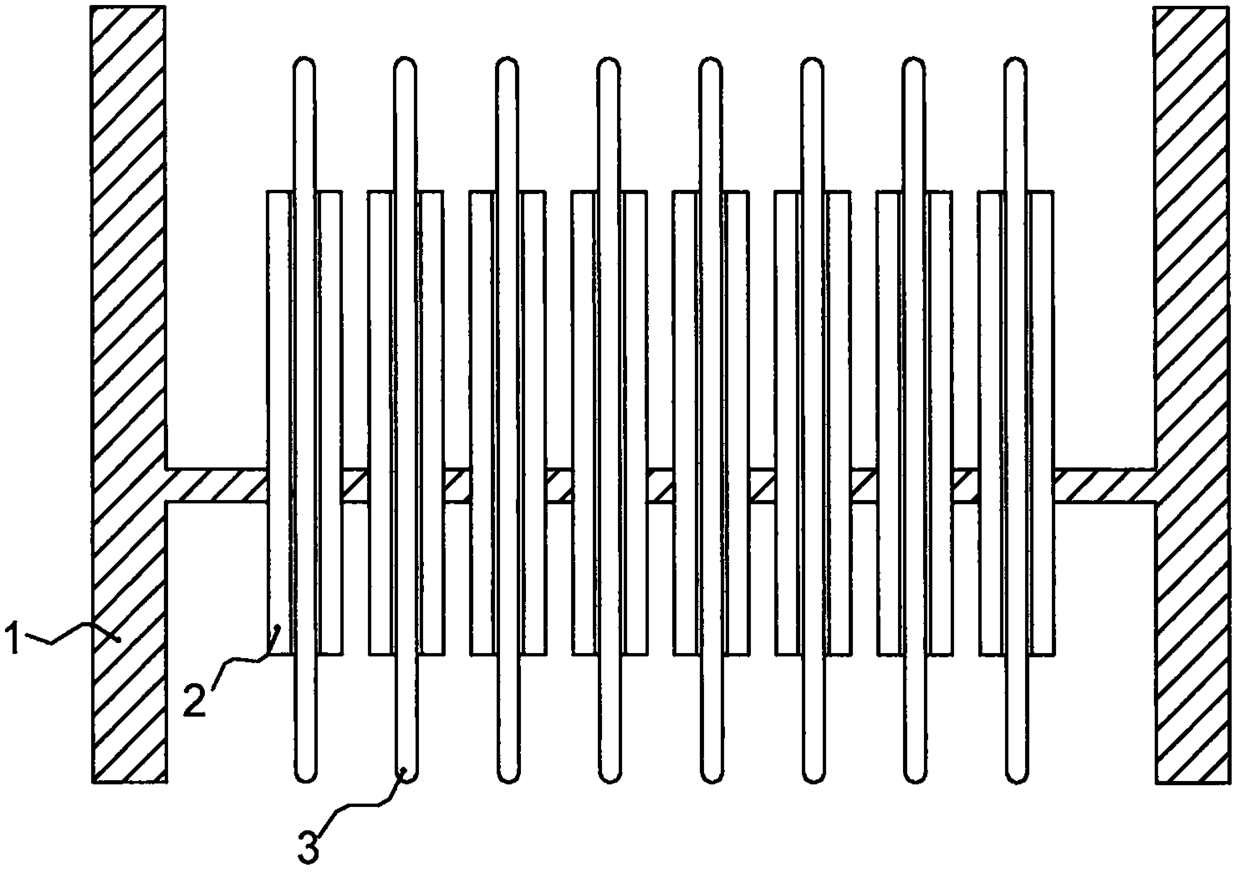

Machine equipment of semiconductor or photovoltaic material

ActiveCN110600398AFirmly connectedFlexible adjustment performanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringGraphite

The invention discloses machining equipment of a semiconductor or a photovoltaic material. The machining equipment comprises a furnace body and a furnace door; an electrode structure is arranged on the furnace door, an adjusting device is arranged on the furnace door and comprises an arc contact surface and a support block; the arc contact surface is arranged between the support block and the furnace door, and a structure matched with the arc contact surface is arranged at a corresponding location of the support block or the furnace body. The invention provides the machining equipment of the semiconductor or photovoltaic material, and the machining equipment is simple in structure, reasonable in electrode mechanism design, capable of realizing longitudinal arrangement of a graphite boat piece due to the perfect combination of the furnace door, and capable of quickly adjusting the furnace door to reach good sealing effect.

Owner:LAPLACE RENEWABLE ENERGY TECH CO LTD

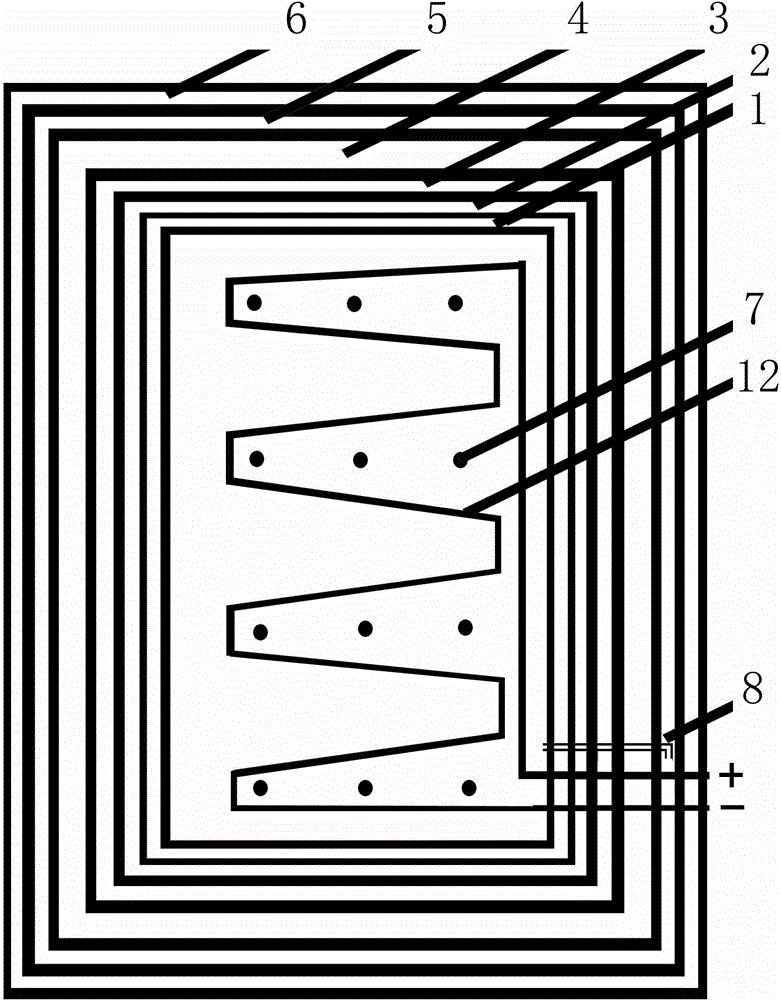

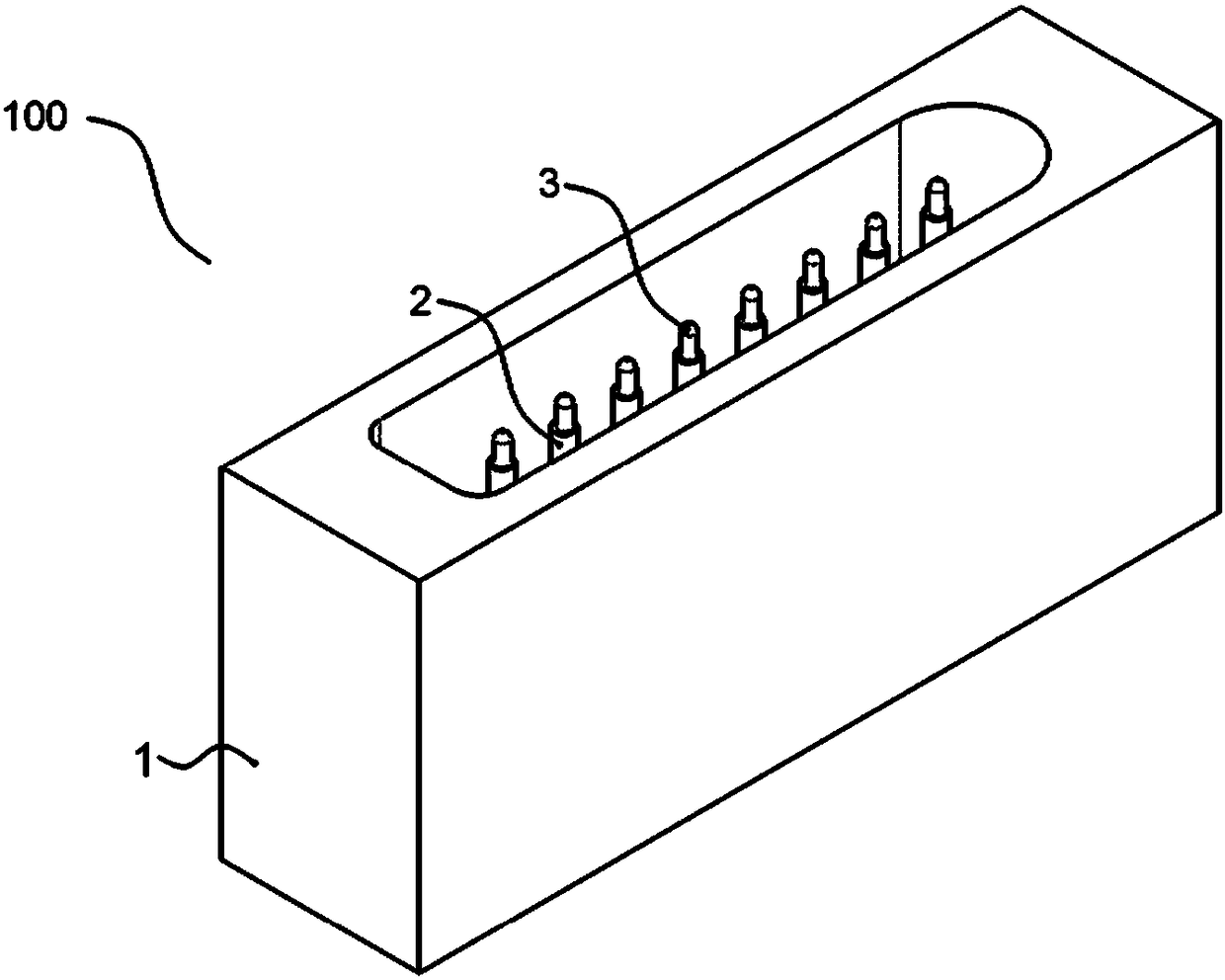

Energy-saving vacuum tempering glass and manufacturing technology thereof

InactiveCN102942311AHigh strengthImprove toughnessGlass/slag layered productsElectrical resistance and conductanceManufacturing technology

The invention relates to the technical field of glass deep-processing, and particularly relates to energy-saving vacuum tempering glass and a manufacturing technology of the energy-saving vacuum tempering glass. The energy-saving vacuum tempering glass comprises glass; a vacuum layer A is arranged between the front glass and the back glass; the end surfaces of the front glass and the back glass are inwards sequentially provided with flexible protective glue, low-temperature glass powder, high-temperature vacuum glass cement, vacuum mud and a protective layers; supporting balls are arranged in the vacuum layer A; the inner surfaces of the front glass and the back glass are provided with at least one layer of electric resistance wires; plastic cement protective strips and vacuumizing nozzles are arranged on the end surfaces of the front glass and the back glass; and the inner layer of the front glass is composited with a transparent anti-explosion film. The energy-saving vacuum tempering glass can be locally heated and has the obvious effect of being firm, breakage-proof, energy-saving and free of frosting. The energy-saving vacuum tempering glass has good vacuum sealing effect, excellent heat preservation and insulation effects and strong practicability and is low in cost. The energy-saving vacuum tempering glass is widely applied to fields such as houses, factories, protective cabinets, refrigerating chambers, automobiles, trains and greenhouses and has good market application prospect.

Owner:苏广庆

A New Type of Vacuum Drying Oven

ActiveCN104864685BGood temperature distributionImprove vacuum sealing performanceDrying gas arrangementsDrying chambers/containersCooling downVacuum drying

Owner:广东科明环境仪器工业有限公司

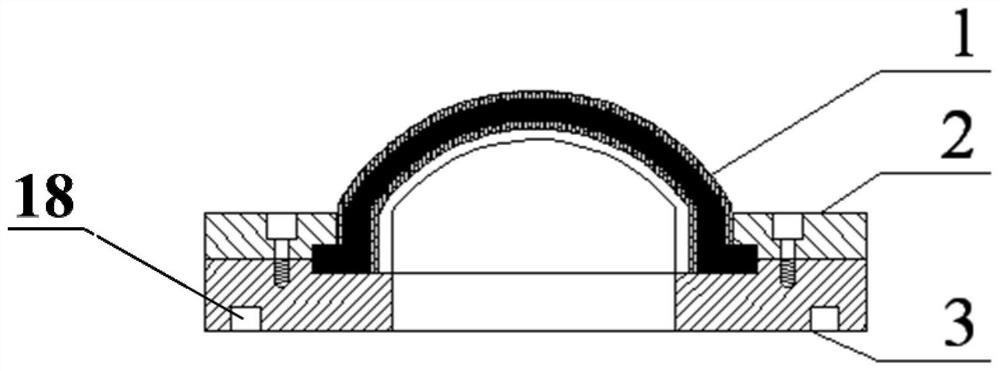

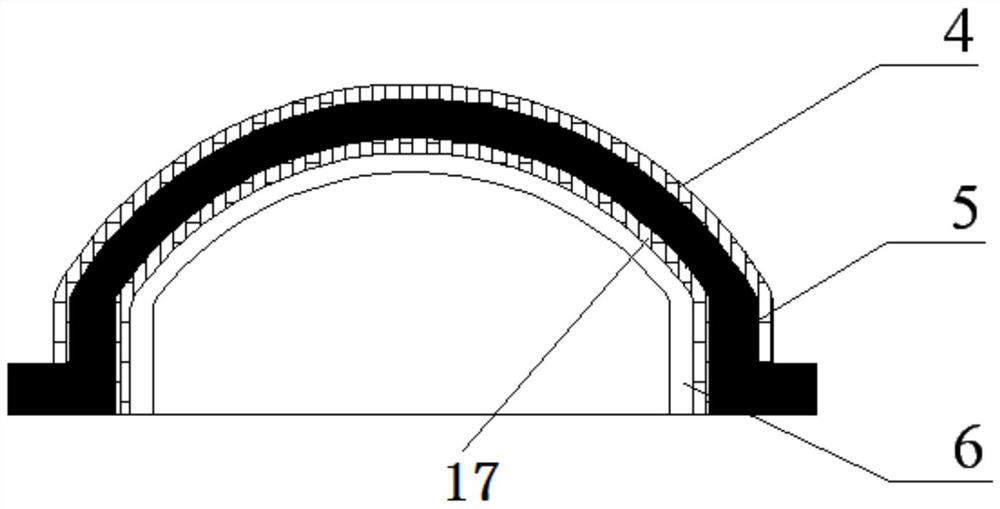

Three-dimensional vacuum cupping device

The invention discloses a three-dimensional vacuum cupping device, and aims at providing a three-dimensional cupping device having a mutually cooperative structure, being capable of practical and operating, ensuring that limbs enter and exit a housing and a sealing ring without limit and abrasion, can realize reliable vacuum sealing to truncus and limbs, being convenient for use and enabling the easily-damaged sealing ring to be durable. The three-dimensional vacuum cupping device comprises a shell, a loop sealing ring, an exhaust nozzle, a soft tube and a vacuum pump, wherein the inner side of the loop sealing ring on the outer side of the port of the shell is provided with a caliber-variable support ring. The three-dimensional vacuum cupping device is suitable for treating rare and stubborn diseases such as muscularconstricture of limb joints, finger stiffness, limb cold, numbness of extremities, amyotrophy, diabetic foot, elbow arm pain and curl, capillary collapse, blood vessel disappearance and the like, and obtains a special and remarkable treatment effect which is not reported in the traditional cupping device. The treatment and the physical therapy health care function on other diseases are waiting for further experimenting and developing.

Owner:刘玉海

Liquid crystal picture screen with improved backlighting

InactiveUS6713946B2Improved backlightingIncrease light sourceDischarge tube luminescnet screensElectroluminescent light sourcesGas-discharge lampCapacitance

A liquid crystal picture screen provided with a backlight system which comprises at least one gas discharge lamp and at least one capacitive coupling system with a dielectric material with the composition[A'a1<n1+>A''a2<n2+> . . . A<n'>an<nn+>] [B'b1<m1+>B''b2<m2+> . . . B<m'>bm<mn+>]O3, wherein the cations A'a1<n1+>A''a2<n2+> . . . A<n'>an<nn+> comprise at least one or several of the cations chosen from the group of Ba<2+>, Pb<2+>, Sr<2+> and Ca<2+>, as well as possibly one or several of the cations chosen from the group of Cs<1+>, Rb<1+>, Tl<1+>, K<1+>, Pb<2+>, Ag<1+>, Sr<2+>, Na<1+>, Bi<3+>, La<3+>, Mg<2+>, Zn<2+>, Ca<2+>, Ce<3+>, Cd<2+>, Pr<3+>, Nd<3+>, Eu<3+>, Gd<3+> and Sm<3+>, andthe cations B'b1<m1+>B''b2<m2+> . . . B<m'>bm<mn+> comprise at least one or several of the cations chosen from the group of Ti<4+>, Zr<4+> and Sn<4+> as well as possibly one or several of the cations chosen from the group of Mn<2+>, Cr<2+>, In<3+>, V<2+>, Fe<2+>, Pb<4+>, Li<1+>, Co<2+>, Sc<3+>, Zn<2+>, Cu<2+>, U<6+>, Mg<2+>, Hf<4+>, Mo<3+>, Ni<2+>, Nb<4+>, Ti<3+>, W<4+>, Mo<4+>, Fe<3+>, Mn<3+>, V<3+>, Re<4+>, Ir<4+>, Ru<4+>, W<5+>, Ta<5+>, Cr<3+>, Ga<3+>, Co<3+>, Mo<5+>, Ni<3+>, Sb<5+>, W<6+>, Nb<5+>, Mo<6+>, Fe<4+>, Re<5+>, V<4+>, Te<6+>, V<5+>, Cu<3+>, Al<3+>, Mn<4+>, Ge<4+>, Y<3+>, Gd<3+>, Dy<3+>, Ho<3+>, Er<3+>, Yb<3+>, Tb<3+> and Lu<3+>, with0.98<=A1+a2+ . . . +an<=1.02,0.98<=B1+b2+ . . . +bm<=1.02,a1+a2+ . . . +an+b1+b2+ . . . +bm<=2,a1*n<1>+a2*n<2>+ . . . +an*n<n>+b1*m<1>+b2*m<2>+ . . . +bm*m<m><=6.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Socket connectors, vacuum electronics, plug connectors and connector assemblies

PendingCN109216992AImprove vacuum sealing performanceHigh Voltage Insulation PropertiesSecuring/insulating coupling contact membersCouplings bases/casesMetallic materialsMiniaturization

Owner:NURAY TECH

A vacuum high-temperature hot-press forming machine

The invention discloses a vacuum high-temperature hot pressing molding machine. The vacuum high-temperature hot pressing molding machine comprises a rack (1) for wholly supporting a molding machine, an upper heat-preservation cold-state vacuum cover (2), a lower heat-preservation cold-state vacuum cover (4) corresponding to the upper heat-preservation cold-state vacuum cover (2), and a vacuumizing device (6) connected with the upper heat-preservation cold-state vacuum cover (2) or the lower heat-preservation cold-state vacuum cover (4), wherein the upper heat-preservation cold-state vacuum cover (2) can move up and down and is internally provided with an upper heating plate (3); the lower heat-preservation cold-state vacuum cover (4) can move front and back and up and down; and the lower heat-preservation cold-state vacuum cover (4) is internally provided with a lower heating plate (5) corresponding to the upper heating plate (3). The vacuum high-temperature hot pressing molding machine is simple in structure, reasonable in design, convenient to use, good in vacuum sealing effect, high in molding temperature, good in molding effect and low in heat dissipation.

Owner:大连天能装备制造有限公司

Ultrahigh vacuum sealing flange structure for non-circular channel of large Tokamak vacuum chamber

InactiveCN111710442AGuaranteed vacuum tightnessImprove vacuum sealing performanceNuclear energy generationThermonuclear fusion reactorCopper wireEngineering

The invention belongs to the field of magnetic confinement fusion (MCF) technologies, and particularly relates to an ultrahigh vacuum sealing flange structure for a non-circular channel of a large Tokamak vacuum chamber. The structure comprises a concave flange, a convex flange and a connecting pipe. Two matched 90-degree sealing steps are machined on the inner sides of the opposite end faces of the concave flange and the convex flange, and a copper wire ring is placed between the two sealing steps, so that a gap is reserved between the concave flange and the convex flange in the axial direction; and the concave flange and the convex flange are connected through a double-end threaded pin or a double-end stud. By means of the structural mode that the oxygen-free copper wire is compressed through the 90-degree sealing steps, the ultrahigh vacuum sealing requirements of non-circular channel window flanges of different shapes can be met, and the machining and maintaining difficulty of thesealing face of a non-circular window is reduced.

Owner:SOUTHWESTERN INST OF PHYSICS

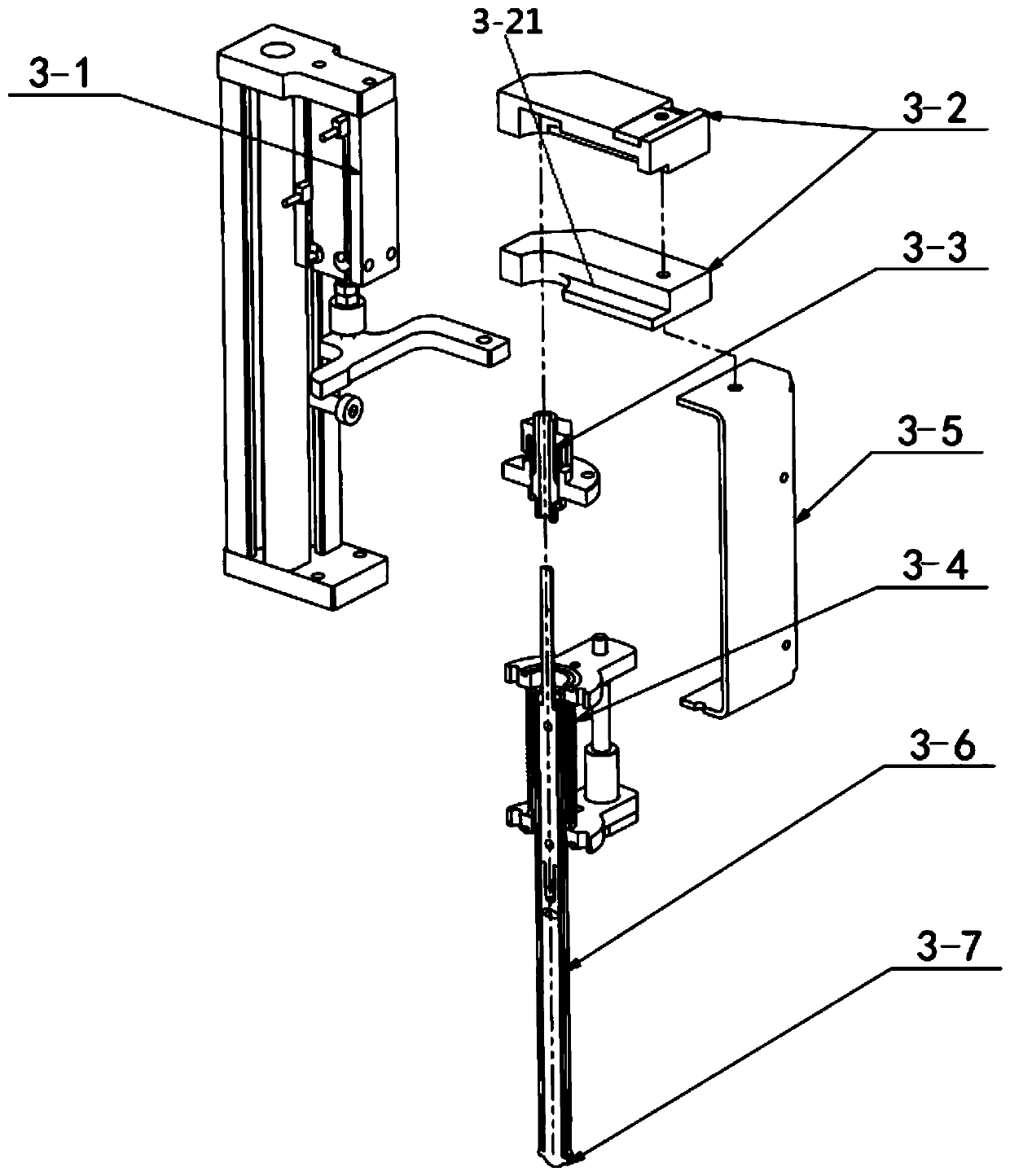

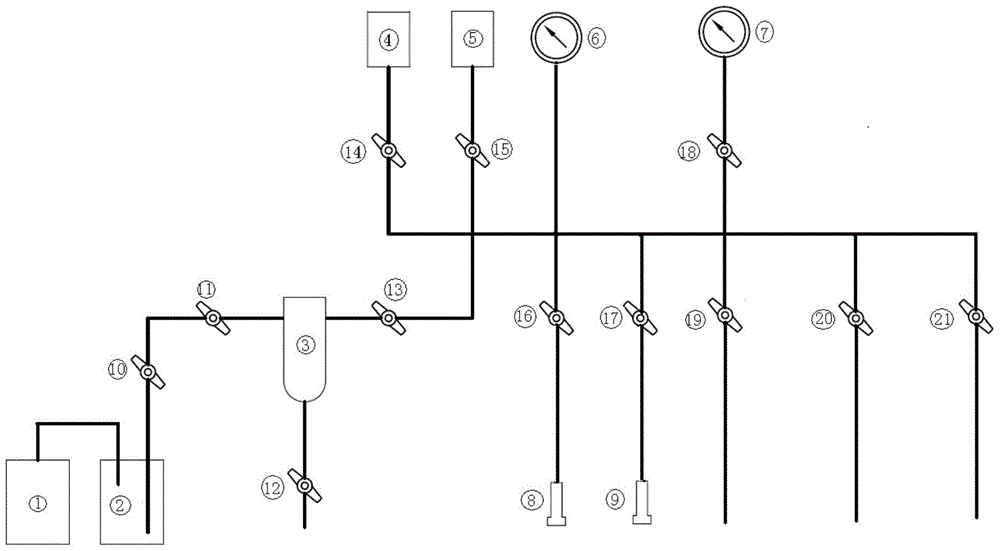

Tritium labeling reaction device

ActiveCN103706297BGuaranteed tightnessPrevent abnormal conditions of excessive stressPressurized chemical processControl valvesBottle

Owner:CHINA INSTITUTE OF ATOMIC ENERGY +1

Semiconductor Processing Equipment

ActiveCN110517974BAvoid electricitySimple structureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGraphite

The invention discloses semiconductor processing equipment, which comprises a furnace body and a furnace door. An electrode structure is arranged on the furnace door, and an adjustment structure is arranged on the furnace door. It is connected with the furnace door through a knob; the axial direction of the adjustment device body is non-parallel to the axial direction of the knob; the invention provides a simple structure, reasonable design of the electrode mechanism, and perfect combination with the furnace door to realize the vertical placement of the graphite boat , and can quickly adjust the furnace door to achieve semiconductor processing equipment with good sealing effect.

Owner:LAPLACE RENEWABLE ENERGY TECH CO LTD

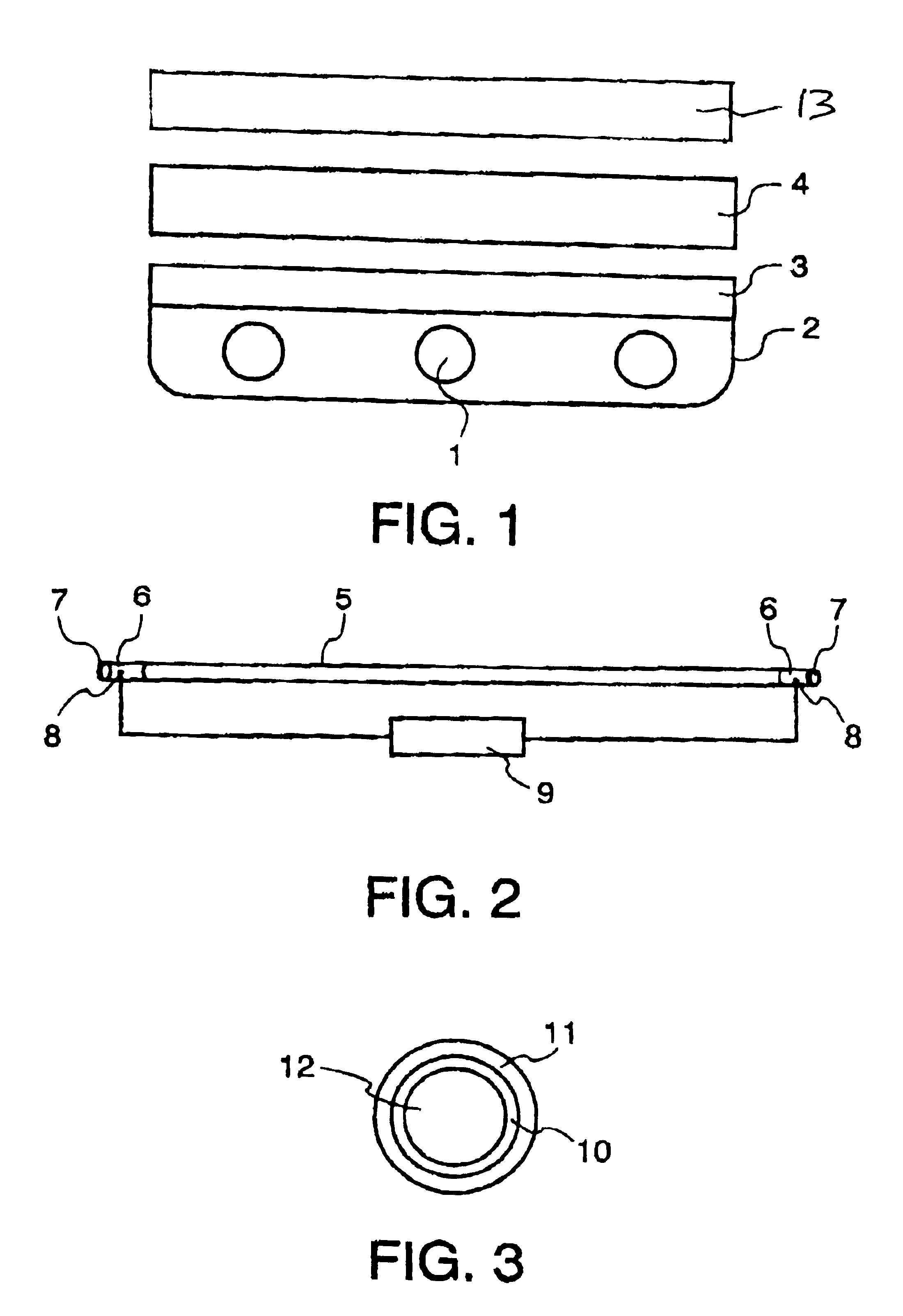

A low-loss high-vacuum-sealed heat-insulated transmission window for millimeter-wave frequency bands

ActiveCN106785245BReduce transmission reflection lossImprove vacuum sealing performanceWaveguide type devicesAntenna detailsReflection lossThermal break

The invention relates to a low-loss, high-vacuum sealed and heat-insulated transmission window for the millimeter wave frequency band, comprising a multi-layer dielectric window and a sealing upper flange and a sealing lower flange respectively installed on the upper and lower sides of the edge of the multi-layer dielectric window; The layered dielectric window includes a first tetrafluoro layer, a quartz layer, a second tetrafluoro layer and a thermal insulation layer arranged in sequence from outside to inside. The invention can not only effectively reduce the transmission reflection loss of electromagnetic wave signals, improve the problem of a large number of interference bands in the existing window, but also greatly improve the vacuum sealing performance, and solve the problem of limited use of the sealed wave-transmissive window of the traditional cryogenic receiver / superconducting receiver , and has a good heat insulation effect, effectively reducing heat radiation.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

Three-dimensional vacuum cupping appliance

The invention discloses a three-dimensional vacuum cupping device, and aims at providing a three-dimensional cupping device having a mutually cooperative structure, being capable of practical and operating, ensuring that limbs enter and exit a housing and a sealing ring without limit and abrasion, can realize reliable vacuum sealing to truncus and limbs, being convenient for use and enabling the easily-damaged sealing ring to be durable. The three-dimensional vacuum cupping device comprises a shell, a loop sealing ring, an exhaust nozzle, a soft tube and a vacuum pump, wherein the inner side of the loop sealing ring on the outer side of the port of the shell is provided with a caliber-variable support ring. The three-dimensional vacuum cupping device is suitable for treating rare and stubborn diseases such as muscularconstricture of limb joints, finger stiffness, limb cold, numbness of extremities, amyotrophy, diabetic foot, elbow arm pain and curl, capillary collapse, blood vessel disappearance and the like, and obtains a special and remarkable treatment effect which is not reported in the traditional cupping device. The treatment and the physical therapy health care function on other diseases are waiting for further experimenting and developing.

Owner:刘玉海

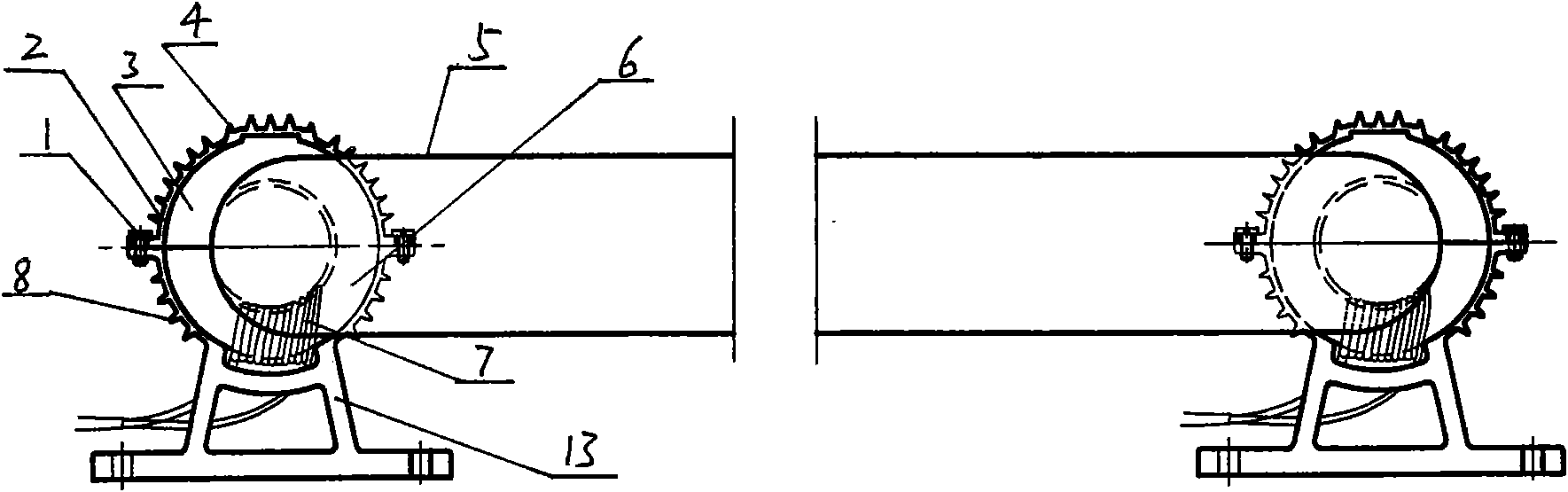

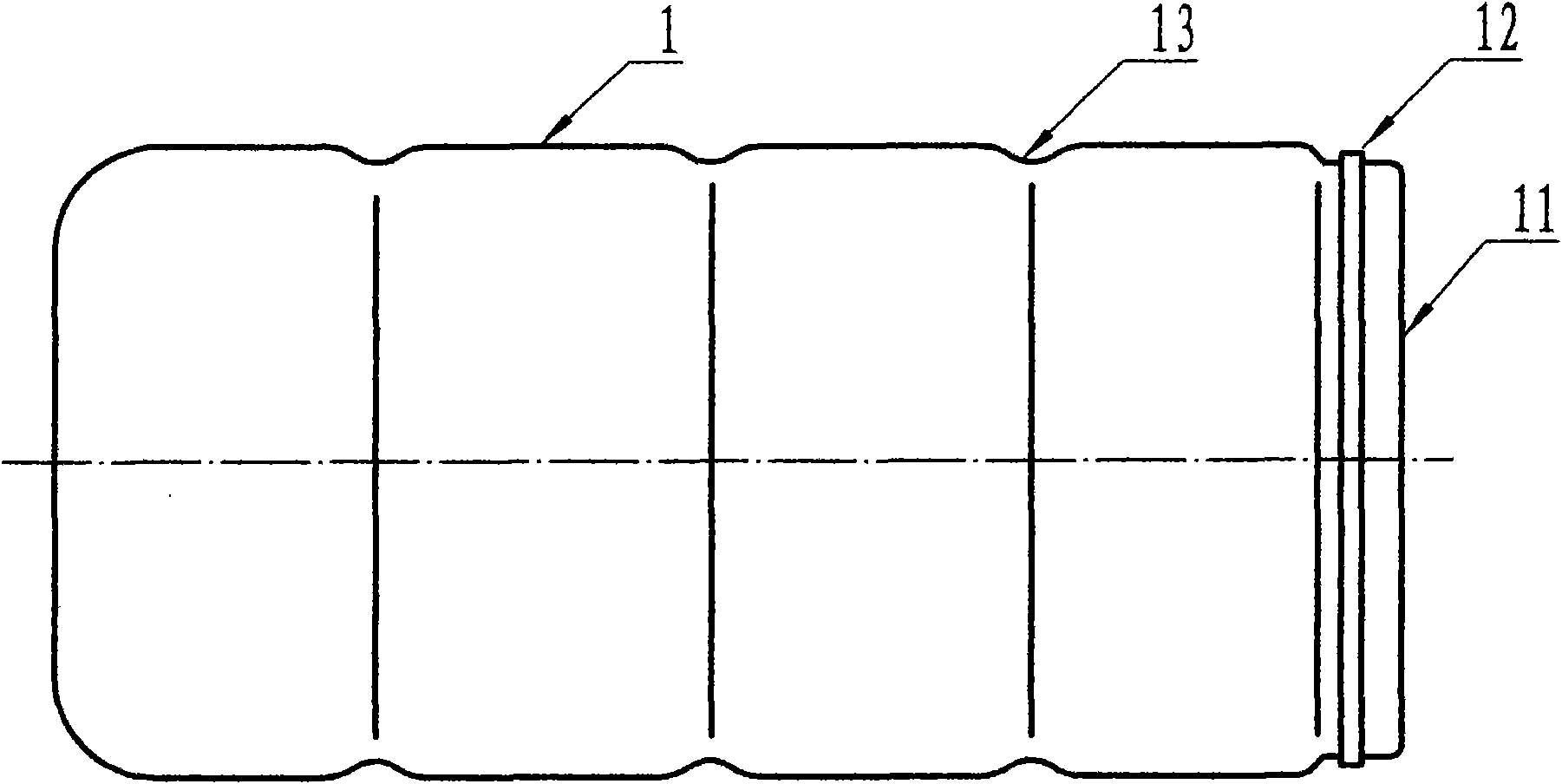

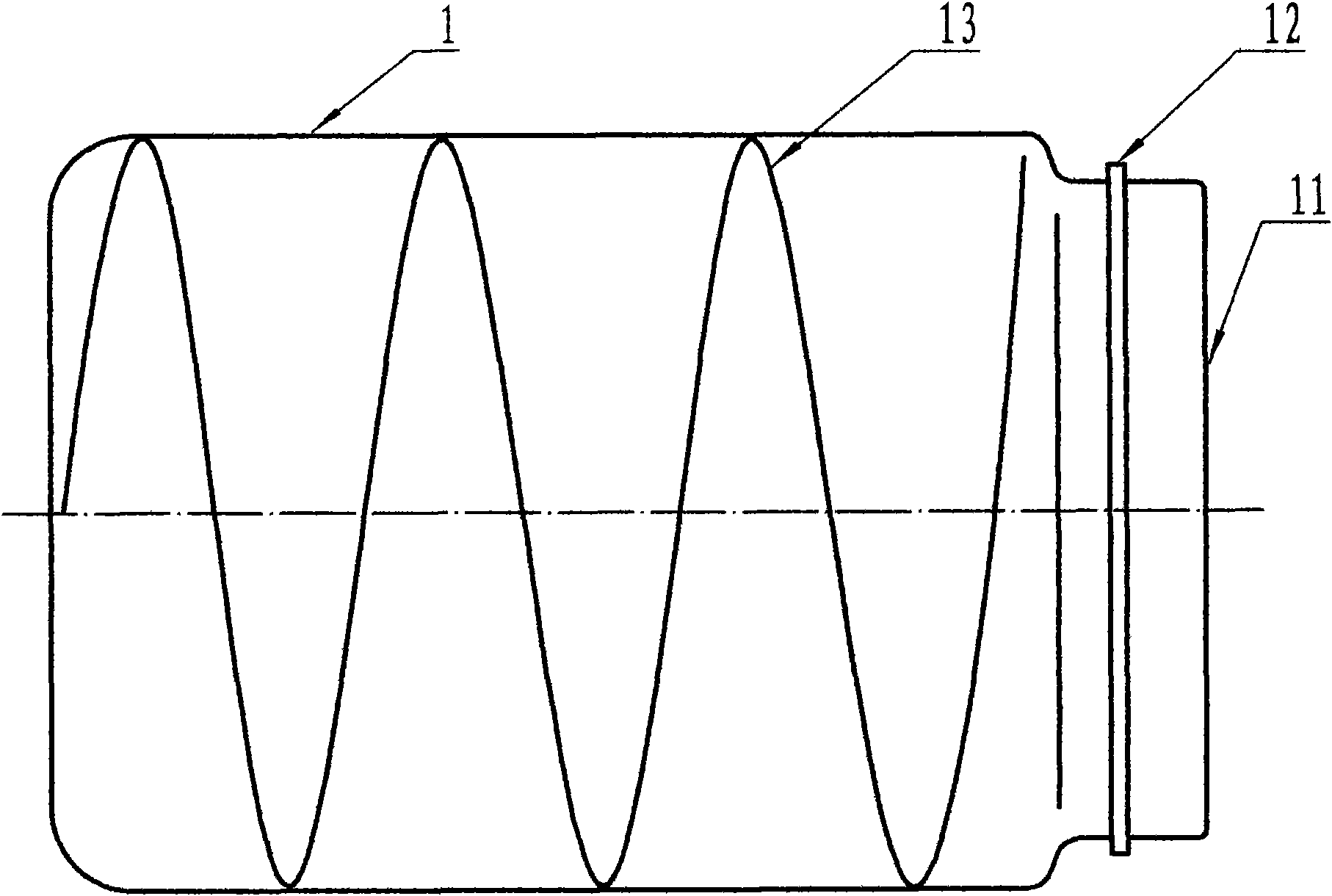

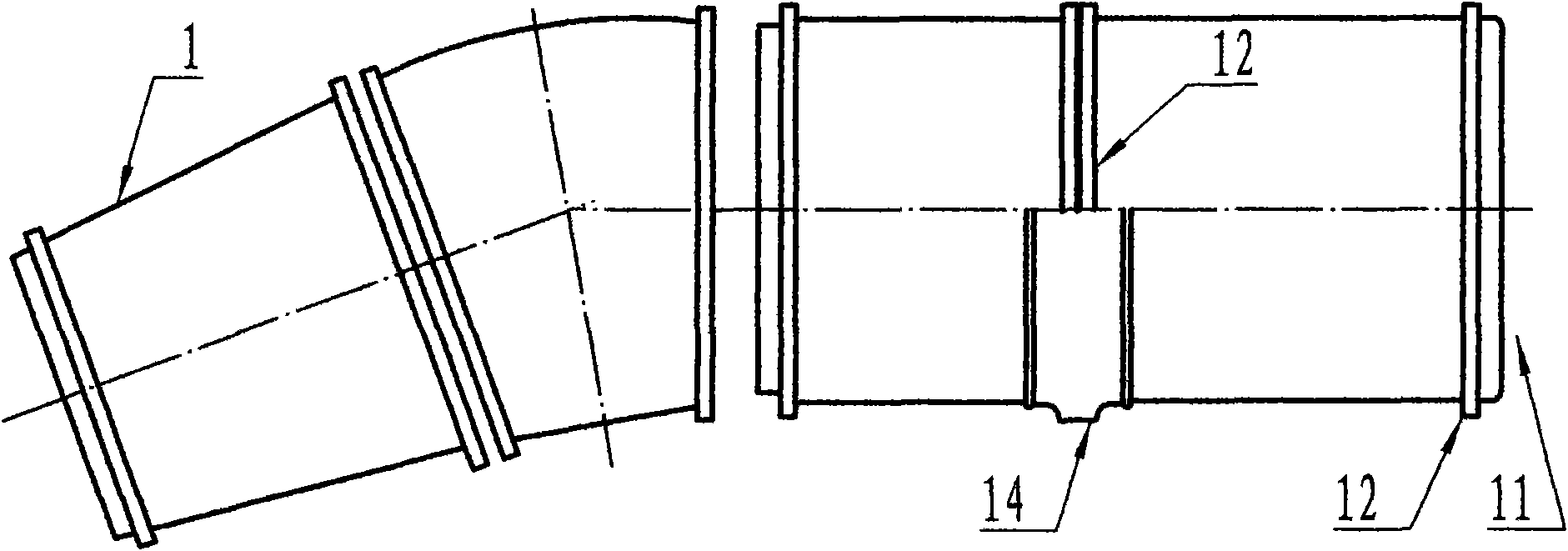

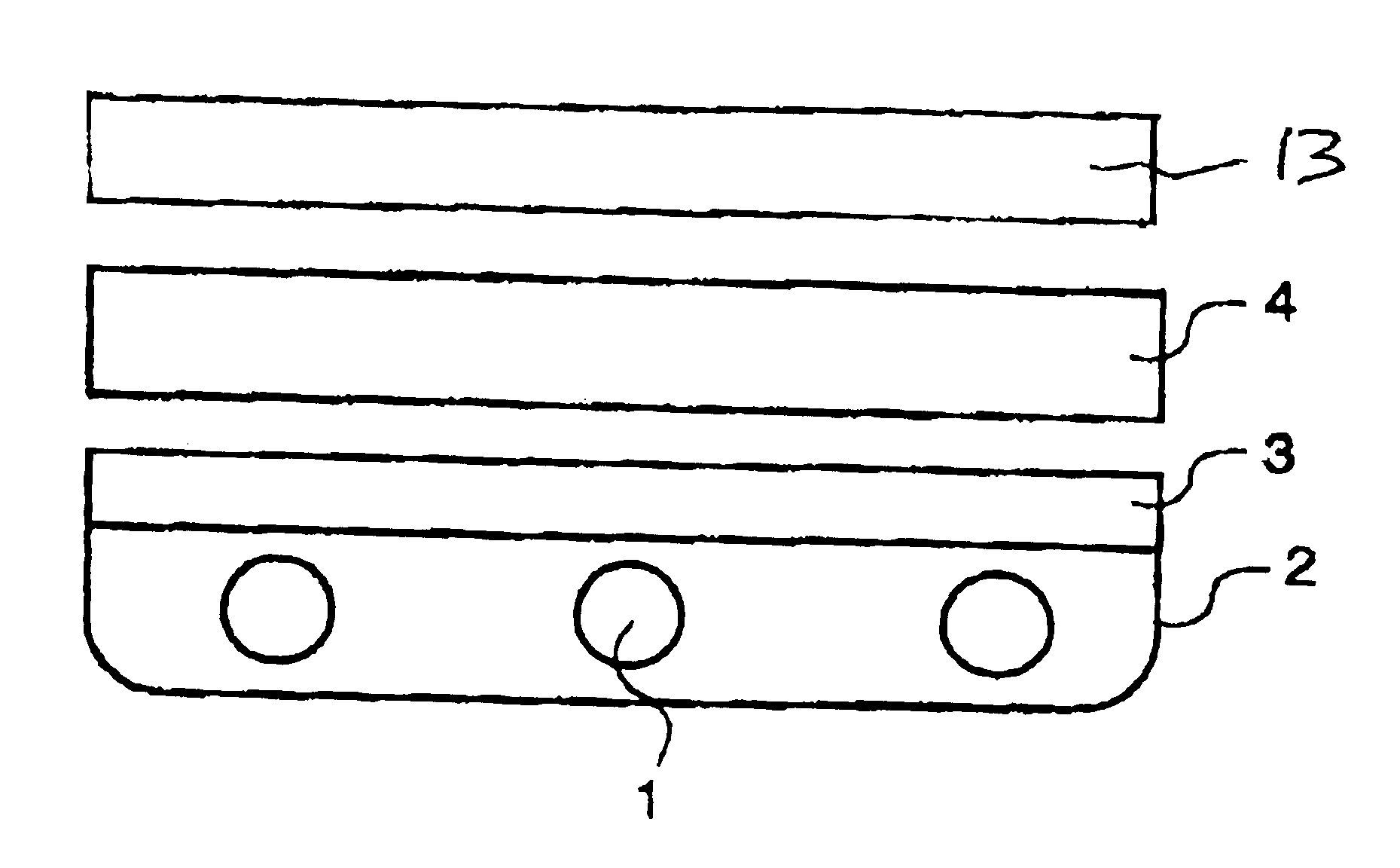

A vacuum gas distributor with high sealing performance and adjustable pumping speed

ActiveCN108916005BIncrease inhalation speedImprove sealingPositive displacement pump componentsPackaging under vacuum/special atmosphereWave structureEngineering

The invention discloses a vacuum gas distribution disc with high sealing performance and adjustable pumping speed. The gas distribution disc comprises a vacuum gas distribution disc body, wherein thevacuum gas distribution disc body comprises a central shaft, a base plate, a lower gas distribution disc, an intermediate gas distribution disc, an upper gas distribution disc, a deflation seat and agas suction disc. The upper side of the central shaft is fixedly connected to the base plate, the upper side of the base plate is movably connected to the lower gas distribution disc, and the upper side of the lower gas distribution disc is provided with the intermediate gas distribution disc. The upper side of the intermediate gas distribution disc is fixedly provided with the upper gas distribution disc, and the upper side of the upper gas distribution disc is connected to the deflation seat in the detachable mode. The upper side of the deflation seat is movably connected to the gas suctiondisc, and the outside of the gas suction disc is fixedly connected with a speed regulation mechanism. The vacuum gas distribution disc is provided with a sealing sleeve. In the gas pumping process ofthe gas suction disc, the sealing sleeve on the outside can prevent external gas from entering the gas suction disc. The sealing sleeve is designed into a wave structure and can be changed with vertical movement of a piston in the gas suction disc, so that the sealing effect can be improved.

Owner:陈红梅

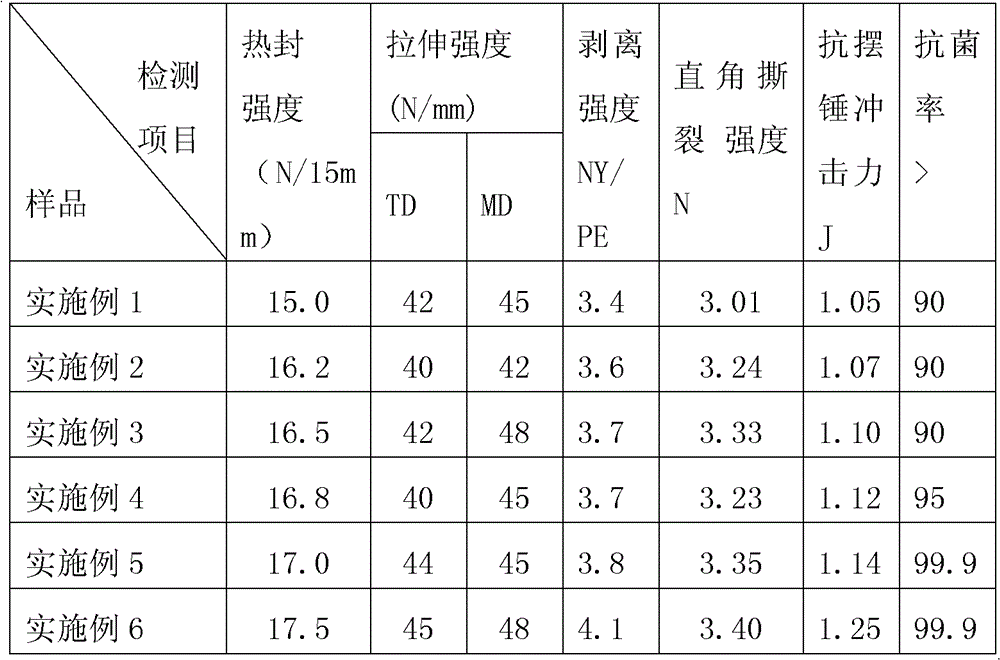

Antibacterial composite film used for vacuum packing of household articles and preparation method thereof

ActiveCN102173149BStrong puncture resistanceHigh compressive strengthSynthetic resin layered productsPackaging under vacuum/special atmosphereComposite filmPolyamide

The invention discloses an antibacterial composite film used for vacuum packing of household articles and a preparation method thereof. The composite film consists of a biaxially oriented polyamide film outer layer, a coating adhesion layer, and an antibacterial heat sealing layer. The preparation method comprises the following steps of: performing extrusion by using a three-layer co-extruder to obtain the antibacterial heat sealing layer; printing the outer film; and compounding the outer layer and the antibacterial heat sealing layer by using an extrusion compounding machine. The antibacterial composite film has excellent puncture resistance, compression strength and sealing property, good vacuum effect and antibacterial effect, and can used for storing the household articles and other antibacterial products.

Owner:GUANGZHOU NOVEL PACKAGING

A non-magnetic RF signal connector for vacuum sealing

ActiveCN103560353BReduce manufacturing costImprove vacuum sealing performanceCouplings bases/casesTwo-part coupling devicesIntegrated designNon magnetic

The invention relates to a non-magnetic RF signal connector for vacuum sealing. The non-magnetic RF signal connector for vacuum sealing comprises a conductive element and a sealing device. The sealing device comprises the sealing of the conductive element. A sealing member body (4) radially passes through a brass assembly body (9) and is connected with a clamping ring (6), an O-shaped ring (7) and a locking nut (8) to be the sealing device which can be movably dismounted integratedly. The sealing device comprises the sealing of the conductive element and the sealing of a vacuum chamber outer wall (1). The sealing of the conductive element is achieved through a contact hole (12) arranged on the sealing member body (4). A sealant (10) is pasted in the contact hole (12). Through two modes of sealing, the vacuum sealing effect is good, the vacuum leak rate is smaller than 1.0*10<-10>Pa.m3 / s, and the non-magnetic RF signal connector has the advantages of simple integrated design structure, low manufacturing cost, and convenient manufacture.

Owner:TIME MEDICAL JIANGSU

A kind of lead-free solder for quartz glass sealing

ActiveCN109822257BImprove vacuum sealing performanceSimple sealing processWelding/cutting media/materialsSoldering mediaTitanium coatingSoldering

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Oxygen-free copper composite welding method

ActiveCN103817451BWeld tightlyImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesUltimate tensile strengthFiller metal

The invention provides an oxygen-free copper composite welding method by combining low pressure diffusion welding with brazing compound welding. The oxygen-free copper composite welding method comprises the steps: step A, preprocessing multiple oxygen-free copper parts to be welded to remove the oxide film on the surfaces of the oxygen-free copper parts; step B, assembling the multiple oxygen-free copper parts, fixing the relative position of each oxygen-free copper part to ensure close contact of welding faces, and carrying out low pressure diffusion welding on the welding faces of the oxygen-free copper parts; step C, placing electric vacuum brazing filler metal in the welding holes preset in the edges of the welding faces and brazing the multiple oxygen-free copper parts. A composite welding head formed through the oxygen-free copper composite welding method is bonded tightly, the precision of welding is high, the vacuum leakproofness is good, and the joint tensile strength is 200-300 MPa, being close to or even higher than the oxygen-free copper base metal strength.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

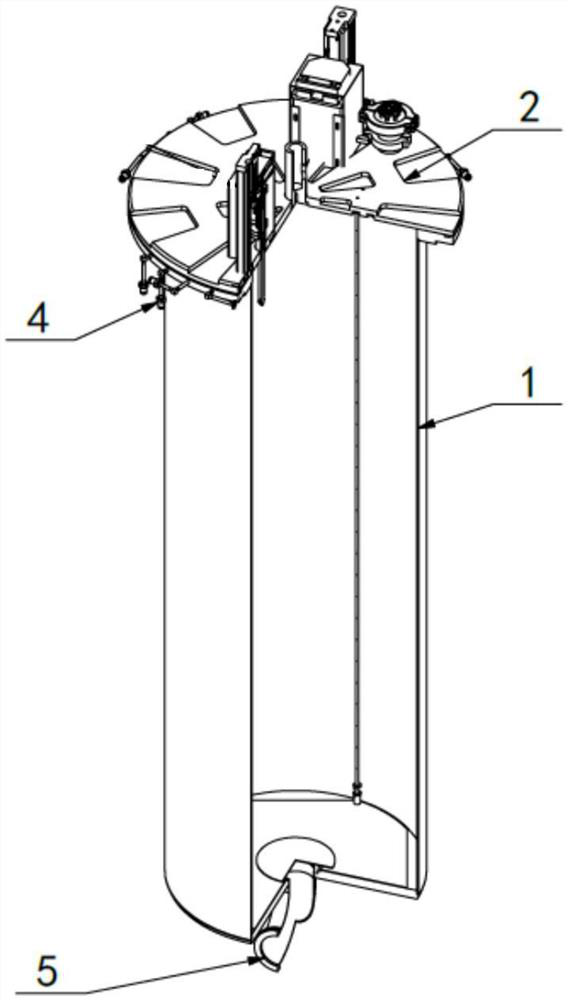

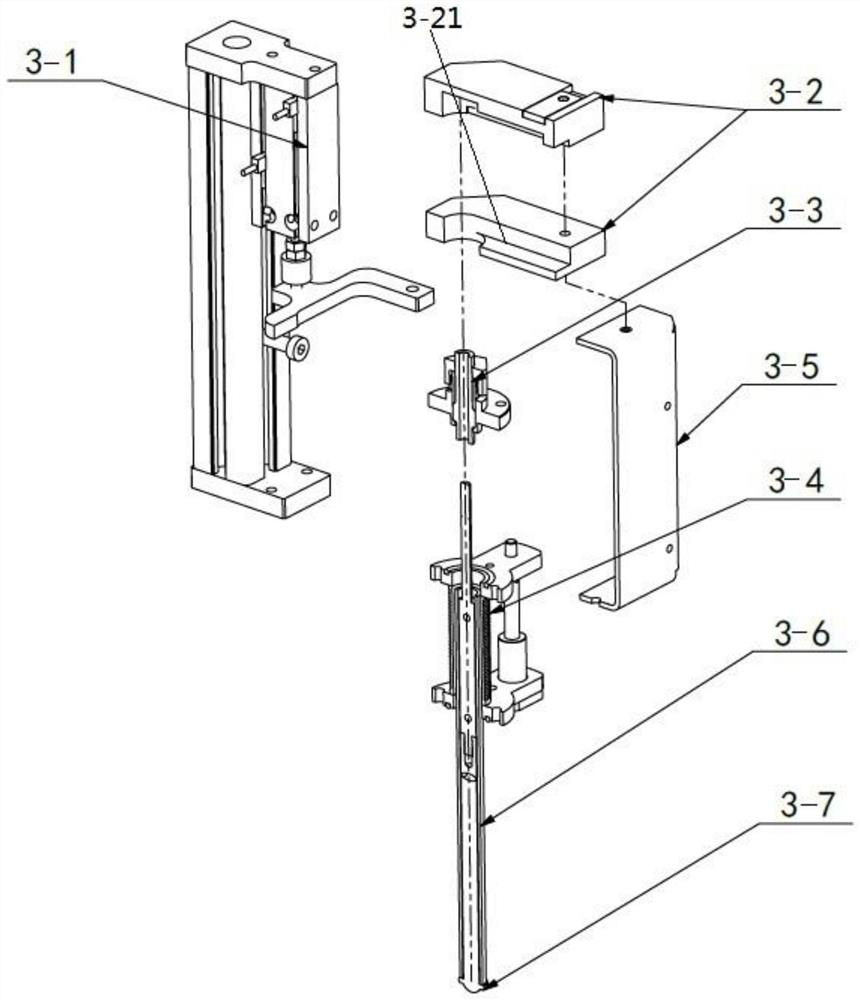

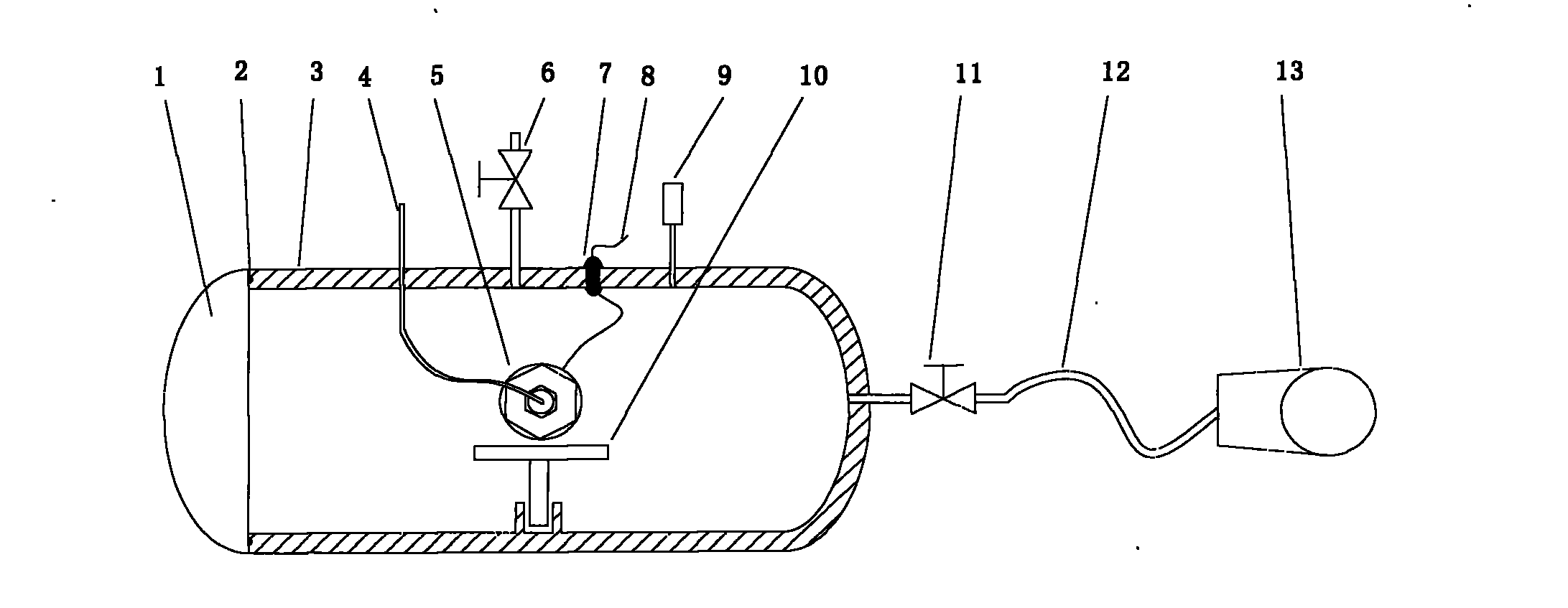

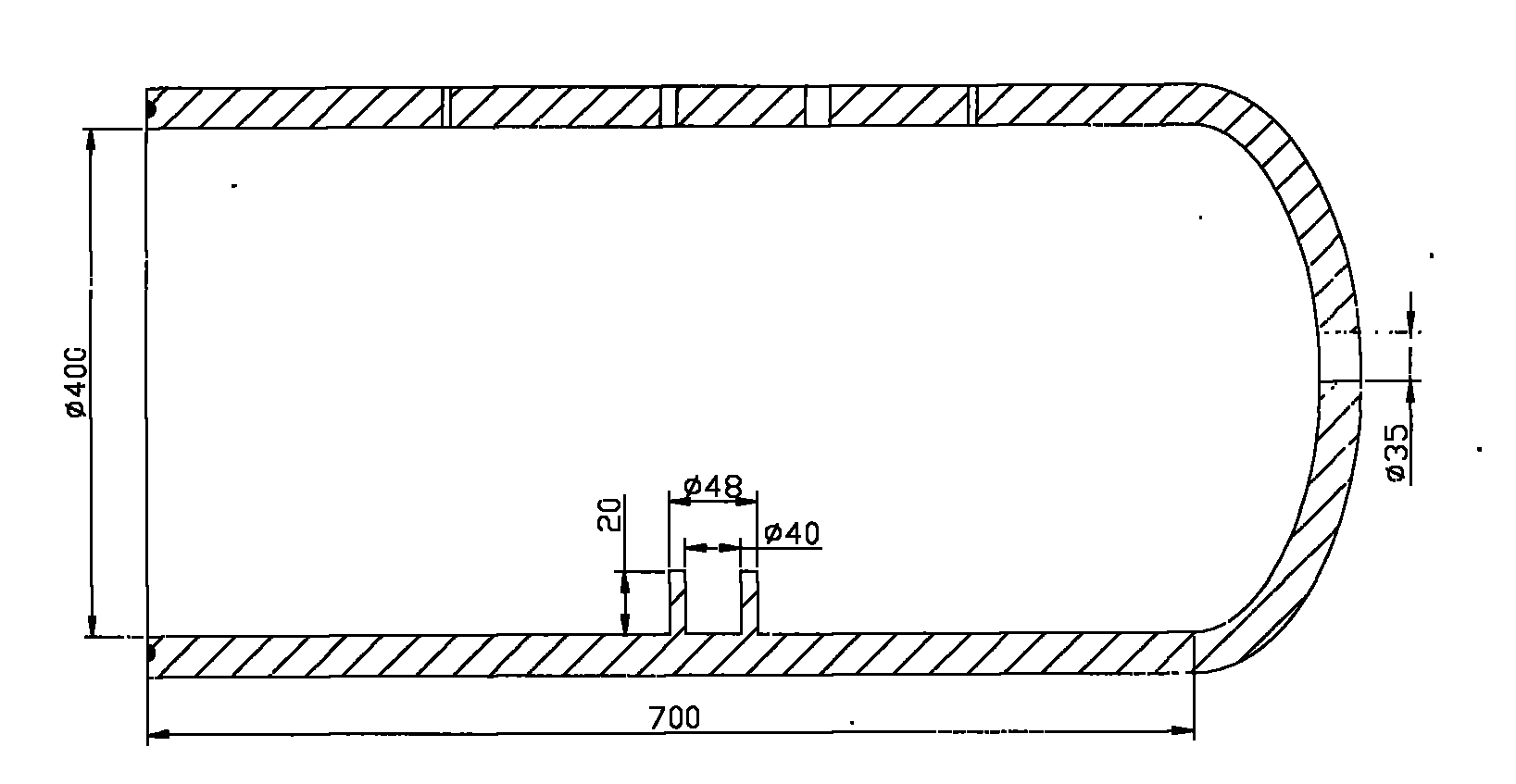

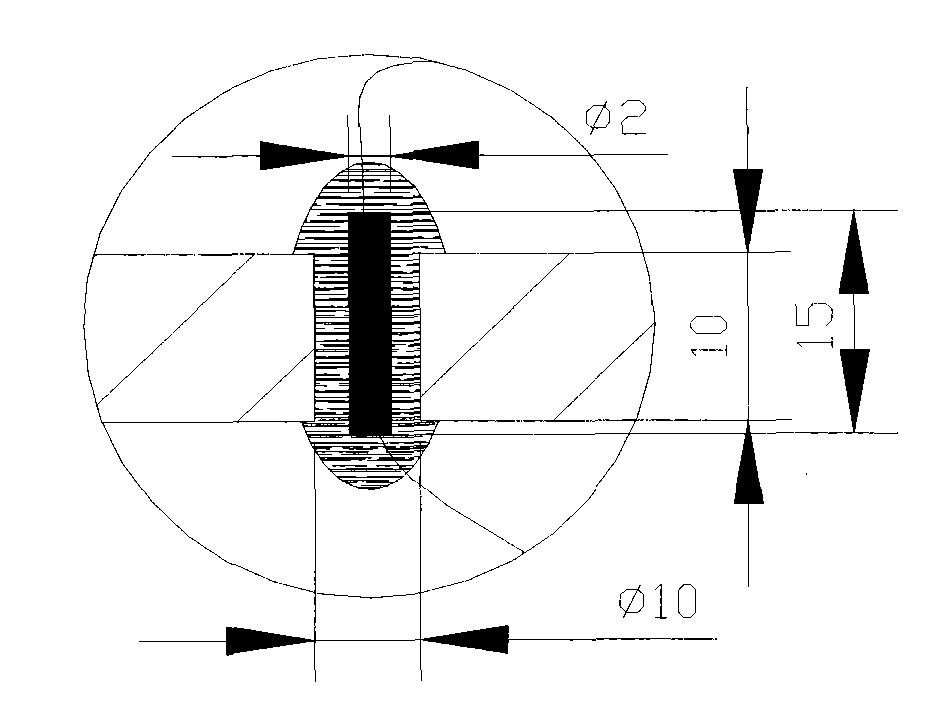

Skid-mounted rocket tank pressure annunciator flight vacuum environment simulator

InactiveCN104122105ASimple structureEasy to implementStructural/machines measurementSystem structureAluminium

The invention discloses a skid-mounted rocket tank pressure annunciator flight vacuum environment simulator which is composed of a vacuum chamber door, a vacuum chamber, a vacuum gauge, a candlestick, a vacuum pump, a platform dolly and the like. The simulator is used for an upper stage rocket tank pressure annunciator and simulating a vacuum condition for the upper stage rocket tank pressure annunciator operating outside the earth's atmosphere. According to the invention, circuit insulation and sealing problems are solved. When the simulator operates, vacuum degree inside the vacuum chamber is better than 1 Pa. The pressure annunciator has a simple installation structure and is convenient to dismount and maintain. Vacuum cement and aluminium bars are used for sealing of pressure annunciator cables passing through the wall of the vacuum chamber. The structure is simple and easy to realize and is good in vacuum seal effect and low in cost. By integrating the vacuum chamber and the vacuum pump into one platform dolly, the structure of the system is compact and the vacuum-pumping effect of the vacuum chamber is enhanced. In addition, the integral body is convenient to move, and maintainability of the system is improved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

A kind of sn-ti-ag ternary alloy solder for quartz glass sealing

ActiveCN109986233BImprove vacuum sealing performanceSimple sealing processWelding/cutting media/materialsSoldering mediaTitanium coatingPhysical chemistry

The invention discloses a Sn-Ti-Ag ternary alloy solder for quartz glass sealing. The matrix of the ternary alloy solder is tin, the weight percent components of Ti and Ag introduced are Ti: 0.1%-1.6%, Ag: 0.1%-2.0%, and the atomic percent components of O introduced are 0.05%-3.9% %, the mass percentage of impurities in the ternary alloy solder is less than or equal to 0.1%. The welding temperature range of the ternary alloy solder is 650℃~800℃, and the welding vacuum degree is less than or equal to 5×10 ‑3 Pa. The ternary alloy solder does not need flux in the quartz glass sealing process, simplifies the quartz glass sealing process, and improves the vacuum sealing reliability of the quartz glass sealing. The ternary alloy solder can be widely used not only in quartz glass sealing, but also in silica glass, which has a softening temperature of not lower than 800 °C and is made of SiO 2 The mutual welding of glass, titanium, oxygen-free copper and metal with titanium coating on the surface as the main component is especially suitable for the preparation of pulsed xenon lamps, which can significantly improve the service life and working reliability of pulsed xenon lamps.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Capacitor dry vacuum environment packaging group

PendingCN111739741AGuarantee the quality of vacuum packagingQuality assuranceFixed capacitor housing/encapsulationEncapsulating capacitors apparatusVacuum pumpingHigh capacitance

The invention discloses a capacitor dry vacuum environment packaging group. Through the arrangement of a vacuum chamber upper cover, a vacuum chamber lower cover and a vacuum pumping pipe, a very goodair drying environment can be provided when the capacitor is subjected to vacuum packaging work, and the normal operation of the vacuum packaging work of the capacitor and the vacuum packaging quality can be guaranteed. By arranging a sealing strengthening structure, a good strengthening and sealing effect on the connection and sealing of the vacuum chamber upper cover and the vacuum chamber lower cover is realized, the quality of the vacuum environment is guaranteed, and further the vacuum packaging quality of the capacitor is guaranteed. Through the sealing connection of an arranged rubbersealing ring, a rubber sealing round block and an aluminum shell, the vacuum tightness is guaranteed. By arranging a clamping groove, a circular sealing groove, a circular sealing ring and an elasticclamping block, the connecting, sealing and fixing functions of the rubber sealing ring and the aluminum shell and the sealing and fixing functions of the rubber sealing circular block and the rubbersealing ring are guaranteed, and then the vacuum sealing performance of the capacitor is improved.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

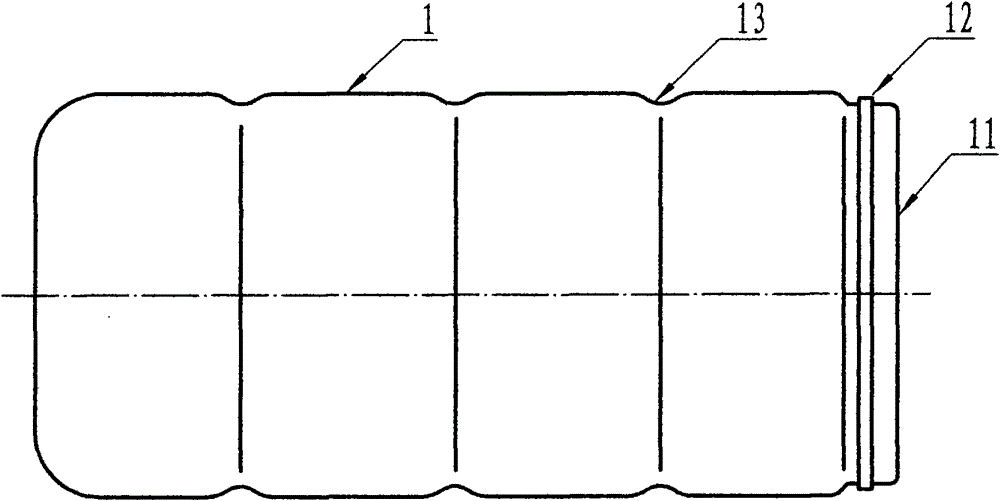

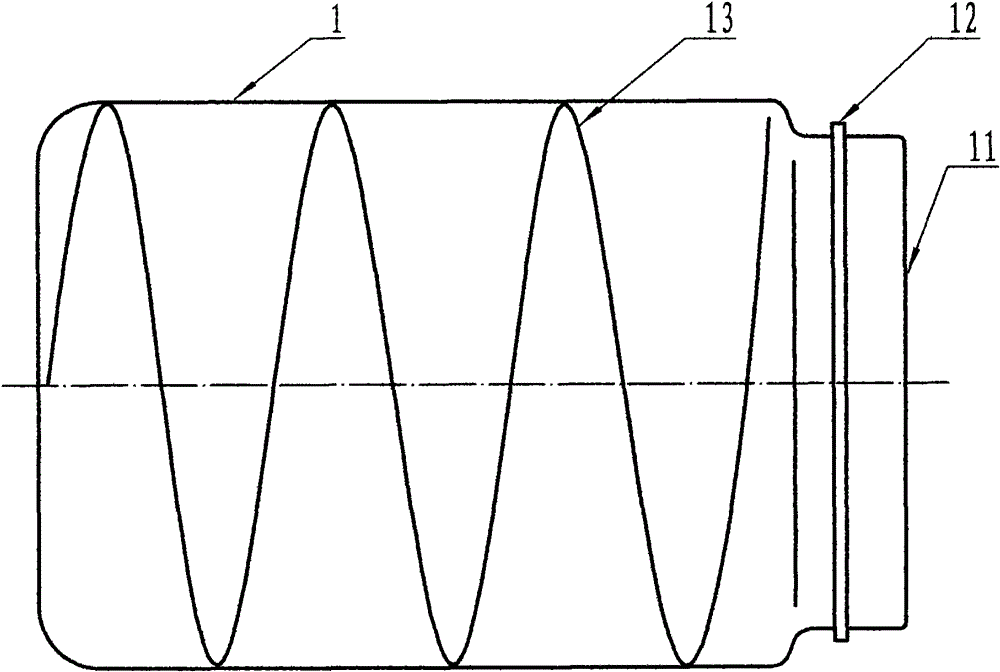

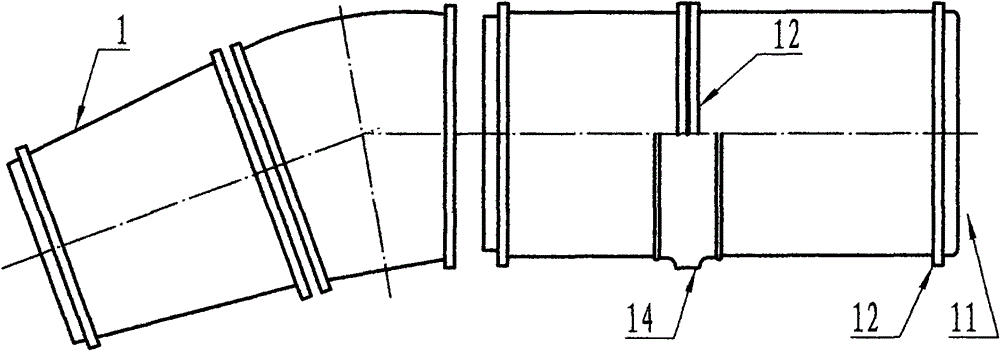

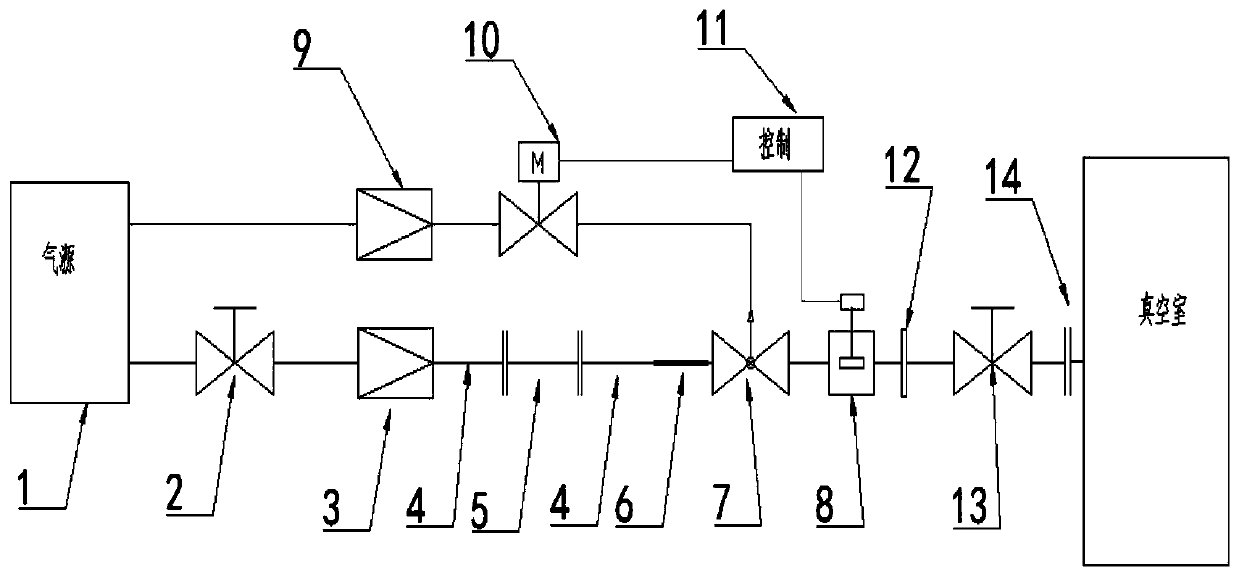

Vacuum air inlet system and air inlet control method thereof

PendingCN111102173AFirmly connectedImprove vacuum sealing performancePositive displacement pump componentsPump controlAutomatic controlControl cell

The invention discloses a vacuum air inlet system and an air inlet control method thereof. The vacuum air inlet system comprises an air supply unit, a transmission unit, a control unit and an air supply terminal, wherein the air supply unit comprises an air source, a manual stop valve, a pressure reducing valve and a corresponding connecting pipeline, and air enters the transmission unit from theair source through the manual stop valve and through adjusting corresponding pressure by the pressure reducing valve; the transmission unit comprises a transmission pipe, an insulating sleeve, a filter and a pneumatic valve; the control adjusting unit comprises a pressure reducing valve, an electromagnetic valve, a flow collector and a controller; and the air supply terminal comprises a vacuum adapter, a vacuum angle valve and a vacuum joint. The system is simple in composition and convenient to mount and dismount, and complex electronic instruments are not needed. A user can select an air source by himself or herself according to needs, and adaptability is high. The system is safe, stable and reliable in work, good in vacuum sealing performance, automatic in control, convenient and simpleto operate and capable of achieving automatic safe air inlet at any time.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

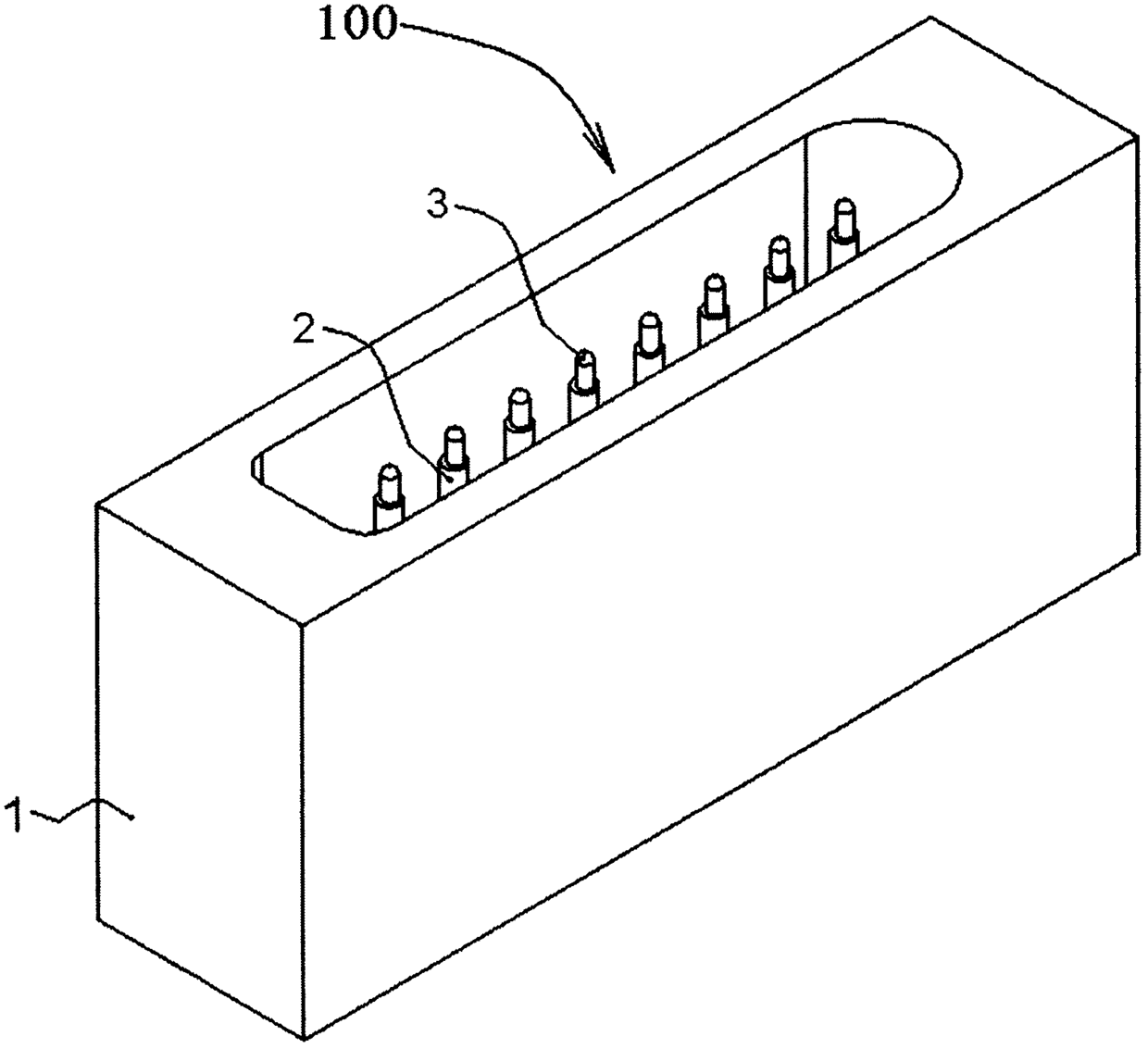

Socket connectors, plug connectors and connector assemblies

PendingCN109216991AImprove vacuum sealing performanceHigh Voltage Insulation PropertiesSecuring/insulating coupling contact membersCouplings bases/casesEngineeringMetallic materials

The invention discloses a socket connector, a plug connector and a connector assembly. The socket connector comprises a housing made of a metal material, and a first through hole is formed in the housing; A ceramic insulator comprising a base fixed in a first through hole and sealingly connected to a housing, and one or more bosses provided with a plurality of second through holes in the base, thebosses extending in an axial direction from at least one side of both sides of the base, each boss provided with an auxiliary through hole communicating with the second through hole; And a pluralityof conductive terminals respectively passing through the second through-hole and the auxiliary through-hole and sealingly mounted to the ceramic insulator.

Owner:NUCTECH CO LTD +1

Lead-free solder for sealing quartz glass

ActiveCN109822257ASimple sealing processImprove vacuum sealing performanceWelding/cutting media/materialsSoldering mediaTitaniumPrimary component

The invention discloses lead-free solder for sealing quartz glass. A matrix of the lead-free solder is tin, and the atomic percent of introduced Ti and O is a follows: 0.2-6% of Ti and 0.05-5.9% of O.The atom ratio of Ti and O is greater than 1, and the mass percent of impurities in the lead-free solder is smaller than or equal to 0.1%. The welding temperature range of the lead-free solder is 600-800 DEG C, and the welding vacuum degree is smaller than or equal to 5*10<-3>Pa. In a quartz glass sealing process, scaling powder is not needed for the lead-free solder for sealing quartz glass, sothat the quartz glass sealing process is simplified and the vacuum sealing reliability of quartz glass sealing is improved. The lead-free solder can be widely applied to quartz glass sealing and can be also applied to welding quartz glass, glass, the softening temperature of which is not lower than 800 DEG C, taking SiO2 as a primary component, a titanium material, metals with titanium plating onthe surface and the like. The lead-free solder is in particular suitable for preparing a pulse xenon lamp, so that the service life of the pulse xenon lamp can be prolonged obviously and the working reliability of the pulse xenon lamp can be improved obviously.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com