Energy-saving vacuum tempering glass and manufacturing technology thereof

A technology of energy-saving glass and tempered glass, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of high cost and hurt people, and achieve low cost, good vacuum sealing effect, and high strength big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

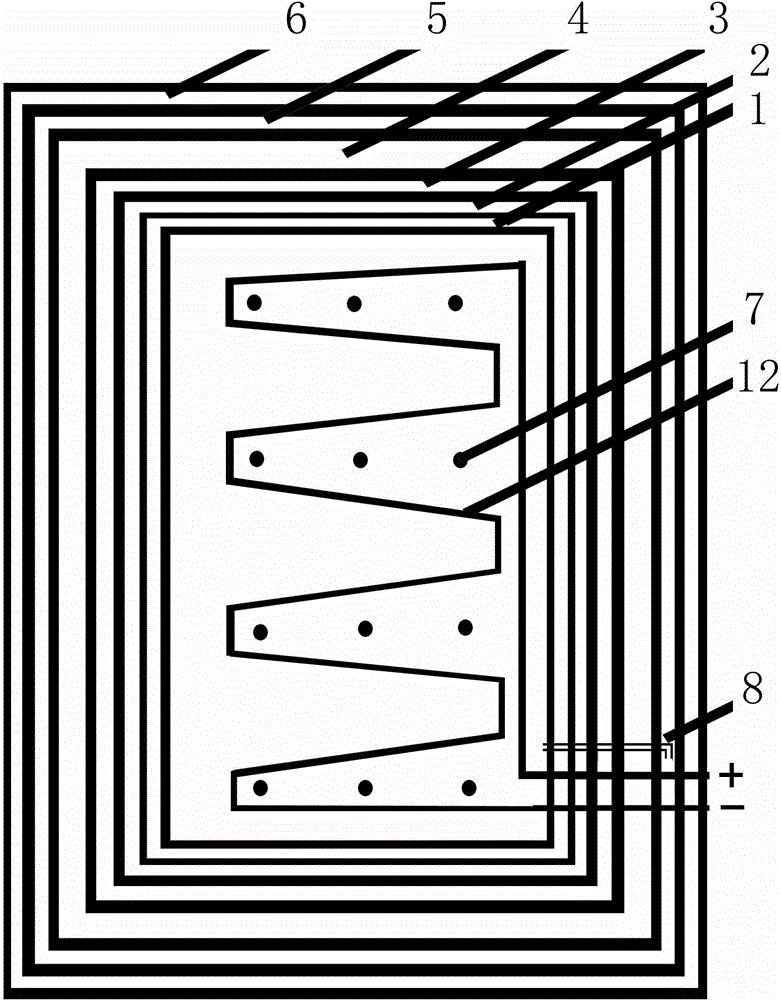

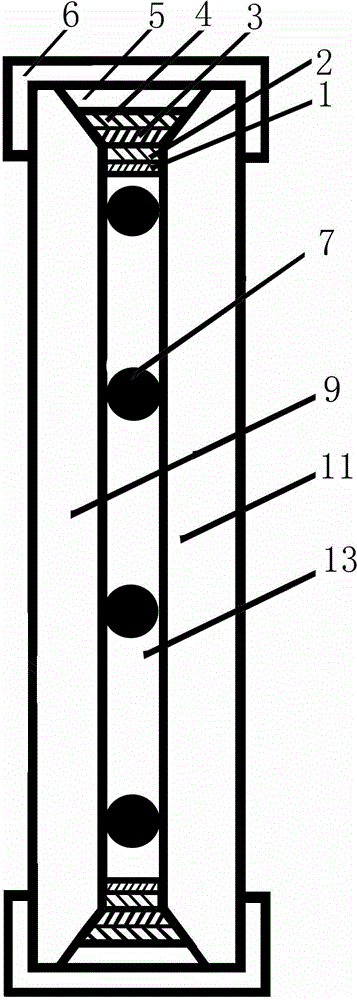

[0034] Such as figure 1 and figure 2 As shown, the present invention is a vacuum tempered energy-saving glass, including glass, and the glass referred to in the present invention is tempered glass. Specifically, a vacuum layer A13 is provided between the front glass 9 and the back glass 11 with chamfered end faces, and a flexible protective glue 5 and a low-temperature glass are sequentially provided on the inside of the front glass 9 and the back glass 11. powder 4, high temperature vacuum glass glue 3, vacuum mud 2, protective layer 1; support beads 7 are arranged in the vacuum layer A13; at least one layer of resistance wire 12 is arranged on the inner surface of the front glass 9 and the back glass 11, The switch of the resistance wire 12 is drawn out of the tempered glass, and the tempered glass layer can be selected to be heated at any time. The end faces of the front glass 9 and the back glass 11 are provided with a plastic protective strip 6; the end faces of the fr...

Embodiment 2

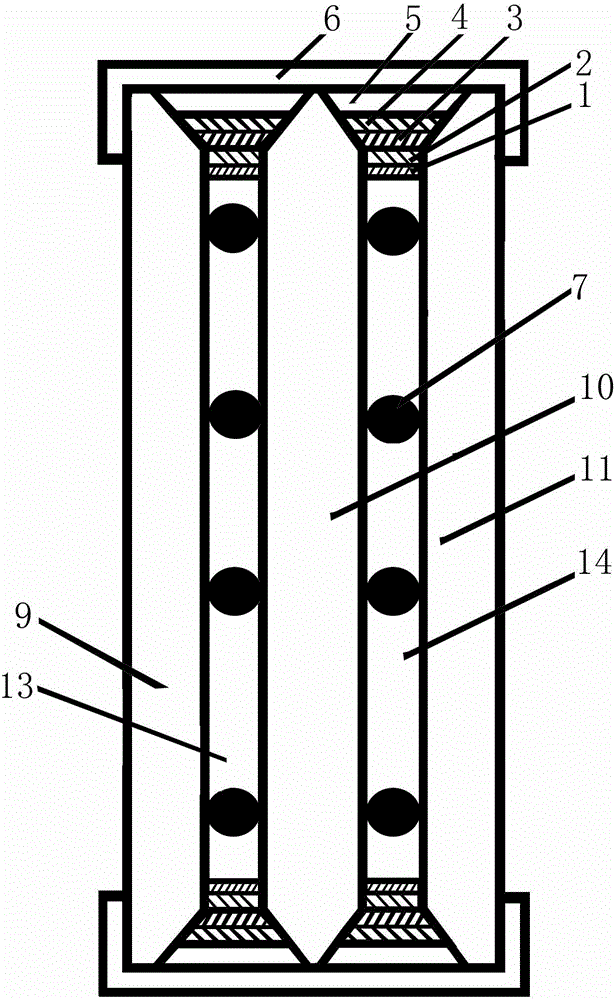

[0044] Such as image 3 As shown, the present invention is a vacuum tempered energy-saving glass, vacuum tempered energy-saving glass, including glass, and the glass referred to in the present invention is tempered glass. Described glass is provided with three layers, is respectively at front sheet glass 9, middle glass 10 and back sheet glass 11; There is a vacuum layer B14 between them. Twelve support beads 7 are arranged in the vacuum layer A13 and the vacuum layer B14.

[0045] Both the end faces of the front glass 9 and the middle glass 10 have chamfers, and the end faces of the middle glass 10 both sides are provided with chamfers. A vacuum nozzle 8 is provided on the end faces of the front glass 9 and the back glass 11, and the inward end of the vacuum nozzle 8 is connected to the vacuum layer A13; Vacuum nozzle, the inward end of the vacuum nozzle 8 is connected to the vacuum layer B14; the inner layer of the front glass 9 is also compounded with a transparent explo...

Embodiment 3

[0055] The supporting beads 7 in the present invention are at least provided with more than one during specific implementation, and can be set as 4, 6, 8, 12, 16, 20, 25, 30...all can be, other same Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com