Patents

Literature

42results about How to "Guaranteed vacuum tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

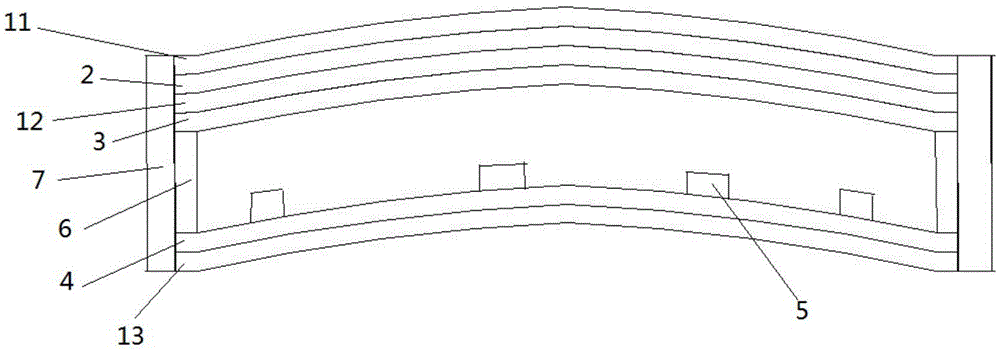

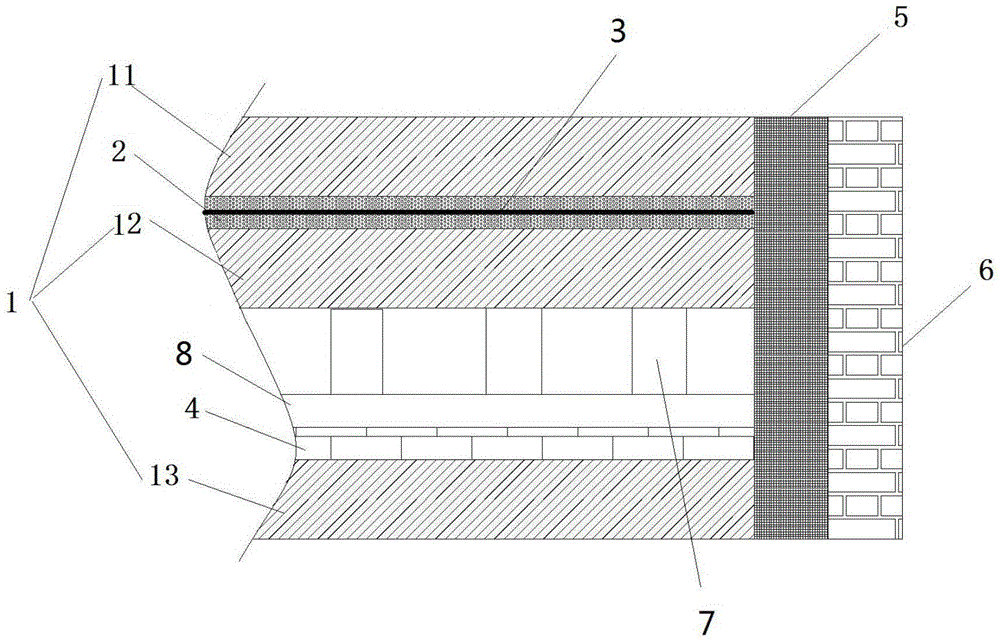

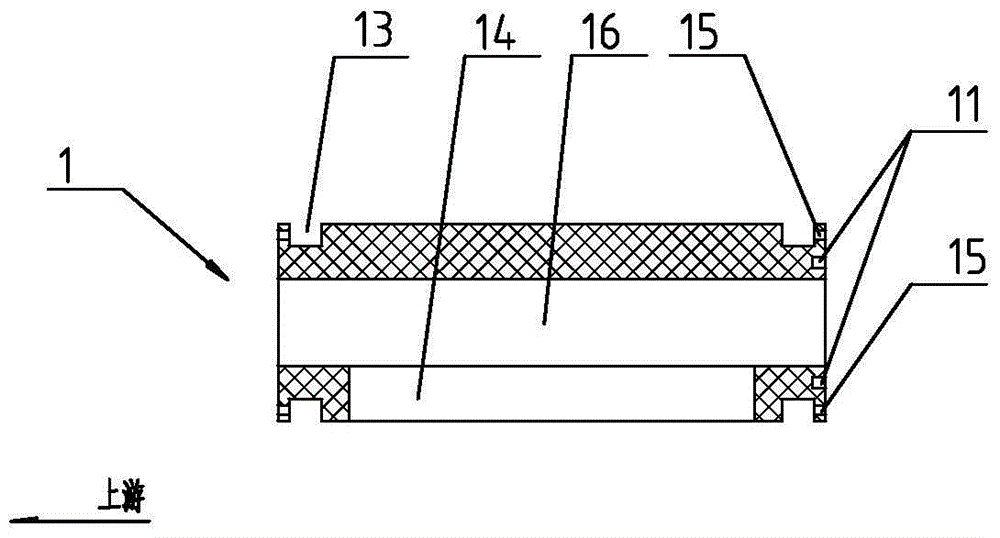

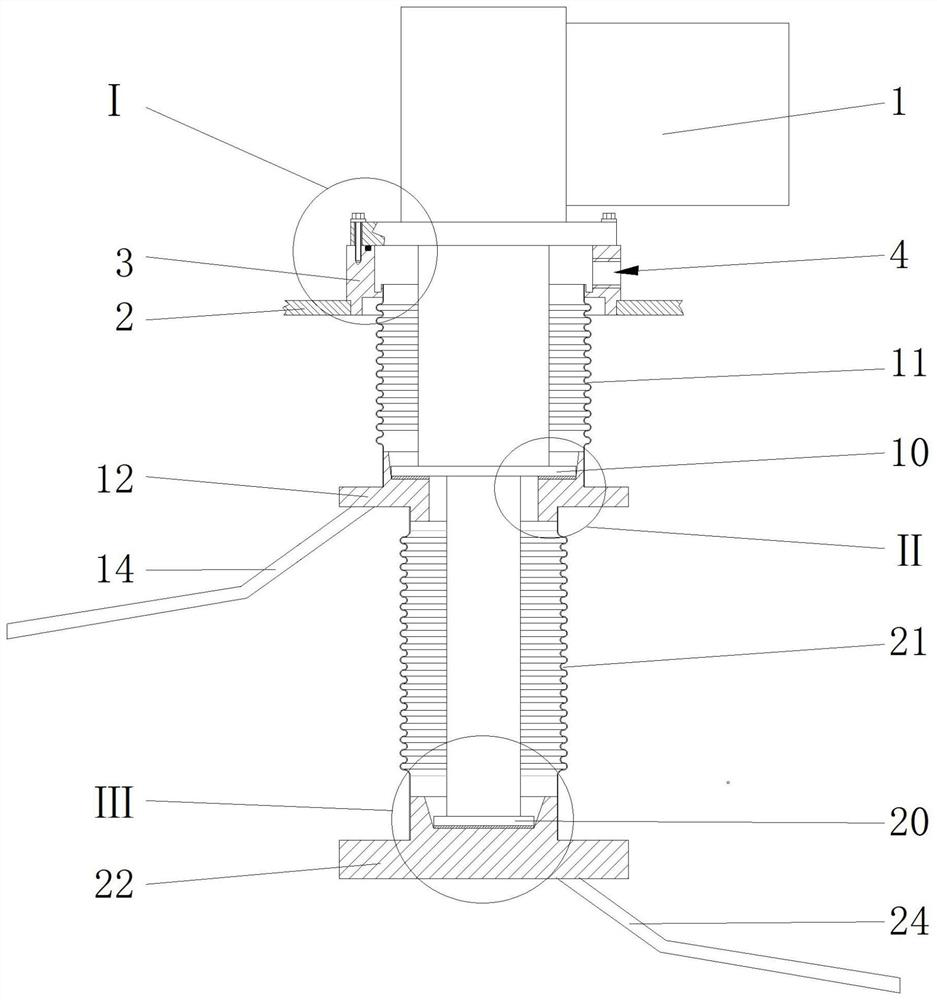

Refrigerating machine jacket structure for superconduction magnet and installation and disassembly method of refrigerating machine jacket structure

ActiveCN106960713AGuaranteed vacuum tightnessGuaranteed conduction heat leakageSuperconducting magnets/coilsFlangeMagnet

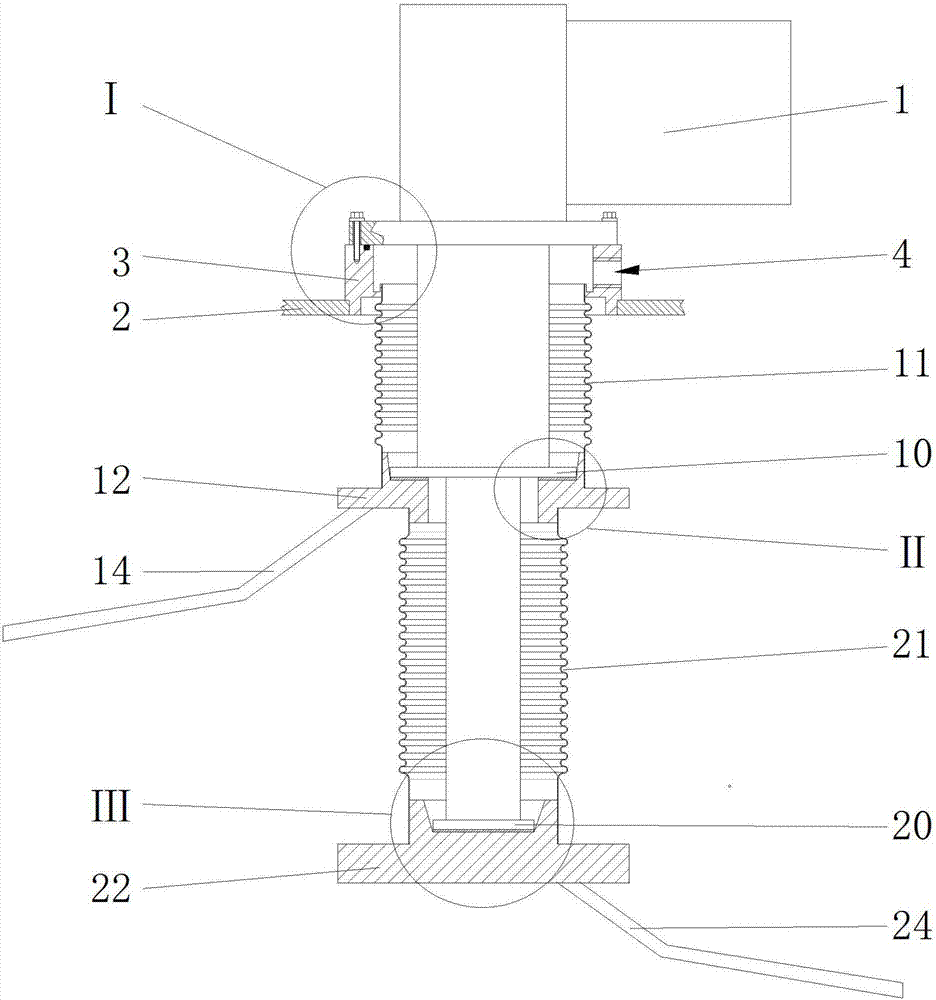

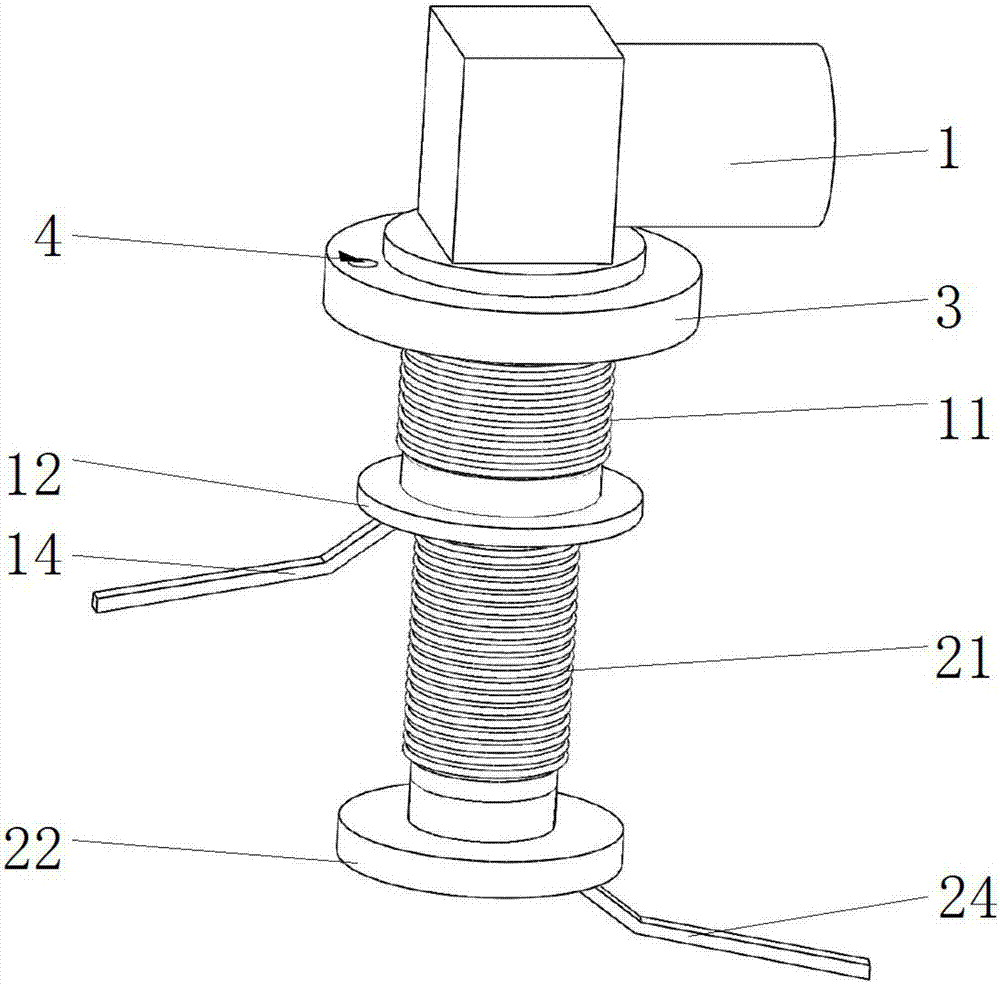

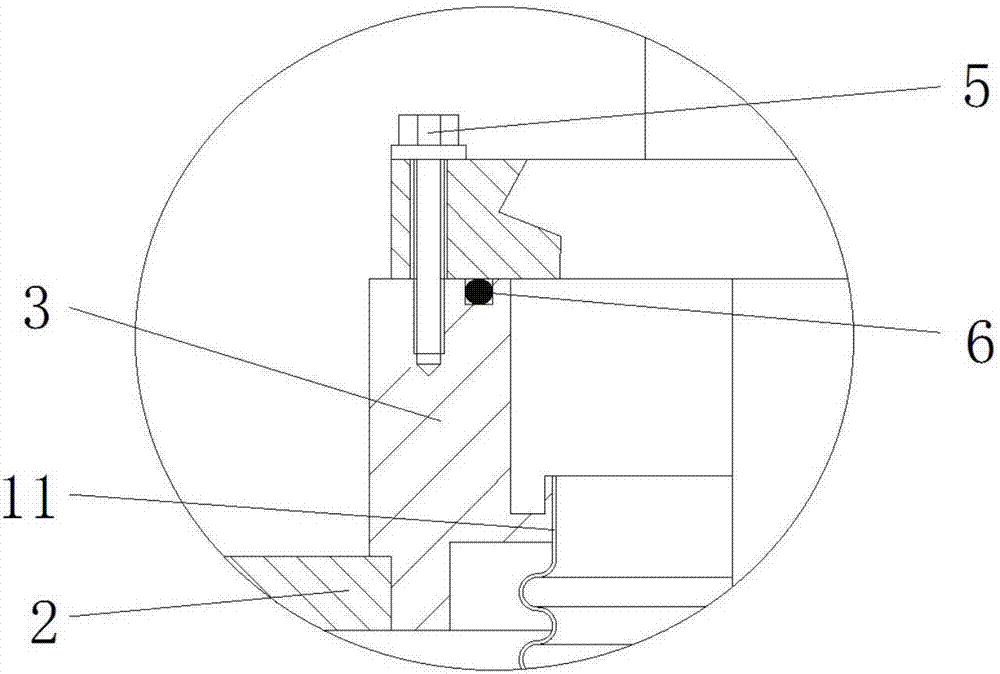

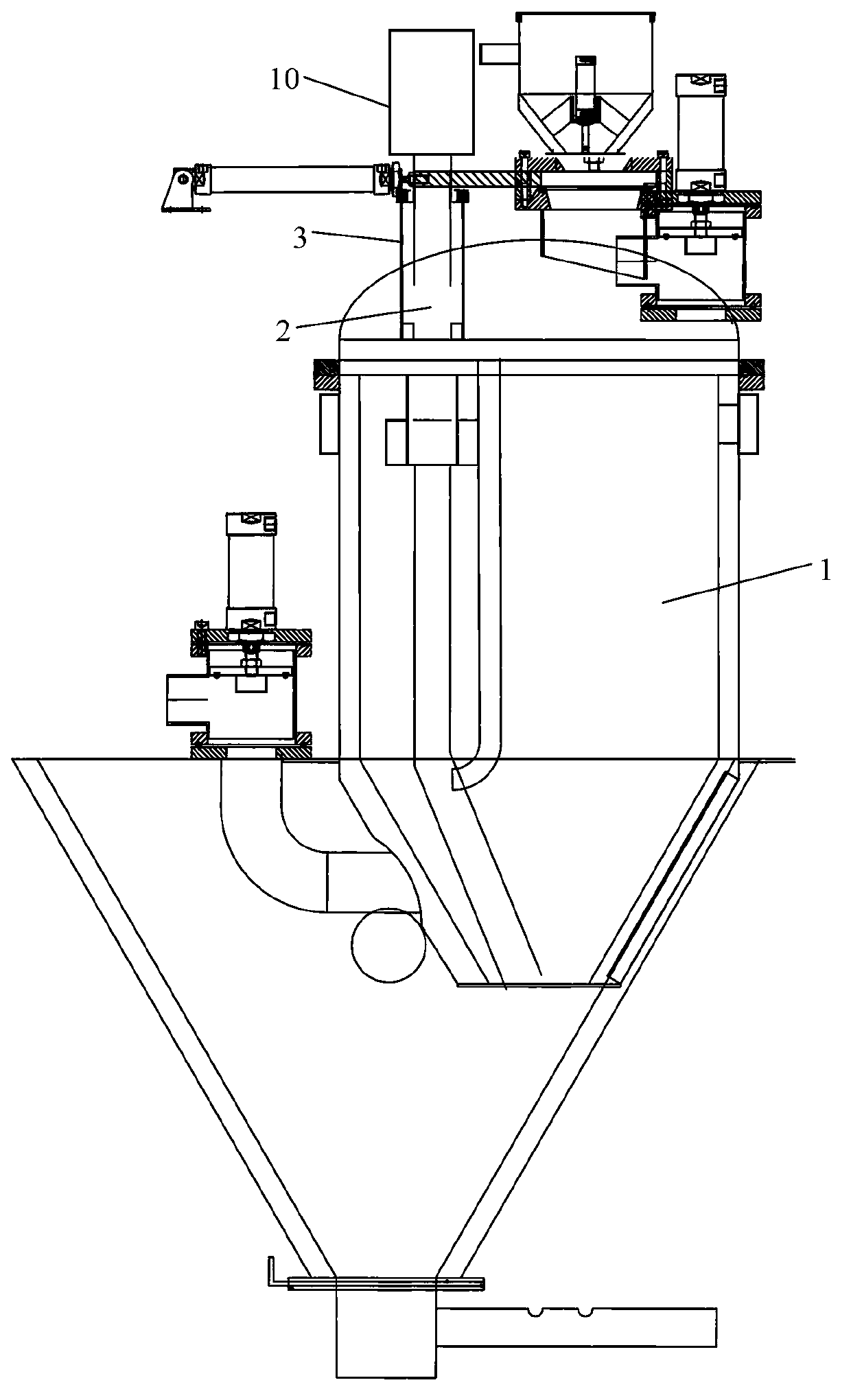

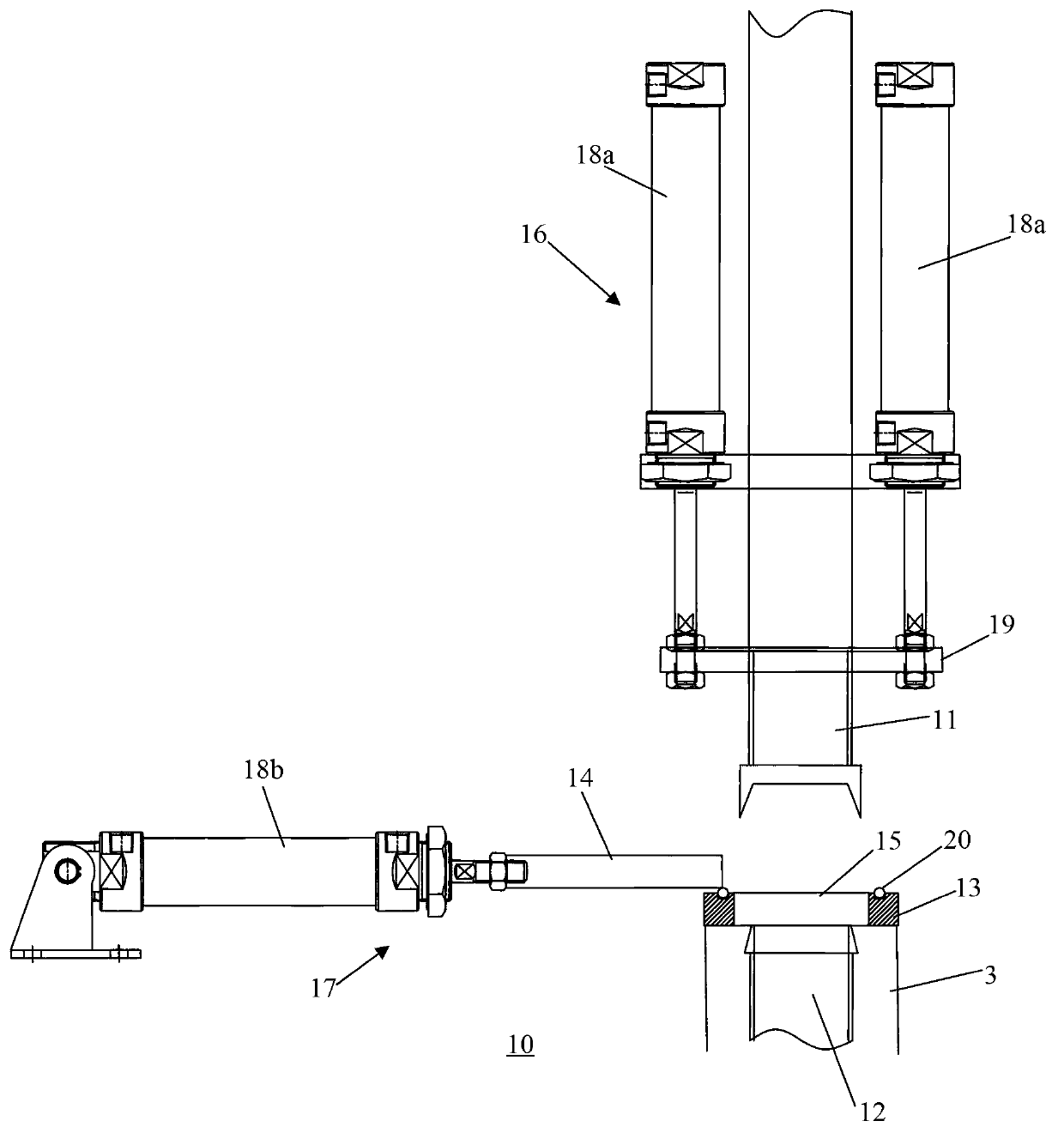

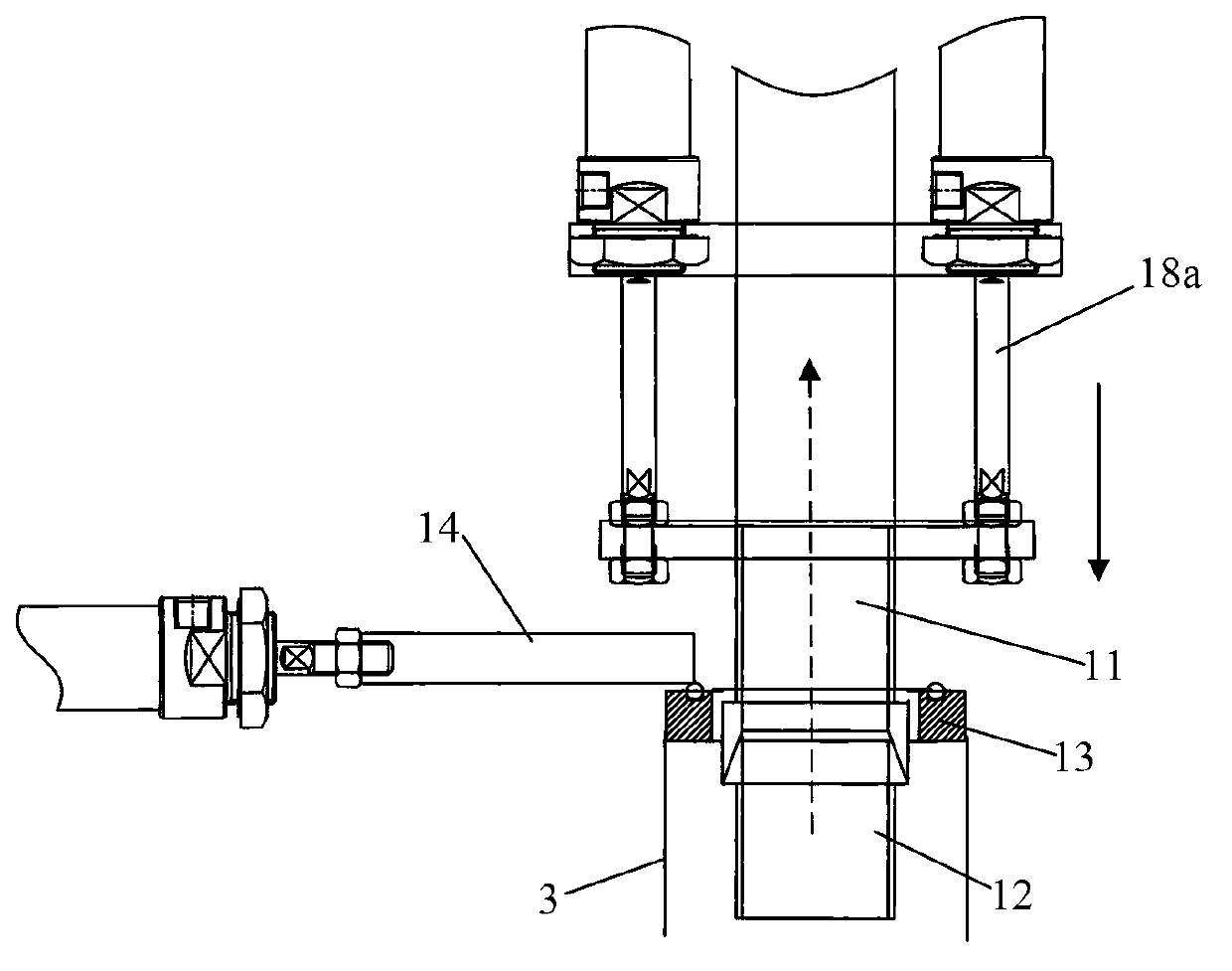

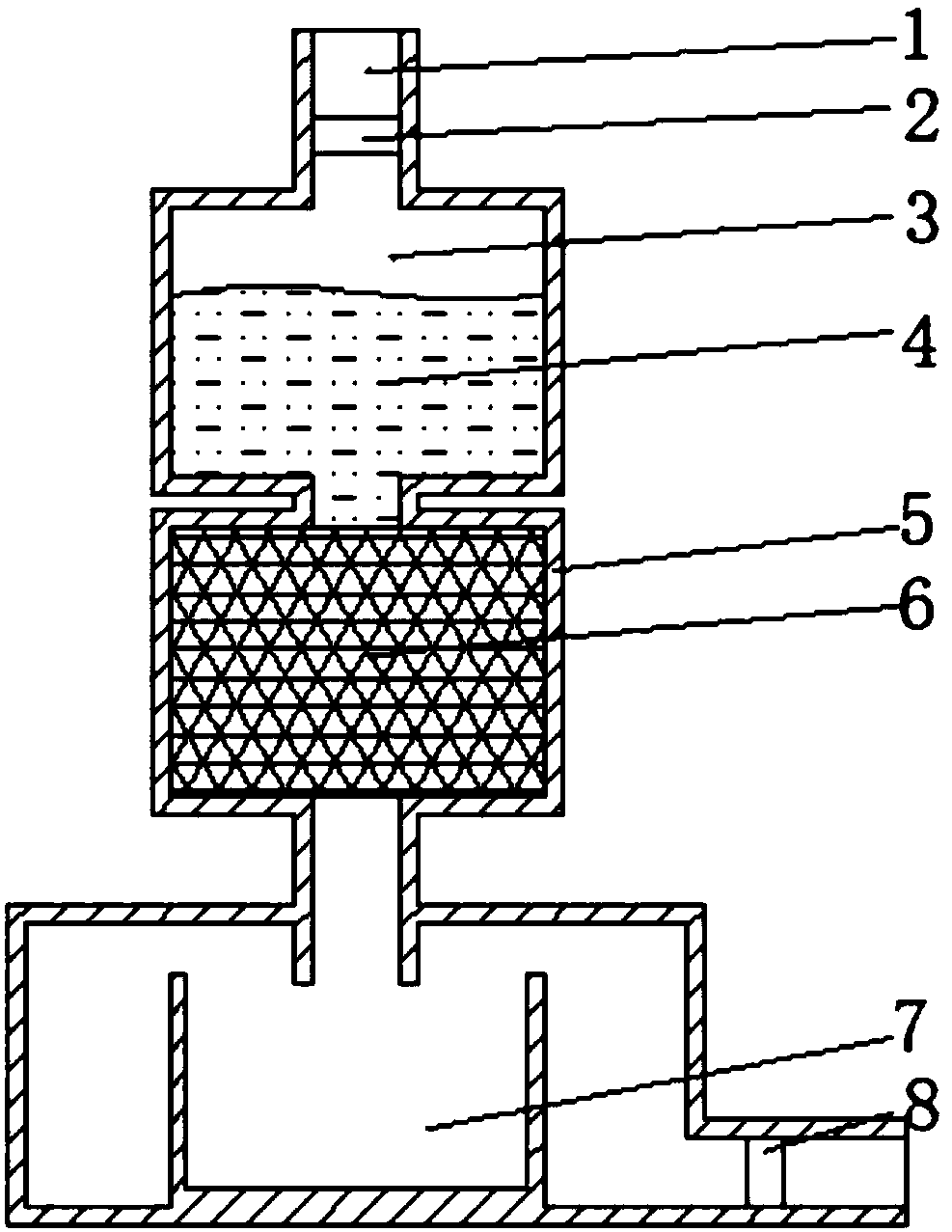

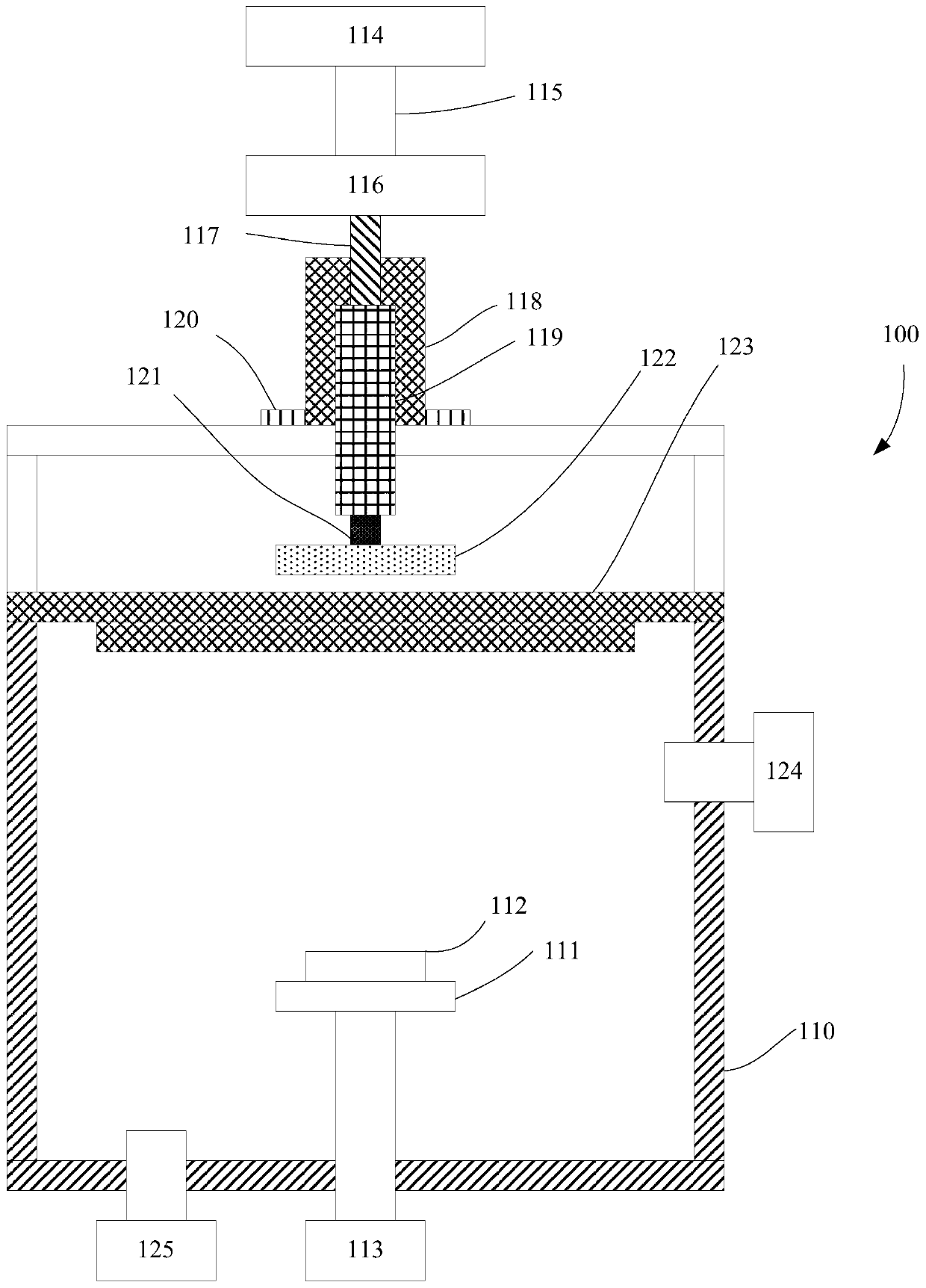

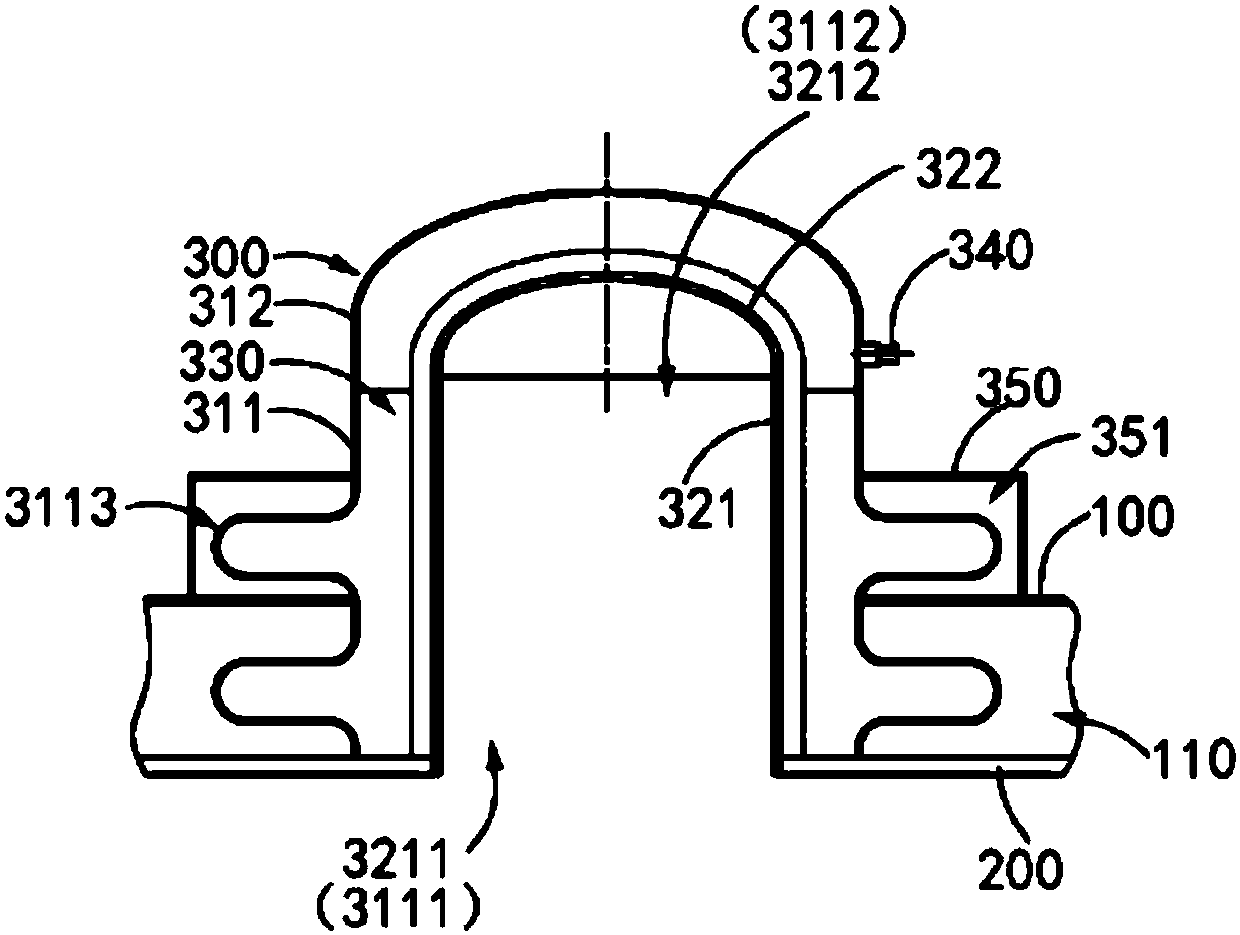

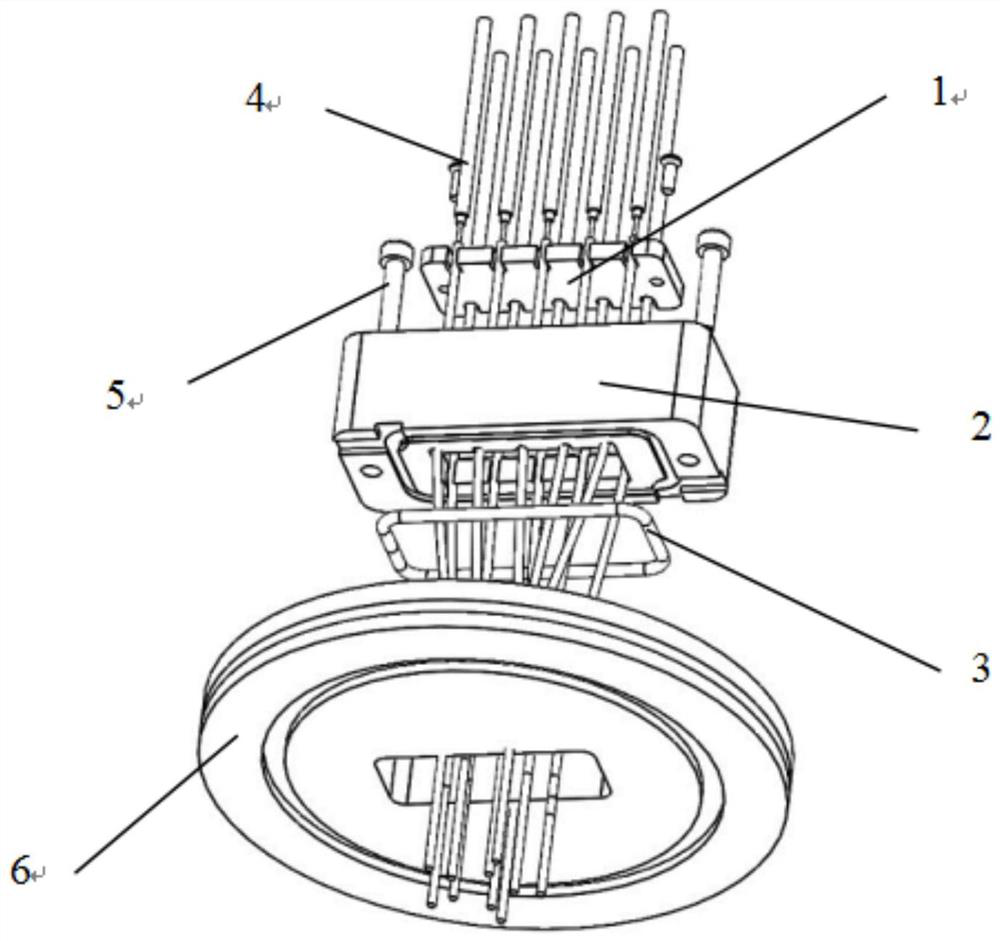

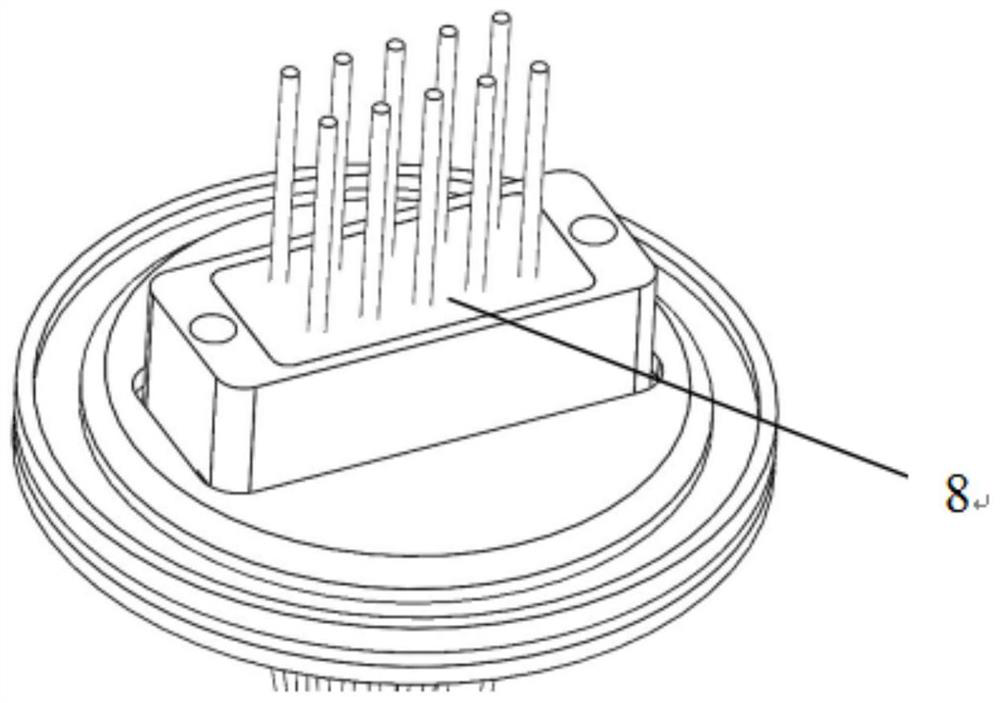

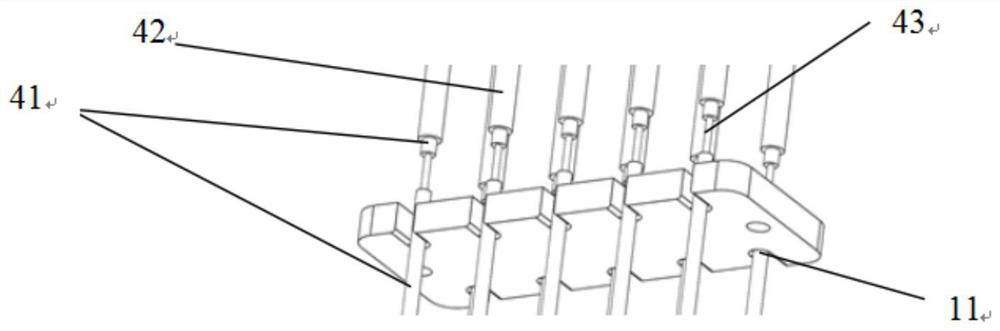

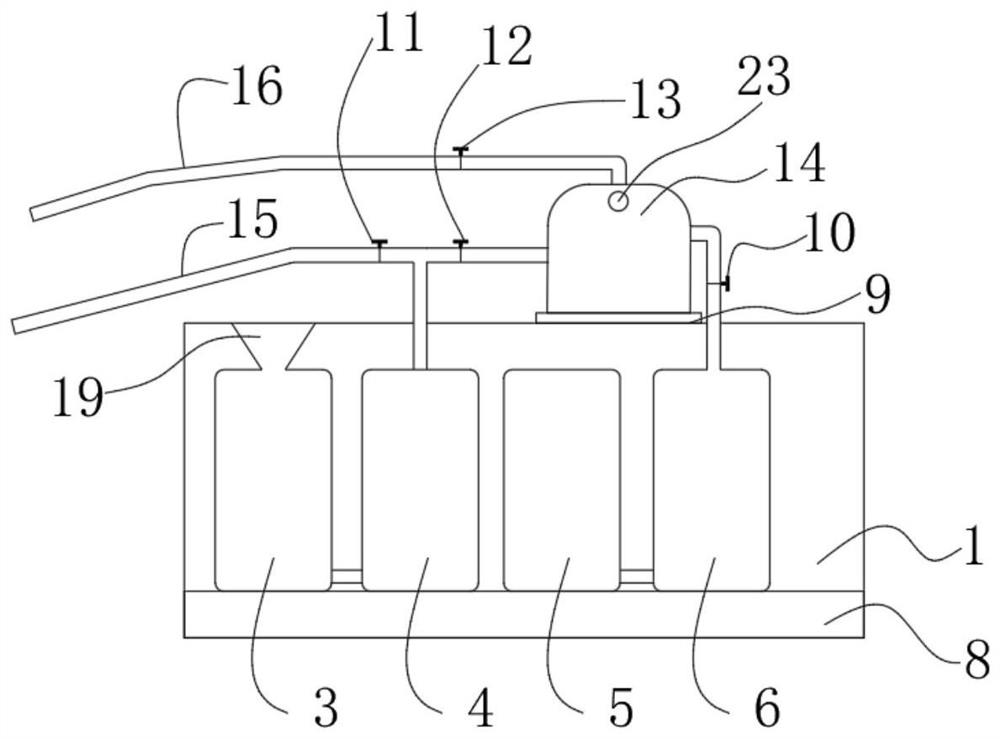

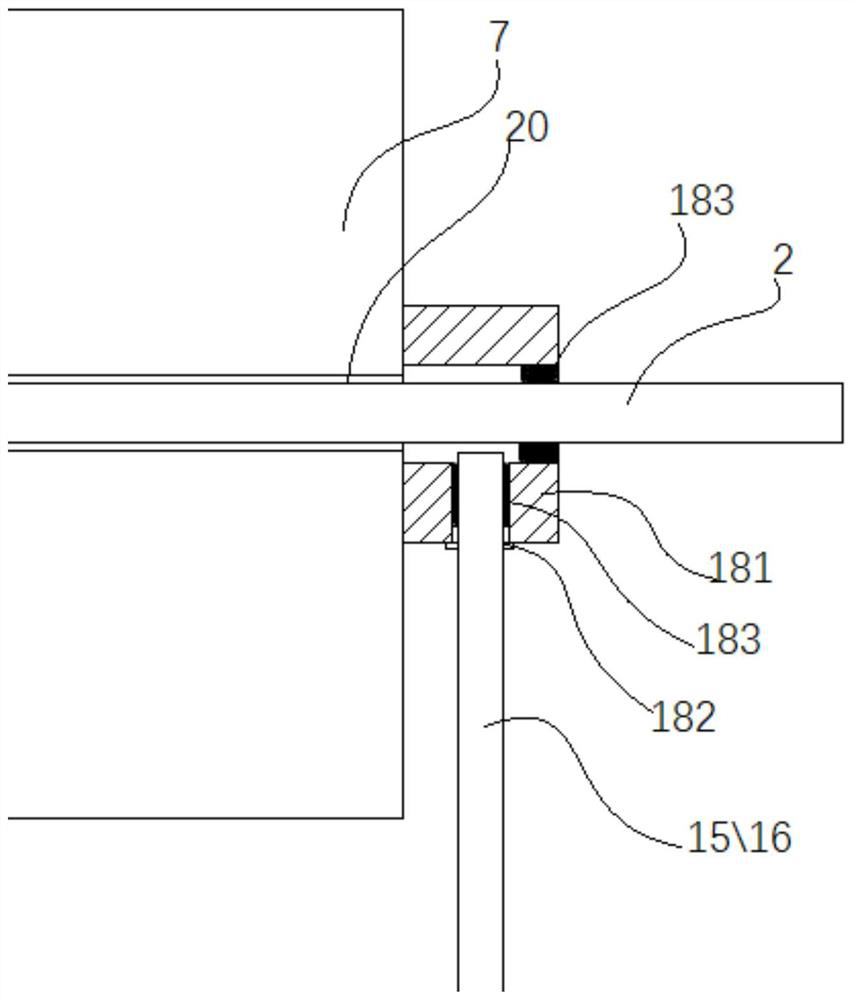

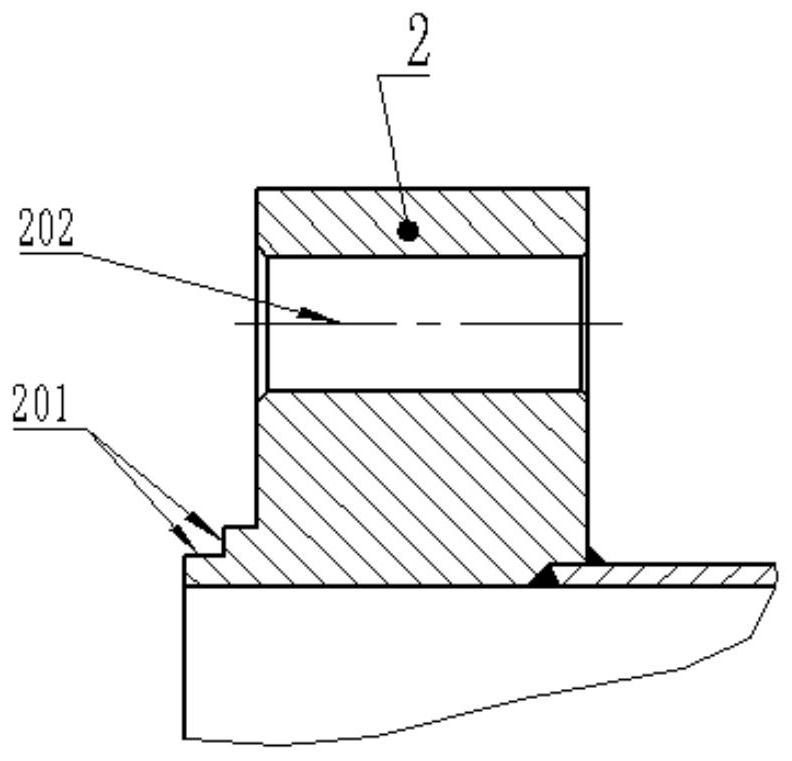

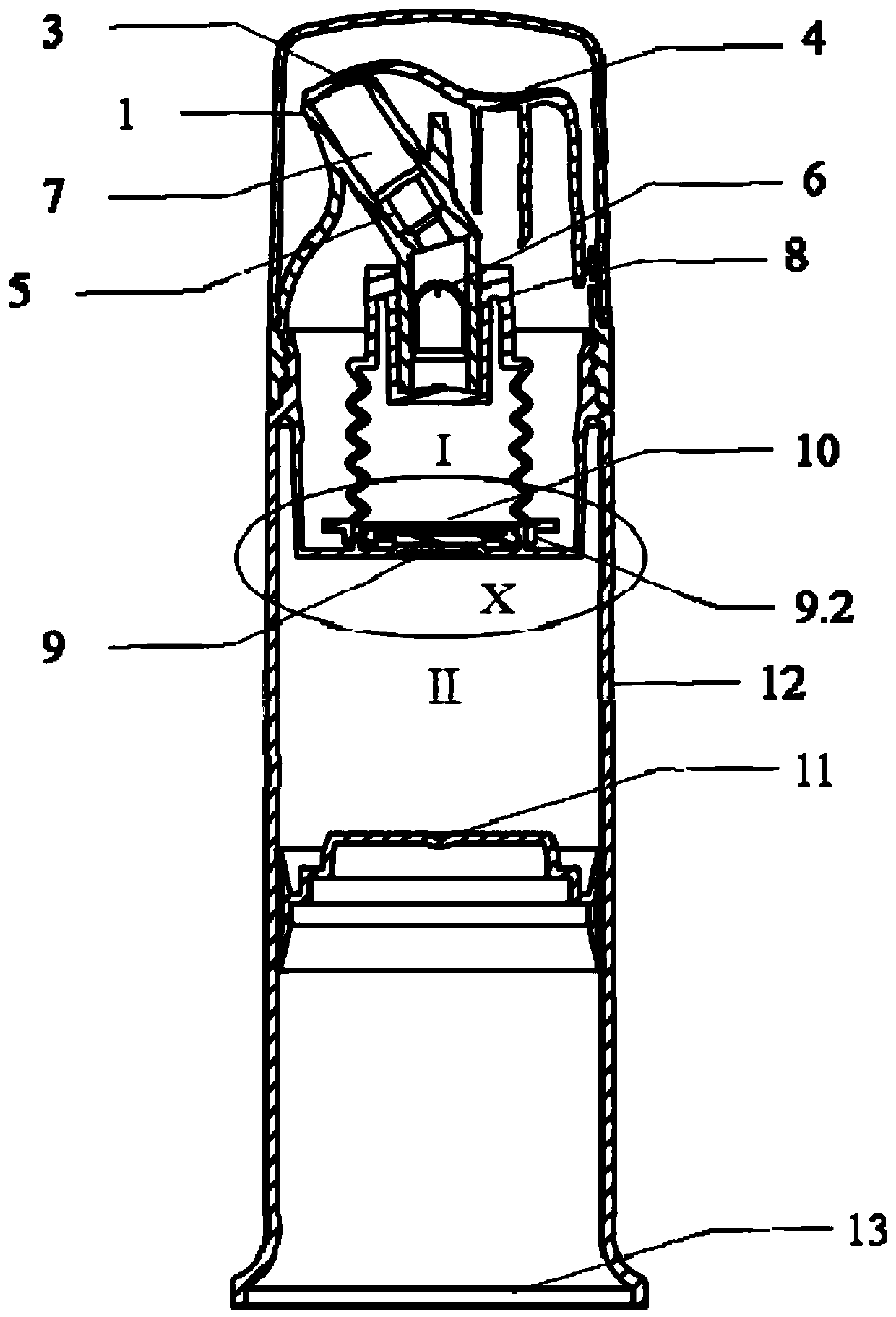

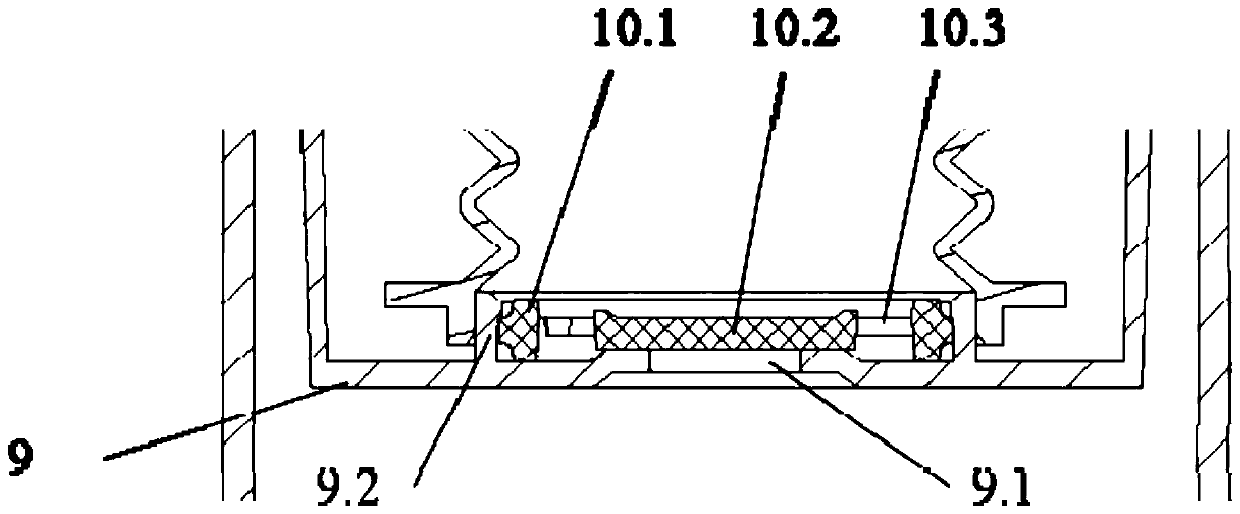

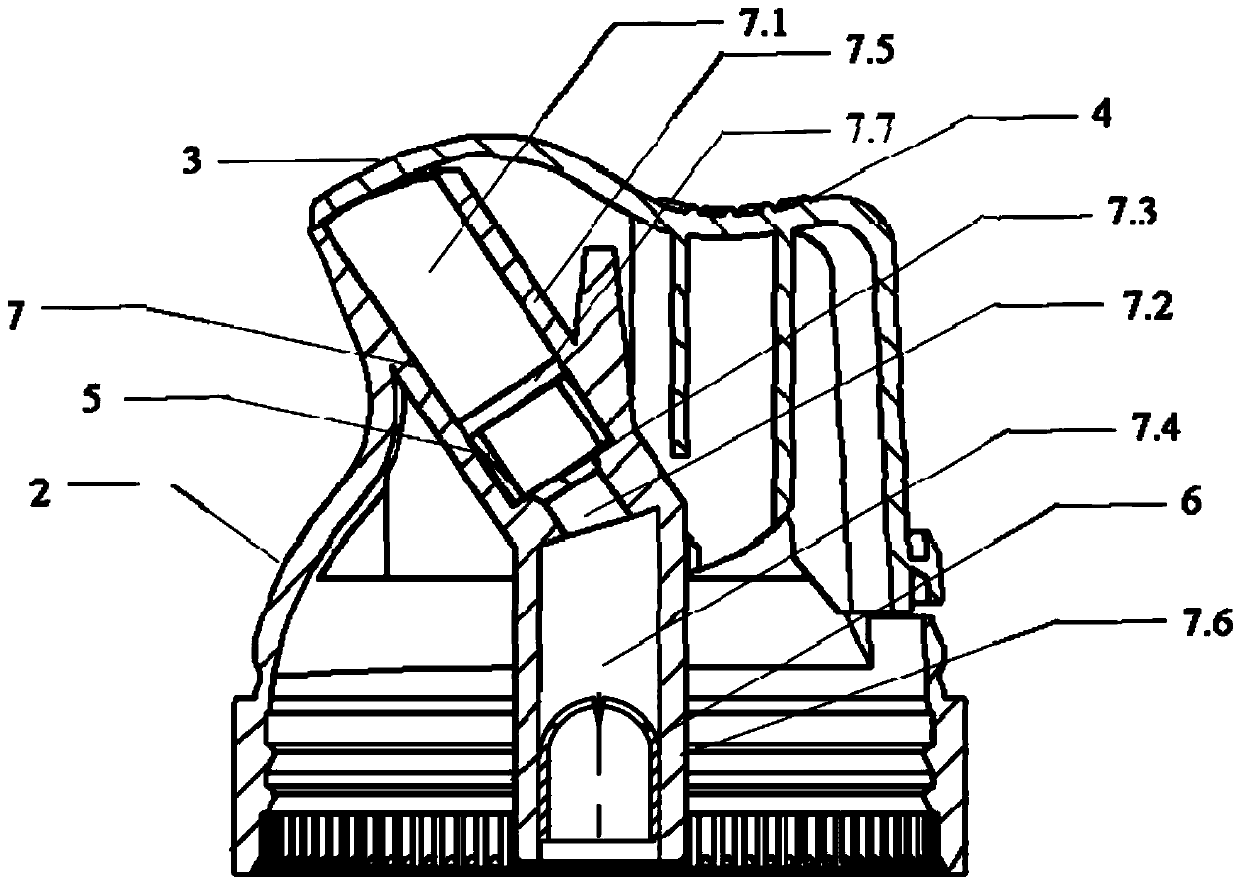

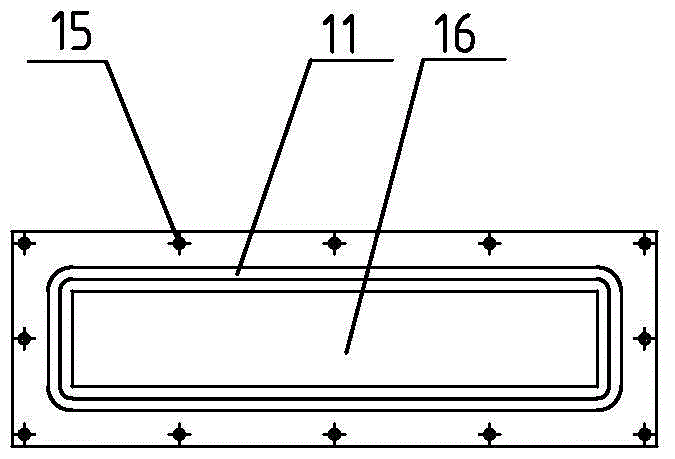

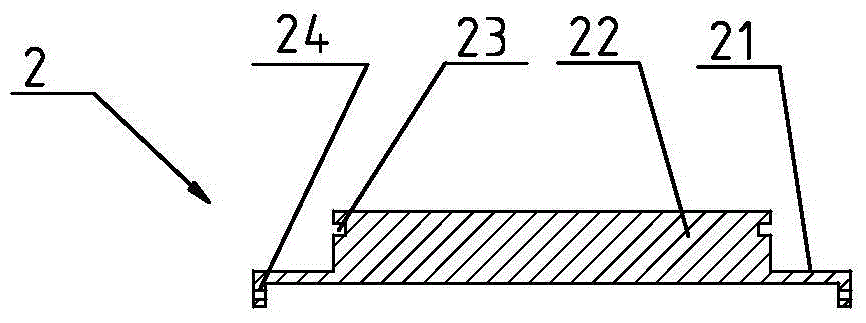

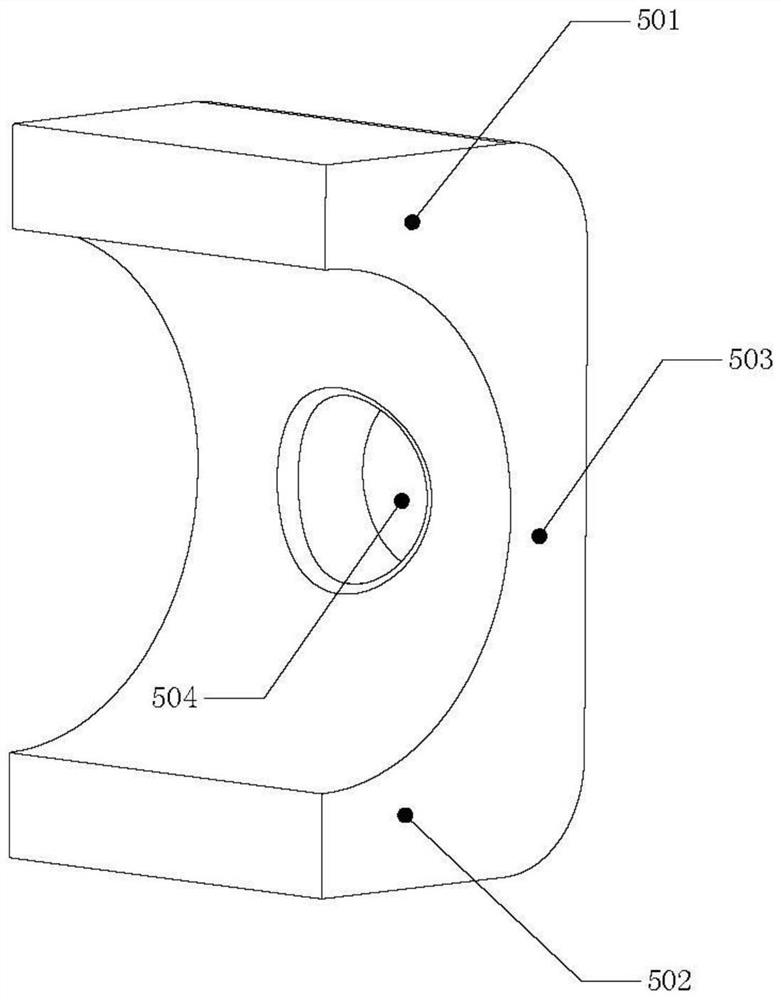

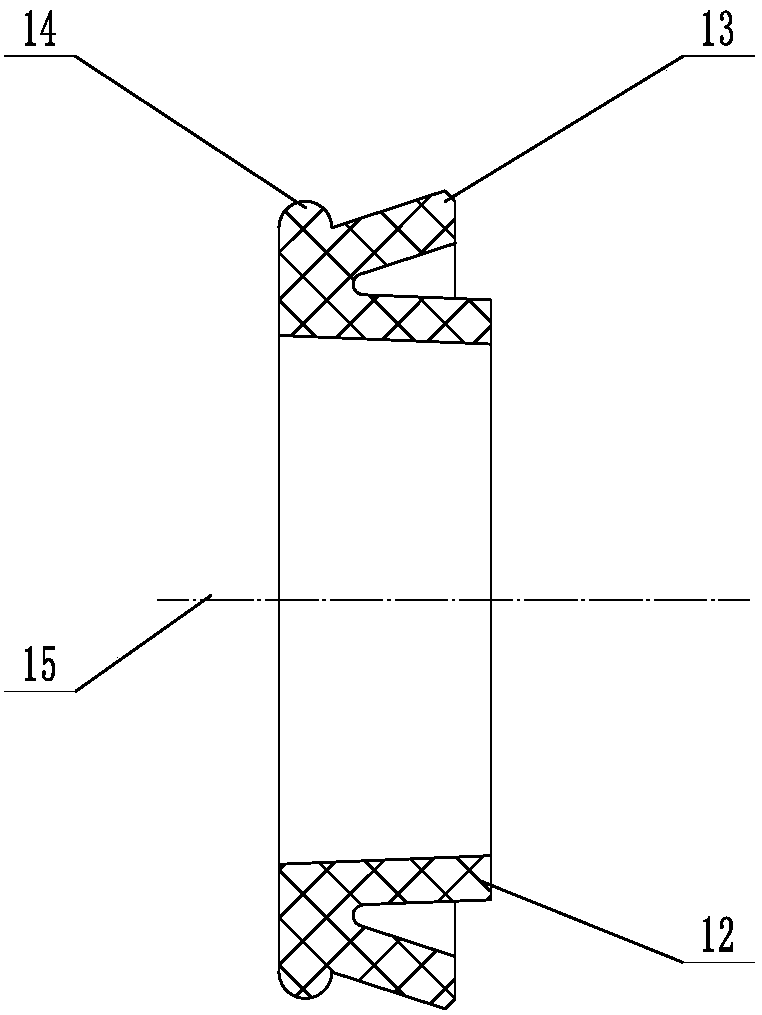

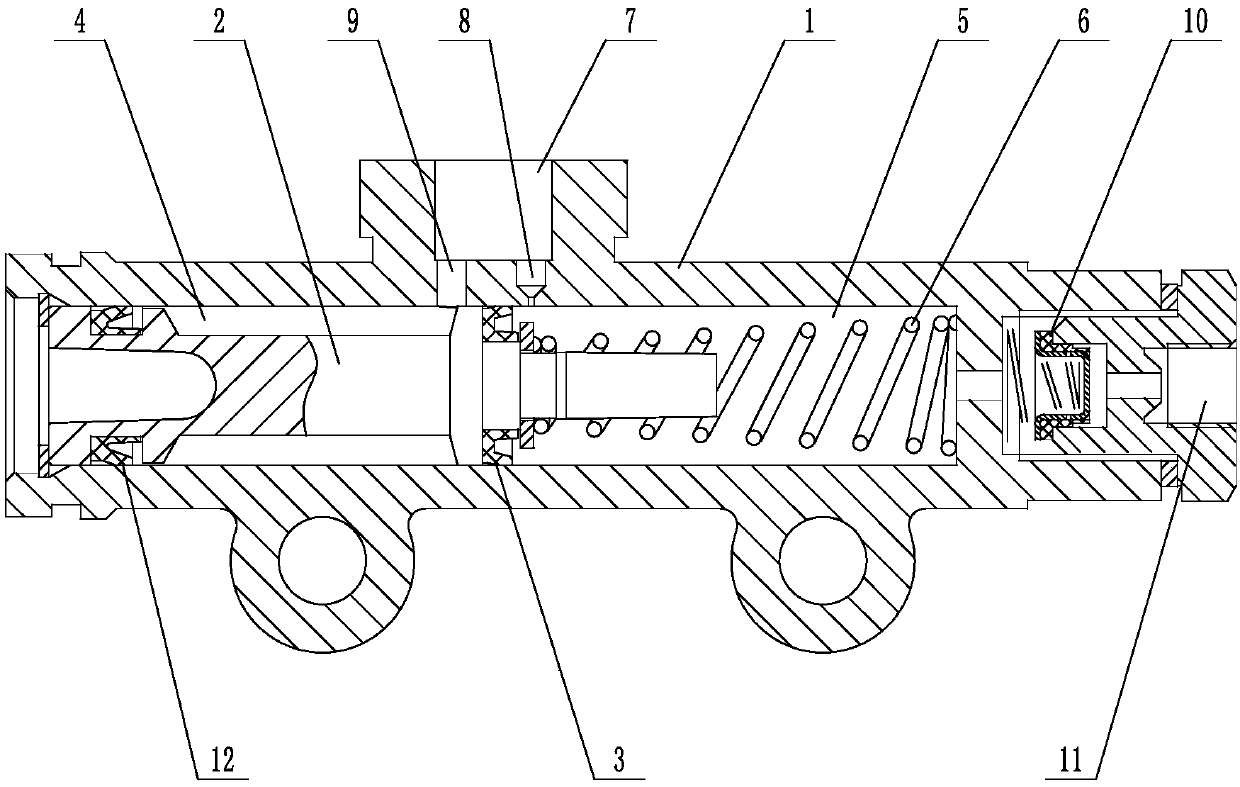

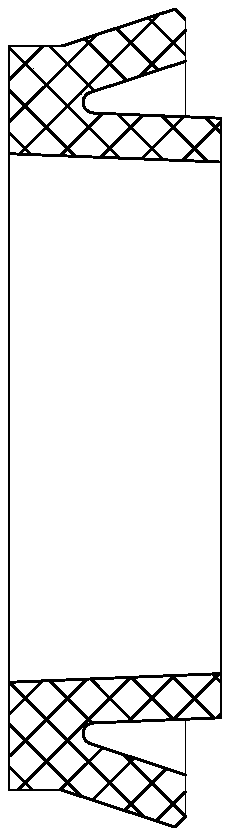

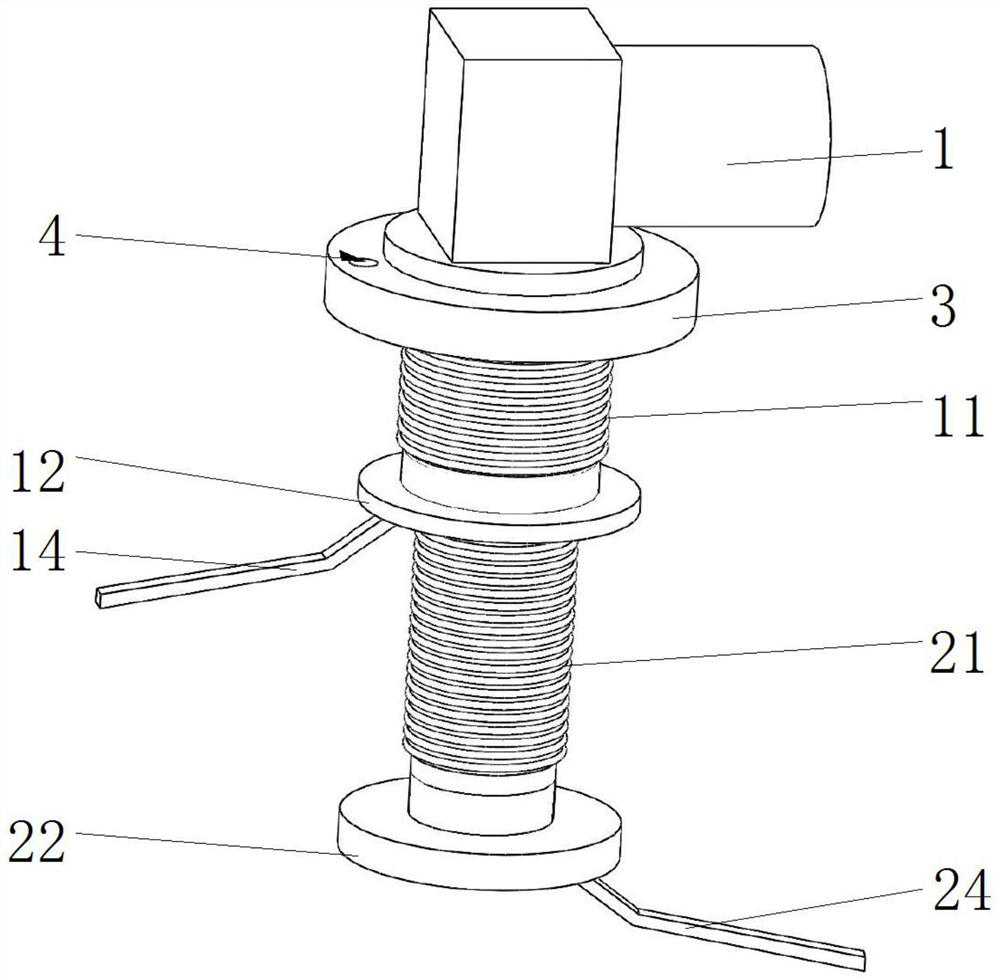

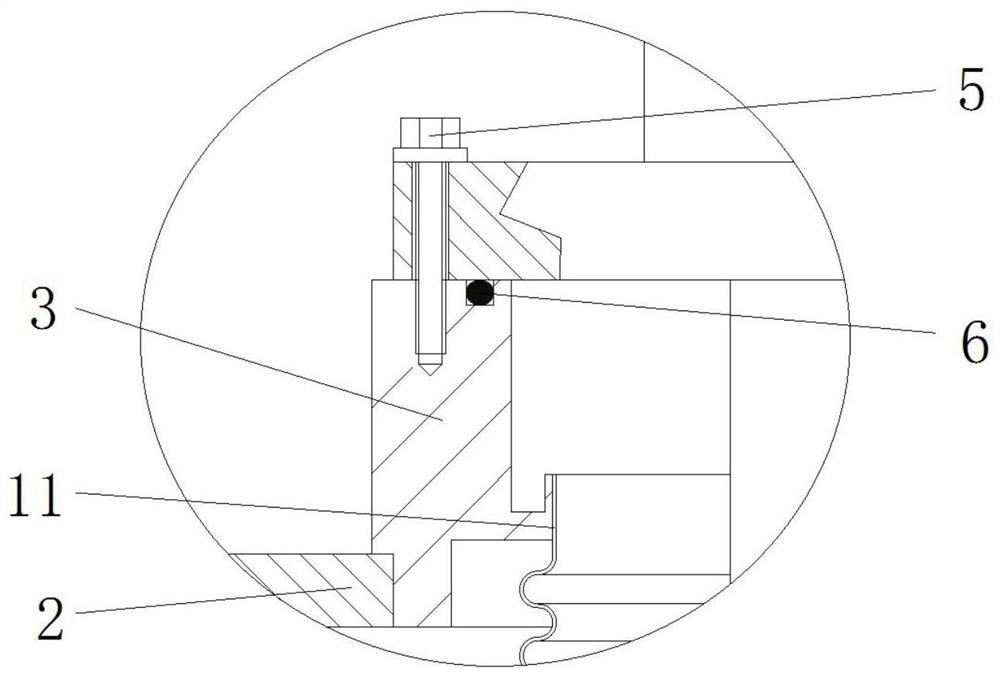

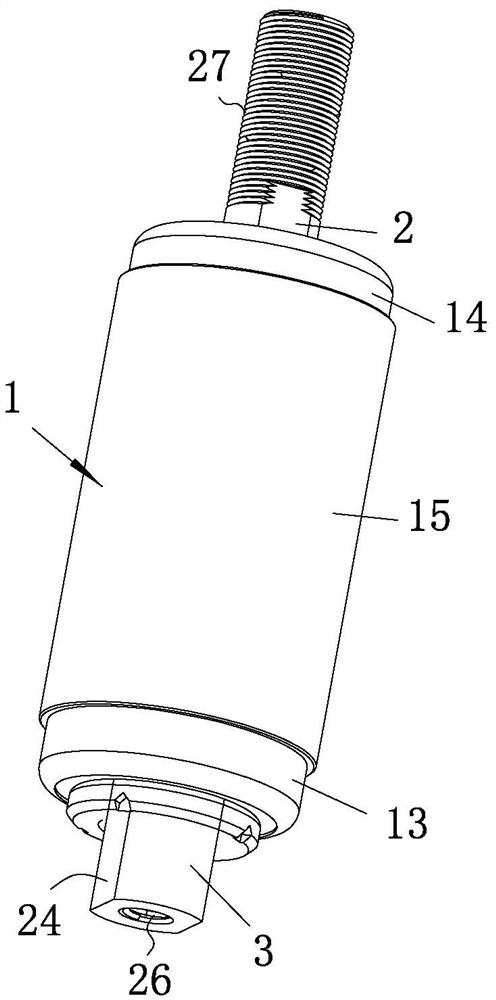

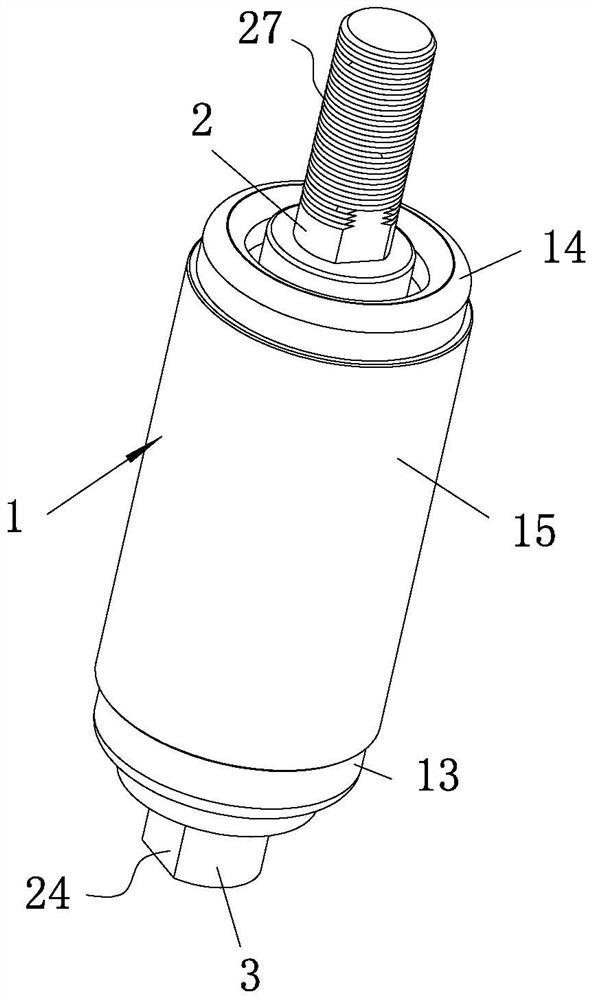

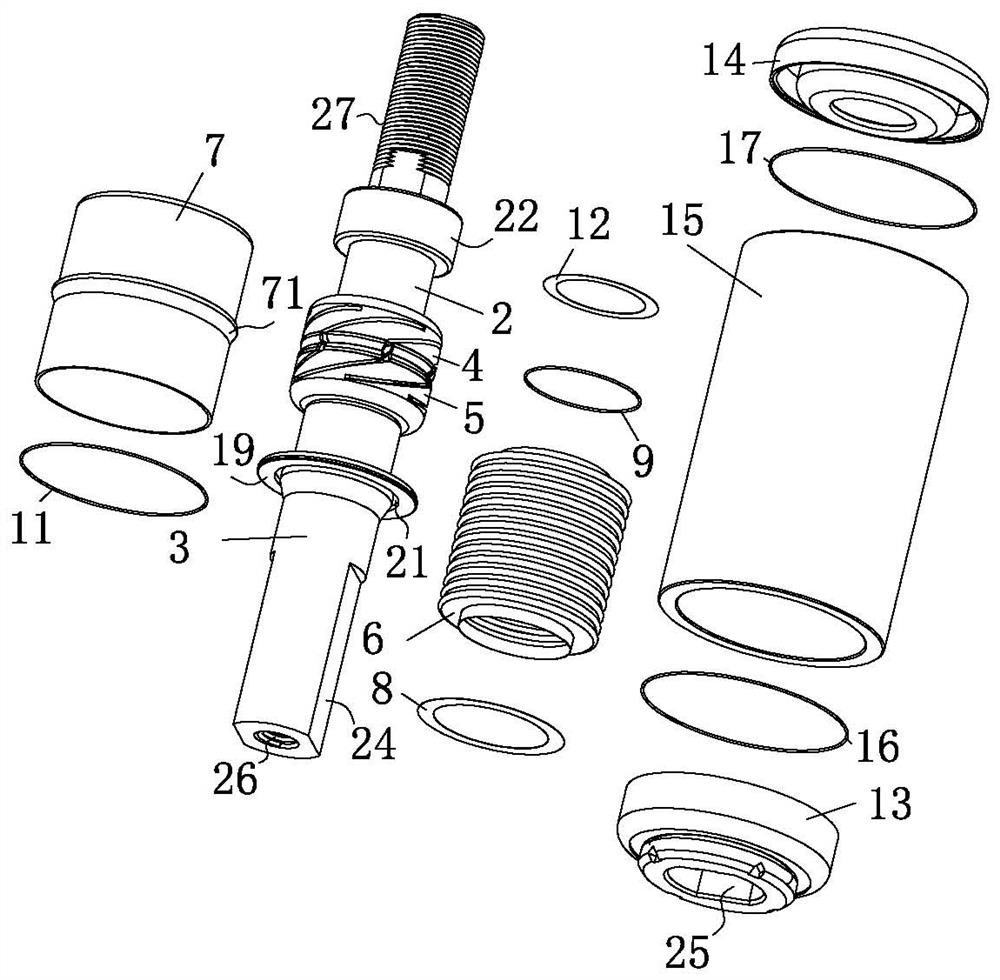

A refrigerating machine jacket structure for a superconduction magnet and an installation and disassembly method of the refrigerating machine jacket structure relate to the technical field of low-temperature engineering and superconduction magnets. The refrigerating machine jacket structure sequentially comprises a refrigerating machine flange seat (3), a primary corrugated pipe (11), a primary flange seat (12), a secondary corrugated pipe (21) and a secondary flange seat (22) from top to bottom, wherein thermal connection is formed between a cold screen and the primary flange seat 12), thermal connection is formed between a superconduction coil and the secondary flange seat (22), the refrigerating machine flange seat (3) and the primary flange seat (12) are connected by the primary corrugated pipe (11), and the primary flange seat (12) and the secondary flange seat (22) are connected by the secondary corrugated pipe (21). The refrigerating machine jacket structure has the characteristics of low conduction thermal leakage, high vacuum tightness, high thermal connection efficiency and long lifetime of a refrigerating machine.

Owner:杭州图锐科技有限公司

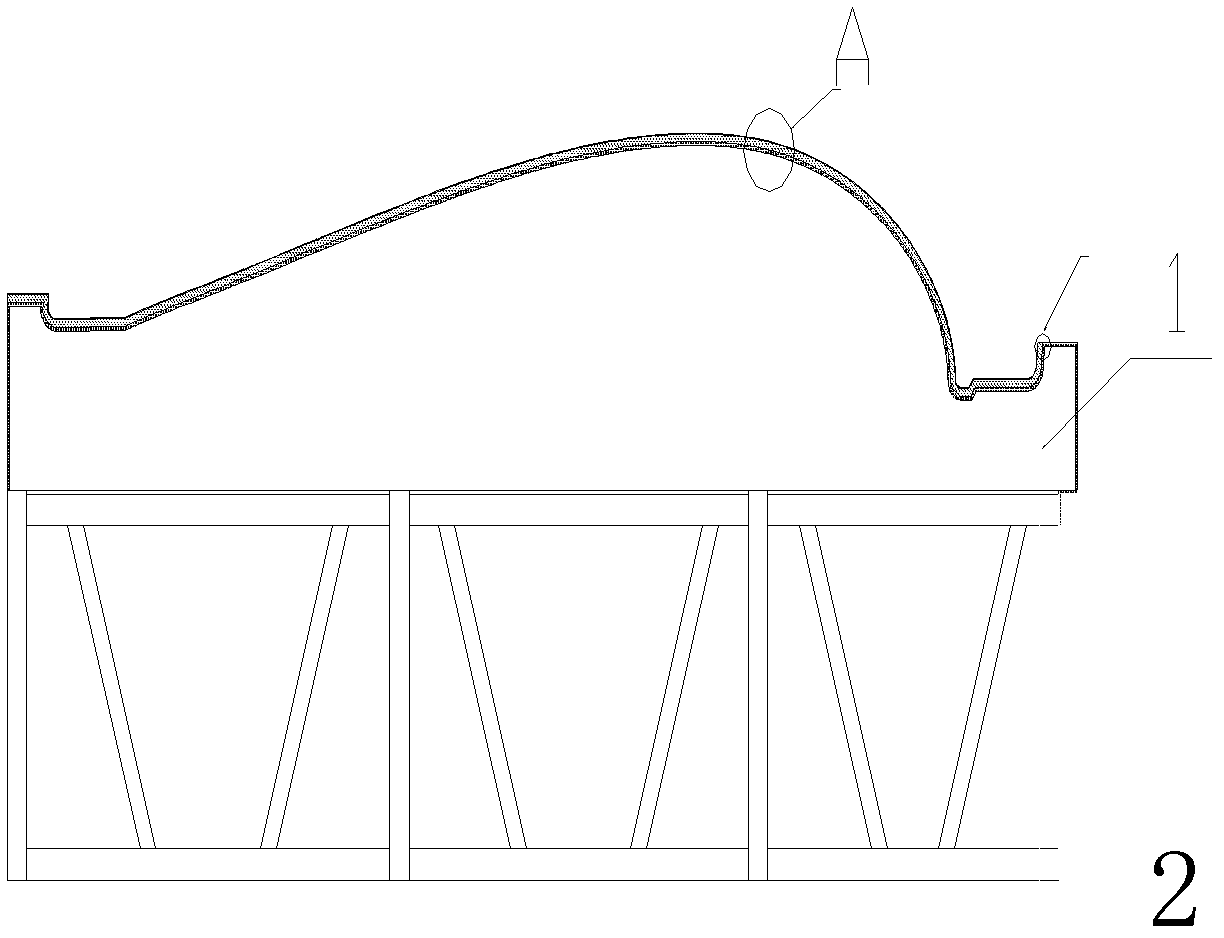

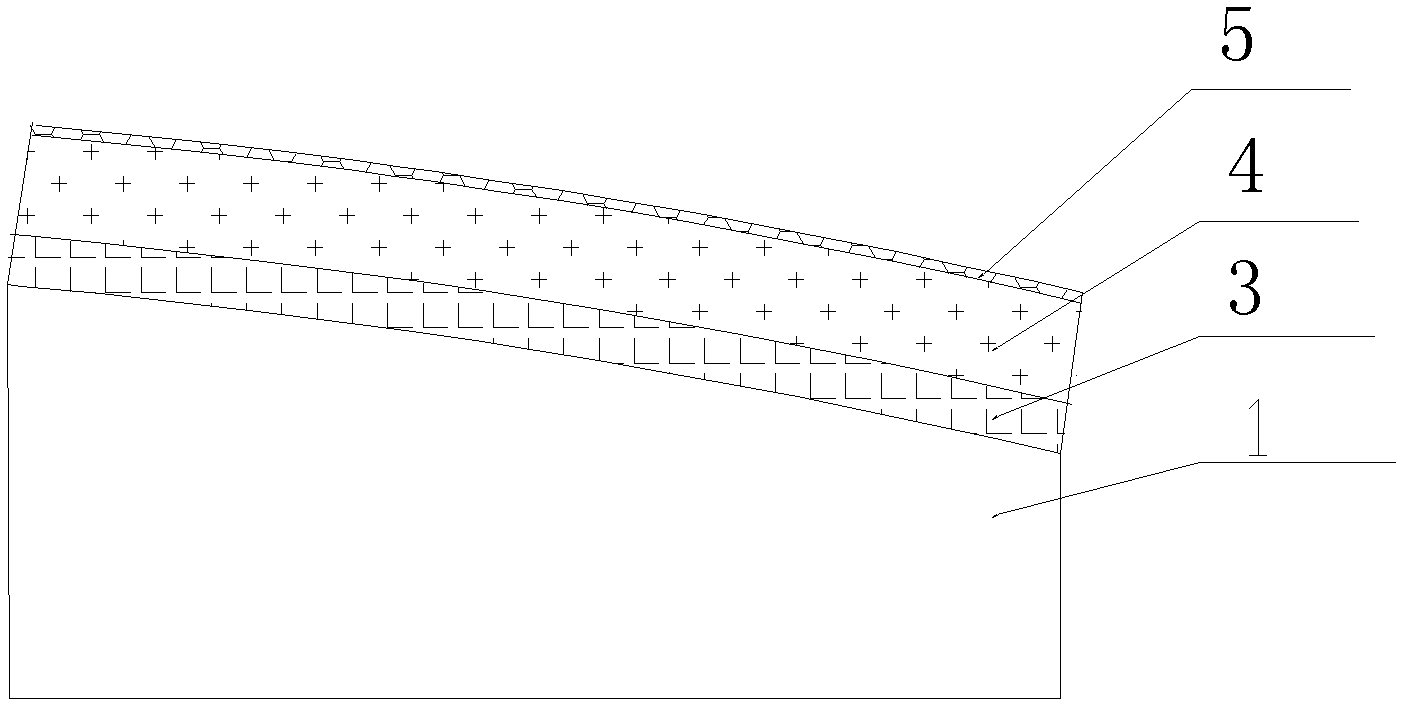

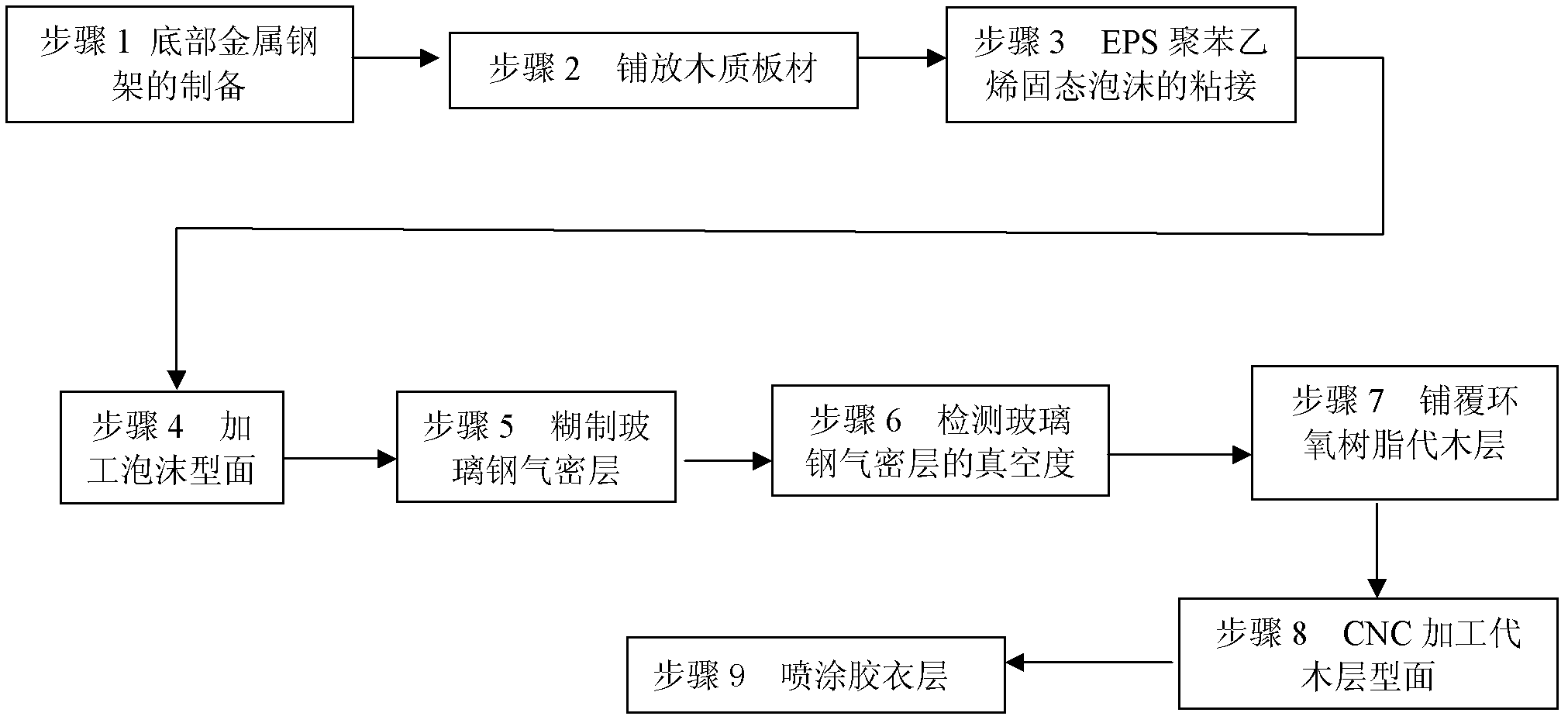

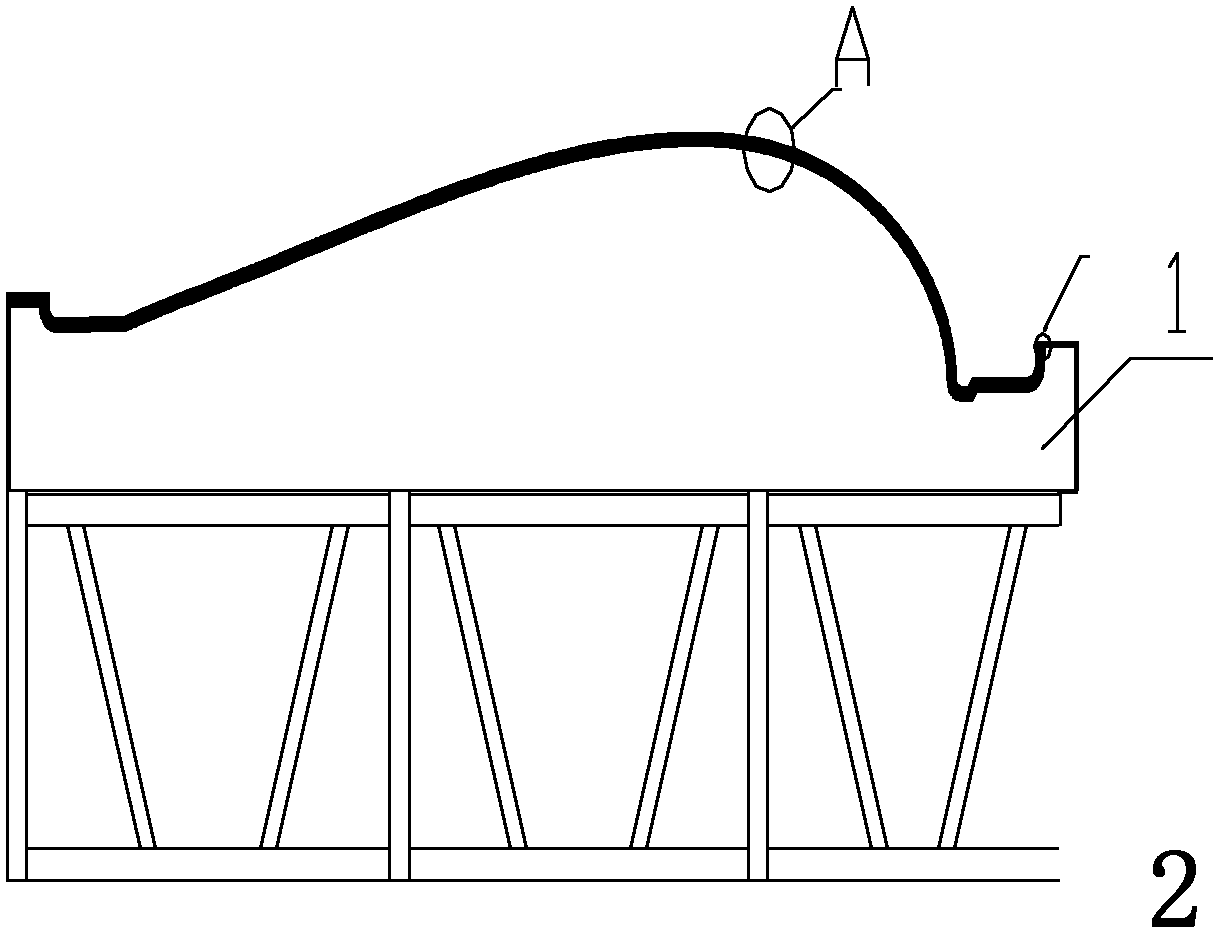

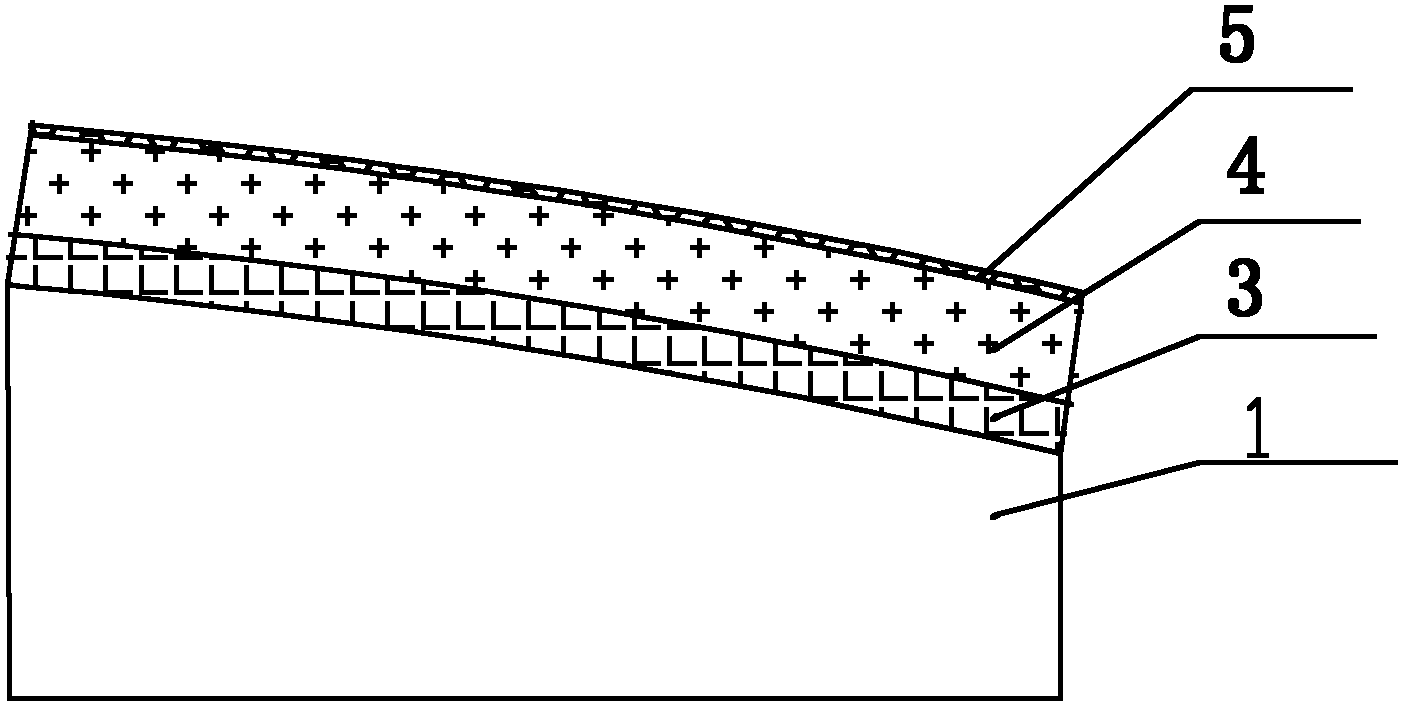

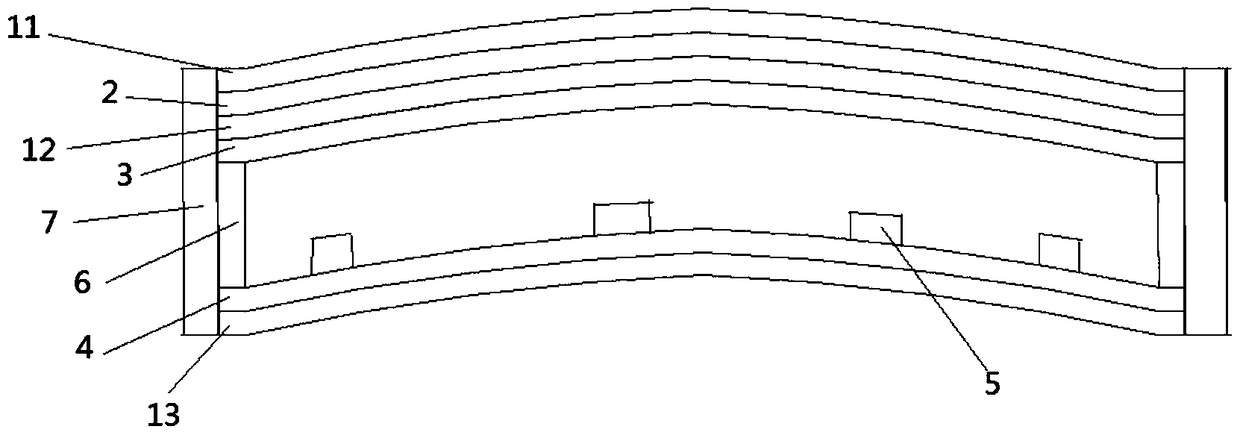

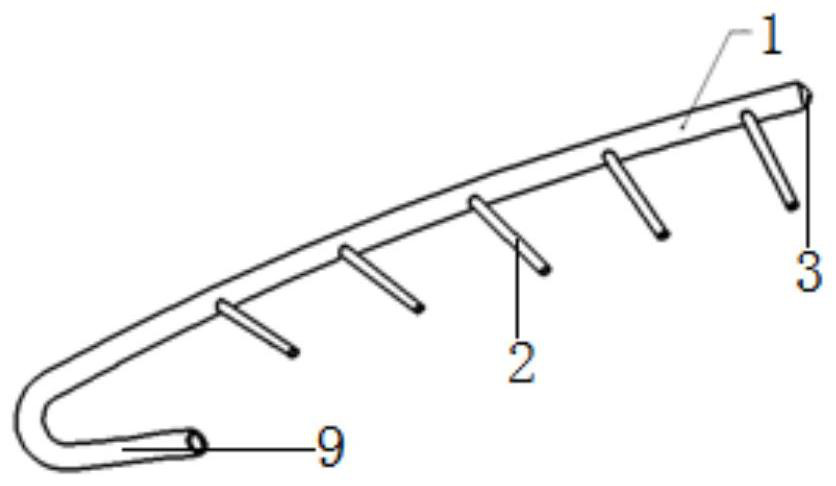

Making process of wind-power blade main model

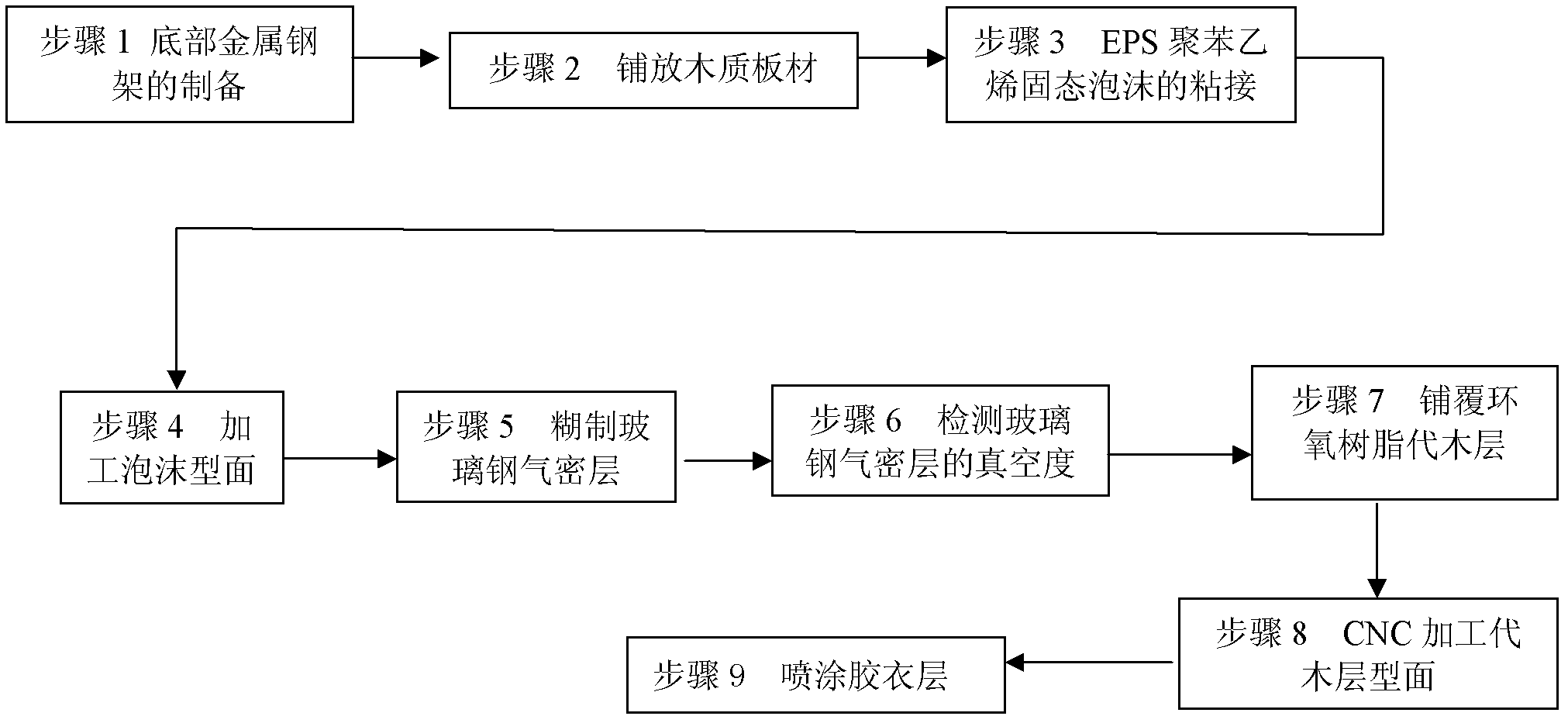

The invention discloses a making process of a wind-power blade main model, which belongs to the technical field of wind-power blade molding. The process comprises the following steps of: 1) making a metal steel frame platform at the bottom; 2) laying a wood plate; 3) coating epoxy resin white carbon black filler on the surface of the wood plate, placing multiple EPS (Expandable Polystyrene) polystyrene solid foams according to the shape of the designed main model in a laminated way, and bonding and fixing the EPS polystyrene solid foams; 4) machining profiles of the EPS polystyrene solid foams; 5) pasting glass fiber reinforced plastic airtight layers on the machined profiles in the step 4); 6) detecting the vacuum degrees of the glass fiber reinforced plastic airtight layers; 7) uniformly spreading wood substituted epoxy resin layers on the surfaces of the glass fiber reinforced plastic airtight layers which satisfy the vacuum degree requirements, controlling the spreading thicknesses at about 15-35 mm and curing the wood substituted epoxy resin layers at normal temperature; and 8) machining the surfaces of the wood substituted epoxy resin layers; and then coating gel coat layers on the wood substituted epoxy resin layers and curing and molding the wood substituted epoxy resin layers to obtain the main model. The main model made by using the process disclosed by the invention has the advantages of high profile precision, easiness for construction operation, low making cost as well as contribution to promotion and application.

Owner:北玻院(滕州)复合材料有限公司

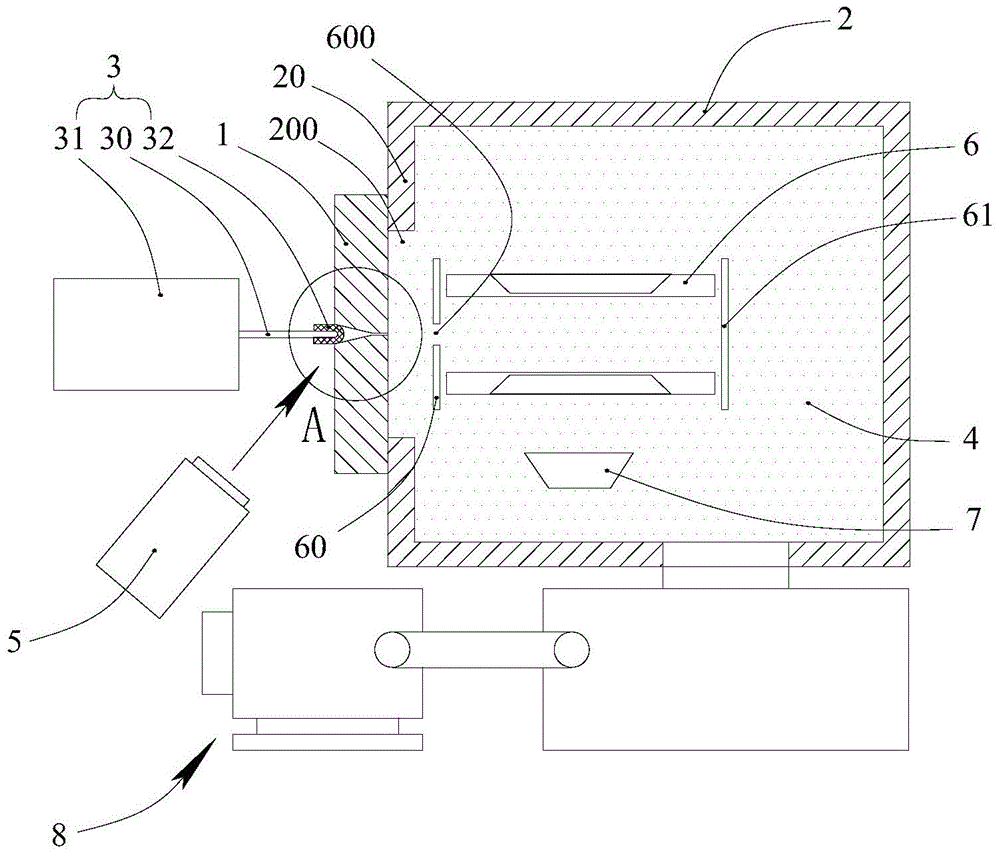

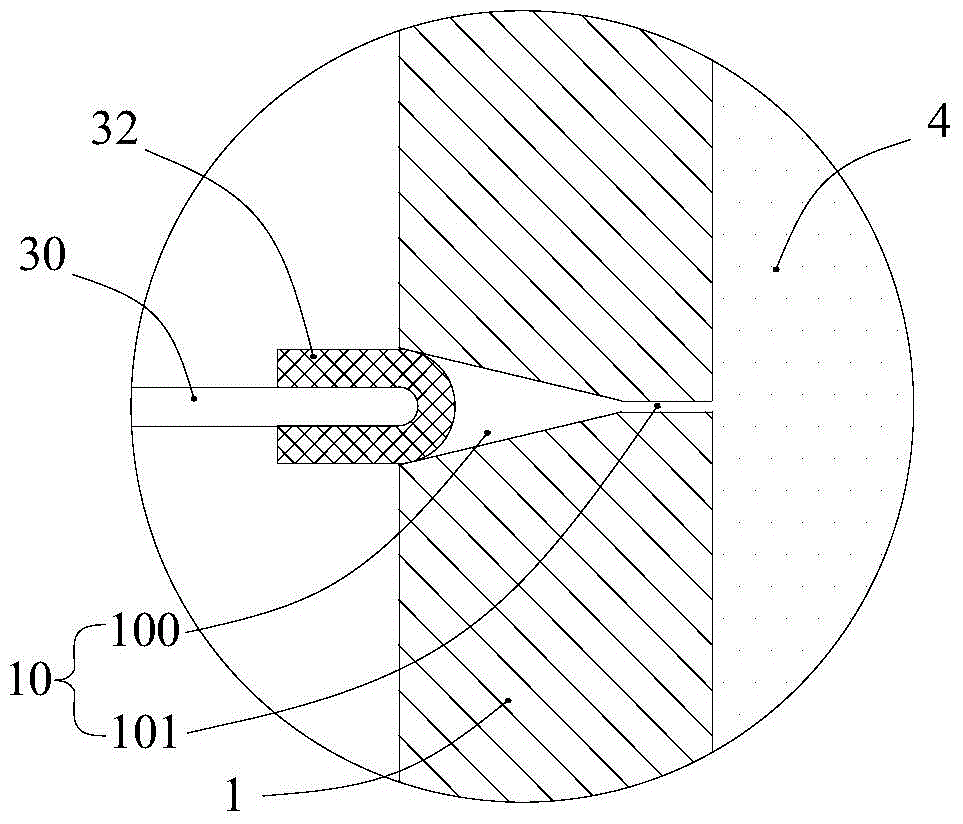

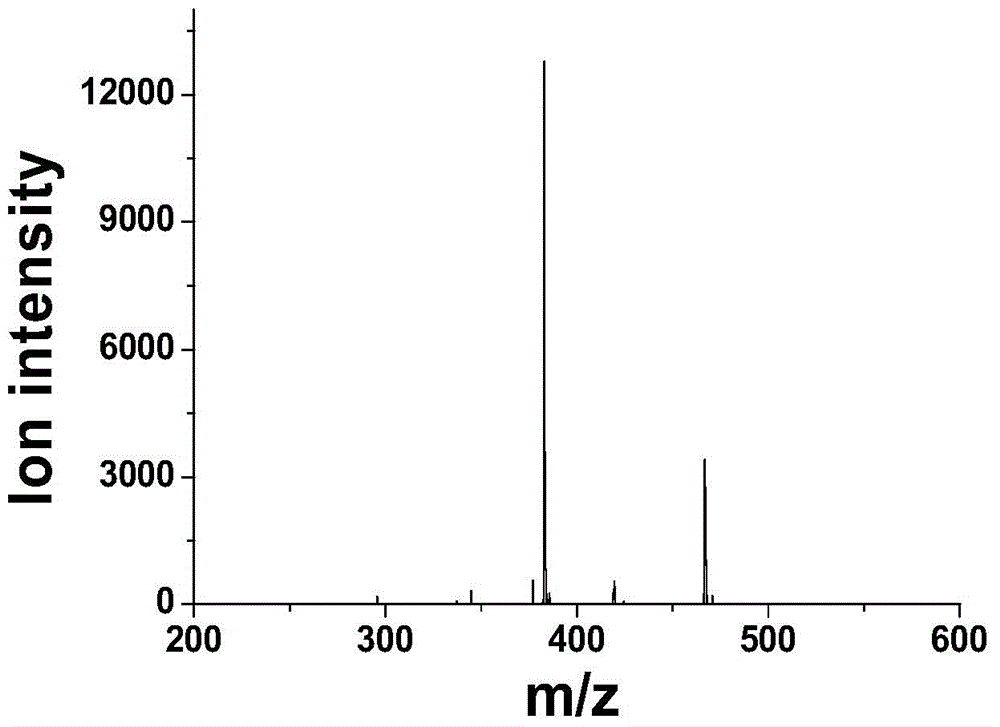

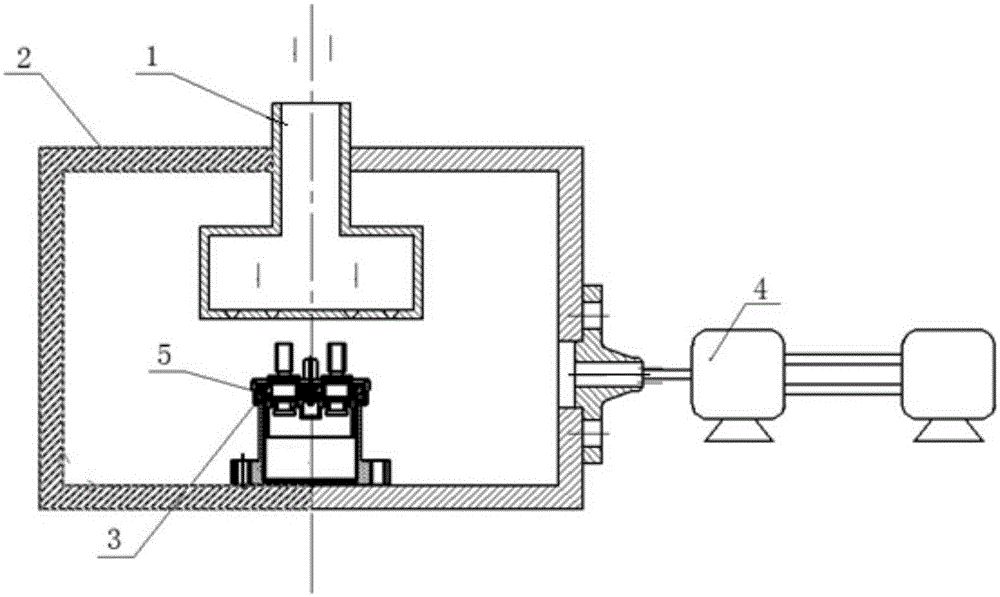

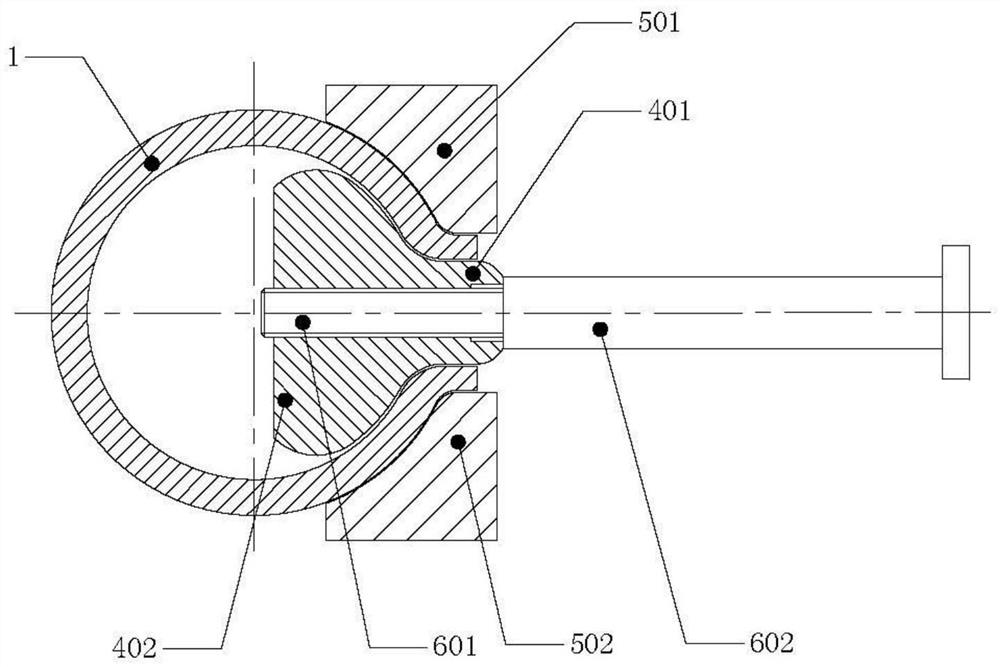

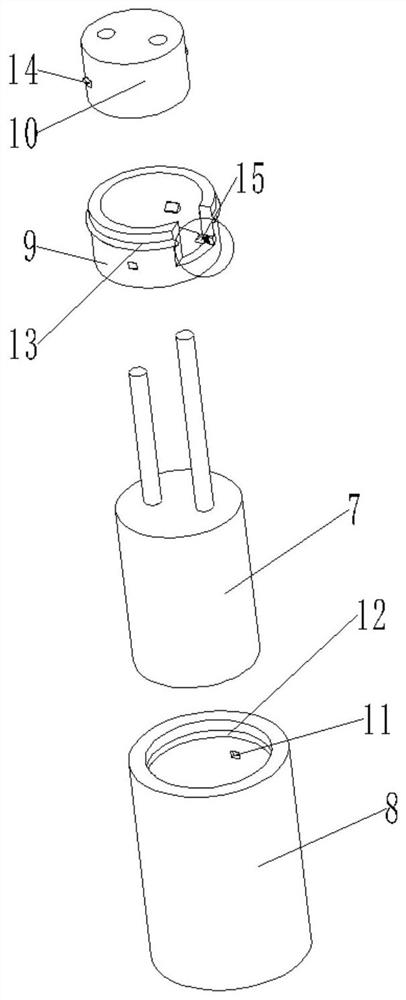

Atmospheric pressure interface device and mass spectrometer

InactiveCN105097411AEasy to manufactureGuaranteed transfer rateComponent separationSamples introduction/extractionBarrel ShapedEngineering

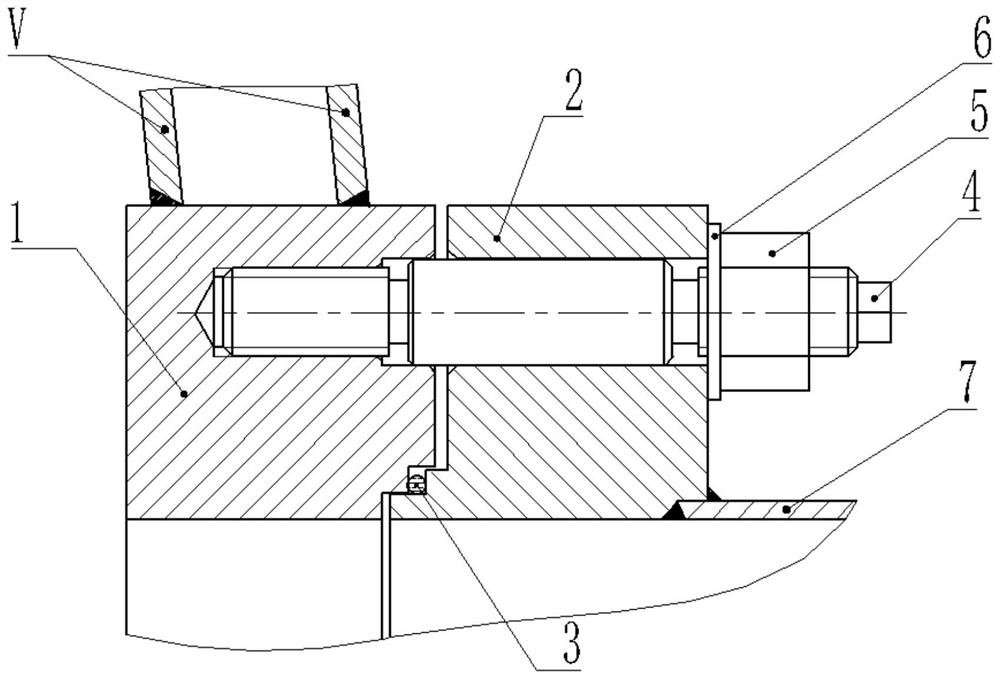

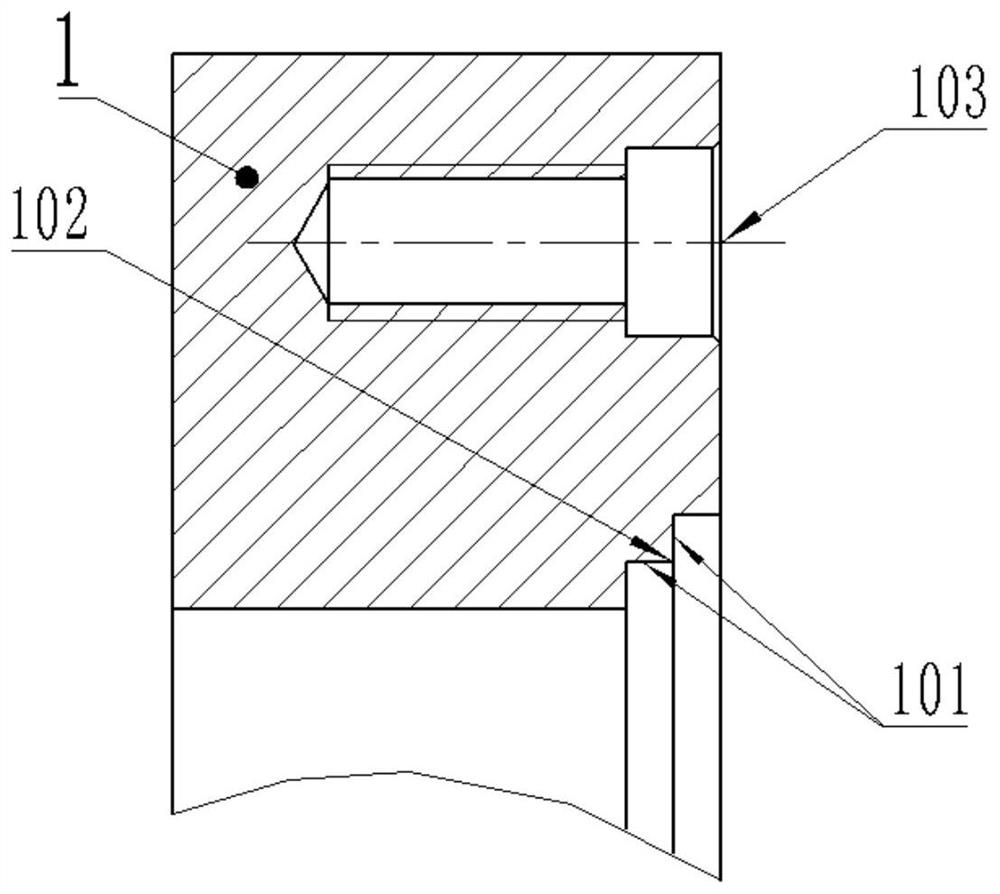

An atmospheric pressure interface device and mass spectrometer; the atmospheric pressure interface device comprises an interface end plate (1) and a sealing device (3); the interface end plate (1) is provided with a through hole (10) thereon; the through hole (10) comprises a tapered hole portion (100) and a cylindrical hole portion (101); the tapered hole portion (100) is in a conical barrel shape, and the end having a larger hole diameter opens on one surface of the interface end plate (1), and corresponds to the sealing device (3); the cylindrical hole part (101) has a cylindrical barrel shape, and one end opens on the other surface of the interface end plate (1), and the other end is connected to the end of the tapered hole portion (100) having a smaller hole diameter; the center line of the tapered hole portion (100) coincides with the center line of the cylindrical hole part (101); and the sealing device (3) is provided outside the interface end plate (1), and seals the through hole (10) in an opening / closing manner. The atmospheric pressure interface device ensures the ion transmission rate and the vacuum sealing performance of a vacuum chamber (4). The mass spectrometer of the present invention is easy to manufacture and has a wide application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for manufacturing high-heat-conductivity molybdenum-copper-nickel alloy

The invention discloses a method for manufacturing high-heat-conductivity molybdenum-copper-nickel alloy. The method includes steps of firstly, mixing: weighing mixed powder of Mo (molybdenum) powder, Cu(copper) powder and Ni (nickel) powder to stir on a centrifugal ball mill for 4 hours; secondly, pressing: placing the mixed powder stirred uniformly into a pressing die for blank pressing; thirdly, sintering in vacuum: placing pressed blank into a vacuum furnace to sinter at a high temperature; fourthly, impregnating copper: melting oxygen-free copper in a hydrogen atmosphere furnace, placing the blank sintered in vacuum to impregnate in melted copper liquid; fifthly, turning: turning the impregnated blank according to the requirements, removing surplus copper layers on the surface; and sixthly, scouring: impregnating turned parts into solution to scour, washing the parts by tap water, and dewatering and drying the parts by alcohol. The molybdenum-copper-nickel alloy manufactured by the above method can be used for metal ceramic structures of high-power traveling wave tubes such as energy transmission windows and collector electrodes and key parts having high requirements for heat radiation.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

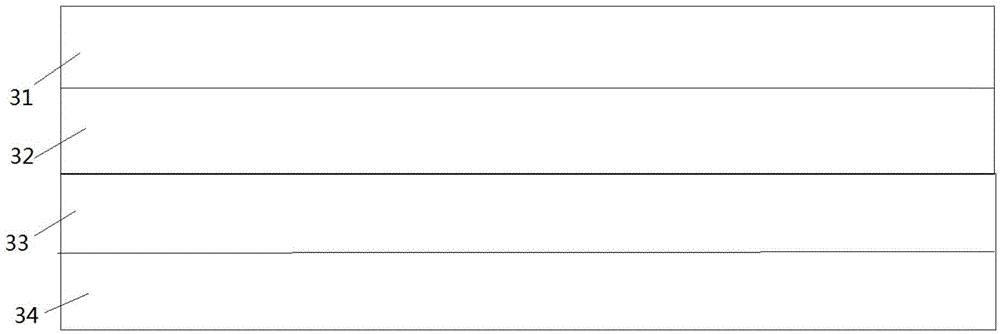

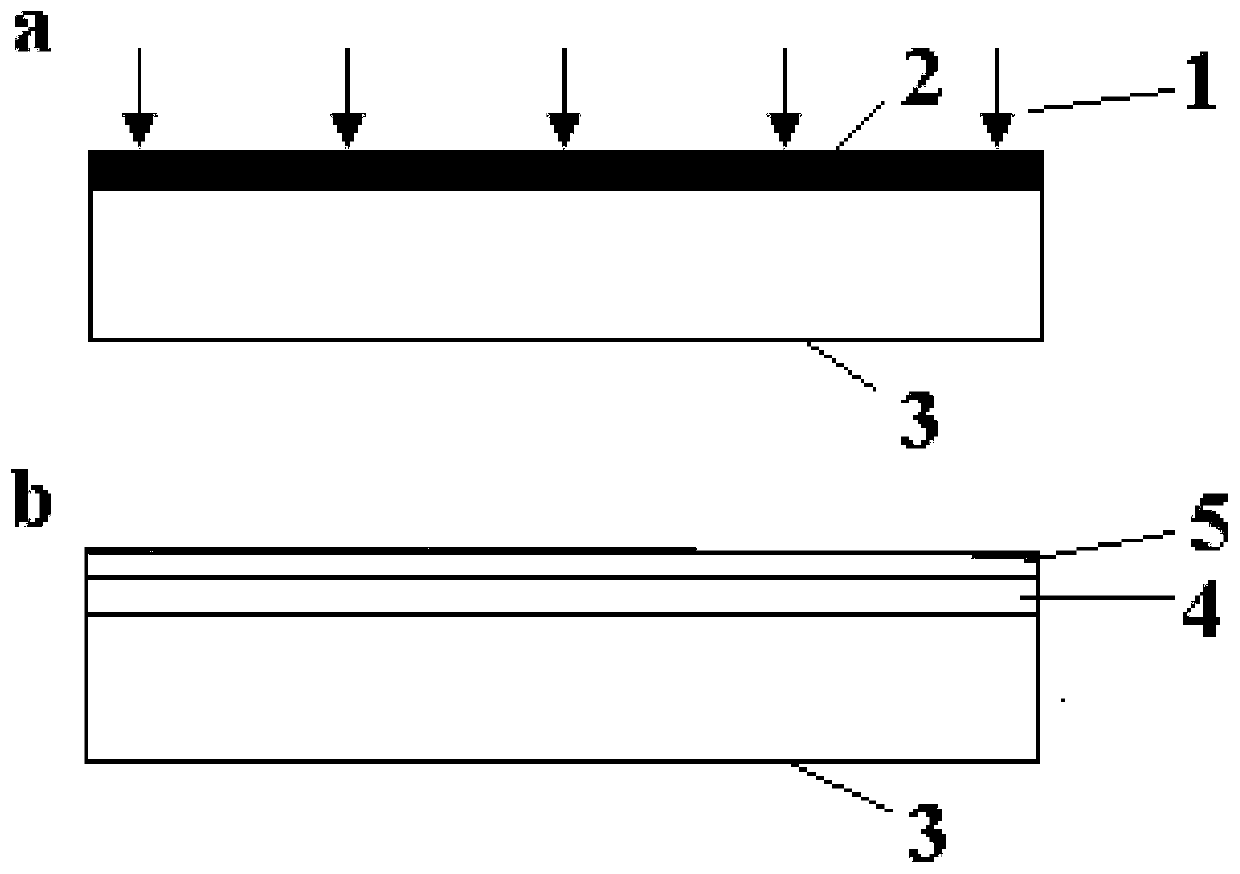

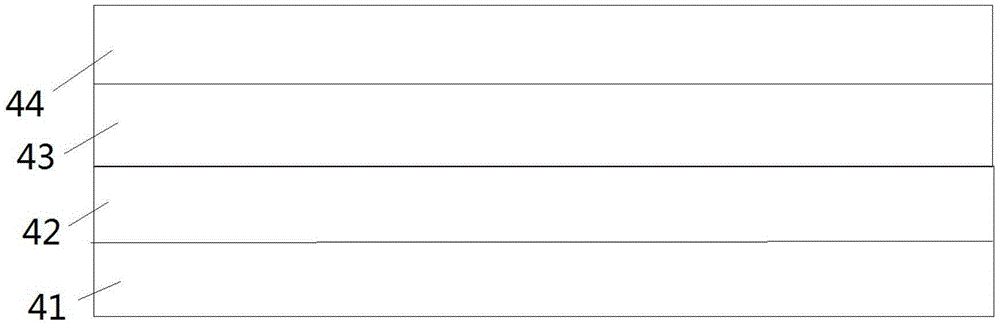

LED light-emitting glass used for outdoor curtain wall and preparation method of LED light-emitting glass

ActiveCN105621903ARetain luminous propertiesEnhanced explosion-proof propertiesMechanical apparatusLighting elementsThermal insulationEngineering

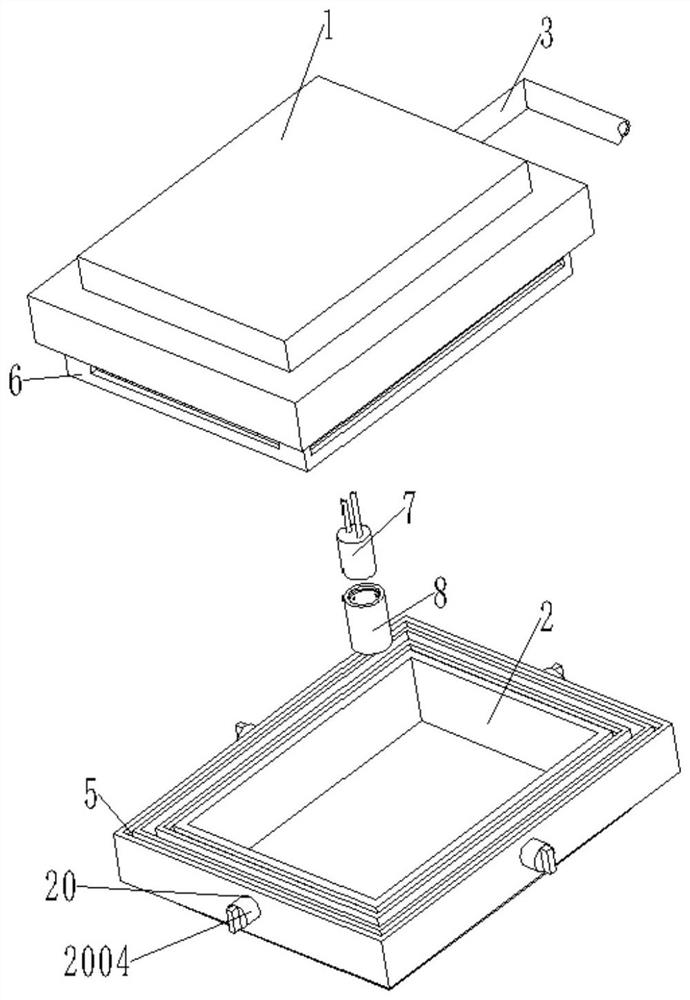

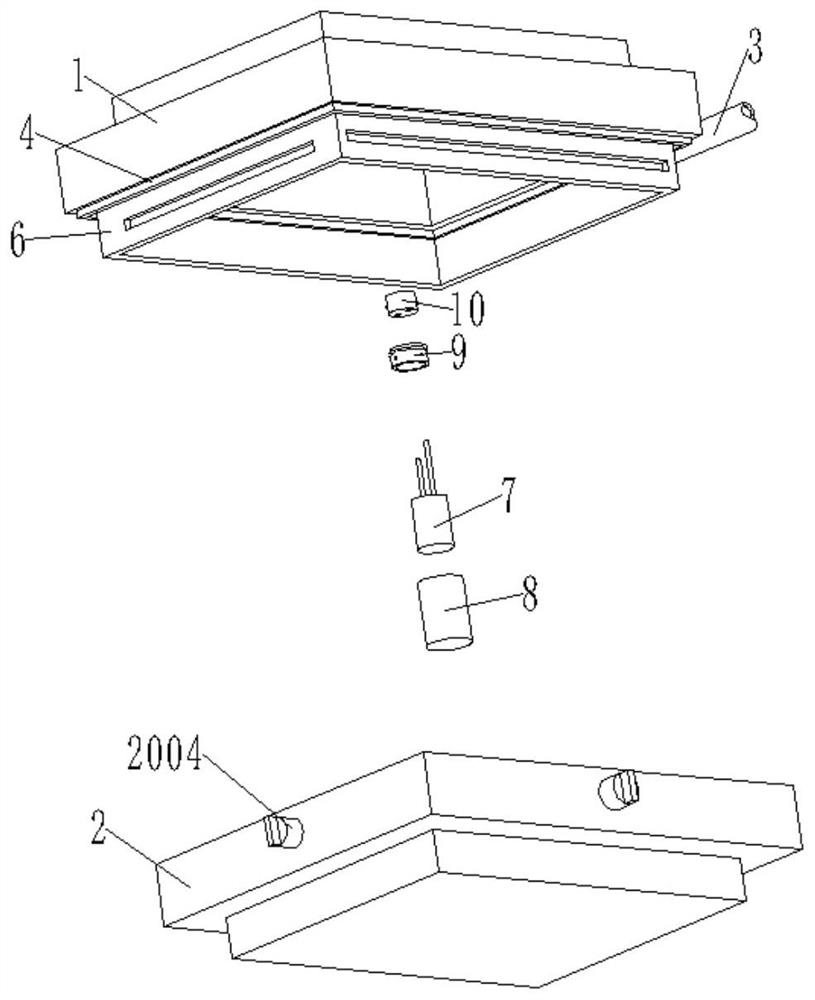

The invention provides LED light-emitting glass used for an outdoor curtain wall and a preparation method of the LED light-emitting glass. The LED light-emitting glass comprises glass layers, a glue clamping layer, an infrared inflection layer, an electric conduction layer, LED lamps, sealing layers and a protection layer. The glass layers include the first glass layer, the second glass layer and the third glass layer which are stacked from top to bottom. The glue clamping layer is arranged between the first glass layer and the second glass layer. The infrared reflection layer is arranged on the lower surface of the second glass layer. The electric conduction layer is arranged on the upper surface of the third glass layer, and circuit grooves are etched in the electric conduction layer. The LED lamps adhere to the circuit grooves through electric conduction silver glue. The seams of the glass layers are filled with the sealing layers. The peripheries of the glass layers are coated with the protection layer. By means of the LED light-emitting glass, the characteristics of LED glass and vacuum glass can be effectively combined, the anti-explosion performance and the heat preservation and thermal insulation property of the LED light-emitting glass are enhanced, and the LED light-emitting glass is suitable for the outdoor curtain wall.

Owner:TAICANG YAOHUA GLASS

Vacuum defoaming device

ActiveCN105126393AGuaranteed vacuum tightnessGood defoaming performanceFoam dispersion/preventionPulp and paper industryColloid

The invention discloses a vacuum defoaming device. The vacuum defoaming device comprises a vacuum chamber used for accommodating workpieces; the vacuum chamber is connected with a vacuum pump and a high pressure air injection nozzle; the high pressure air injection nozzle is opened, and high pressure air enters into the vacuum chamber quickly, so that foams on the surfaces of colloids on the workpieces break because of rapid change of inside-outside pressure different, and the high pressure gas which enters into the vacuum chamber quickly is applied onto the surfaces of the foams so as to broke the foams. Excellent defoaming effect can be achieved; product surface quality is increased; vacuum sealing effect of the workpieces is ensured; and product quality is improved.

Owner:ANHUI RIZEN AUTO PARTS

Energy transmission window sheet for terahertz band vacuum device and preparation method thereof

ActiveCN110416039AHigh mechanical strengthImprove surface roughnessDiamondCold cathode manufactureHigh fractureSurface layer

Owner:NO 12 RES INST OF CETC

Metal net anti-explosive vacuum thermal insulation glass and preparing method thereof

ActiveCN105599383AHas explosion-proof propertiesImprove securityGlass/slag layered productsCoatingsThermal insulationReflective layer

The invention provides metal net anti-explosive vacuum thermal insulation glass and a preparing method thereof. The glass comprises a glass layer comprising a first glass layer, a second glass layer and a third glass layer from top to bottom, a glue clamping layer arranged between the first glass layer and the second glass layer, a metal net embedded into the glue clamping layer, an infrared reflection layer arranged at the upper surface of the third glass layer, a strain protection layer arranged at the upper surface of the infrared reflection layer, a sealing layer coating one side of the glass layer along a direction vertical to the glass layer, a protection layer longitudinally coating the outer side of the sealing layer, and a group of supporters arranged between the second glass layer and the strain protection layer. Thermal insulation and anti-explosive performances of the vacuum glass are effectively improved.

Owner:TAICANG YAOHUA GLASS

Discharge device of vacuum drying device

The invention discloses a discharge device of a vacuum drying device. The discharge device is connected with a discharge port of a drying cylinder and comprises an outer sleeve, an upper discharge pipe, a lower discharge pipe, a valve seat and a valve plate. The outer sleeve is sleeved outside the lower discharge pipe, the bottom of the outer sleeve and the bottom of the lower discharge pipe are both communicated with the discharge port, the upper discharge pipe is arranged above the outer sleeve, the valve seat is provided with a valve hole and fixedly arranged at the upper end of the outer sleeve, a lifting driving mechanism is further arranged on the upper discharge pipe and can be used for controlling the upper discharge pipe to penetrate through the valve hole to butt against or be separated from the lower discharge pipe, the valve plate is arranged above one side of the valve seat, and a translation driving mechanism is arranged at one end of the valve seat and used for controlling the valve plate to be closed horizontally or open the valve hole. The discharge device can guarantee vacuum tightness of the drying cylinder when the drying cylinder performs drying and can guarantee smooth discharge of a discharge pipe during discharge. Through clearance arrangement of the valve hole and the lower discharge pipe, the valve plate or a valve can be prevented from being clamped by inlet-outlet materials effectively, and air tightness of the discharge device is improved.

Owner:戴克

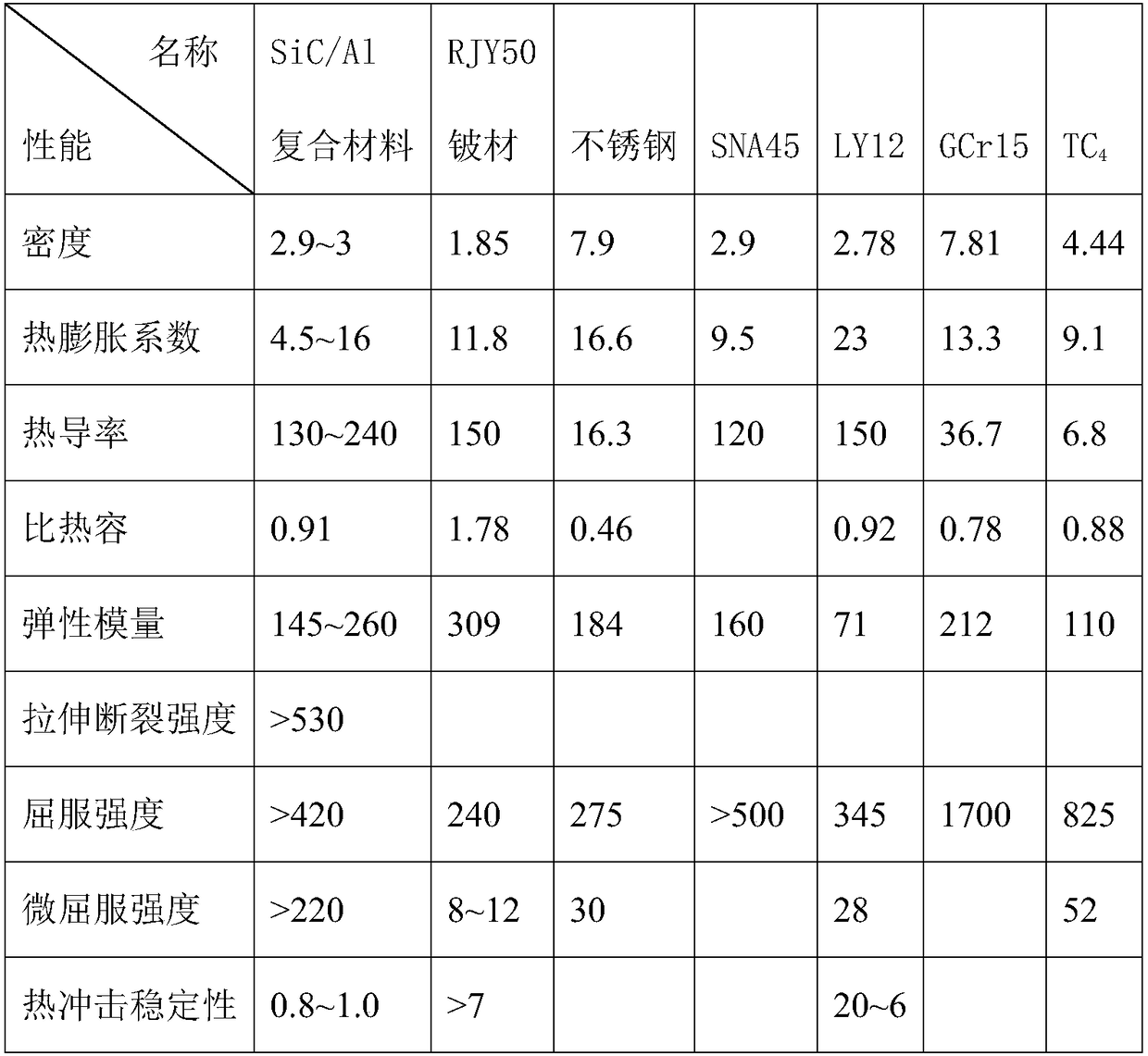

Preparation method of aluminum-based ceramic composite material

The invention discloses a preparation method of an aluminum-based ceramic composite material. A porous ceramic blank is placed into a lower cavity of a hearth, an aluminum ingot is placed into an upper cavity of the hearth, vacuum heat injection squeezing-infiltration is performed, a sintering furnace is closed after infiltration, vacuum is pumped and kept, temperature is kept after one-time temperature rise, a manual valve is opened, inert gas is injected, infiltration is finished under atmospheric pressure, and finally, furnace cooling is performed to reach room temperature after infiltration to prepare the aluminum-based ceramic composite material. By vacuum heat injection squeezing sintering, the aluminum-based ceramic composite material is successfully prepared, the prepared aluminum-based ceramic composite material meets strength requirements and machining requirements, and the preparation method is simple in process, easy in operation and suitable for manufacturing parts needinglight weight, good conductivity, high strength and high temperature resistance.

Owner:西安朗赛精密机械有限公司

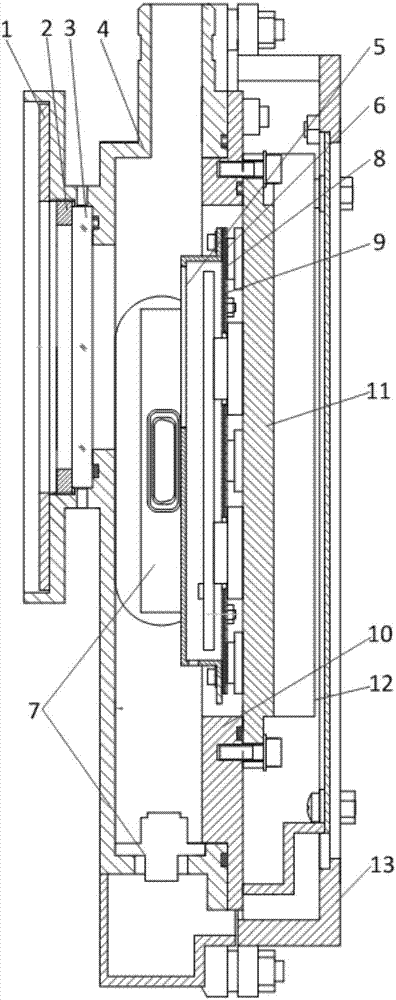

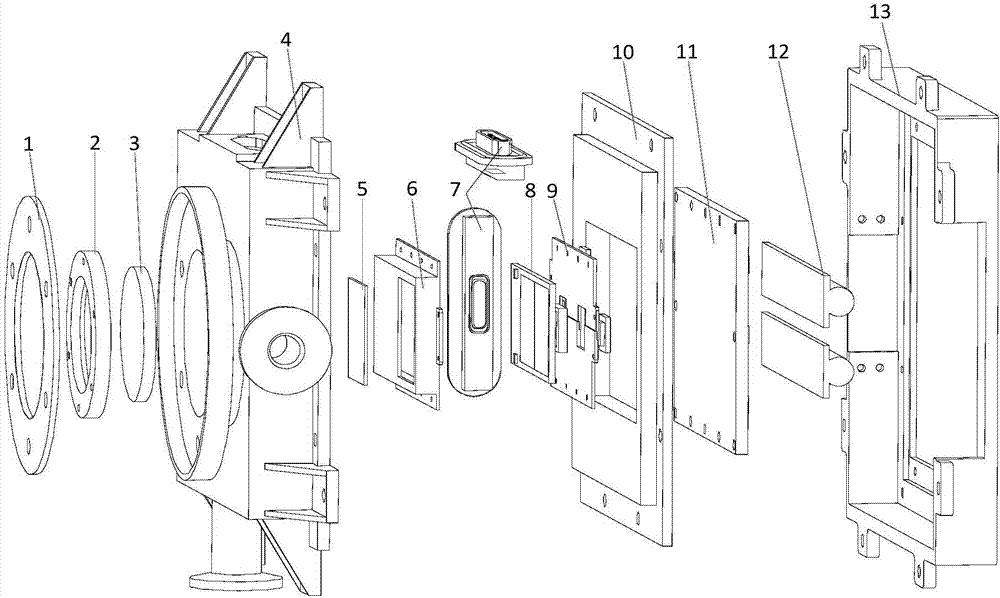

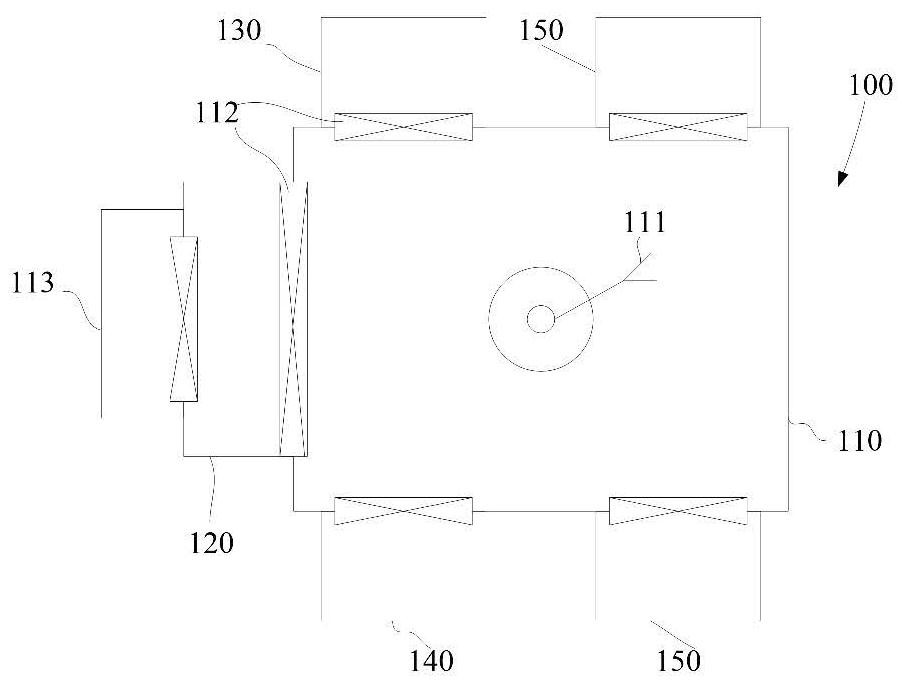

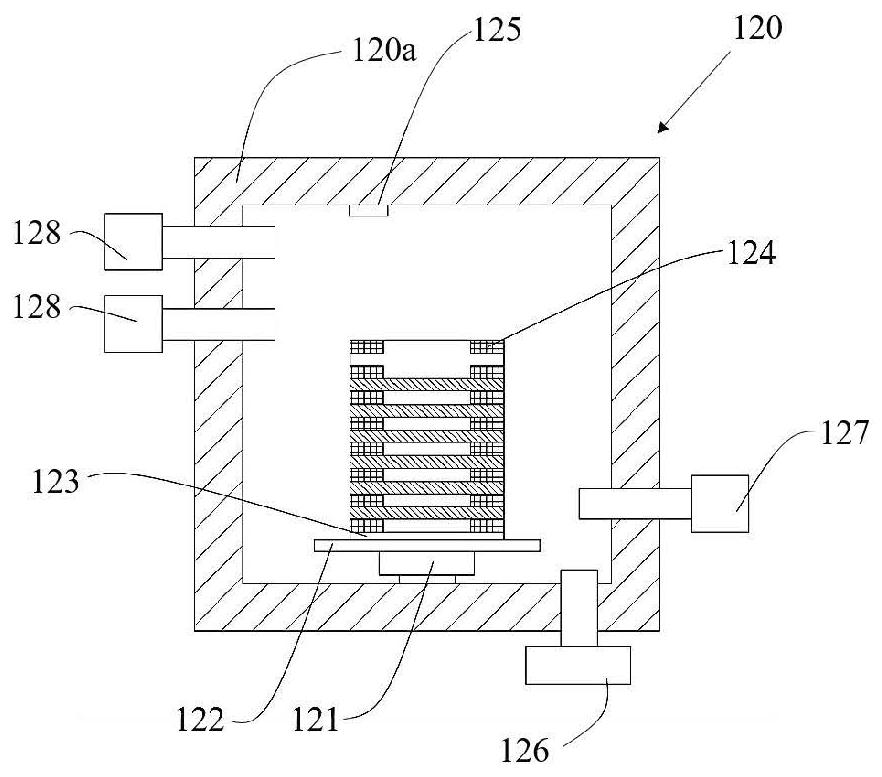

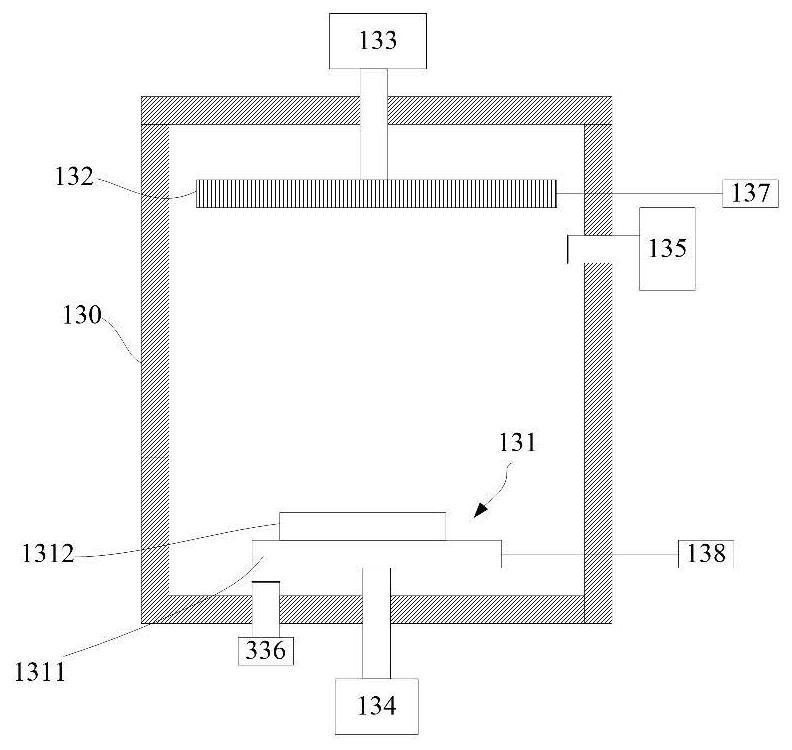

Active-cooling vacuum-sealing focal plane assembly of space camera

ActiveCN107045251ASolve pollutionSolve thermal stressCamera body detailsActive coolingHeat sensitive

The invention provides an active-cooling vacuum-sealing focal plane assembly of a space camera. Via the assembly, a detector can be cooled below -60 DEG C, and the problem that a traditional focal plane detector of the camera causes steam pollution during cooling is solved. The assembly comprises a focal plane case trimming pad, a clamping ring, a vacuum glass window, a vacuum focal plane case, a vacuum sealing connector, a cooling assembly, a focal plane case pedestal, a focal plane case base plate, heat tubes, a relay box, thermistors and thermoelectric coolers, the vacuum glass window seals and compresses a light inlet via the clamping ring, and the focal plane case trimming pad is arranged in the front end of the clamping ring; the cooling assembly comprises a cold screen window, a cold screen, an active cooling CCD assembly and a cold screen base plate; the cold screen window is installed in a gap of the cold screen; the back side of the cold screen base plate is provided with the thermistors and thermoelectric coolers; and the cooling assembly, the focal plane case pedestal, the focal plane case base plate and the heat tubes are all arranged in a cavity formed by the vacuum focal plane case and the relay box, and the heat tubes are arranged in the back side of the focal plane case base plate.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Semiconductor device and using method thereof

PendingCN110643961ASimple structureGuaranteed vacuum tightnessVacuum evaporation coatingSputtering coatingDevice materialMechanical engineering

The invention provides a semiconductor device and a using method thereof. The semiconductor device comprises a transition cavity, at least one carrying table, a cooling plate, an air extraction port,and an exhaust port, wherein the transition cavity is arranged in front of a growth cavity; the at least one carrying table is arranged in the transition cavity, and allows at least one tray to be placed, the tray allows a substrate to be placed, and the at least one carrying table is allowed to rise and / or fall; the cooling plate is arranged in the transition cavity, and the cooling plate and theat least one carrying table are oppositely arranged; the air extraction port is arranged on one side of the transition cavity, and the transition cavity is vacuumized through the air extraction port;and the exhaust port is arranged on one side of the transition cavity, and the transition cavity is subjected to vacuum breaking treatment through the exhaust port. The semiconductor device is simplein structure and is capable of improving the uniformity of coatings. The invention further provides the using method of the semiconductor device.

Owner:SHENZHEN JING XIANG TECH CO LTD

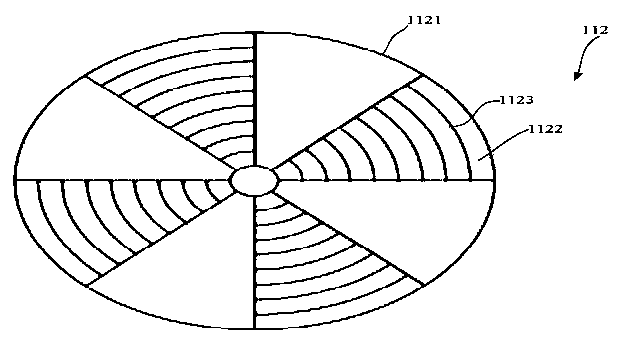

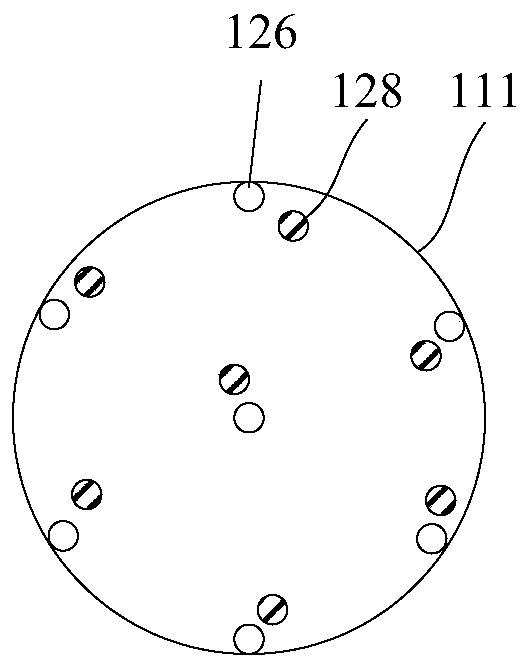

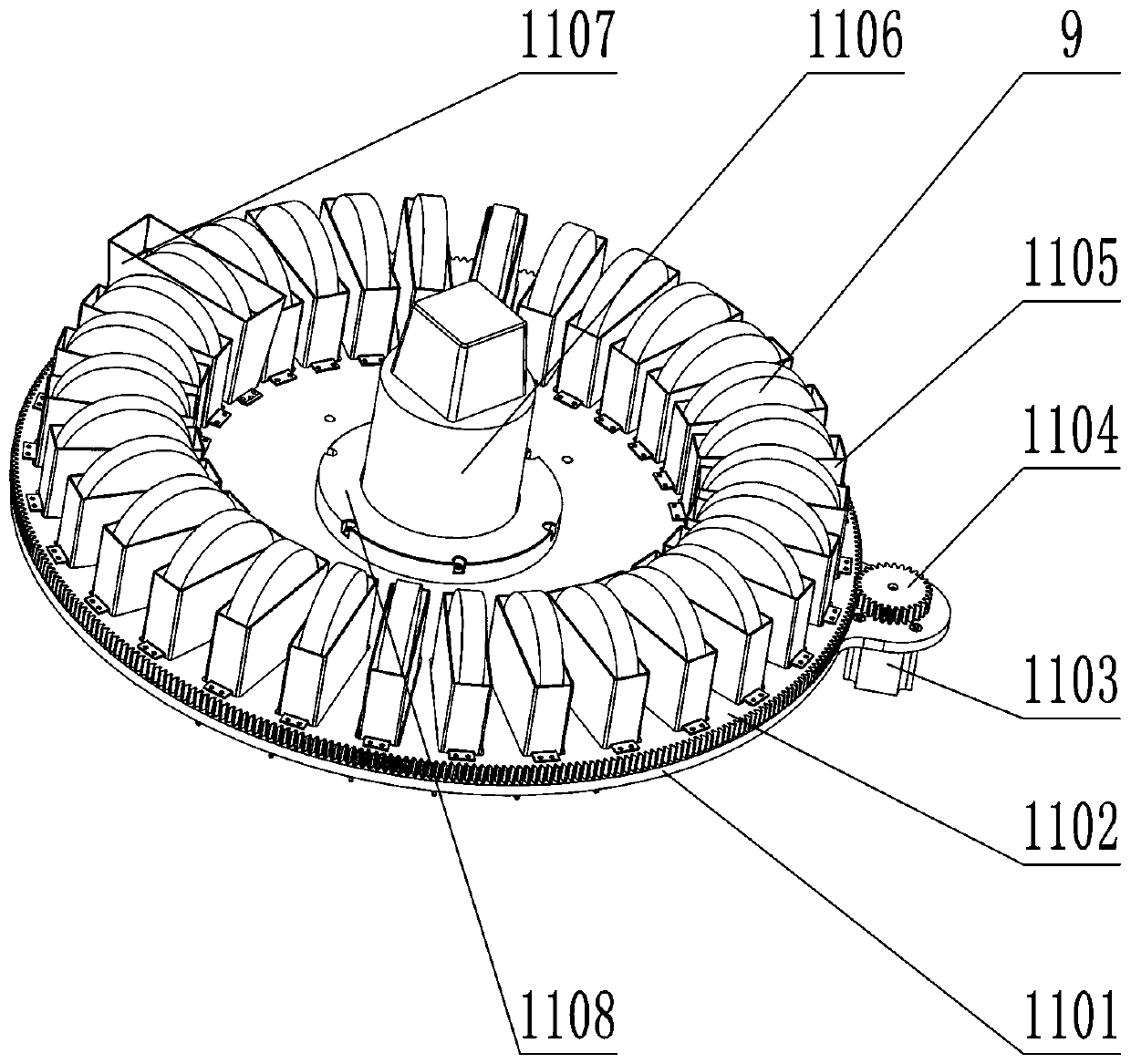

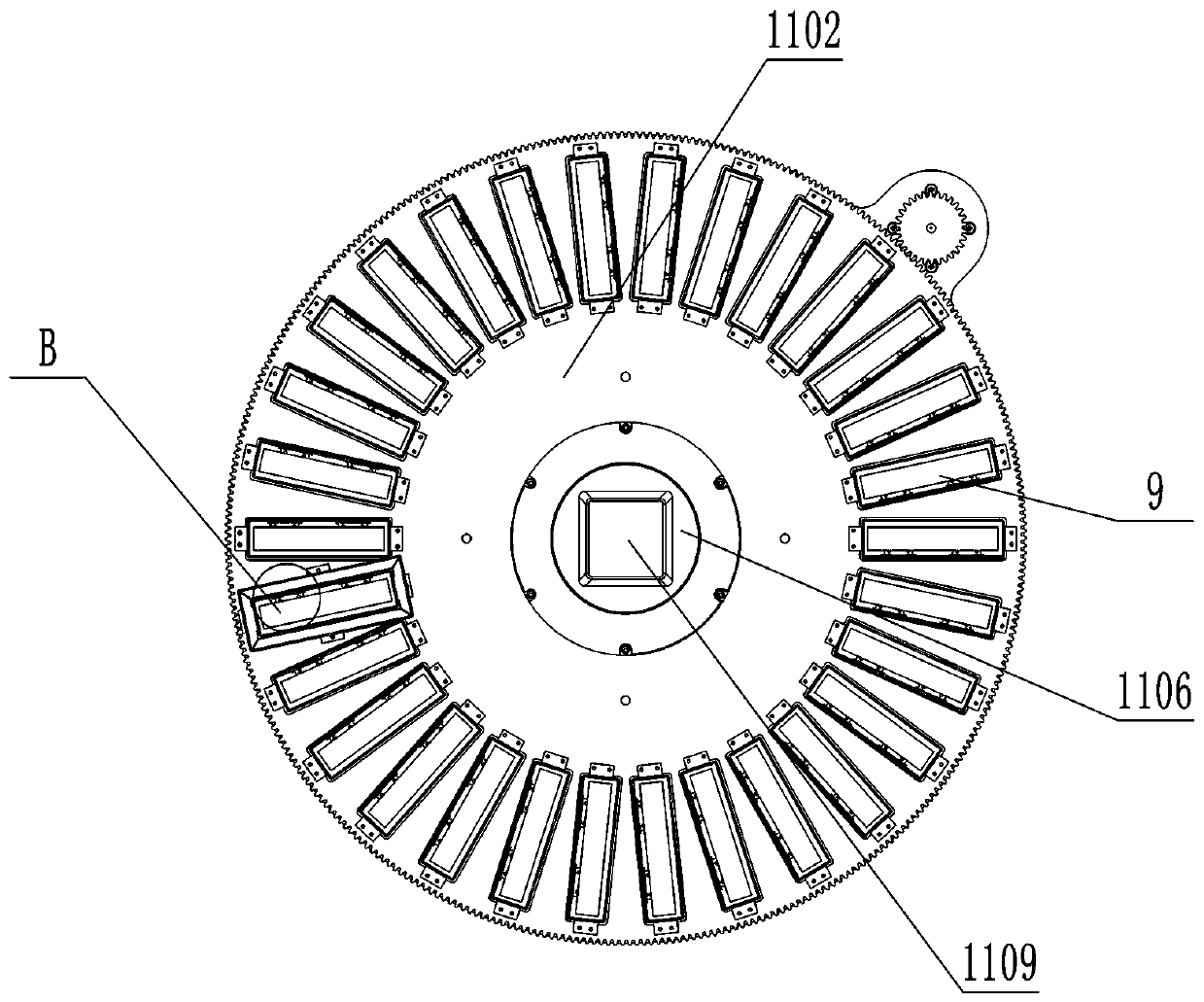

Feeding device for metal nano-powder production

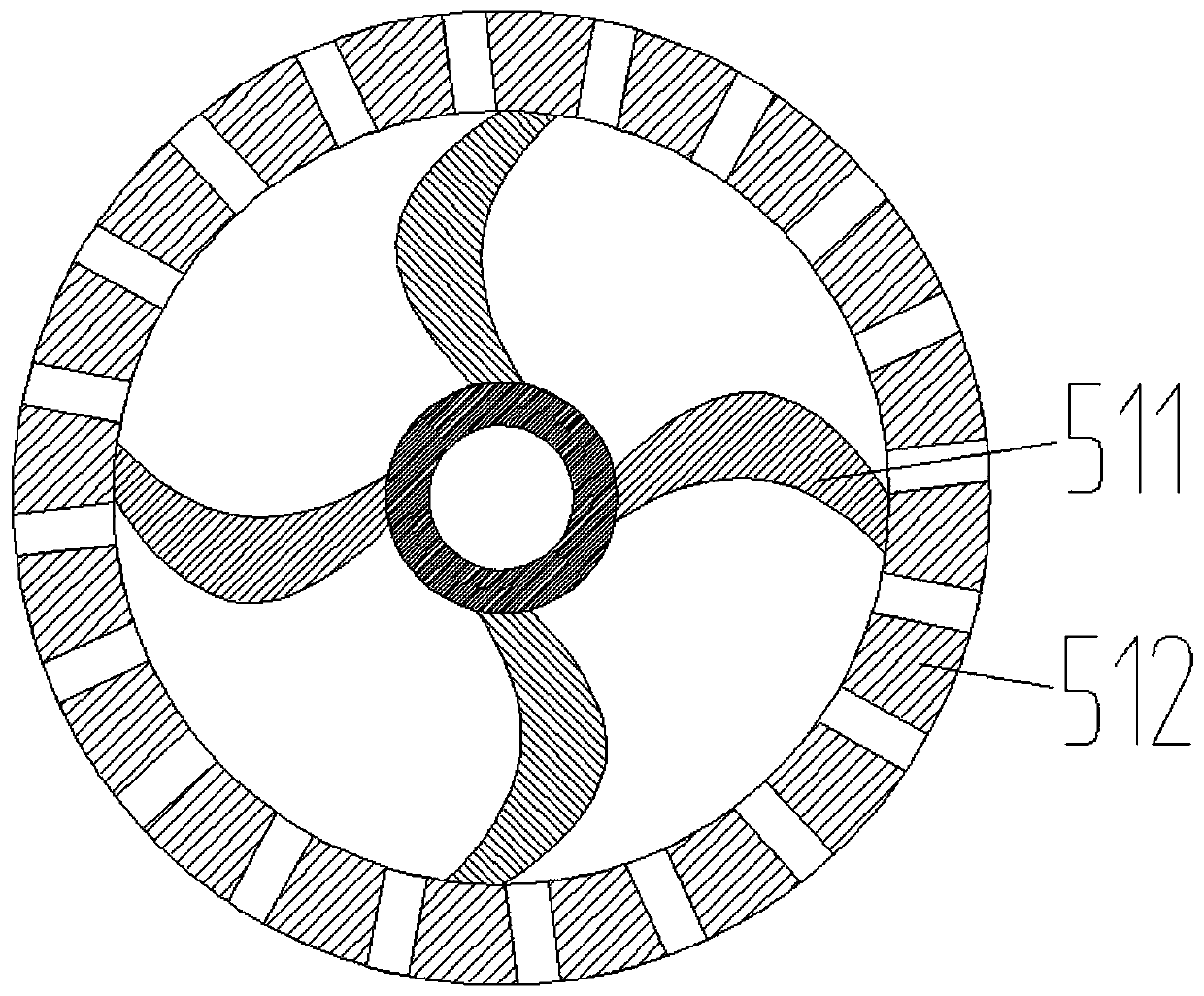

PendingCN110027925AGuaranteed continuityGuaranteed continuous feedingLoading/unloadingDrive motorEngineering

The invention discloses a feeding device for metal nano-powder production, and relates to the field of metal nano-powder production equipment. The feeding device comprises a box body, a box cover is hinged to the top of the box body, a material storage mechanism is arranged in the box body, a discharge pipe is arranged at the bottom of the box body, the upper end of the discharge pipe extends intothe box body and is connected with a material storage mechanism, the material storage mechanism comprises a plurality of disc-shaped storage devices which are vertically stacked in the box body, thedisc-shaped storage device comprises a tray, a connecting shaft is coaxially arranged in the middle of the tray, a bulge is arranged at the upper end of the connecting shaft, a clamping groove matchedwith the bulge is formed in the bottom of the connecting shaft, a rotating gear disc is coaxially arranged on the connecting shaft, a driving motor is arranged on the tray, a driving motor is connected with the driving gear, leakage holes are uniformly formed in the upper end surface of the rotating gear disc around the shaft, a hopper is arranged at the position, corresponding to the material leaking hole, of the rotating gear disc, a baffle is hinged to the bottom of the hopper, a leaking plate hole is formed in the position, corresponding to the baffle, of the tray, leaking plate hole is communicated with the top of the discharging pipe, and has the advantages of being capable of continuously feeding materials and high in production efficiency.

Owner:纳华(宁波)新材料科技有限公司

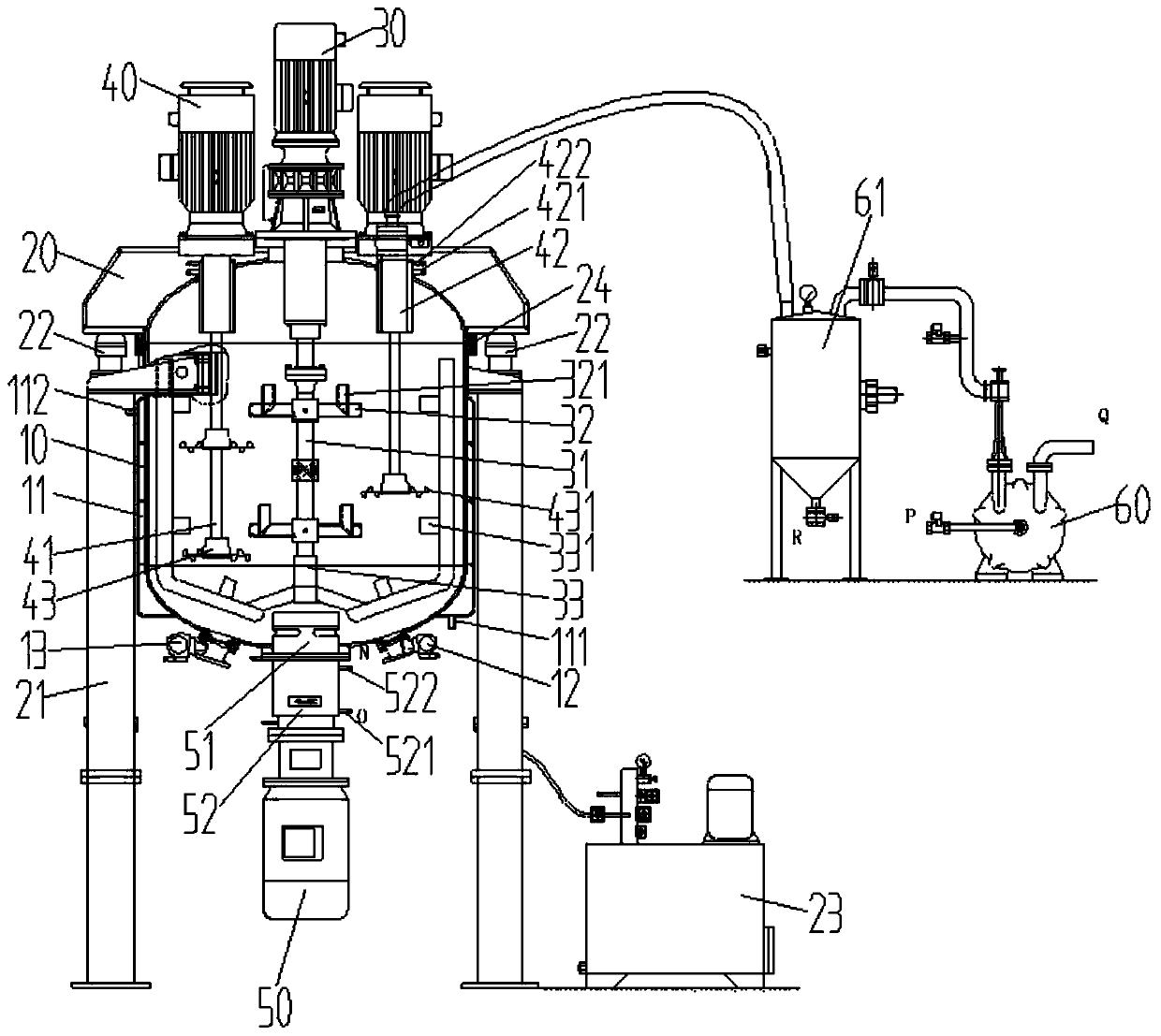

Double-oil-cylinder double-high-speed dispersing bottom homogenizer vacuum emulsifying paste making machine

PendingCN109745899AVersatileUniform emulsification reactionRotary stirring mixersTransportation and packagingHydraulic cylinderVacuum pumping

The invention provides a double-oil-cylinder double-high-speed dispersing bottom homogenizer vacuum emulsifying paste making machine, the double-oil-cylinder double-high-speed dispersing bottom homogenizer vacuum emulsifying paste making machine comprises a pot body and a pot cover arranged at the upper part of the pot body, hydraulic cylinders are arranged on the left side and the right side of the pot cover, the hydraulic cylinder is fixedly arranged on a cross beam connected with two uprights; a discharge valve and a feed valve are arranged at the bottom part of the pot body; a stirring mechanism is arranged on the pot cover and is located on the center position of the pot cover, dispersing mechanisms are respectively arranged on the left side and the right side of the stirring mechanism; a homogenizing mechanism is arranged on the middle position of the bottom part of the pot body and comprises a third motor, a drive end of the third motor is in transmission connection with a homogenizer, the homogenizer is arranged in the pot body; and a vacuum pumping system is connected on the pot cover, and comprises a vacuum pump. The double-oil-cylinder double-high-speed dispersing bottomhomogenizer vacuum emulsifying paste making machine has rich functions, so that the emulsifying reaction of a paste body is evener, less bubble is produced, the particle is thinner, and the paste body is more transparent and smoother.

Owner:江阴绿源环保科技有限公司

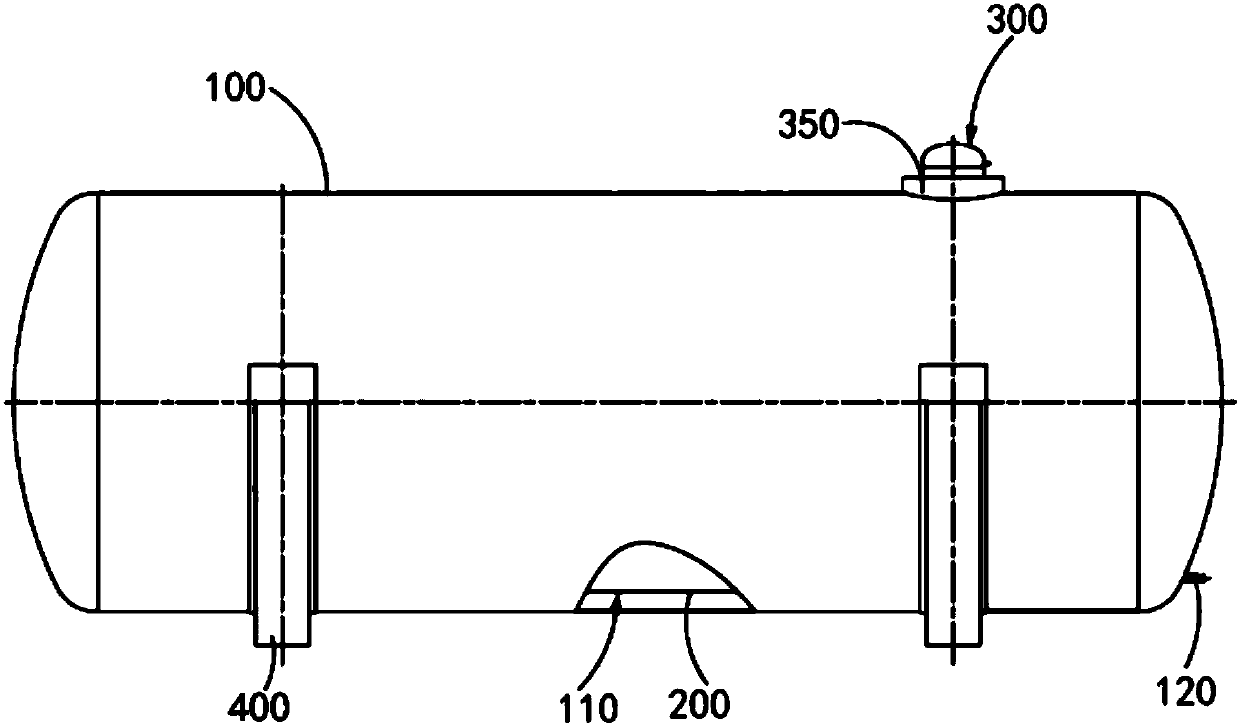

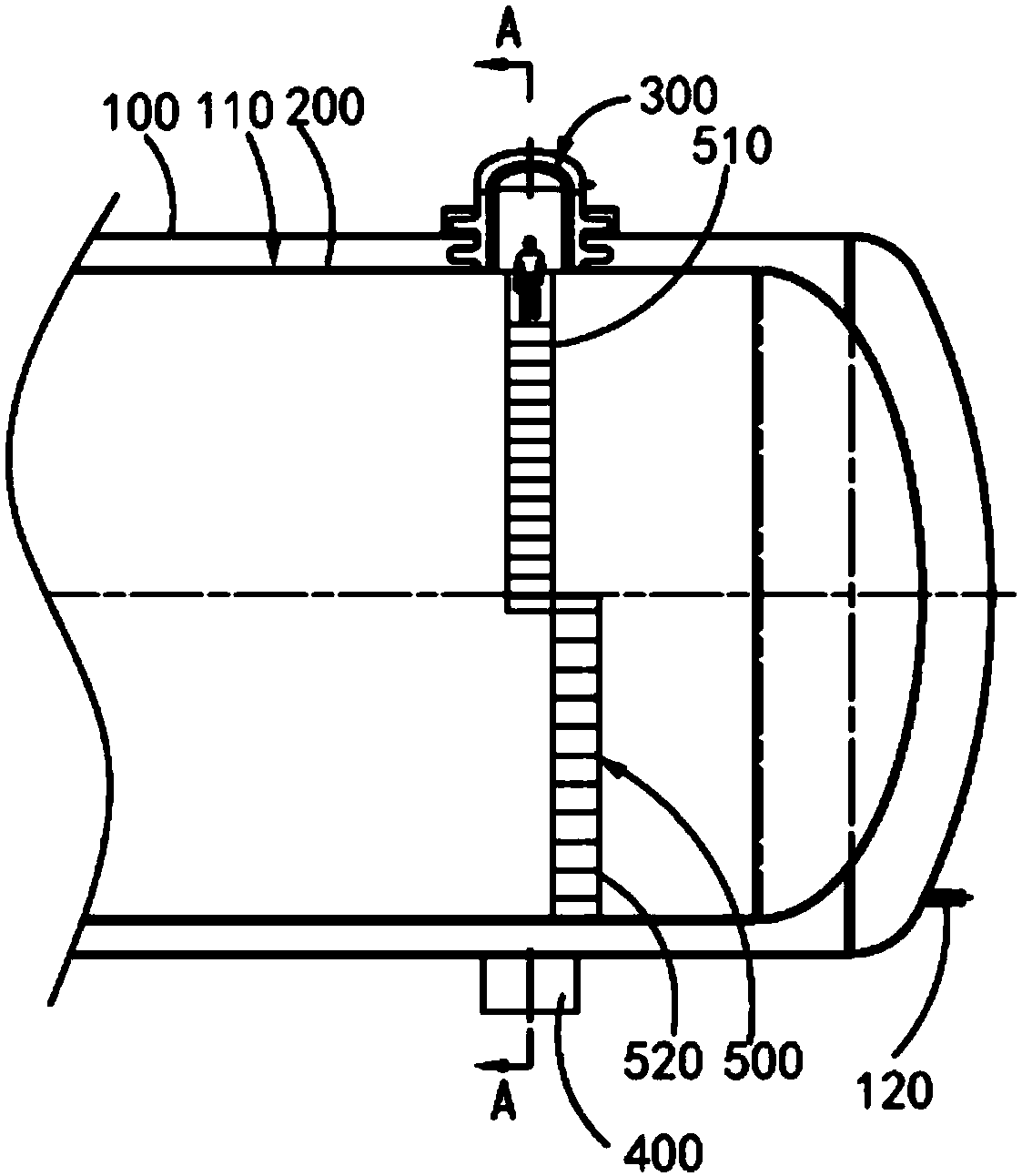

Manhole device and vacuum heat insulation low-temperature storage tank with manhole device

PendingCN110056761AMeet the needs of tank inspectionGuaranteed vacuum tightnessVessel mounting detailsVessel wallsVacuum pumpingAgricultural engineering

The invention discloses a manhole device and a vacuum heat insulation low-temperature storage tank with the manhole device. The vacuum heat insulation low-temperature storage tank comprises an outer shell and an inner container arranged in the outer shell, and a third interlayer with the vacuum environment is formed between the outer shell and the inner container. The manhole device comprises an outer hole assembly and an inner hole assembly. The outer hole assembly comprises an outer barrel and an outer cover. The outer barrel is provided with a first barrel port and a second barrel port, wherein the first barrel port is connected to the outer wall of the inner container, and the second barrel port stretches out of the outer shell. The outer cover is arranged on the second barrel port inan opening and closing manner. The inner hole assembly comprises an inner barrel and an inner cover. The inner barrel is sleeved with the outer barrel and provided with a third barrel port and a fourth barrel port, the third barrel port communicates with the inner container, and the fourth barrel port corresponds to the second barrel port. The inner cover is arranged on the fourth barrel port in an opening and closing manner. The outer diameter of the inner barrel is smaller than the inner diameter of the outer barrel, a first interlayer is formed between the outer hole assembly and the innerhole assembly, and the outer barrel is provided with a vacuum pumping port so that the first interlayer can be subjected to vacuum pumping.

Owner:ZHANGJIAGANG CIMC SANCTUM CRYOGENIC EQUIP +2

Optical fiber introduction device and optical fiber introduction method

The invention relates to the technical field of vacuum chambers, in particular to an optical fiber leading-in device and an optical fiber leading-in method for a vacuum chamber. The invention aims to provide an optical fiber leading-in device and an optical fiber leading-in method which are higher in air tightness when an optical fiber is led into a vacuum cavity. The optical fiber leading-in device comprises a blocking piece, a glue pouring seat, a vacuum pouring glue layer and a sealing bonding glue layer, a first groove body is formed in the edge of the blocking piece, a first annular boss and a second annular boss are arranged on the inner wall of the glue pouring seat, a second groove body is formed in the edge, close to a center hole, of the first annular boss, and a third groove body is formed in the edge, close to the center hole, of the second annular boss. The first groove body and the second groove body correspond to each other, the blocking piece is placed on the first annular boss, the blocking piece and the first annular boss are connected with each other, the first groove body and the second groove body which correspond to each other form a fixing groove used for containing a bare wire of one optical fiber, and the vacuum pouring sealant layer covers the blocking piece. And the sealing adhesive layer is covered on the vacuum pouring sealant layer.

Owner:BEIJING U PRECISION TECH

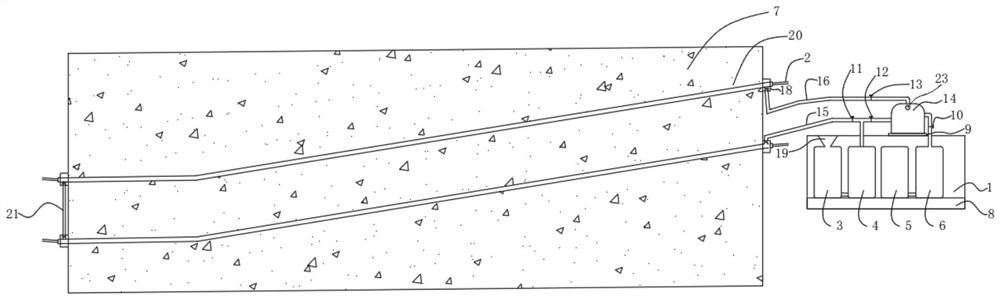

Post-tensioning prestressed box girder double-duct type vacuum-assisted mud jacking system and construction method thereof

InactiveCN112176874AGuaranteed vacuum tightnessAvoid pollutionBridge erection/assemblyBridge materialsPre stressArchitectural engineering

The invention discloses a post-tensioning prestressed box girder double-duct type vacuum-assisted mud jacking system and a construction method thereof. A sealing assembly seals the two ends of two prestressed reinforcement ducts respectively, the two ends of a communicating pipe are in sealed connection with the tail ends of the two prestressed reinforcement ducts respectively, and a vacuum degreemeasuring piece is used for measuring the vacuum degree of the prestressed reinforcement ducts; an vacuum-assisted mud jacking machine comprises a mud stirring bin provided with a mud inlet and a stirring mechanism, a mud jacking pump with the inlet connected with the mud stirring bin, a waste mud bin provided with a pressure release valve, a negative pressure bin, and a vacuum pump with the inlet connected with the negative pressure bin. The outlet of the mud jacking pump is divided into two paths, one path is in sealed connection with one prestressed reinforcement hole channel through a mudjacking pipe with a first valve, the other path is communicated with the waste mud bin through a pipeline with a second valve, and the waste mud bin is in sealed connection with the head end of the other prestressed reinforcement hole channel through a vacuum pipe with a third valve. The negative pressure bin is communicated with the waste mud bin through a pipeline with a fourth valve. Double-hole-channel one-time grouting can be achieved, and operation is convenient and fast.

Owner:CHINA FIRST METALLURGICAL GROUP

Ultrahigh vacuum sealing flange structure for non-circular channel of large Tokamak vacuum chamber

InactiveCN111710442AGuaranteed vacuum tightnessImprove vacuum sealing performanceNuclear energy generationThermonuclear fusion reactorCopper wireEngineering

The invention belongs to the field of magnetic confinement fusion (MCF) technologies, and particularly relates to an ultrahigh vacuum sealing flange structure for a non-circular channel of a large Tokamak vacuum chamber. The structure comprises a concave flange, a convex flange and a connecting pipe. Two matched 90-degree sealing steps are machined on the inner sides of the opposite end faces of the concave flange and the convex flange, and a copper wire ring is placed between the two sealing steps, so that a gap is reserved between the concave flange and the convex flange in the axial direction; and the concave flange and the convex flange are connected through a double-end threaded pin or a double-end stud. By means of the structural mode that the oxygen-free copper wire is compressed through the 90-degree sealing steps, the ultrahigh vacuum sealing requirements of non-circular channel window flanges of different shapes can be met, and the machining and maintaining difficulty of thesealing face of a non-circular window is reduced.

Owner:SOUTHWESTERN INST OF PHYSICS

Semiconductor device

PendingCN113871332AGuaranteed vacuum tightnessSimple structureSemiconductor/solid-state device manufacturingConveyor partsDevice materialThin membrane

The invention provides a semiconductor device, which comprises a preheating cavity. The preheating cavity comprises a shell, a heater arranged at the bottom of the shell and used for placing a substrate, an electrode arranged at the top of the shell and positioned above the substrate, and a lifting rotating mechanism connected with the electrode. According to the semiconductor device provided by the invention, the steps of thin film deposition can be simplified.

Owner:苏州辰华半导体技术有限公司

Making process of wind-power blade main model

Owner:北玻院(滕州)复合材料有限公司

A kind of LED light-emitting glass for outdoor curtain wall and preparation method thereof

ActiveCN105621903BRetain luminous propertiesEnhanced explosion-proof propertiesMechanical apparatusLighting elementsThermal insulationEngineering

The invention provides LED light-emitting glass used for an outdoor curtain wall and a preparation method of the LED light-emitting glass. The LED light-emitting glass comprises glass layers, a glue clamping layer, an infrared inflection layer, an electric conduction layer, LED lamps, sealing layers and a protection layer. The glass layers include the first glass layer, the second glass layer and the third glass layer which are stacked from top to bottom. The glue clamping layer is arranged between the first glass layer and the second glass layer. The infrared reflection layer is arranged on the lower surface of the second glass layer. The electric conduction layer is arranged on the upper surface of the third glass layer, and circuit grooves are etched in the electric conduction layer. The LED lamps adhere to the circuit grooves through electric conduction silver glue. The seams of the glass layers are filled with the sealing layers. The peripheries of the glass layers are coated with the protection layer. By means of the LED light-emitting glass, the characteristics of LED glass and vacuum glass can be effectively combined, the anti-explosion performance and the heat preservation and thermal insulation property of the LED light-emitting glass are enhanced, and the LED light-emitting glass is suitable for the outdoor curtain wall.

Owner:TAICANG YAOHUA GLASS

Vacuum pump bottle

ActiveCN109573308BFirmly connectedNot easy to fall offClosuresSingle-unit apparatusElastomerEngineering

The invention relates to a vacuum-pumped packaging bottle, which comprises a pump head and an elastic body. A discharge pipe is arranged in the pump head, and two through holes arranged in sequence along the discharge direction and close to each other are arranged in the discharge pipe, and the two through holes are connected together. One-way connected one-way valve, the fluid in the discharge pipe can only flow from the end of the one-way valve far away from the discharge port to the end close to the discharge port. The elastic body is mainly composed of a pressing cylinder, a telescopic cylinder and an annular connecting piece. Both ends of the tube are open, and the two open ends located on both sides of the connecting piece and close to each other are respectively connected with the inner ring and outer ring of the connecting piece. The hollow discharge cylinder has a plurality of discharge openings on the side wall of the hollow discharge cylinder. The parts in the vacuum-pumped packaging bottle of the present invention are compact and reliable, firmly connected, not easy to fall off during use, simple in structure, convenient in operation, can automatically cut off the paste, prevent paste backflow, and have good vacuum sealing performance.

Owner:ANHUI JND PLASTIC PACKAGING CO LTD

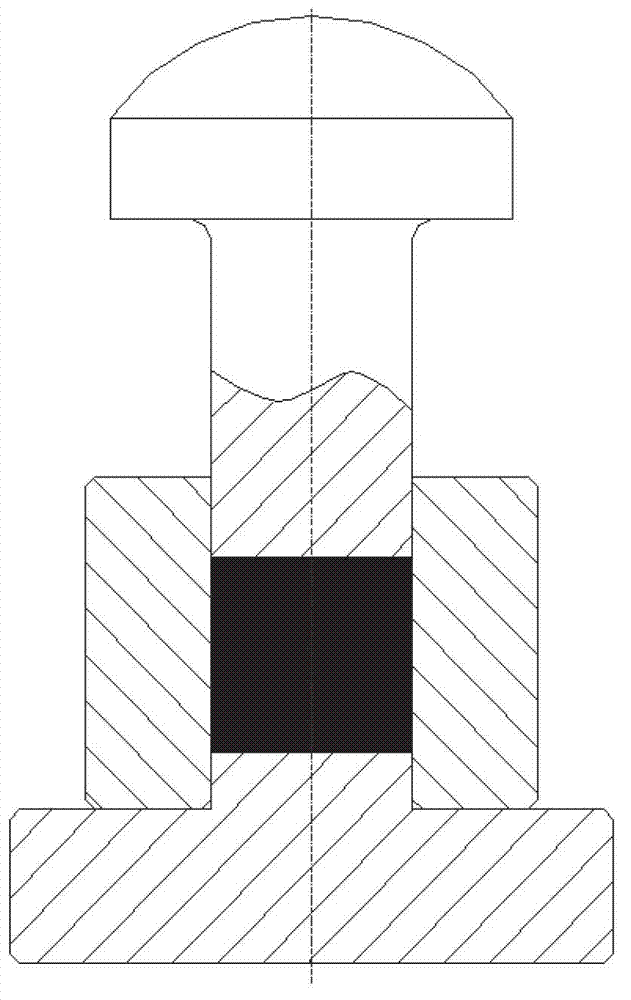

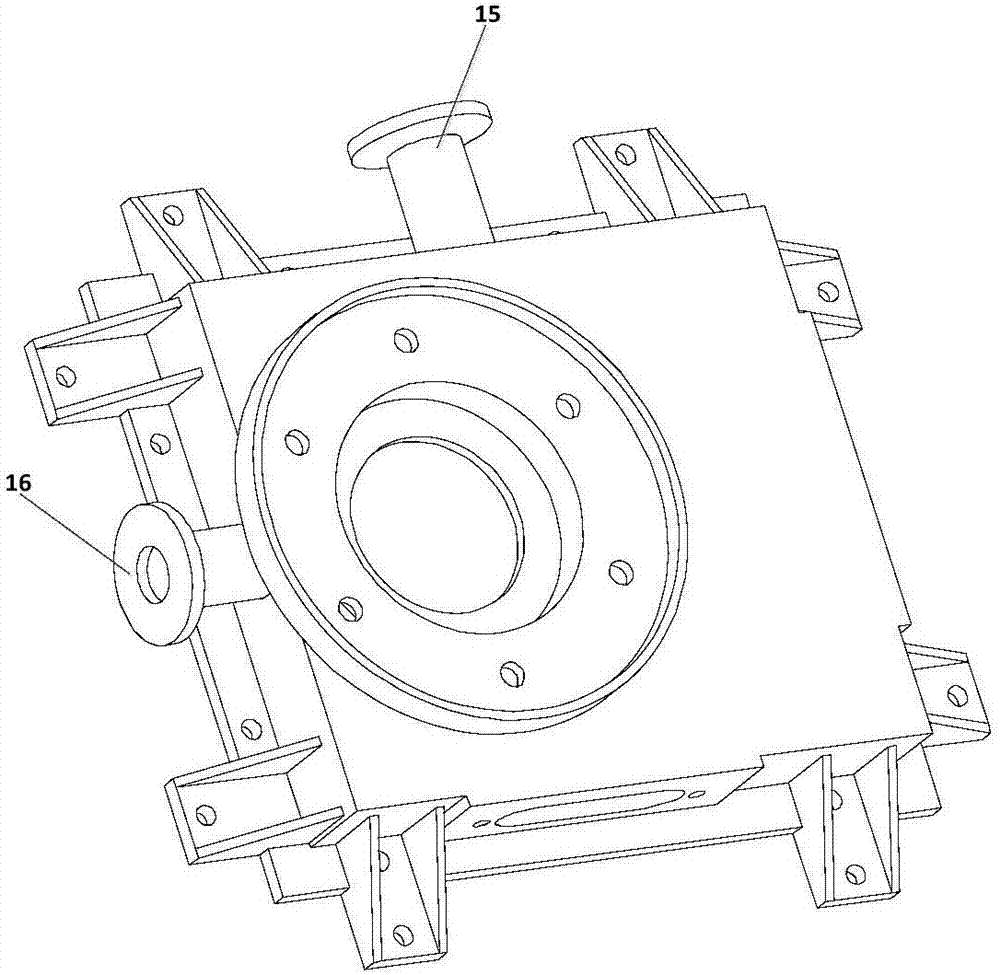

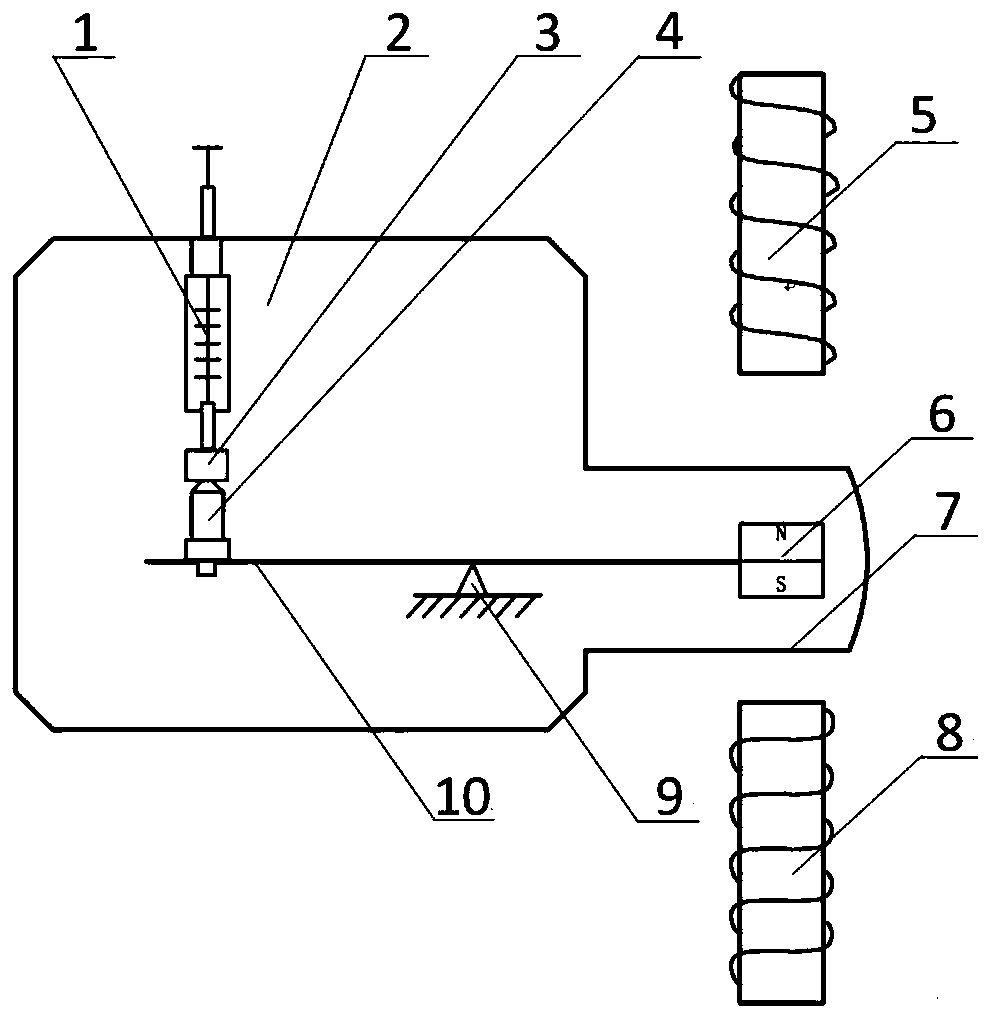

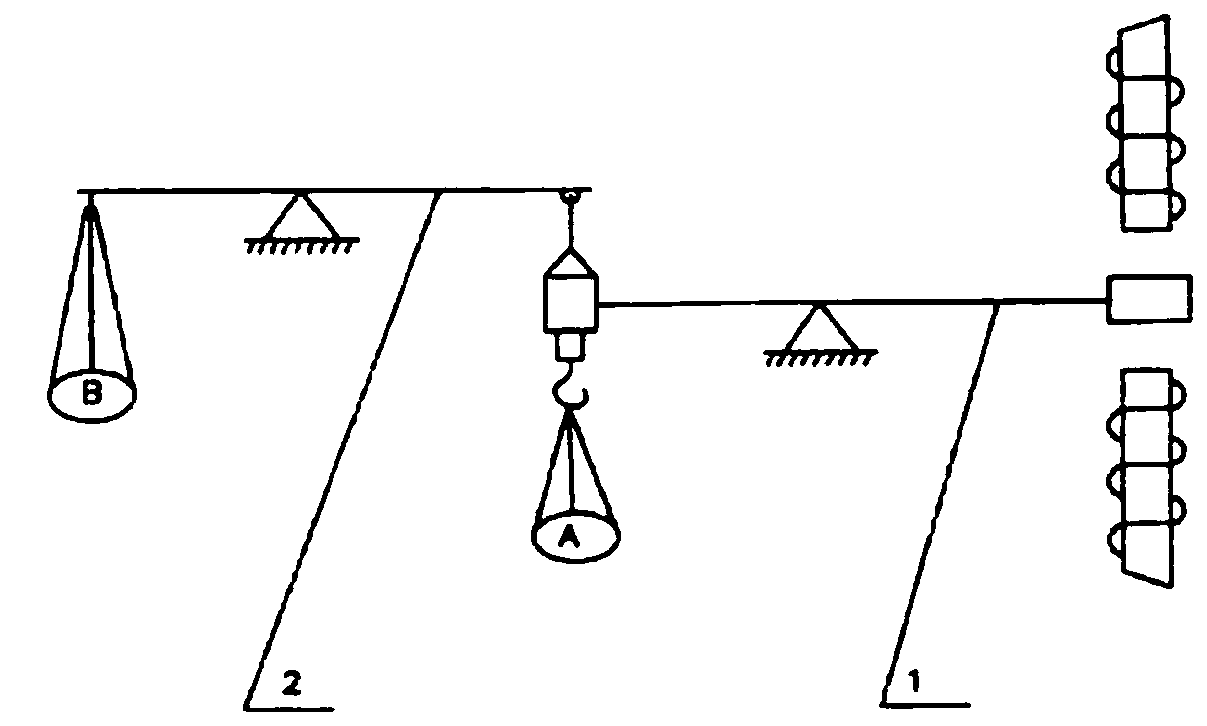

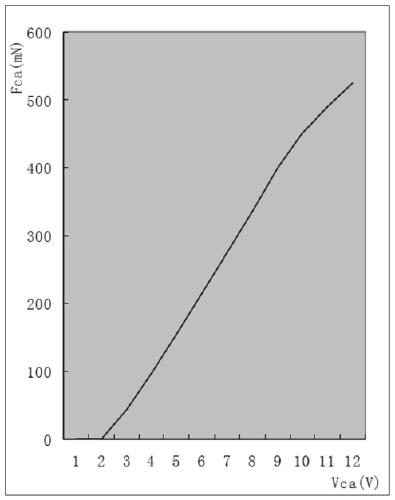

Method and device for testing friction pair material pair adhesion coefficient

ActiveCN108333103BEasy to measureRealize the test of the coefficient of adhesionUsing mechanical meansMaterial analysisAdhesion coefficientEngineering

The invention provides a method and device for testing the adhesion coefficient of a friction pair couple material. The method and device provided by the invention can realize loading and unloading ofnormal test load on the couple material in vacuum and ultrahigh vacuum environments and accurate measurement of cold welding force (adhesive force). According to the testing method for the adhesion coefficient of friction pair couple material, the action force generated by electromagnetic coils and magnets is transmitted to the couple material via a balancing lever so as to realize loading and unloading of the couple material in a vacuum environment, and thus, the measurement of cold welding force and adhesive force is accomplished; and a ratio of the cold welding force to the adhesive forceis calculated so as to obtain the adhesion coefficient of couple material in the vacuum environment.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

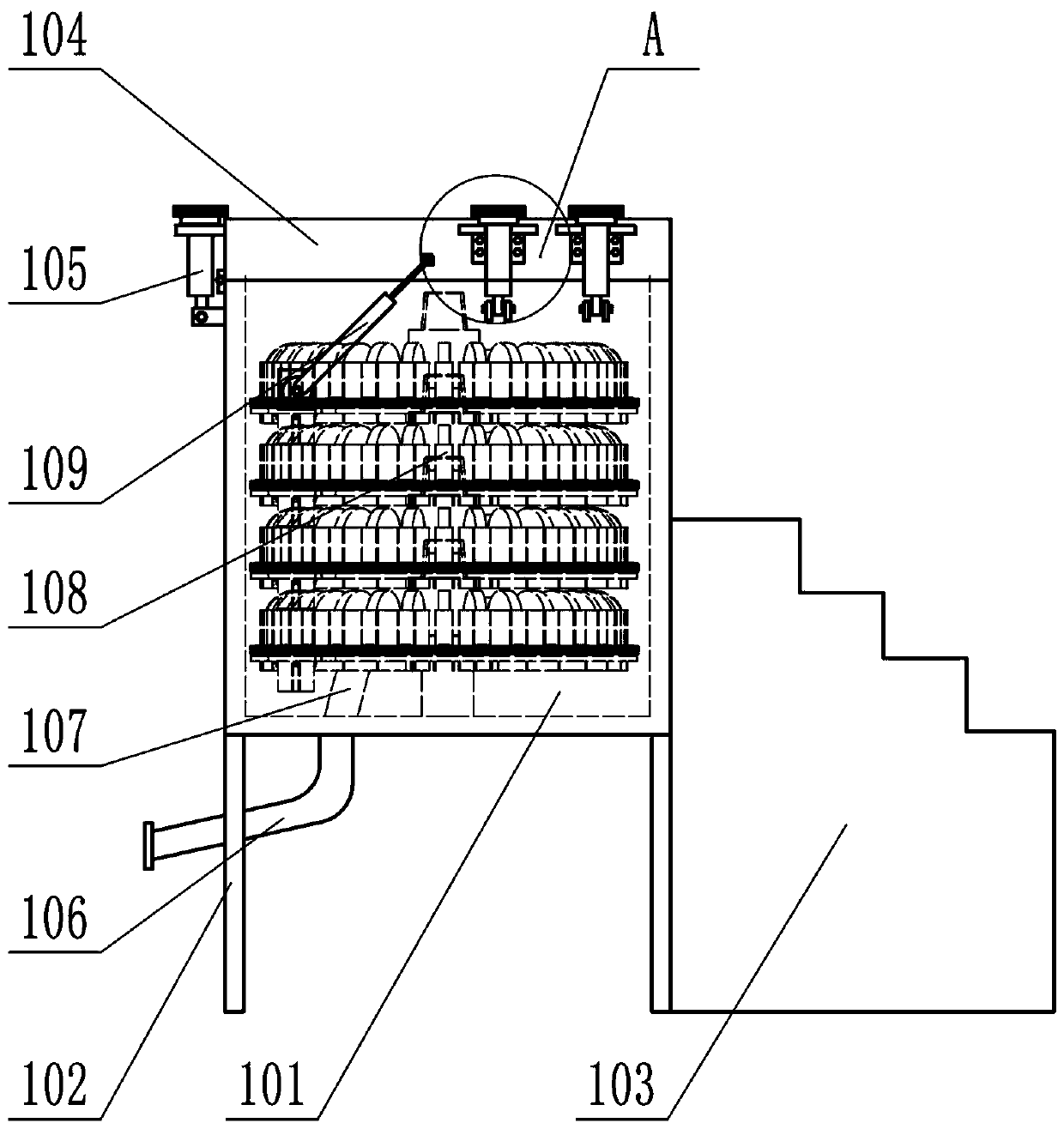

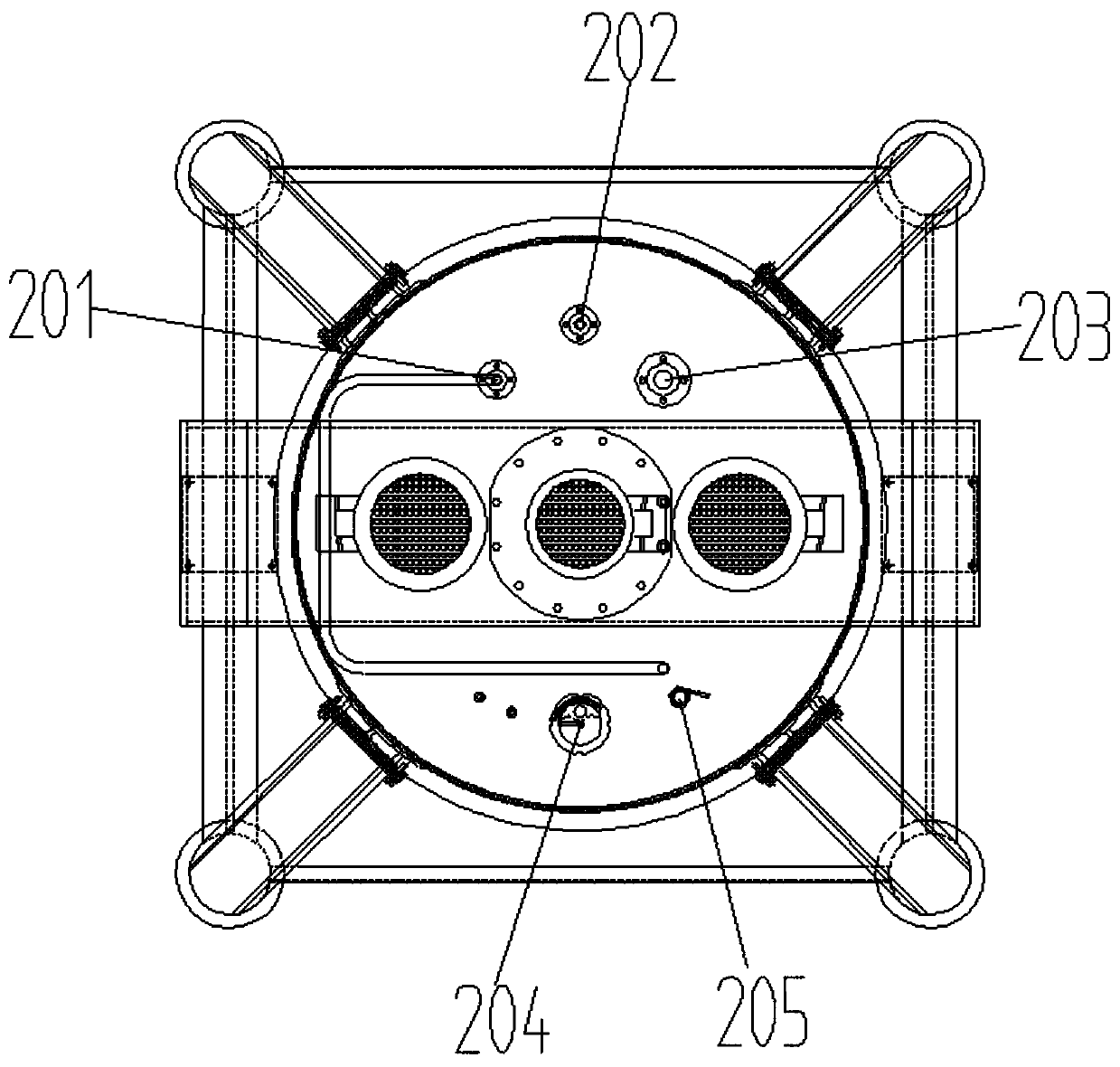

Modular continuous microwave freeze-drying chamber and microwave freeze-drying equipment containing said freeze-drying chamber

ActiveCN104964521BTo overcome the difference in temperature change and deformationGuaranteed vacuum tightnessDrying using combination processesHeating arrangementMicrowave cavityFreeze-drying

The invention relates to a modularization continuous microwave freeze-drying cavity which comprises a chamber body and a shielding plate. A boss part is arranged in the middle of the shielding plate, and body sealing ring grooves are formed in the four sides of the boss part. A shielding plate installation channel is formed in the middle of the bottom face of the chamber body. Grooves are formed in the two ends of the outer surface of the chamber body in the length direction of the chamber body, and positioning pin assembling holes are formed in the grooves. Adjacent sealing ring grooves are formed in the part, around the hollow structure, of one side end face of the chamber body. By means of the modularization continuous microwave freeze-drying cavity, the temperature change deformation difference caused by inconformity of coefficients of linear expansion between a freeze-drying bin made of nonmetal wave-transmitting materials and the microwave shielding plate made of metal materials is effectively overcome, and the vacuum sealing performance is ensured; a metal connecting piece between a chamber body and a shielding plate in the conventional technology is removed, and the microwave loading uniformity in the freeze-drying process is ensured; assembling is achieved through modularization design, and the requirements for increasing the yield and expanding production are effectively met.

Owner:周川

Manufacturing method for water collecting pipe in vacuum chamber of Tokamak device

PendingCN114799752AReduce welding difficulty and number of weldsGuaranteed vacuum tightnessNuclear energy generationWeld seamTokamak

The invention discloses a method for manufacturing a water collecting pipe in a vacuum chamber of a Tokamak device. The method comprises the following steps: respectively blanking a main pipe and a branch pipe of the water collecting pipe; a bottom hole is machined in the position of the branch pipe on the main pipe; a branch pipe flange of the main pipe is drawn out at each bottom hole, the pipe drawing area of the main pipe is heated to 900-1150 DEG C during drawing, and the length of the outer surface of the drawn branch pipe flange is larger than or equal to 3 mm; welding grooves in the welding positions of the main pipe, the branch pipe and the end socket are machined respectively; welding the branch pipes and the end sockets; the thickness of the pipe wall of the main pipe is 2-3 mm, and the thickness of the wall of the branch pipe is 2 mm. The branch pipe flanges are drawn on the main pipe, so that the welding difficulty of the branch pipes and the number of welding seams are reduced, the welding seams can be subjected to radiographic inspection, and the vacuum airtightness and the long-term use quality of the water collecting pipe are guaranteed; and the deformation resistance of drawing is reduced by high-temperature drawing, so that the relative permeability can be stably kept to be less than 1.04.

Owner:SOUTHWESTERN INST OF PHYSICS

Automobile hydraulic braking main cylinder secondary leather cup

InactiveCN107826093AControl deformationLarge amount of compressionPiston ringsBraking action transmissionMaster cylinderEngineering

The invention discloses an auxiliary leather cup of an automobile hydraulic brake master cylinder, and a component of an automobile hydraulic brake master cylinder, including a bowl body, the outer wall of the bowl body is provided with a sealing main lip, and the outer wall bottom of the bowl body is The end is provided with a sealing auxiliary lip, and the bottom side wall of the sealing auxiliary lip is in the same plane as the bottom end of the bowl and the plane is perpendicular to the axis of the bowl. The beneficial effect of the invention is that the vacuum degree requirement of the main cylinder is fully guaranteed, and the assembly is relatively simple, the movement resistance of the piston is reduced, and the service life of the main cylinder is prolonged.

Owner:诸城市骏恒汽车部件有限公司

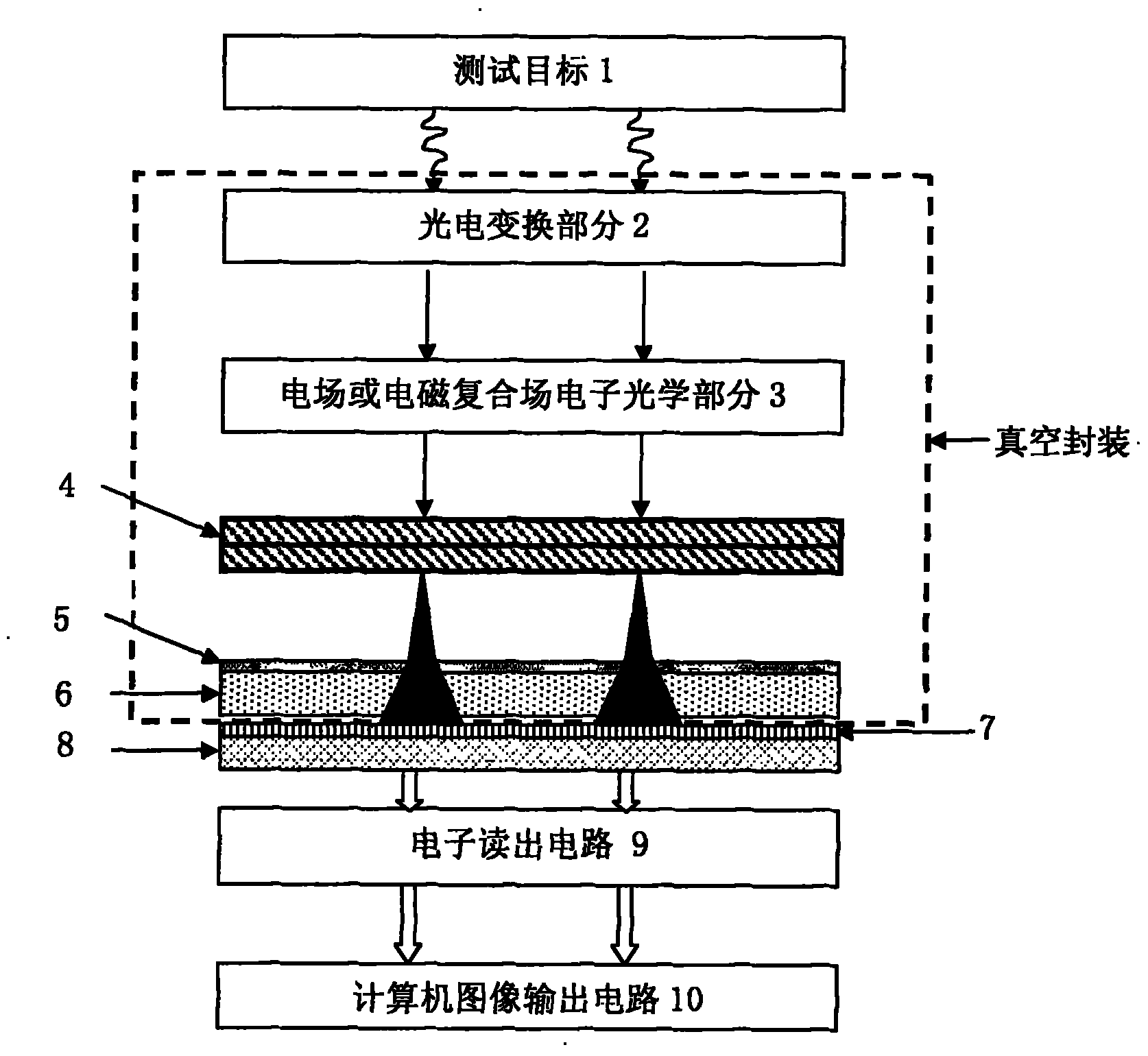

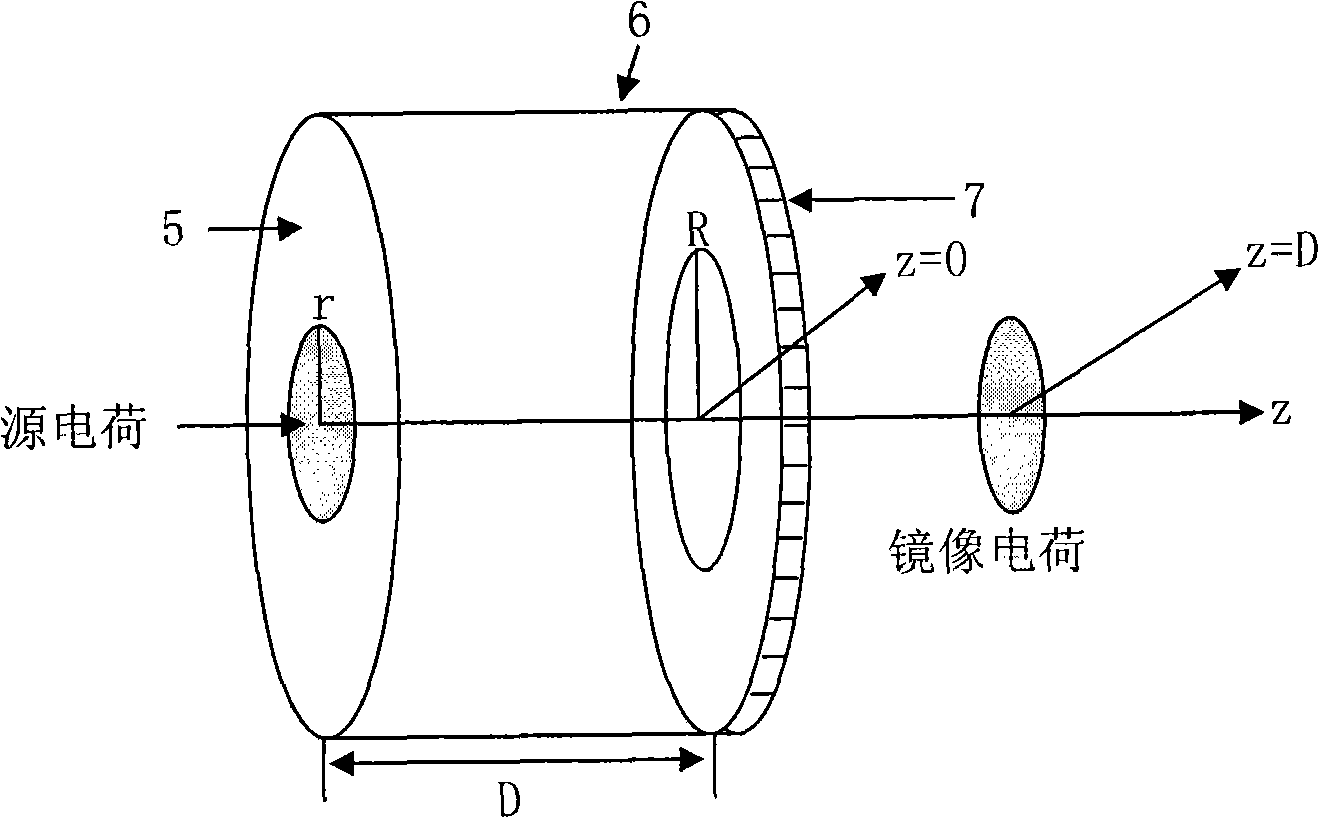

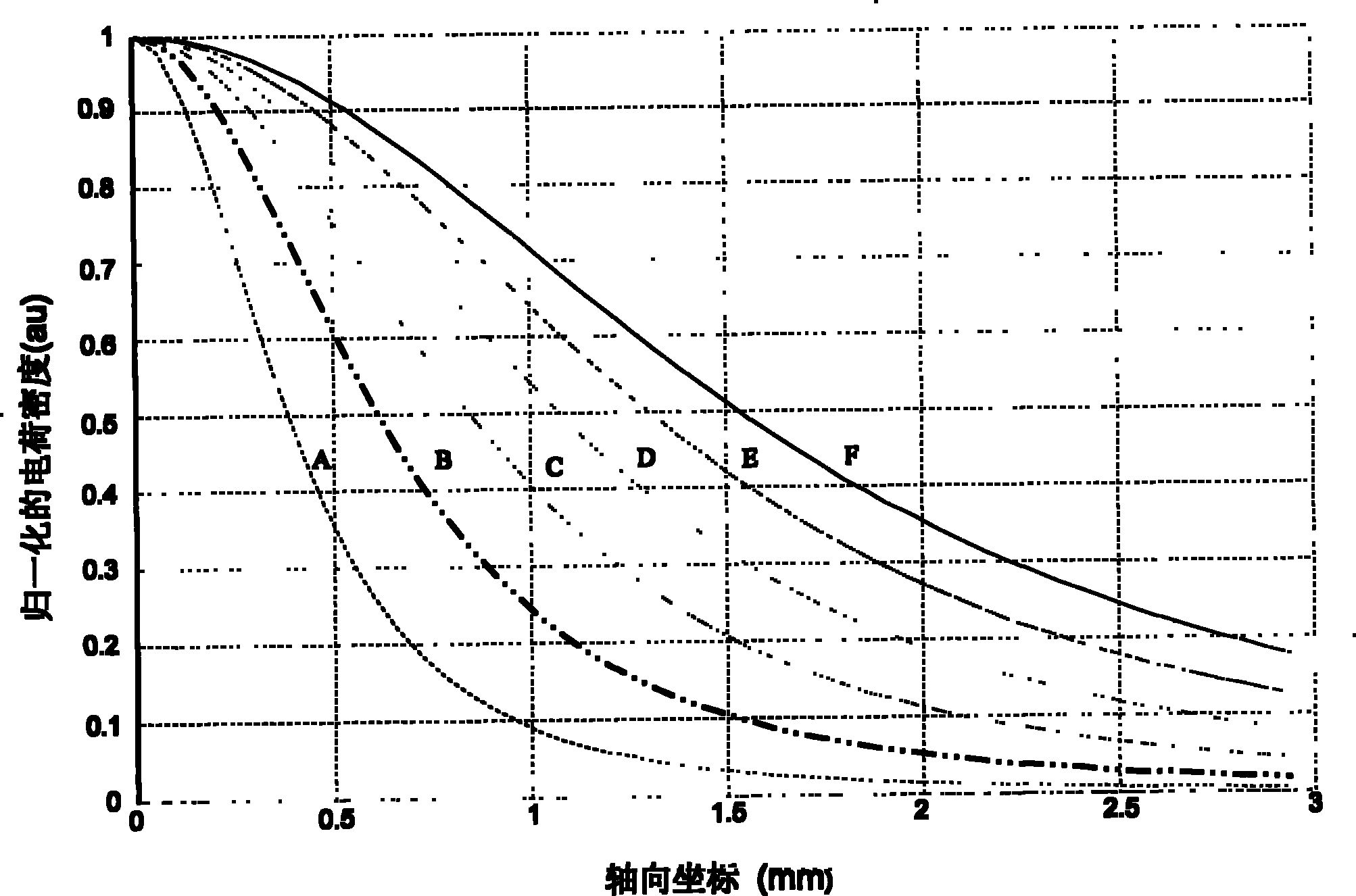

Electric charge induction image forming method based on semiconductor layer

InactiveCN101478645BGuaranteed isolationSimplifies electronics designTelevision system detailsImage pickup tubesImaging qualityImage detection

The present invention relates to a charge induction imaging method based on semiconductor layer, wherein the charge induction imaging method comprises the following steps: 1) changing the fluorescent screen of photoelectronic imaging device to the semiconductor layer with a substrate, setting a position sensitive anode at the outer side of vacuum at the back surface of substrate of semiconductor layer, and the range of square resistance of semiconductor layer is 100Momega / piece to 1000Momega / piece; 2) receiving the light signal of measured object by the photoelectronic conversion part of photoelectronic image device, transmitting photon into an electron optical system, entering a microchannel plate after focusing for multiplication, and forming an electron cloud; 3) bombarding the semiconductor layer after the microchannel plate with the electron cloud after electric field acceleration; 4) collecting the charges on the semiconductor layer through charge induction by the position sensitive anode at the back surface of substrate of semiconductor layer; and 5) realizing imaging detection through exteriorly connecting the position sensitive anode with an electron read-out circuit and a computer image output circuit. The charge induction imaging method of the invention settles the technical problems of inferior imaging quality, hard vacuum closing and inconvenient anode changing inprior art.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

A refrigerator jacket structure for a superconducting magnet and its installation and disassembly method

ActiveCN106960713BGuaranteed vacuum tightnessGuaranteed conduction heat leakageSuperconducting magnets/coilsSuperconducting CoilsEngineering

A refrigerator jacket structure for superconducting magnets and methods for its installation and disassembly, which relate to the technical fields of cryogenic engineering and superconducting magnets; from top to bottom, it includes a refrigerator flange seat (3), a first-stage bellows ( 11), the first-stage flange seat (12) that forms a thermal connection with the cold shield, the second-stage bellows (21), and the second-stage flange seat (22) that forms a thermal connection with the superconducting coil; the flange seat of the refrigerator (3) is connected with the primary flange seat (12) through the primary bellows (11), and between the primary flange seat (12) and the secondary flange seat (22) through the secondary bellows (21 ) connection; it has the characteristics of low conduction heat leakage, high vacuum sealing performance, high thermal connection efficiency, and long life of the refrigerator.

Owner:杭州图锐科技有限公司

Improved vacuum arc-extinguishing chamber

PendingCN112216553AFor a solid connectionAchieving a welded sealHigh-tension/heavy-dress switchesAir-break switchesPhysicsEngineering

The invention relates to the technical field of vacuum arc-extinguishing chambers, and particularly discloses an improved vacuum arc-extinguishing chamber, which comprises an insulating shell, a static contact and a movable moving contact. A corrugated pipe and a shielding cylinder are positioned in the insulating shell, the corrugated pipe sleeves the outer side of the moving contact, and a firstsolder ring is welded to seal a gap between one end of the corrugated pipe and the insulating shell; the second welding flux ring is used for welding and sealing a gap between the other end of the corrugated pipe and the moving contact; the shielding cylinder surrounds and sleeves the outer side of the first contact and the outer side of the second contact; the third solder ring is welded with the shielding cylinder and the insulating shell; the fourth solder ring is used for welding and sealing a gap between the static contact and the insulating shell. By means of the arrangement of the first solder ring, the second solder ring and the fourth solder ring, welding sealing of the first contact, the second contact and the insulating shell is achieved, and the vacuum sealing performance of the first contact and the second contact is fully guaranteed. By means of the arrangement of the third solder ring, stable connection between the shielding cylinder and the insulating shell is achieved, and the electromagnetic shielding performance of the first contact and the second contact is fully guaranteed.

Owner:SANYOU CORP LTD

Capacitor dry vacuum environment packaging group

PendingCN111739741AGuarantee the quality of vacuum packagingQuality assuranceFixed capacitor housing/encapsulationEncapsulating capacitors apparatusVacuum pumpingHigh capacitance

The invention discloses a capacitor dry vacuum environment packaging group. Through the arrangement of a vacuum chamber upper cover, a vacuum chamber lower cover and a vacuum pumping pipe, a very goodair drying environment can be provided when the capacitor is subjected to vacuum packaging work, and the normal operation of the vacuum packaging work of the capacitor and the vacuum packaging quality can be guaranteed. By arranging a sealing strengthening structure, a good strengthening and sealing effect on the connection and sealing of the vacuum chamber upper cover and the vacuum chamber lower cover is realized, the quality of the vacuum environment is guaranteed, and further the vacuum packaging quality of the capacitor is guaranteed. Through the sealing connection of an arranged rubbersealing ring, a rubber sealing round block and an aluminum shell, the vacuum tightness is guaranteed. By arranging a clamping groove, a circular sealing groove, a circular sealing ring and an elasticclamping block, the connecting, sealing and fixing functions of the rubber sealing ring and the aluminum shell and the sealing and fixing functions of the rubber sealing circular block and the rubbersealing ring are guaranteed, and then the vacuum sealing performance of the capacitor is improved.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com