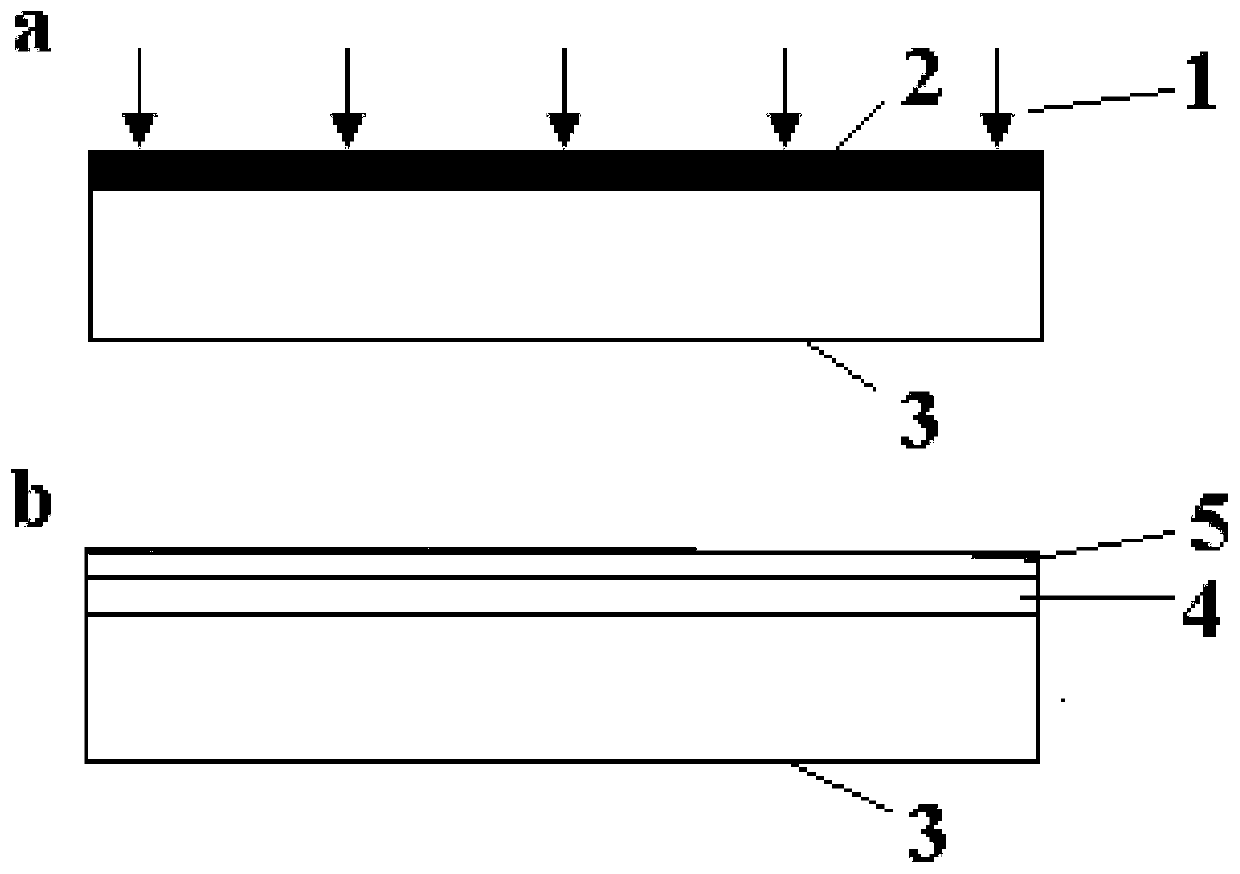

Energy transmission window sheet for terahertz band vacuum device and preparation method thereof

A vacuum device and terahertz technology, which is applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc., can solve problems affecting the sealing performance and strength of brazing, poor bonding force of metallization layers, and air leakage of energy transmission windows and other issues, to achieve the effect of improving mechanical strength, increasing binding force and reducing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Put the composite diamond on the sample stage of the microwave plasma chemical vapor deposition equipment, and make the nucleation face upward;

[0041] Microwave H on the nucleation surface 2 / O 2 Mixed atmosphere plasma etching, control oxygen flow rate to 5sccm, hydrogen flow rate to 95sccm, air pressure to 13KPa, microwave power to 2.2KW, substrate temperature to 850°C, remove 4μm surface layer containing defects and non-diamond phase on the nucleation surface;

[0042] Then carry out the growth of the microcrystalline diamond film, control the flow of methane to 3sccm, the flow of hydrogen to 300sccm, the air pressure to 18.6KPa, the microwave power to 2.4KW, the substrate temperature to 900°C, and the growth thickness to be 10μm.

[0043] Then, the ultra-nanocrystalline diamond film is grown on the microcrystalline diamond film, and the methane gas flow is controlled to be 1.5 sccm, the argon gas flow is 240 sccm, the hydrogen gas flow is 6 sccm, the air pressure...

Embodiment 2

[0046] Put the composite diamond on the sample stage of the microwave plasma chemical vapor deposition equipment, and make the nucleation face upward;

[0047] Microwave H on the nucleation surface 2 / O 2 Mixed atmosphere plasma etching, control oxygen flow rate to 5sccm, hydrogen flow rate to 95sccm, air pressure to 13KPa, microwave power to 2.2KW, substrate temperature to 850°C, remove 4μm surface layer containing defects and non-diamond phase on the nucleation surface;

[0048] Then carry out the growth of the microcrystalline diamond film, control the flow of methane to 3sccm, the flow of hydrogen to 300sccm, the air pressure to 18.6KPa, the microwave power to 2.4KW, the substrate temperature to 900°C, and the growth thickness to be 10μm.

[0049] Then carry out the growth of nanocrystalline diamond film on the microcrystalline diamond film, control the methane gas flow to be 6sccm, the hydrogen flow to be 200sccm, the air pressure to be 17.3KPa, the microwave power to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com