Manufacturing method for water collecting pipe in vacuum chamber of Tokamak device

A tokamak and manufacturing method technology, applied in the field of magnetic confinement nuclear fusion device manufacturing, can solve the problems that the water collection pipe manufacturing process cannot meet the vacuum airtightness use requirements, etc., to ensure long-term use quality, reduce deformation resistance, and reduce welding Effect of Difficulty and Number of Welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

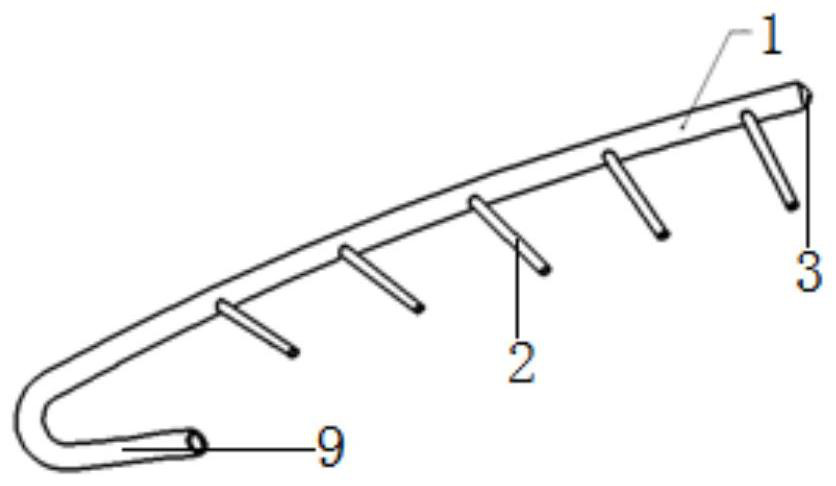

[0051] manufactured as figure 1 The water collecting pipe shown is composed of a main pipe 1. The main pipe 1 has an arc shape with a small curvature. The thickness of the pipe wall of the main pipe 1 is 2mm to 3mm; The thickness is 2mm; one end of the main pipe 1 is welded with a head 3, and the other end of the main pipe 1 is bent at a certain angle in the form of an elbow and has an opening with a large curvature. Manufactured as follows:

[0052] Step 1: Expand the blanking

[0053] First, open the main pipe 1 and branch pipe 2 of the water collection pipe, and use stainless steel pipes to cut the main pipe 1 and branch pipe 2 respectively. Control the wall thickness of the main pipe 1 raw material to be 1mm larger than the minimum required wall thickness of the finished product to compensate for the bending and pulling of the main pipe 1. Pull out the thinning of the flange. The raw material of the stainless steel pipe is qualified for non-destructive testing and the m...

Embodiment 2

[0074] manufactured as figure 1 The water collecting pipe shown is composed of a main pipe 1. The main pipe 1 has an arc shape with a small curvature. The thickness of the pipe wall of the main pipe 1 is 2mm to 3mm; The thickness is 2mm; one end of the main pipe 1 is welded with a head 3, and the other end of the main pipe 1 is bent at a certain angle in the form of an elbow and has an opening with a large curvature. Manufactured as follows:

[0075] The contents of Steps 1 and 2 are consistent with those of Embodiment 1.

[0076] Step 3: Process the main pipe and draw the bottom hole

[0077] The bottom hole before the drawing process is processed at the position of the branch pipe 2 on the main pipe 1, and the diameter of the drawing bottom hole is 6 mm smaller than the inner diameter of the branch pipe 2.

[0078] Step 4: Pull the flange of branch pipe 2 of main pipe 1

[0079] Use a drawing die to pull out the flange of the branch pipe 2 of the main pipe 1. During dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com