Automobile hydraulic braking main cylinder secondary leather cup

A technology of hydraulic brakes and auxiliary cups, which is applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problems of difficult assembly, increased piston movement resistance, and shortened life, and achieve simple assembly and reduced piston movement resistance. Small, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The front and back directions involved in the present invention are as follows: the direction in which the piston 2 moves during braking is the front, and the opposite direction is the back.

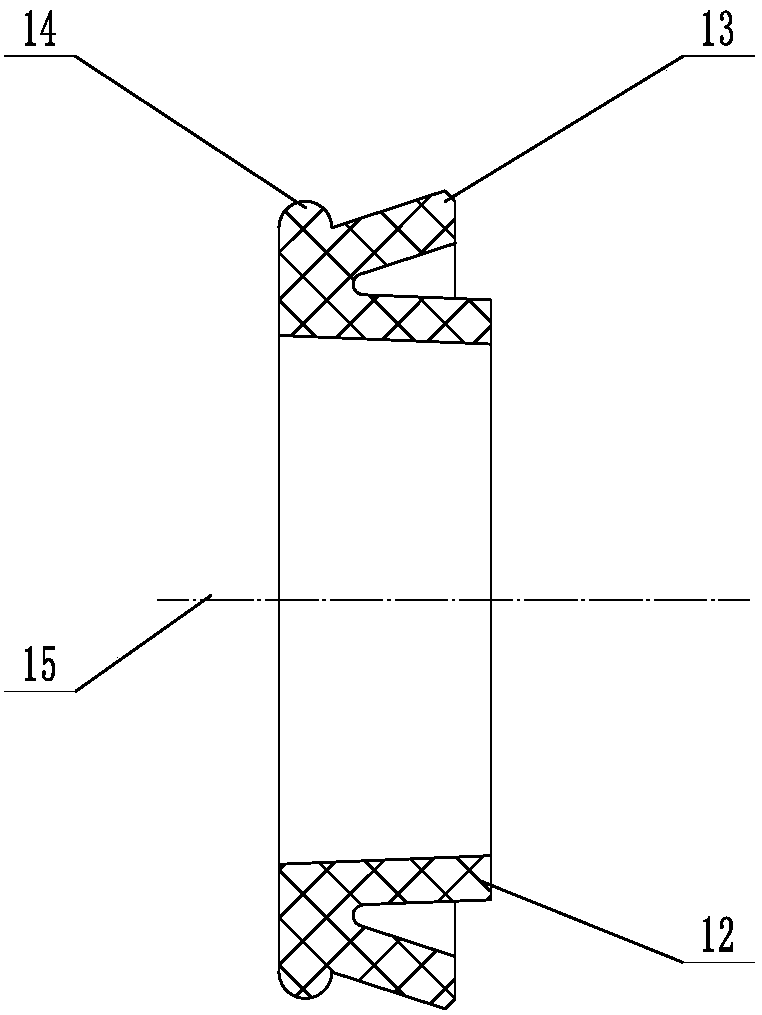

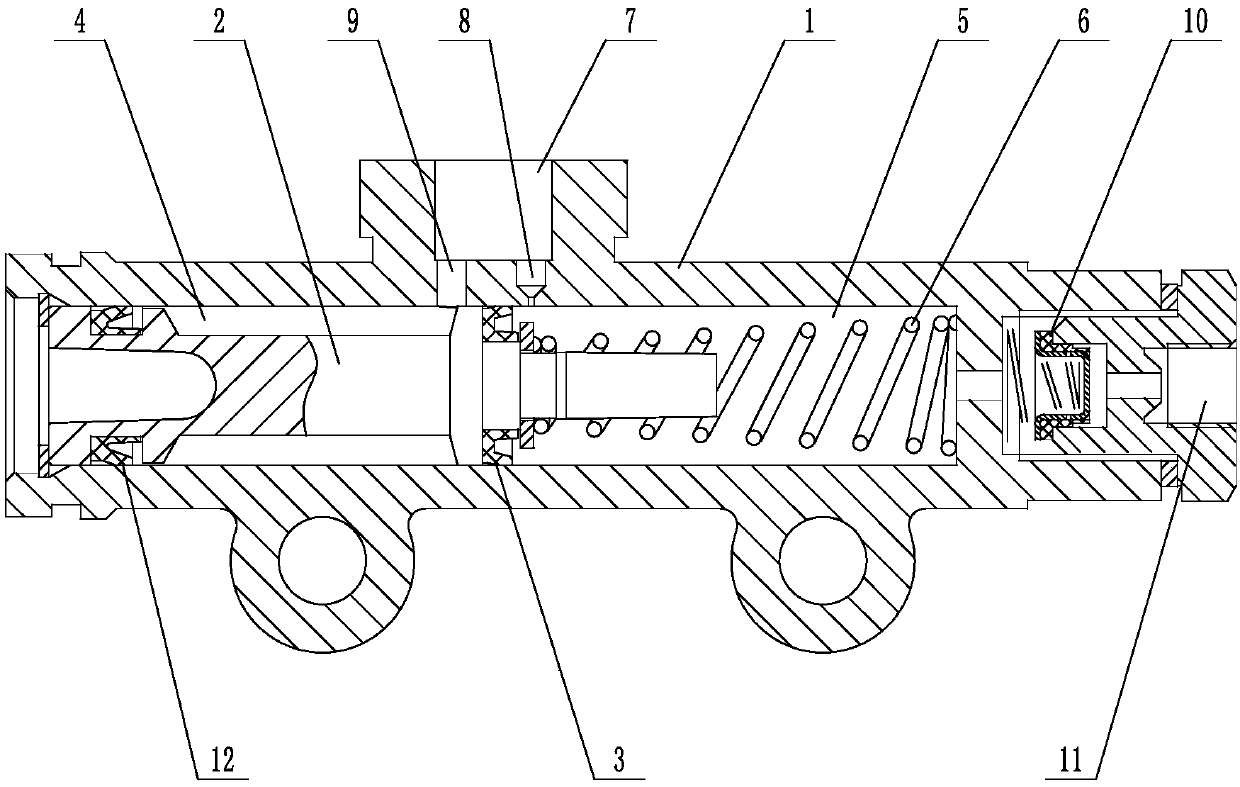

[0020] Such as Figure 1-2 As shown, the brake master cylinder of the automobile hydraulic brake includes a cylinder body 1, a piston 2 installed in the inner cavity of the cylinder body 1, and a main cup 3 set close to the head of the piston 2 is sleeved on the front of the piston 2.

[0021] The main cup 3 divides the inner chamber of the cylinder body 1 into a liquid storage chamber 4 at the rear and a brake chamber 5 at the front. The brake chamber 5 is equipped with a return spring 6 that drives the piston 2 to reset, that is, the return spring 6 The front end of the position spring 6 leans against the front end wall of the inner cavity of the cylinder body 1, and the rear end is sleeved on the front end of the piston 2 . The cylinder body 1 is provided with an oil inlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com