Patents

Literature

32results about How to "Requirements for maintaining vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

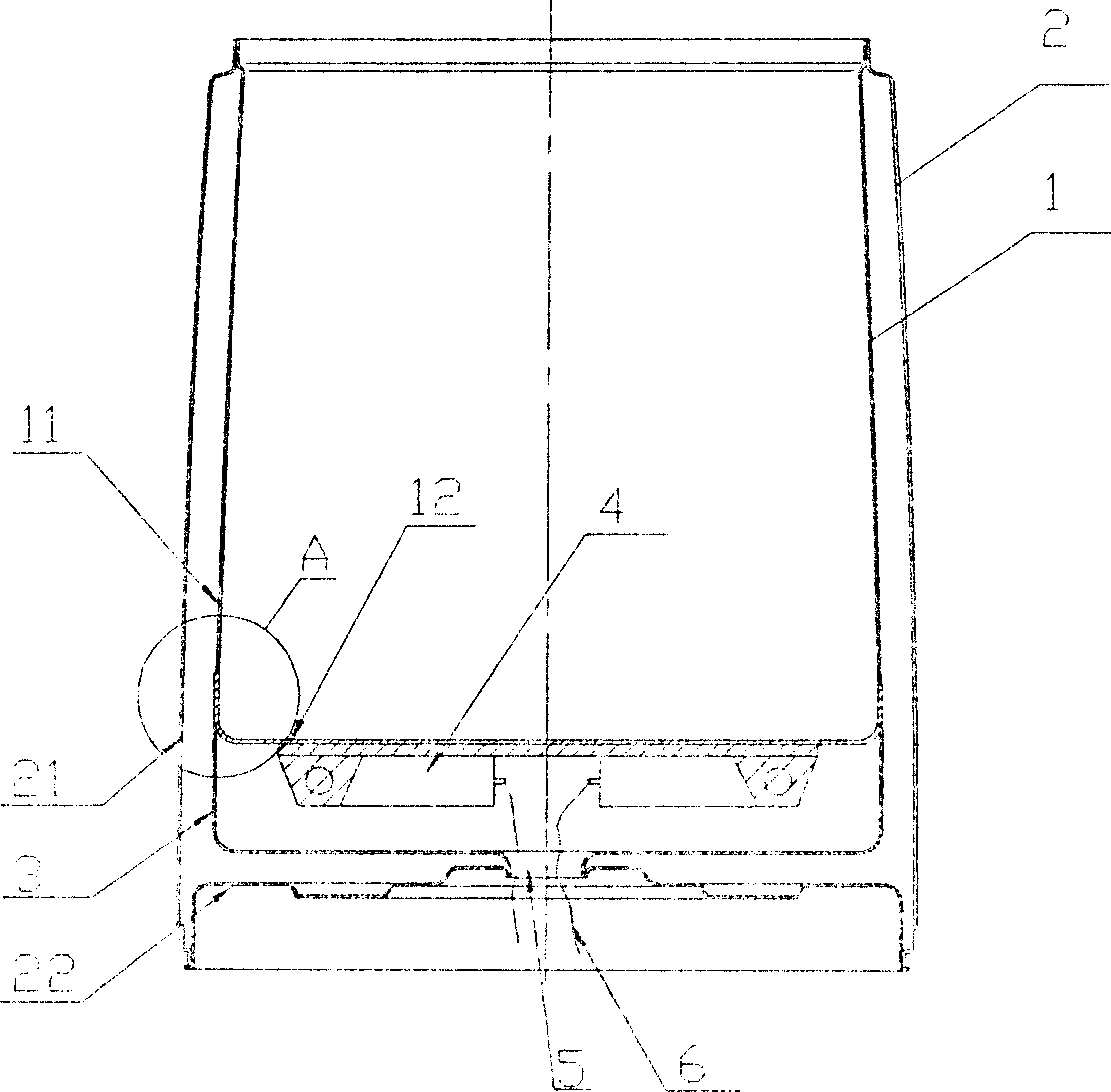

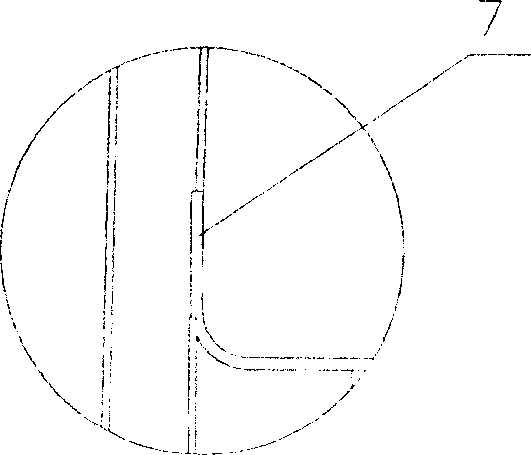

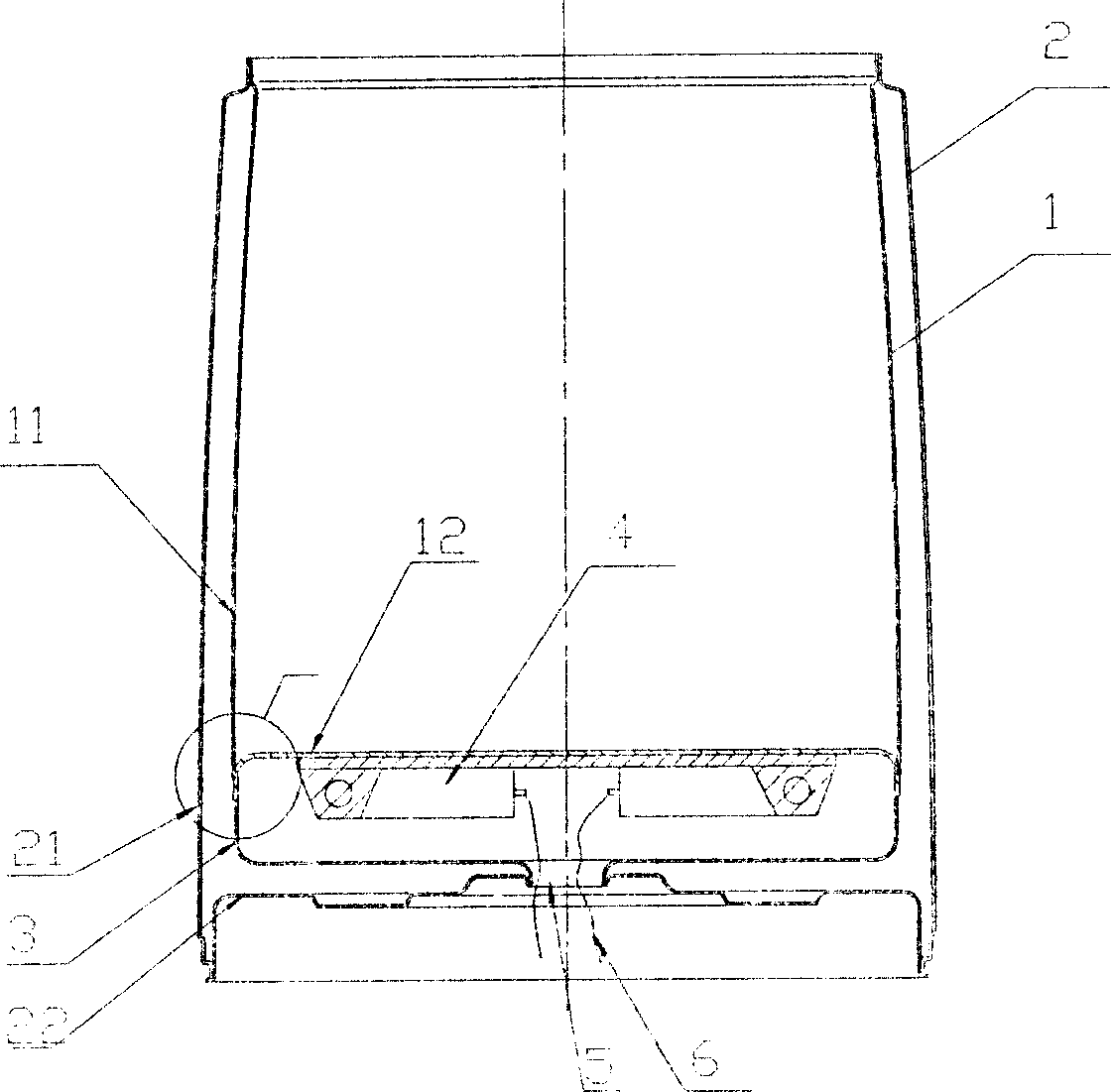

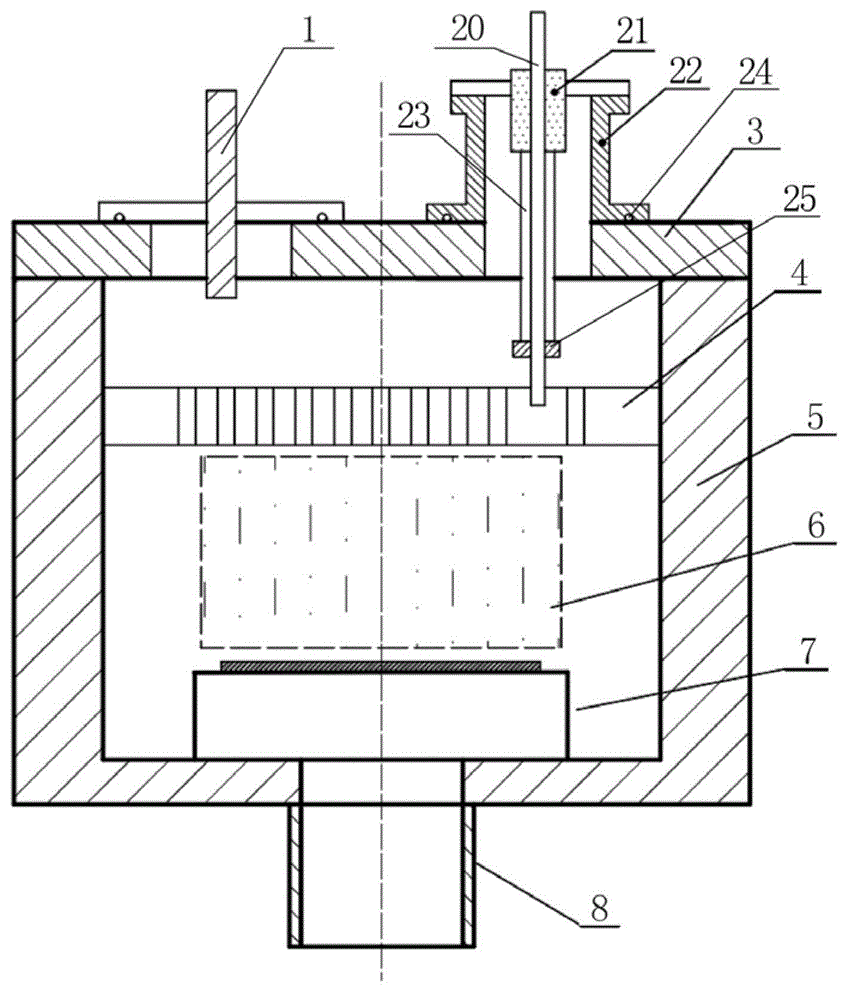

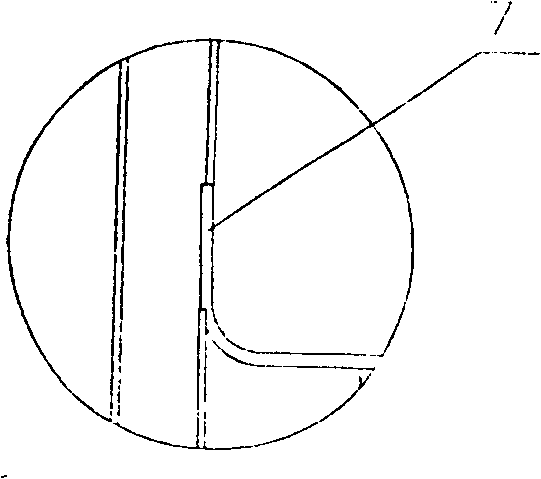

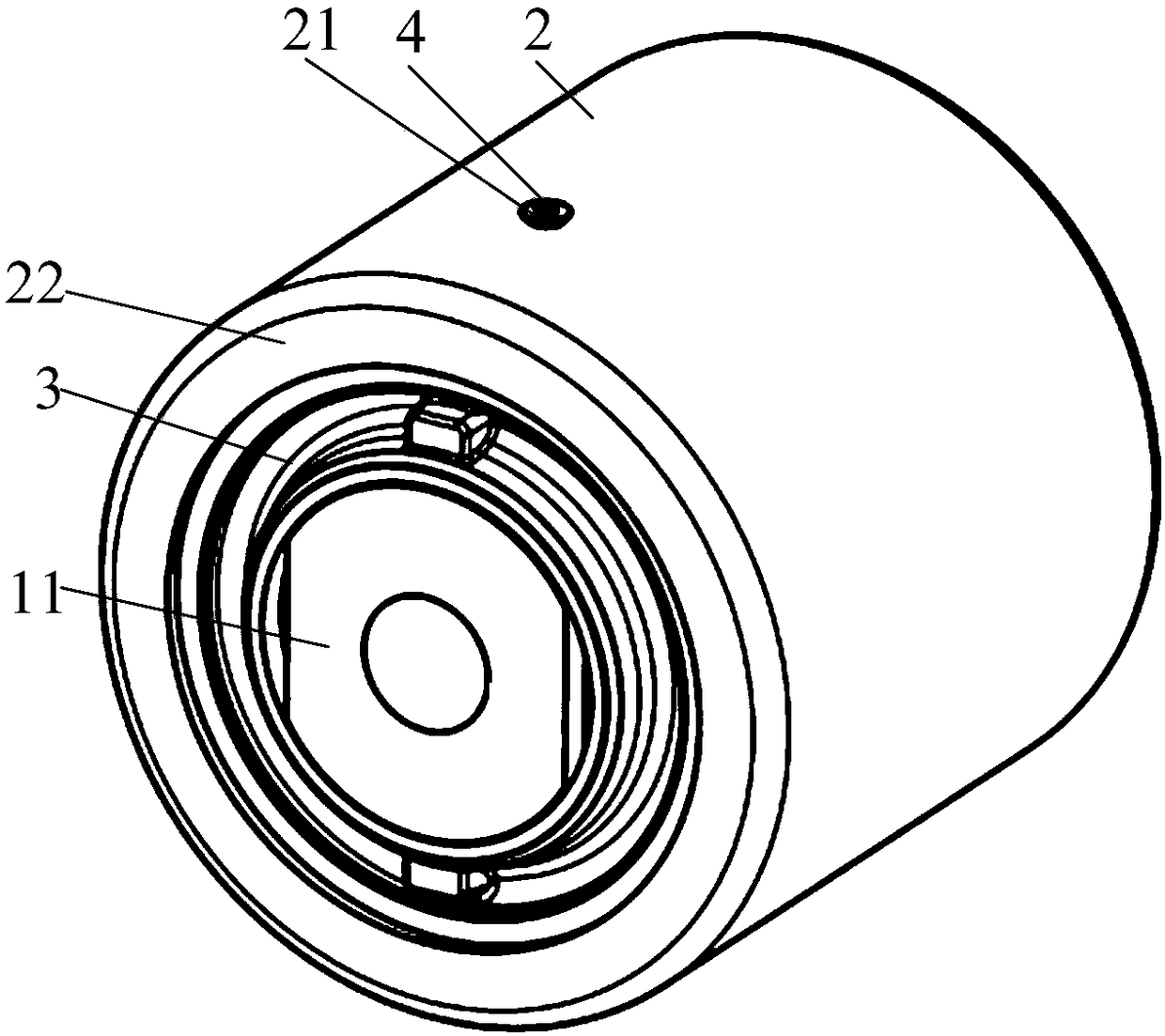

Glass liner structure of vacuum electric heating vessel

InactiveCN1911148AImprove manufacturabilityGuarantee welding qualityNon-pressured vesselsWarming devicesElectric heatingSignal lines

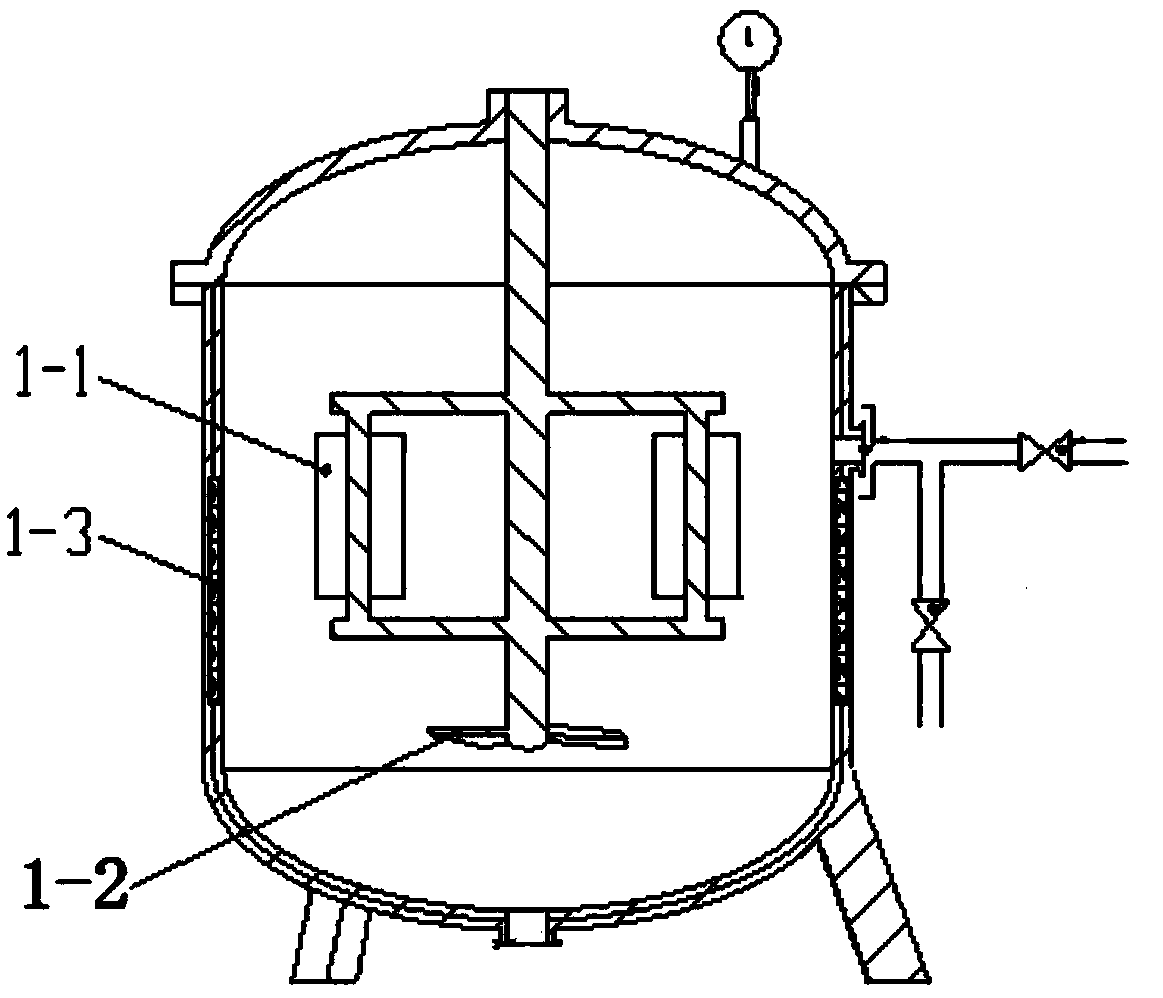

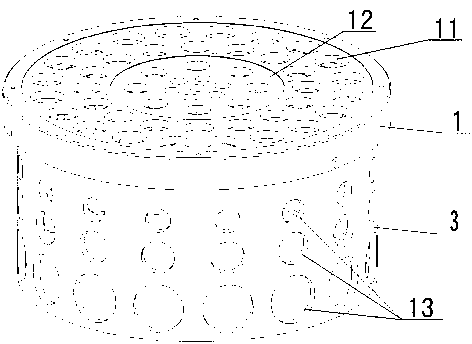

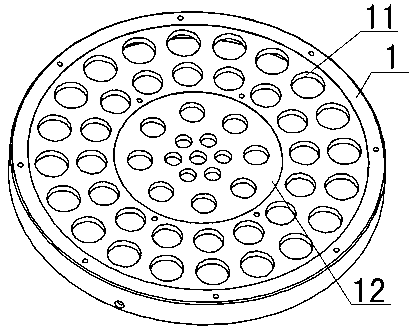

A main body structure of an electrically heated container with vacuum layer is composed of an internal container, an external casing, a sealed vacuum layer between said internal container and external casing, and an electric heater with power cord and signal lines. Its all units are welded for high sealing performance.

Owner:白明军 +1

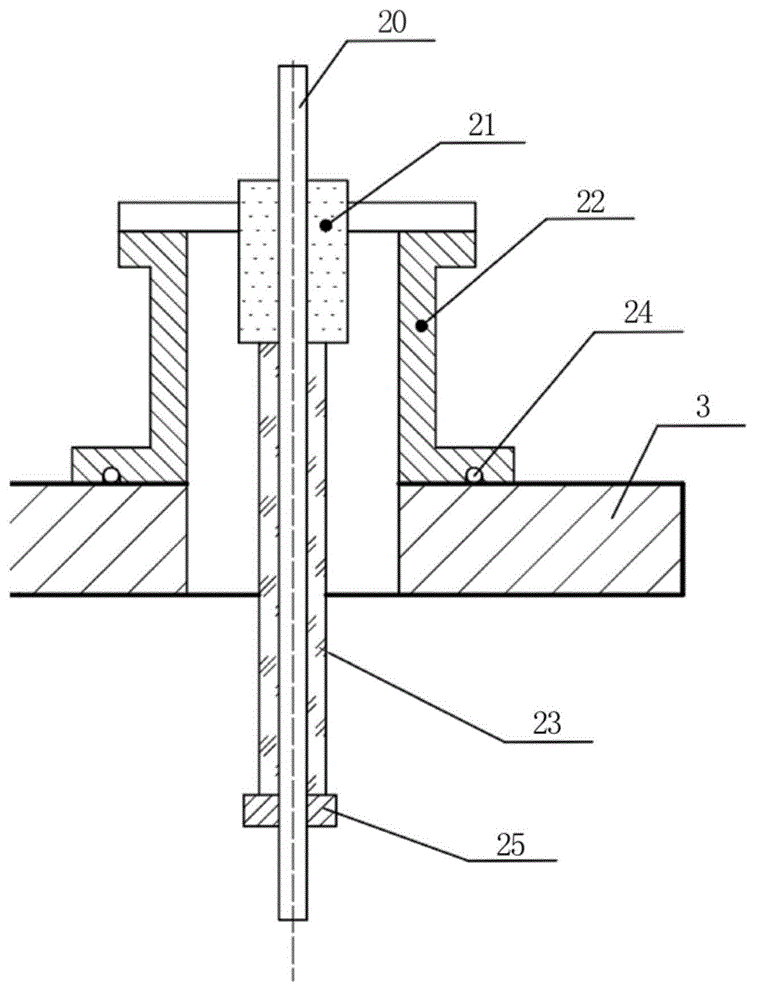

Electrode introducing structure

ActiveCN103065918ARequirements for maintaining vacuumReduce or avoid non-uniform ignitionElectric discharge tubesEngineeringElectrode

The invention relates to the technical field of plasma process equipment, in particular to an electrode introducing structure. The electrode introducing structure is used for the plasma process equipment and comprises an electrode and an insulation protective structure covered on the electrode. The insulation protective structure comprises a cylindrical first insulation cover and a cylindrical second insulation cover arranged below the first insulation cover. The second insulation cover is fixed on the electrode. The first insulation cover is fixed on the upper end of a cavity cover of the plasma process equipment. The electrode introducing structure is capable of reducing or avoiding the problem of uneven plasma glow and the like caused by protection and electric insulation and the like, free from air escape under the condition of plasma glow and capable of meeting the requirement of vacuum degree of a vacuum cavity.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

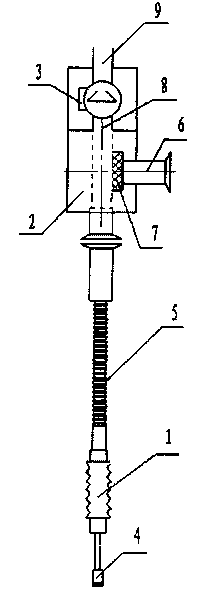

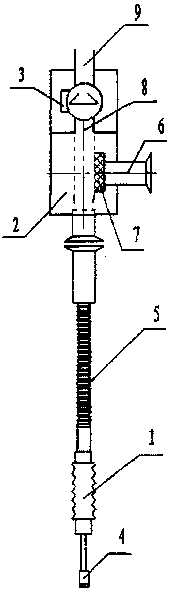

Speedy suction gun device

InactiveCN101706351AEffective filteringRequirements for maintaining vacuumDetection of fluid at leakage pointAir pumpEngineering

The invention discloses a speedy suction gun device. The invention is characterized in that the speedy suction gun device comprises a valve seat, the valve seat is internally provided with a through hole, two ends of the through hole are connected with suckers and the gas inlet of a miniature gas pump by hoses, the gas outlet of the miniature gas pump communicates with the atmosphere; the valve seat is provided with leakage detection holes to communicate with the through hole, and a gas separator is arranged on the leakage detection holes. The invention can avoid the problem of slow response time of a common suction gun, shortens response time and improves leakage detection efficiency. The adoption of the helium separator effectively filters such impurities as dust, macromolecular gases and the like, ensures volume degree requirement of the helium mass spectrum leak detector, avoids contamination ad prolongs service life of the detector. And meanwhile the invention combined with the mass spectrum leak detector can be widely applied to leakage detection of various aeration equipments and instruments.

Owner:晋兵

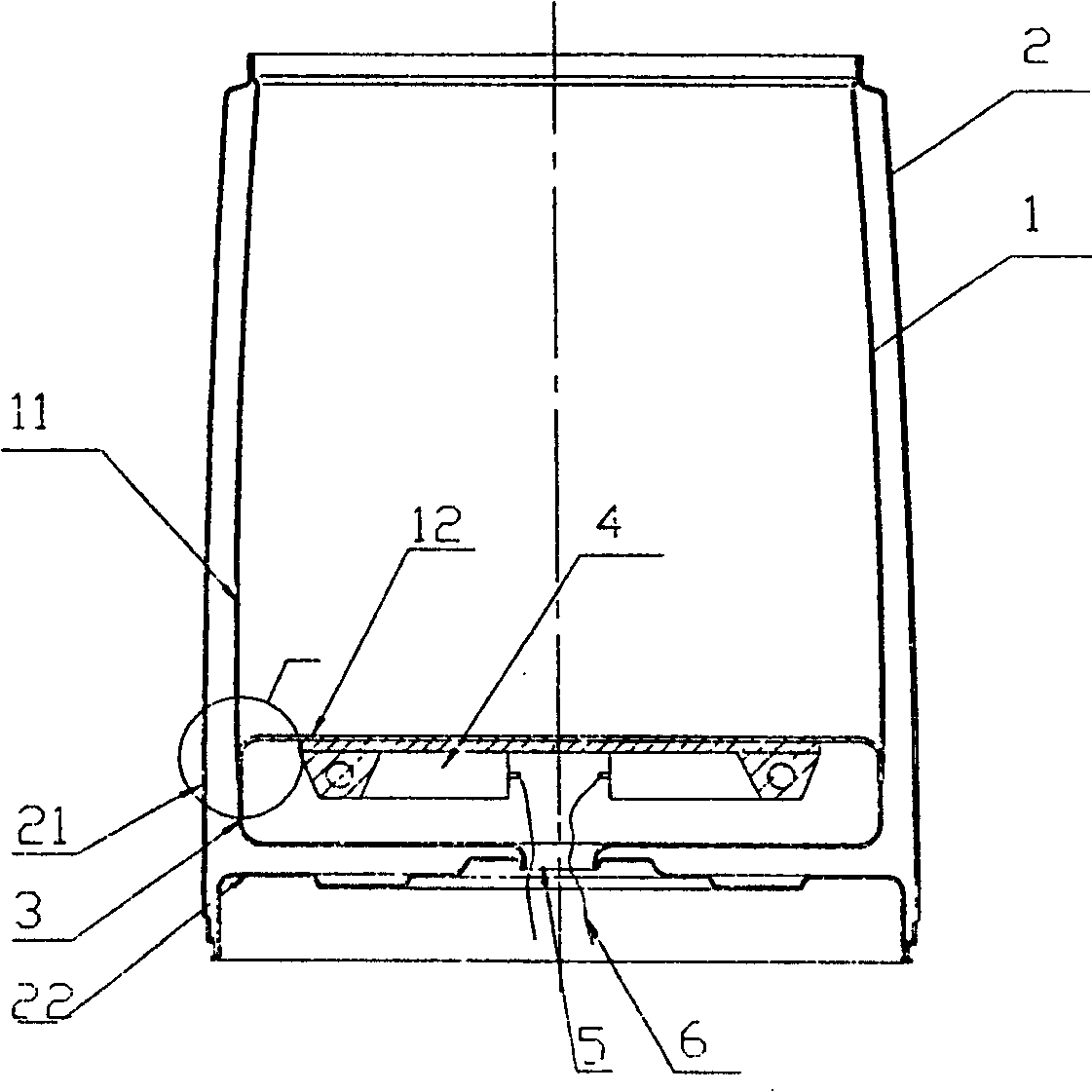

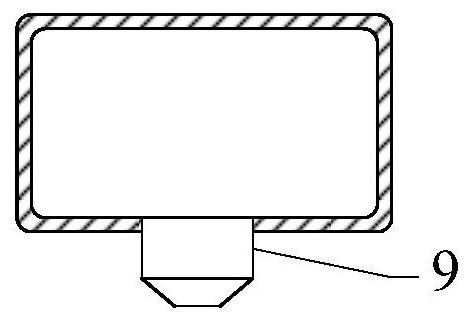

Glass liner structure of vacuum electric heating vessel

InactiveCN100441131CImprove craftsmanshipEasy to weldNon-pressured vesselsWarming devicesSignal linesElectric heating

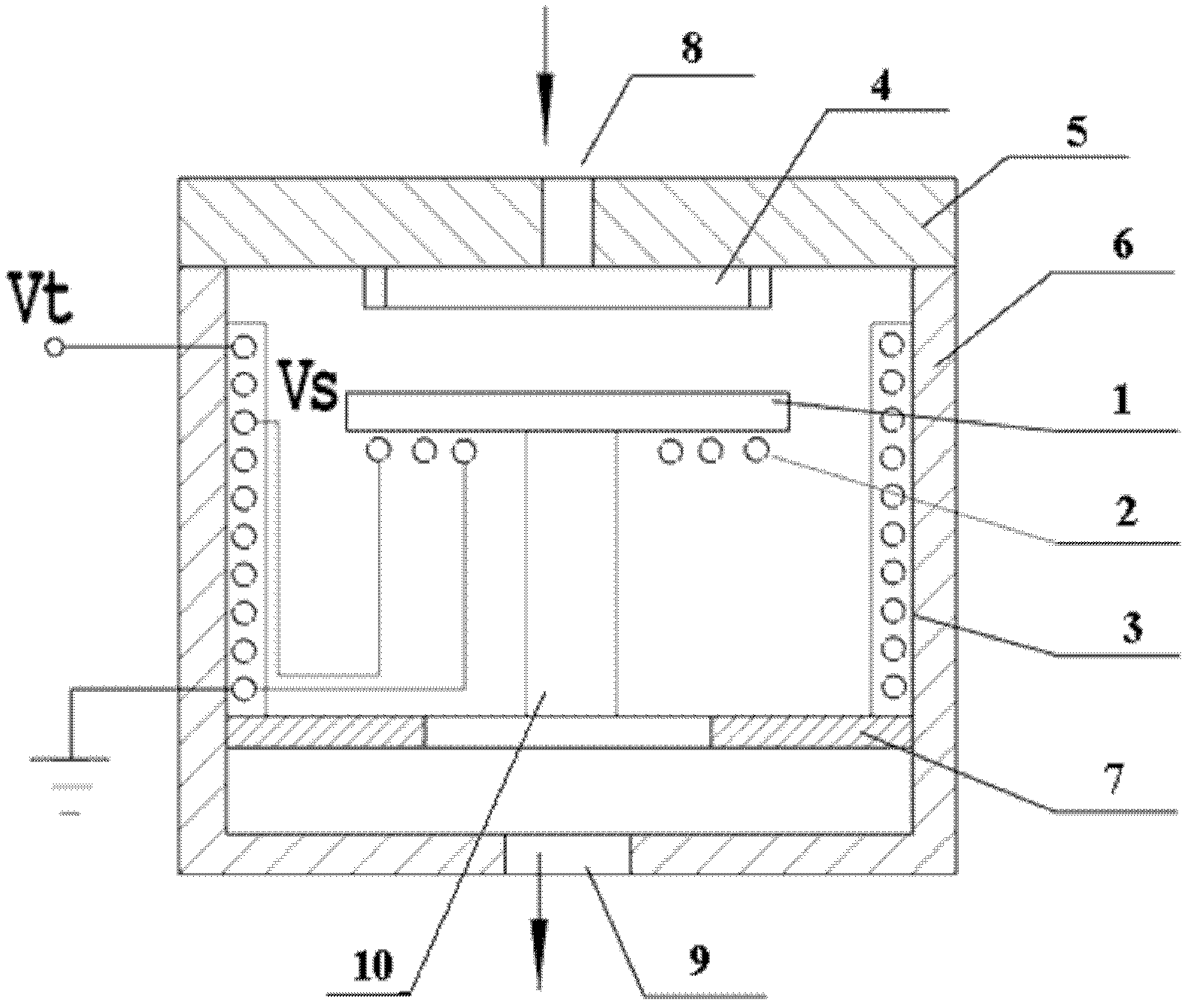

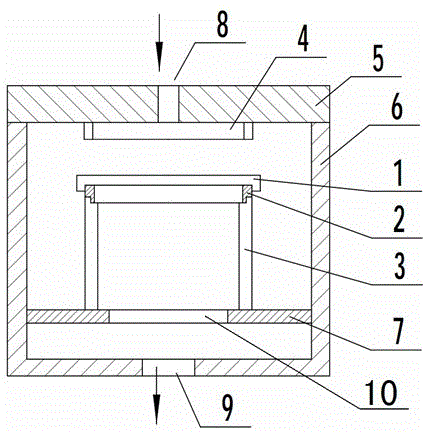

The invention relates to a vacuum electric heating container tank structure, which includes an inner tank (1), an outer tank (2), a vacuum connection layer (3) and an electric heating device (4). Sealing and welding at the opening of the tank, characterized in that the vacuum connection layer (3) is arranged between the bottom of the inner tank and the bottom of the outer tank, and its edge is sealed and welded with the bottom of the inner tank, and the inside of the electric heating device (4) Between the bladder (1) and the vacuum connection layer (3), and between the bottom of the inner bladder and the bottom of the inner bladder, there is a passage for power lines or signal lines to pass through. hole (5), and the edges of the above two through holes (5) are correspondingly sealed and welded. The invention can greatly improve the craftsmanship of the structure of the vacuum electric heating container body, facilitate welding, improve the quality of welds, ensure the vacuum degree of the container body, and improve the heat preservation effect of the vacuum electric heating container.

Owner:白明军 +1

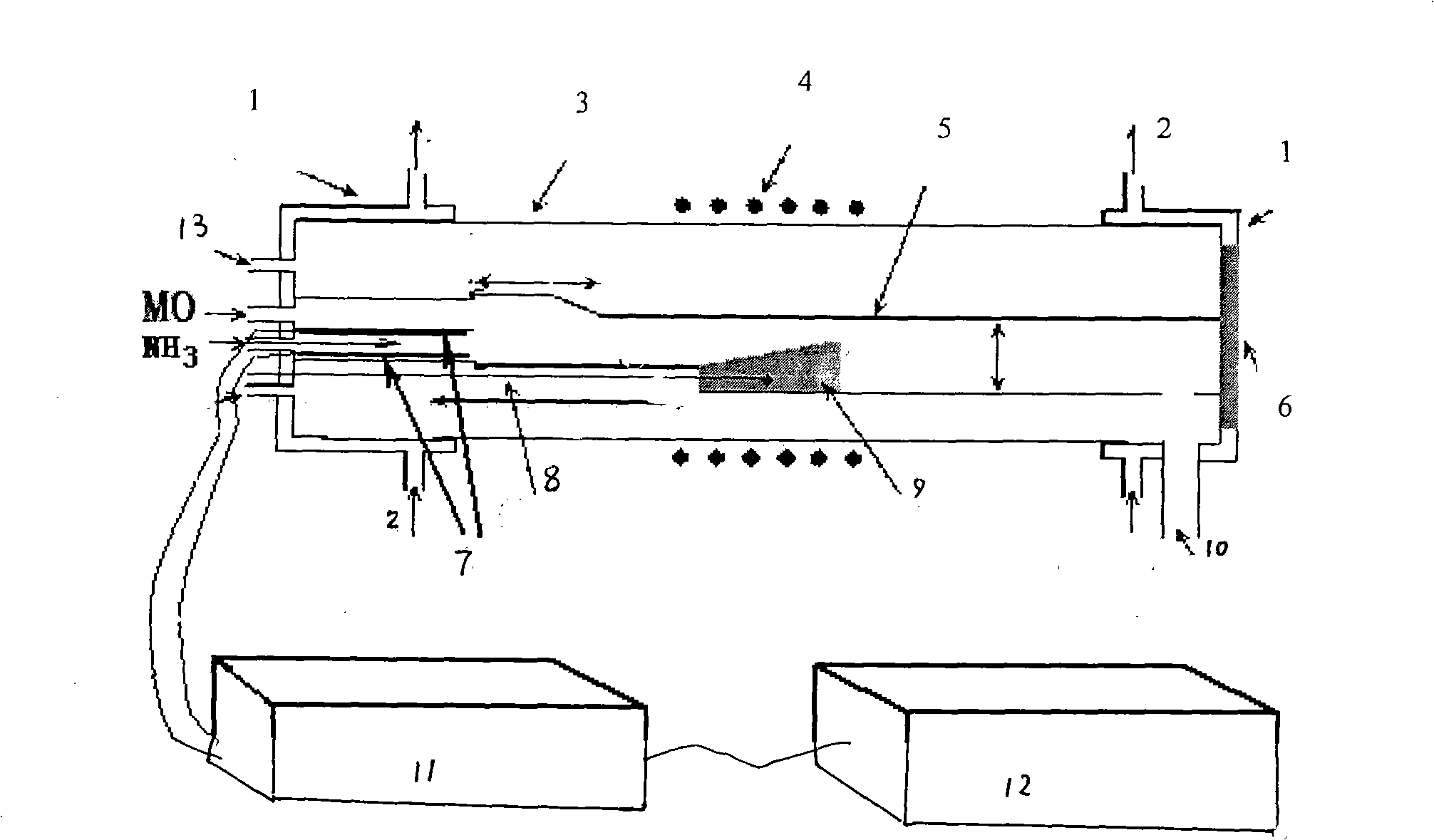

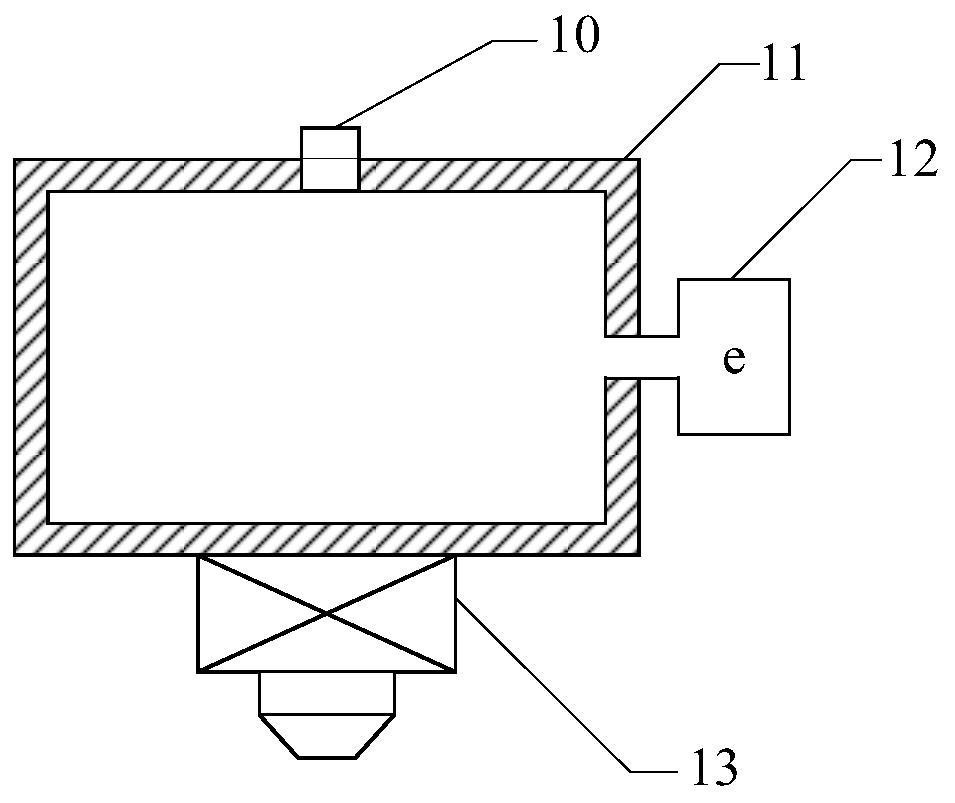

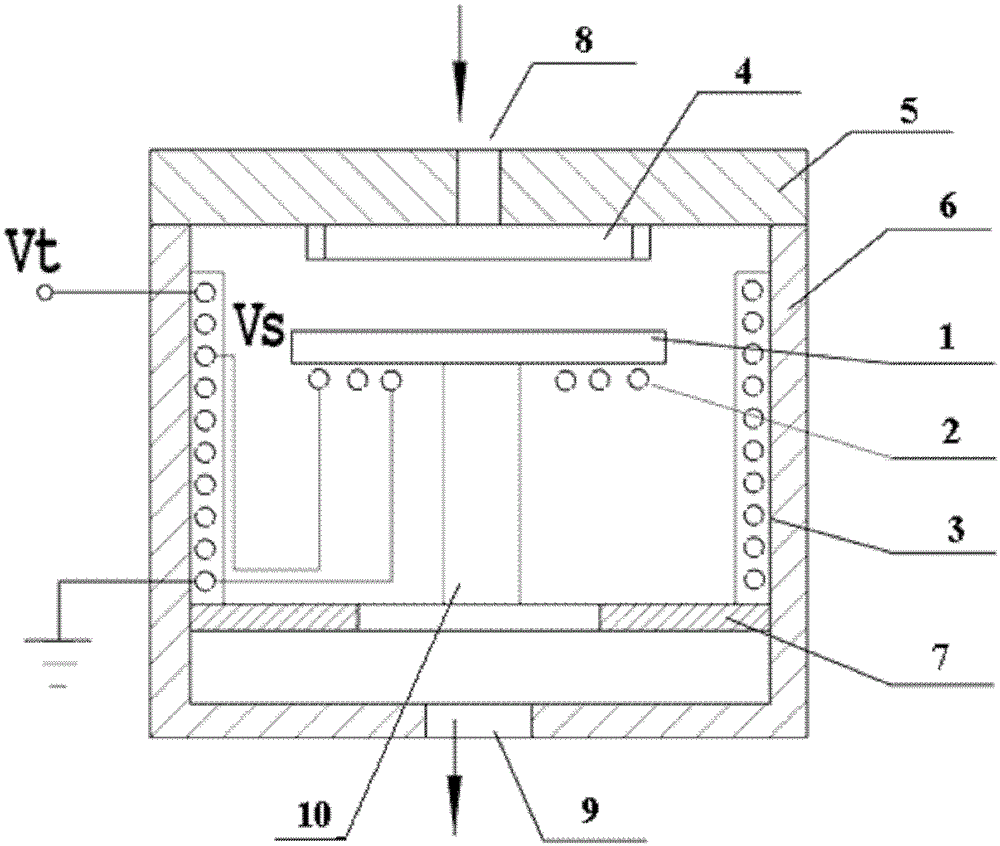

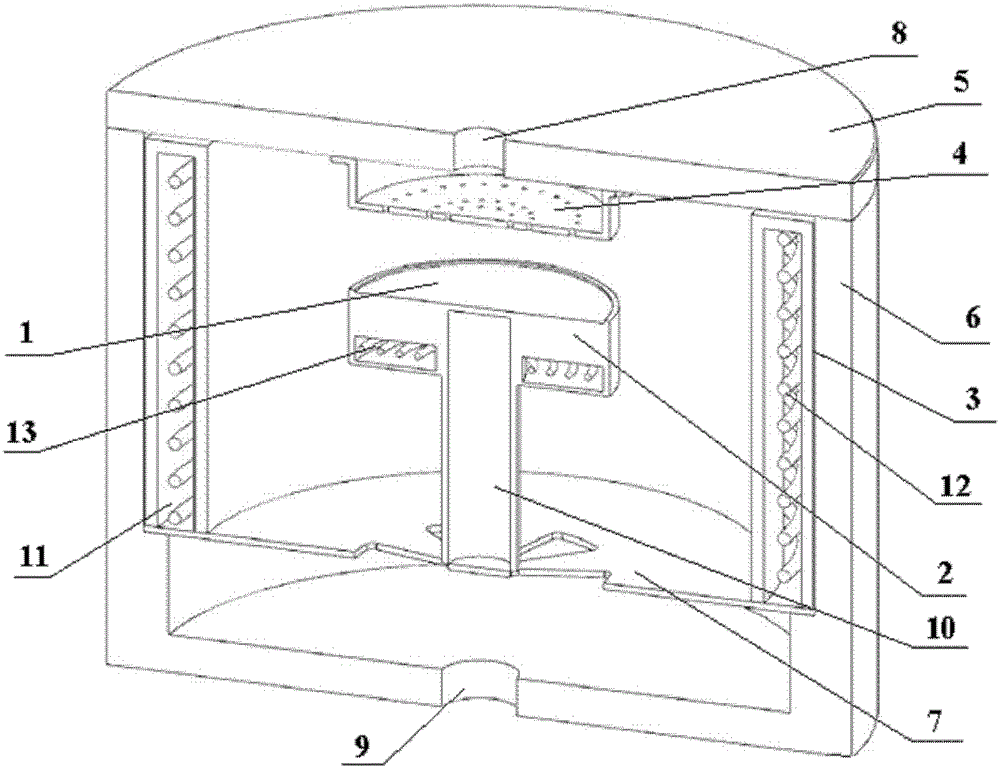

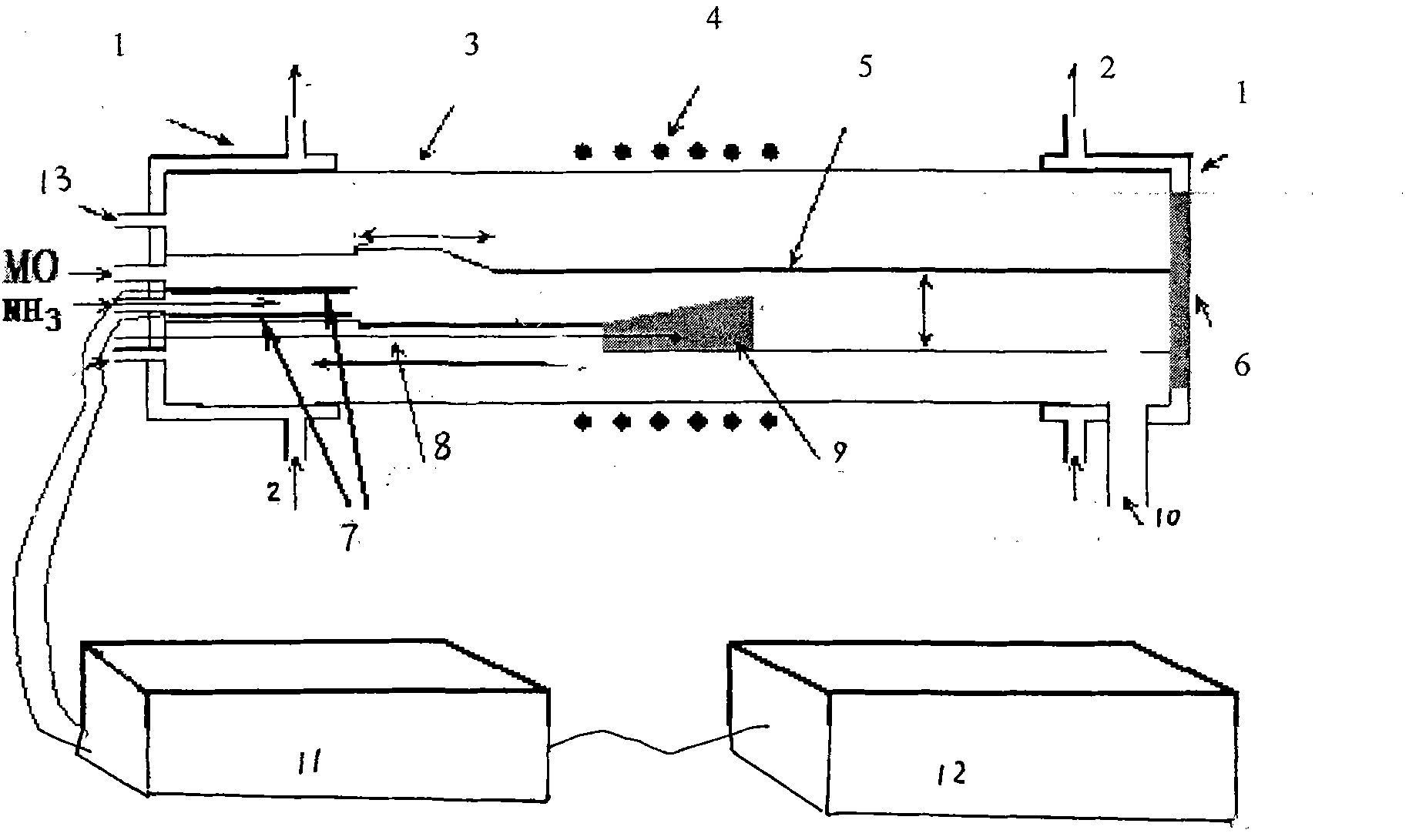

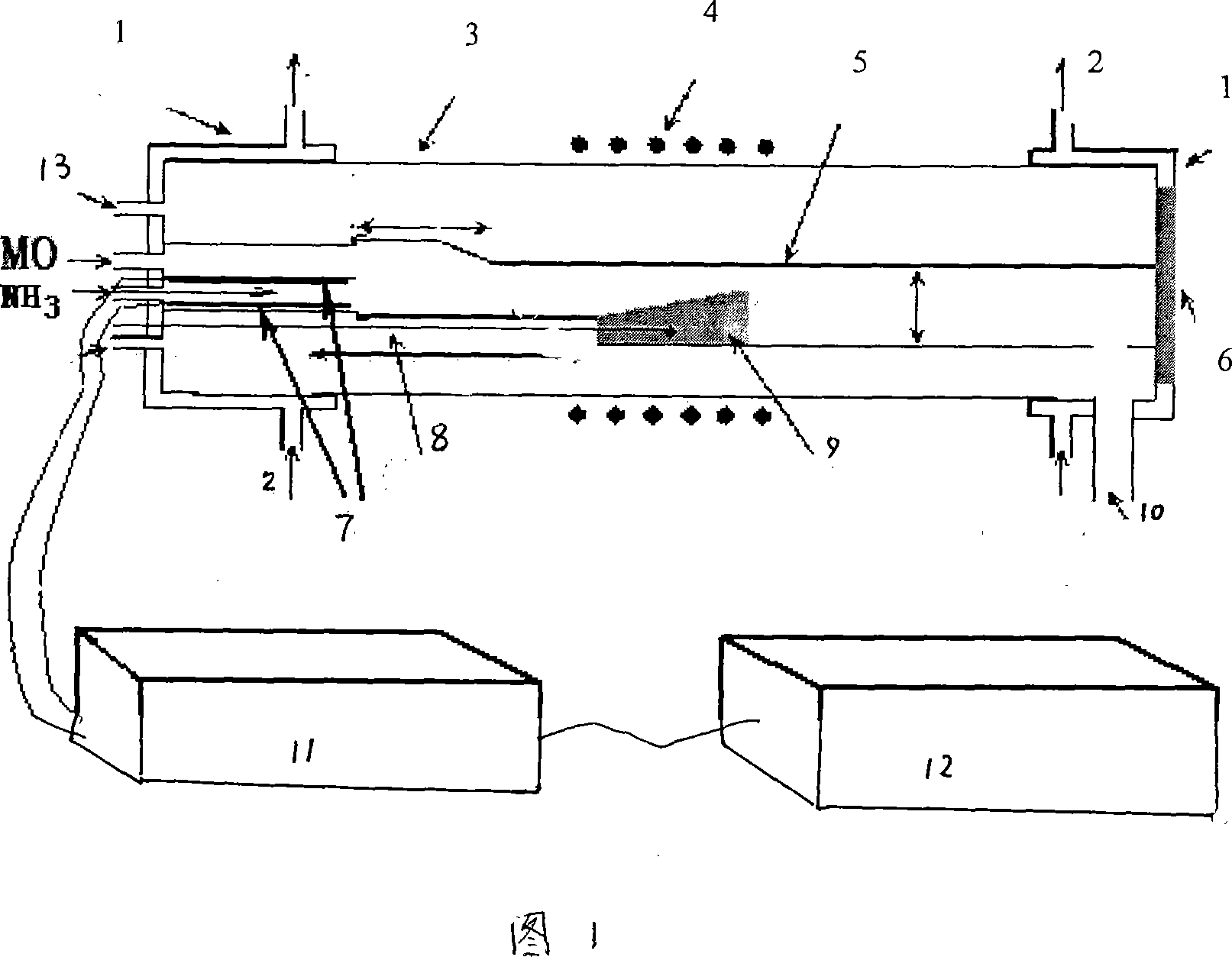

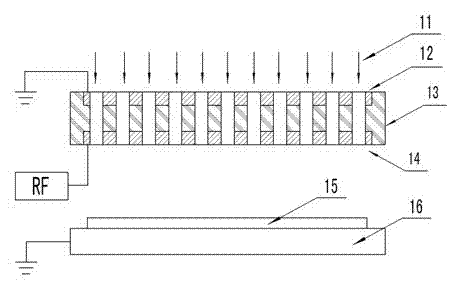

Nitrogen source ionization method and device for semiconductor material vapor deposition growth system

InactiveCN101307485AImprove growth qualityImprove decomposition ratePolycrystalline material growthFrom chemically reactive gasesCapacitanceSemiconductor materials

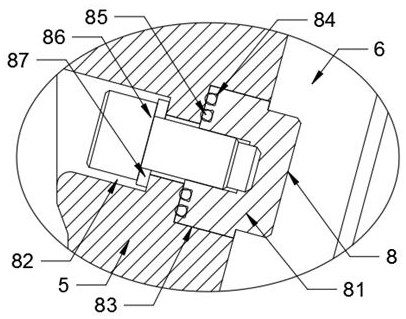

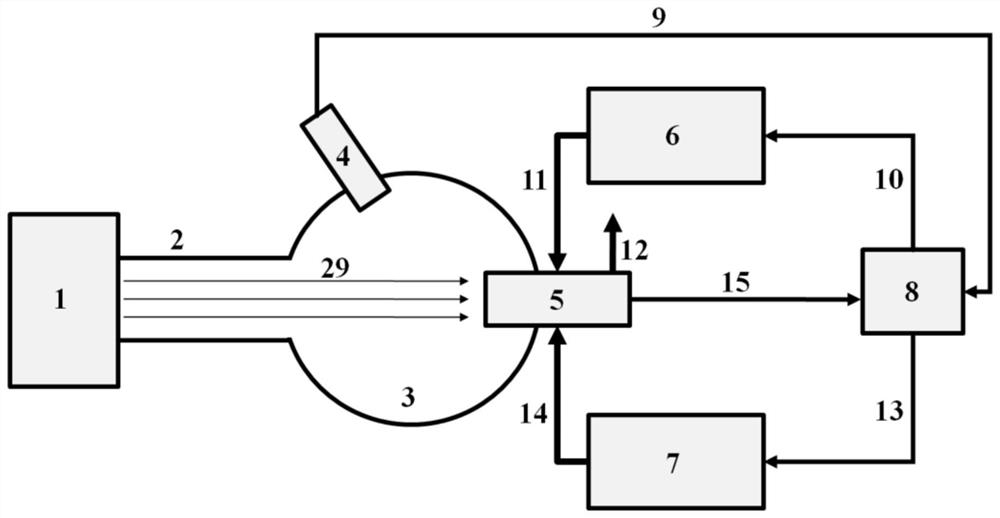

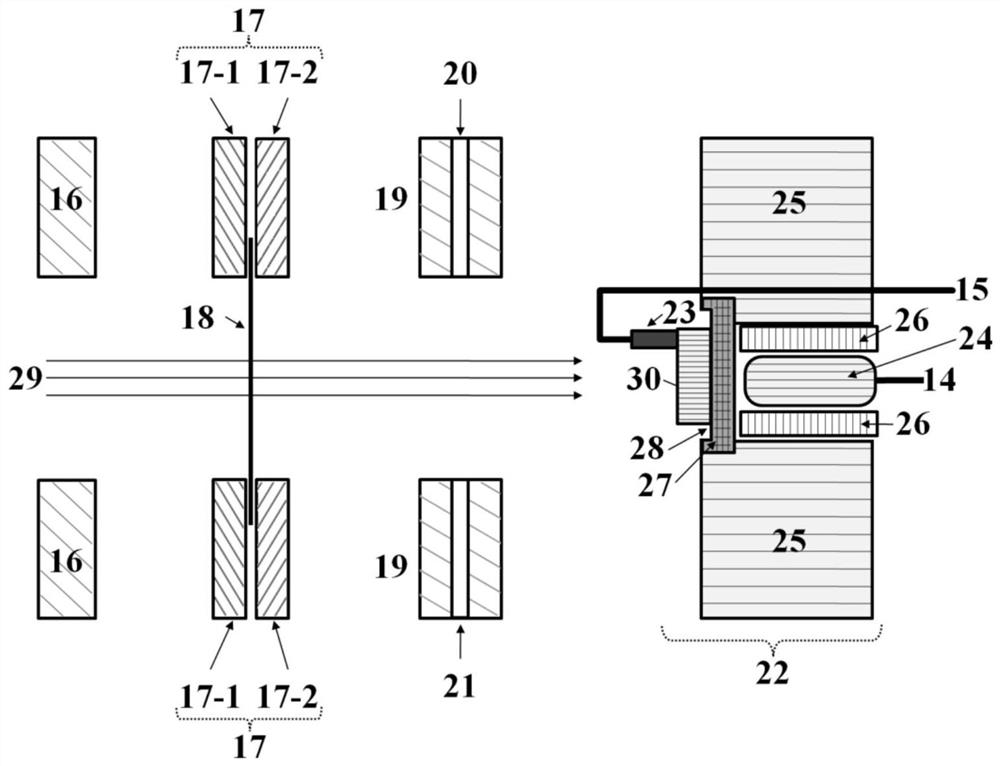

The invention provides a nitrogen sources ionizing method applied to a gas phase deposition growth system of semiconductor materials. In a growth system of semiconductor materials such as CVD, MOCVD, HVPE and MBE, etc., an external radio frequency field is applied to ionize nitrogen sources. The high frequency electric current is applied to electrodes of capacitances or inductance coils, and the high frequency electric field is applied by a gas path arranged between the capacitance plates or circling the inductance coils to speed up electrons and ionize gas molecules to generate plasmas. The device consists of a metallic flange(1), a cooling water pipeline(2), a quartz outer cover(3), a quartz fairing(5), a metal cover(6), a parallel plate capacitor(7), a thermoelectric couple(8), graphite(9), a bleeder hole(10), a radio frequency adapter(11), a radio frequency power source(12) and an air inlet(13), wherein the metallic flange(1) and the metal cover(6) are arranged on both ends of the quartz outer cover(3), and the gas path circling the air inlet(13) or the gas path of a growth platform is provided with capacitances or inductance coupling elements.

Owner:NANJING UNIV

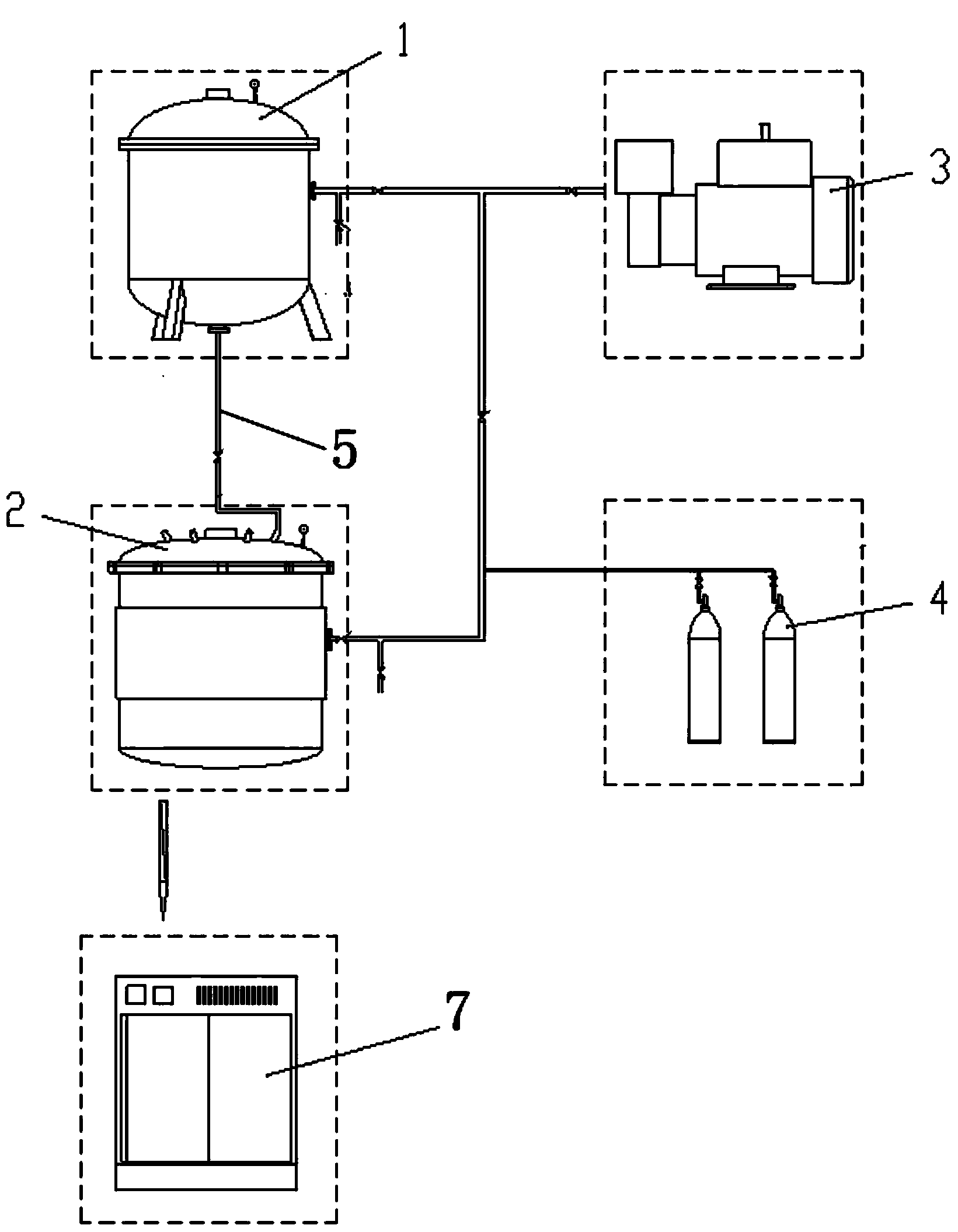

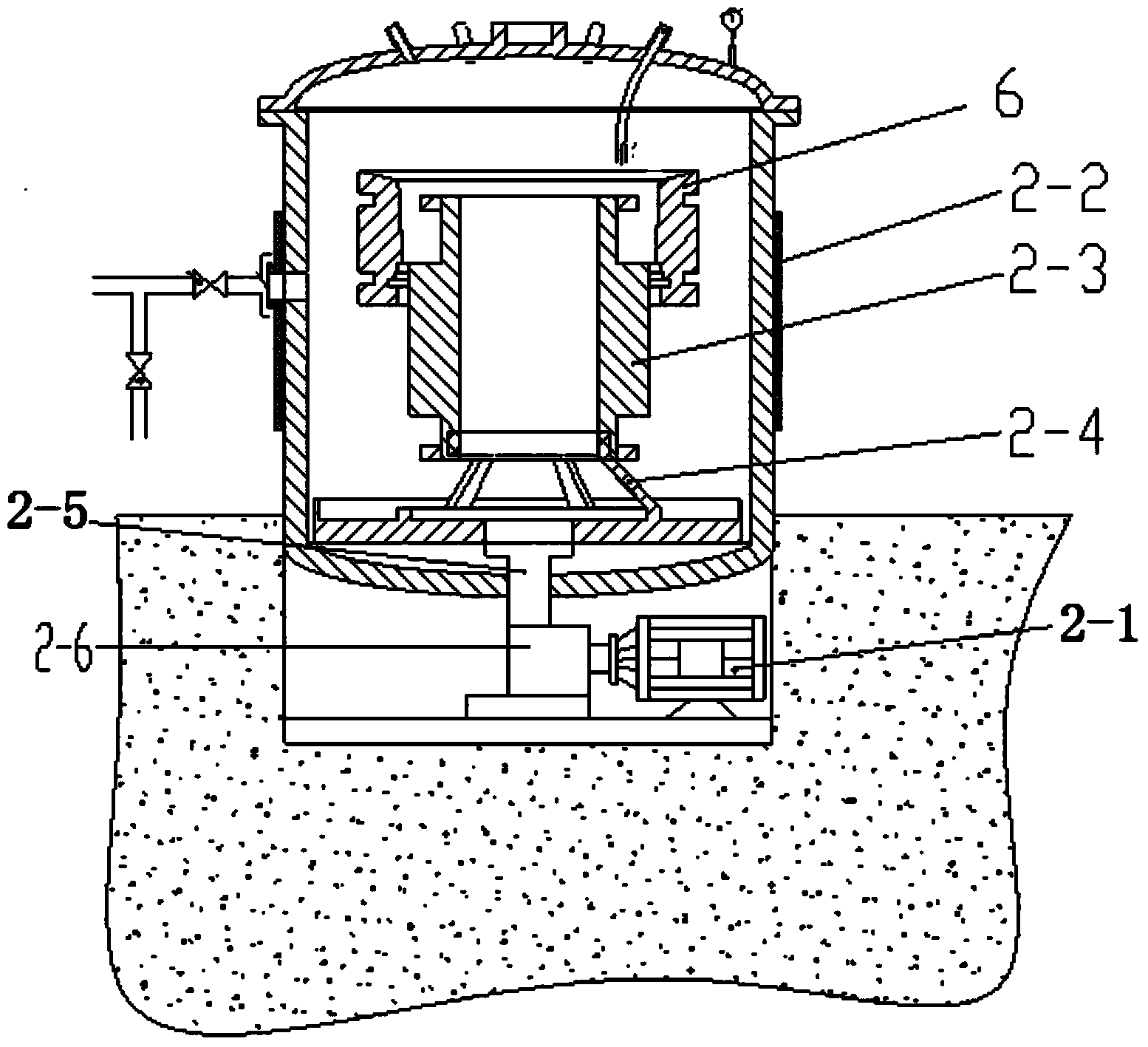

System and method for vacuum pouring of insulation resin used for motor rotor

InactiveCN104410229ARequirements for maintaining vacuumConducive to constant temperature curingApplying solid insulationEmulsionHigh pressure

The invention relates to a system for vacuum pouring of insulation resin used for a motor rotor. The system comprises a vacuum glue filling tank, a vacuum pump, a high-pressure inert gas transmitting device, a vacuum emulsion machine and a glue transmitting pipe, wherein the vacuum pump and the high-pressure inert gas transmitting device are respectively connected with the vacuum glue filling tank by virtue of a pipeline; the vacuum emulsion machine is connected with the vacuum glue filling tank by virtue of the glue transmitting pipe; a stirring device is arranged in the vacuum emulsion machine; the vacuum emulsion machine is provided with a device which is connected with the vacuum pump; the resin to be filled with glue is mixed in the vacuum emulsion machine. According to the system, the vacuum emulsion machine is additionally arranged, the vacuum degree requirement during mixing of the resin is ensured; the discharge of the gas in the resin is facilitated. The invention also relates to a method for vacuum pouring of the insulation resin for the motor rotor.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

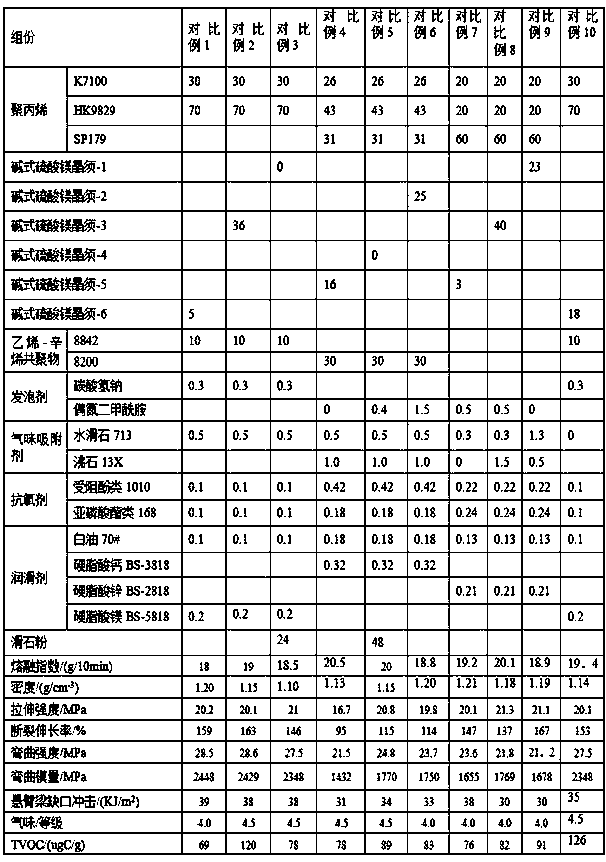

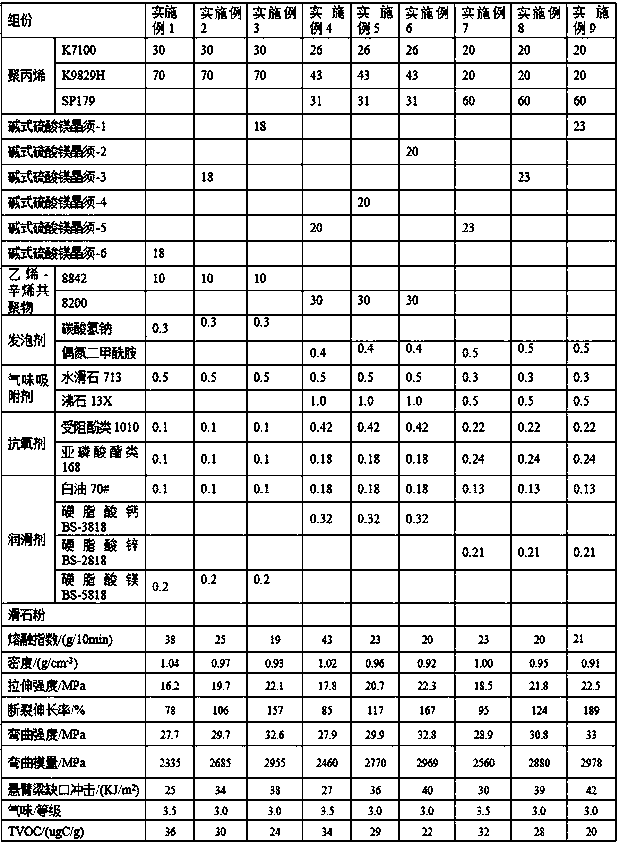

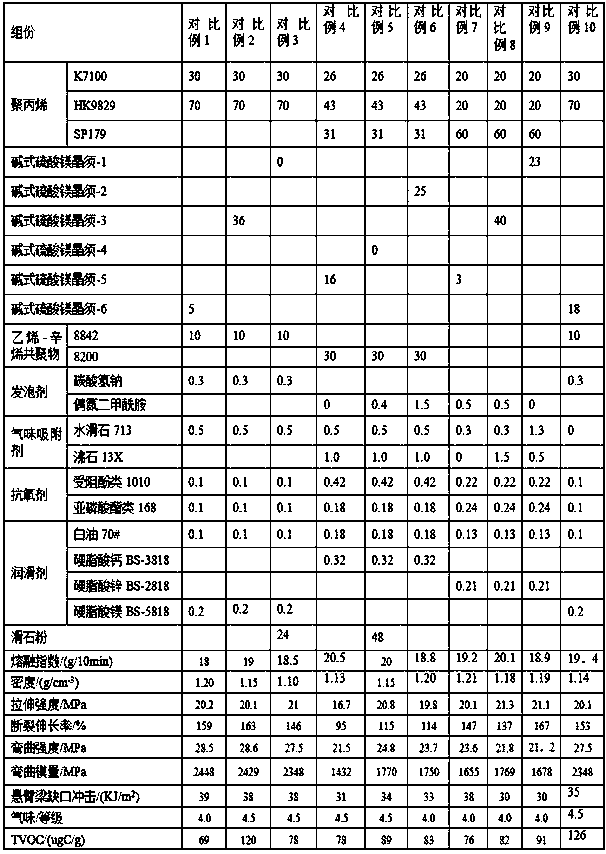

Polypropylene composition and preparation method thereof

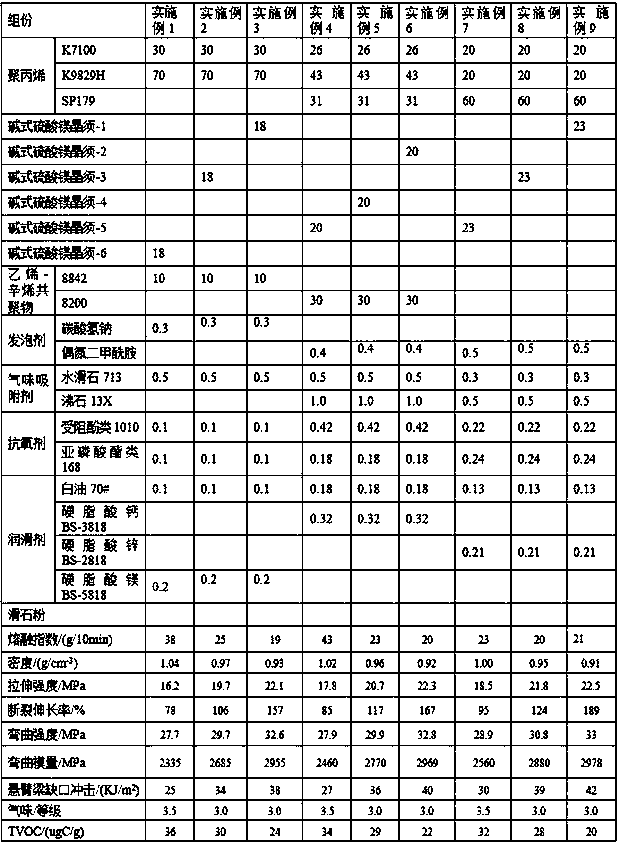

The invention discloses a polypropylene composition which comprises, by weight parts, 100 parts of polypropylene, 10-30 parts of basic magnesium sulfate whisker, 0.1-1.0 part of foaming agent, 0.5-1.5 parts of smell adsorbent and 10-30 parts of flexibilizer. By simultaneously adding basic magnesium sulfate whisker and foaming agent of a specific content, compared with the situation that only basic magnesium sulfate whisker is added, the weight of a workpiece can be greatly reduced while the comprehensive mechanical property is not reduced, and thus the lightweight requirements of an automobile are met. By adding the smell adsorbent of a specific content and adopting single vacuum design of a twin-screw extruder, it is guaranteed that the vacuum degree requirements are not larger than -0.08 bar, micromolecular volatile matter can be pumped away, and the devolatilization effect is improved obviously. The prepared polypropylene composition is low in smell and emission characteristics, the lightweight requirements of the automobile and low-smell low-emission performances of automobile interior part materials can be met, and the application prospect is wide.

Owner:JIANGSU KINGFA ENVIRONMENTAL PROTECTION SCI &TECH CO LTD

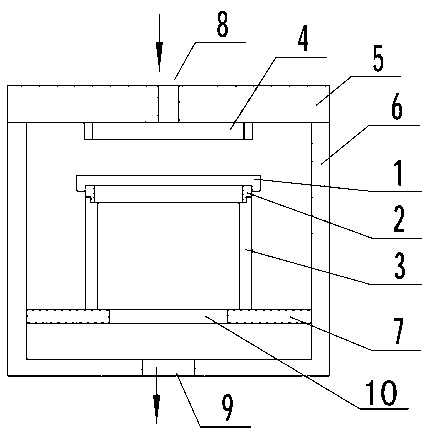

Cavity heating device

ActiveCN103208440ANo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCavity wall

Disclosed is a cavity heating device. The cavity heating device comprises a cavity wall heating structure and / or a slide holder heating structure. The cavity wall heating structure is arranged on the inner wall of a reaction cavity. The slide holder heating structure is arranged at the bottom of a slide holder. The cavity heating device can reduce or avoid nonuniformity caused by the fact that plasma starting is unsymmetrical in structure in the plasma etching process. An electrode fixing structure is free of air discharge under the plasma starting condition and can meet requirement of a vacuum cavity for vacuum degree.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

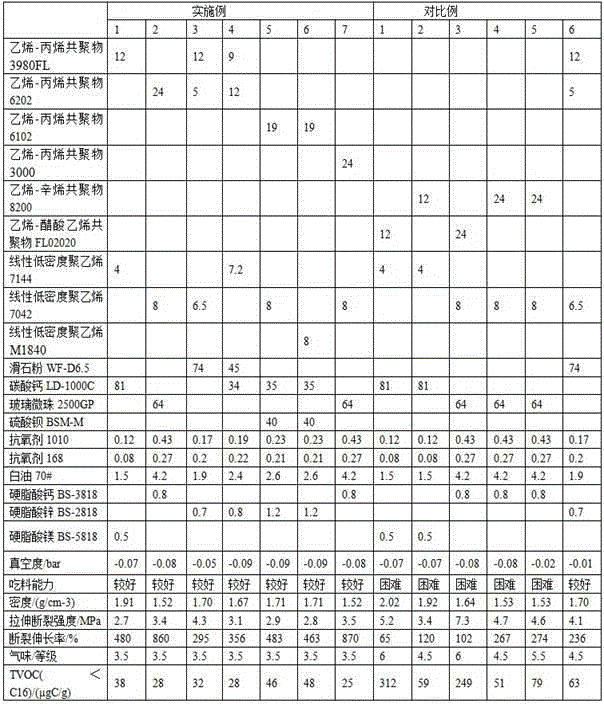

Low-odor and low-volatile automobile heavy sound insulation mat material and preparation method thereof

The present invention discloses a low-odor and low-volatile automobile heavy sound insulation mat material and a preparation method thereof. The materiel comprises the following components: 12-24 parts of ethylene-propylene copolymer, 4-8 parts of linear low-density polyethylene and 64-81 parts of an inorganic filler. The preparation method comprises the following steps: after mixing the materials, feeding the mixture into a twin screw extruder for melt extrusion, granulating, drying, cooling and package to obtain the material, wherein, the twin screw extruder is designed in a double-vacuum manner, and the requirement of a vacuum degree is less than or equal to -0.05 bar. According to the method disclosed by the present invention, by using the ethylene-propylene copolymer and the linear low density polyethylene to replace a conventional ethylene-vinyl acetate copolymer and ethylene-octene copolymer, the odor and volatile matters of the material are significantly improved; and the prepared and obtained vehicle heavy sound insulation mat material has the advantages of low odor, low volatile and the like, can meet the requirement of each big host factory for an automobile interior material, and has a wide application prospect.

Owner:KINGFA SCI & TECH CO LTD +2

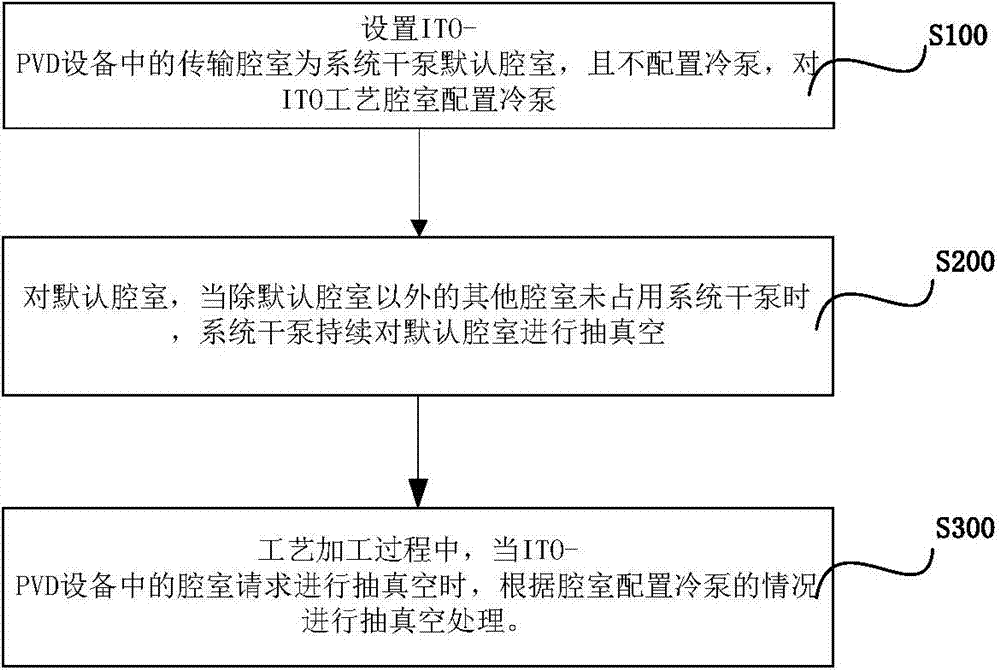

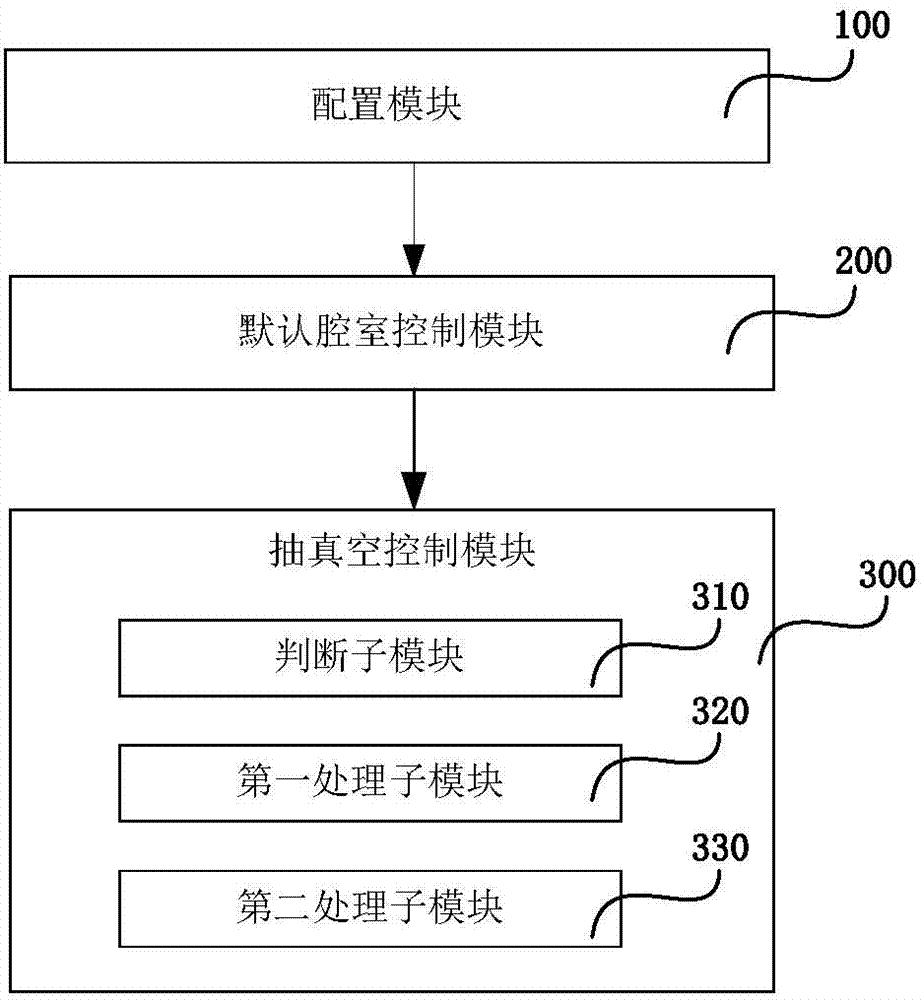

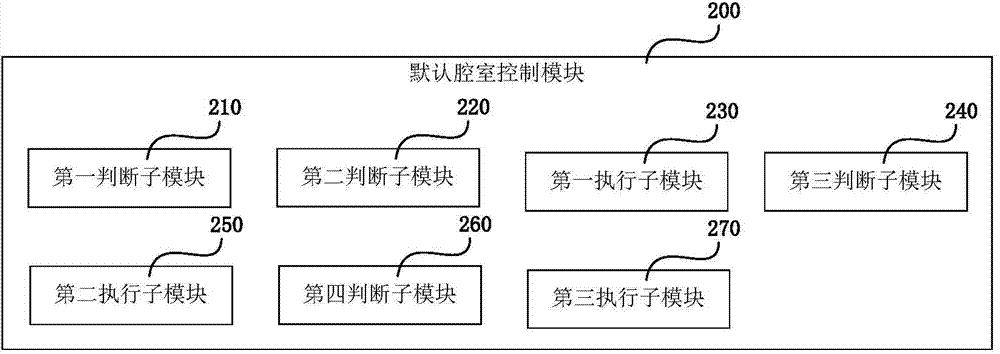

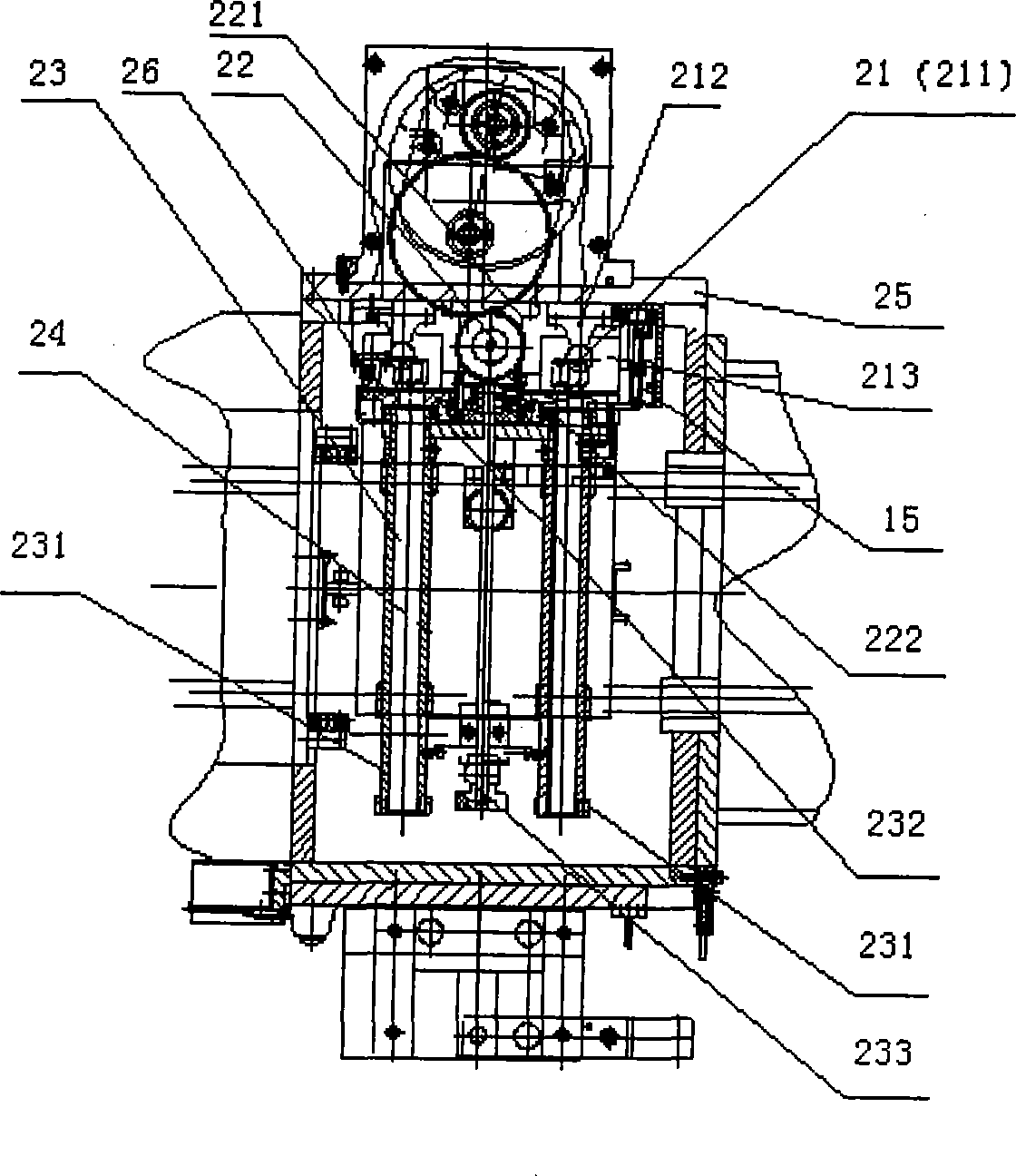

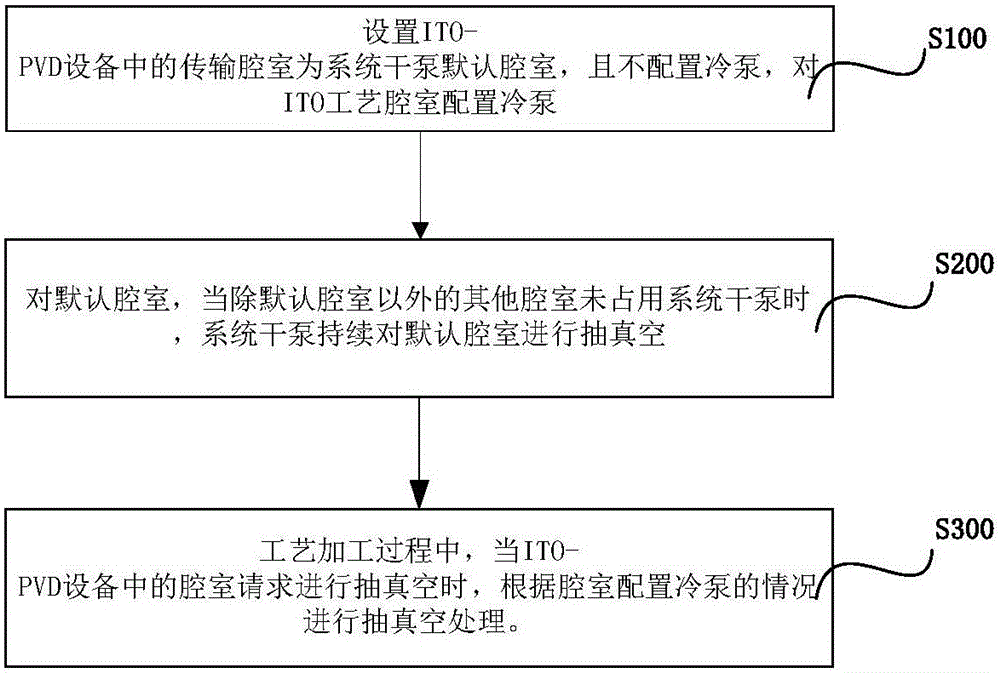

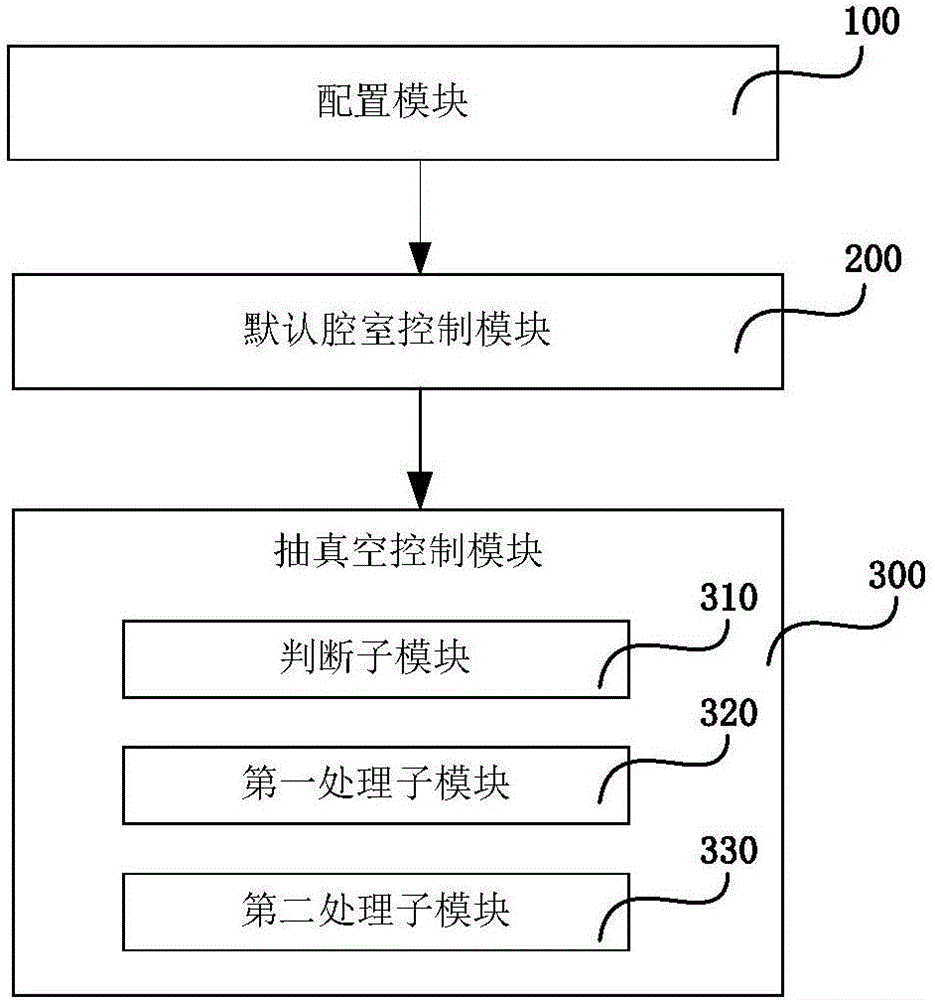

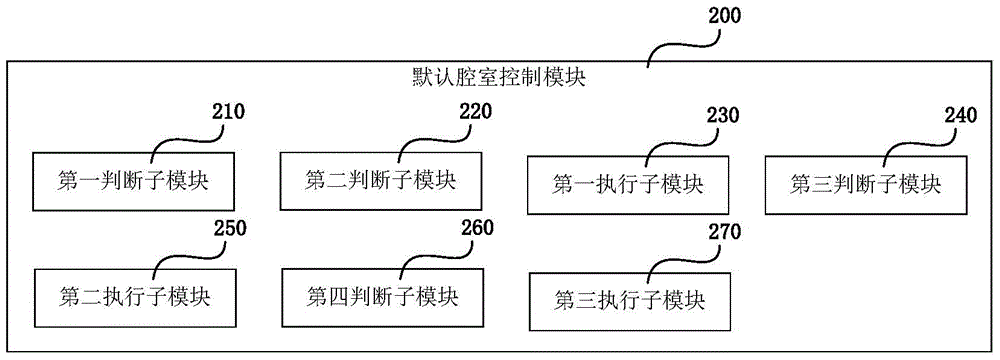

Vacuuming control method and system of ITO-PVD equipment

ActiveCN104746033AAvoid damageRequirements for maintaining vacuumVacuum evaporation coatingSputtering coatingEmbedded system

The invention discloses a vacuuming control method and a system of ITO-PVD equipment, wherein the method comprises the following steps: a transmission cavity in the ITO-PVD equipment is set as a default cavity of a system dry pump, and is not allocated with a cold pump, and a cold pump is allocated for an ITO process cavity; for the default cavity, when other cavities besides the default cavity do not occupy the system dry pump, the system dry pump continuously vacuums the default cavity; and in the processing procedure, when the cavity in the ITO-PVD equipment requests for vacuuming, the vacuuming is performed according to the cold pump allocating condition of the cavity. The method saves the equipment cost and can effectively prevent the collision between hardware equipment when guaranteeing the vacuum degree requirement in the equipment processing.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

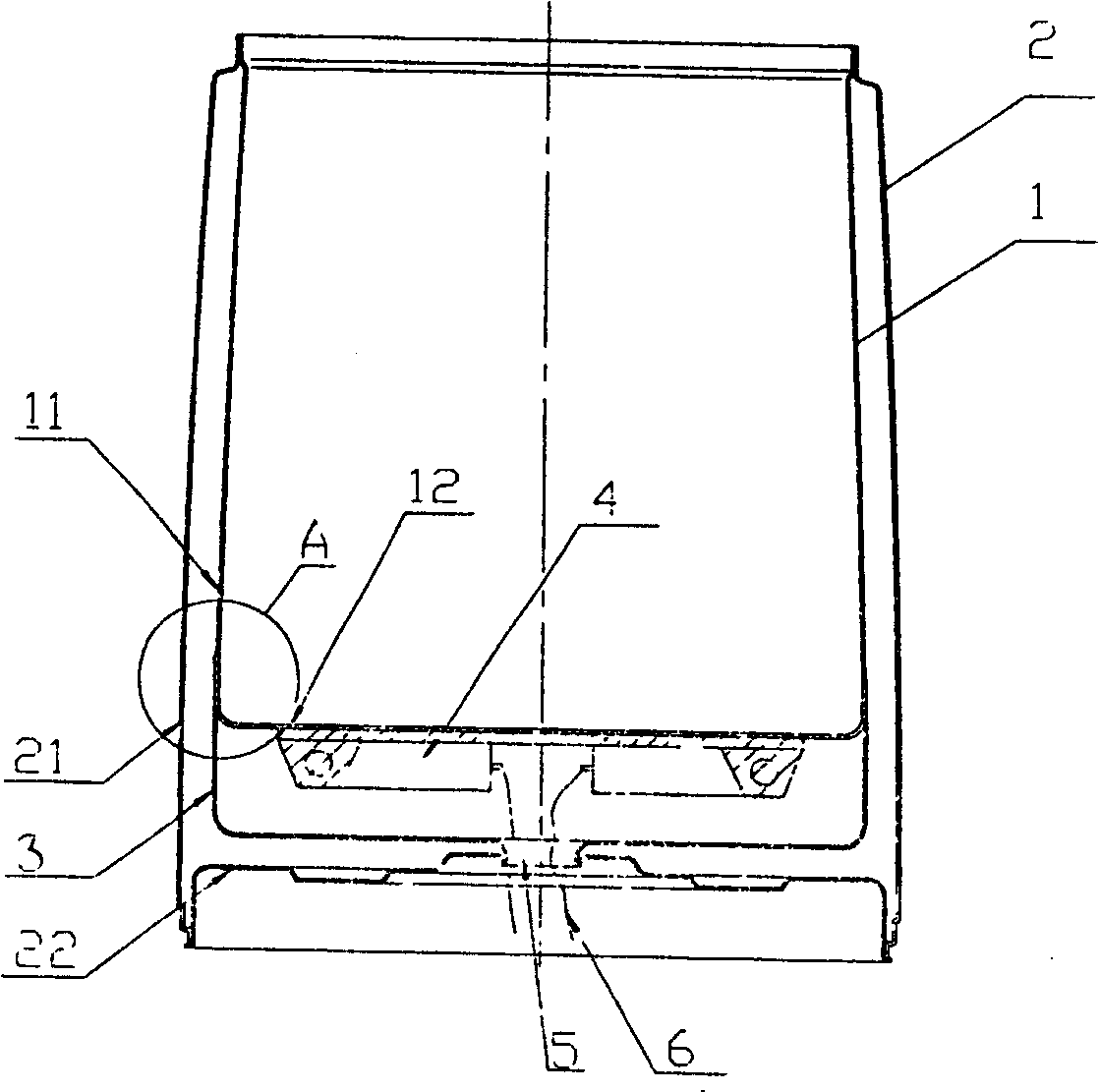

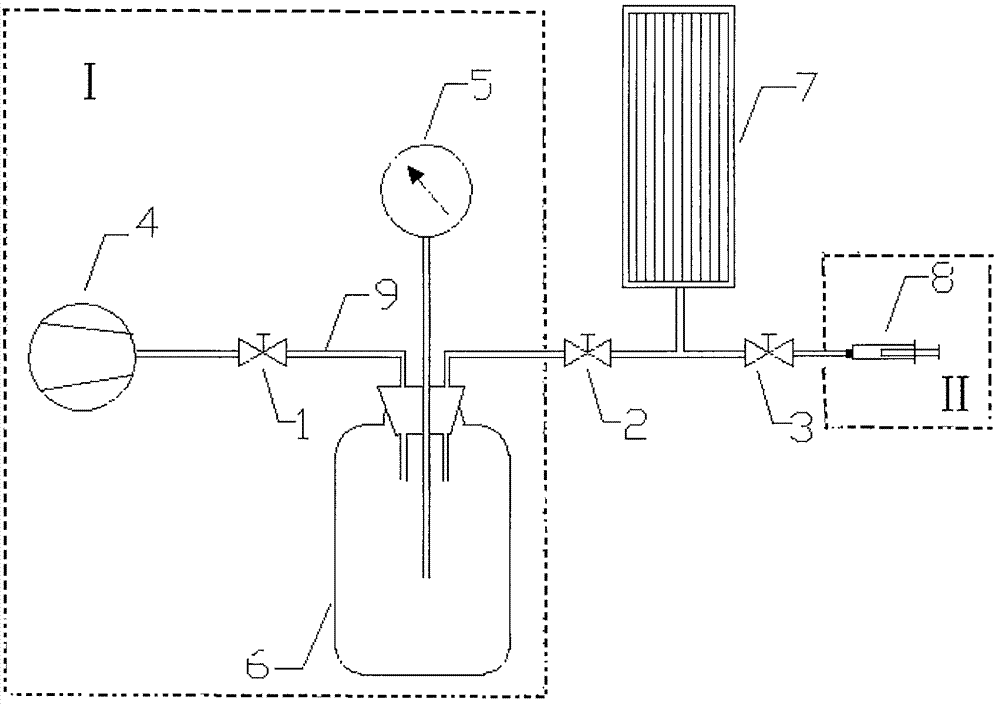

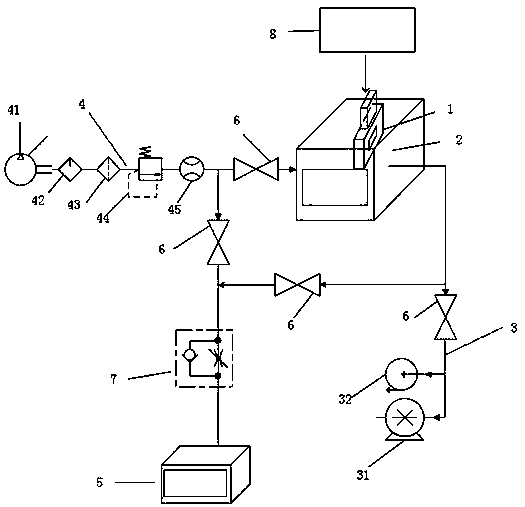

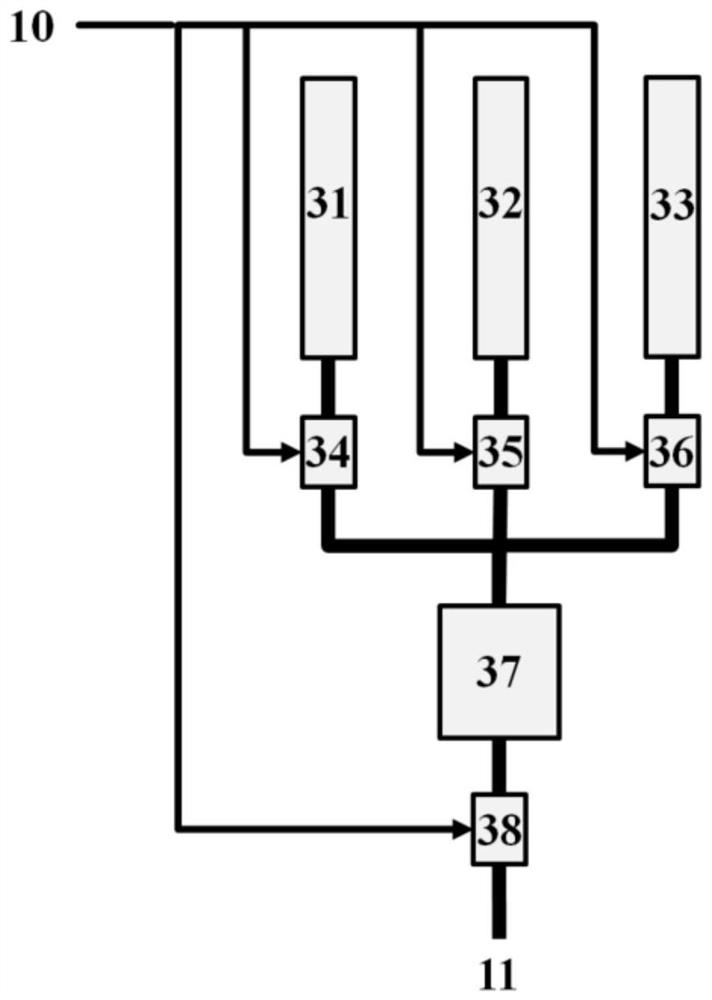

Flat plate micro heat pipe vacuumizing and liquid injection device and method thereof

PendingCN106931814AAvoid errorsRealize automatic and precise injectionIndirect heat exchangersGas cylinderCapillary Tubing

The invention provides a flat plate micro heat pipe vacuumizing and liquid injection device and a use method thereof. The flat plate micro heat pipe vacuumizing and liquid injection device is composed of a vacuumizing part and a liquid injection part. The vacuumizing part is composed of a vacuum pump, a vacuum meter, an air collection bottle and a capillary tube. The vacuum pump is used for vacuumizing a flat plate micro heat pipe and the air collection bottle. The vacuum meter is used for observation of the vacuum degree. The liquid injection part is composed of an injector and a capillary tube. Liquid is injected into the flat plate micro heat pipe through the injector. In the vacuumizing and liquid injection processes, connection of the flat plate micro heat pipe and all parts is controlled by a manual valve. The flat plate micro heat pipe vacuumizing and liquid injection device is simple in structure, low in cost, high in precision of the vacuum degree and liquid injection volume, easy to operate and reliable in operation.

Owner:GUANGDONG UNIV OF TECH

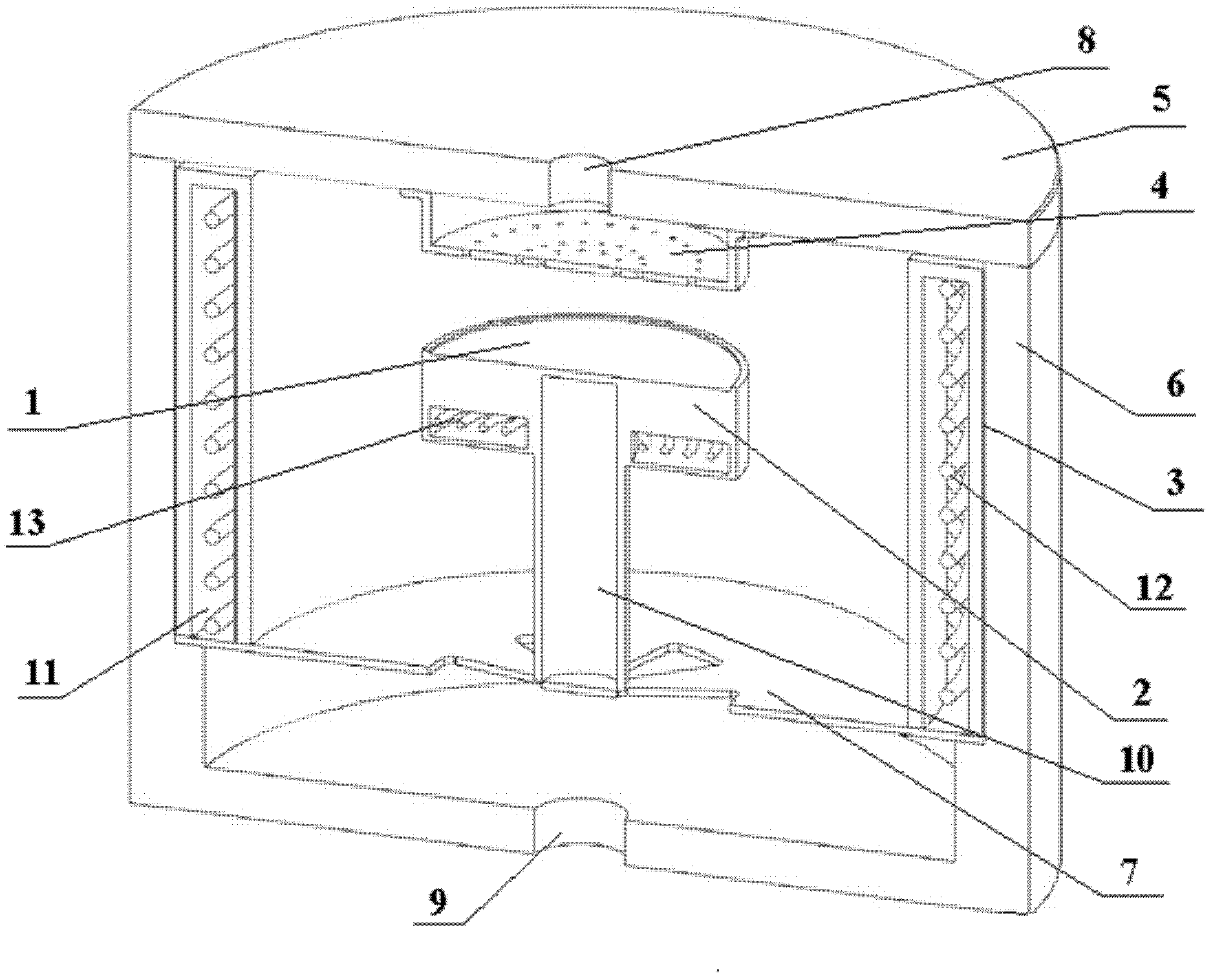

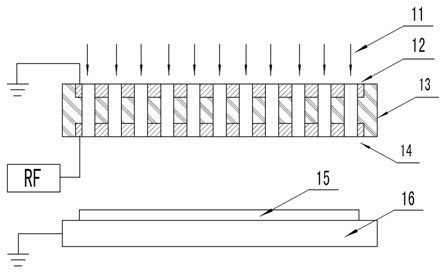

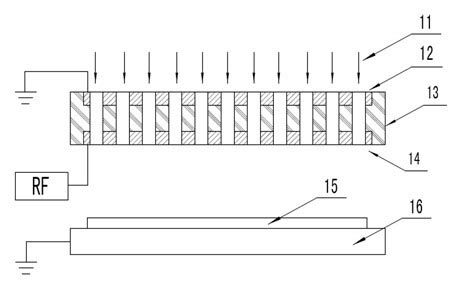

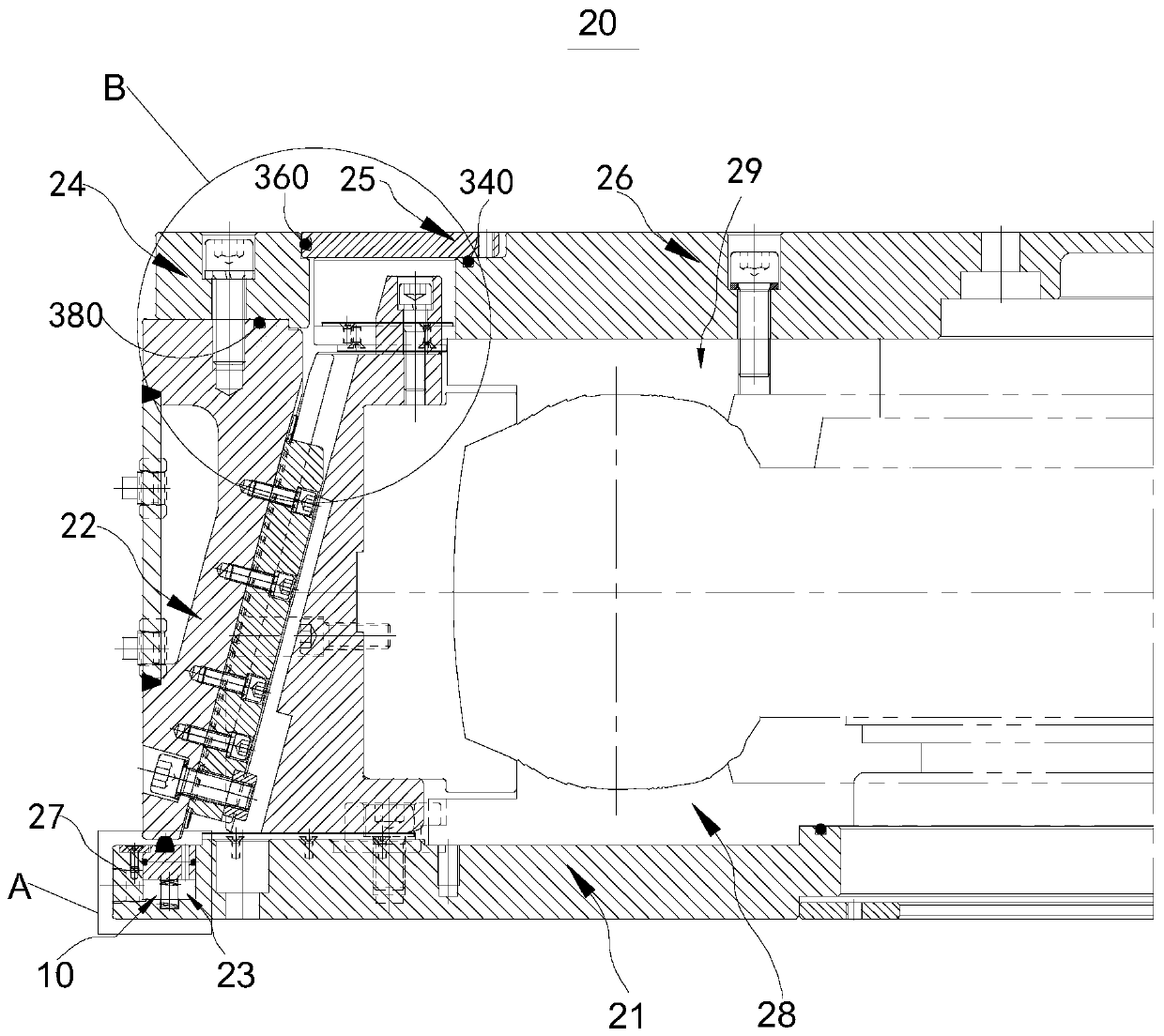

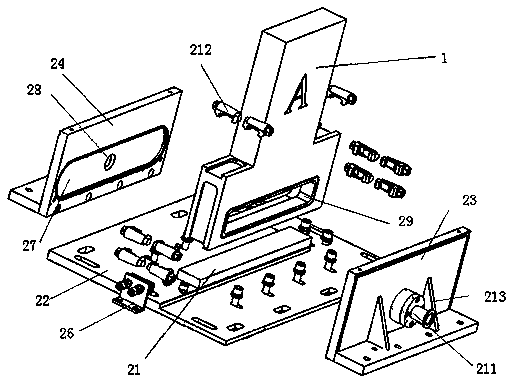

A flat plate electrode fixing structure

ActiveCN102290312ANo outgassingWide distribution of uniformityElectric discharge tubesEngineeringRadio frequency

The invention discloses a plate electrode fixing structure, belonging to the technical field of plasma etching. The plate electrode fixing structure comprises an insulating support, the insulating support is provided with a plurality of air inlets, and upper electrodes and lower electrodes are arranged around the air inlets. The insulating support is 5-1,000mm thick and is made of an insulating material such as ceramic, quartz, polytetrafluoroethylene or polycarbonate. The frequency of a radio-frequency power supply applied between the upper electrodes and the lower electrodes is 0-10GHz. Thedistance between the upper electrodes and the lower electrodes is 2-1,000mm. the area diameter of the upper electrodes and the lower electrodes is 20-3,000mm. By adopting the plate electrode fixing structure, the scope of uniform distribution of a plasma starter can be widened, and particularly good edge uniformity can be achieved. When the plasma starter is used, no air discharging can be causedby the plate electrode fixing structure, and a vacuum chamber can meet vacuum requirements.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

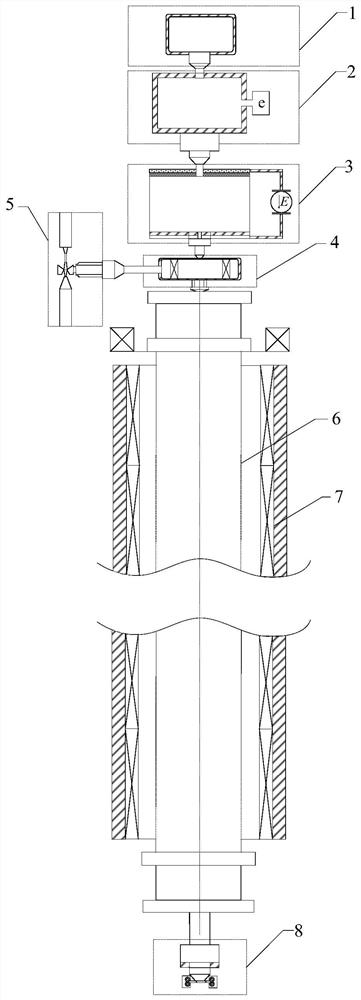

Micro-fiber high-energy implantation facility for manufacturing three-dimensional reinforced carbon fiber composite material

The invention discloses a micro-fiber high-energy implantation facility for manufacturing a three-dimensional reinforced carbon fiber composite material. The facility comprises a micro reinforced fiber feeding module, a micro reinforced fiber directional arrangement module, a micro reinforced fiber electrification module, a micro reinforced fiber accelerator injection module, a vacuum generation device module, a high-voltage electrostatic acceleration module, an accelerator bunching module and a micro reinforced fiber leading-out control module. According to the micro-fiber high-energy implantation facility, large-scale micro reinforced fibers which are subjected to charging treatment and meet the target charge-to-mass ratio magnitude requirement serve as a high-energy implanted fiber source, a high-voltage electrostatic acceleration electric field is adopted to accelerate and energize the array type large-scale micro reinforced fibers which are uniformly and directionally arranged, and therefore the speed and the energy of the array type large-scale micro reinforced fibers can meet the implantation requirements; and the micro reinforced fibers are injected into a two-dimensional laminated structure prepreg target reinforced area through the output kinetic energy of the micro reinforced fibers, and manufacturing of the three-dimensional reinforced carbon fiber composite material is achieved.

Owner:ZHEJIANG UNIV

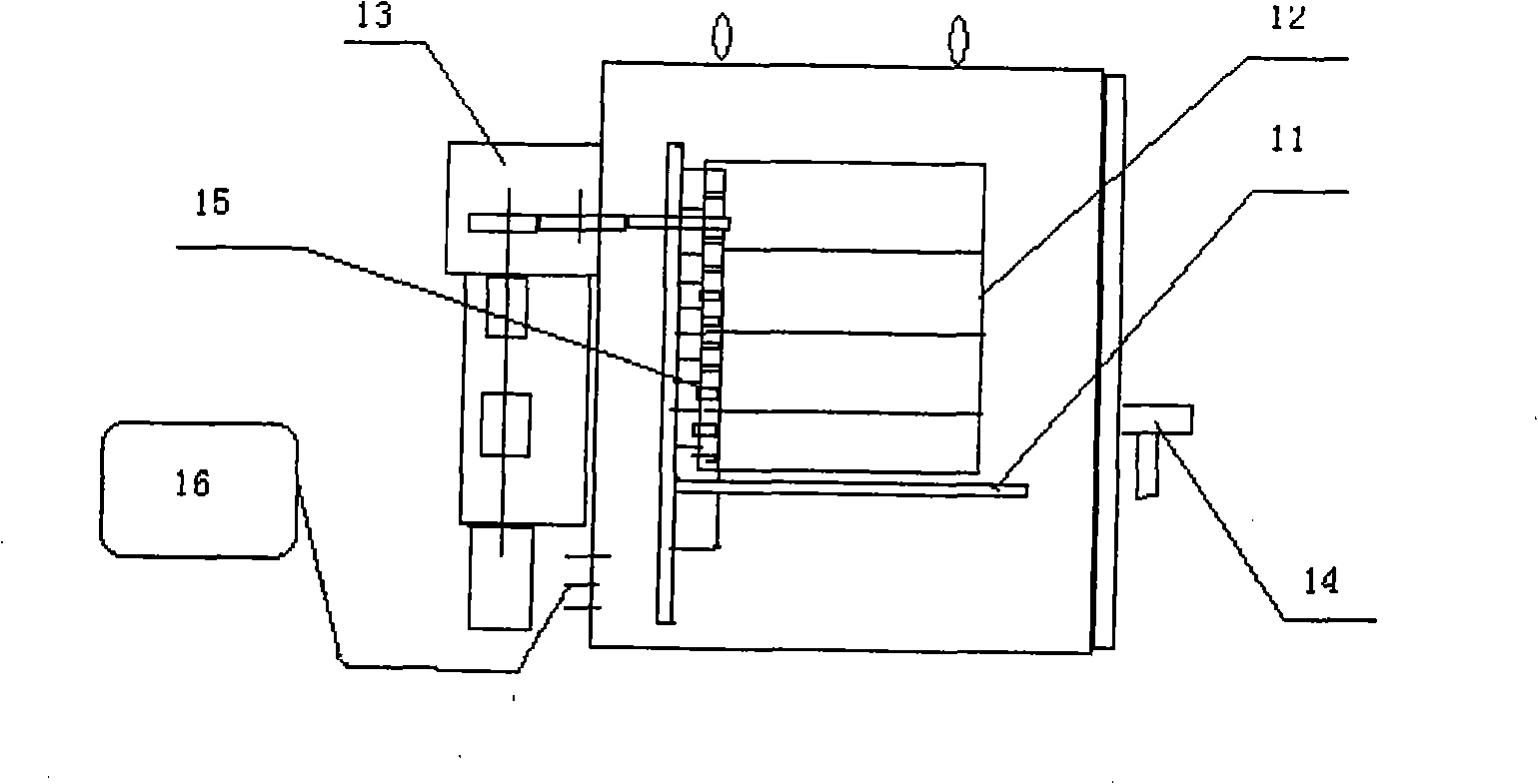

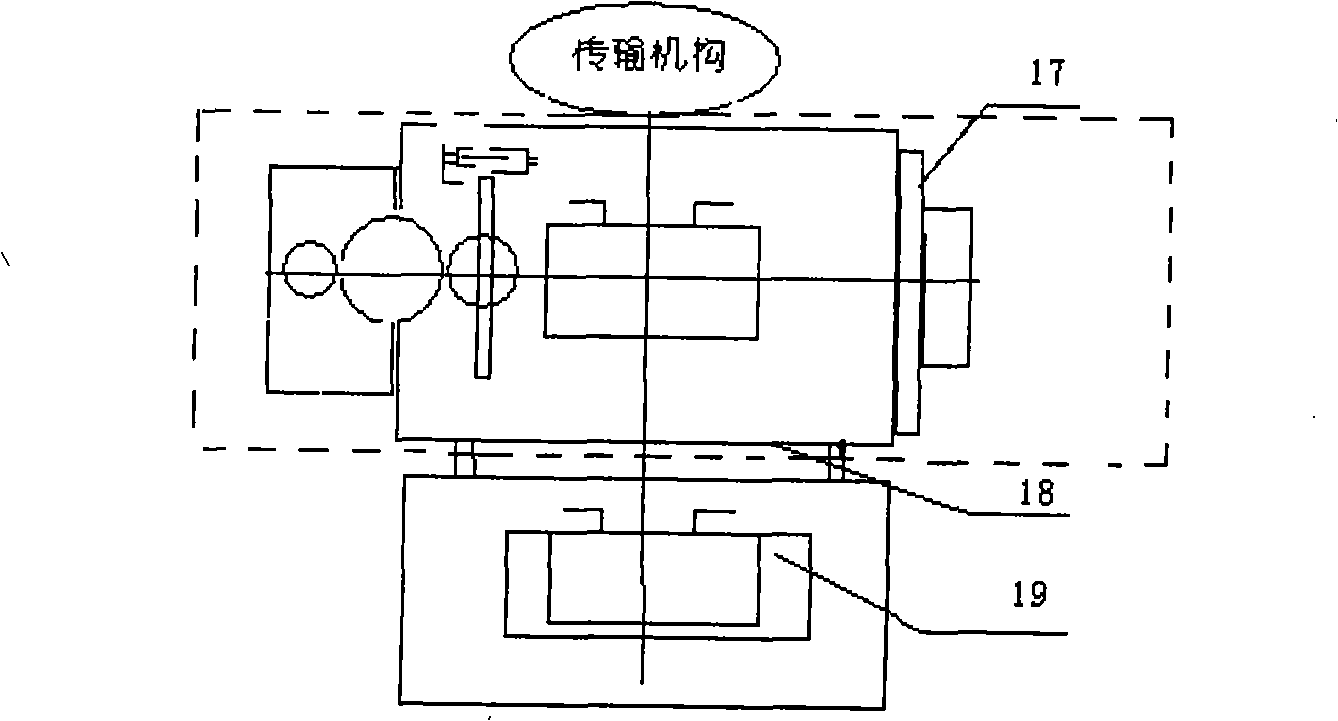

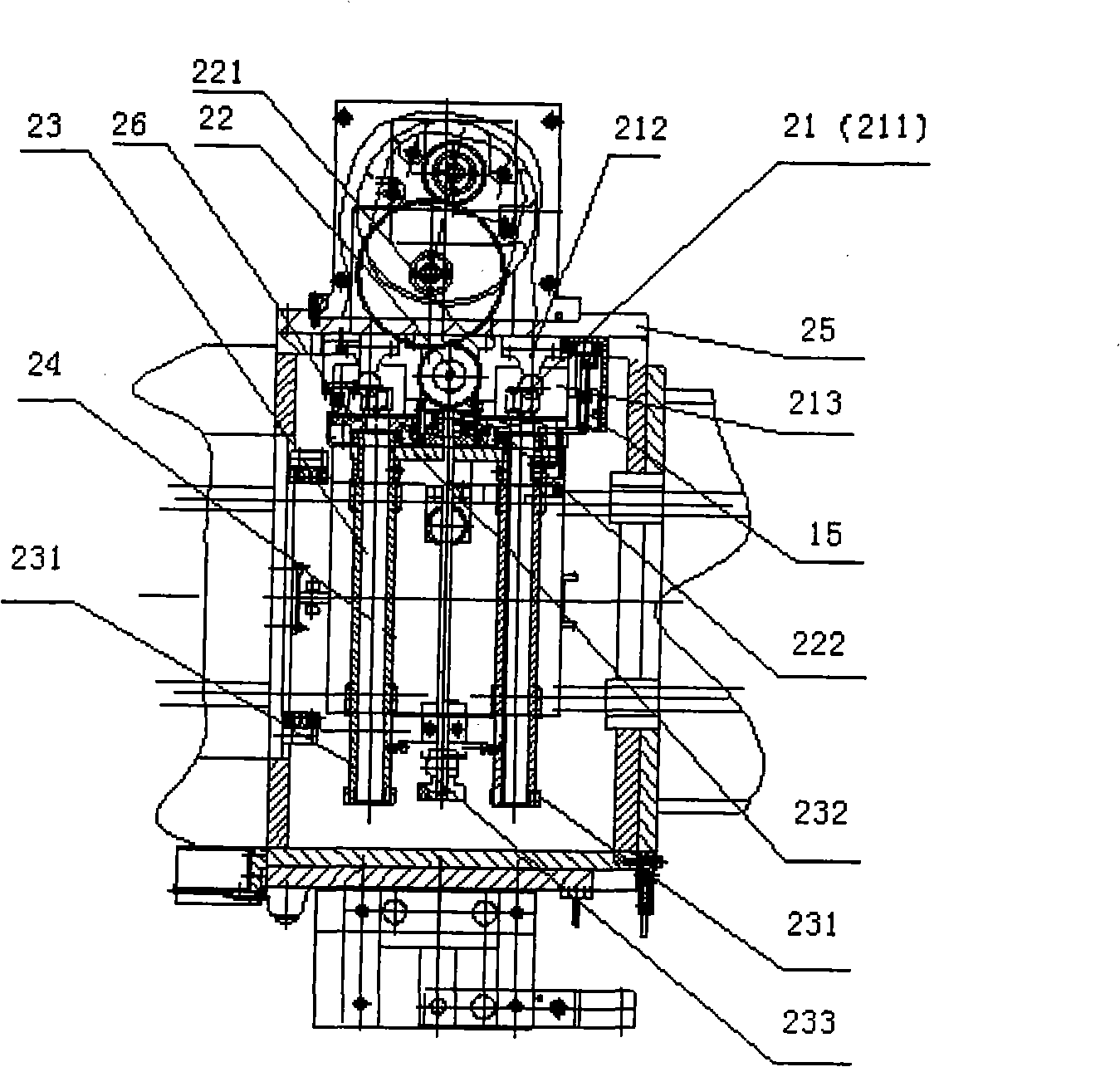

Electron-beam exposure device film jacket library system

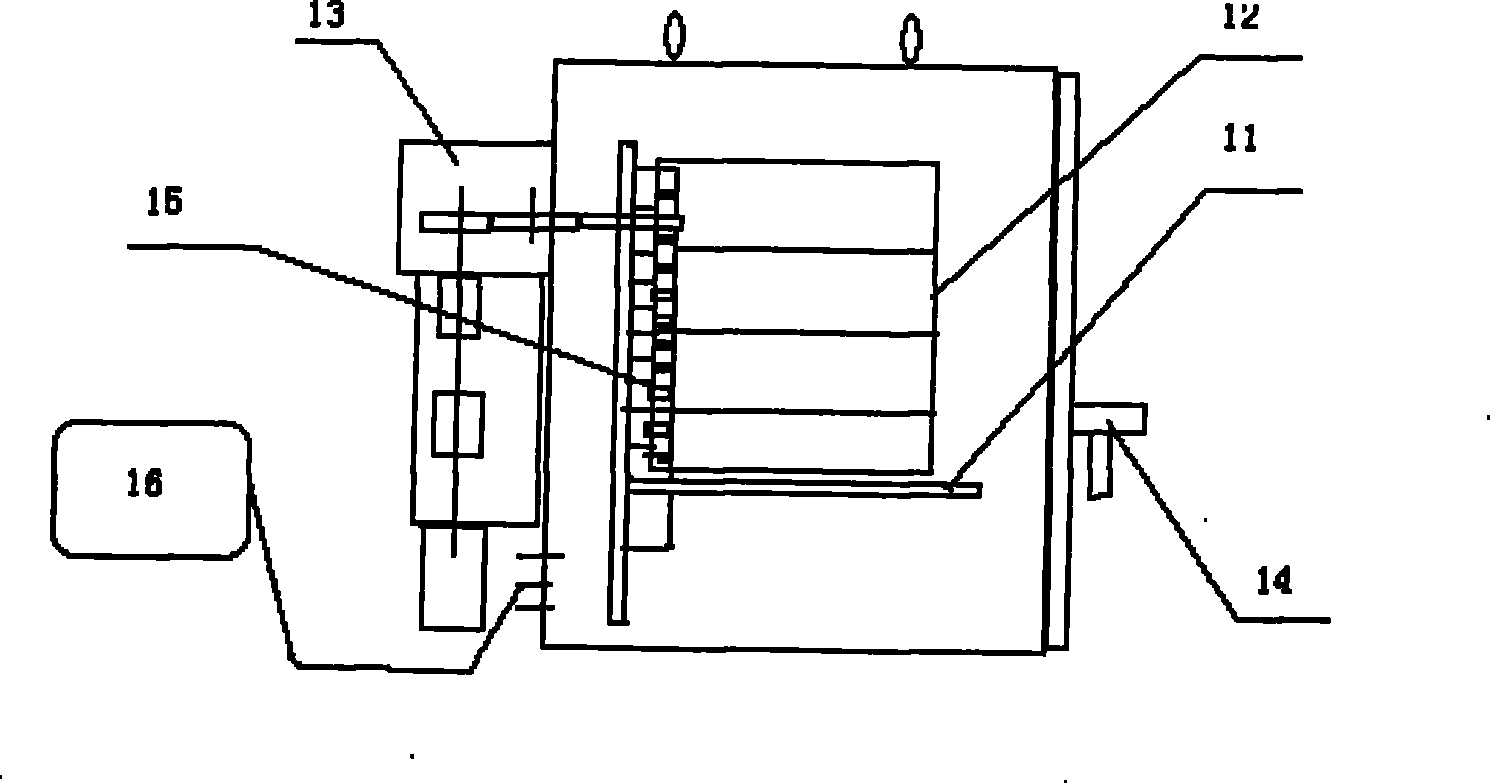

InactiveCN101261453AShorten the time of feeding and picking up the filmHigh positioning accuracyControl using feedbackPhotomechanical exposure apparatusElectric machineryDrive motor

The invention relates to an electron beam exposure machine film clip library system with encoding identification, which is composed of a Z-direction motion stage, a film frame which is used for placing film clips, a gear box, an ascending and descending stage and a computer control system, a drive motor drives a gear in the gear box to rotate under the control of the computer control system, thus driving the Z-direction motion stage to do the Z-direction motion and allowing the film frame to do the Z-direction motion, the film clips on the film frame are driven to move upward or downward to the film receiving position of a valve port, the film clips are selectively sent to a film carrying stage for carrying out the exposure, at this time, the valve port and a door of the film clip library are closed simultaneously, the valve port is opened after the completion of the exposure of one film clip, then the film clip is retaken to the film clip library for preservation, and the exposure valve port is immediately closed; the computer control system further controls the Z-direction motion stage to move upward or downward to the position of the next film clip which needs to be exposed, then the valve port is opened again to carry out the exposure of the next film clip, and the process revolves like this till the film clips are completely exposed. The electron beam exposure machine film clip library system shortens the time of sending and taking the films, improves the positioning precision of sending and taking the films and ensures the exposure quality of the film clips.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

chamber heating device

ActiveCN103208440BNo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCavity wall

Disclosed is a cavity heating device. The cavity heating device comprises a cavity wall heating structure and / or a slide holder heating structure. The cavity wall heating structure is arranged on the inner wall of a reaction cavity. The slide holder heating structure is arranged at the bottom of a slide holder. The cavity heating device can reduce or avoid nonuniformity caused by the fact that plasma starting is unsymmetrical in structure in the plasma etching process. An electrode fixing structure is free of air discharge under the plasma starting condition and can meet requirement of a vacuum cavity for vacuum degree.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

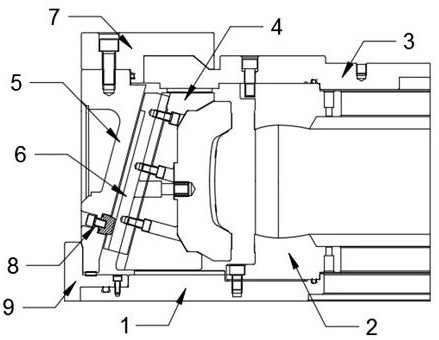

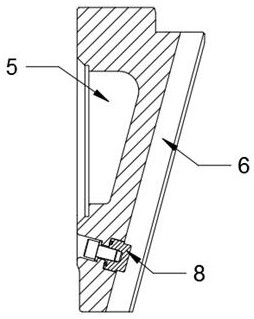

Limiting block sealing device and vacuumizing tire mold

Owner:合肥大道模具有限责任公司

A fastening and sealing device and assembly and disassembly method for a high-temperature ball mill tank

ActiveCN111215201BRequirements for maintaining vacuumQuick release functionGrain treatmentsStructural engineeringPumping vacuum

The invention relates to a fastening and sealing device for a high-temperature ball mill tank and an assembly and disassembly method. It has a ball mill cylinder with one end open and an end cover fixedly connected to the open end of the ball mill cylinder through bolt sealing. The end is connected with an exhaust pipe for extracting the vacuum in the ball mill cylinder, and a lock clamp mechanism is provided between the ball mill cylinder body and the end cover. The clip hasp and the lock angle seat are fixed on the end cover. One end of the lock clip hasp is connected with the lock clip closing rod, and the other end of the lock clip hasp is turned over and folded on the lock angle seat. The present invention adopts the combination of bolts and locking mechanism before ball milling, which ensures the requirements of the ball mill cylinder for vacuum degree during vacuuming, and then removes the bolts for locking, and only retains the locking mechanism for locking during high-temperature ball milling, realizing The function of quick disassembly of the end cover of the ball mill tank at high temperature after operation is realized, which further meets the operation requirements of special materials.

Owner:CHANGZHOU UNIV

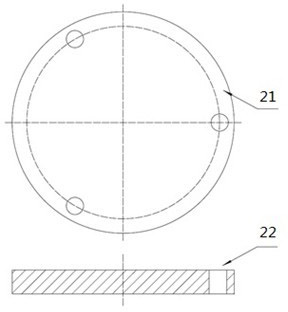

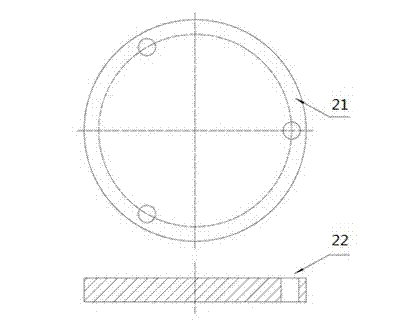

a slide deck

ActiveCN103208409BNo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringChip carrier

The invention discloses a chip carrier and belongs to the technical field of plasma body processes. The chip carrier comprises a cavity, a cavity upper cover, an electrode, a chip fixing disc, a fixing disc supporting ring and a supporting disc. A chip fixing structure of the chip carrier comprises the chip fixing disc and the fixing disc supporting ring. An unevenness phenomenon caused by an asymmetric structure when a plasma body is started can be reduced or avoided, and a gas homogenizing structure is simplified. Under the starting condition of the plasma body, the chip carrier does not cause a gas escape phenomenon, so that the requirement of a chip for the cavity vacuum degree can be kept.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Electron-beam exposure device film jacket library system

InactiveCN101261453BGuaranteed Exposure QualityShorten the timePhotomechanical exposure apparatusControl using feedbackComputer control systemDrive motor

The invention relates to an electron beam exposure machine film clip library system with encoding identification, which is composed of a Z-direction motion stage, a film frame which is used for placing film clips, a gear box, an ascending and descending stage and a computer control system, a drive motor drives a gear in the gear box to rotate under the control of the computer control system, thusdriving the Z-direction motion stage to do the Z-direction motion and allowing the film frame to do the Z-direction motion, the film clips on the film frame are driven to move upward or downward to the film receiving position of a valve port, the film clips are selectively sent to a film carrying stage for carrying out the exposure, at this time, the valve port and a door of the film clip libraryare closed simultaneously, the valve port is opened after the completion of the exposure of one film clip, then the film clip is retaken to the film clip library for preservation, and the exposure valve port is immediately closed; the computer control system further controls the Z-direction motion stage to move upward or downward to the position of the next film clip which needs to be exposed, then the valve port is opened again to carry out the exposure of the next film clip, and the process revolves like this till the film clips are completely exposed. The electron beam exposure machine film clip library system shortens the time of sending and taking the films, improves the positioning precision of sending and taking the films and ensures the exposure quality of the film clips.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Method and system for vacuuming control of ito-pvd equipment

ActiveCN104746033BAvoid damageRequirements for maintaining vacuumVacuum evaporation coatingSputtering coatingEmbedded system

The invention discloses a vacuuming control method and a system of ITO-PVD equipment, wherein the method comprises the following steps: a transmission cavity in the ITO-PVD equipment is set as a default cavity of a system dry pump, and is not allocated with a cold pump, and a cold pump is allocated for an ITO process cavity; for the default cavity, when other cavities besides the default cavity do not occupy the system dry pump, the system dry pump continuously vacuums the default cavity; and in the processing procedure, when the cavity in the ITO-PVD equipment requests for vacuuming, the vacuuming is performed according to the cold pump allocating condition of the cavity. The method saves the equipment cost and can effectively prevent the collision between hardware equipment when guaranteeing the vacuum degree requirement in the equipment processing.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

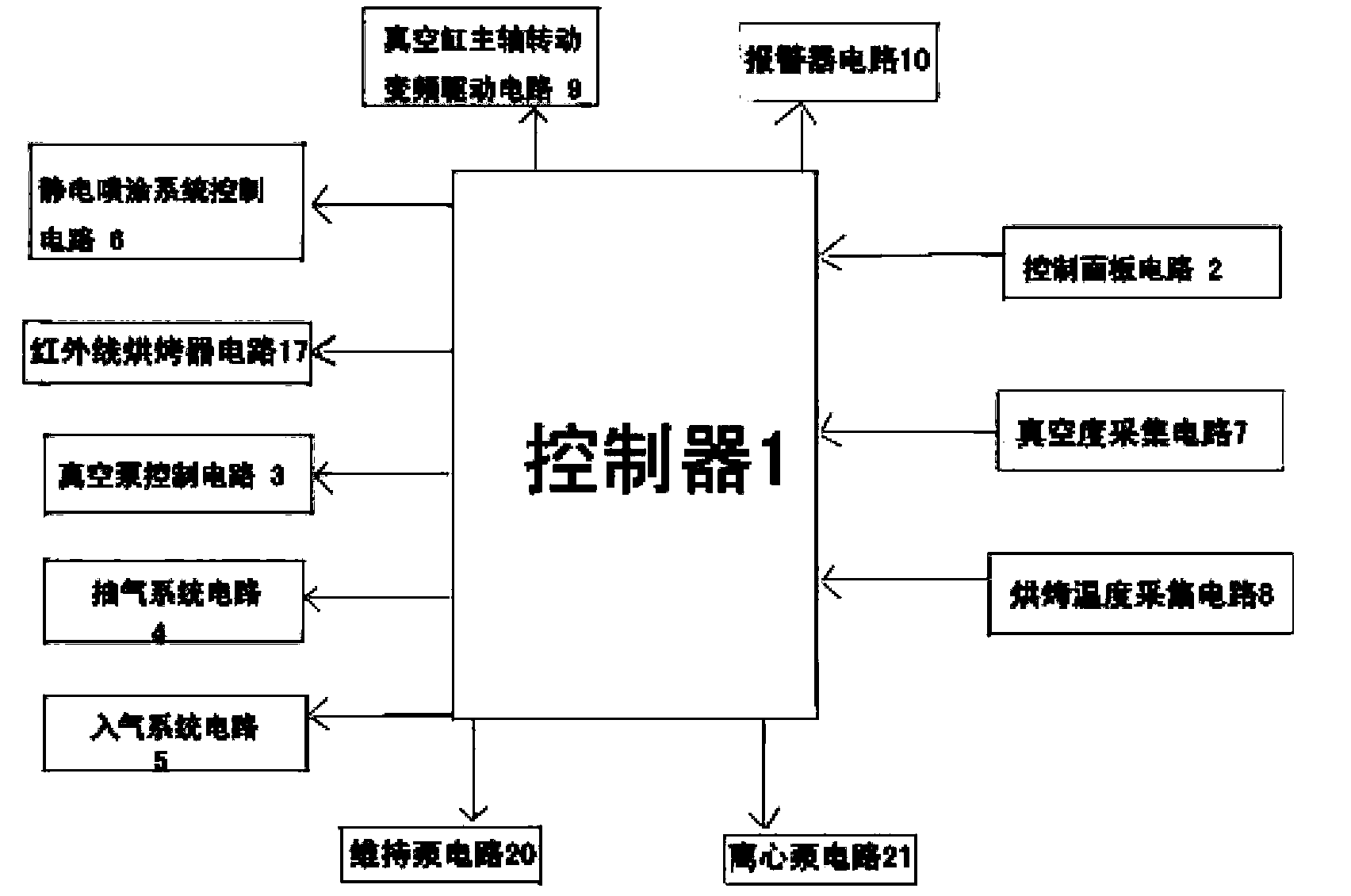

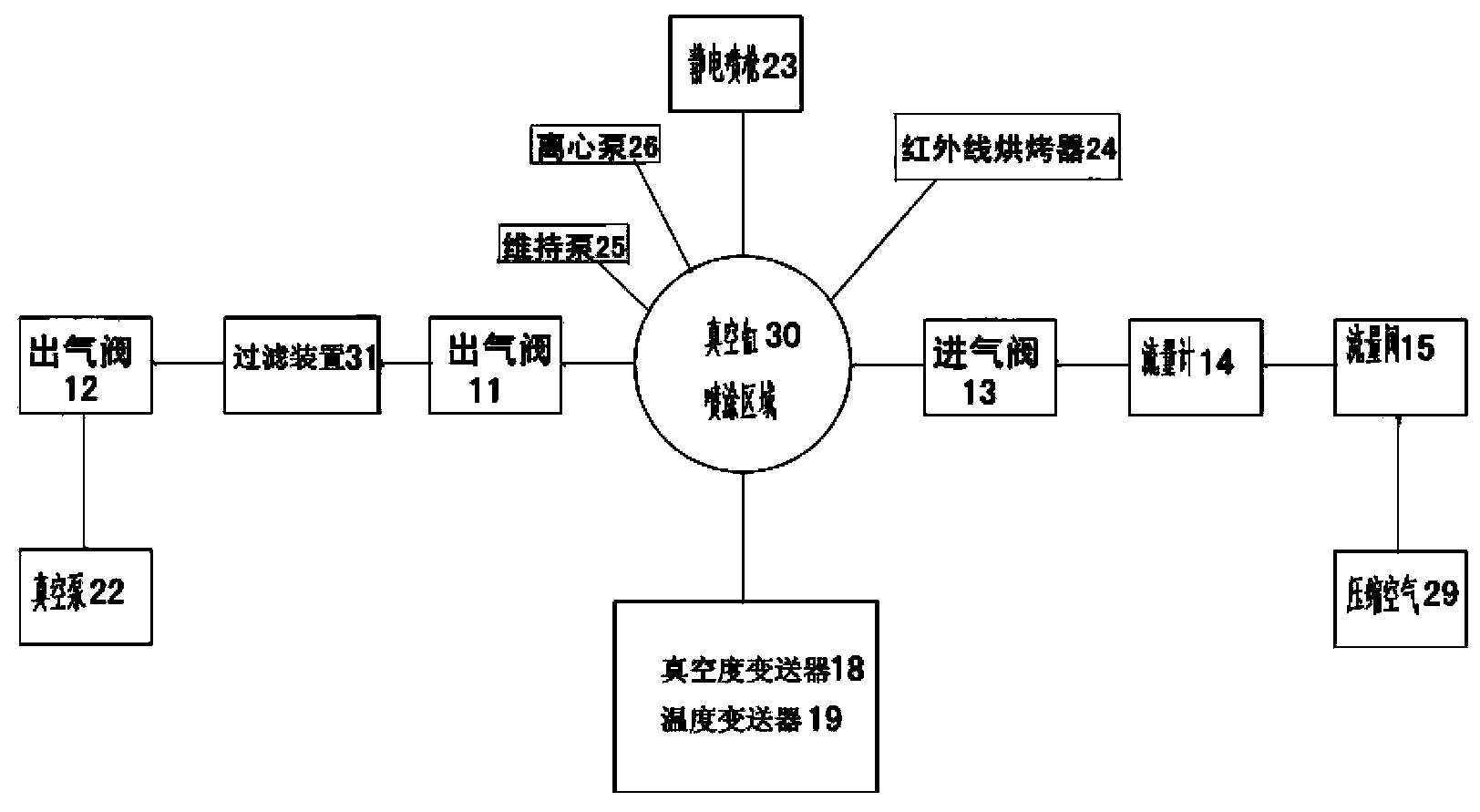

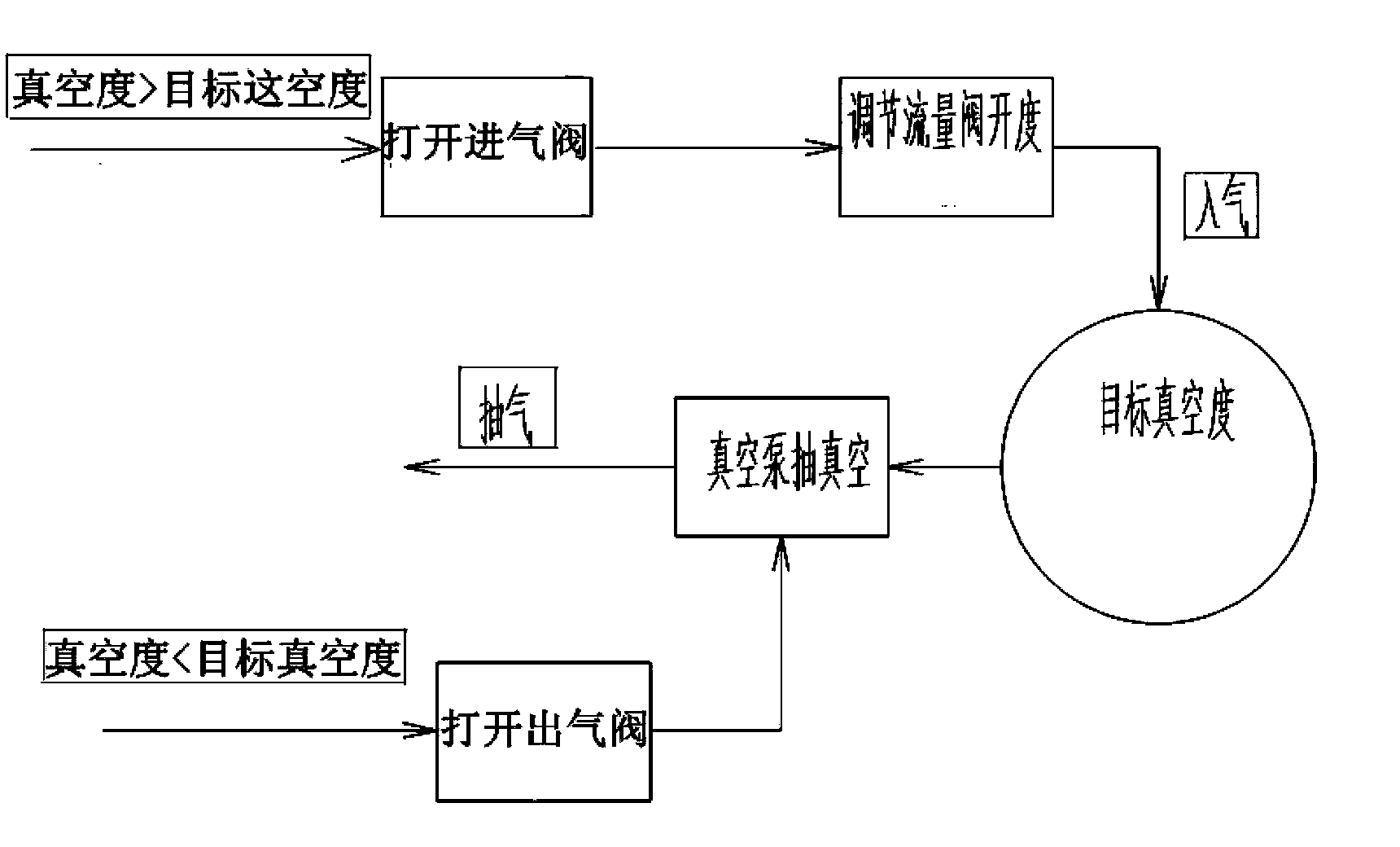

Vacuum electrostatic spraying control system

ActiveCN102631999BReduce the influence of artificial factorsReduce manufacturing costGasless sprayingControl systemFrequency conversion

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

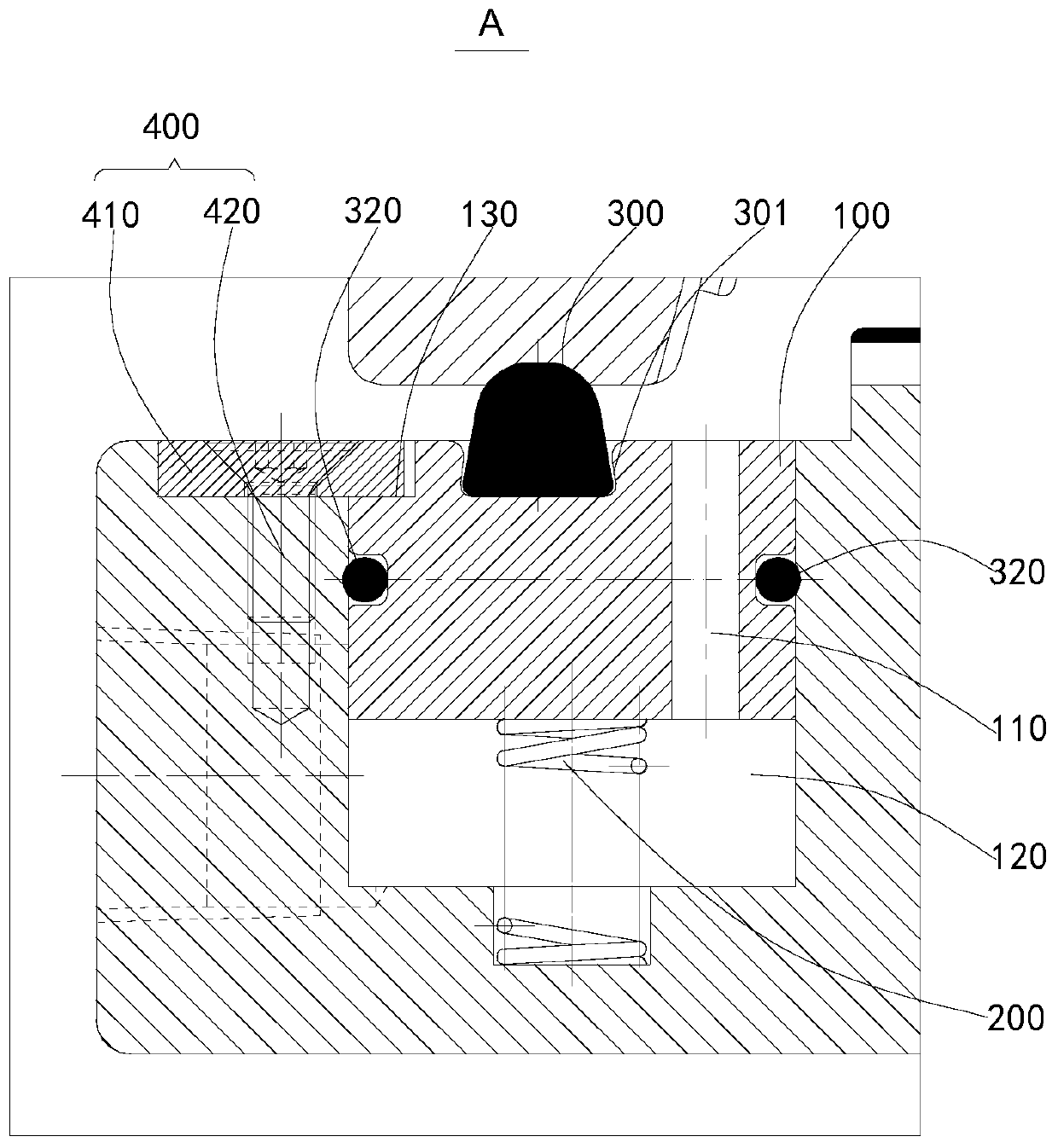

Automobile hydraulic braking main cylinder secondary leather cup

InactiveCN107826093AControl deformationLarge amount of compressionPiston ringsBraking action transmissionMaster cylinderEngineering

The invention discloses an auxiliary leather cup of an automobile hydraulic brake master cylinder, and a component of an automobile hydraulic brake master cylinder, including a bowl body, the outer wall of the bowl body is provided with a sealing main lip, and the outer wall bottom of the bowl body is The end is provided with a sealing auxiliary lip, and the bottom side wall of the sealing auxiliary lip is in the same plane as the bottom end of the bowl and the plane is perpendicular to the axis of the bowl. The beneficial effect of the invention is that the vacuum degree requirement of the main cylinder is fully guaranteed, and the assembly is relatively simple, the movement resistance of the piston is reduced, and the service life of the main cylinder is prolonged.

Owner:诸城市骏恒汽车部件有限公司

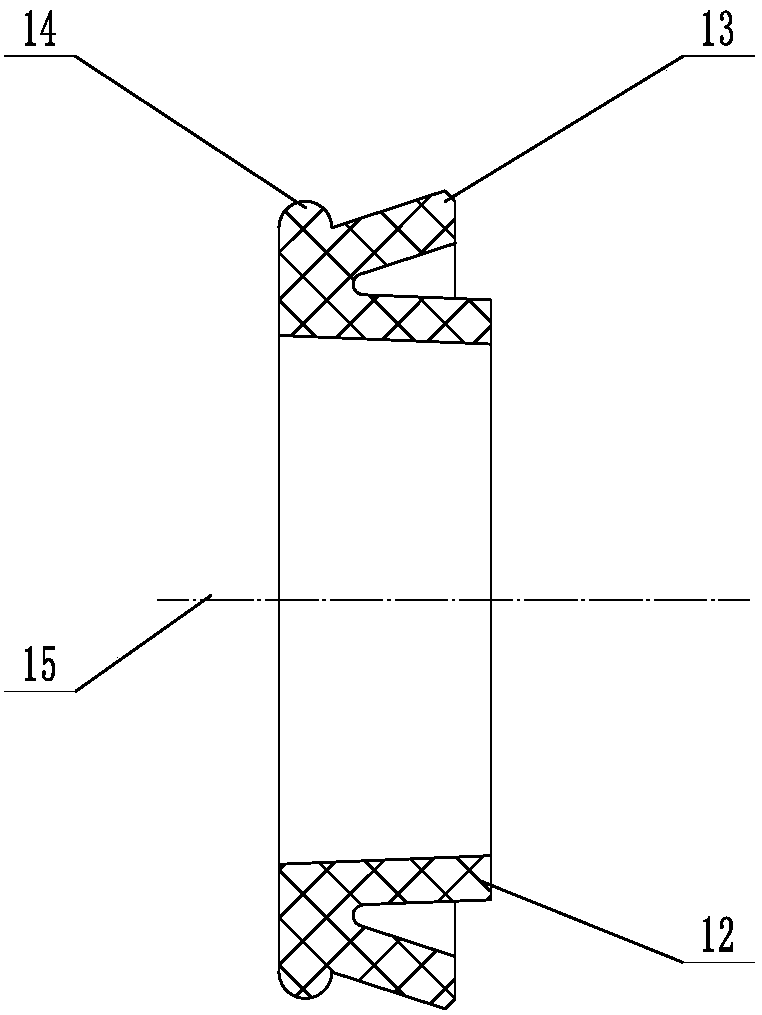

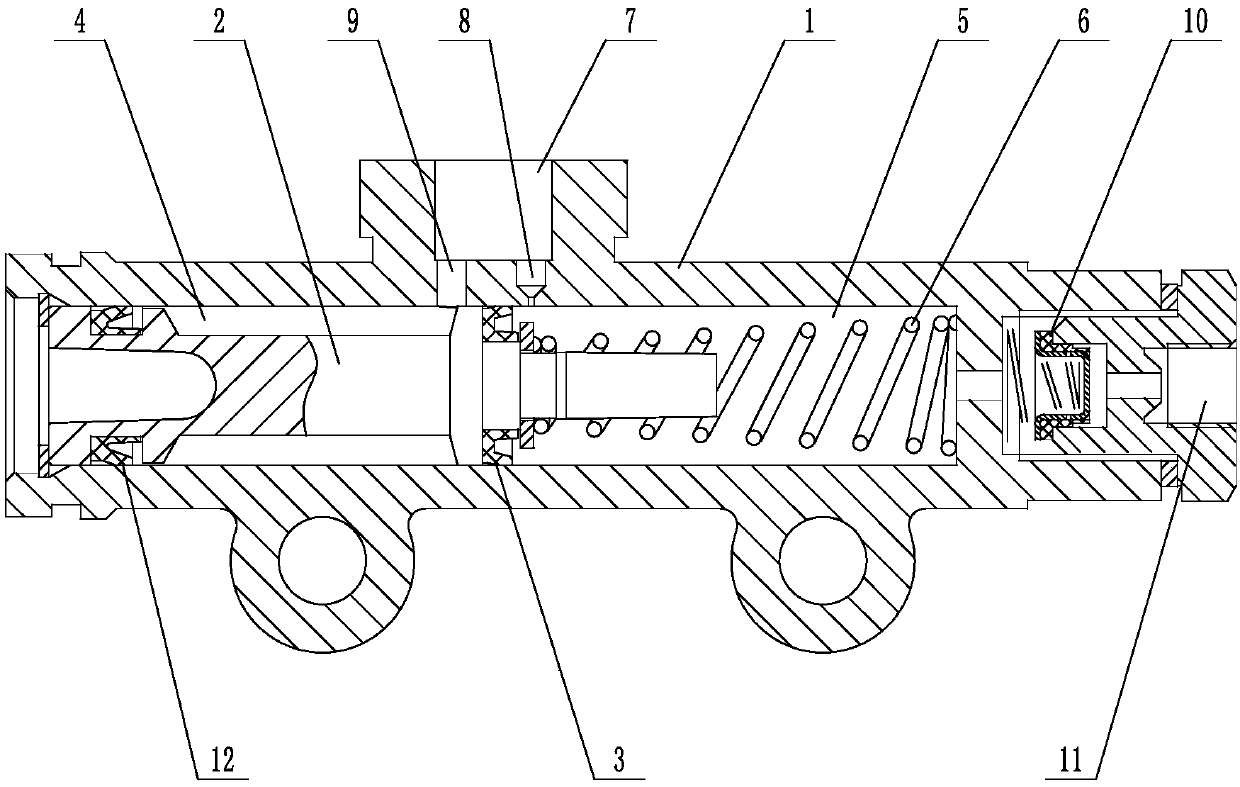

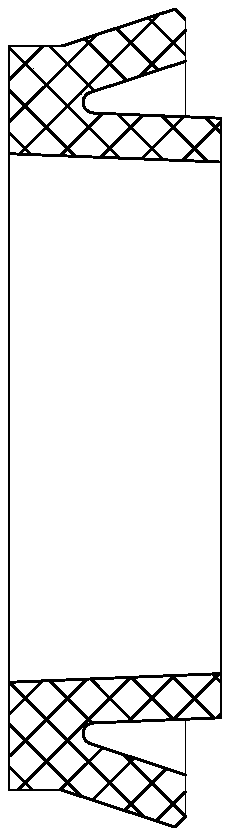

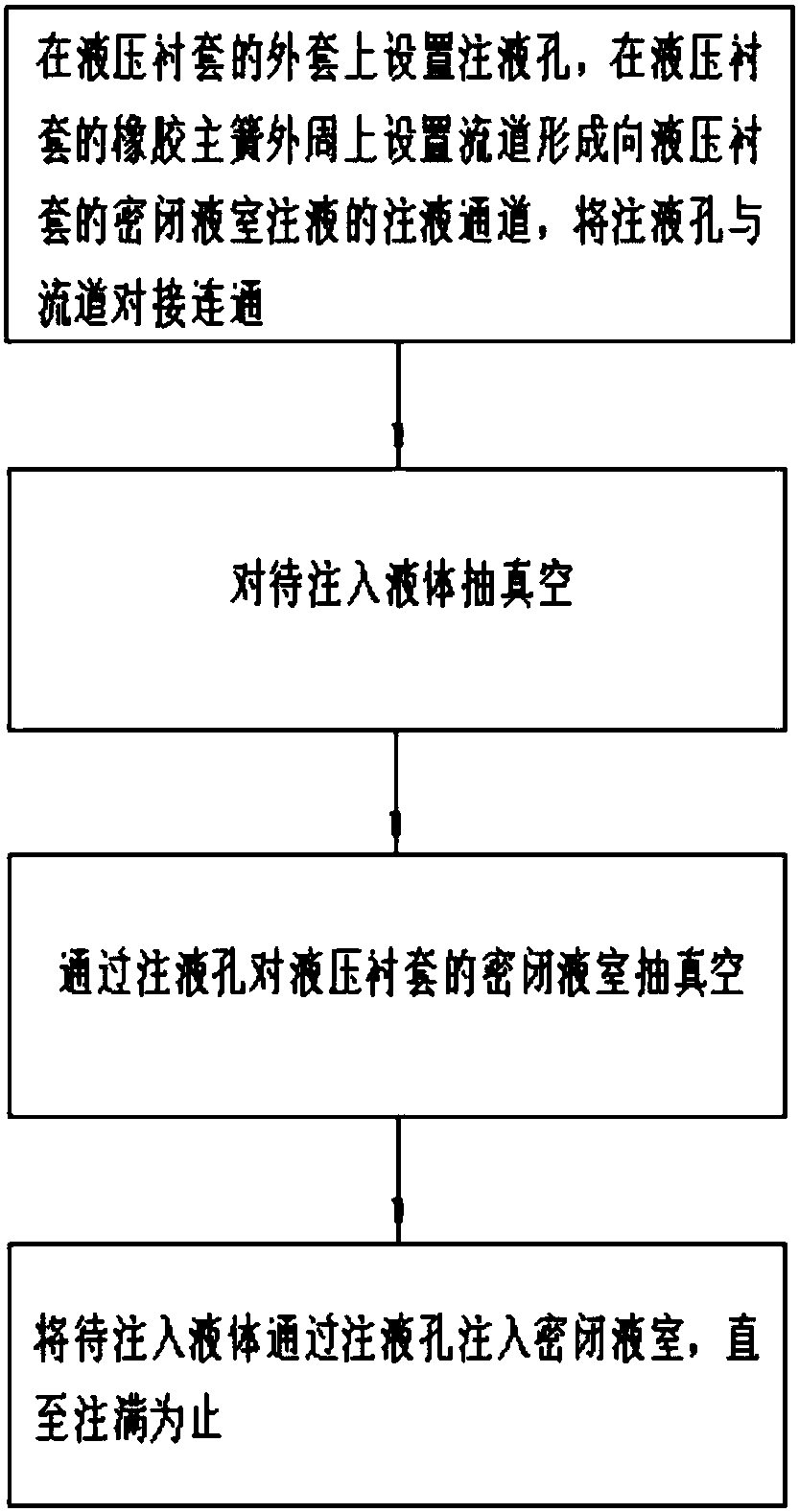

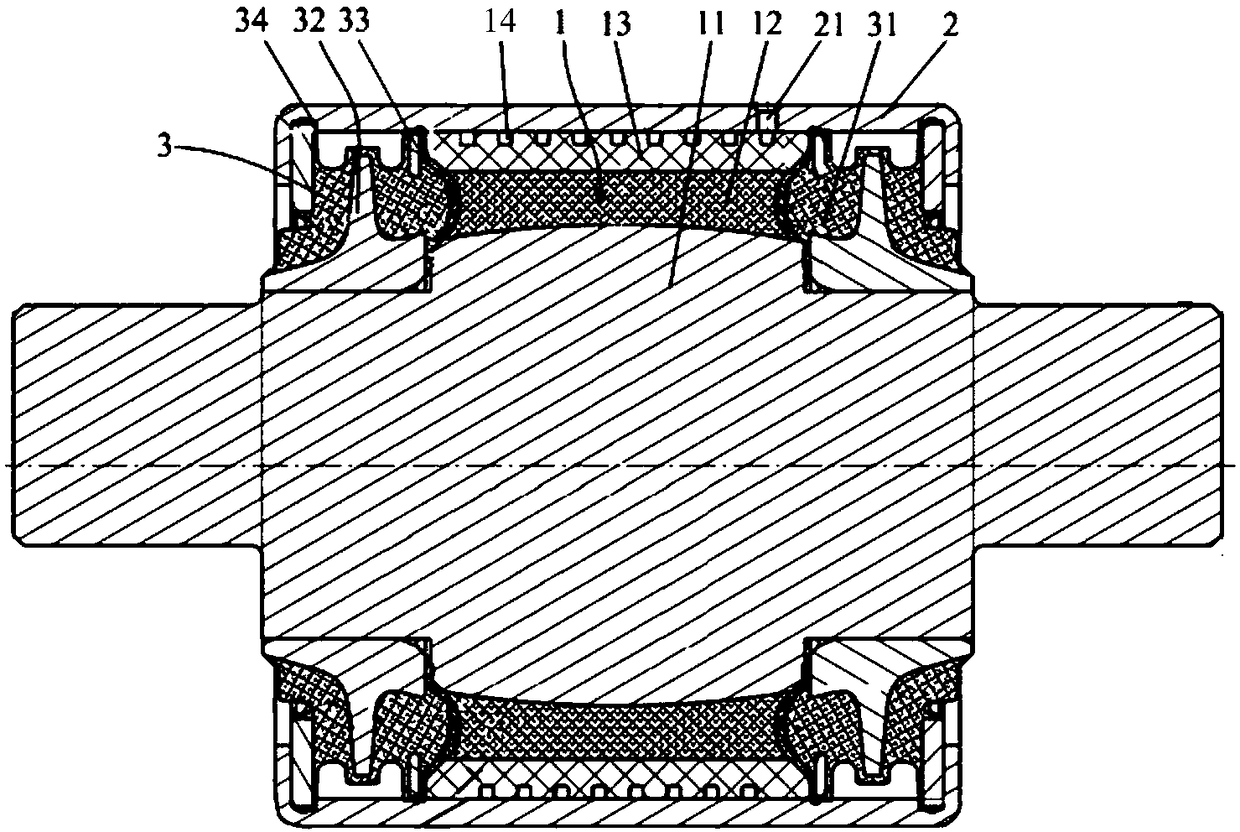

Liquid injection method for hydraulic bushing for rail transit

InactiveCN108150587ANot easy to residueRequirements for maintaining vacuumSpringsSprings/dampers design characteristicsEngineeringRail transit

The invention provides a liquid injection method for a hydraulic bushing for rail transit. The liquid injection method comprises the following steps that (1) a liquid injection hole is formed in an outer sleeve of the hydraulic bushing, a flow channel is formed in the periphery of a rubber main spring of the hydraulic bushing to form a liquid injection channel for injecting liquid into an airtightliquid chamber of the hydraulic bushing, and the liquid injection hole communicates with the flow channel in an butted mode; (2) the to-be-injected liquid is subjected to vacuumizing; (3) the airtight liquid chamber of the hydraulic bushing is subjected to vacuumizing through the liquid injection hole; and (4) the to-be-injected liquid is injected into the airtight liquid chamber through the liquid injection hole till filling is achieved. The liquid injection method has the advantages of guaranteeing the vacuum degree requirement of the airtight liquid chamber, and being easy to machine and high in precision.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A kind of polypropylene composition and preparation method thereof

The invention discloses a polypropylene composition which comprises, by weight parts, 100 parts of polypropylene, 10-30 parts of basic magnesium sulfate whisker, 0.1-1.0 part of foaming agent, 0.5-1.5 parts of smell adsorbent and 10-30 parts of flexibilizer. By simultaneously adding basic magnesium sulfate whisker and foaming agent of a specific content, compared with the situation that only basic magnesium sulfate whisker is added, the weight of a workpiece can be greatly reduced while the comprehensive mechanical property is not reduced, and thus the lightweight requirements of an automobile are met. By adding the smell adsorbent of a specific content and adopting single vacuum design of a twin-screw extruder, it is guaranteed that the vacuum degree requirements are not larger than -0.08 bar, micromolecular volatile matter can be pumped away, and the devolatilization effect is improved obviously. The prepared polypropylene composition is low in smell and emission characteristics, the lightweight requirements of the automobile and low-smell low-emission performances of automobile interior part materials can be met, and the application prospect is wide.

Owner:JIANGSU KINGFA ENVIRONMENTAL PROTECTION SCI &TECH CO LTD

Nitrogen source ionization method and device for semiconductor material vapor deposition growth system

InactiveCN101307485BGuaranteed tightnessGuaranteed heating functionPolycrystalline material growthFrom chemically reactive gasesCapacitanceSemiconductor materials

Owner:NANJING UNIV

A vacuum sealing device and vacuum tire mold

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

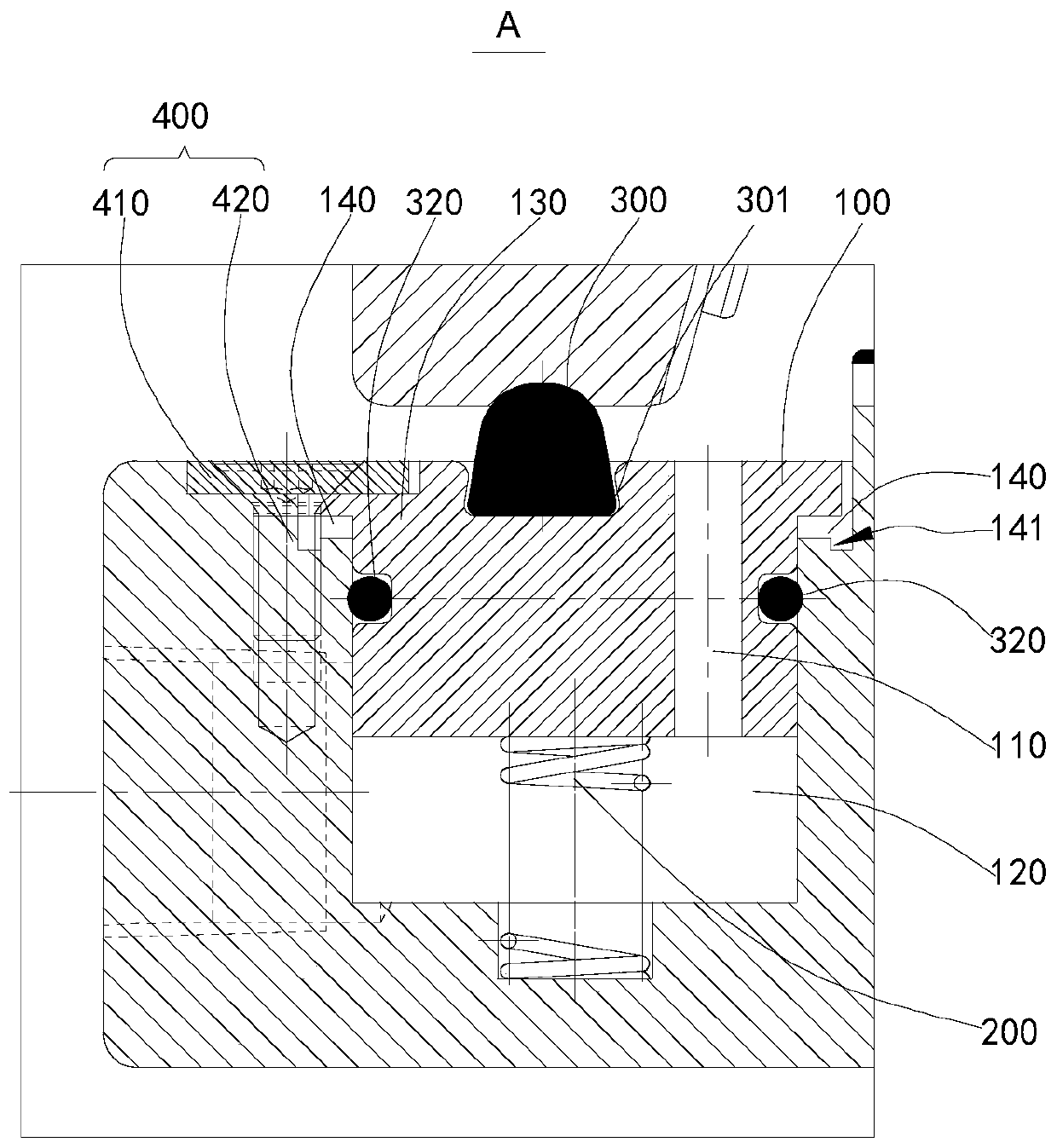

System for detecting number of fallen particles during working process of valve

ActiveCN109406134ASimple detection principleEasy to operateMachine valve testingIndividual particle analysisParticle counterMechanical engineering

The invention discloses a system for detecting the number of fallen particles during the working process of a valve, comprising a vacuum device, a to-be-detected valve, a to-be-detected valve drivingdevice, a gas injecting device and a particle counter, wherein the vacuum device comprises a cavity and a vacuuming device; the to-be-detected valve driving device is connected to the to-be-detected valve; the to-be-detected valve is placed in the cavity; and the vacuum device is connected to the gas injecting device and the particle counter. The system can detect the number of fallen particles during the working process of the valve, so that a manufacturer and a purchaser of the valve can accurately understand the number of the fallen particles of the valve, thereby solving the problem that the quality of a semiconductor or photovoltaic module is affected because the number of the fallen particles of the valve does not meet a requirement.

Owner:九川真空科技成都有限公司 +1

Plate electrode fixing structure

ActiveCN102290312BNo outgassingWide distribution of uniformityElectric discharge tubesEngineeringPolycarbonate

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Chip carrier

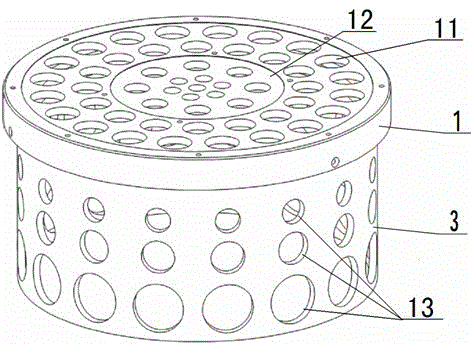

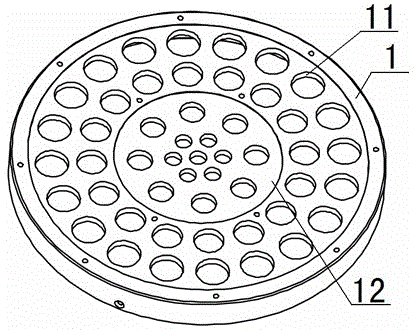

ActiveCN103208409ANo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringChip carrier

The invention discloses a chip carrier and belongs to the technical field of plasma body processes. The chip carrier comprises a cavity, a cavity upper cover, an electrode, a chip fixing disc, a fixing disc supporting ring and a supporting disc. A chip fixing structure of the chip carrier comprises the chip fixing disc and the fixing disc supporting ring. An unevenness phenomenon caused by an asymmetric structure when a plasma body is started can be reduced or avoided, and a gas homogenizing structure is simplified. Under the starting condition of the plasma body, the chip carrier does not cause a gas escape phenomenon, so that the requirement of a chip for the cavity vacuum degree can be kept.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Test method and test device for multi-field coupling performance of tritium-blocking coating based on accelerator ion irradiation

InactiveCN110208311BAccurate evaluationAchieve isolationMaterial analysis using wave/particle radiationMaterial heat developmentNuclear engineeringTandem accelerator

The invention discloses a method for testing the multi-field coupling performance of a tritium-blocking coating based on accelerator ion irradiation and a testing device thereof. The method is to use the accelerator to generate energy-carrying ions to irradiate the tritium-resistant coating sample; the gas injection system injects the gas medium into the flange to infiltrate the tritium-resistant coating sample; the temperature control system controls the heating table to irradiate the tritium-resistant coating. The samples are thermally cycled; then processed by the computer program control system. The device includes an electrostatic tandem accelerator, a vacuum chamber, an infrared thermometer, a sample stage, a gas injection system, a temperature control system, a computer program control system and various signal transmission lines; it realizes the multi-field coupling performance test of the anti-tritium coating. The test method and test device of the present invention can realize the multi-field coupling performance test of ion irradiation, thermal cycle and gas permeation on the fusion reactor tritium-resistant coating sample; thus more reliable and accurate evaluation of the tritium-resistant coating in service under actual working conditions Performance, with research and practical application value.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com