Nitrogen source ionization method and device for semiconductor material vapor deposition growth system

A vapor deposition, semiconductor technology, applied in the direction of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve the problems of high price, research field, production limitation, etc., and achieve the effect of good material growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

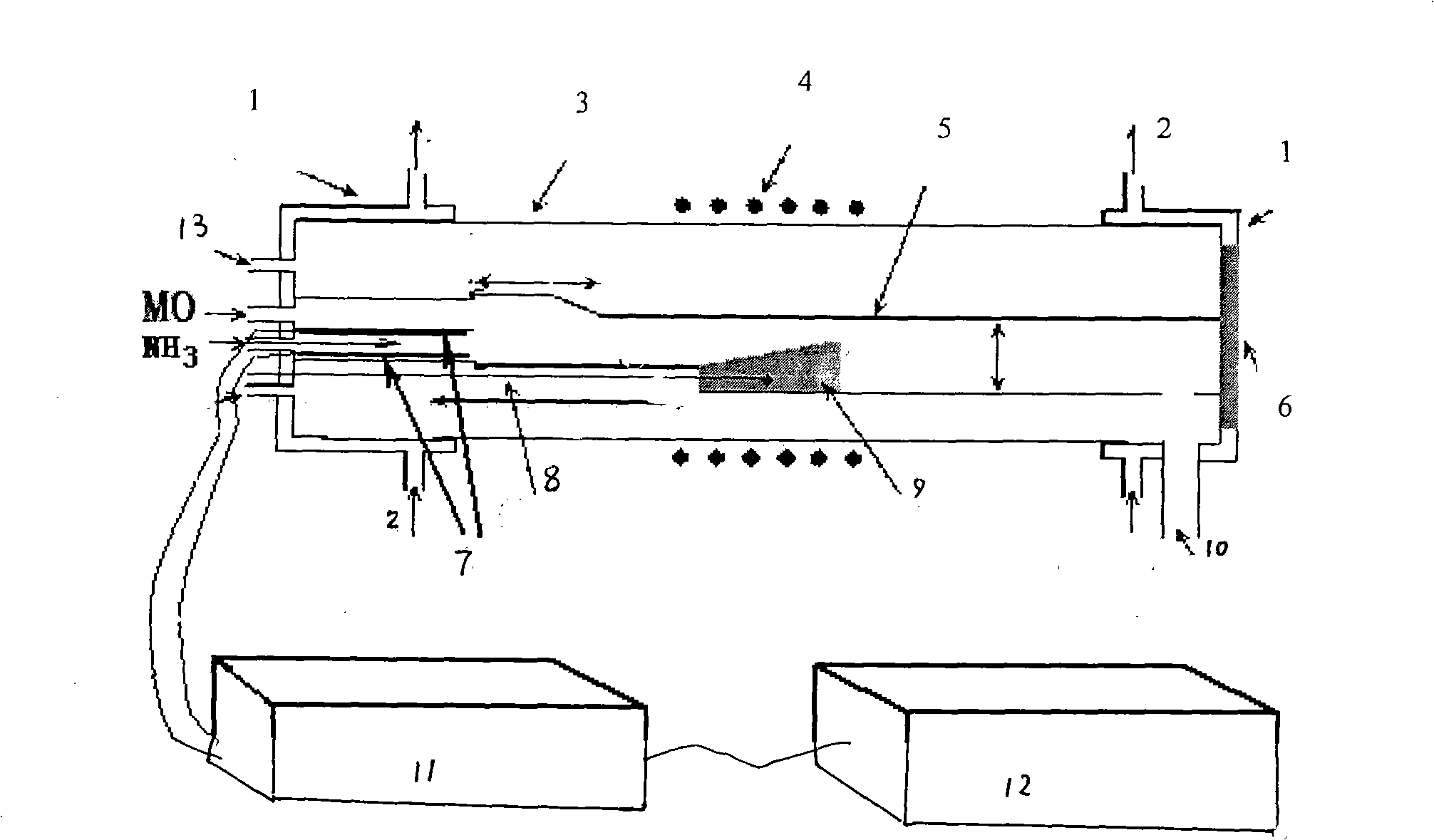

[0022] The invention relates to a novel nitrogen source ionization device used in semiconductor material growth systems such as CVD, MOCVD, HVPE and MBE. In order to improve the decomposition efficiency of ammonia molecules, parallel plate capacitors or cylindrical capacitors of radio frequency power are installed at the source inlets of nitride semiconductor growth equipment such as CVD and MOCVD. The ammonia gas is ionized by applying an external radio frequency field. The radio frequency discharge mode is a capacitive coupling type, that is, through a power matcher, a high frequency current is added to two parallel plate electrodes, and the electrons are accelerated by the electric field between the parallel capacitor plates to ionize. gas molecules, thereby creating a plasma in the parallel plates. The radio frequency capacitor can be used for ionization and decomposition of nitrogen sources that are not easy to be thermally decomposed at room temperature, such as the deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com