Patents

Literature

44results about How to "Eliminates the risk of cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

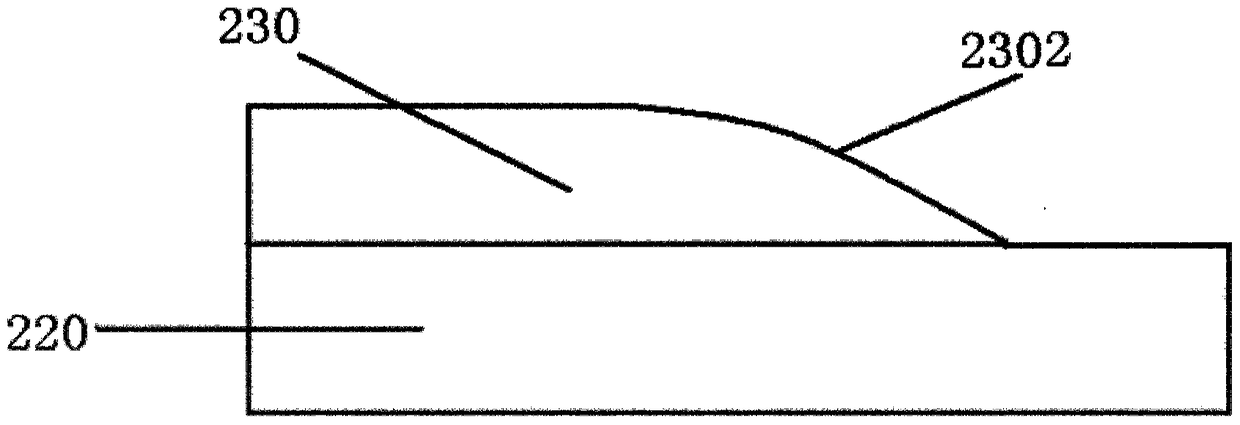

Laminated packaging materials and packaging containers produced therefrom

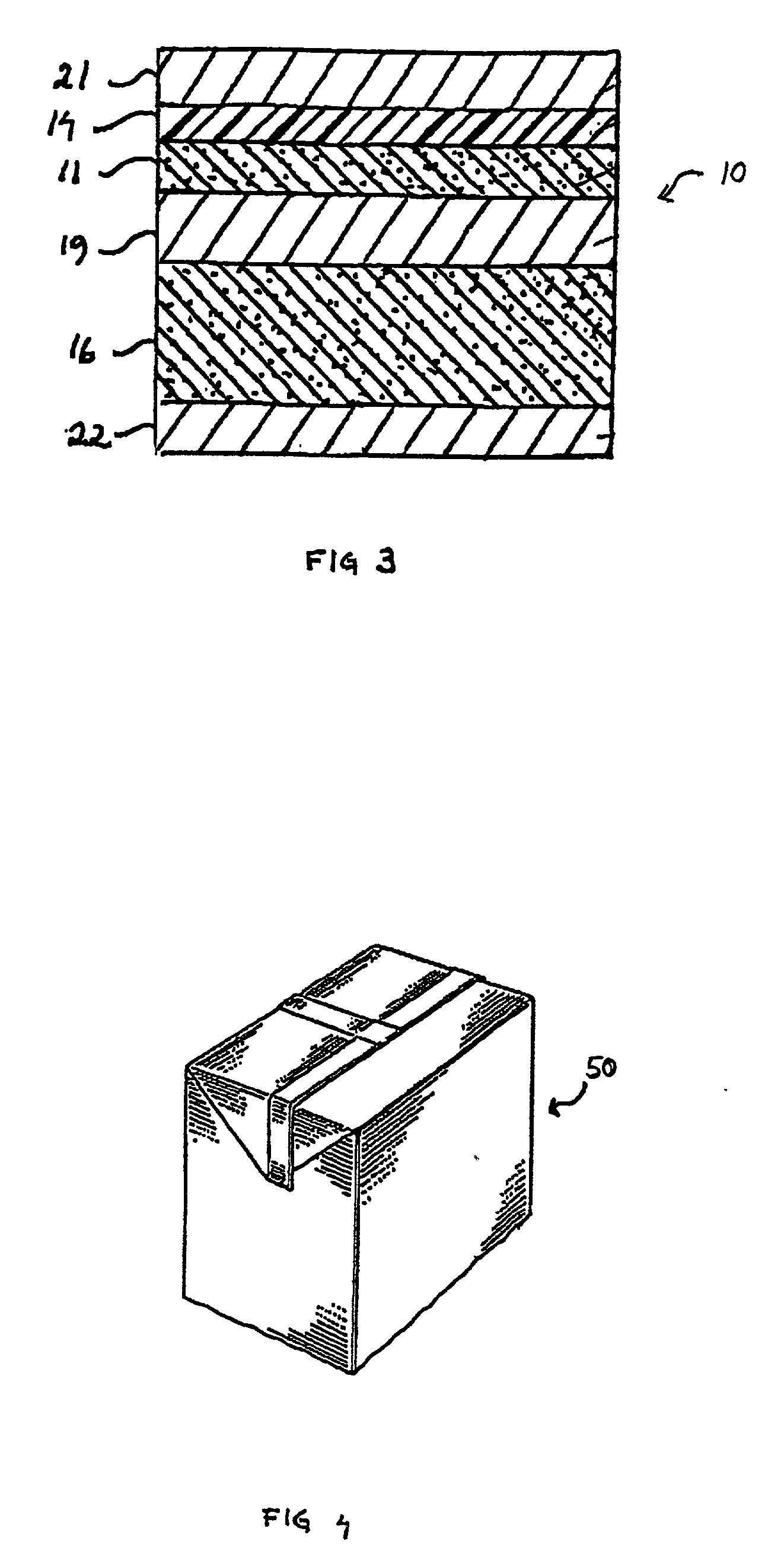

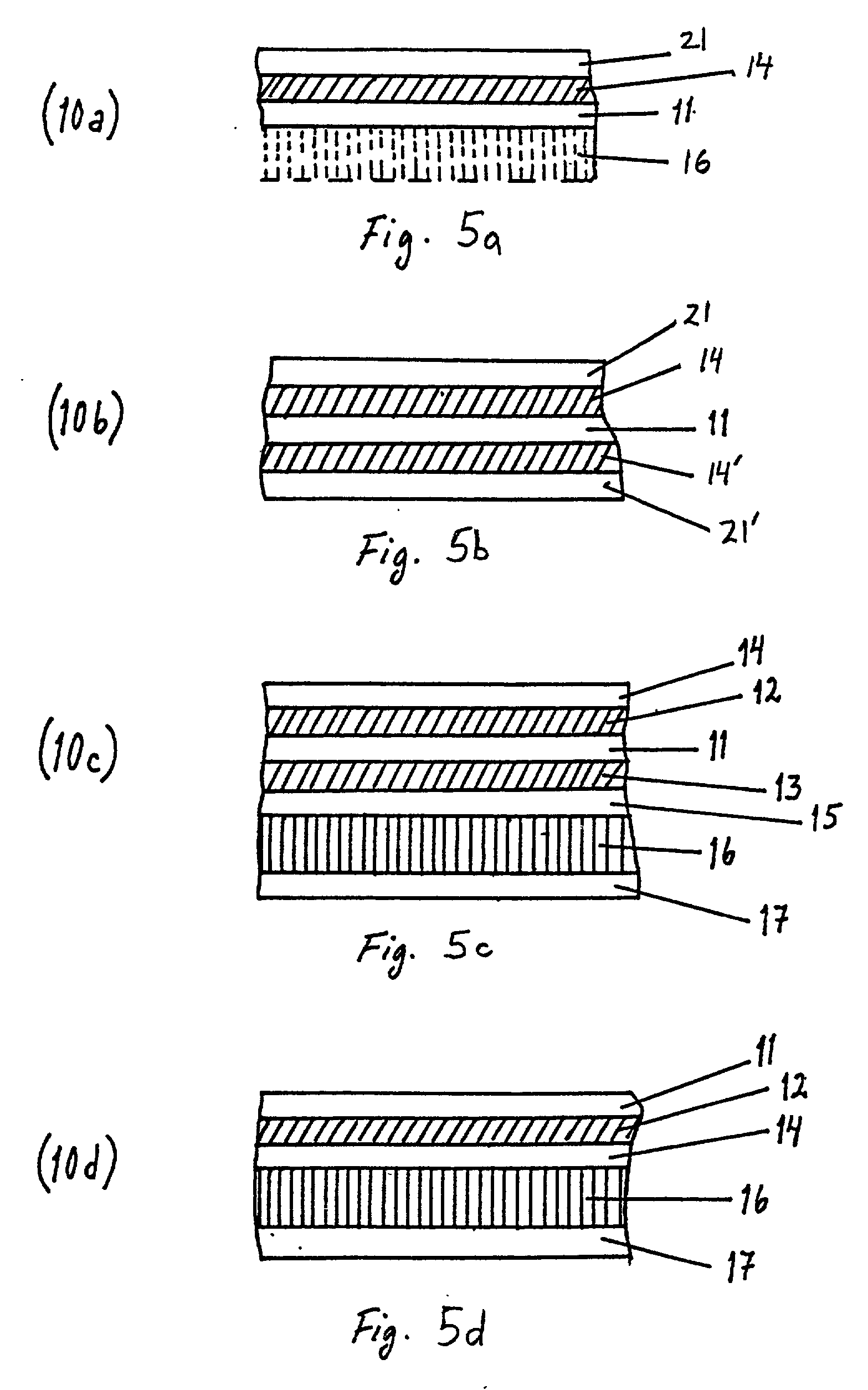

InactiveUS20030205319A1Eliminates the risk of crackingExcellent gas barrier performanceFlexible coversWrappersCardboardEngineering

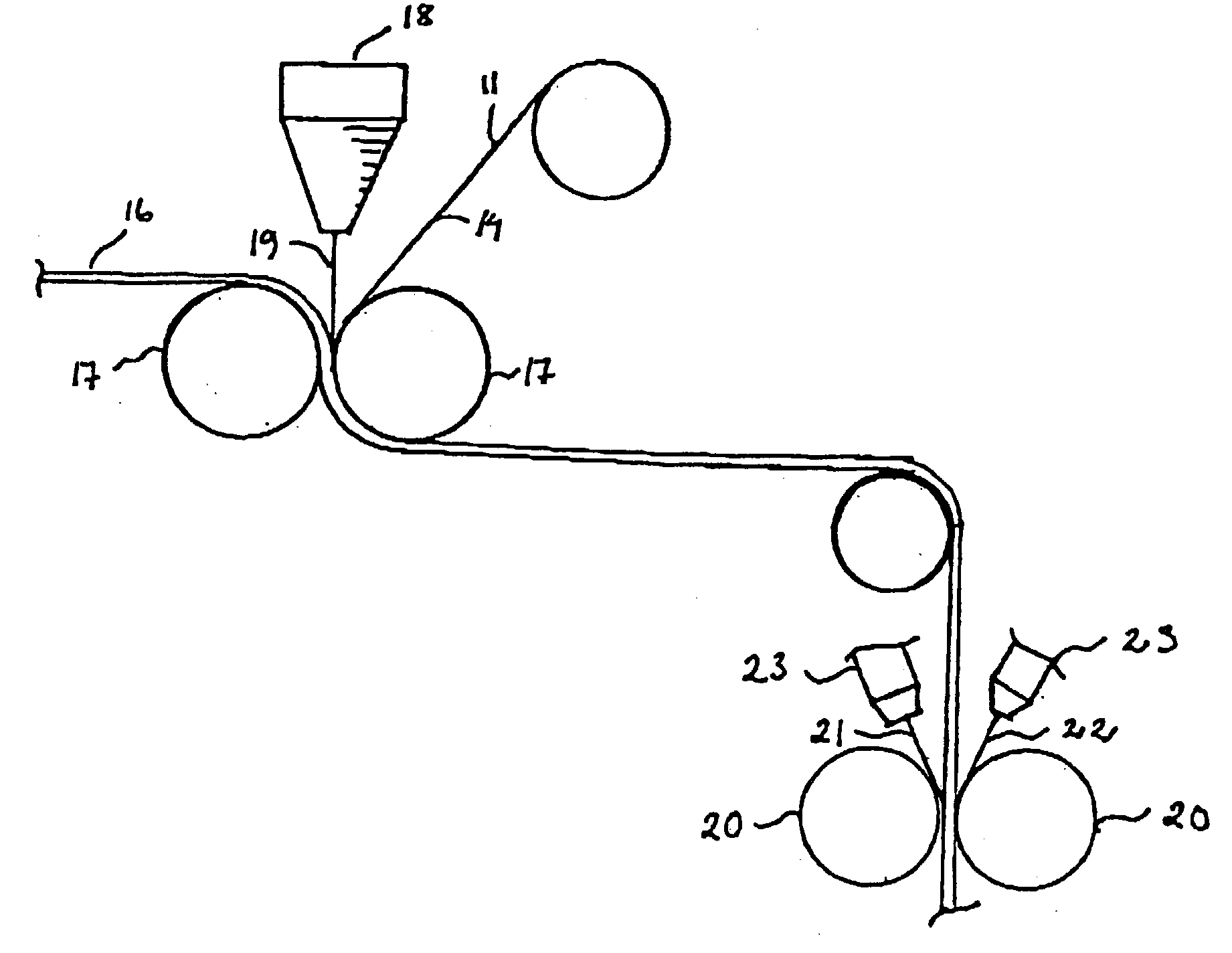

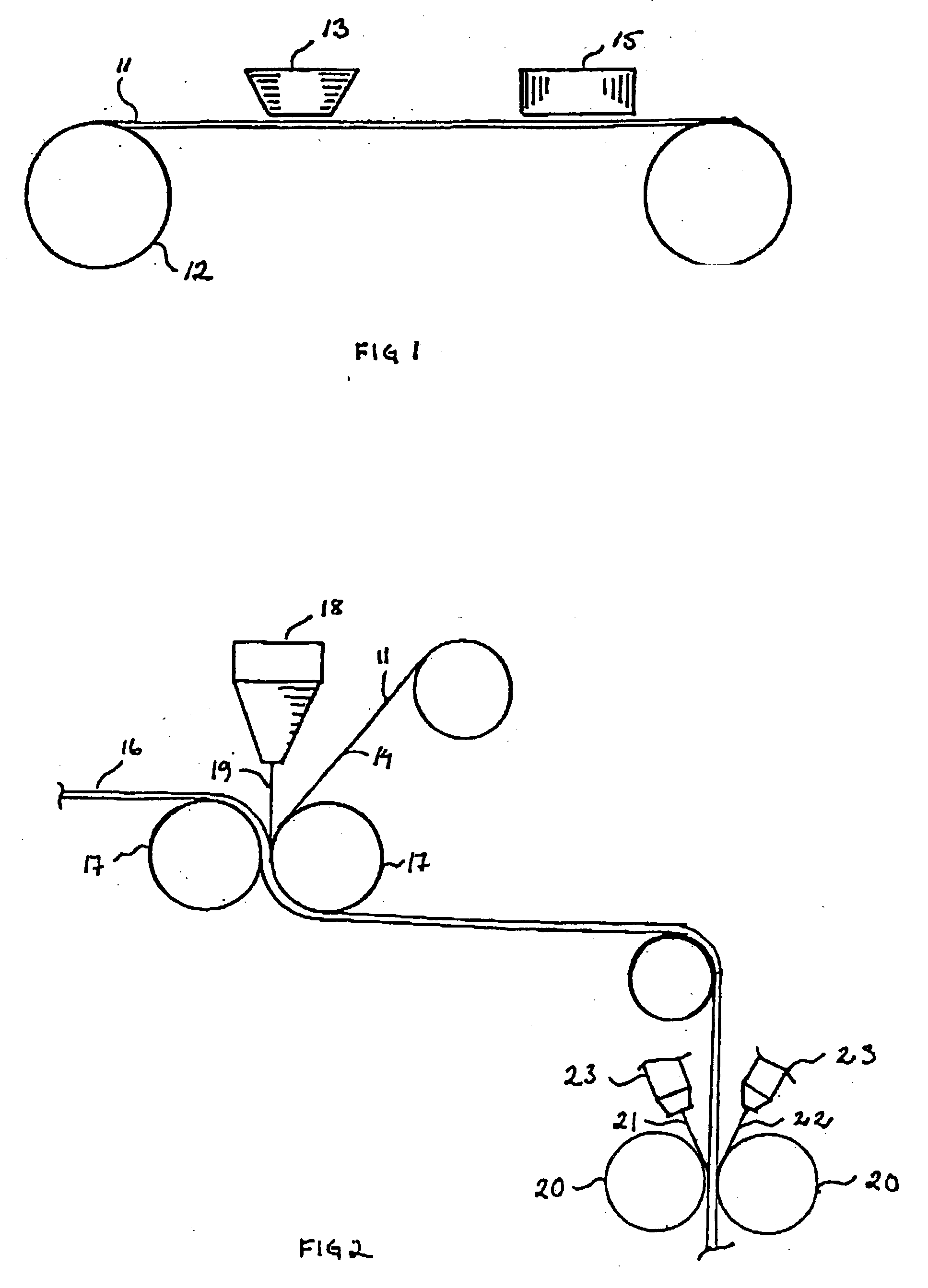

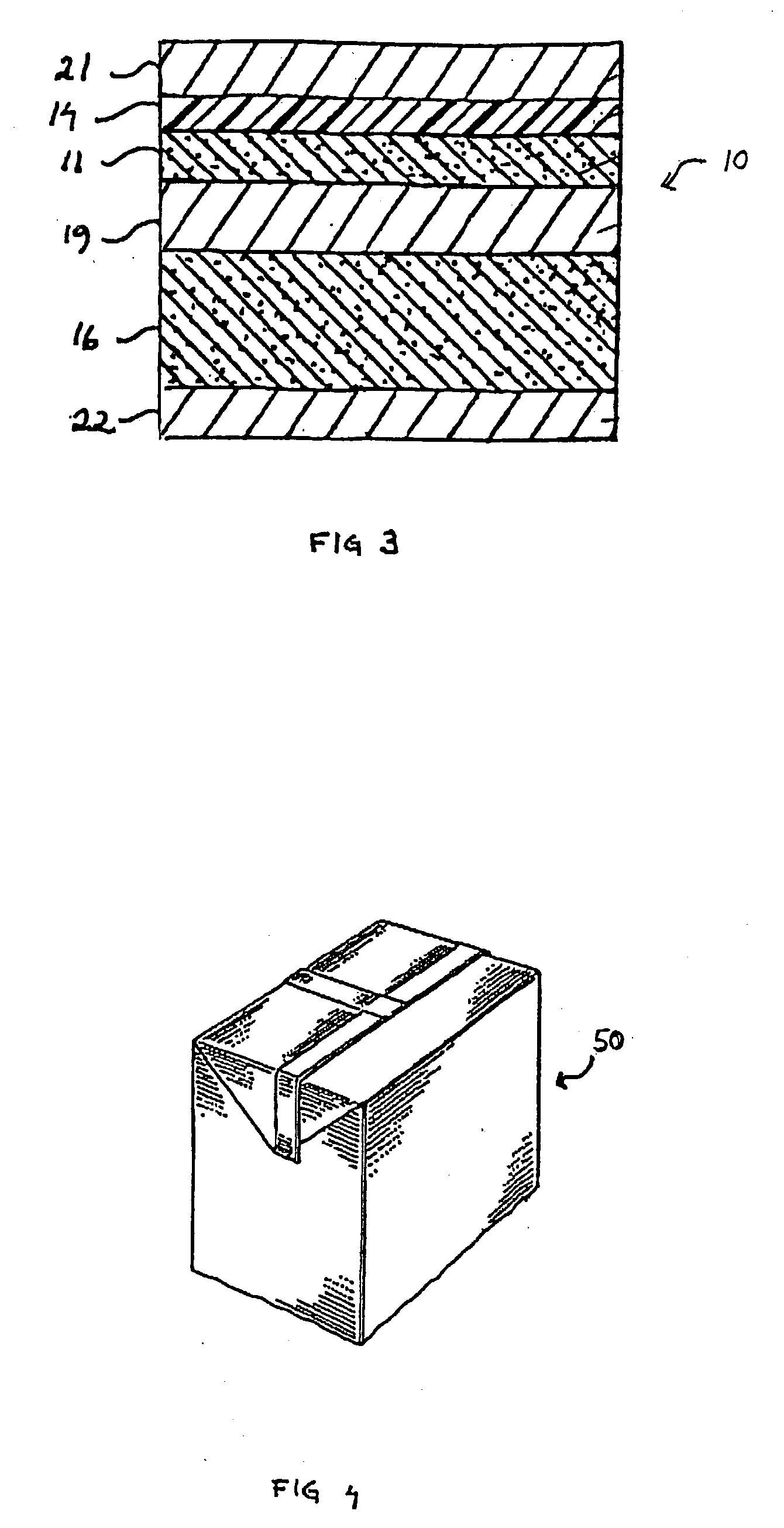

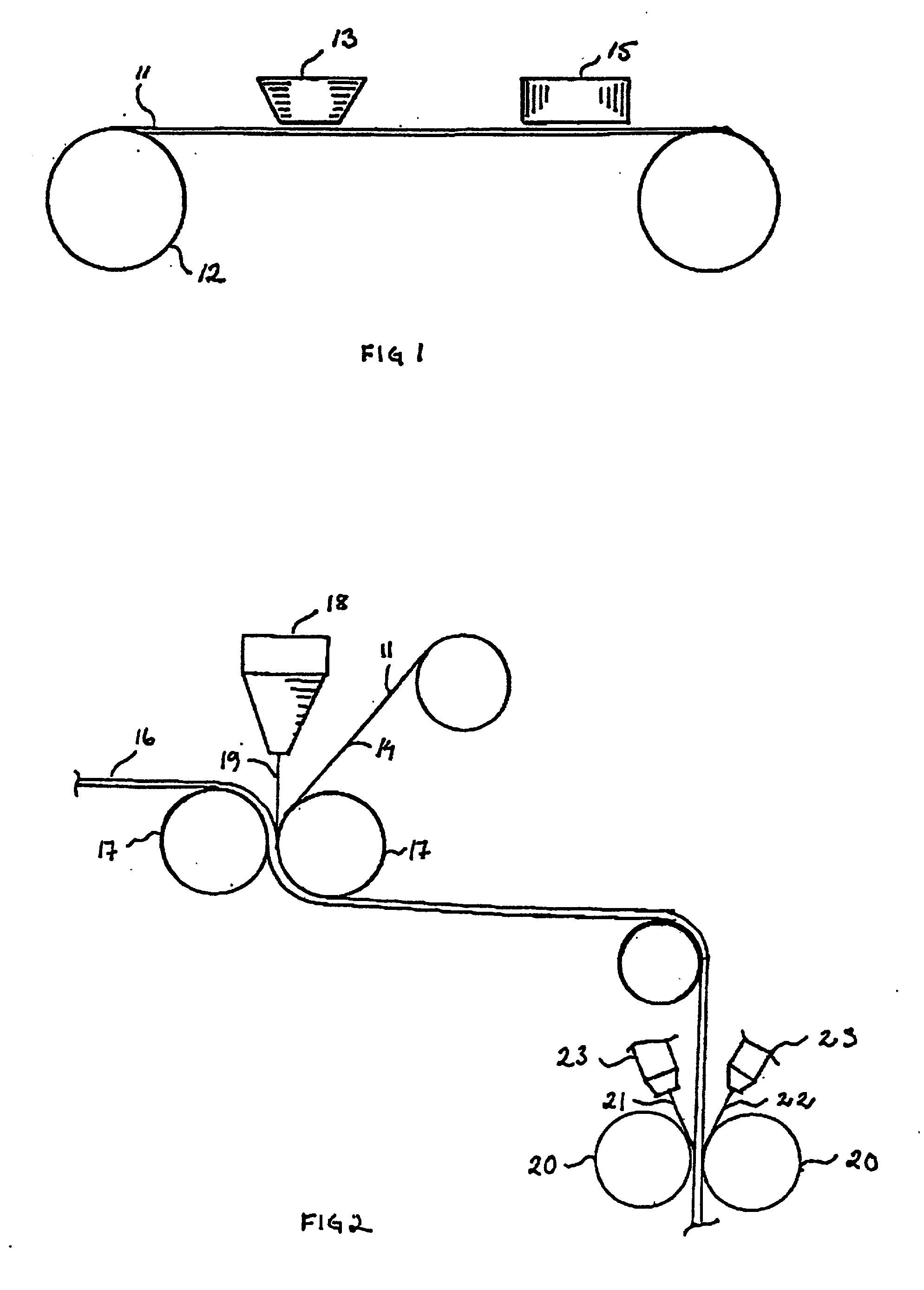

The invention relates to a method of producing a laminated packaging material including a core layer of paper or paperboard and a barrier layer applied on one side of the core layer. The invention also relates to a laminated packaging material produced according to the method, as well as a packaging container which is produced from the laminated packaging material.

Owner:BENGTSSON JORGEN +3

Laminated packaging materials and packaging containers produced therefrom

InactiveUS20010005550A1Improve gas barrier propertyIncrease thicknessFlexible coversWrappersPaper sheetEngineering

The invention relates to a method of producing a laminated packaging material including a core layer of paper or paperboard and a barrier layer applied on one side of the core layer. The invention also relates to a laminated packaging material produced according to the method, as well as a packaging container which is produced from the laminated packaging material.

Owner:BENGTSSON JORGEN +3

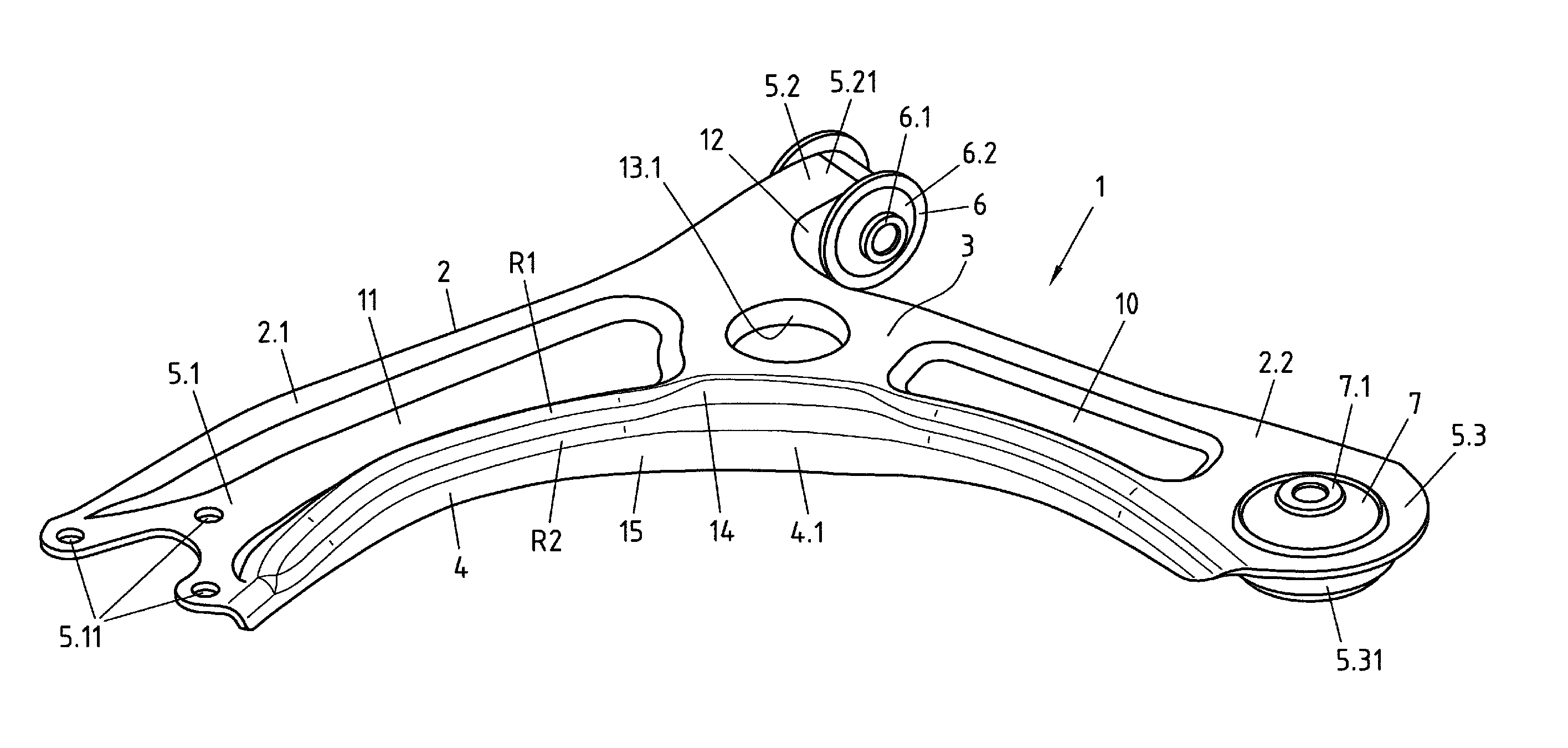

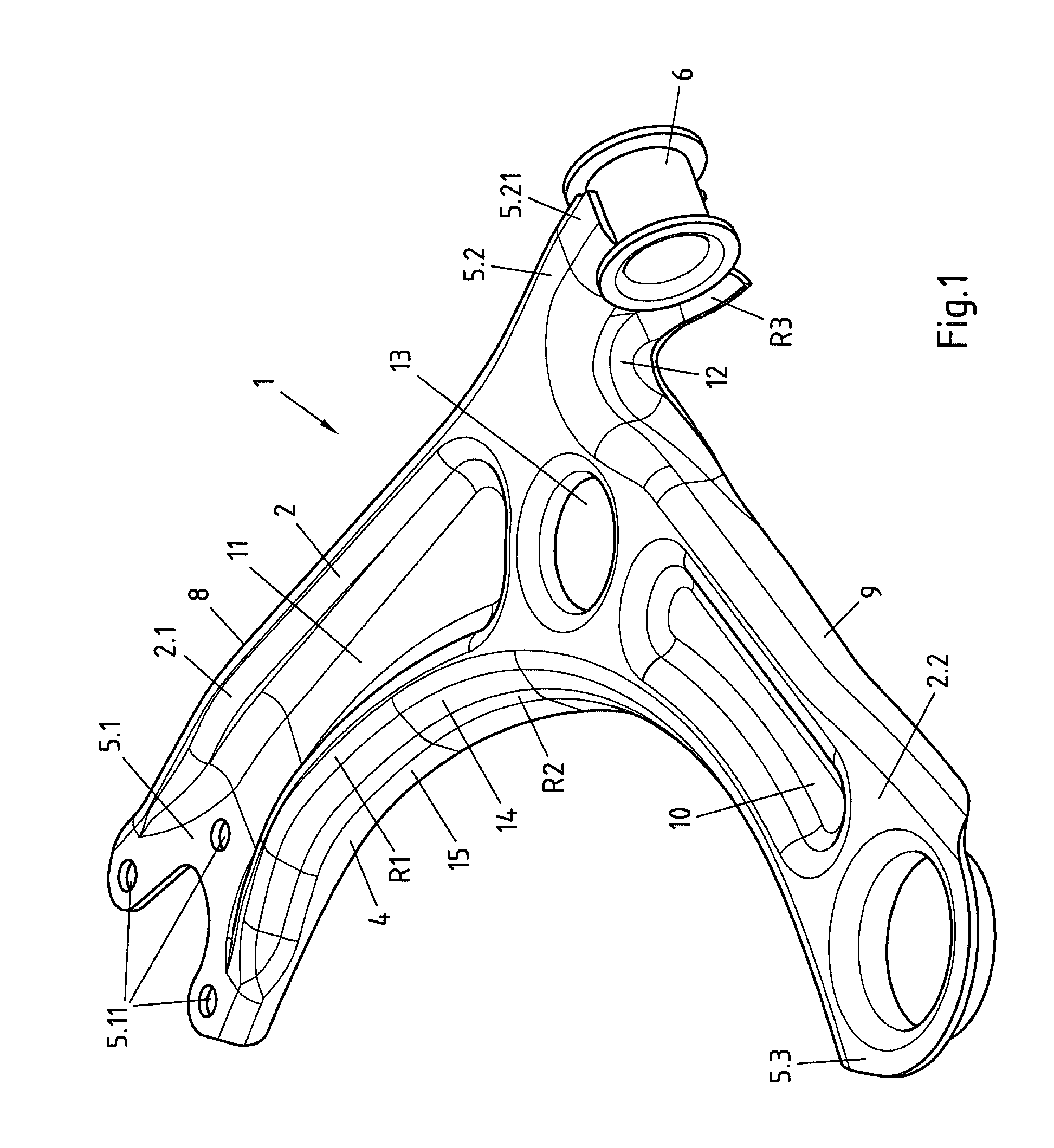

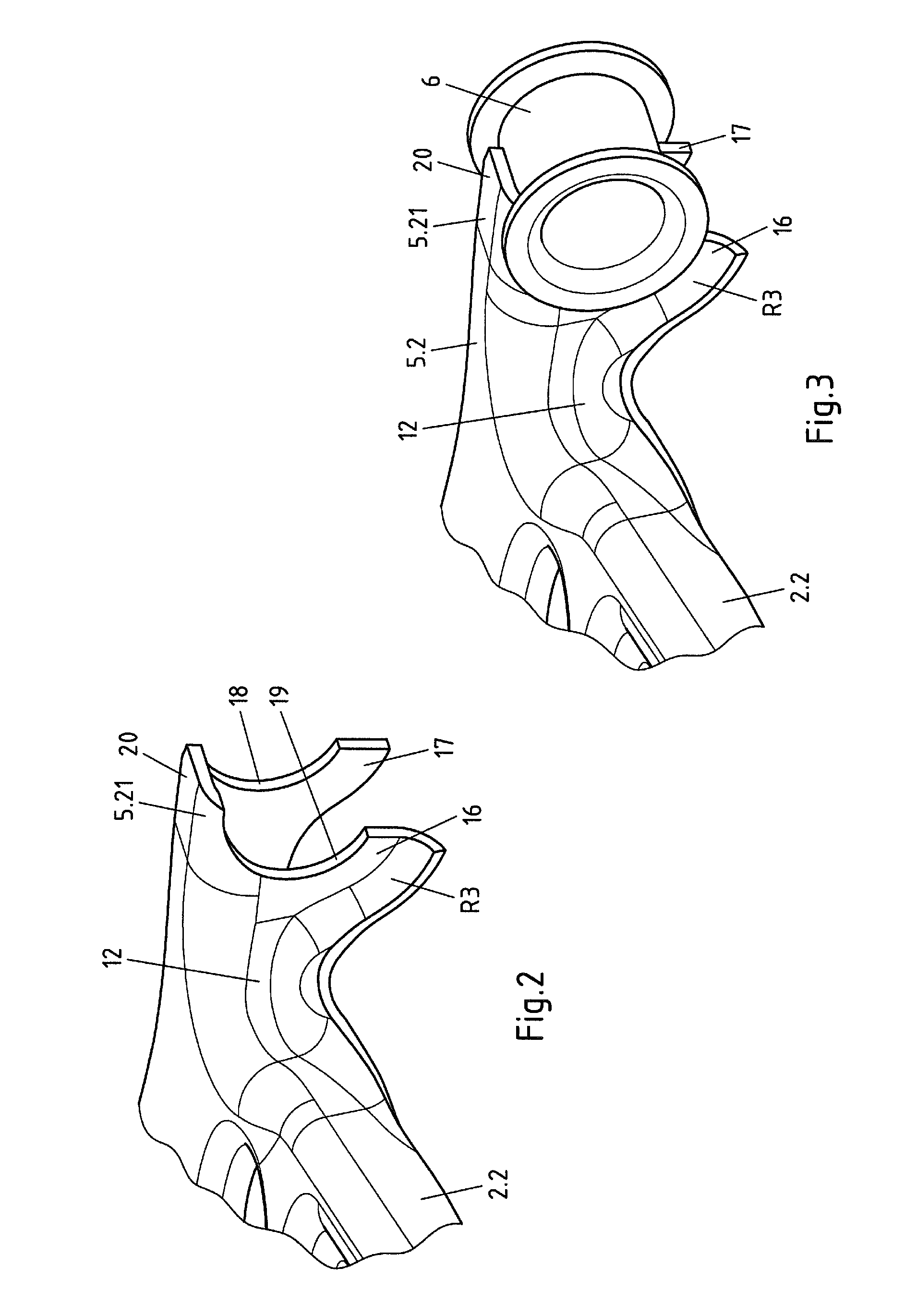

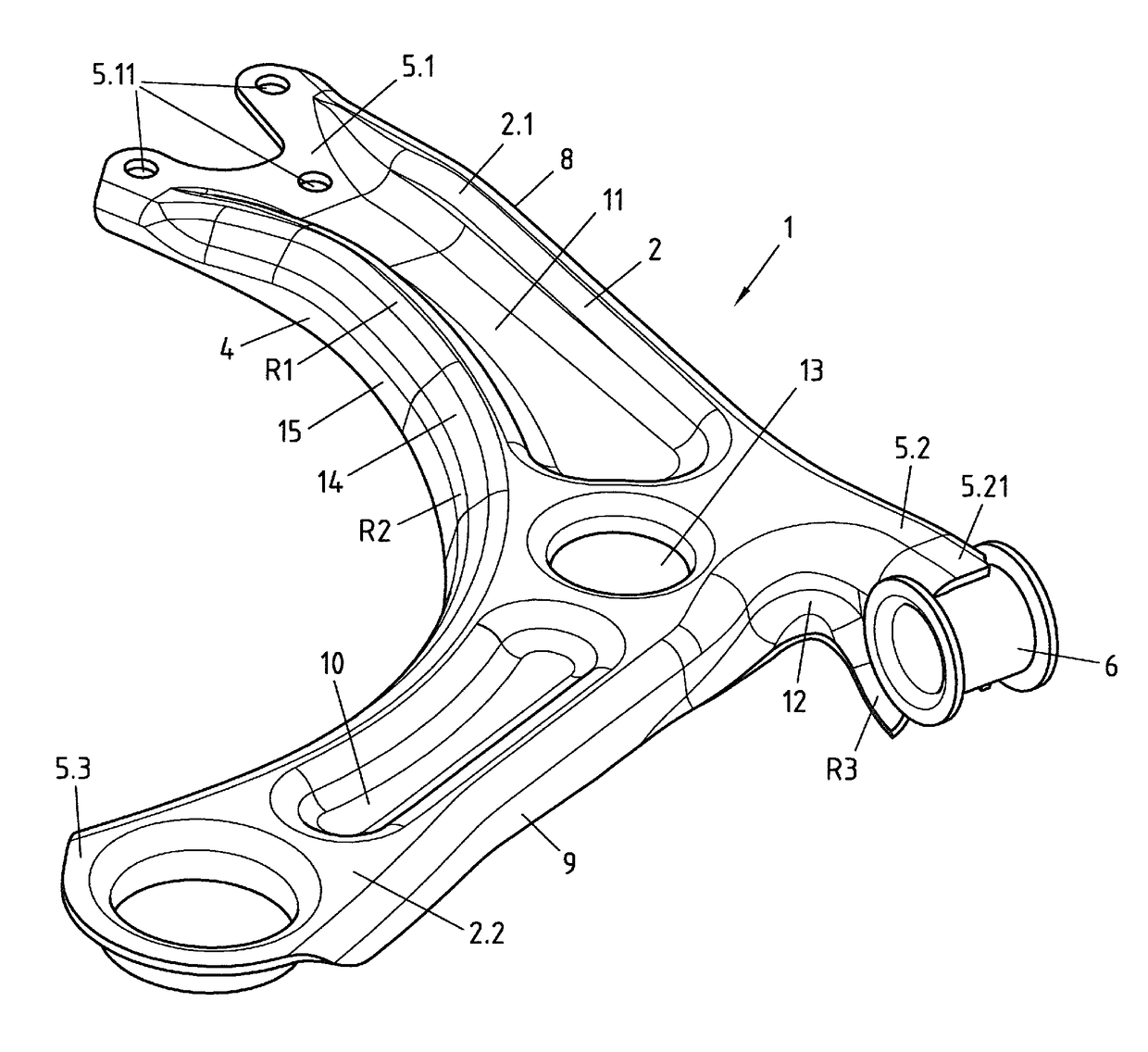

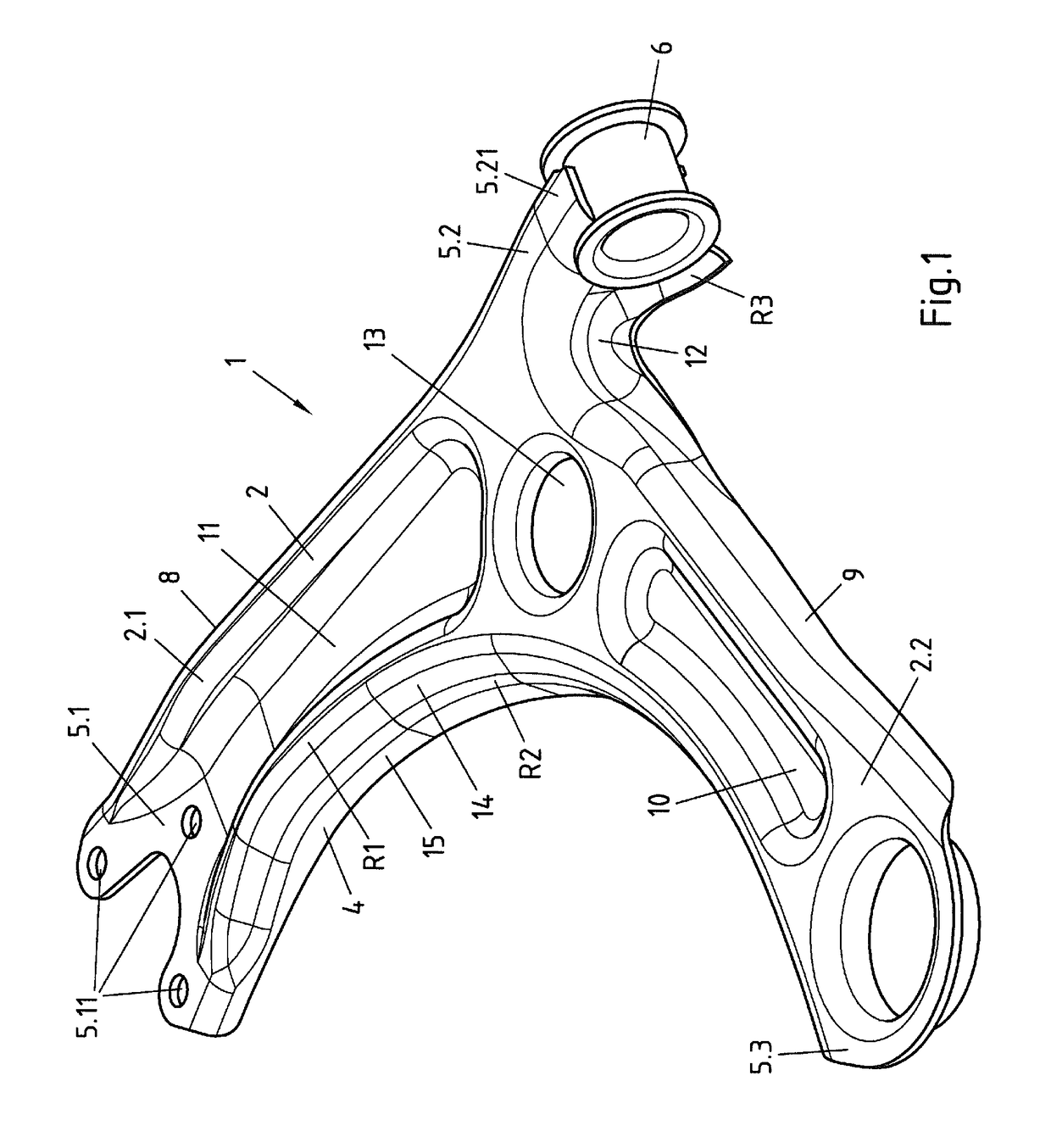

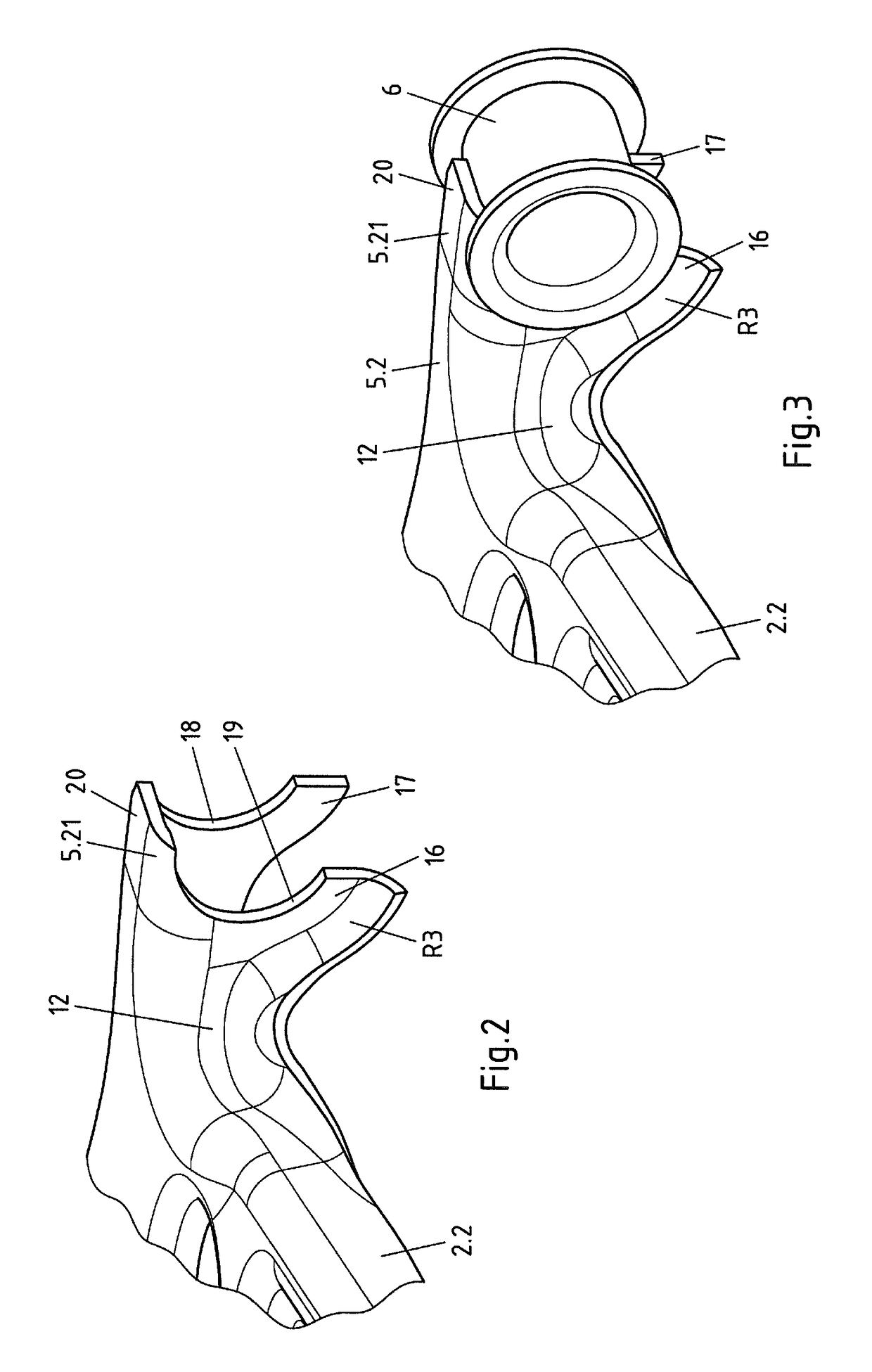

Method for Producing a Chassis Link

ActiveUS20150283595A1Improve component stiffnessConvenient lengthPivoted suspension armsAdhesivesEngineeringDeep drawing

A method for producing a chassis link includes shaping a single-shell main body from a sheet metal blank and deforming the sheet metal blank by deep drawing, which includes pre-drawing during which an indentation is produced on the main body and in which the indentation is trimmed and a bush is attached to a projection on the main body once the indentation has been trimmed. The sheet metal blank is pre-drawn such that the indentation is given a radius that matches the bush to be attached such that there is no further need for a further forming operation on the indentation once the indentation has been trimmed.

Owner:AUTOTECH ENG DEUT

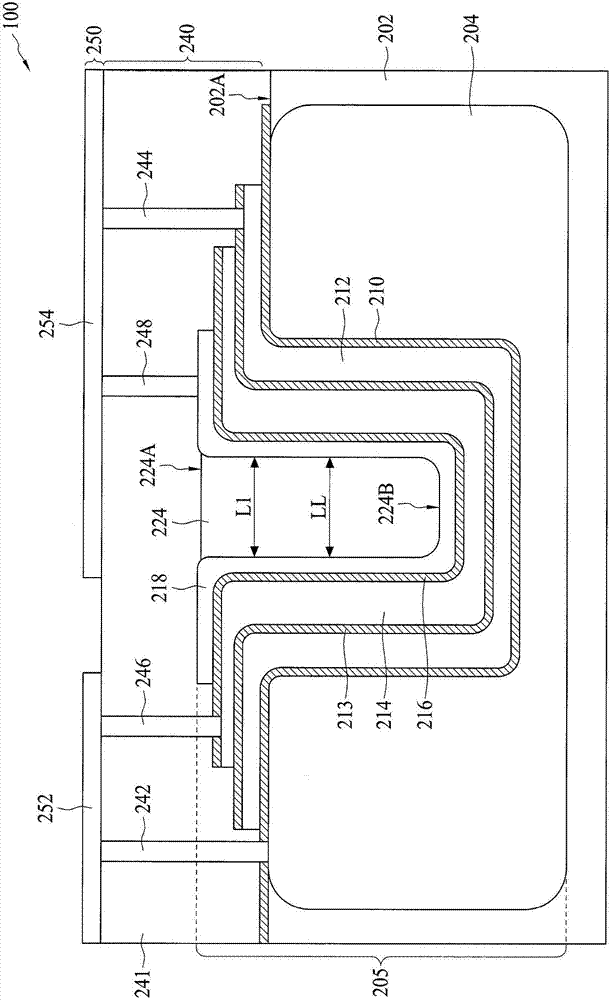

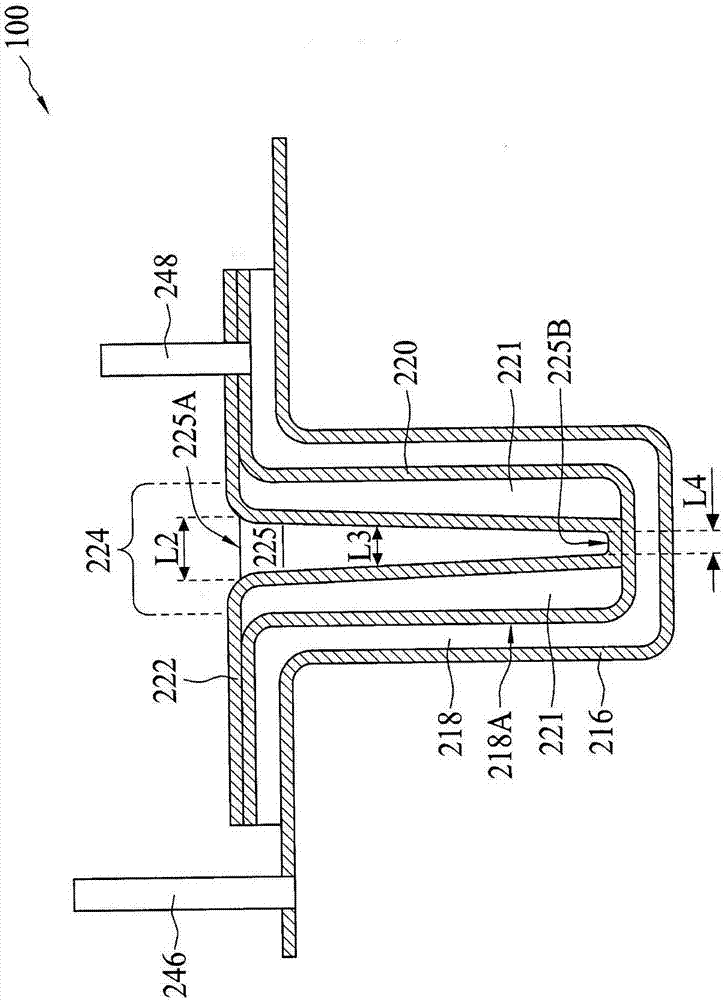

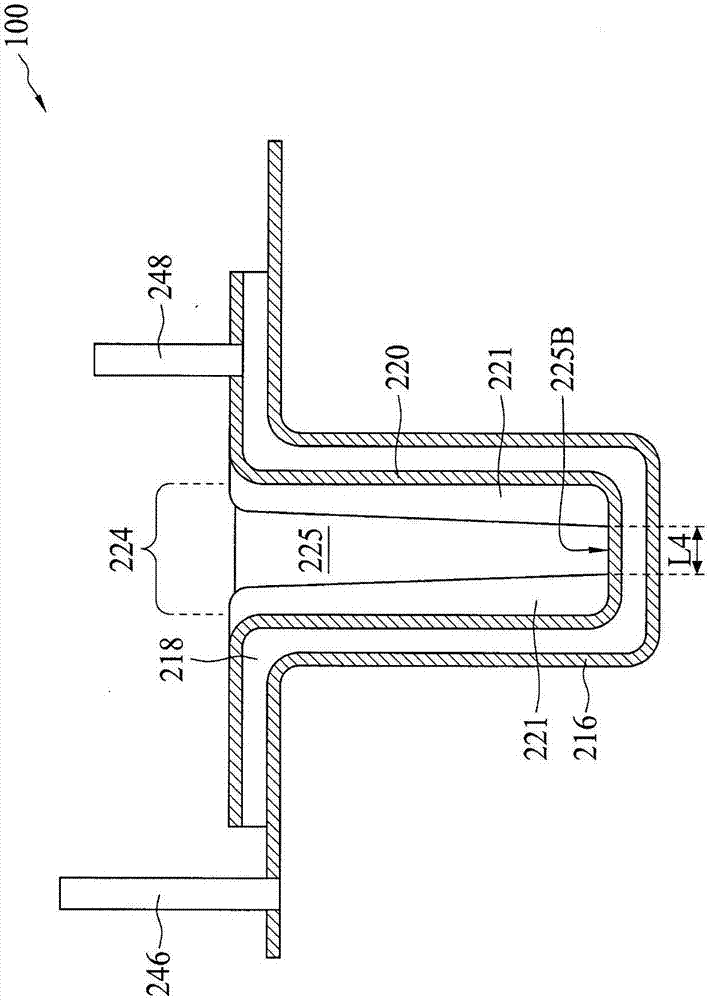

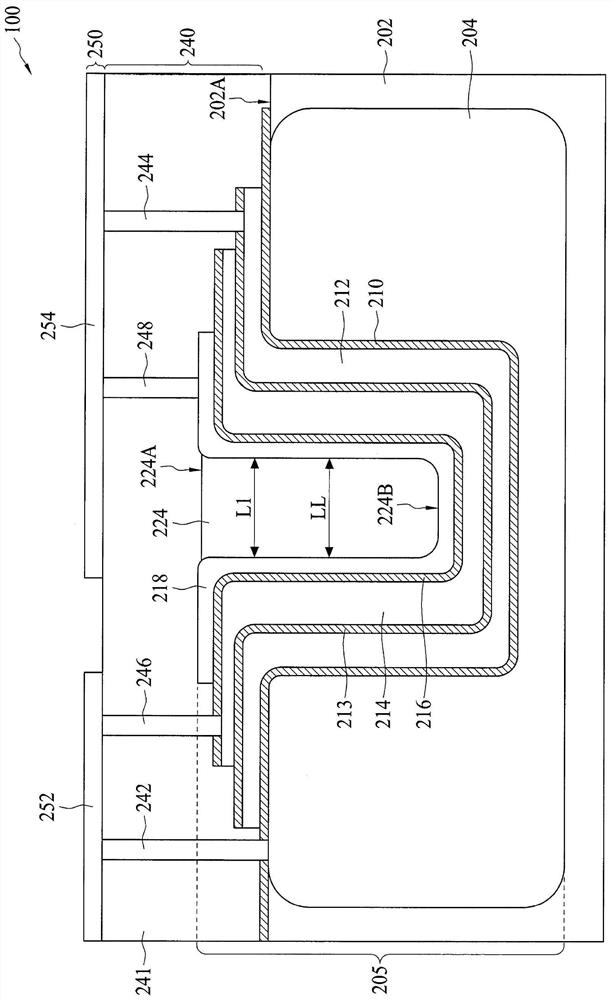

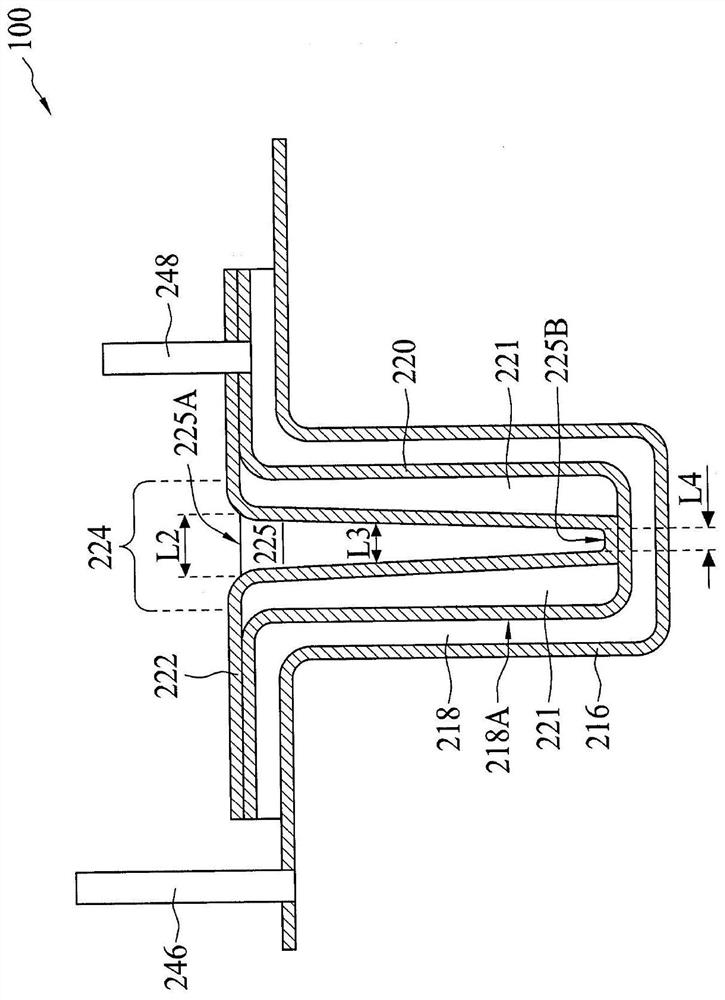

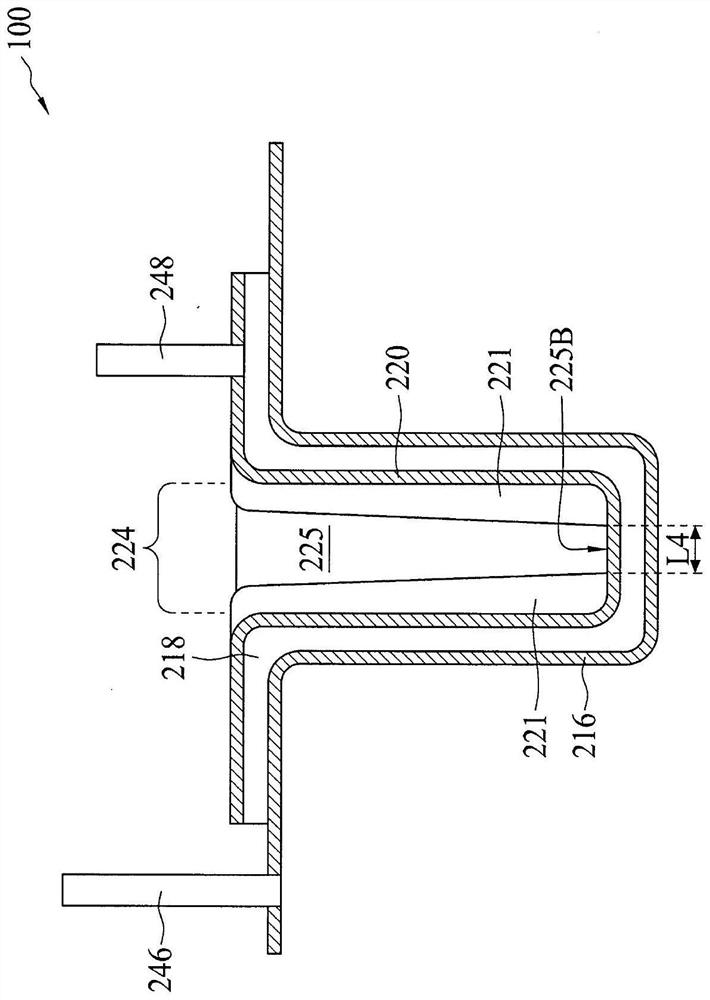

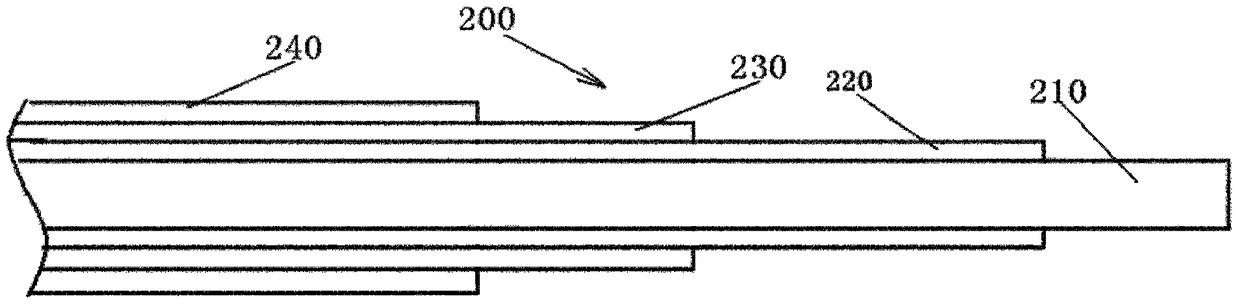

Semiconductor structure and manufacturing method thereof

ActiveCN107204323AEasy to fillSimple structureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The present disclosure provides a semiconductor structure which comprises a semiconductive substrate and a doped region in the semiconductive substrate. The doped region has a conductivity type opposite to the semiconductive substrate. The semiconductor structure also includes a capacitor in the doped region where the capacitor comprises a plurality of electrodes and the plurality of electrodes are insulated with one another. The semiconductor structure further includes a plug in the capacitor and surrounded by the plurality of electrodes.

Owner:TAIWAN SEMICON MFG CO LTD

Method for manufacturing sheet-shaped packaging materials

InactiveCN104309259AEasy packaging and formingImprove stiffnessLamination ancillary operationsLaminationCompound aEngineering

Owner:彭小玲

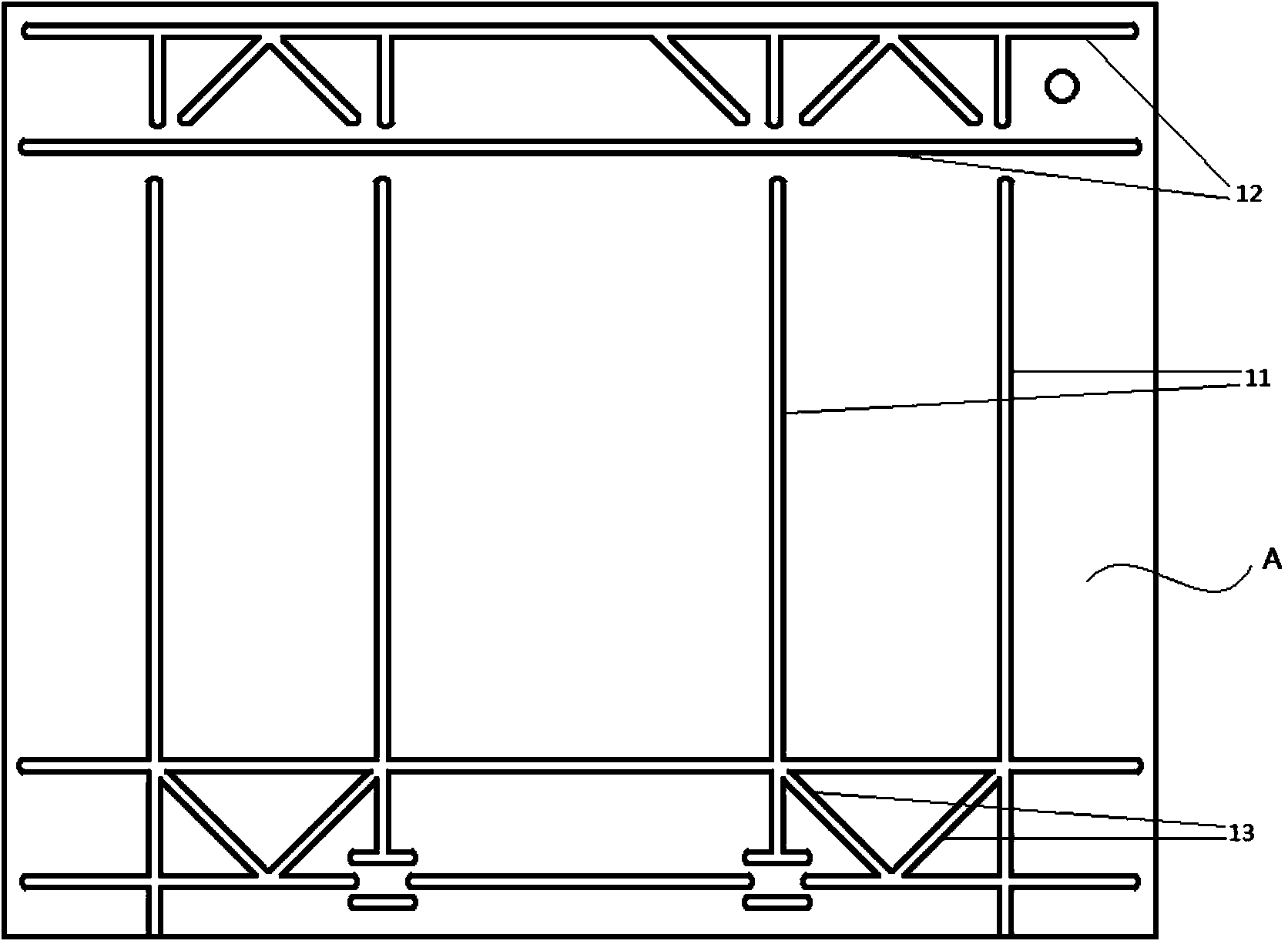

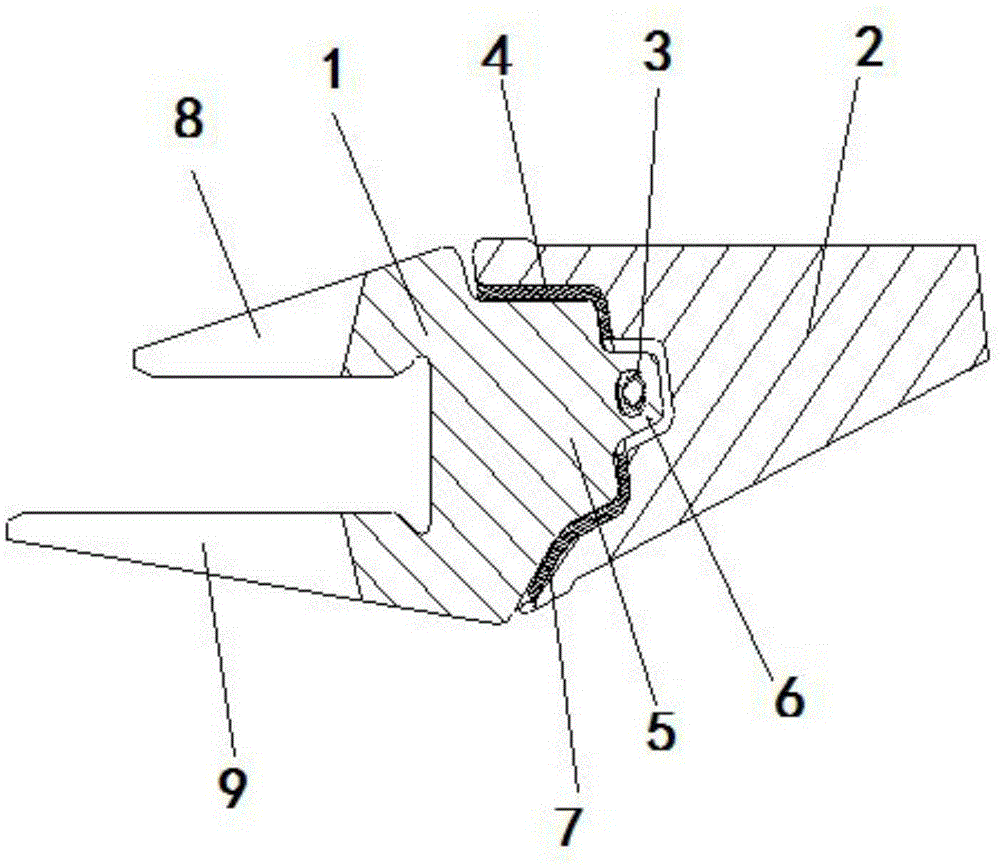

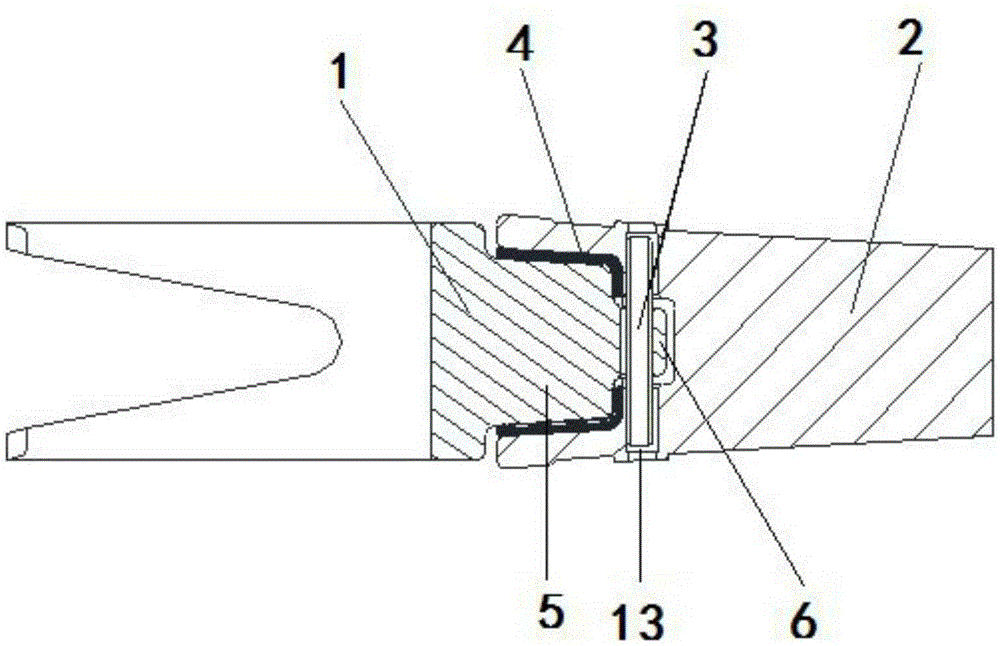

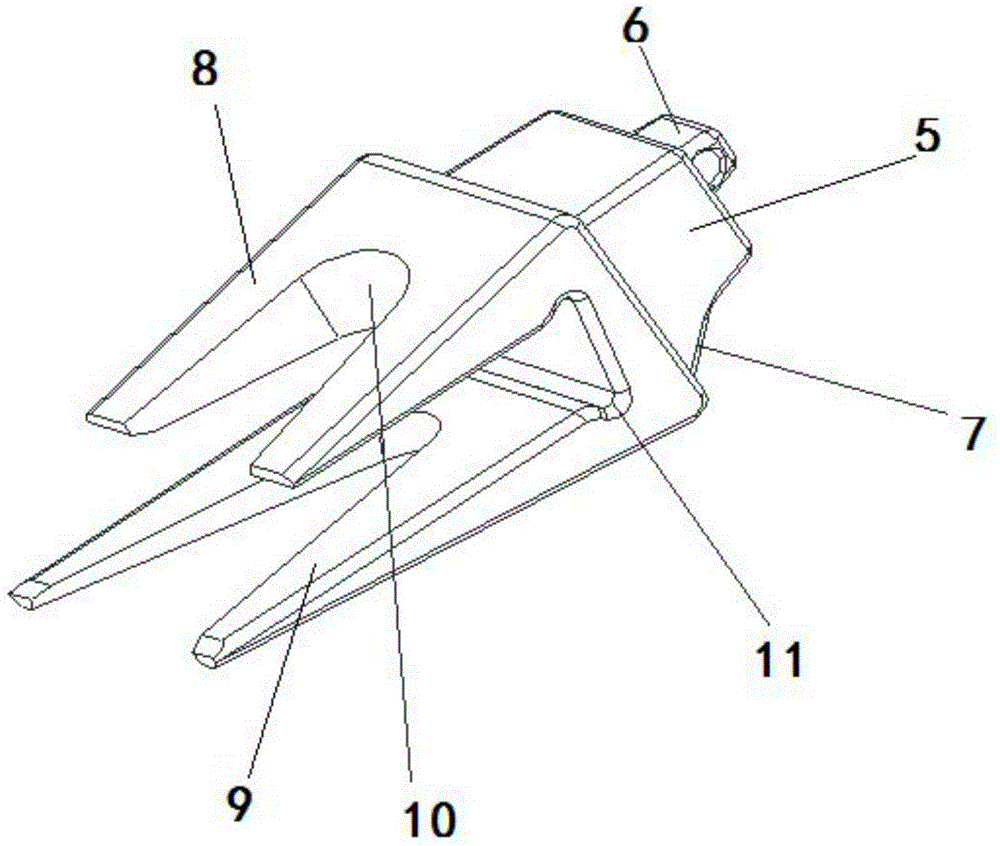

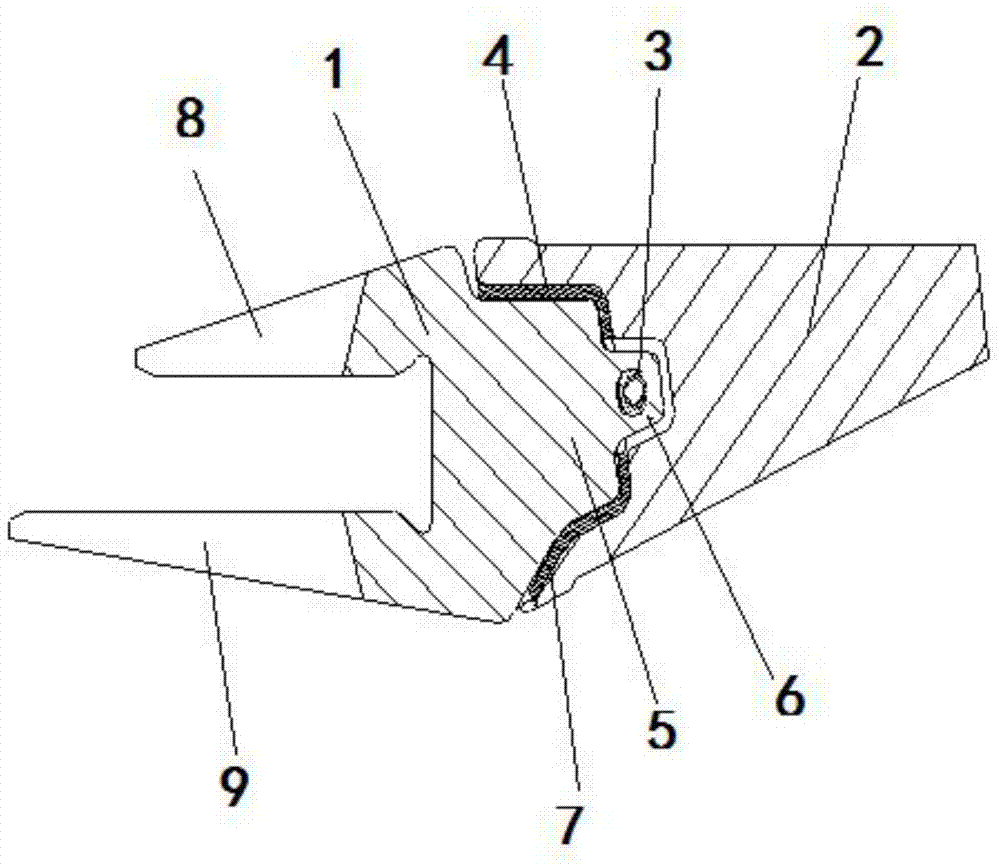

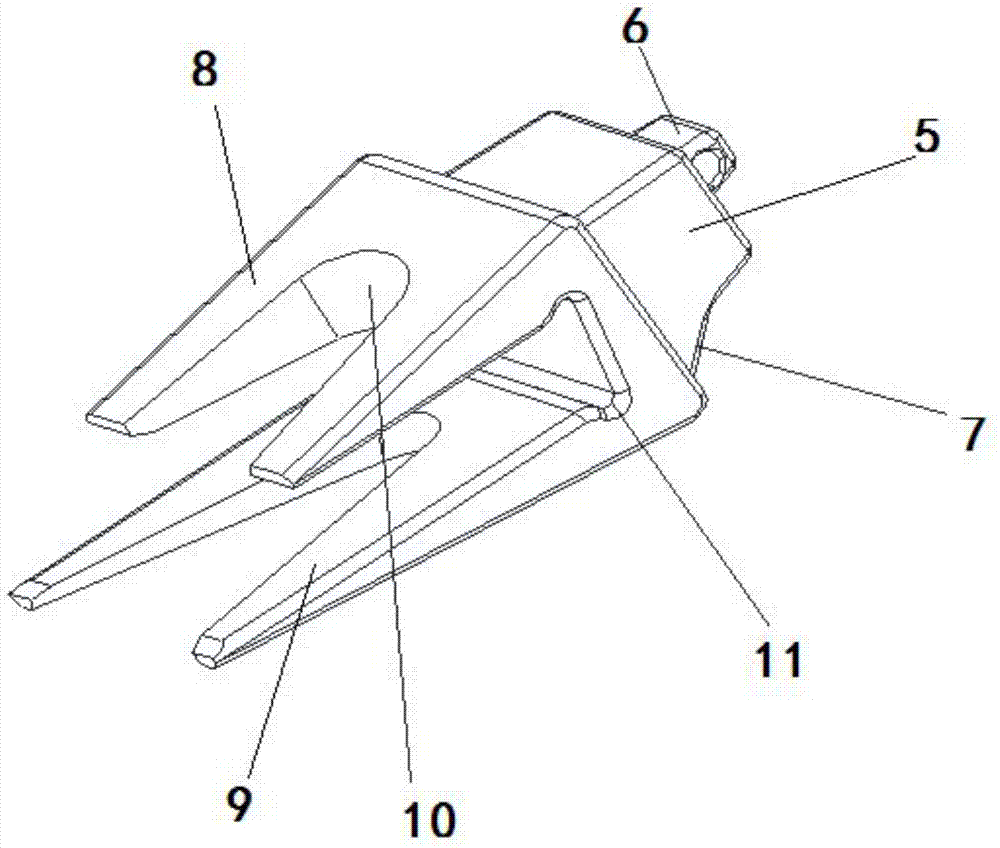

Novel buffer type tooth holder and bucket tooth combining device of excavator

ActiveCN105332400ASimple structureEliminate shockSoil-shifting machines/dredgersEngineeringCavity wall

The invention discloses a novel buffer type tooth holder and bucket tooth combining device of an excavator. The novel buffer type tooth holder and bucket tooth combining device comprises a tooth holder, a bucket tooth, a bayonet lock and a shock pad, wherein the tooth holder comprises a tooth holder head and a tooth holder tail; the tooth holder head comprises a boss, a bayonet lock positioning seat and a transitional reinforcing rib; the boss, the bayonet lock positioning seat and the transitional reinforcing rib are integrally formed; the bayonet lock positioning seat is positioned at the end part, away from the tooth holder head, of the boss; the transitional reinforcing rib is connected with the boss and the tail; the transitional reinforcing rib and a lower connecting plate are positioned at the same side; the bayonet lock is of a hollow steel tube structure; the inner wall of a mounting cavity of the bucket tooth sheathes and adheres to the boss of the tooth holder head; a gap is formed between the inner wall of the mounting cavity of the bucket tooth and the bayonet lock positioning seat of the tooth holder head; the shock pad is directly poured on the inner cavity wall of one circumference where the bucket tooth is attached to the boss of the tooth holder head. The novel buffer type tooth holder and bucket tooth combined device disclosed by the invention has the advantages that various acting forces generated among the tooth holder, the bucket tooth, the bayonet lock, external materials, an edge plate and the like are improved by improvement measures, the service life of the tooth holder is prolonged, the cost of materials is reduced, and the working efficiency is improved.

Owner:RUGAO HUAYANG ALUMINUM PROD

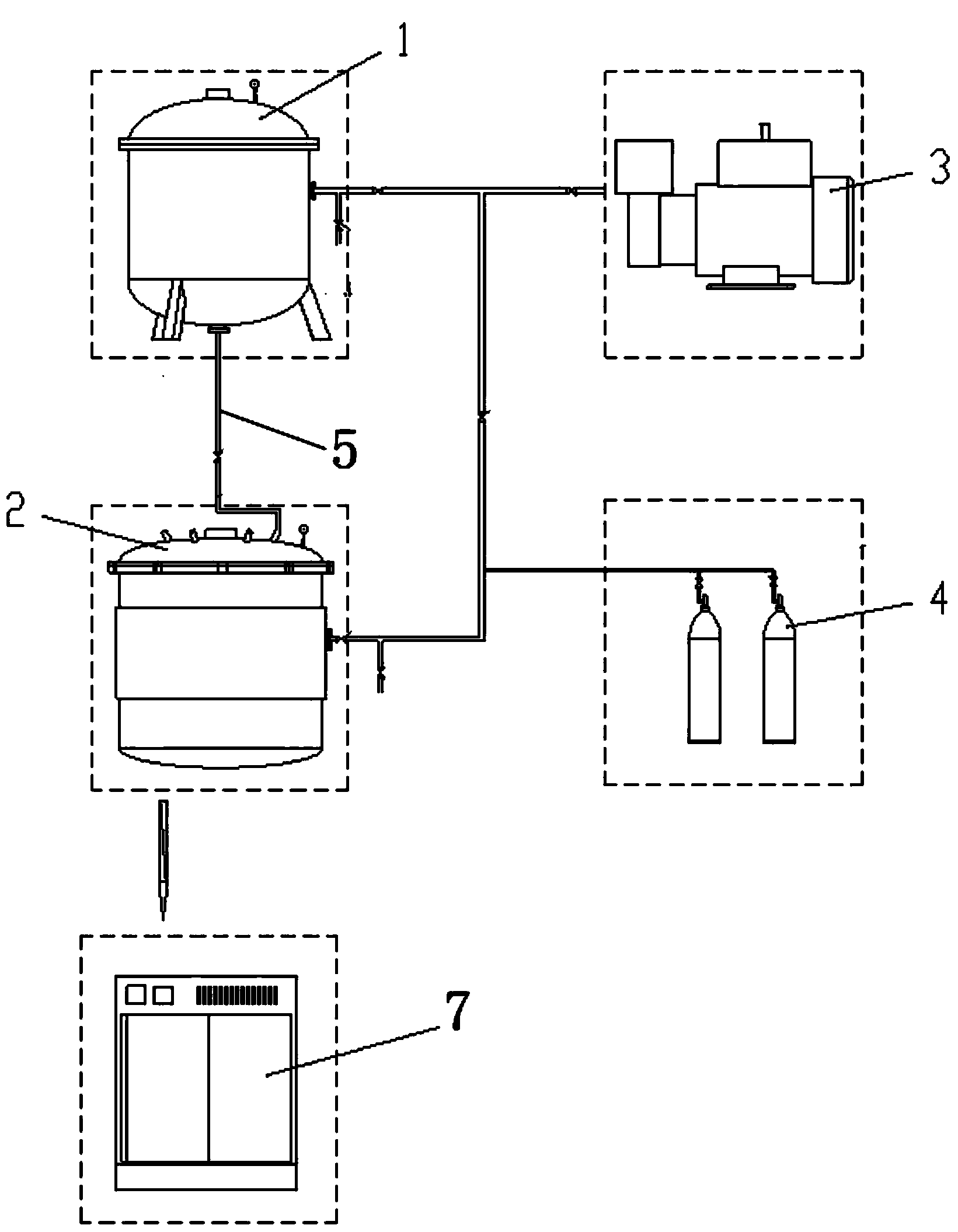

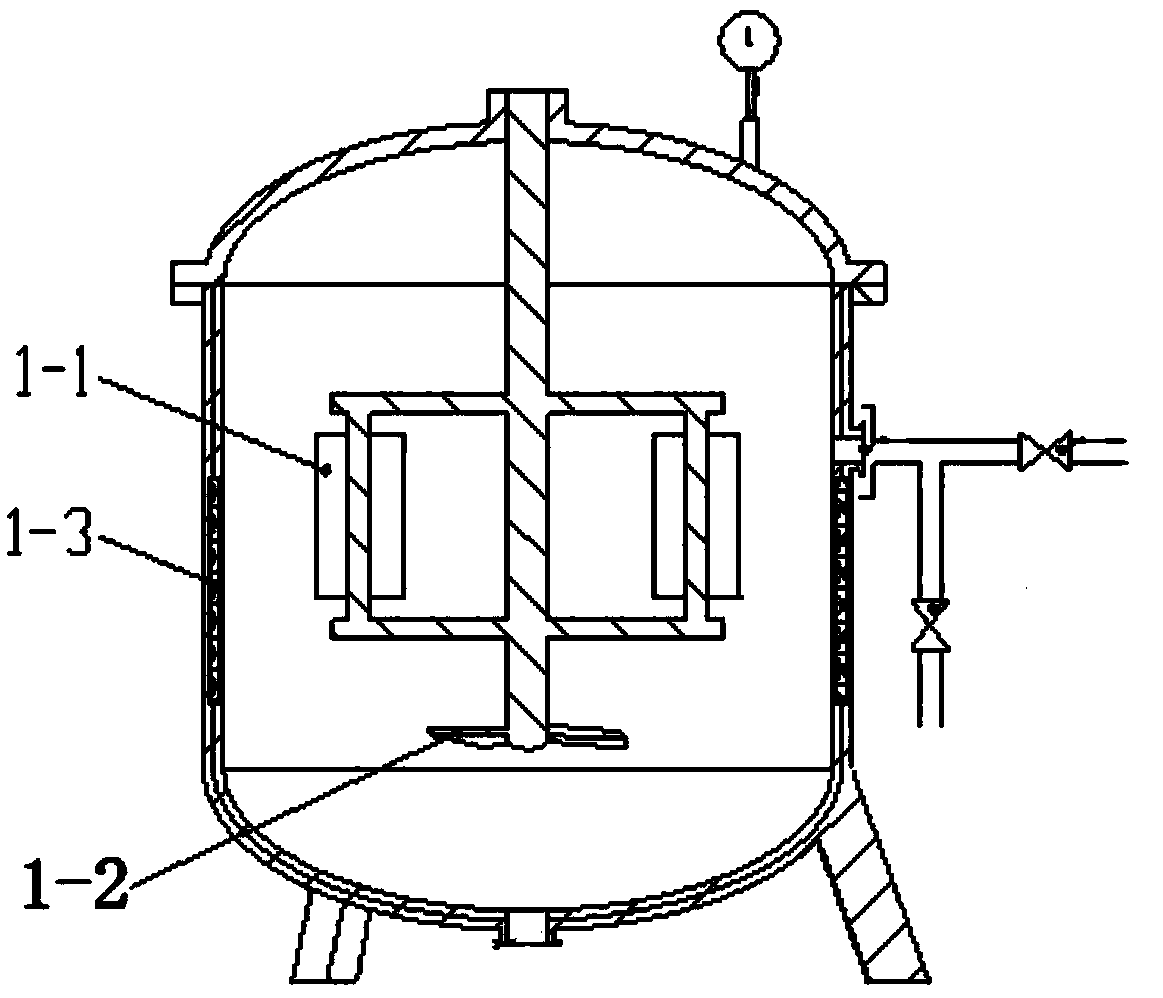

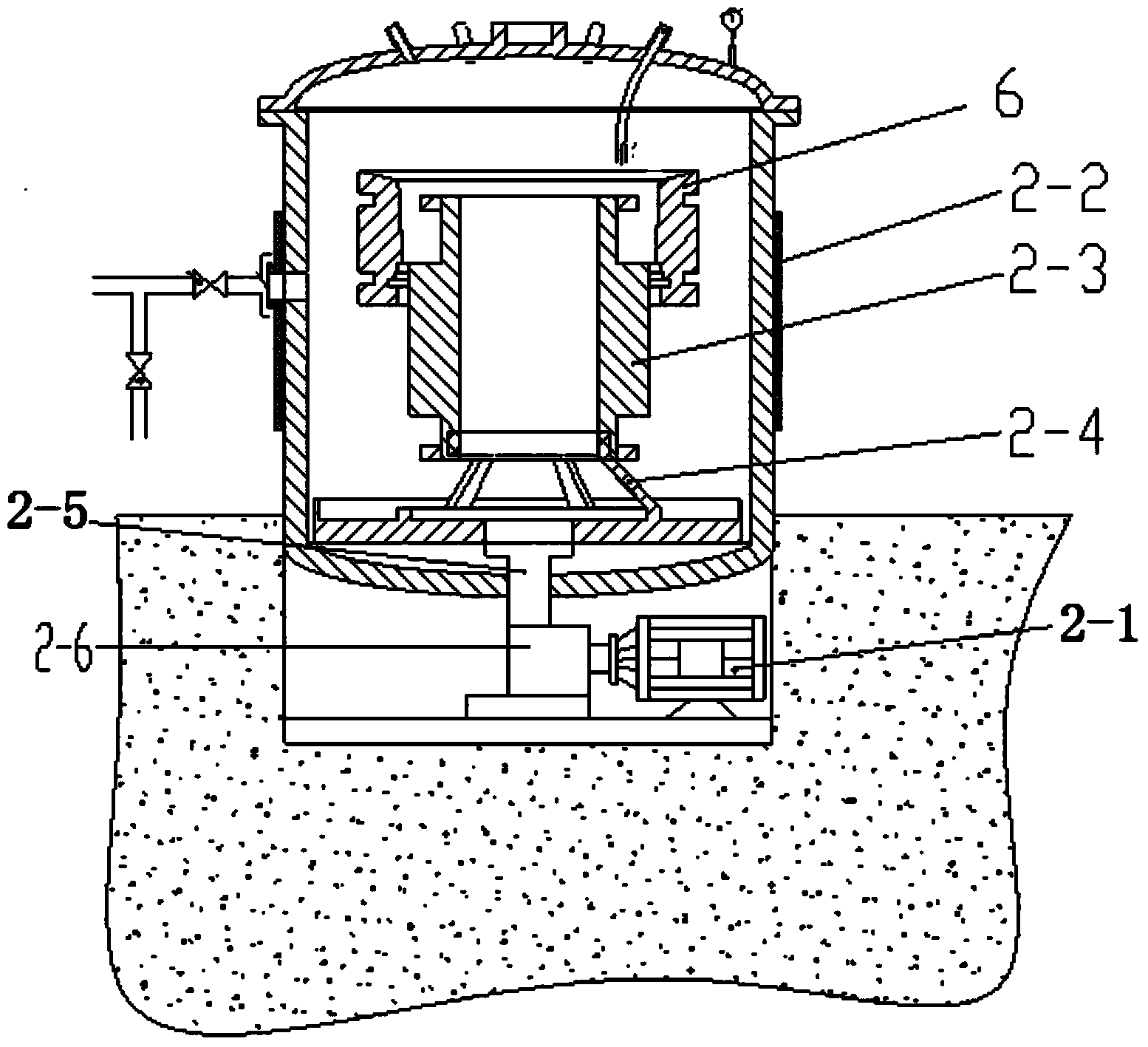

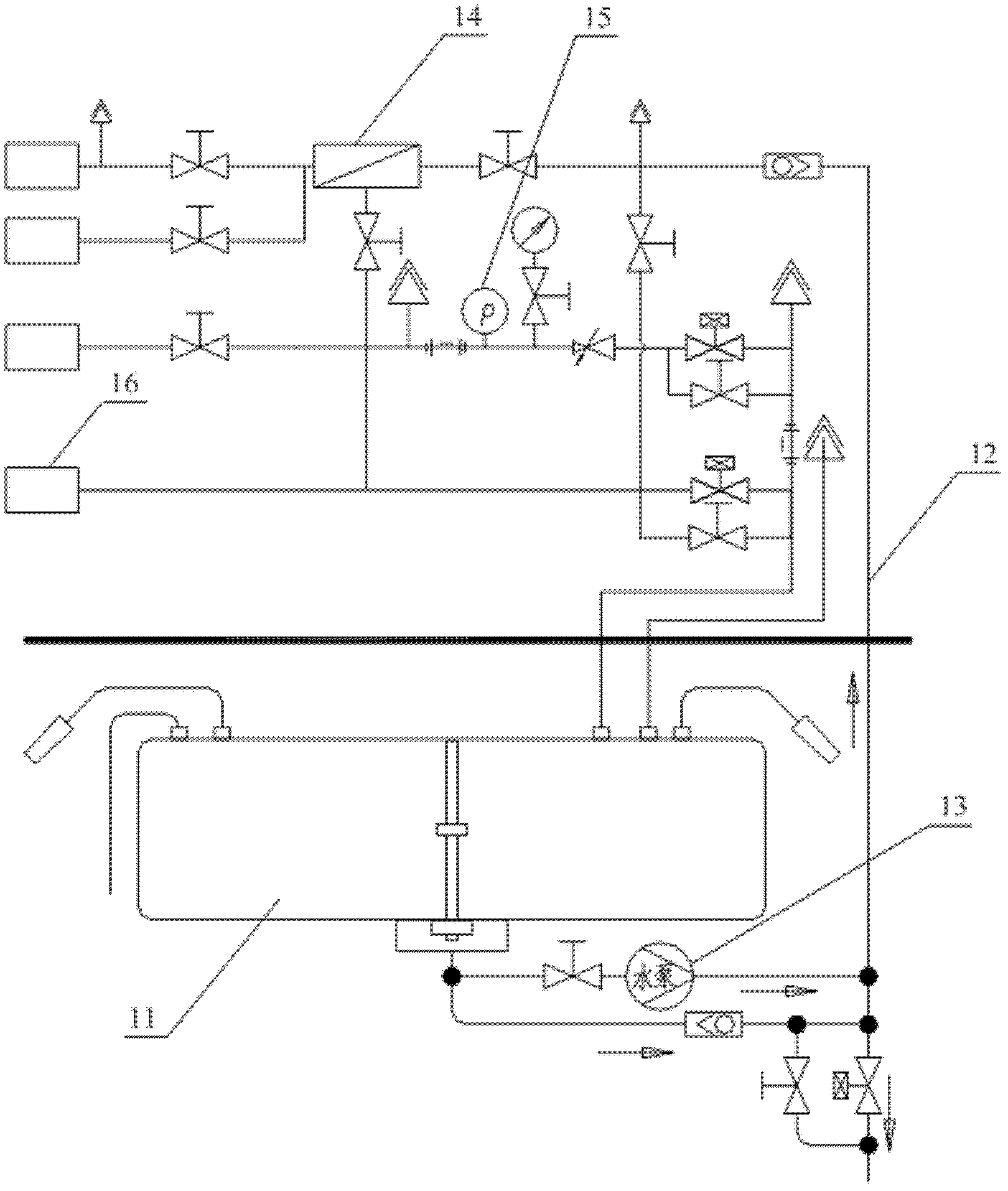

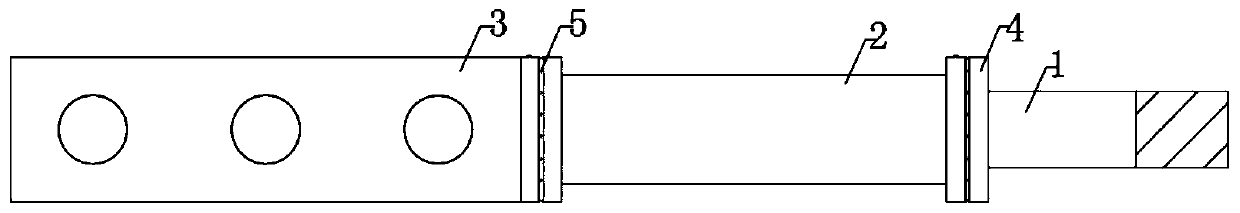

System and method for vacuum pouring of insulation resin used for motor rotor

InactiveCN104410229ARequirements for maintaining vacuumConducive to constant temperature curingApplying solid insulationEmulsionHigh pressure

The invention relates to a system for vacuum pouring of insulation resin used for a motor rotor. The system comprises a vacuum glue filling tank, a vacuum pump, a high-pressure inert gas transmitting device, a vacuum emulsion machine and a glue transmitting pipe, wherein the vacuum pump and the high-pressure inert gas transmitting device are respectively connected with the vacuum glue filling tank by virtue of a pipeline; the vacuum emulsion machine is connected with the vacuum glue filling tank by virtue of the glue transmitting pipe; a stirring device is arranged in the vacuum emulsion machine; the vacuum emulsion machine is provided with a device which is connected with the vacuum pump; the resin to be filled with glue is mixed in the vacuum emulsion machine. According to the system, the vacuum emulsion machine is additionally arranged, the vacuum degree requirement during mixing of the resin is ensured; the discharge of the gas in the resin is facilitated. The invention also relates to a method for vacuum pouring of the insulation resin for the motor rotor.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

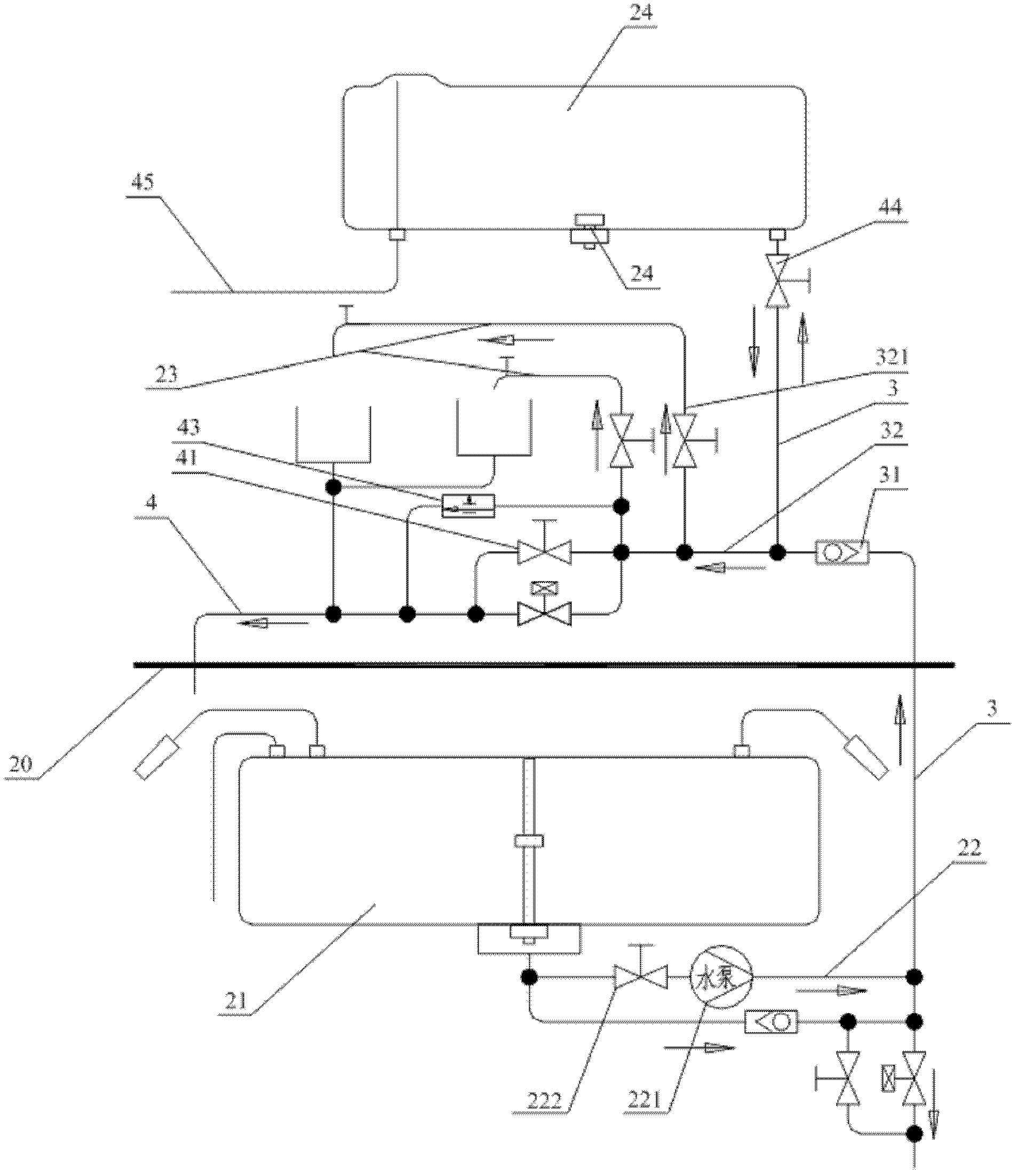

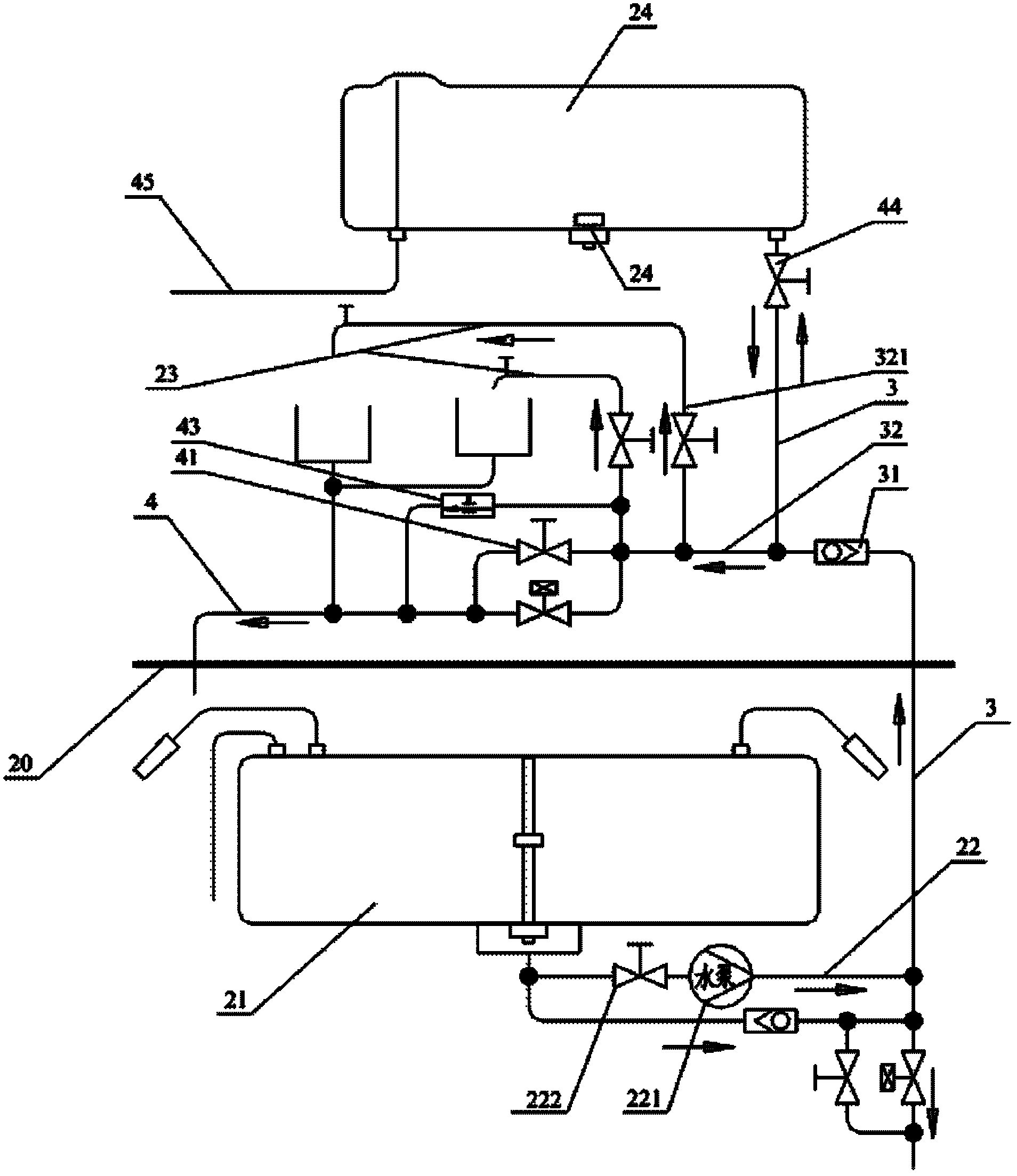

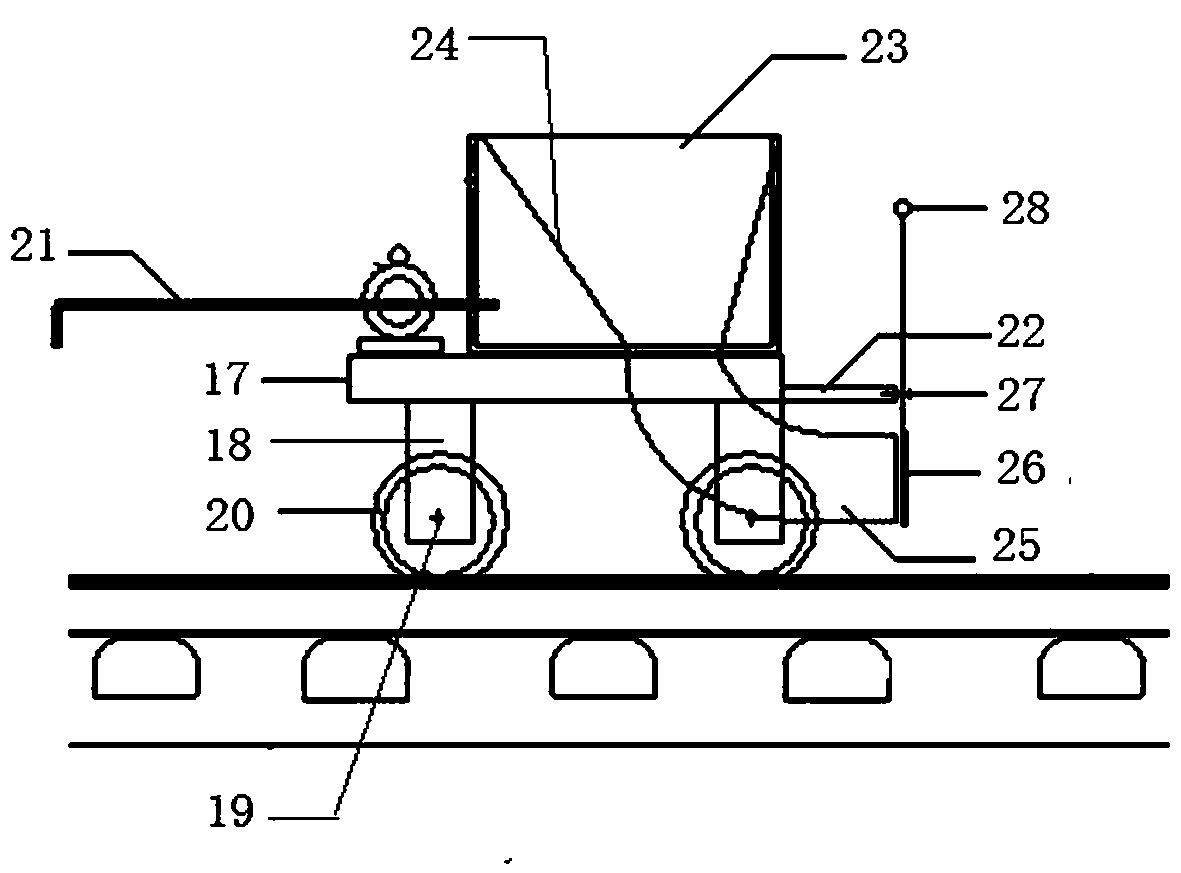

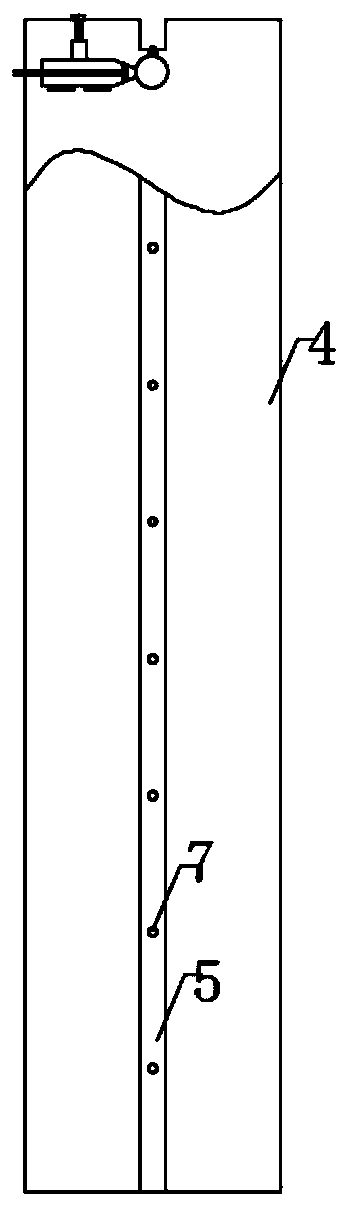

Water supply system of railway vehicle

ActiveCN102514590AAvoid Line LeaksEliminates pipe breakoutsSanitationRailway auxillary equipmentWater supply networkEngineering

The invention provides a water supply system of a railway vehicle, which comprises a water tank, a water pumping device, water consumption equipment, a control module and a middle water tank. The water tank is arranged below an underframe of a vehicle body, the water consumption equipment is disposed above the underframe of the vehicle body, the middle water tank is positioned above the water consumption equipment, an acquisition device is disposed in the middle water tank, a water outlet pipe of the water tank is communicated with the water pumping device while the other end of the water tank is communicated with the middle water tank via a water supply pipeline, a check valve which is used for preventing water in the middle water tank from flowing back to the water pumping device is arranged on the water supply pipeline, a distributing pipeline which is used for supplying water for the water consumption equipment is disposed on the water supply pipeline, the tail end of the distributing pipeline is connected with a drain pipe, and the control module is respectively connected with the acquisition device and the water pumping device, so that the water pumping device is started when an acquired liquid level signal value is lower than a preset value and then closed after a preset time. The water supply system of the railway vehicle has the advantages that leakage of the pipeline due to excessive pressure of the system is prevented, hidden dangers of bursting of the pipeline due to excessive water injection when a pressure sensor fails are eliminated, and operational reliability of the system is improved.

Owner:CRRC TANGSHAN CO LTD

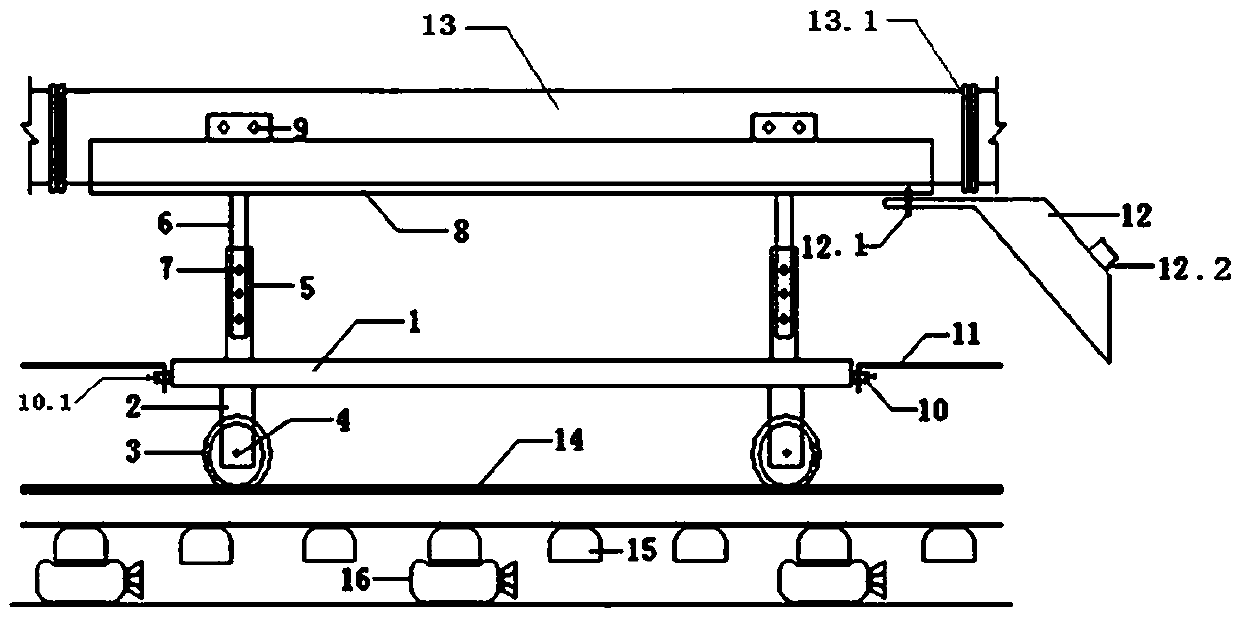

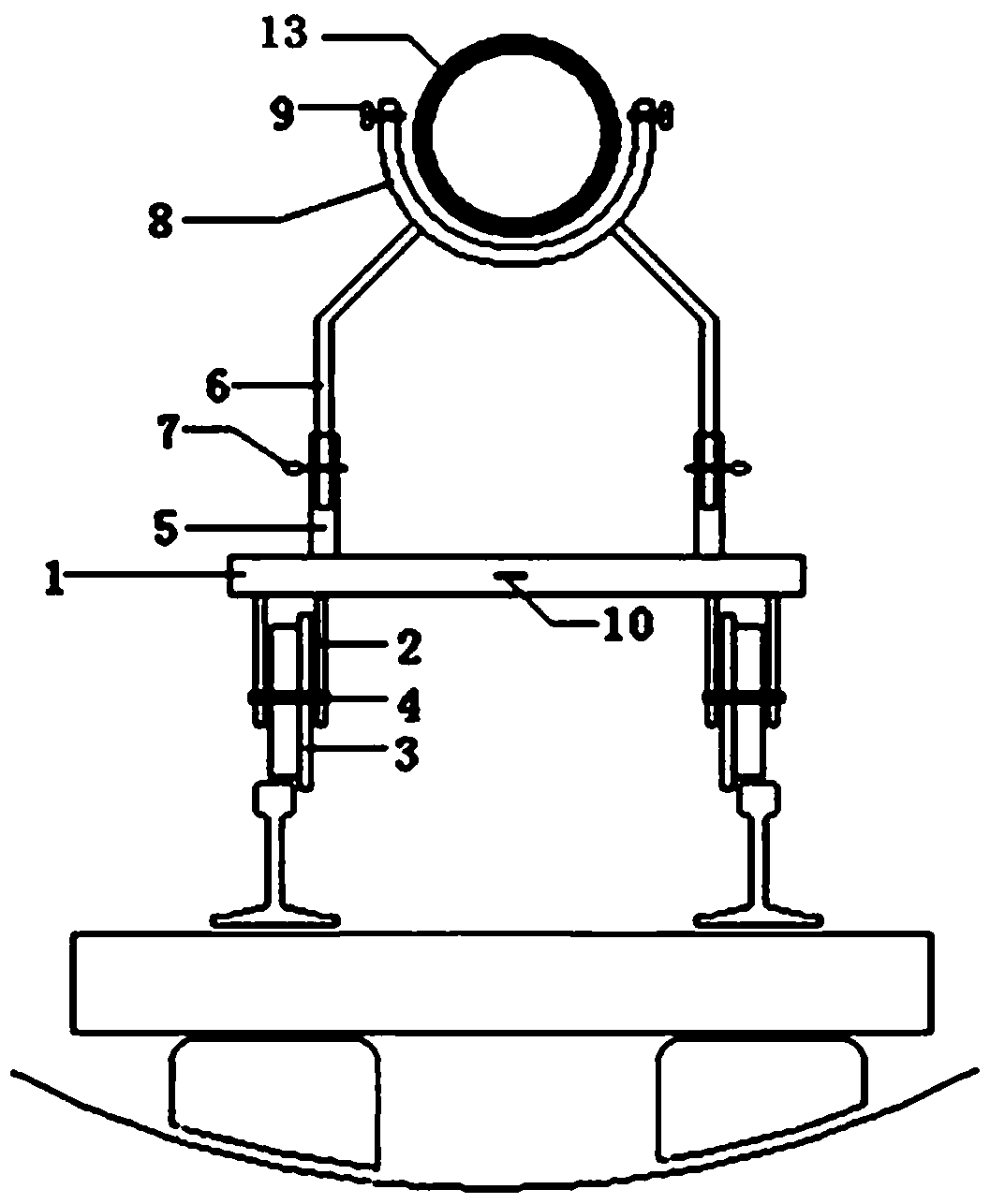

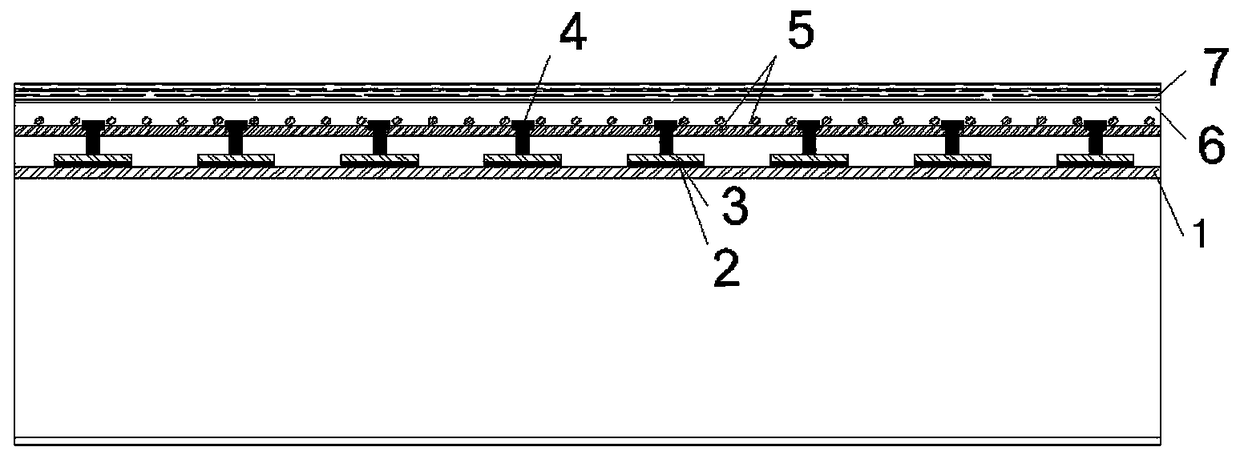

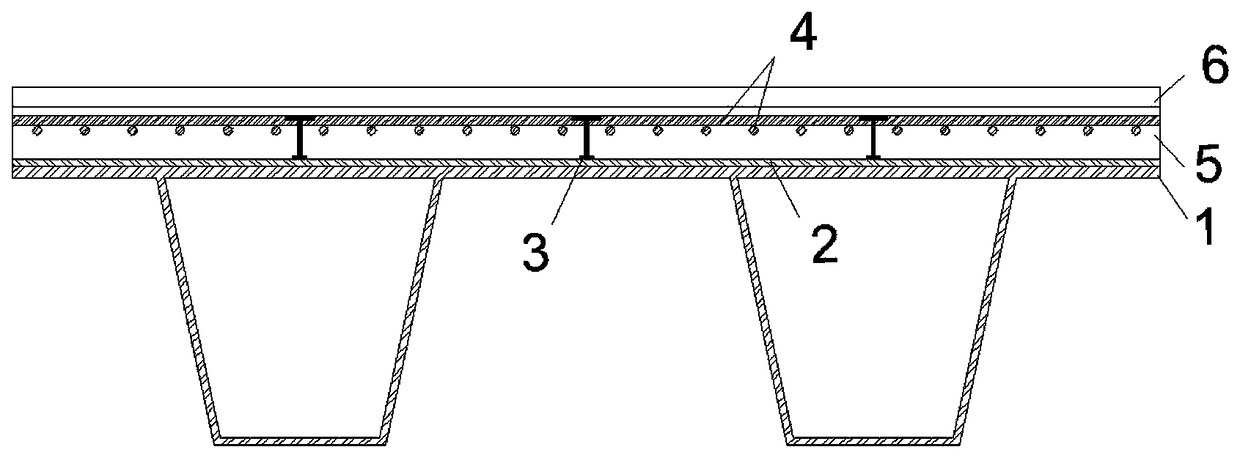

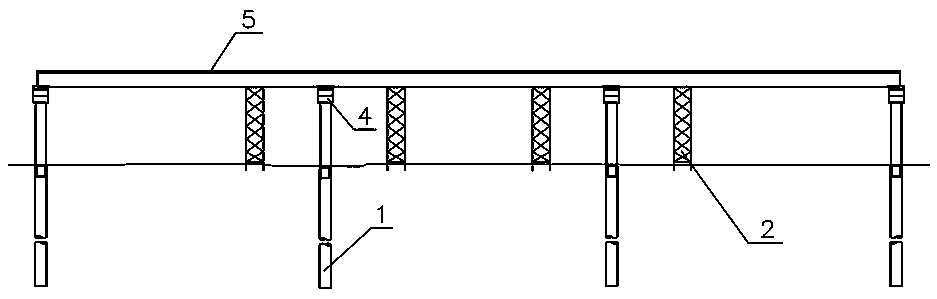

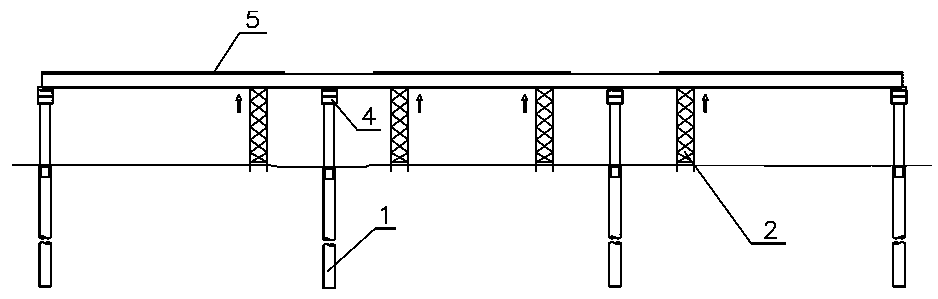

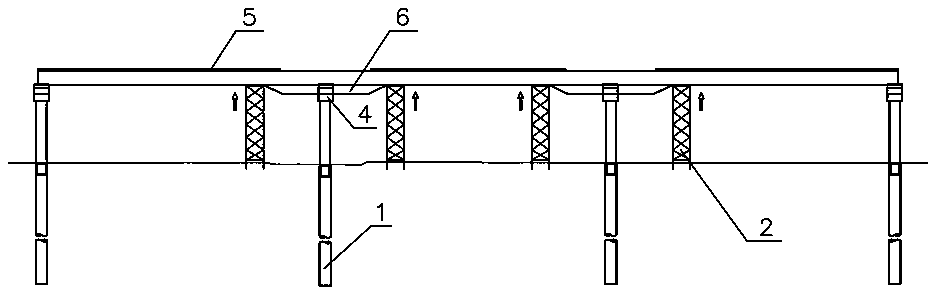

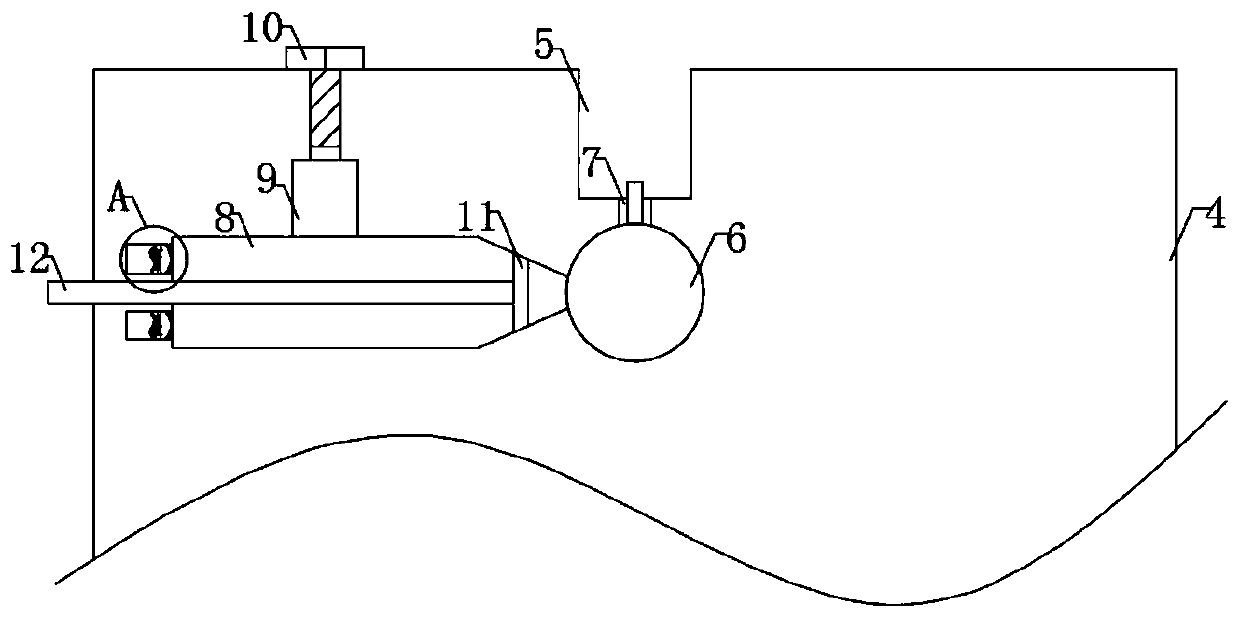

Reverse operating construction method for pouring monolithic track bed in separated tunnel of metro section

ActiveCN107653755AReduced pumping distanceEliminates the risk of crackingRailway track constructionEngineeringPollution

The invention specifically relates to a reverse operating construction method for pouring a monolithic track bed in a separated tunnel of a metro section, and solves the problems of slow constructionprogress, easiness in cracking of concrete of the track bed, serious pollution at the construction site, high labour intensity and high costs in pouring of the monolithic track bed in the separated tunnel of the metro section currently. The reverse operating construction method comprises: a, assembling a track skeleton and pushing the track skeleton to a track-laying operation surface; b, beddingsand pillows and paving the track skeleton in place; c, longitudinally firmly connecting the joint of two rail; d, manufacturing a rail-mounted concrete pump pipe bracket; e, manufacturing a rail-mounted concrete three-point material-deployment funnel; f, performing segment-by-segment track lifting from the distal end of the tunnel, then adjusting the spatial position, and arranging a downhill ramp; g, pushing the rail-mounted concrete pump pipe bracket and the rail-mounted concrete three-point material-deployment funnel to a track bed pouring area; and h, performing precise concrete materialdeployment and pouring on the track bed by manually controlling the positions of an arc material-deployment chute and a discharge port. The reverse operating construction method avoids the quality problem of track bed cracking inducted by the fact that the track bed bears loads too early.

Owner:CHINA RAILWAY NO 17 BUREAU GRP

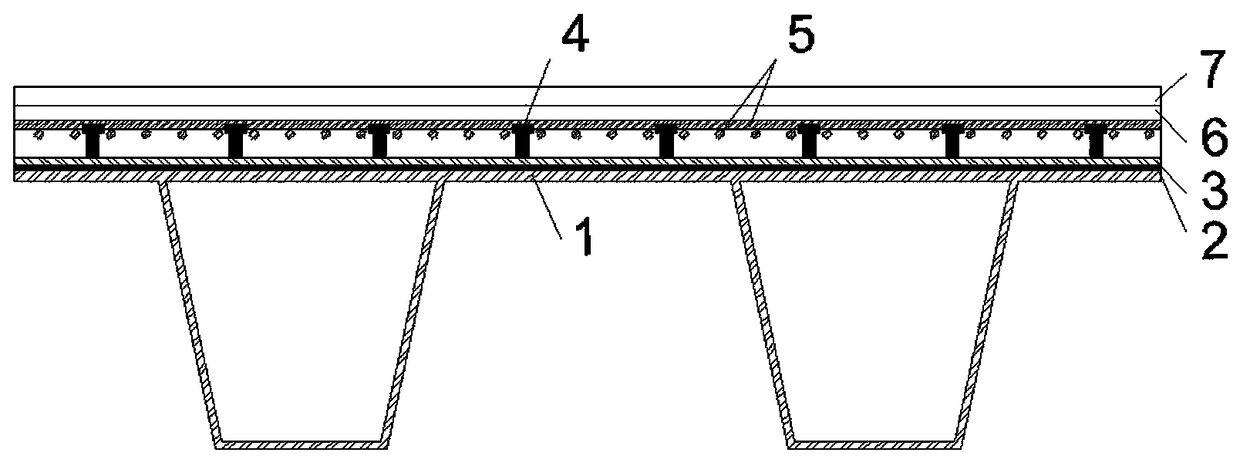

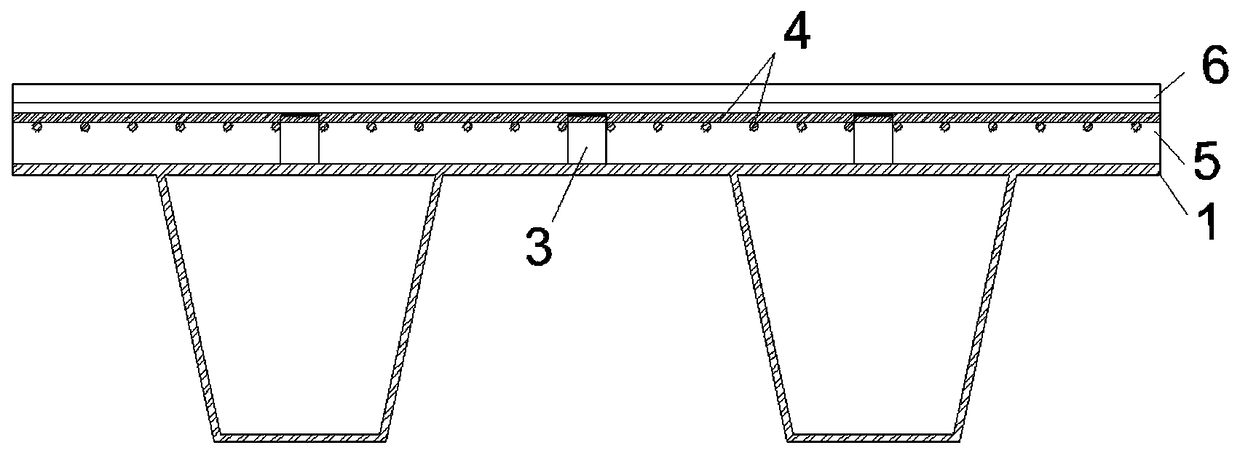

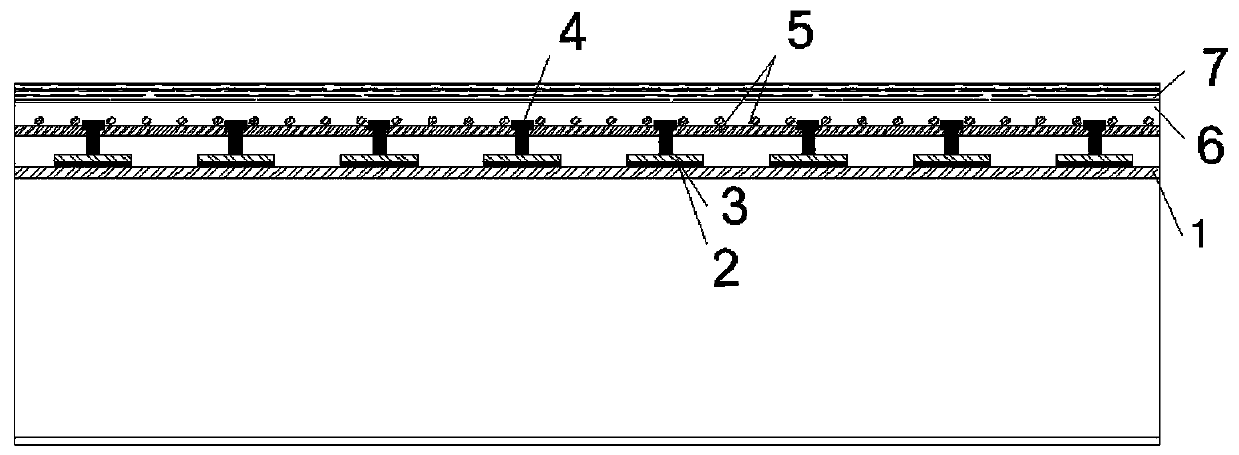

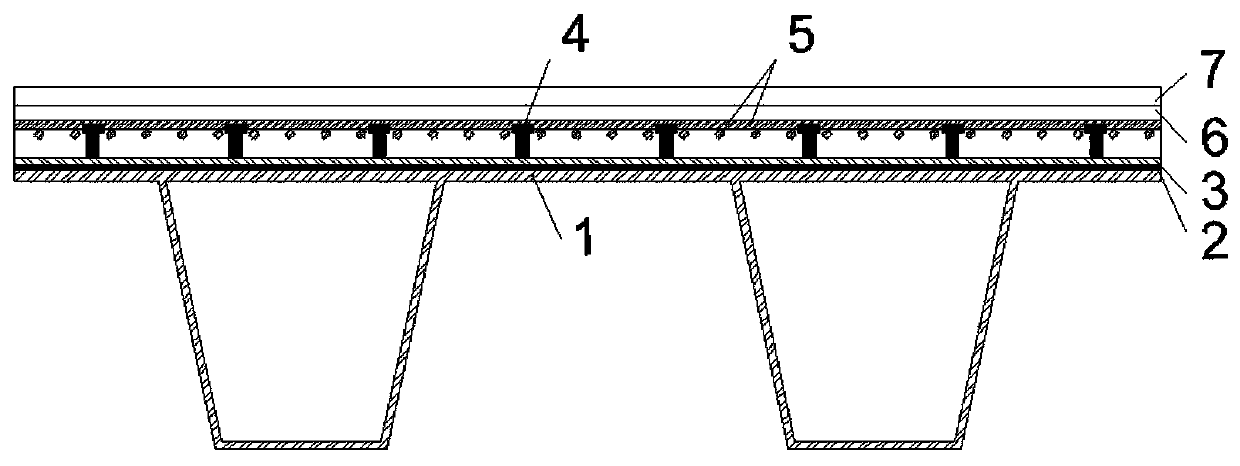

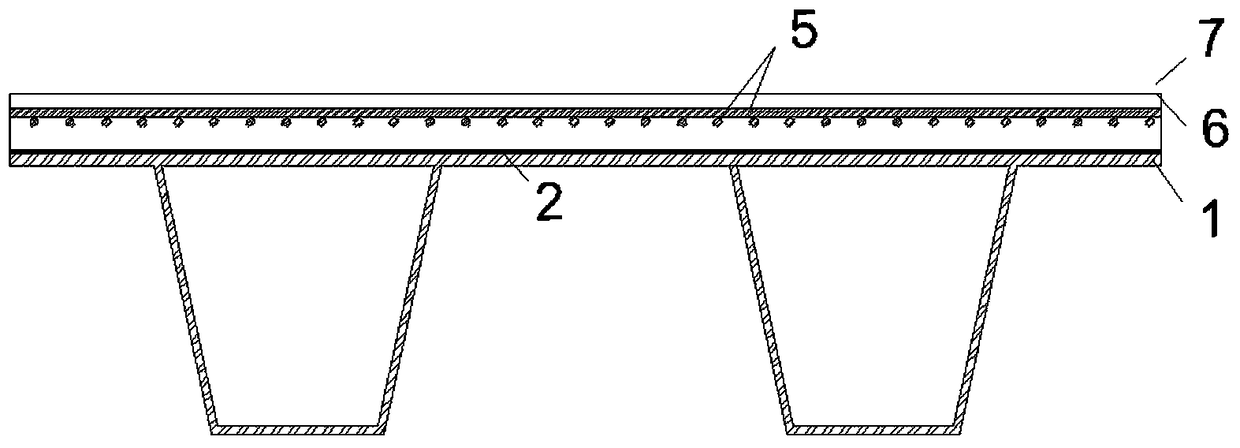

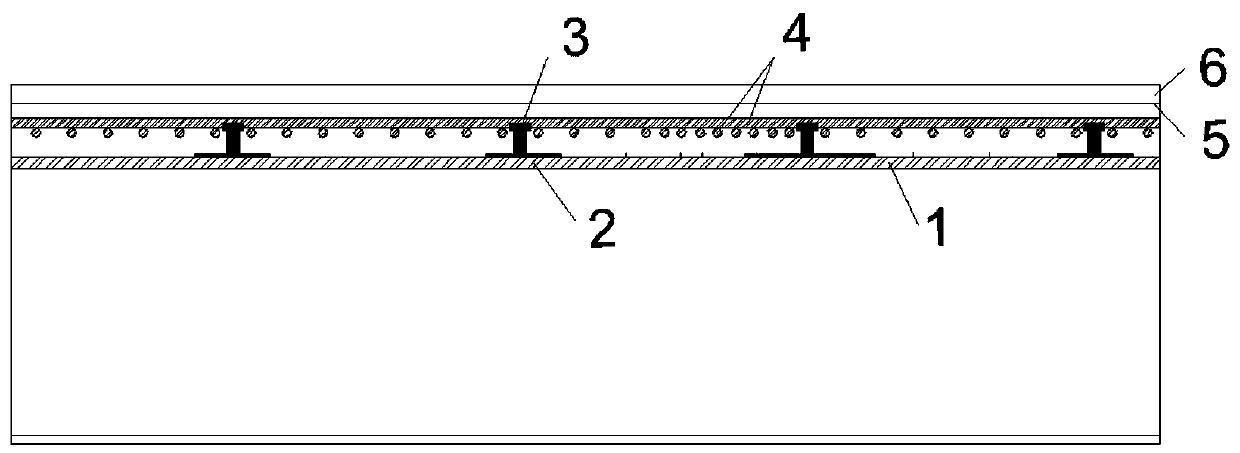

Reinforcing structure for fatigue cracked steel bridge panel

InactiveCN109338905AReduce transverse tensile stressAvoid crackingBridge structural detailsBridge erection/assemblyFiberCarbon fibers

The invention relate to a reinforcing structure for a fatigue cracked steel bridge panel. According to the technical scheme, the reinforcing structure for the fatigue cracked steel bridge panel comprises the cracked steel bridge panel, carbon fiber reinforcing battens, metal reinforcing battens, shear connecting parts, steel fabrics, an ultra-high performance concrete layer and a wearing layer, wherein the carbon fiber reinforcing battens are bonded to the cracked steel panel through organic structural adhesives; the shear connecting parts are welded to the metal reinforcing battens; and the metal reinforcing battens with the shear connecting parts are bonded above the carbon fiber reinforcing battens through organic structural adhesives, the steel fabrics are placed on the cracked steel bridge panel, the steel fabrics are composed of longitudinal steel bars and transverse steel bars, the longitudinal steel bars and the transverse steel bars are crisscrossed, the ultra-high performanceconcrete layer is arranged on the cracked steel bridge panel in a pouring mode, the carbon fiber reinforcing battens, the metal reinforcing battens, the shear connecting parts and the steel fabrics are covered with the ultra-high performance concrete layer, the ultra-high performance concrete layer is connected with the cracked steel bridge panel, and the ultra-high performance concrete layer iscovered with the wearing layer.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Cold forging process for rotor and reverse hole extrusion die

InactiveCN106001341AThe cold forging process is easy to operateImprove securityForging/hammering/pressing machinesPunchingMachining

The invention discloses a cold forging process for a rotor. The cold forging process comprises the steps of blanking, reverse hole extrusion and machining. The step of reverse hole extrusion specifically comprises the procedures that a blank is arranged in a lower die chamber and is located on a low die punching needle, a volume dividing space is reserved between the lower die punching needle and the inner wall of a lower die, an upper die punching needle punches downwards, a crossed blind hole is formed at one end of the blank, the punch needle of the upper die punching needle is in contact with the inner wall of the lower die by a sleeving washer so as to limit the blank to flow along a direction reverse to the punching direction, the blank flows along the punching direction to fill up the volume dividing space, a cylindrical blind hold is formed at the other end of the blank, an opening is formed along the direction of the diameter of the cylindrical blind hole, the depth of the opening is the same to that of the cylindrical blind hole, the internal tissue of the rotor formed by the cold forging process of the rotor is dense, thus completely eradicating the risk of product breakage and fracture, and improving the safety of vehicle; and the invention further provides a reverse hole extrusion die which is used for forming the rotor.

Owner:BINKE AUTOMOBILE FASTENER KUNSHAN

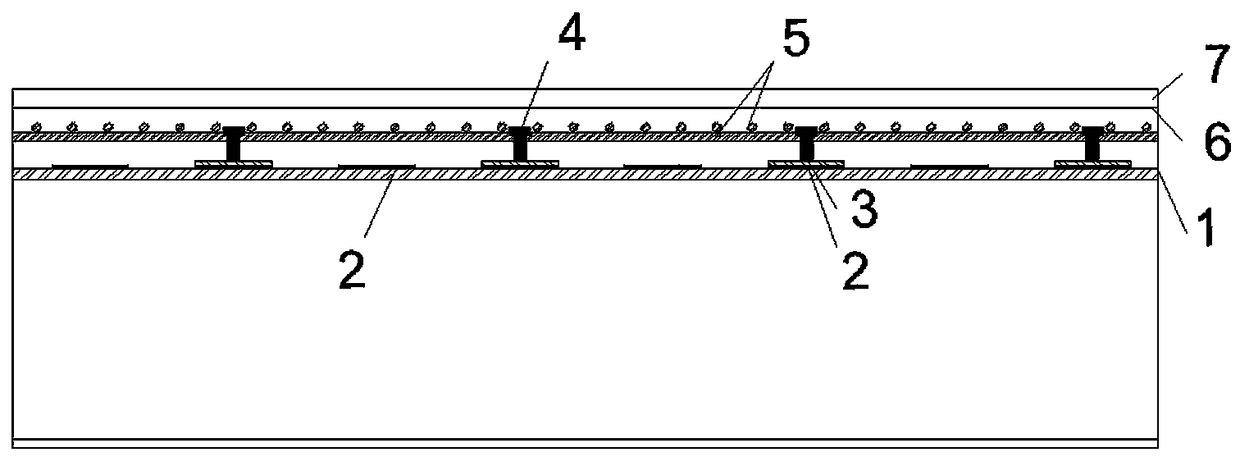

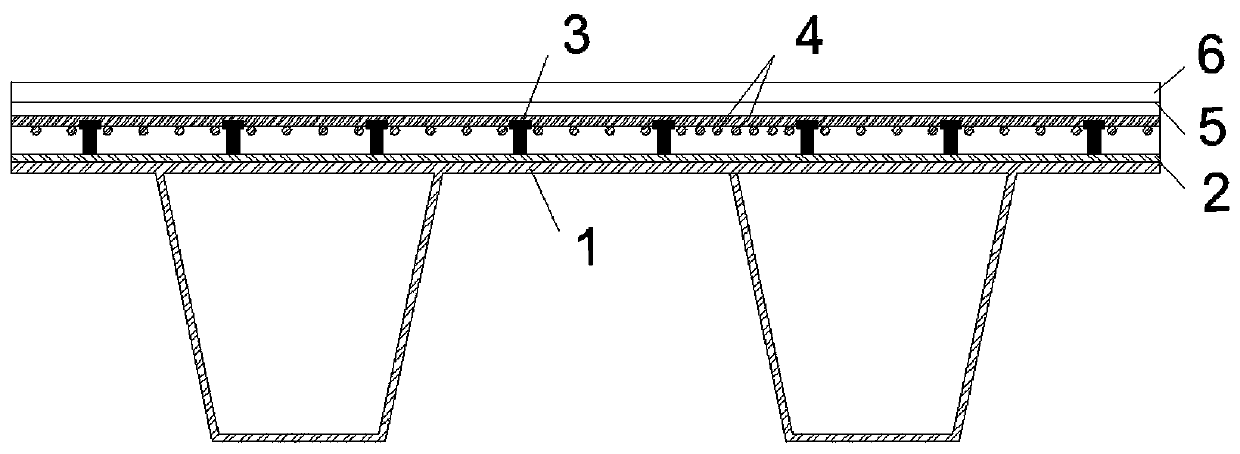

Reinforcement structure for solving cracked steel bridge deck by using lightweight aggregate concrete

InactiveCN109338902AImprove stabilityImprove fatigue resistanceBridge structural detailsBridge erection/assemblyBridge deckFiber-reinforced composite

The invention relates to a reinforcement structure for solving a cracked steel bridge deck by using lightweight aggregate concrete. According to key points of the technical scheme, the reinforcement structure comprises the fatigued cracked steel bridge deck, shear connecting pieces, fiber reinforced composite layers, reinforcing meshes and a lightweight aggregate concrete layer. The fatigued cracked steel bridge deck is provided with the shear connecting pieces, and the reinforcing meshes are placed on the fatigued cracked steel bridge deck. The fiber reinforced composite layers are laid on the crack parts of the fatigued cracked steel bridge deck, and the lightweight aggregate concrete layer is poured on the fatigued cracked steel bridge deck and covers the shear connecting pieces, the fiber reinforced composite layers and the reinforcing meshes to be connected with the fatigued cracked steel bridge deck. The shear connecting pieces are connected to the fiber reinforced composite layers, and the shear connecting pieces are arranged in the transverse bridge direction of the fatigued cracked steel bridge deck by fiber reinforced composites. The shear connecting pieces are arranged on the fatigued cracked steel bridge deck, and the fiber reinforced composite layers connected with the shear connecting pieces are laid between the shear connecting pieces connected with the steel bridge deck, wherein the spacing of the adjacent shear connecting pieces is 100-300 mm.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Method for producing a chassis link

ActiveUS10081044B2Eliminates the risk of crackingCost-effectivePivoted suspension armsAdhesivesEngineeringDeep drawing

A method for producing a chassis link includes shaping a single-shell main body from a sheet metal blank and deforming the sheet metal blank by deep drawing, which includes pre-drawing during which an indentation is produced on the main body and in which the indentation is trimmed and a bush is attached to a projection on the main body once the indentation has been trimmed. The sheet metal blank is pre-drawn such that the indentation is given a radius that matches the bush to be attached such that there is no further need for a further forming operation on the indentation once the indentation has been trimmed.

Owner:AUTOTECH ENG DEUT

A system reinforcing method for a steel plate combined continuous beam

InactiveCN109695205AImprove bearing capacityImprove the ability to resist torsional distortionBridge erection/assemblyBridge strengtheningBridge deckEngineering

The invention discloses a system reinforcing method for a steel plate combined continuous beam. The system reinforcing method comprises the steps that a temporary support is erected near a bending moment zero point of the combined beam; secondly, the composite beam is jacked for the first time, a support system on a cover beam of the middle pier is removed, and damaged concrete of a bridge deck ina hogging moment area of the top of the middle pier is chiseled away; then, secondary jacking is conducted, a prefabricated channel beam is hoisted to be installed on the middle pier cover beam, andthe upper flange of the prefabricated channel beam is connected with the lower flange of an H-shaped beam in a welded mode; meanwhile, longitudinal ribs and vertical ribs are implanted into the middlepier cover beam, and studs are welded to the inner side of a steel web of the H-shaped beam; finally, concrete is poured, the temporary support is dismantled, and construction is completed. On one hand, the bearing capacity and torsional distortion resistance of the steel plate combined continuous beam can be greatly improved, on the other hand, the problem of bridge deck slab cracking in the hogging moment area of the steel plate combined continuous beam can be effectively solved, and the purpose of reinforcing an existing steel plate combined continuous beam system is achieved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

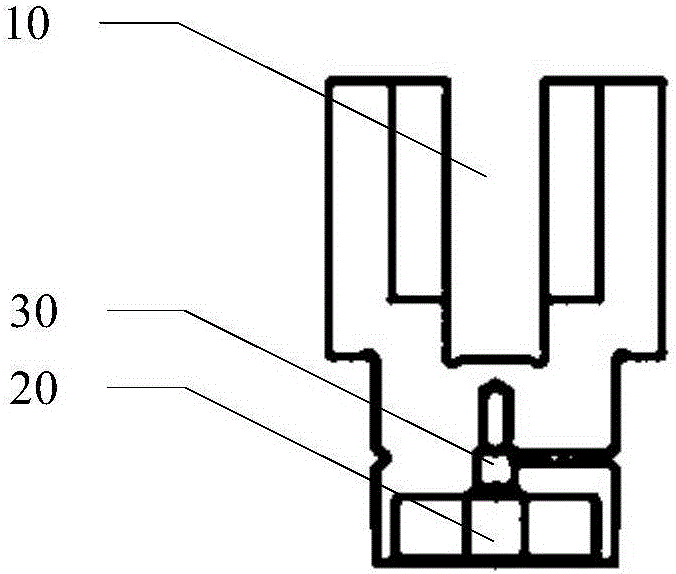

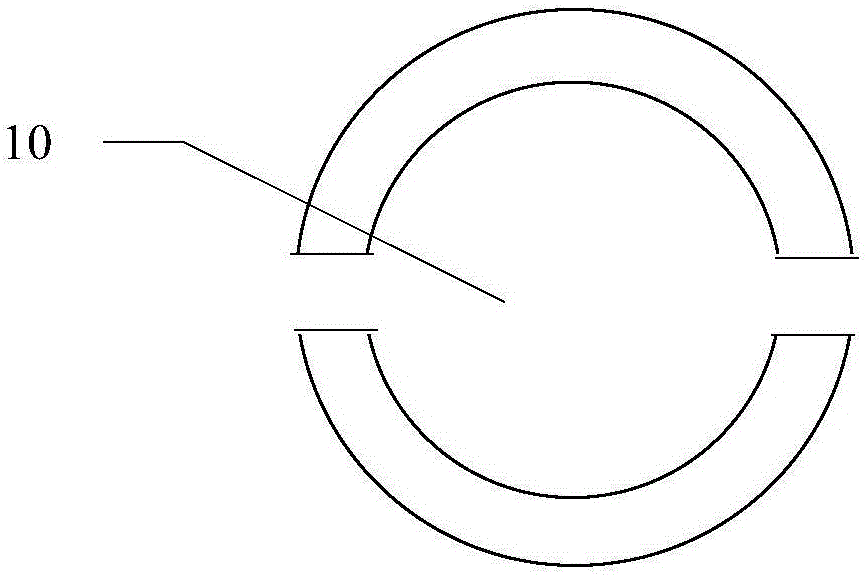

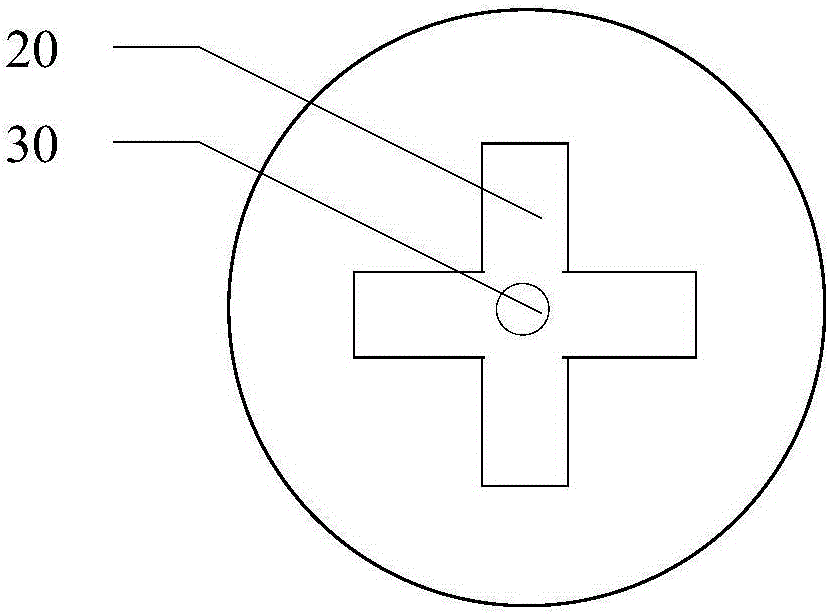

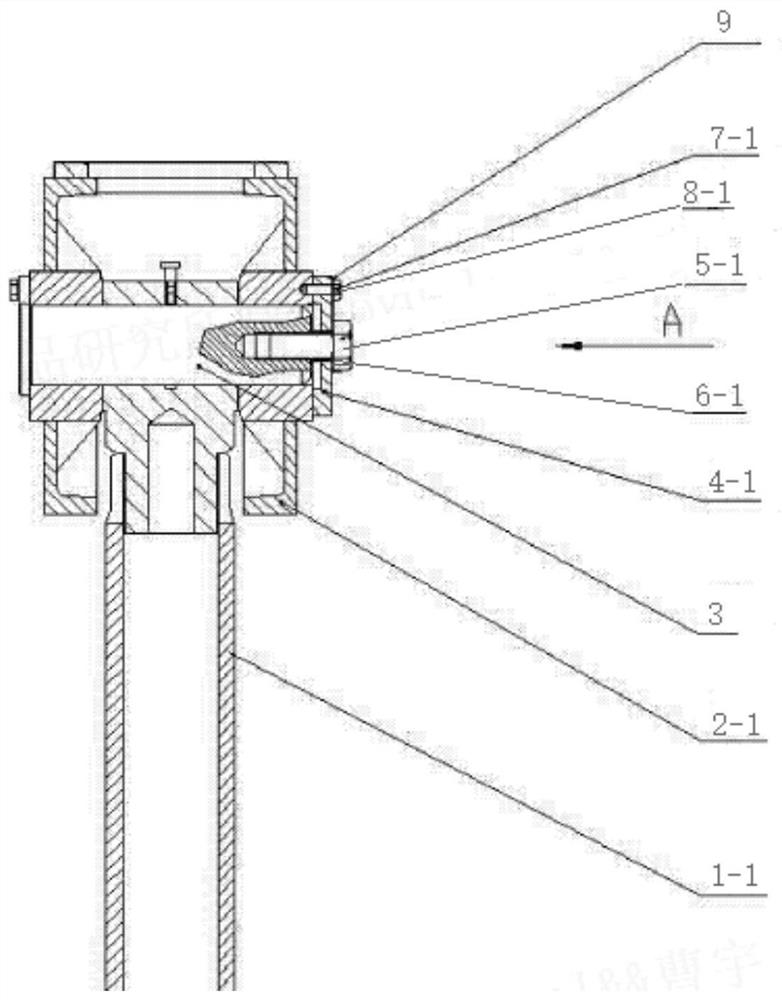

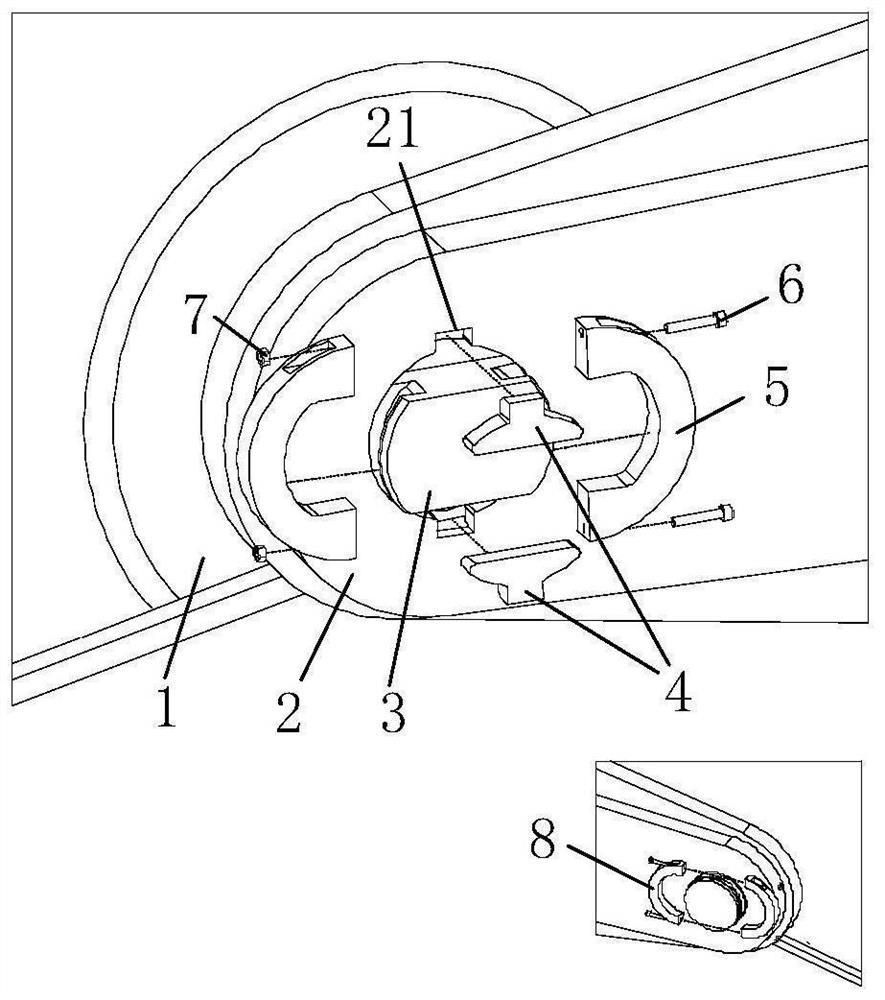

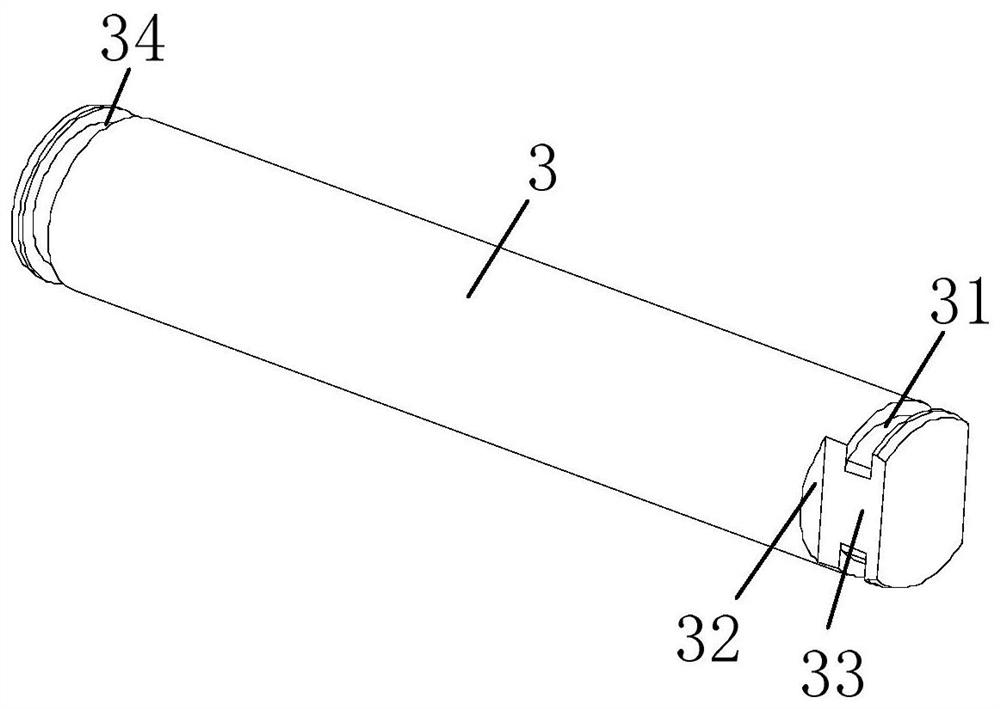

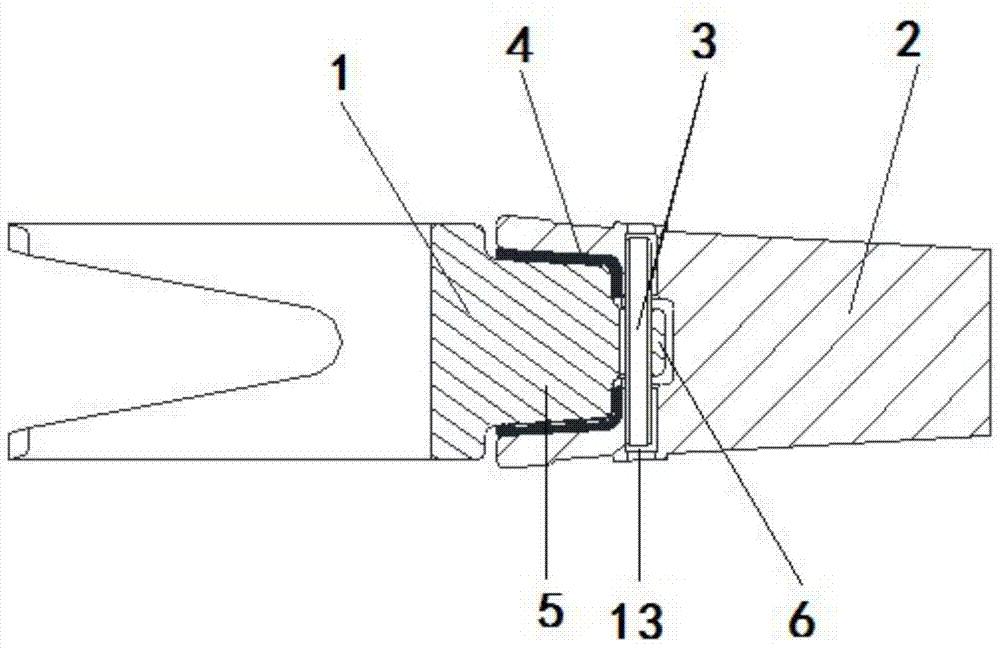

Welding-free pin shaft and stop device

ActiveCN112664531AEliminates the risk of crackingImprove reliabilityFastening meansStops deviceStructural engineering

The invention discloses a welding-free pin shaft and a stop device. The limit of the rotary motion of the pin shaft is realized through the matching of a stop block and the pin shaft, and the effect of limiting the axial movement of the pin shaft is achieved by utilizing the buckling between an annular groove in the pin shaft and left and right stop rings. According to the welding-free pin shaft and the stop device, hole punching in a shaft end surface and a base body part is avoided through assembling, and cracking risks caused by welding are thoroughly avoided; and all components are simple in structure, the overall structure is compact, the occupied space is small, the pin shaft is easy and convenient to disassemble and assemble, and the application range is wide.

Owner:XCMG EXCAVATOR MACHINERY

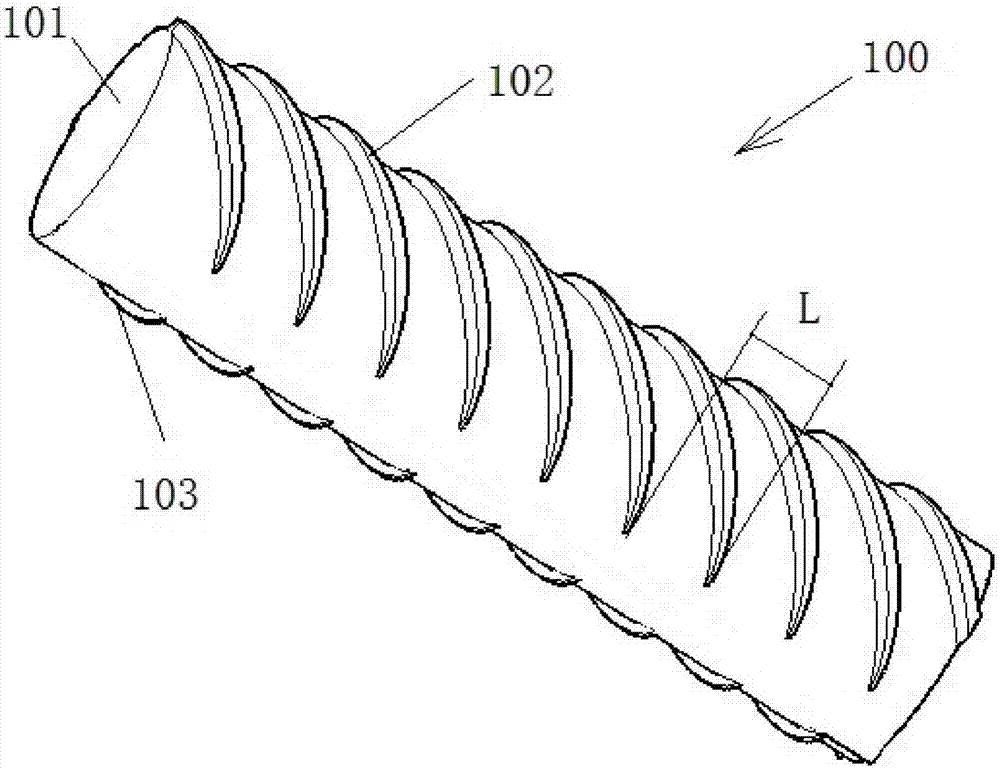

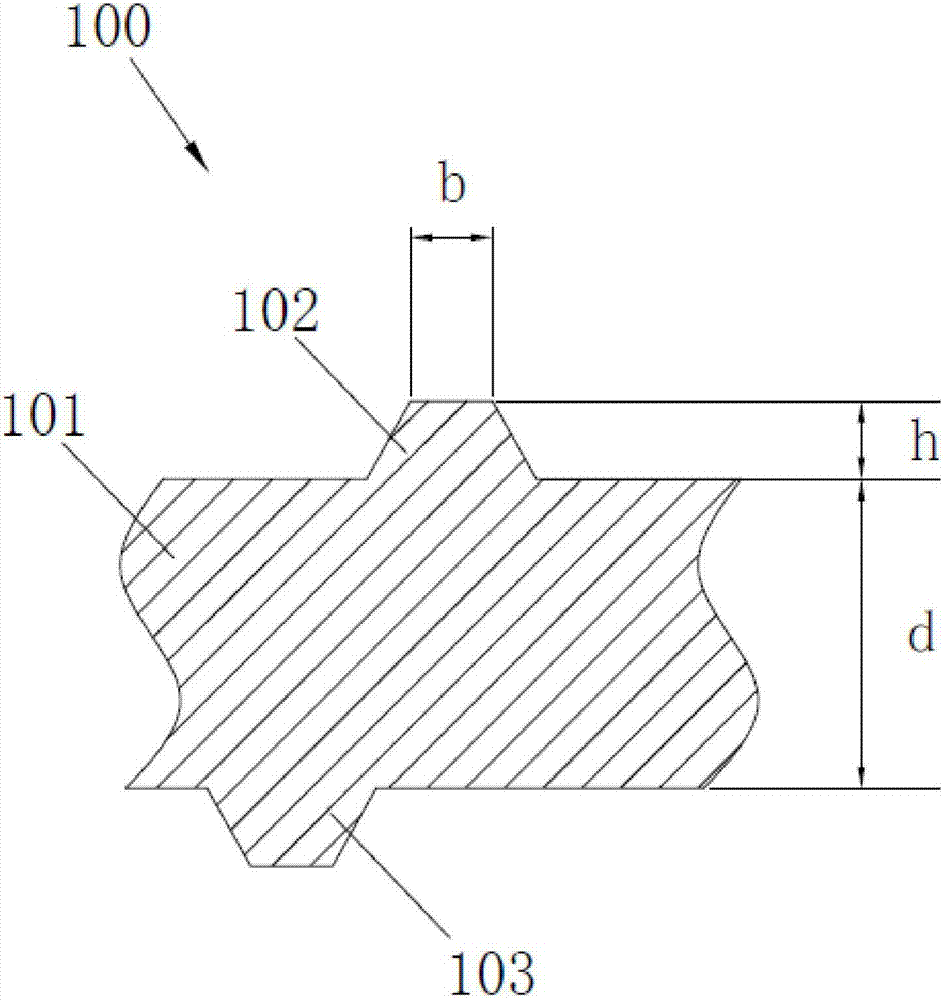

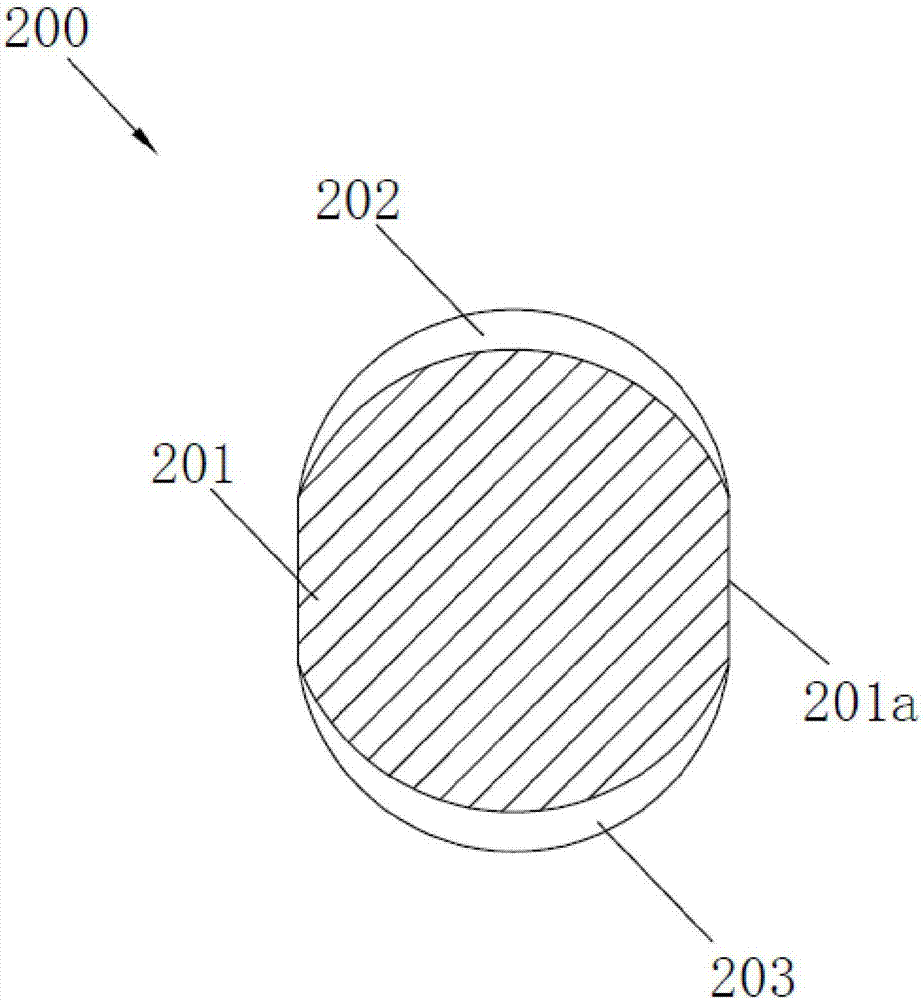

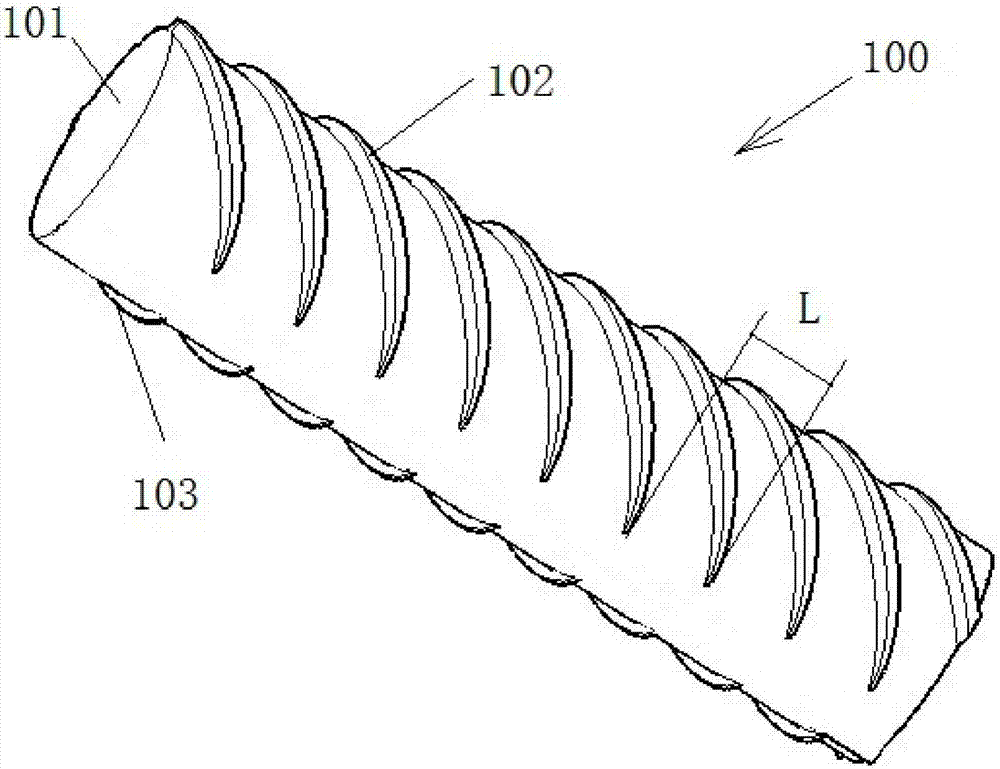

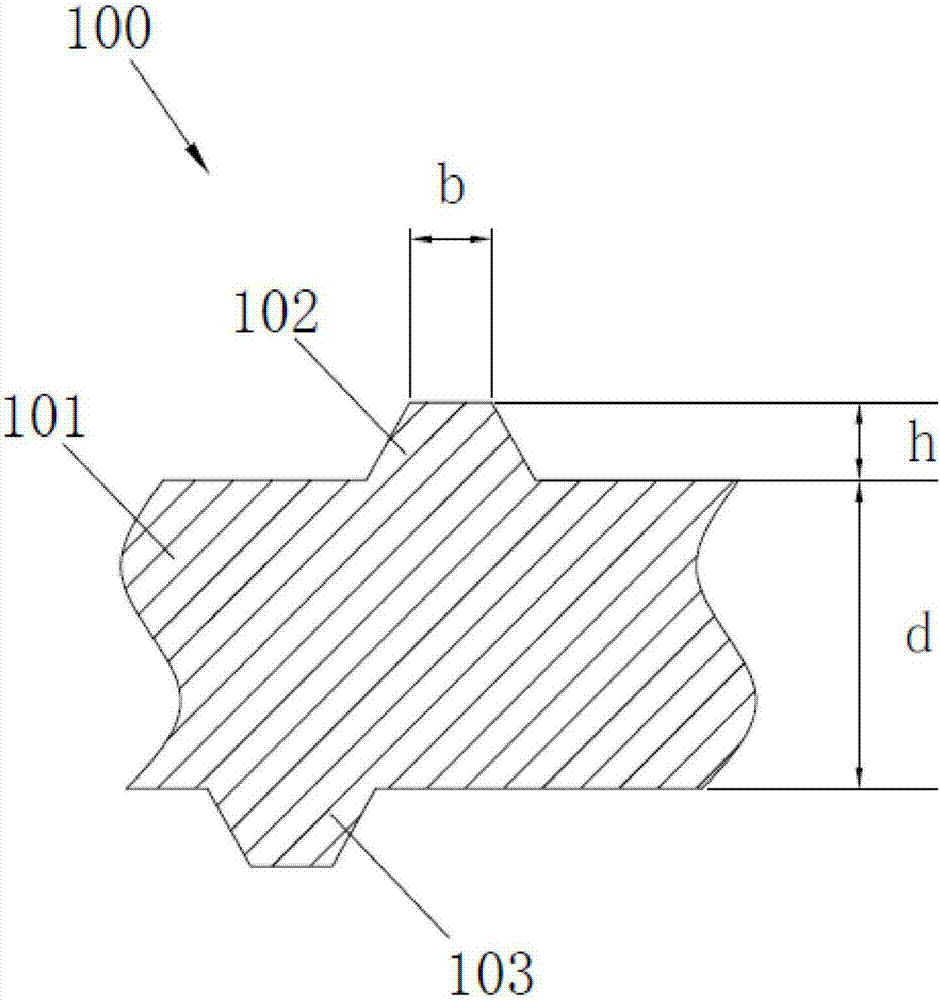

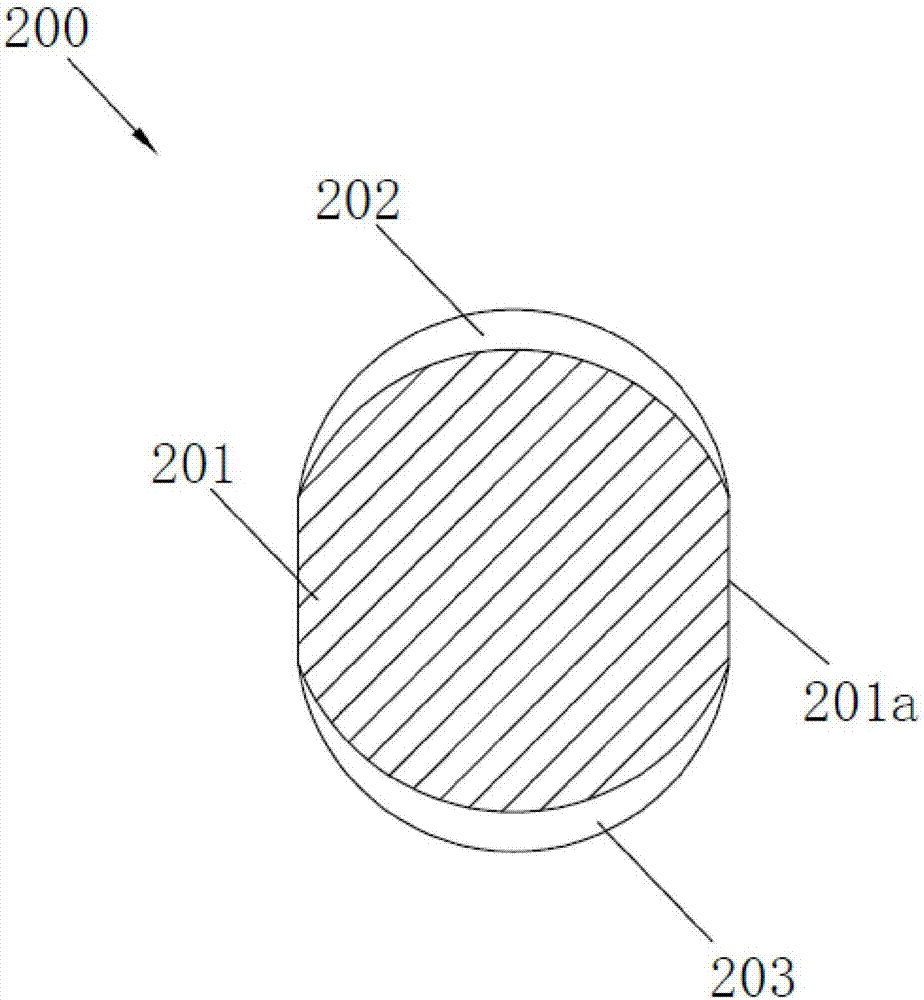

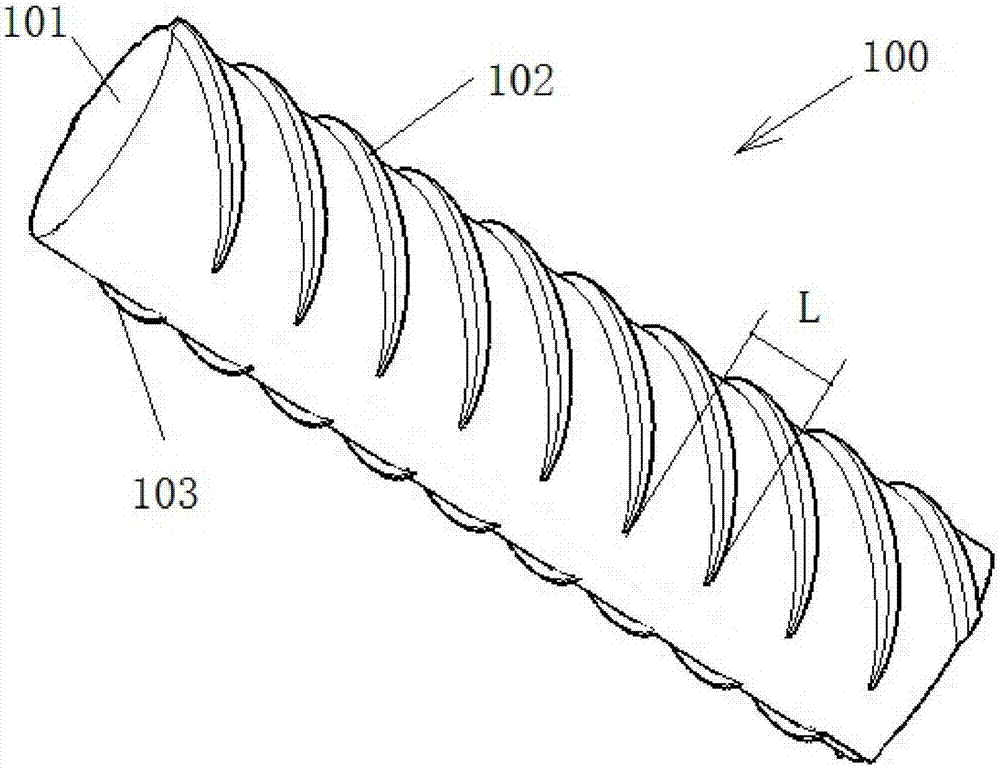

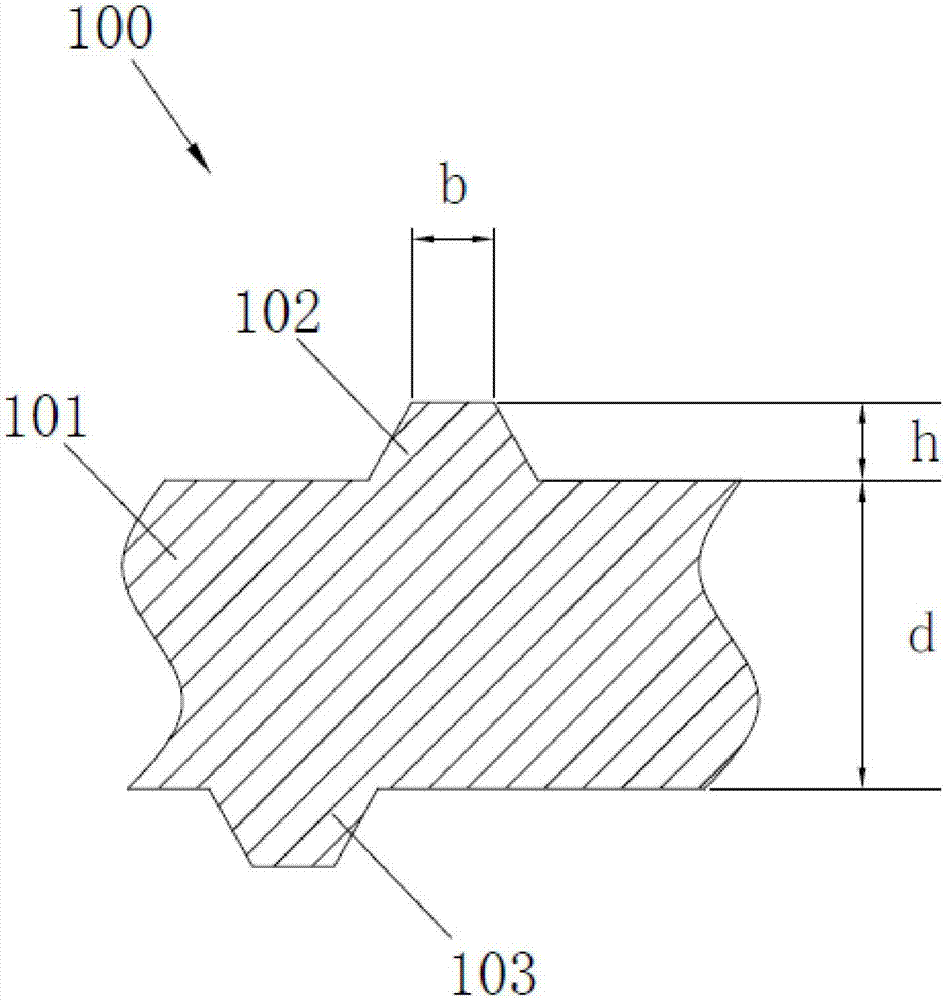

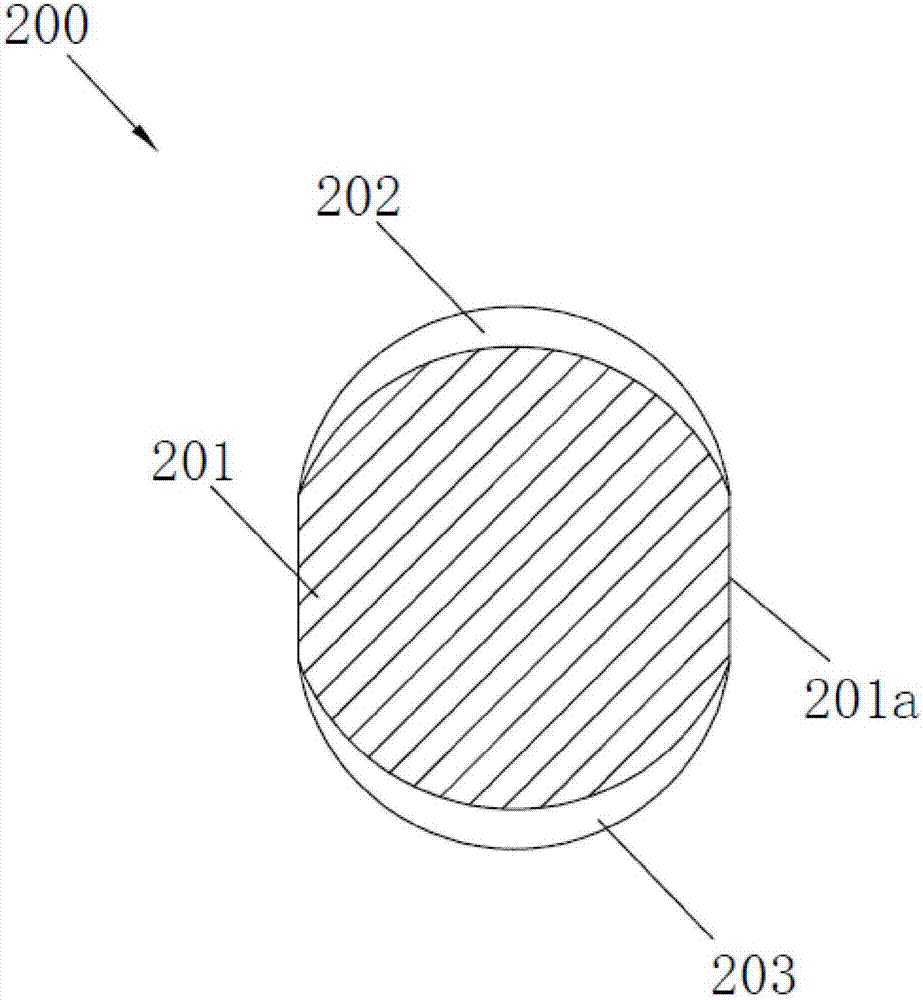

Reinforcing steel bar applicable to concrete

InactiveCN107090948ASmooth outlineImprove firmnessBuilding reinforcementsReinforced concreteSteel bar

The invention discloses a reinforcing steel bar applicable to concrete, which comprises a reinforcing steel bar body and a plurality of cross ribs. The maximum size of the cross section of the reinforcing steel bar body is d, the maximum size of each cross rib projected from the reinforcing steel bar body is h, the width of the top of each cross rib projected from the reinforcing steel bar body is defined as rib top width b, and the distance between each two adjacent cross ribs in the length direction of the reinforcing steel bar body is defined as rib spacing L; the cross ribs are divided into two groups, which are respectively arranged on both sides of the reinforcing steel bar body; the parts, which are between the two groups of cross ribs, of the cross section of the reinforcing steel bar body are smooth curves or / and straight lines; the value range of the maximum size h of each cross rib projected from the reinforcing steel bar body is between 0.08d and 0.2d; the value range of the rib top width b is between 0.05d and 0.15d; and the value range of the rib spacing L is between 0.3d and 3d. The reinforcing steel bar applicable to concrete has the following advantages: by improving the shape and size parameters of the reinforcing steel bar, the reinforcing steel bar body has a smooth external profile, a structure which has the risk of cracking is eliminated when the reinforcing steel bar is combined with concrete, and thereby the degree of firmness of reinforced concrete formed by the reinforcing steel bar is increased.

Owner:江苏森林建筑新材料股份有限公司

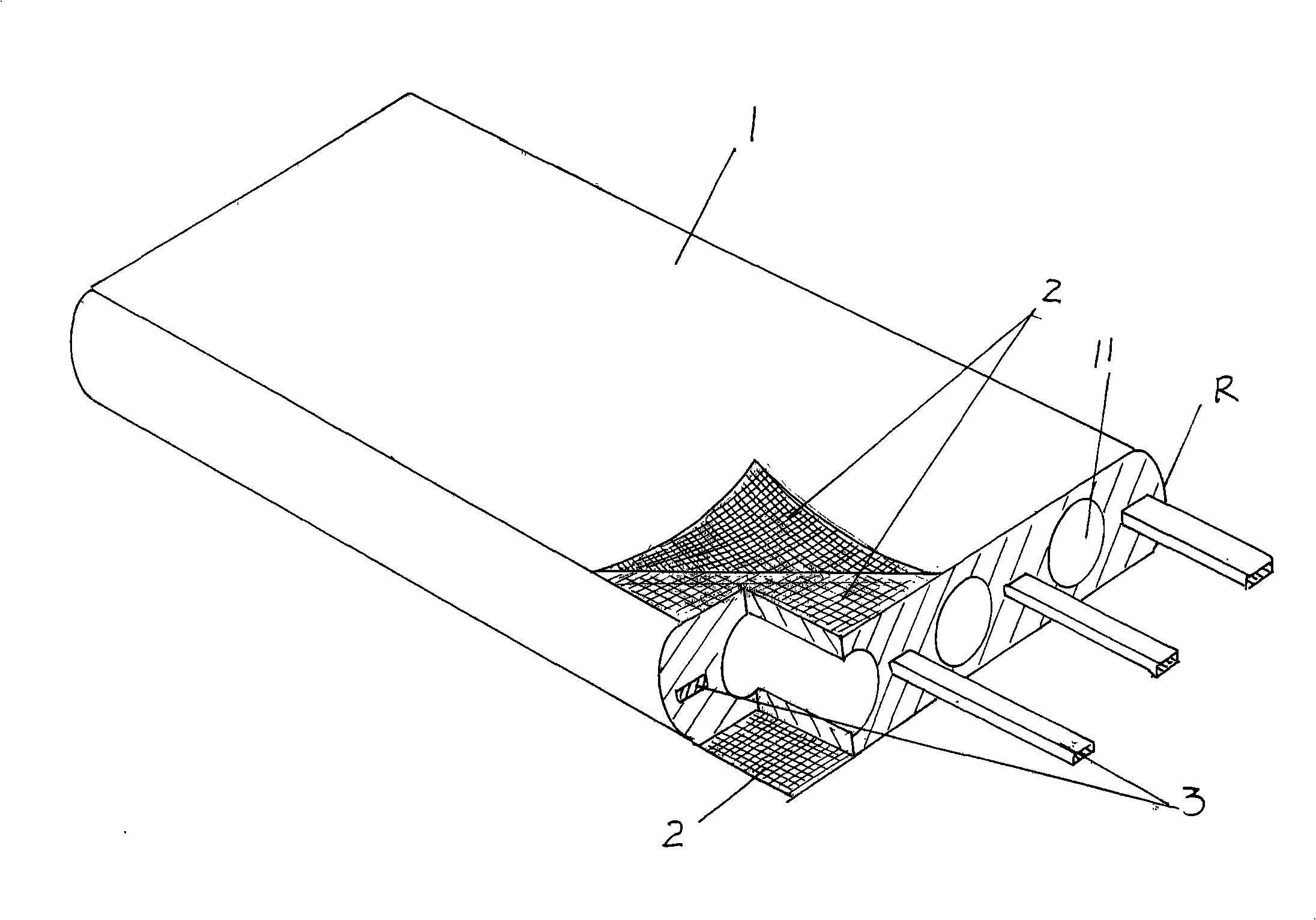

Light weight high intensity fireproof roof substrate

InactiveCN101265740APrevent crackingEliminates the risk of crackingRoof covering using slabs/sheetsBuilding materialHigh intensity

A roof boarding of light weight, high strength and fireproof is provided, which belongs to the technology field of building material. The roof boarding comprises a boarding body, boarding holes provided at intervals in the interlayer in a length direction of the boarding body and at least one layer of net cloth combining with the upper and the lower surfaces of the boarding body. The roof boarding is characterized in that non-metal reinforcing bars used for increasing the strength of the boarding body are further arranged in the interlayer in the length direction of the boarding body. The roof boarding has the advantage that the non-metal reinforcing bars used for increasing the strength of the boarding body are added in the interlayer in the length direction of the boarding body, thereby avoiding cracking when in use.

Owner:张福兴

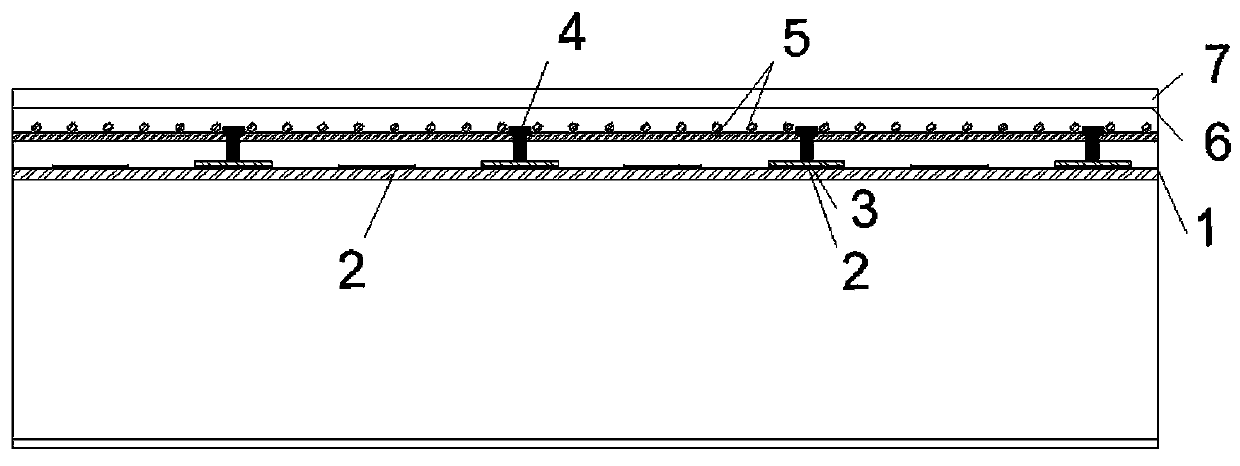

Strengthening structure for fatigue cracked steel bridge deck

PendingCN110499717AReduce transverse tensile stressAvoid crackingBridge structural detailsBridge erection/assemblyFiberCarbon fibers

The invention discloses a strengthening structure for a fatigue cracked steel bridge deck. According to the technical scheme, the strengthening structure is characterized by comprising the cracked steel bridge deck, carbon fiber reinforced battens, metal reinforced battens, shear connecting pieces, reinforcing meshes, an ultrahigh-performance concrete layer and a wearing layer. The carbon fiber reinforced battens are arranged on the cracked steel bridge deck; the shear force connecting pieces are welded to the metal reinforced battens; the metal reinforced battens with the shear force connecting pieces are arranged above the carbon fiber reinforced battens; the reinforcement meshes are placed on the cracked steel deck; the ultrahigh-performance concrete layer is poured on the cracked steelbridge deck; the carbon fiber reinforced battens, the metal reinforced battens, the shear force connecting pieces and the reinforcing meshes are arranged in a covering manner to be connected with thecracked steel bridge deck; and the wearing layer is arranged on the top face of the ultrahigh-performance concrete layer in a covering manner.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

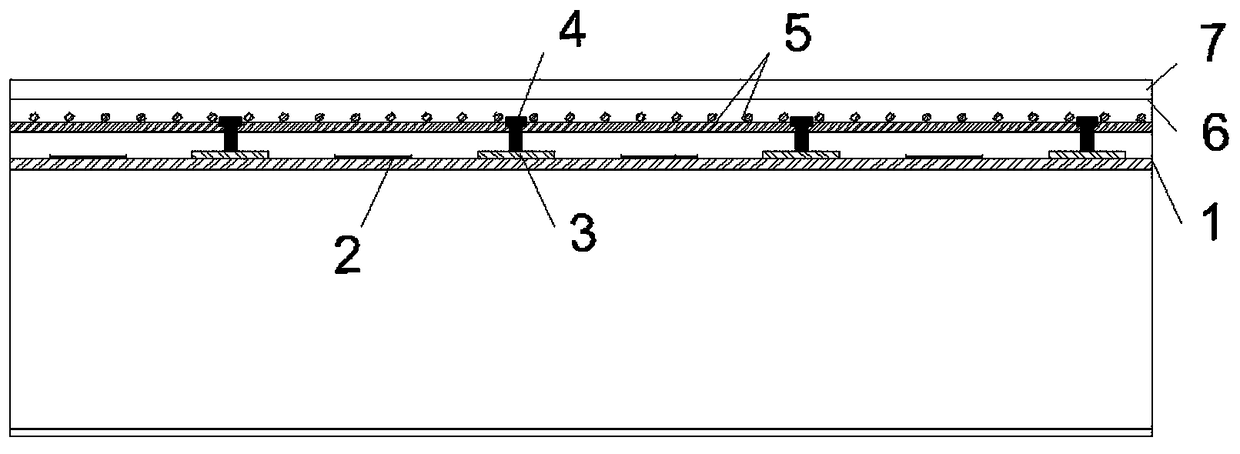

Reinforcing structure for cracked steel bridge panel

InactiveCN109338904AImprove fatigue lifeIncreased durabilityBridge structural detailsBridge erection/assemblyAdhesiveSurface plate

The invention relate to a reinforcing structure for a cracked steel bridge panel. According to the technical scheme, the reinforcing structure for the cracked steel bridge panel comprises the crackedsteel bridge panel, carbon fiber reinforcing battens, metal reinforcing battens, shear connecting parts, steel fabrics, an ultra-high performance concrete layer and a wearing layer, wherein the carbonfiber reinforcing battens are bonded to the cracked steel panel through organic structural adhesives; the shear connecting parts are welded to the metal reinforcing battens; the metal reinforcing battens with the shear connecting parts are directly welded or cemented on the cracked steel bridge panel, and alternately arranged with the carbon fiber reinforcing battens in parallel; and the steel fabrics are placed on the cracked steel bridge panel, the steel fabrics are composed of longitudinal steel bars and transverse steel bars, the longitudinal steel bars and the transverse steel bars are crisscrossed, the ultra-high performance concrete layer is arranged on the cracked steel bridge panel in a pouring mode, the carbon fiber reinforcing battens, the metal reinforcing battens, the shear connecting parts and the steel fabrics are covered with the ultra-high performance concrete layer, the ultra-high performance concrete layer is connected with the cracked steel bridge panel, and the ultra-high performance concrete layer is covered with the wearing layer.

Owner:湖南中路华程桥梁科技股份有限公司

Reinforcing steel bar applicable to concrete

InactiveCN107090946ASmooth outlineImprove firmnessBuilding reinforcementsReinforced concreteSteel bar

The invention discloses a reinforcing steel bar applicable to concrete, which comprises a reinforcing steel bar body and a plurality of cross ribs. The maximum size of the cross section of the reinforcing steel bar body is d, the maximum size of each cross rib projected from the reinforcing steel bar body is h, the width of the top of each cross rib projected from the reinforcing steel bar body is defined as rib top width b, and the distance between each two adjacent cross ribs in the length direction of the reinforcing steel bar body is defined as rib spacing L; the cross ribs are divided into two groups, which are respectively arranged on both sides of the reinforcing steel bar body; the parts, which are between the two groups of cross ribs, of the cross section of the reinforcing steel bar body are smooth curves or / and straight lines; the value range of the maximum size h of each cross rib projected from the reinforcing steel bar body is between 0.03d and 0.2d; the value range of the rib top width b is between 0.04d and 0.1d; and the value range of the rib spacing L is between 0.3d and 0.8d. By improving the shape and size parameters of the reinforcing steel bar, the invention ensures that the reinforcing steel bar body has a smooth external profile, a structure which has the risk of cracking is eliminated when the reinforcing steel bar is combined with concrete, and thereby the degree of firmness of reinforced concrete formed by the reinforcing steel bar is increased.

Owner:江苏森林建筑新材料股份有限公司

Reinforcing steel bar applicable to concrete

InactiveCN107090947ASmooth outlineImprove firmnessBuilding reinforcementsReinforced concreteSteel bar

The invention discloses a steel bar suitable for concrete, which comprises a steel bar body and several transverse ribs, the transverse ribs protrude from the steel bar body, the maximum dimension of the cross section of the steel bar body is d, and the maximum dimension of the transverse rib protruding from the steel bar body is h, the width of the top of the transverse rib protruding from the steel bar body is defined as the rib top width b, and the distance between two adjacent transverse ribs in the length direction of the steel bar body is defined as the rib spacing L; the transverse ribs are divided into two groups , respectively set on both sides of the steel bar body; the cross section of the steel bar body is a smooth curve or \ and straight line between the two sets of transverse ribs; the value range of the maximum dimension of the transverse rib protruding from the steel bar body is 0.08 d to 0.2d; the range of rib top width b is 0.05d to 0.15d. The benefit of the present invention is that by improving the shape and size parameters of the steel bar, the steel bar body has a relatively smooth outer contour, eliminating the structure with the risk of cracking when combined with concrete, thereby improving the firmness of the reinforced concrete made of steel bars.

Owner:江苏森林建筑新材料股份有限公司

A combination device of a new buffer excavator gear seat and bucket teeth

Owner:RUGAO HUAYANG ALUMINUM PROD

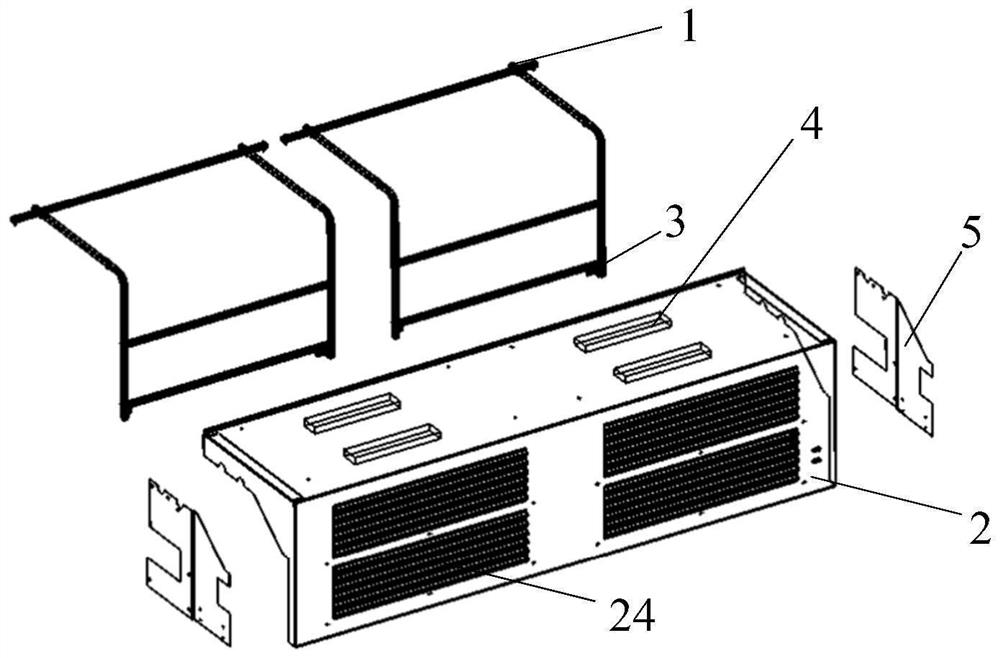

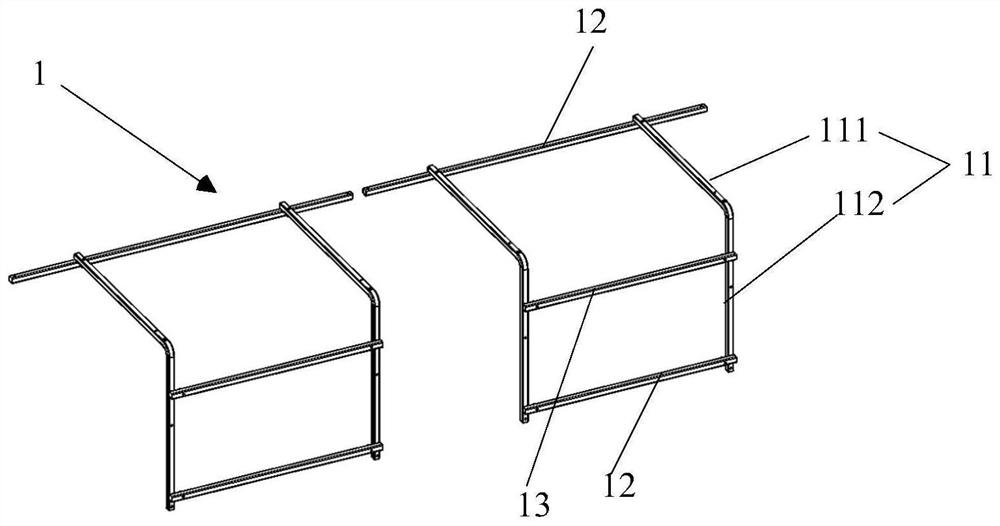

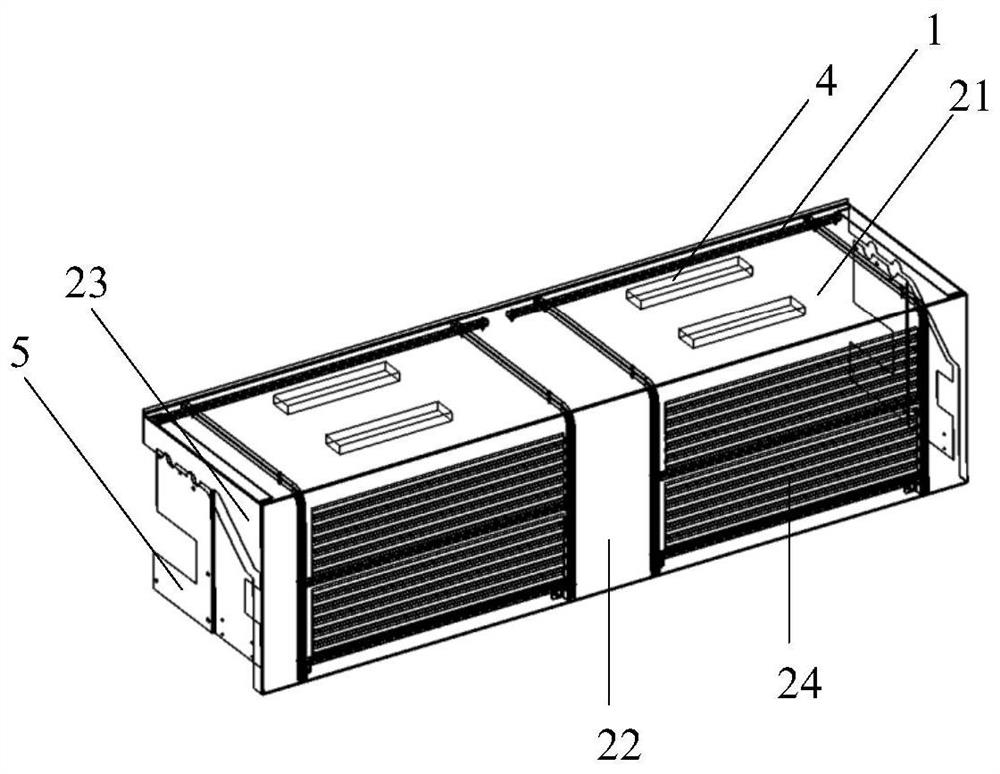

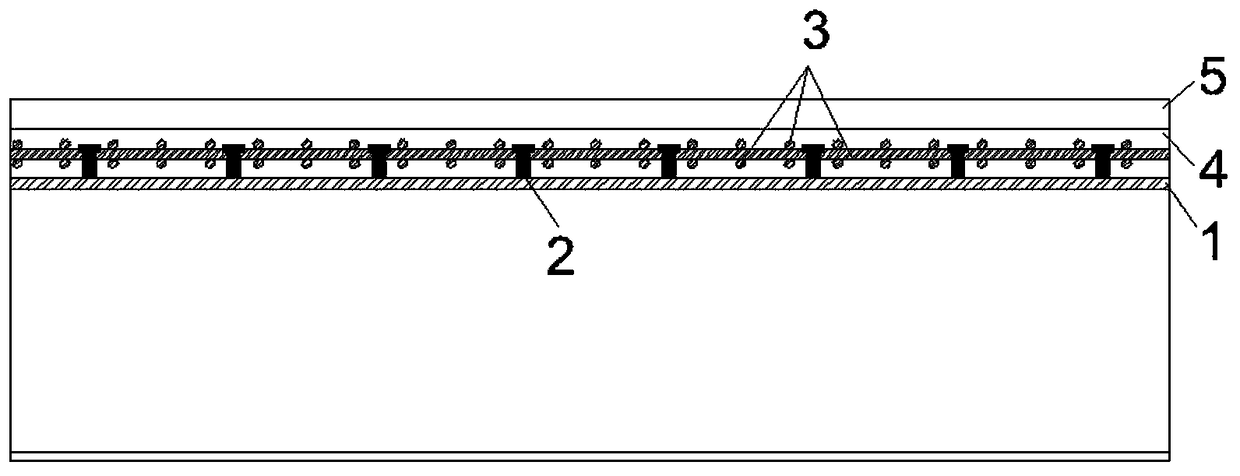

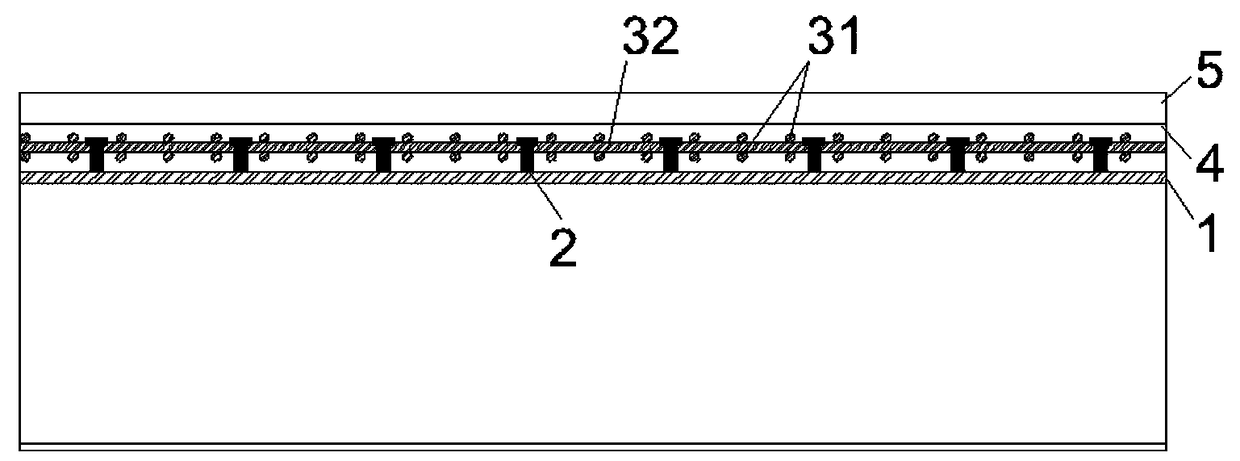

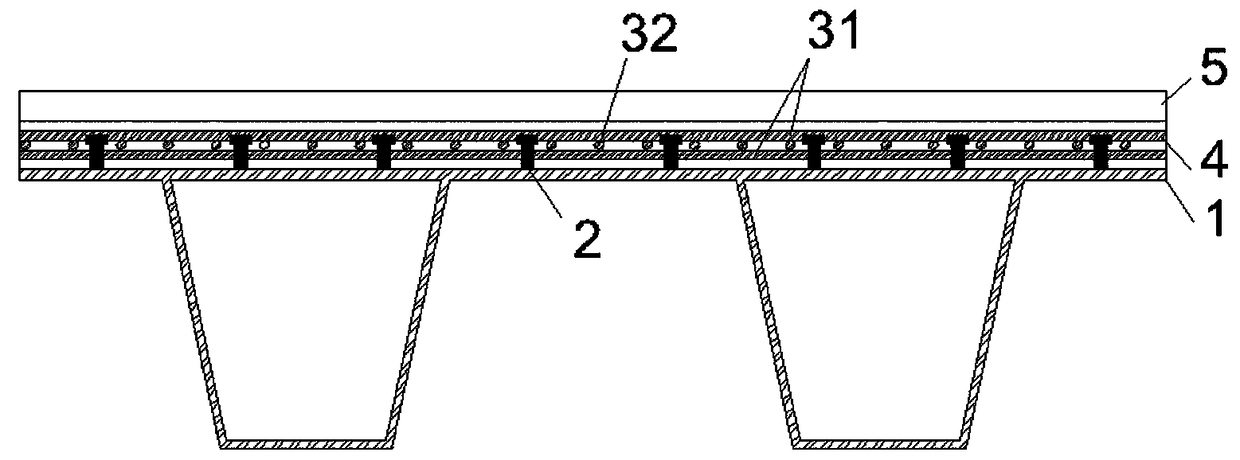

Water retaining cover for power battery of new energy commercial vehicle

PendingCN113386546ABeautiful and functionalImprove connection strengthBattery isolationElectric propulsion mountingElectrical batteryCommercial vehicle

The invention relates to the technical field of vehicle power device accessories, in particular to a new energy commercial vehicle power battery water retaining cover. The water retaining cover for the power battery of the new energy commercial vehicle comprises two buffer frames arranged at an interval, bolts, a water-based damping coating and a side top water retaining cover; wherein at least two bolt holes are formed in each of the two buffer frames which are arranged at an interval; the bolts with the same number as the bolt holes are used for fixing the buffer frame to the battery frame; the water-based damping coating is used for being sprayed to the joint where the buffer frame and the battery frame are fixed through bolts; the shape of the side top water retaining cover is matched with that of the buffering frames, and the side top water retaining cover is arranged on the outer sides of the two buffering frames and used for retaining water. According to the scheme, the problem that in the prior art, a rain baffle is directly arranged on the outer side of the battery frame, and the rain baffle and the battery frame resonate together and are torn due to vibration can be solved.

Owner:DONGFENG COMML VEHICLE CO LTD

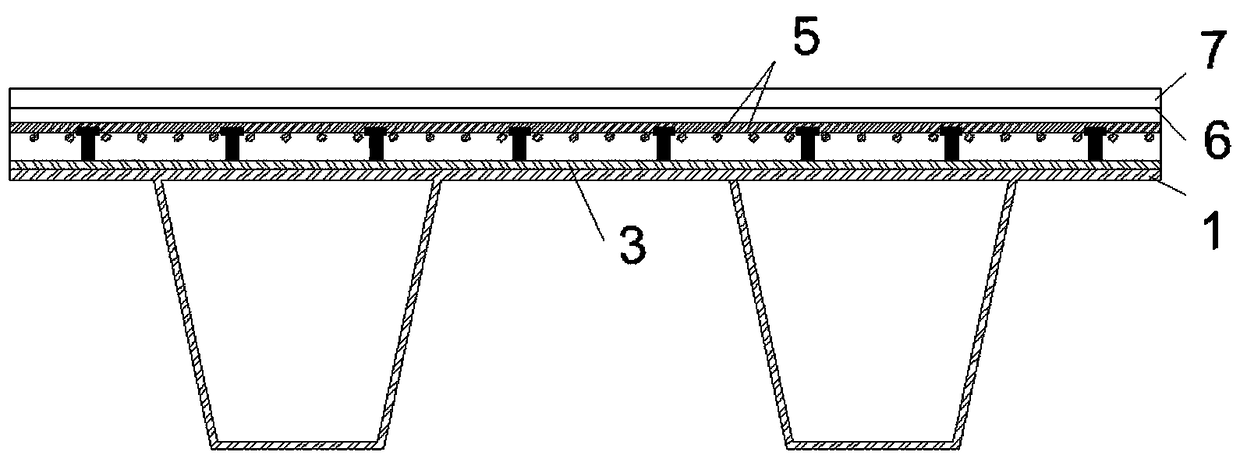

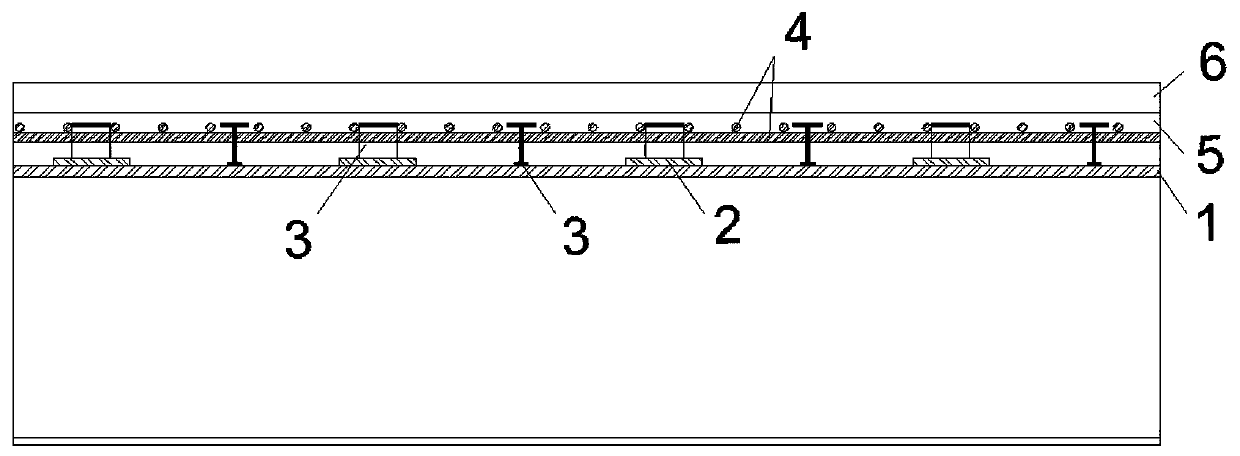

Light bridge deck composite reinforcement structure for solving bridge deck fatigue cracking problem

PendingCN109338907AReduce transverse tensile stressAvoid crackingBridge structural detailsBridge erection/assemblyBridge deckStructural engineering

The invention discloses a light bridge deck composite reinforcement structure for solving the bridge deck fatigue cracking problem. According to key points of the technical scheme, the light bridge deck composite reinforcement structure comprises a cracked steel bridge deck, shear connecting pieces, reinforcing meshes, an ultra-high performance concrete layer and a wearing layer. The cracked steelbridge deck is provided with the shear connecting pieces, and the reinforcing meshes are placed on the cracked steel bridge deck. The ultra-high performance concrete layer is poured onto the crackedsteel bridge deck and covers the connecting pieces and the reinforcing meshes to be connected with the cracked steel bridge deck. The wearing layer covers the ultra-high performance concrete layer.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Combined strengthening structure adopting light-weight aggregate concrete for repairing cracked steel bridge deck

PendingCN110499715AImprove stabilityImprove fatigue resistanceBridge structural detailsBridge erection/assemblyBridge deckFiber-reinforced composite

The invention discloses a combined strengthening structure adopting light-weight aggregate concrete for repairing a cracked steel bridge deck. According to the technical scheme, the combined strengthening structure is characterized by comprising the fatigue cracked steel bridge deck, shear force connecting pieces, a fiber reinforced composite material layer, reinforcing meshes and a light-weight aggregate concrete layer; the fiber reinforced composite material layer is laid on the cracked part of the fatigue cracked steel bridge deck, the reinforcing meshes are placed on the fatigue cracked steel bridge deck; the shear force connecting pieces are arranged on the fiber reinforced composite material layer; the light-weight aggregate concrete layer is poured on the fatigue cracked steel bridge deck; and the shear force connecting pieces, the fiber reinforced composite material layer and the reinforcing meshes are arranged in a covering manner to be connected with the fatigue cracked steelbridge deck.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Semiconductor structure and manufacturing method thereof

ActiveCN107204323BEasy to fillSimple structureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The embodiment of the present invention provides a semiconductor structure and a manufacturing method thereof, which includes a semiconductive substrate and a doped region in the semiconductive substrate. The doped region has a conductivity type opposite to that of the semiconductive substrate. The semiconductor structure also includes a capacitor in the doped region, where the capacitor includes a plurality of electrodes and the plurality of electrodes are insulated from each other. The semiconductor structure further includes a plug in the capacitor and surrounded by a plurality of electrodes.

Owner:TAIWAN SEMICON MFG CO LTD

Method for supporting overall arch body of underground roadway

ActiveCN112983462AImprove the support effectImprove safety production environmentUnderground chambersTunnel liningRock bolt

Owner:NANJING MEISHAN METALLURGY DEV +1

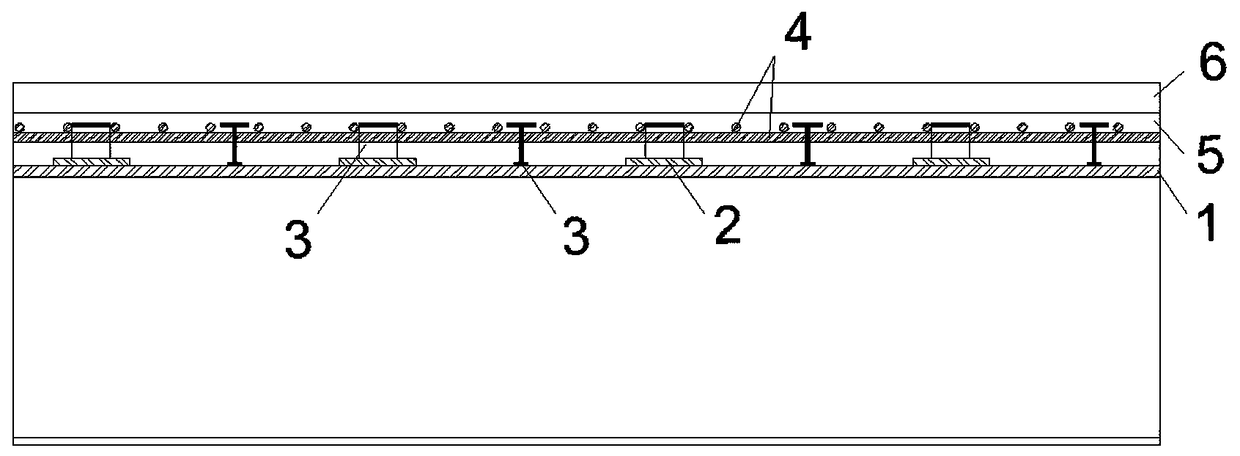

Cold shrinkable cable lug, cold shrinkable termination assembly and method of terminating cables

ActiveCN106300214BSmall physical propertiesEliminates the risk of crackingInsulating bodiesCable terminationsIsolation layerEngineering

A cold shrinkable terminal assembly for terminating cables, comprising: a cold shrinkable terminal including a terminal body configured to be fixed to the cable joint; and a support tube, the terminal body is pre-expanded to a preset On the support tube of the composite gap filler, the composite gap filler covers at least the cutout of the exposed conductive shielding layer when the cold shrink terminal is fixed to the cable joint. The composite gap filling glue includes: a filling layer, which is in contact with the outer wall of the support tube; and an isolation layer, located between the filling layer and the terminal body, and the isolation layer is made of a material different from that used to make the terminal body. The invention also provides a cold-shrinkable cable terminal and a method for terminating cables. Since the isolation layer of the composite gap filling rubber is made of a material different from that of the terminal body, it can avoid direct contact between the filling layer and the terminal body made of silicone rubber material, effectively preventing the swelling of the filling layer on the terminal body and causing terminal failure. The reduction of physical properties of the body eliminates the risk of cracking of the terminal body.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Screen shaft with self-lubricating mechanism and method thereof

ActiveCN109236842BExtended maintenance cycleImprove adsorption capacityDigital data processing detailsShaftsFriction weldingSand blasting

The invention discloses a screen shaft with a self lubricating mechanism and a processing method thereof. The screen shaft comprises a first shaft body, a second shaft body, a third shaft body and twoguide rings, wherein one end of the first shaft body is connected with one end of the second shaft body through one guide ring; the other end of the second shaft body is connected with the third shaft body through the other guide ring; the two guide rings are used as the contact position parts of the screen shaft and the external connection component; a self lubricating mechanism is arranged in each of the two guide rings; through the self lubricating mechanism, the slidable performance is maintained by of the outer side of the guide ring is maintained; an oil guide wire is formed by windingfive identical cotton wires; the oil guide wire forms self drainage on of the lubricating oil in the an oil storage groove. The processing method of the screen shaft uses the sand blasting and multi-time heat treatment; so that the ideal performance can be reached; meanwhile, the shaft body and the guide ring uses friction welding; , so that the energy consumption is low; , the welding performanceis good; and the connecting surface appearance is attractive; the installed oil guide wire performs long effect self lubrication on the guide rings; , so that the maintenance period of the screen shaft is increased to a great degree.

Owner:安徽俊康泰电子科技有限公司

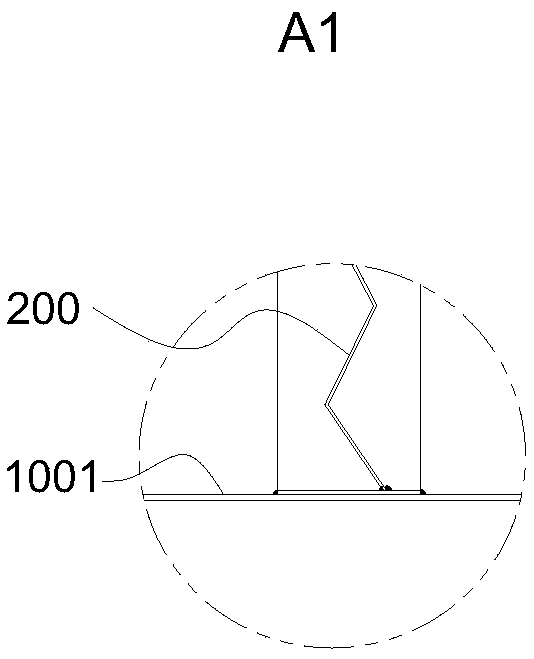

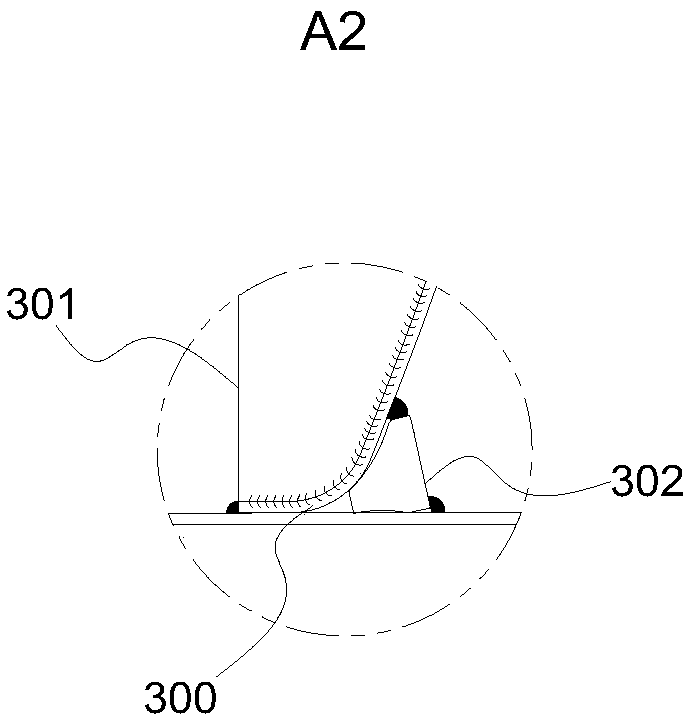

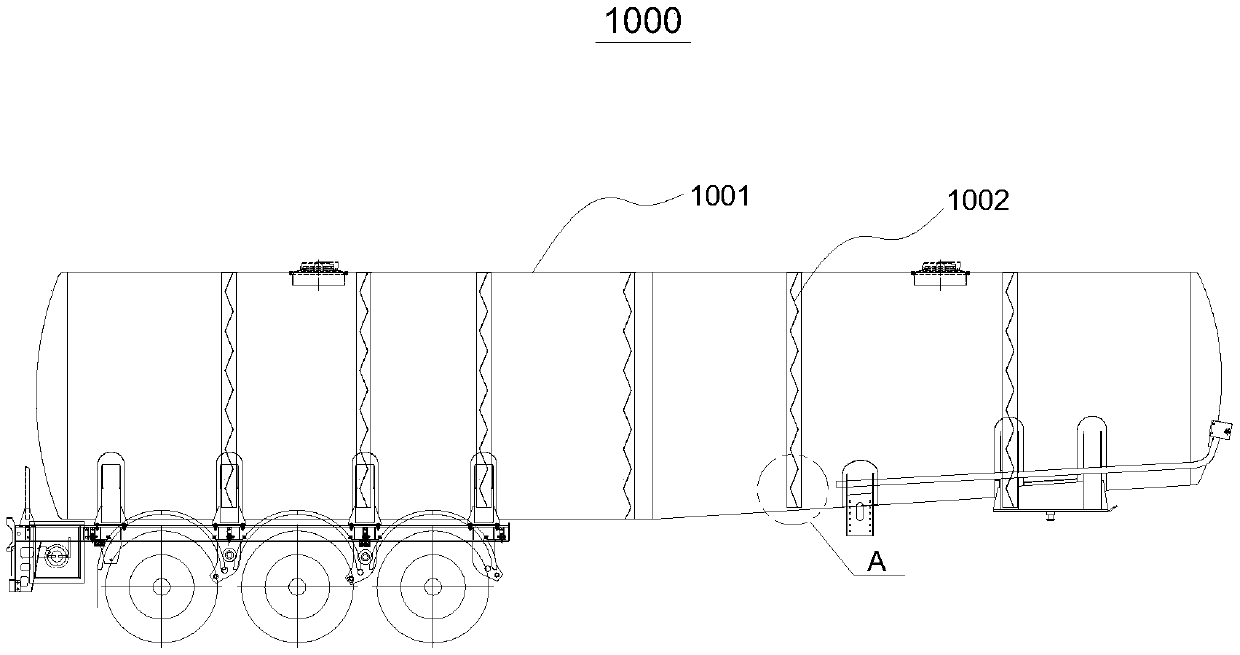

Liquid tank truck and anti-wave plate assembly thereof

PendingCN111099193AImprove the state of stressImprove economic efficiency and product qualityLarge containersBuffer tankStructural engineering

The invention provides a liquid tank truck and an anti-wave plate assembly thereof, and relates to the technical field of liquid tank transport vehicles. The anti-wave plate assembly is transversely mounted inside a tank body of the liquid tank truck, and the anti-wave plate assembly comprises connecting structures and an anti-wave plate substrate. Each connecting structure comprises a connectingmain body and an extension piece integrally formed on the connecting main body. The connecting main body is in an arc shape and comprises an outer convex part and an inner concave part, wherein the outer convex part and the inner concave part are positioned on the two sides. The outer convex part is attached to the inner wall of the tank body in a surrounding manner along the surface extending with the arc contour of the outer convex part. The extension piece comprises an integrally formed base part extending from the inner concave part and a connecting part extending from the end of the basepart in a bending manner. The connecting part is correspondingly connected with the periphery of the anti-wave plate substrate, so that the anti-wave plate substrate is fixedly connected with the inner wall of the tank body. The anti-wave plate assembly is simple in structure and high in strength; and the anti-wave plate assembly has the advantages of being capable of supporting the whole tank body and buffering the liquid wave impact in the tank.

Owner:中集车辆(江门市)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com