Reverse operating construction method for pouring monolithic track bed in separated tunnel of metro section

A technology of integral ballast bed and construction method, applied in the directions of roads, buildings, tracks, etc., can solve the problems of easy cracking of ballast concrete, slow construction progress, pollution on construction site, etc., so as to shorten the pumping distance, increase the load capacity, and reduce the construction The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The reverse construction method of integral ballast bed pouring in the separate tunnel of the subway section, a. Assemble the rail bar and hoist it on the rail transport vehicle, and then push the rail bar to the track laying work surface by the rail transport vehicle;

[0020] b. The rail row is gradually laid in place towards the far end of the tunnel by the track laying unit, and sand pillows 16 are laid at intervals below the sleepers 15 at positions corresponding to the rails 14 until the section is connected to form a longitudinal temporary rail transit logistics channel;

[0021] c. Set splints on both sides of the rail waist at the joint of any two rails 14, and use U-shaped clamps to fix them firmly;

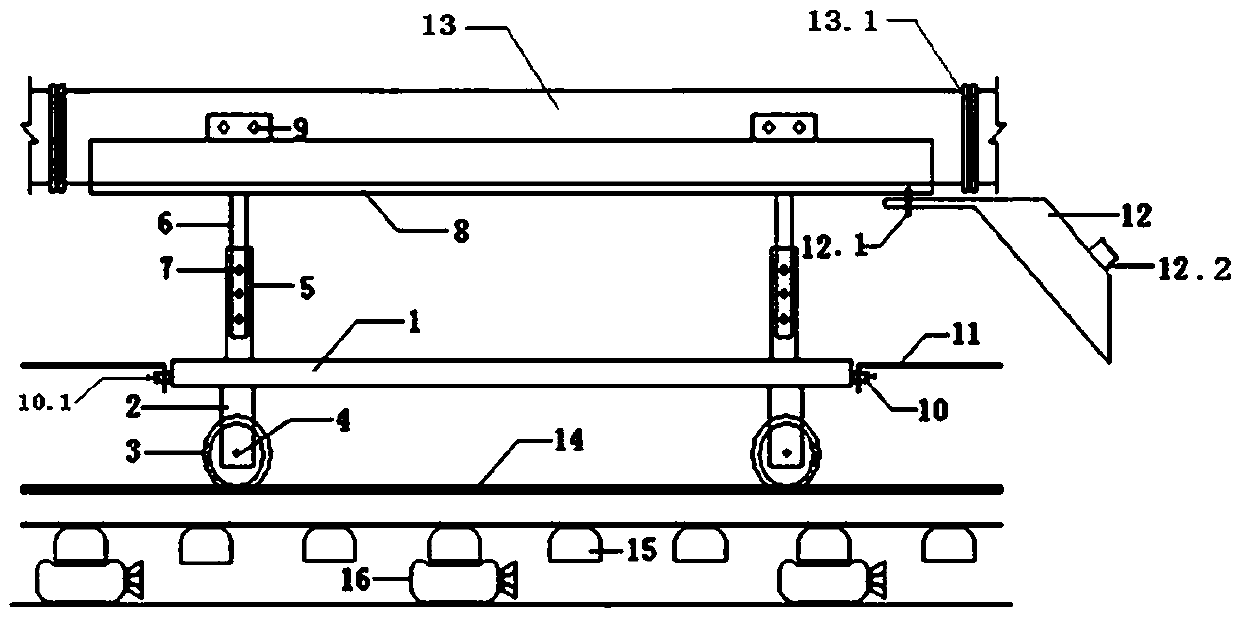

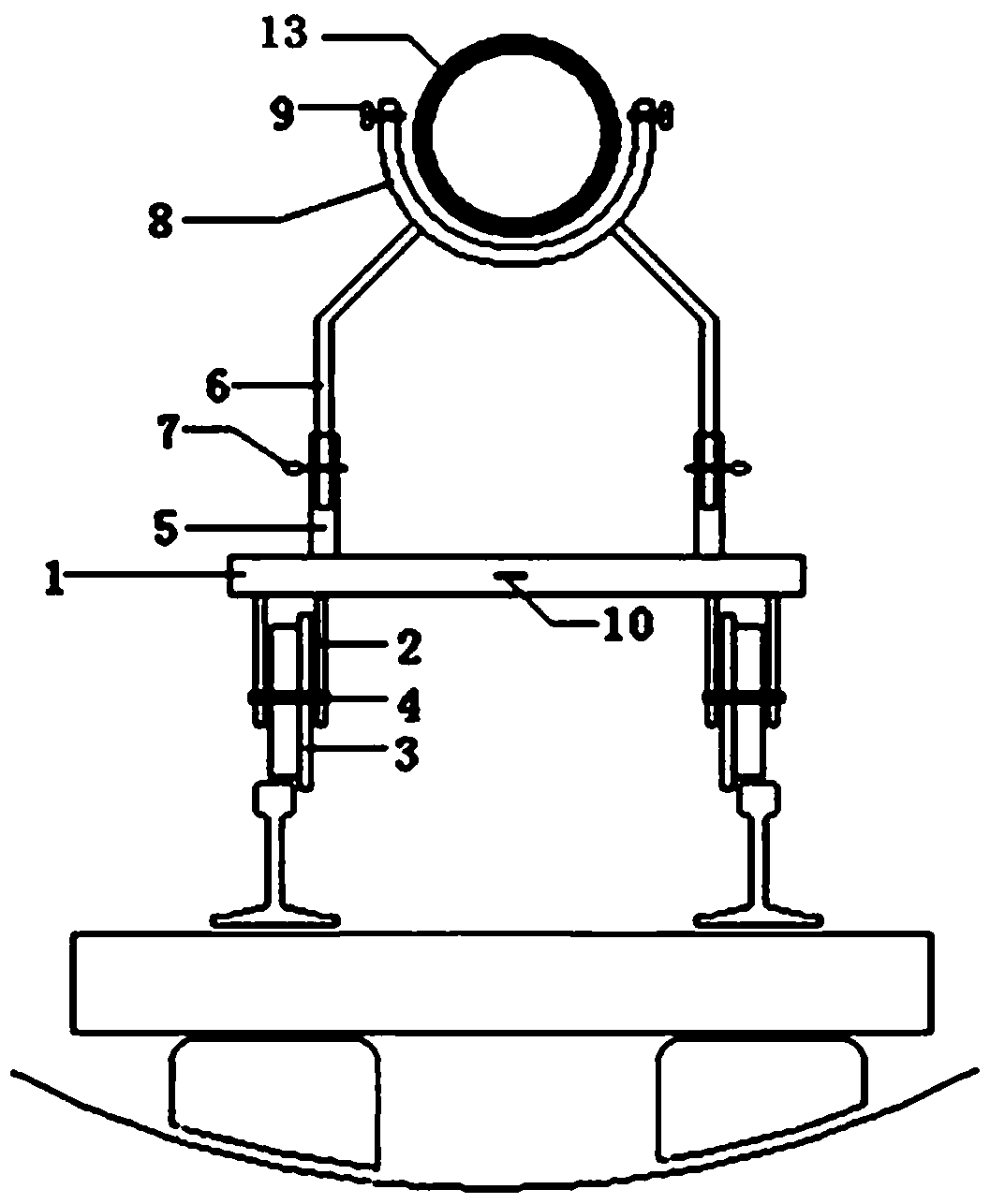

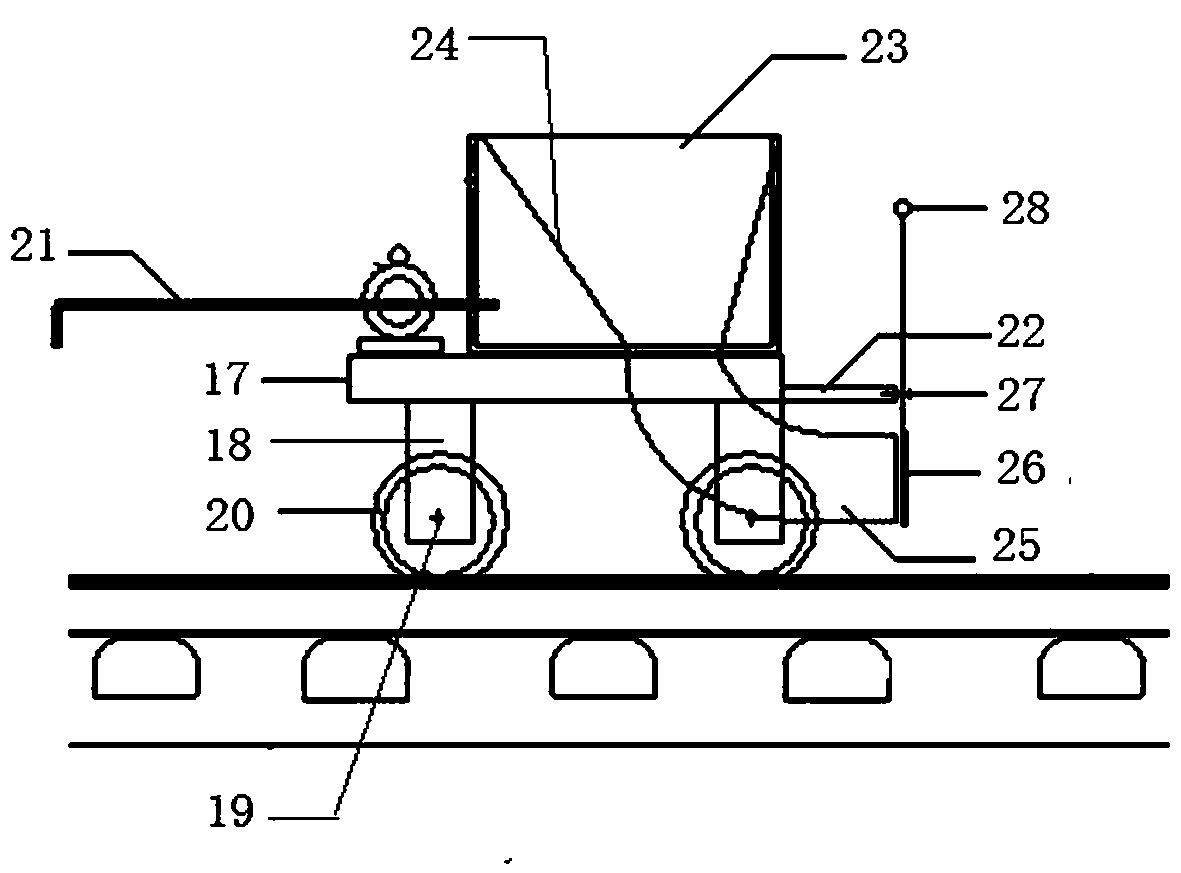

[0022] d. Make the rail-type concrete pump pipe bracket. The rail-type concrete pump pipe bracket is composed of several pump pipe bracket bodies. The pump pipe bracket body includes the frame 1, the left and right sides of the bottom end of the frame 1 The wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com