Patents

Literature

59results about How to "Reduce construction pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

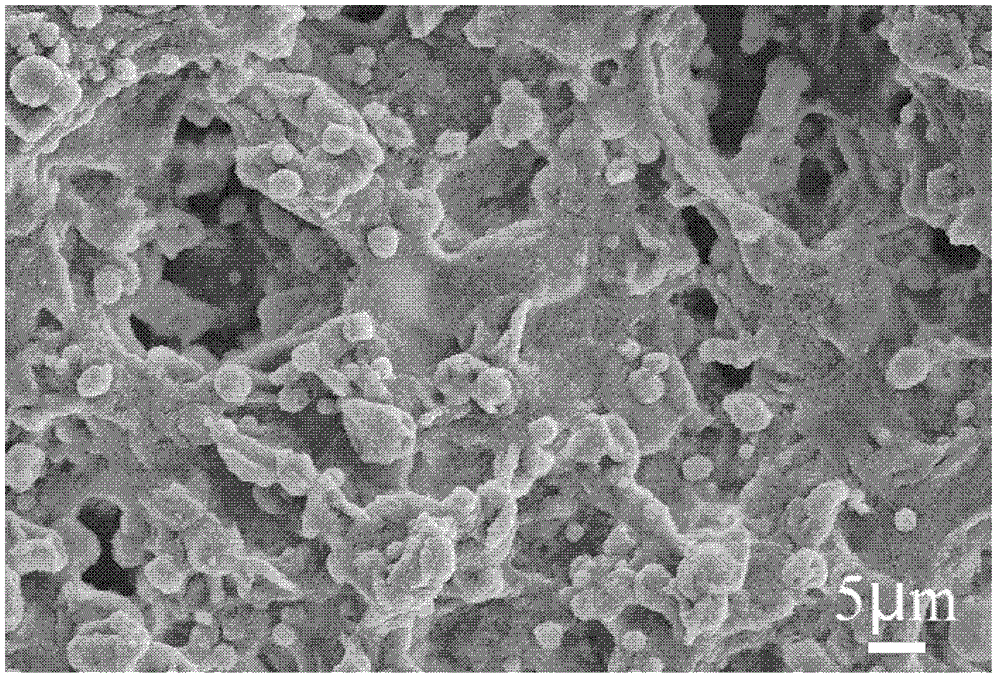

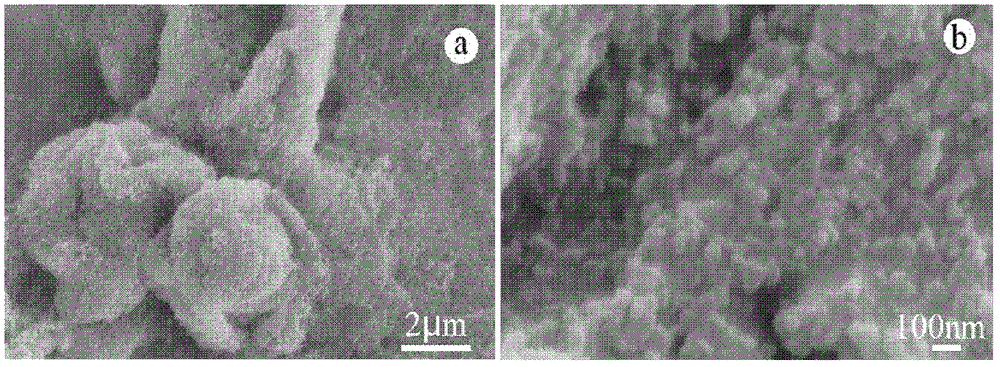

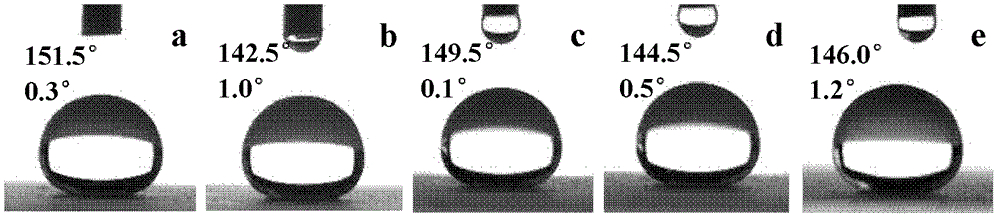

Super hydrophobic self-cleaning coating and preparation method thereof

The invention belongs to the technical field of preparation of nano materials, and in particular relates to a super hydrophobic self-cleaning coating and a preparation method thereof. The method comprises the following steps of: dispersing hydrophobic silicon resin and hydrophilic nano SiO2 particles into an organic solvent to obtain dispersion; and spraying the dispersion on a clean and dry glass sheet substrate, drying, and thus obtaining the super hydrophobic self-cleaning coating. The coating has a hierarchical structure compounded by using organic and inorganic components, namely the hydrophobic silicon resin and the hydrophilic nano SiO2 particles, and the structure has compound micro-nano surface topography; and the compound micro-nano hierarchical structure is constructed by spheroid-like protrusions with the diameters of 1 to 10 microns and agglomerate spheres with the diameters of 20 to 100 nanometers on the surface of the coating, wherein the spheroid-like protrusions are constructed by agglomerate spheres with the diameters of 20 to 100 nanometers. The contact angle between the coating and water is 140 to 155 degrees, and the rolling angles of water drops on the surface of the coating are less than 2 degrees.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

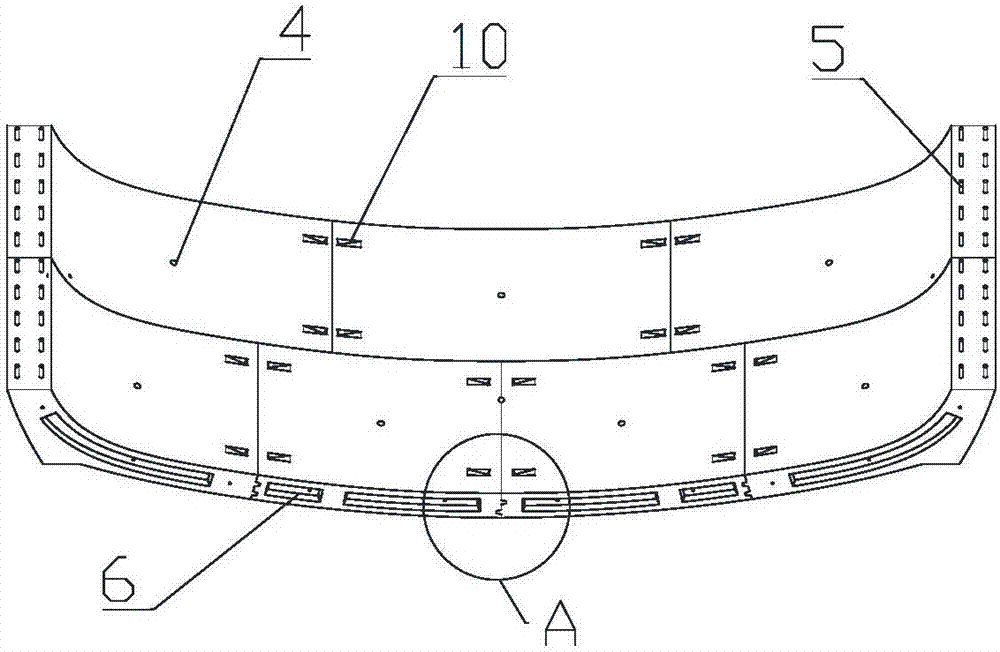

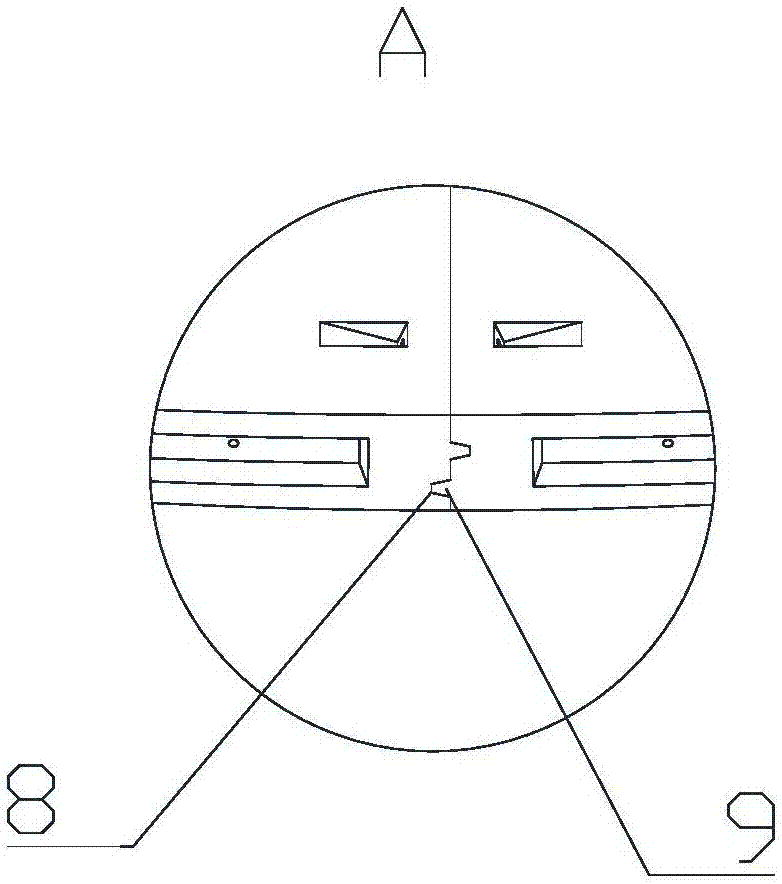

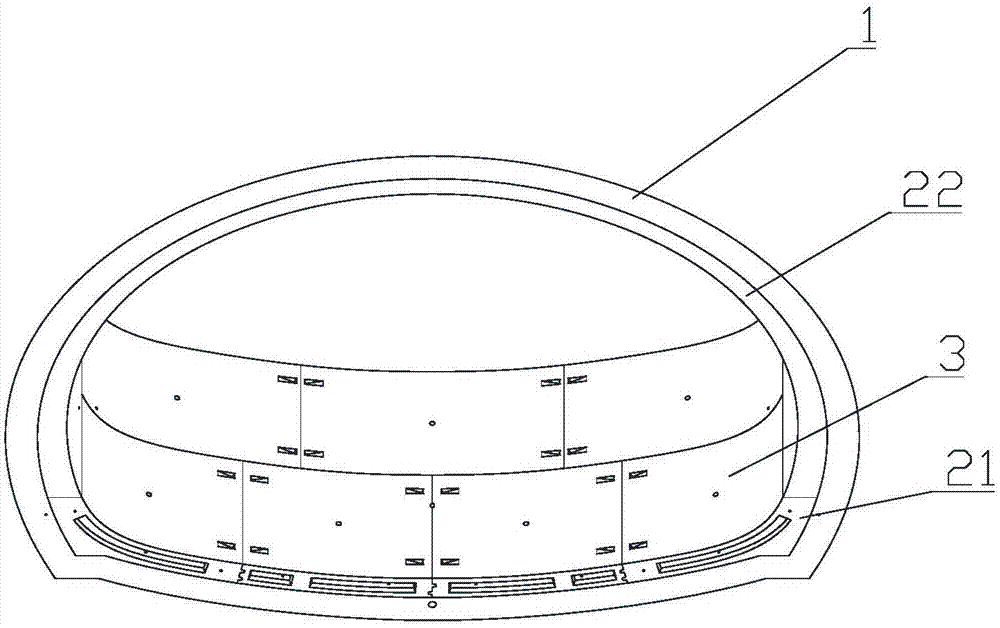

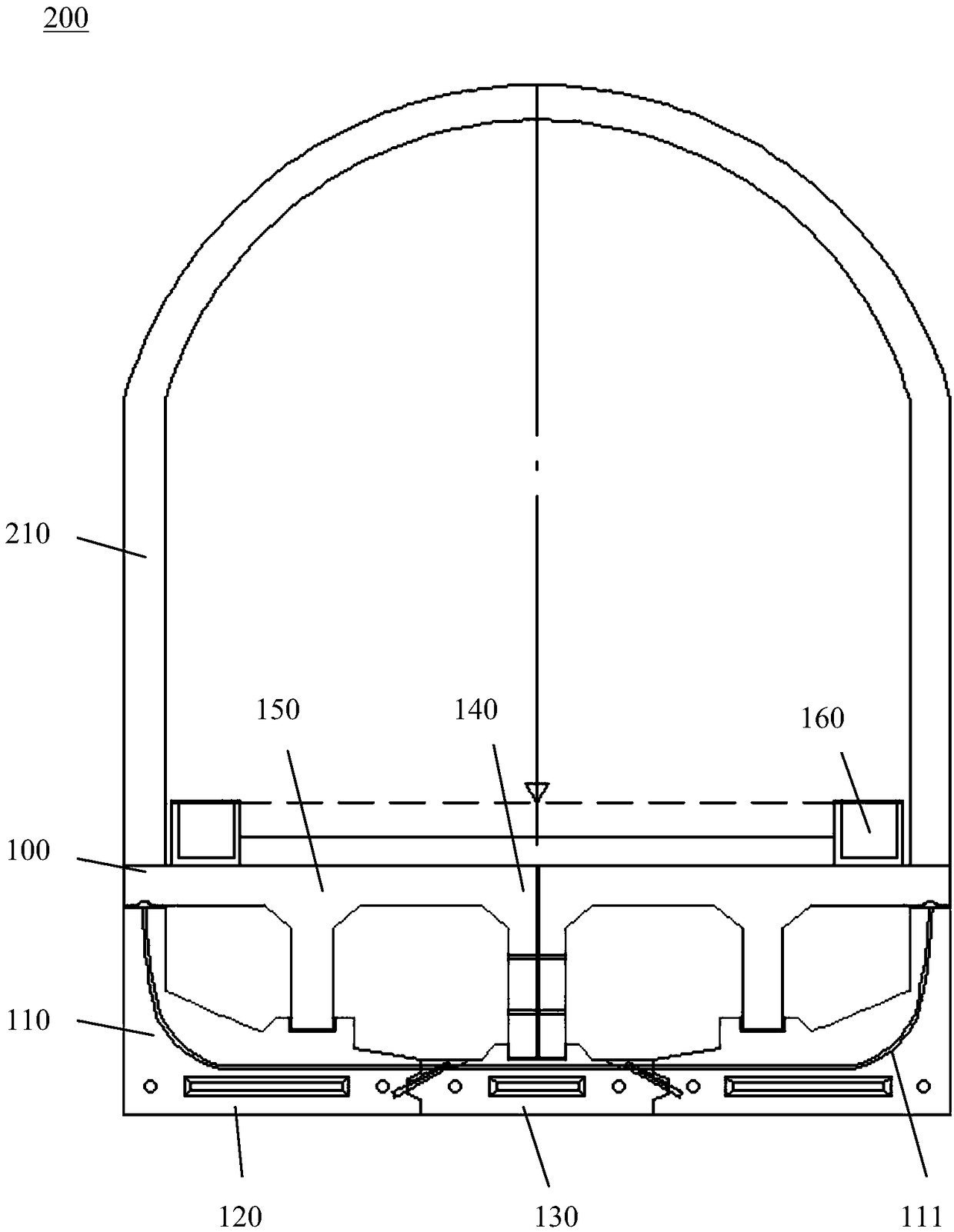

Prefabricated assembly type tunnel inverted arch, tunnel structure and construction method of tunnel structure

The invention relates to the technical field of tunnel engineering and discloses a prefabricated assembly type tunnel inverted arch. The prefabricated assembly type tunnel inverted arch comprises multiple rows of splicing units sequentially arranged in the extending direction of a tunnel. Each row of the splicing unit comprises multiple splicing blocks with arc-shaped cross sections. Joint seams of adjacent splicing blocks in the splicing units and joint seams of adjacent splicing blocks in the adjacent splicing units are staggered. Connecting rebars connected with a tunnel arch wall are reserved at the tops of the outer side faces of the prefabricated blocks on the two sides of each row of the splicing unit. In the building process of the prefabricated assembly type tunnel inverted arch and a trench structure, the prefabricated assembly type tunnel inverted arch has the beneficial effects that the resource energy is saved, the construction pollution is reduced, the labor production efficiency is improved, the labor intensity of workers is lowered, and the quality safety level is increased; and the potential hazards that the stress of the tunnel is not uniform, the deformation is likely to generate and the cracking is likely to generate can be prevented. The invention further discloses a tunnel structure with the prefabricated assembly type tunnel inverted arch and a construction method of the tunnel structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

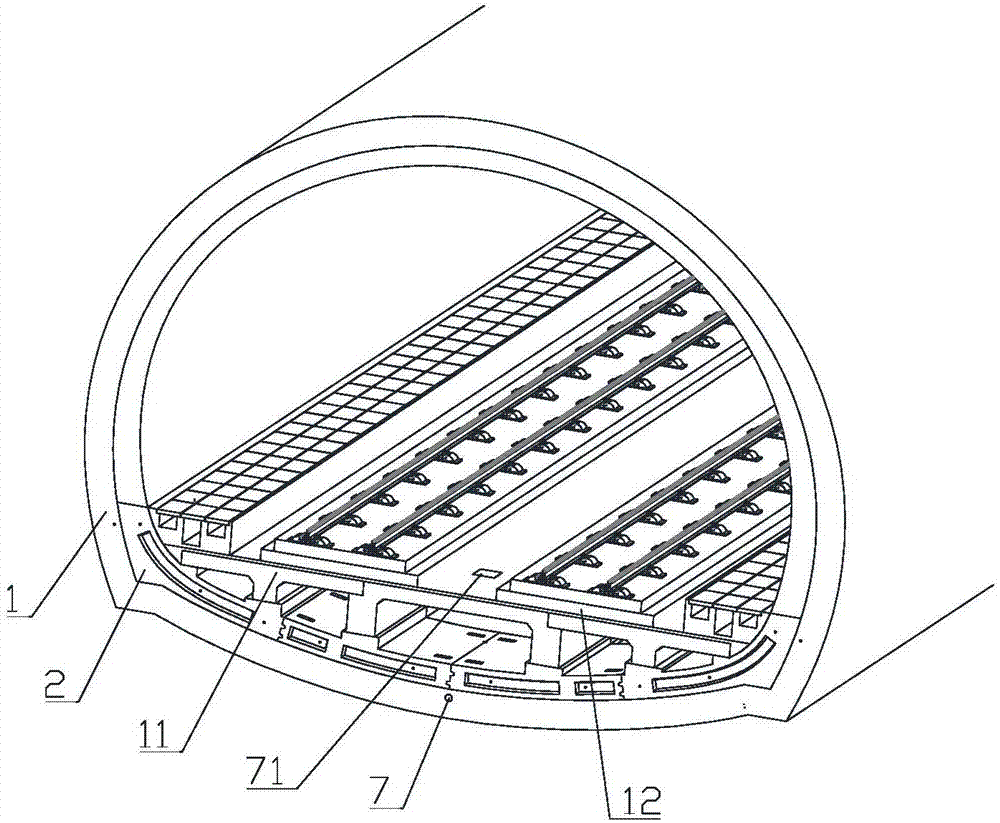

Tunnel bottom prefabricated assembly type tunnel structure and construction method thereof

PendingCN107387117ASimple structureReduce construction costsUnderground chambersTunnel liningDisease injuryBuilding construction

The invention relates to the technical field of tunnel engineering and discloses a tunnel bottom prefabricated assembly type tunnel structure. The tunnel bottom prefabricated assembly type tunnel structure comprises a primary support, a secondary lining, a drainage system and a filling layer. Six protrusions are arranged on the secondary lining, and the six protrusions are arranged at intervals in the transverse direction of a tunnel. Each protrusion extends in the extending direction of the tunnel. A box type plate prefabricated block and two T type plate prefabricated blocks located on the two sides of the box type plate prefabricated plate and connected with the box type plate prefabricated block are adopted for the filling layer. The box type plate prefabricated block comprises a top plate, a left vertical plate and a right vertical plate, wherein the left vertical plate and the right vertical plate are arranged on the two sides of the lower portion of the top plate. The left vertical plate, the right vertical plate, vertical plates of the two T type plate prefabricated blocks and the ends, away from the box type plate prefabricated block, of the two T type plate prefabricated blocks are correspondingly and fixedly connected with the six protrusions. By the adoption of the tunnel structure, the diseases of the delamination, cracking, bottom bulging, sinking, mud pumping and the like of the tunnel foundation can be solved effectively, the construction pollution is reduced, and the labor production efficiency is improved. The invention further discloses a construction method of the tunnel structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

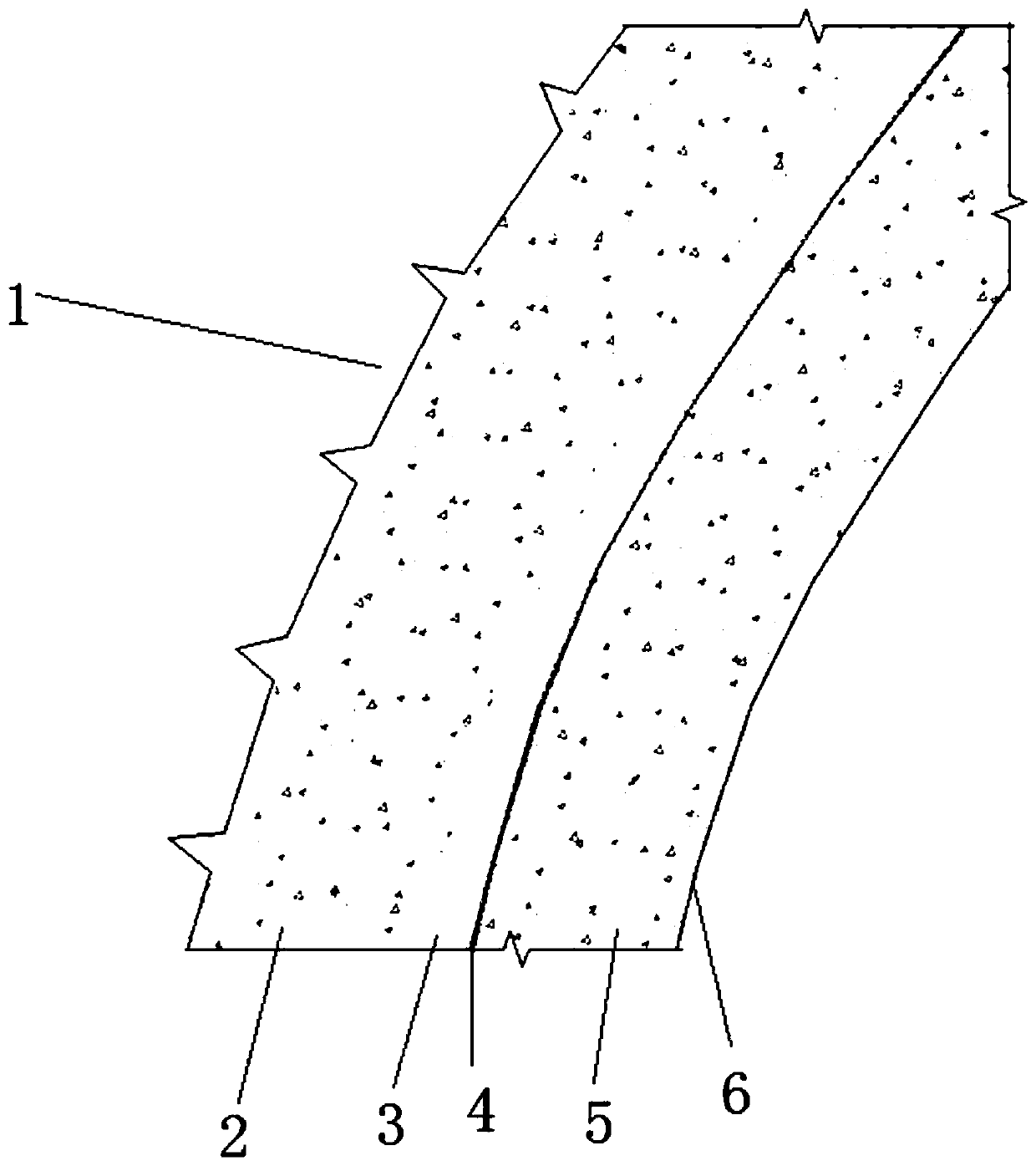

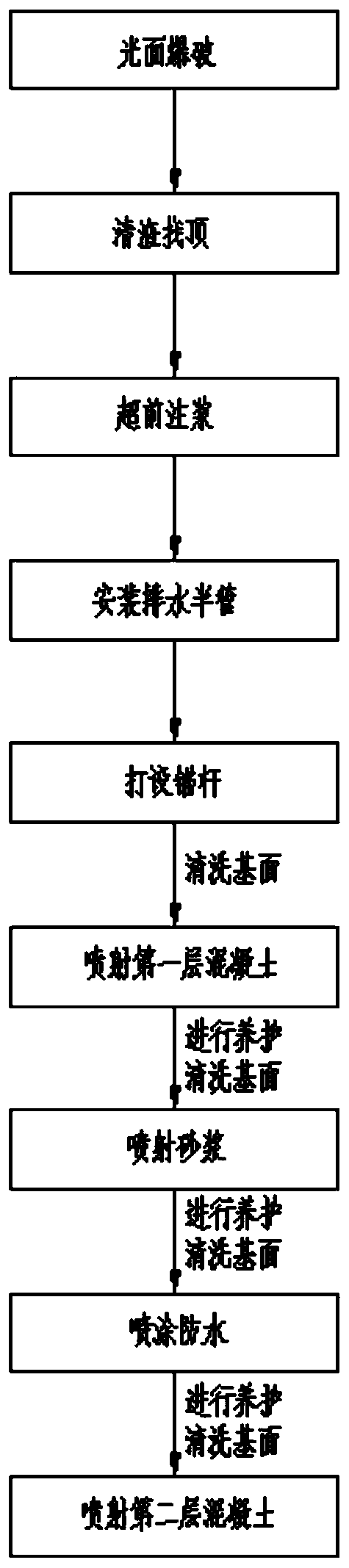

Waterproof type single-layer lining structure applicable to fourth level surrounding rock double-line track and manufacturing method thereof

ActiveCN110359915AEven by forceSimple construction processUnderground chambersTunnel liningFiberRock bolt

The invention discloses a waterproof type single-layer lining structure applicable to a fourth level surrounding rock double-line track. The waterproof type single-layer lining structure applicable tothe fourth level surrounding rock double-line track comprises fourth-level surrounding rocks subjected to smooth blasting treatment and further comprises omega-shaped spring drainage half pipes and anchored rods arranged in the fourth-level surrounding rocks in a struck manner. The anchored rods are perpendicular to the rock surfaces of the fourth-level surrounding rocks. The rock surfaces of thefourth-level surrounding rocks are further subjected to washing, injection of a first layer crude fiber concrete and curing, injection of mortar and curing, spraying of a waterproof material and curing, ejection of a second layer fine fiber concrete and curing in sequence. According to the waterproof type single-layer lining structure applicable to the fourth level surrounding rock double-track tunnel involved, force bearing of the single-layer lining structure formed by the technology is uniform; the structure has certain deformation resistant capacity; the construction technology is simple;the construction period is short; construction pollution is reduced; the structure is low-carbon and environment-friendly and widely applied to projects of fourth-level surrounding rock double-tracktunnel lining structures.

Owner:中铁科学研究院有限公司

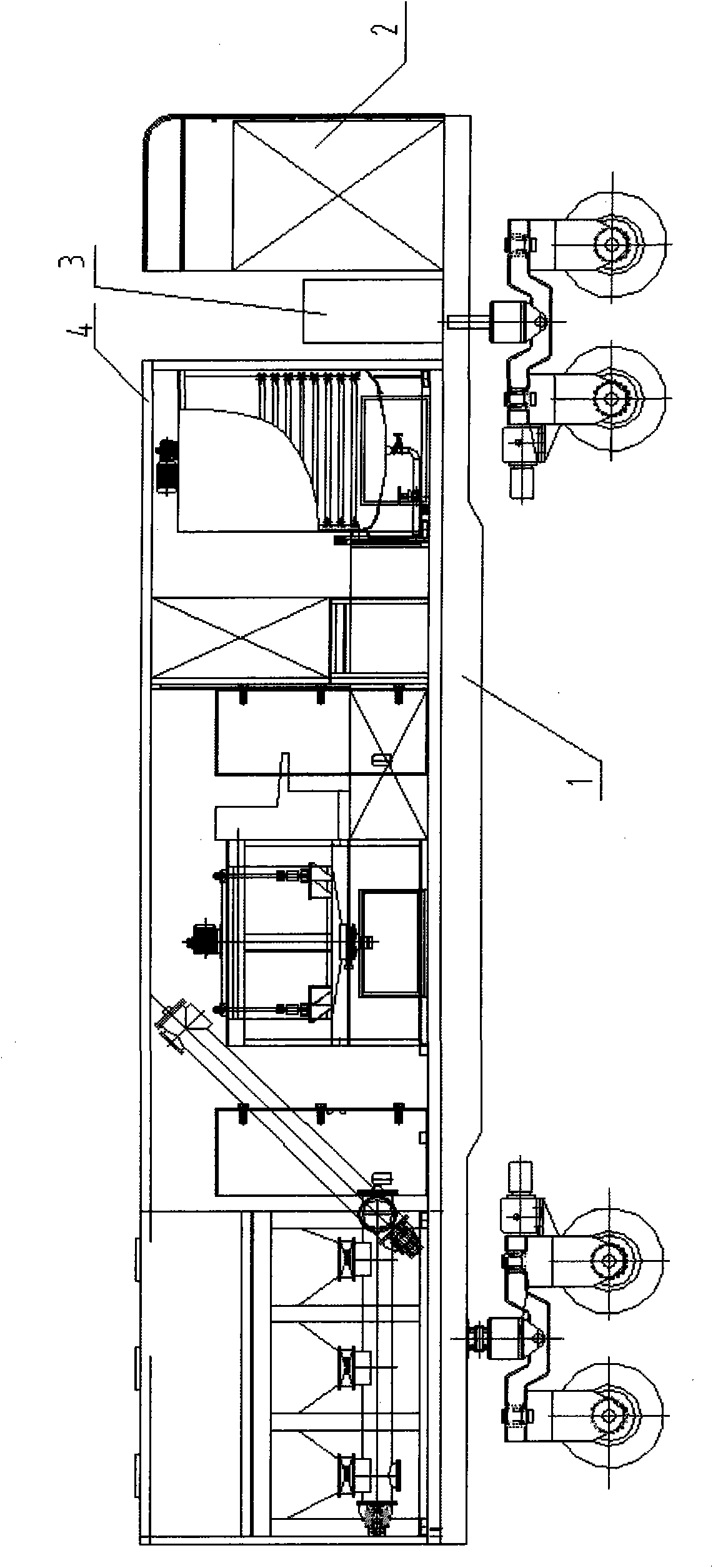

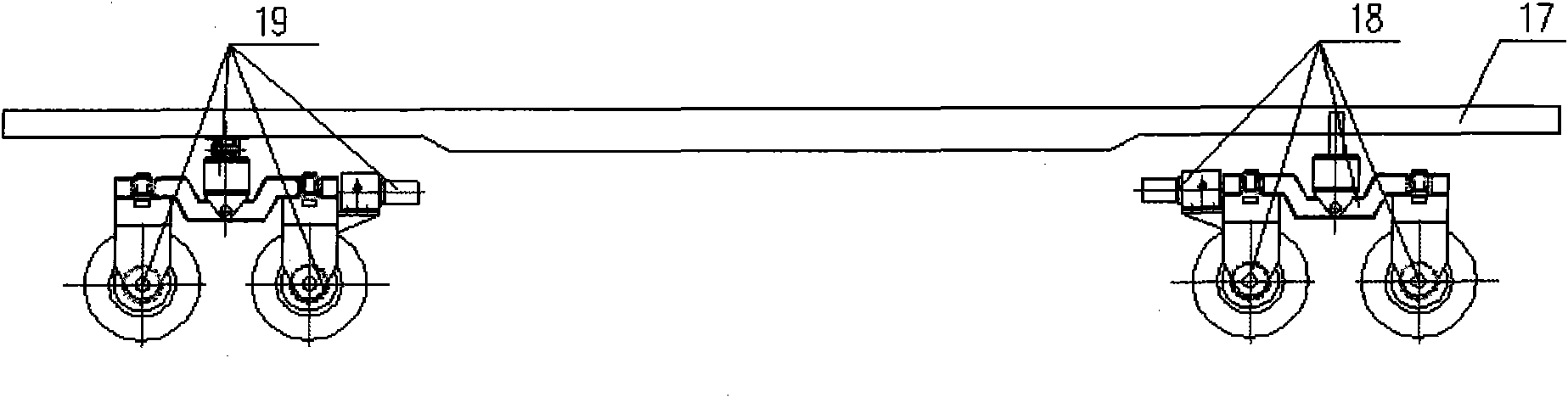

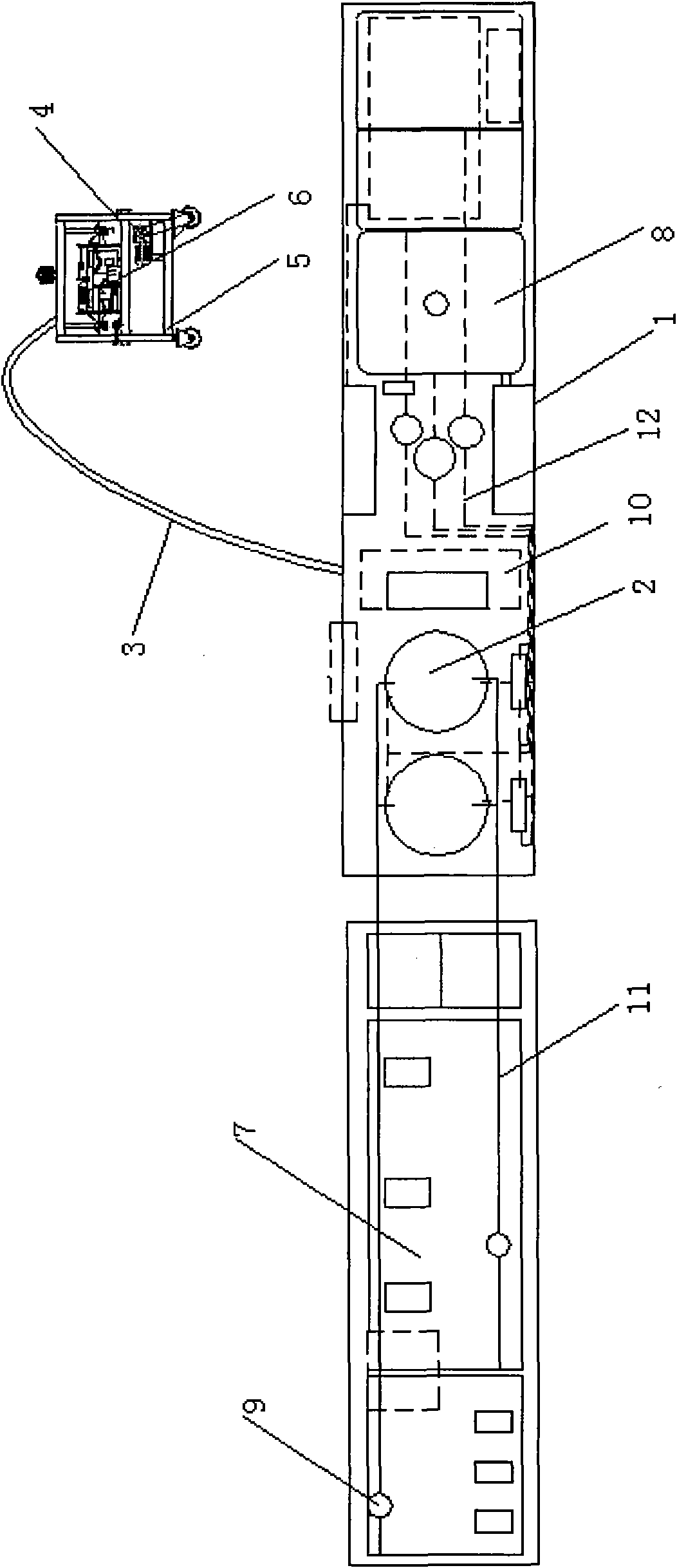

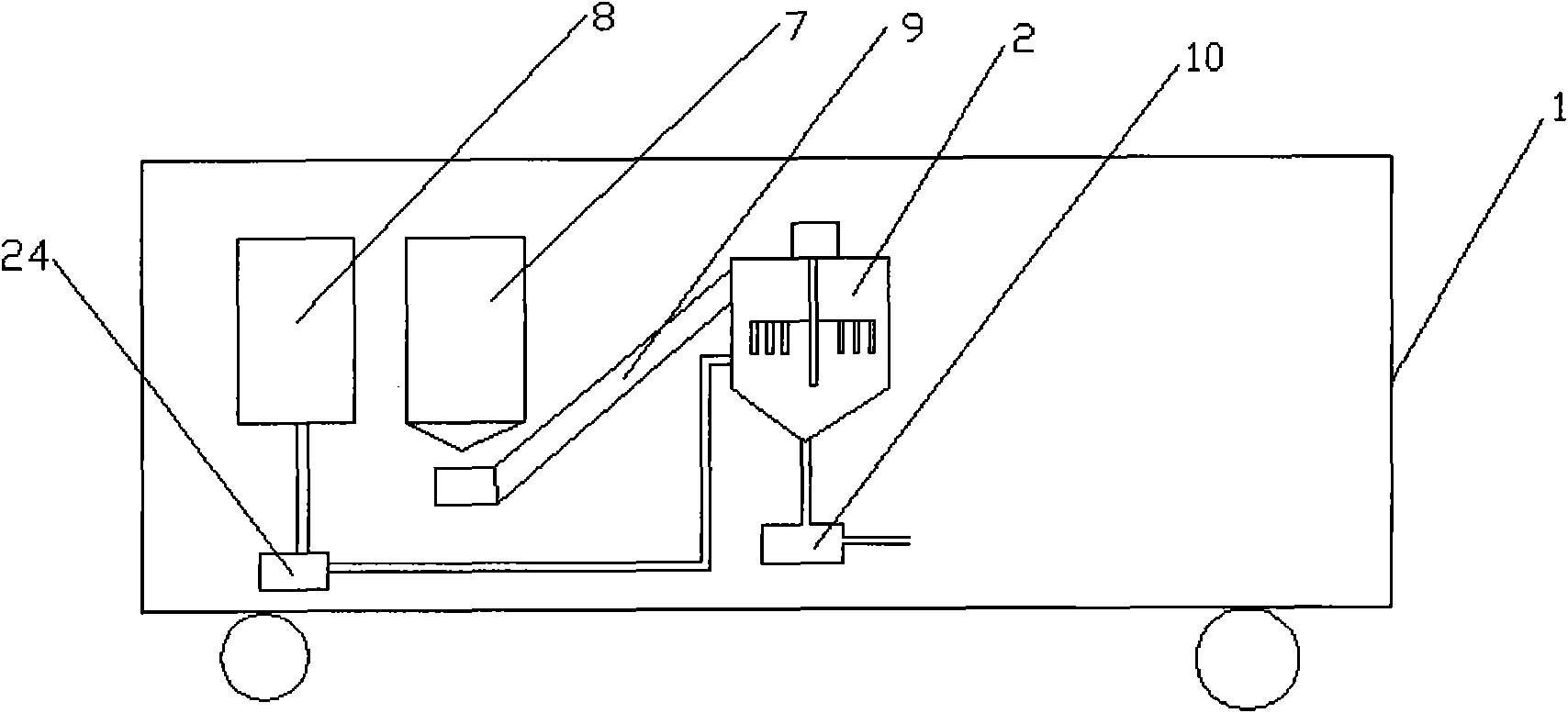

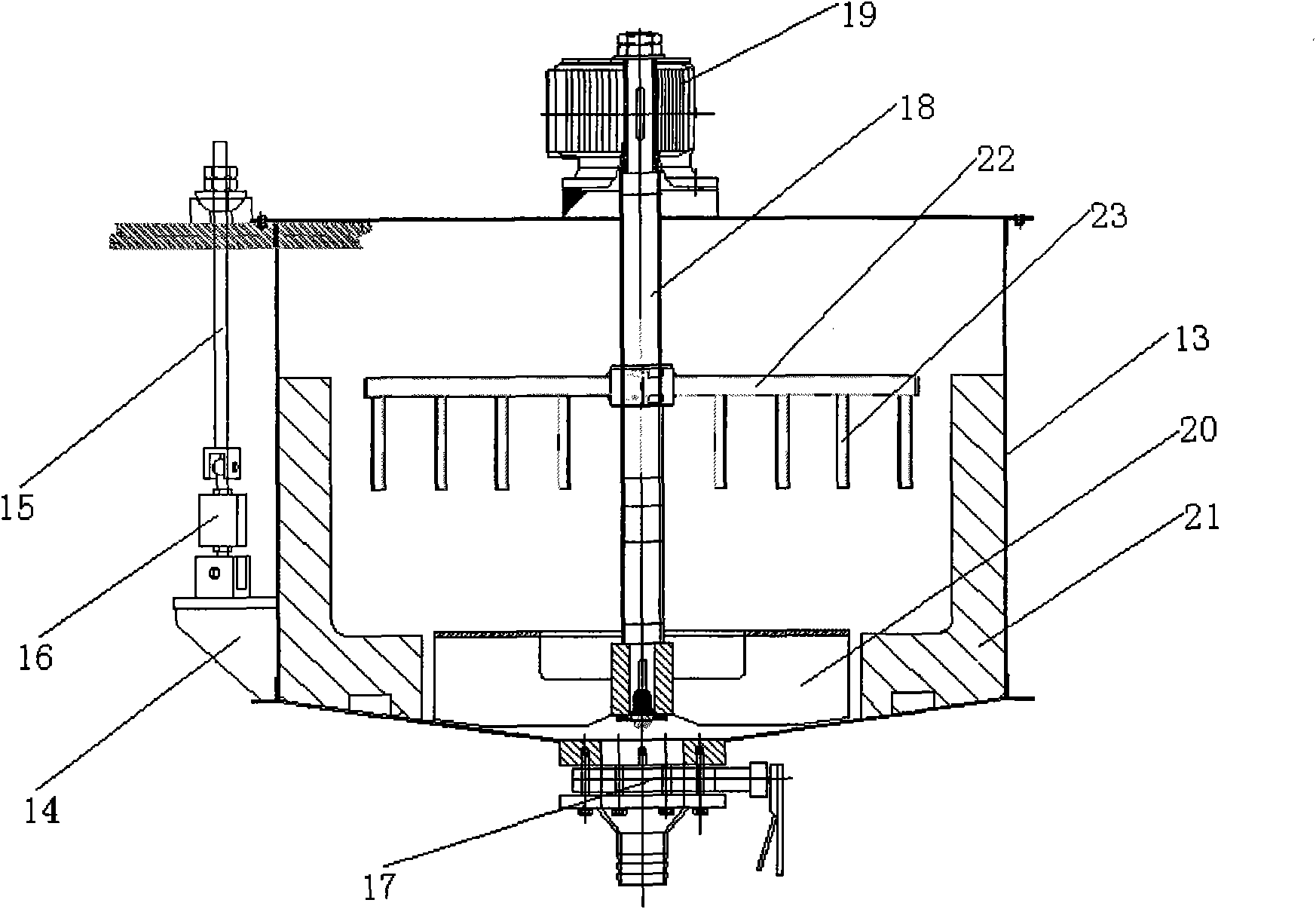

Tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle

InactiveCN101913203ALess auxiliary equipmentAutomated control of construction productionCement mixing apparatusAutomatic controlEngineering

The invention discloses a tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle which comprises a special chassis and a vehicle-mounted container framework, wherein the special chassis comprises a traveling system and can carry out online traveling or inter-plate traveling, and the spacing interval between traveling tire groups is adjustable; a stirring tank is arranged in the vehicle-mounted container framework, and a liquid material and dry material supply system is connected at the outside of the stirring tank; and the liquid material and dry material supply system comprises a dry powder bin and a liquid material storage tank, and the dry powder bin is connected into a cylindrical tank body of the stirring tank through a screw conveyor. The tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle adopts the tire type online or inter-plate traveling way, the design of the large-capacity bin and the material storage tank and high and low elastic modulus cement-emulsified asphalt mortar universal formula program software for realizing the arbitrary adjustment of a mortar formula, thereby automatically controlling the material mixing process, the loading process and the metering process, improving the construction efficiency, saving the production cost, leading the production quality of mortar to meet the requirements on construction technical conditions and leading the construction process to realize energy conservation and environmental protection.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

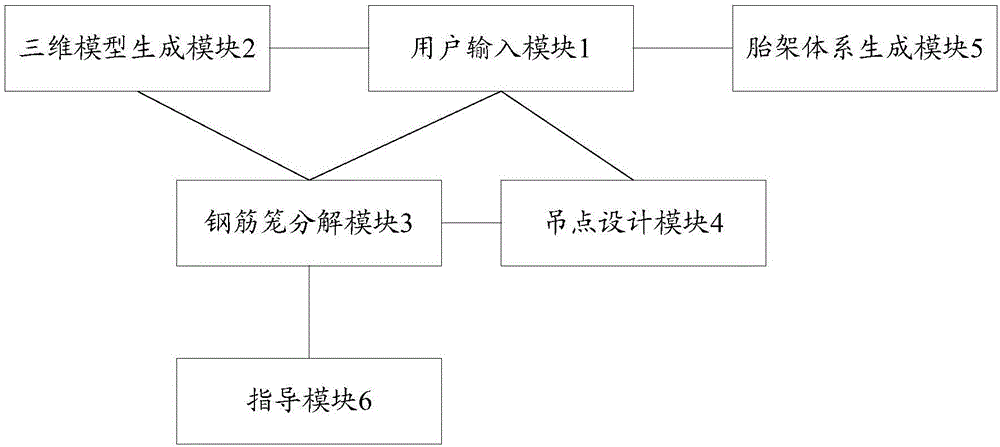

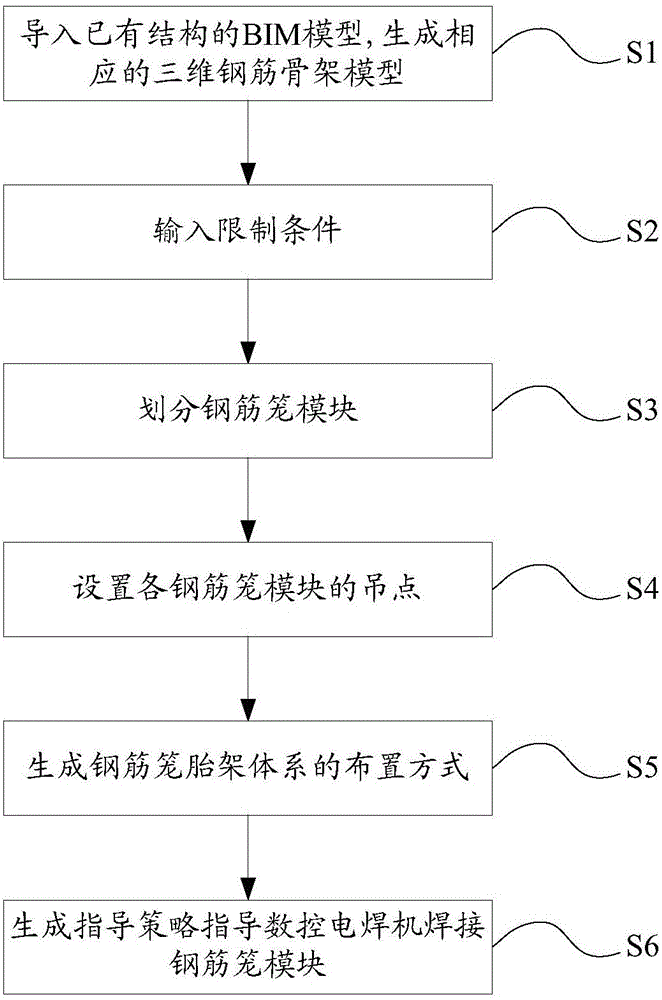

Prefabricated reinforcement cage modular decomposition system and method

ActiveCN106649989AIncrease the level of mechanizationAchieve standardizationGeometric CADConstraint-based CADDecompositionUser input

The invention discloses a prefabricated reinforcement cage modular decomposition system and method. The system comprises a user input module, a three-dimensional model generating module, a reinforcement cage decomposition module, a suspension centre design module, a bed-jig system generating module and a guidance module. A BIM model with an existing structure and limiting conditions are input and led through the user input module, a corresponding three-dimensional reinforcement skeleton model is generated through the three-dimensional model generating module according to the led BIM module, the three-dimensional reinforcement skeleton model is divided into reinforcement cage modules which meet the limiting conditions through the reinforcement cage decomposition module, the suspension centre of each reinforcement cage module is set and a suspension centre reinforcing scheme is given through the suspension centre design module according to lifting equipment, an arrangement form of a reinforcement cage bed-jig system is generated through the bed-jig system generating module, and a guiding strategy which guides a digital controlled electric welding machine to weld the reinforcement cage modules is generated through the guidance module. According to the prefabricated reinforcement cage modular decomposition system and method, the three-dimensional reinforcement skeleton model is divided into multiple reinforcement cage modules, the construction efficiency is improved, and the construction pollution is reduced.

Owner:SHANGHAI NO 7 CONSTR

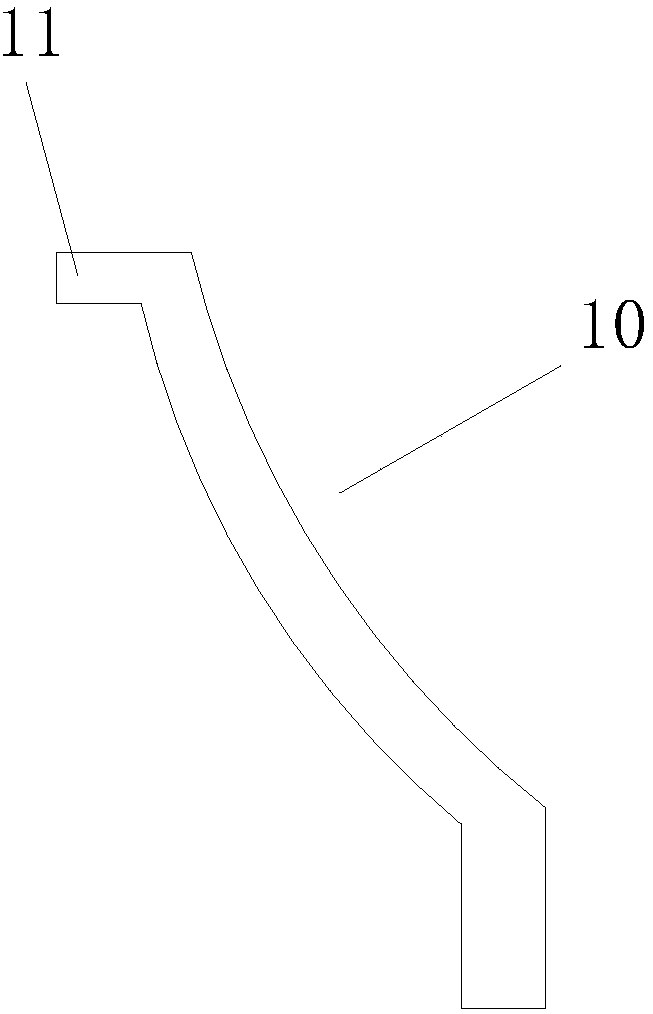

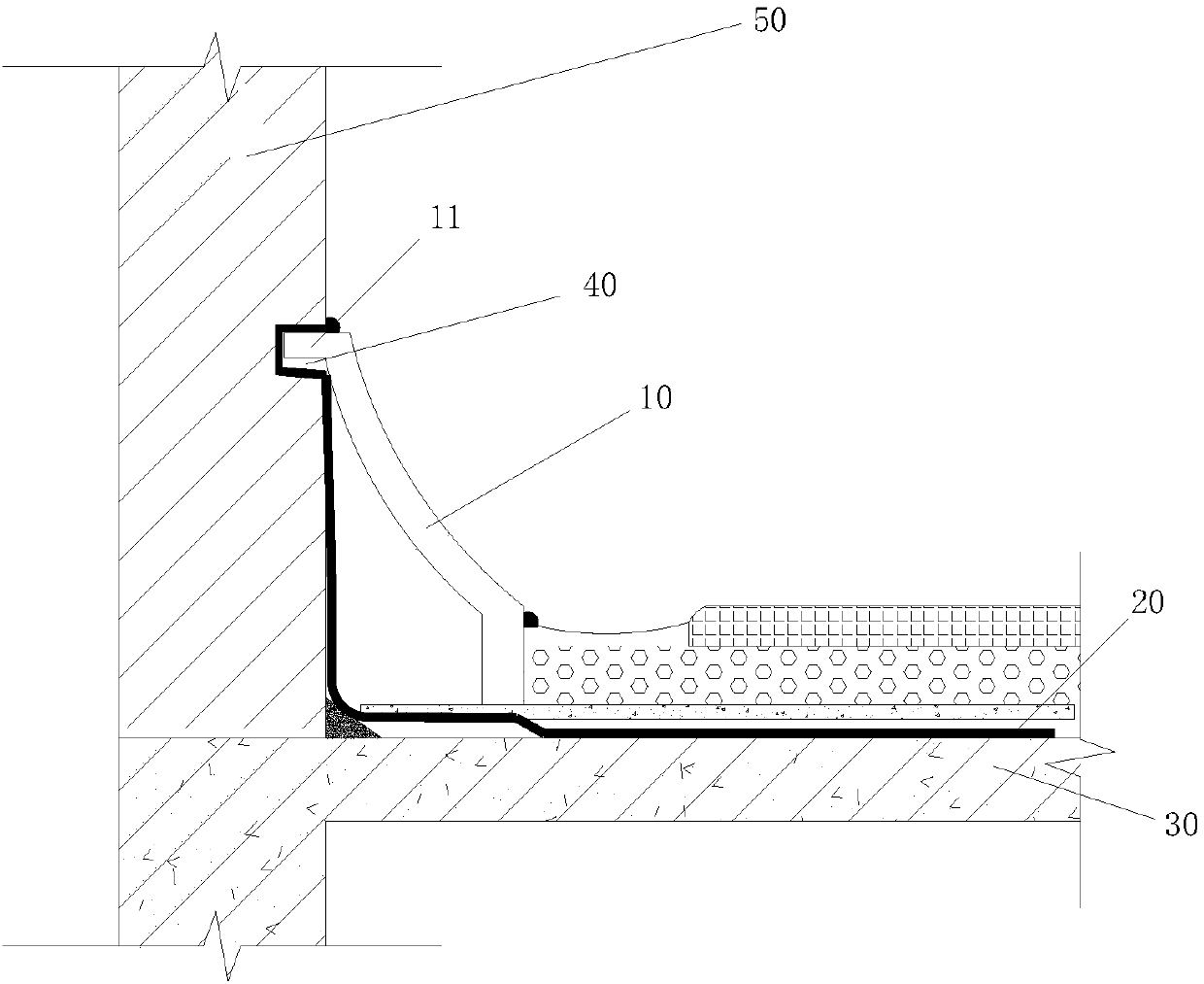

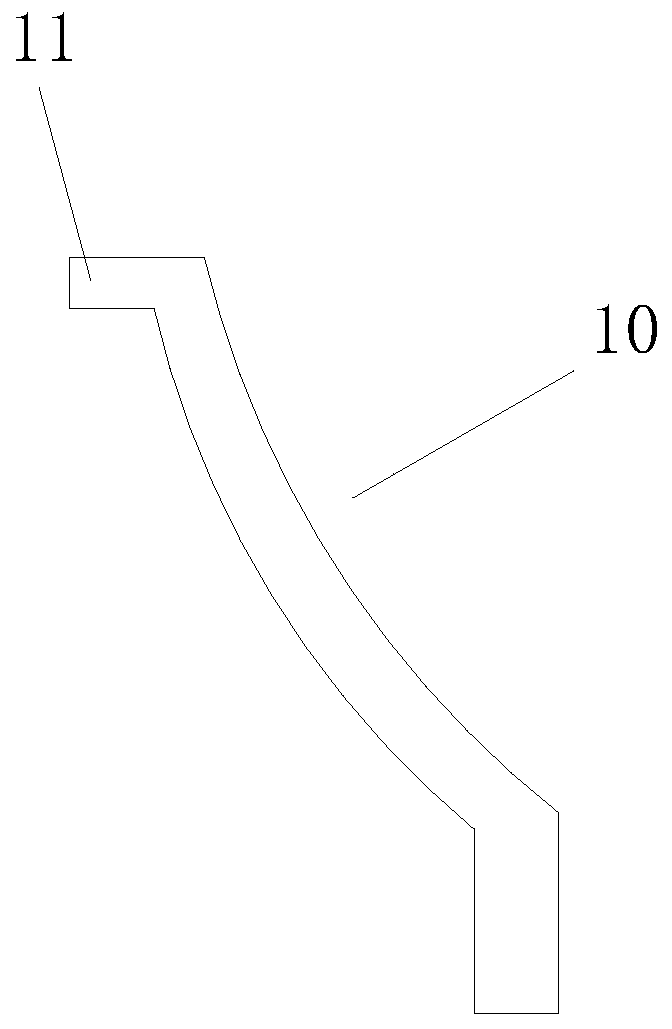

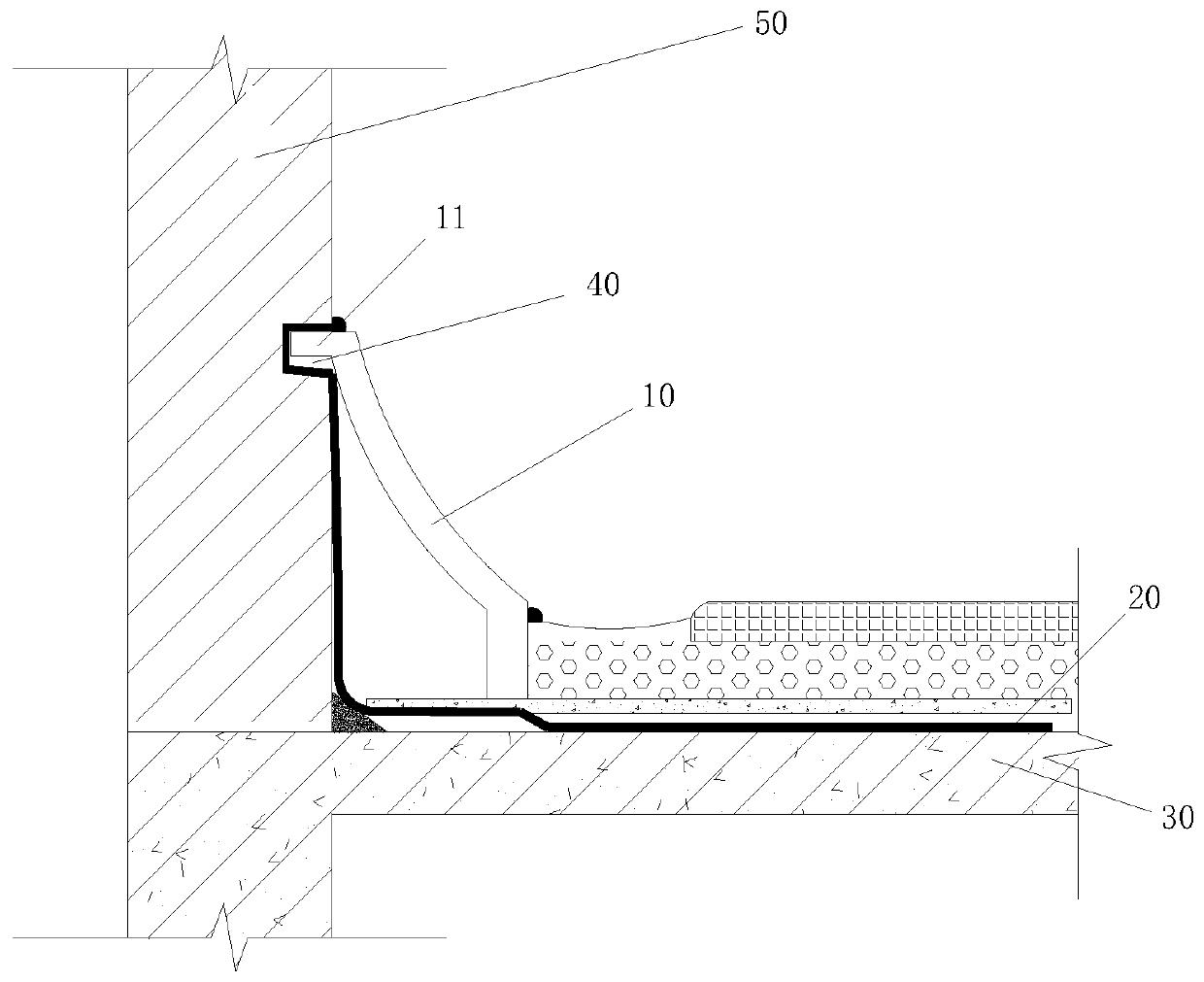

Constructing method for flashing structure of parapet wall

ActiveCN107558671AFast pre-productionConstruction quality is easy to controlRoof drainageRoof covering insulationsWater leakageSurface layer

The invention provides a constructing method for a flashing structure of a parapet wall. The constructing method comprises the construction steps of prefabricating flashing members, installing the flashing members, filling and compacting between the adjacent flashing members, coating a waterproof coating material and the like. The constructing method adopts a mode of prefabricating the flashing members, rapid pre-production of the flashing members is realized, the construction efficiency is improved, construction quality of the flashing members is convenient to control, and processing workshopconcentrated machining forming is achieved; construction pollution can be effectively reduced, construction materials are saved, and construction waste is reduced; phenomena of cracking and hollowingon the surfaces of the prefabricated flashing members cannot happen, and common technical problems are overcome; by using air permeability between the prefabricated members and a waterproof layer, the effect of heat resistance of the prefabricated members is good, deformation of the waterproof layer caused by water temperature changes is reduced, falling-off and water leakage of the waterproof layer can be effectively prevented, and the waterproof service life is prolonged; and the prefabricated flashing structure has a better appearance effect, the flashing height, width and radian are consistent, a later waterproof coating surface layer cannot fall off, and the long-term aesthetic effect can be achieved.

Owner:坤发建筑有限公司

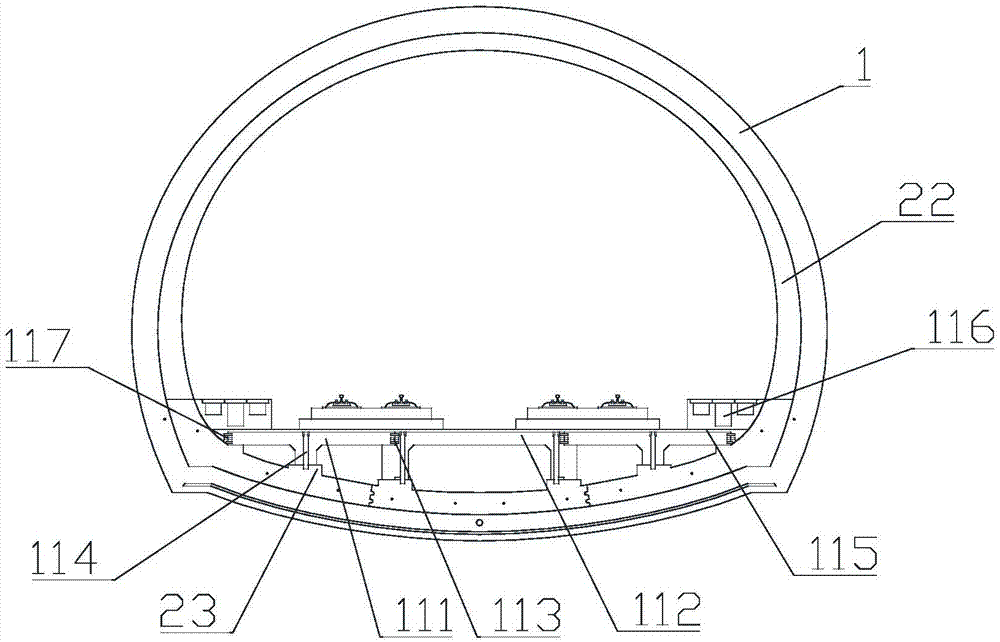

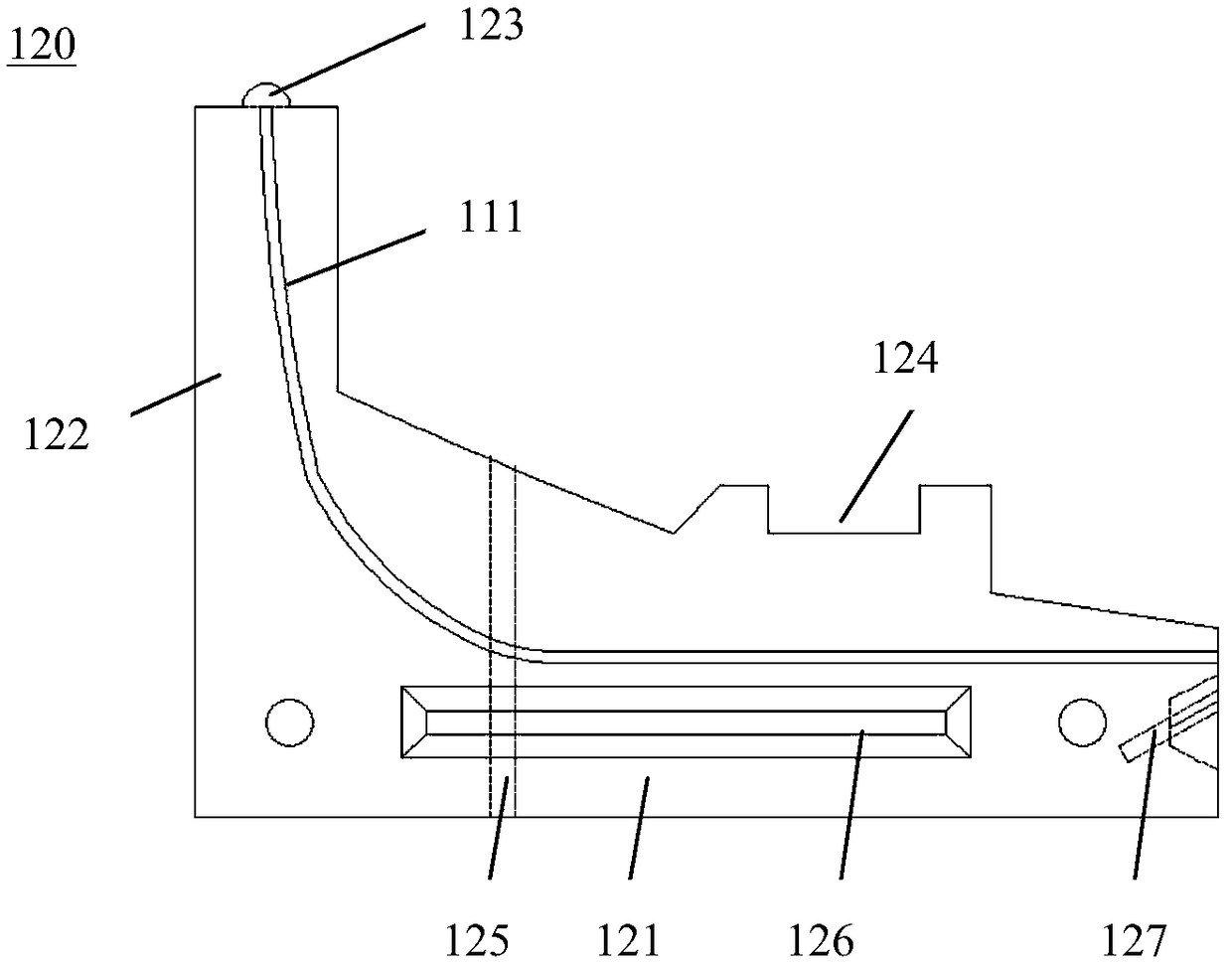

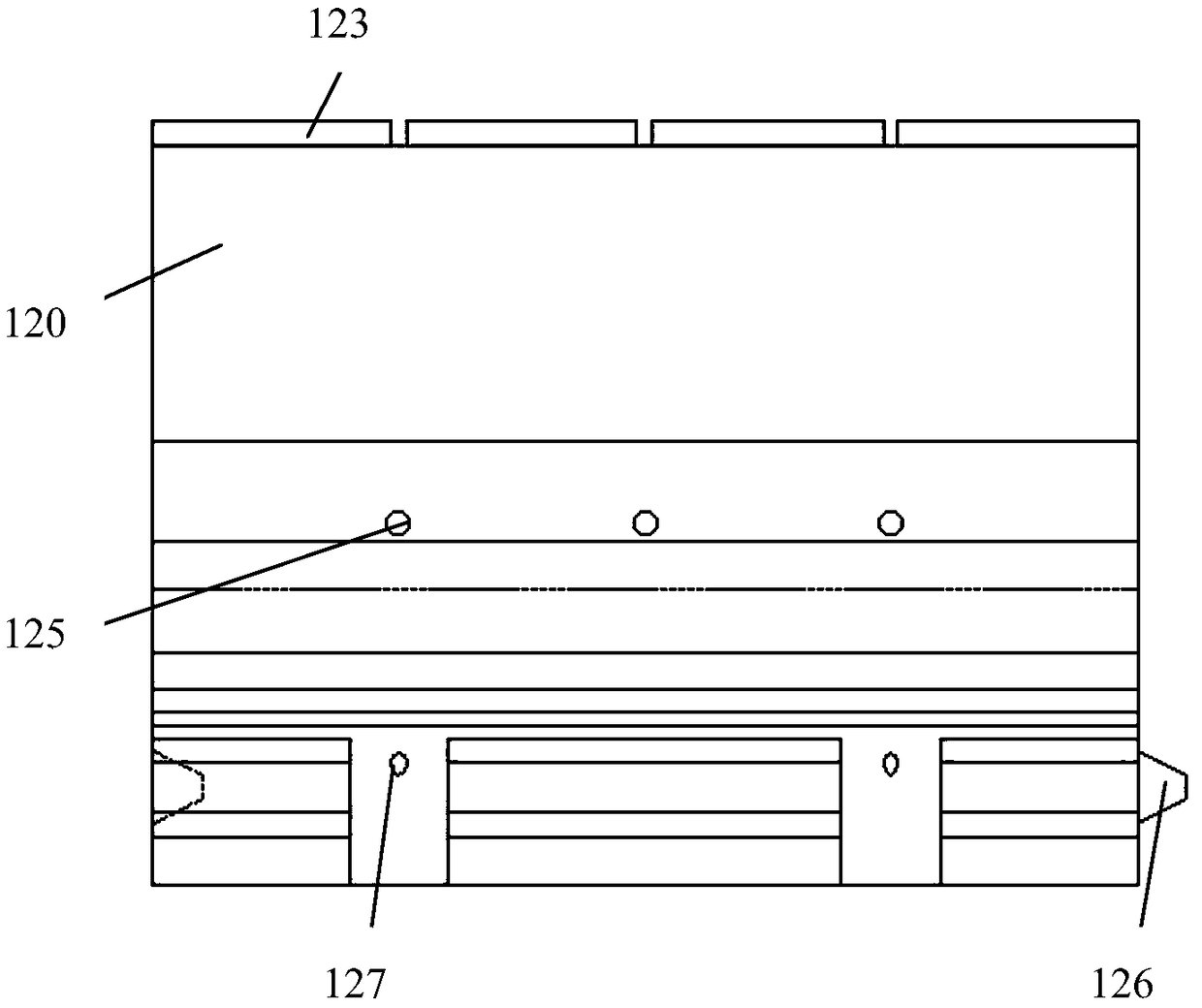

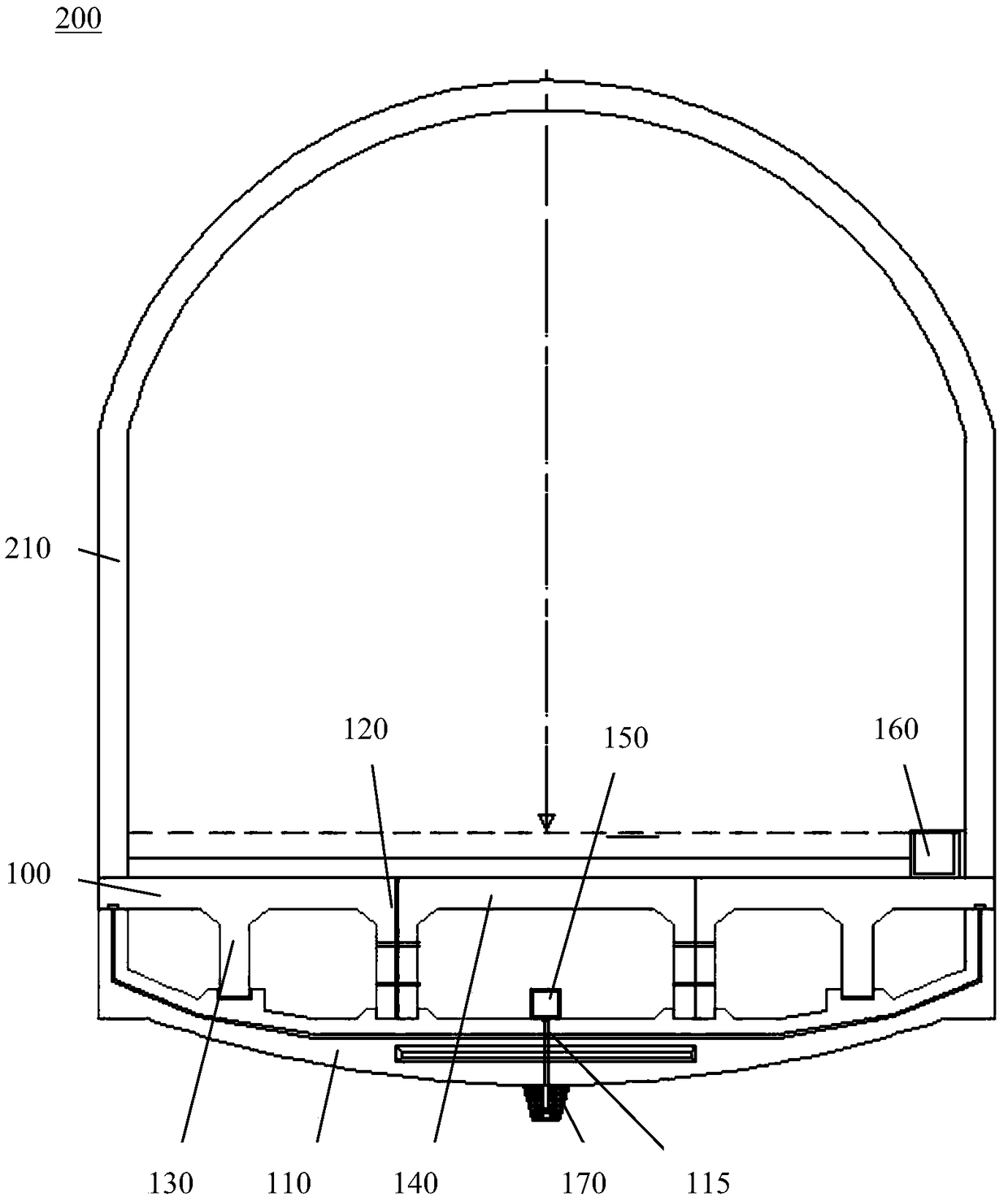

Tunnel base and a construction method thereof

The invention provides a tunnel base. The tunnel base comprises: an inverted arch bottom layer arranged at the bottom of the tunnel; the inverted arch bottom layer comprises two first inverted arch prefabricated blocks arranged in a mirror image at the bottom of the tunnel; and a second inverted arch prefabricated block assembled between the two first inverted arch prefabricated blocks; and a second inverted arch prefabricated block assembled between the first inverted arch prefabricated blocks. A prefabricated filling layer installed on the upper part of the inverted arch bottom layer, wherein the prefabricated filling layer comprises two F-shaped prefabricated blocks respectively connected with the bottom of the arch walls on both sides of the tunnel and arranged in a mirror image; Wherein the prefabricated filling layer is adapted to be installed with the inverted arch bottom layer, and the inverted arch bottom layer and the prefabricated filling layer are continuously arranged along the longitudinal direction of the tunnel bottom to form a tunnel base.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Tunnel base and method for constructing same

PendingCN109252874AStable supportEasy maintenanceUnderground chambersTunnel liningStructural engineeringMirror image

The invention provides a tunnel base which comprises inverted arch prefabricated blocks and prefabricated filled layers. The inverted arch prefabricated blocks are arranged at the bottom of a tunnel;the prefabricated filled layers are mounted on the upper portions of the inverted arch prefabricated blocks, each prefabricated filled layer comprises two F-shaped prefabricated blocks and an n-shapedprefabricated block, the F-shaped prefabricated blocks of each prefabricated filled layer are connected with the bottoms of arch walls on two sides of the tunnel and are in mirror image arrangement,and each n-shaped prefabricated block is arranged between the two corresponding F-shaped prefabricated blocks in a fixedly connected manner; the prefabricated filled layers are mounted with the inverted arch prefabricated blocks in a matched manner, and the inverted arch prefabricated blocks and the prefabricated filled layers are longitudinally continuously arranged along the bottom of the tunnelto form the tunnel base.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

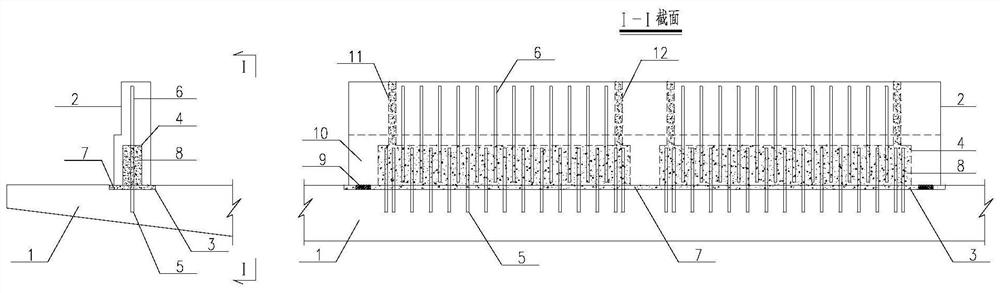

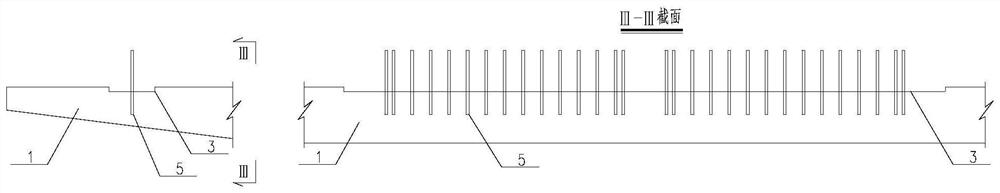

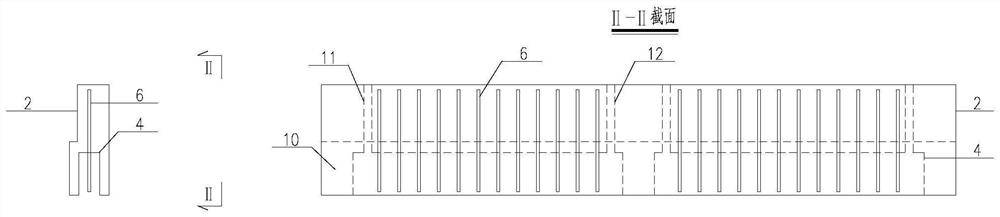

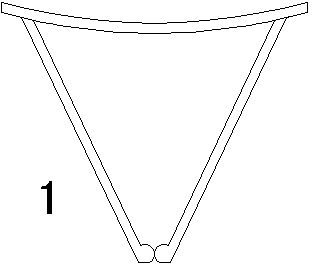

Rainwater channel with rain and dirt flow dividing function and construction method thereof

PendingCN108005218AComponent Quality AssuranceSave formworkFatty/oily/floating substances removal devicesSewerage structuresThin sheetPollution

The invention relates to the field of municipal engineering, in particular to a rainwater channel with a rain and dirt flow dividing function and a construction method thereof. The rainwater channel with the rain and dirt flow dividing function comprises a rainwater channel body, a flow dividing plate and a cover plate; the rainwater channel body is a trapezoid channel with the narrow bottom and the wide top, half spaces are arranged on the two sides of the inner wall of the rainwater channel body, the flow dividing plate is arranged on the half spaces, and the flow dividing plate is a hollowsheet; the hollow sheet is filled with filter balls; the cover plate is arranged on the top of the rainwater channel body, and a plurality of water inlets are formed in the cover plate; the rainwaterchannel body and the flow dividing sheet are prefabricated, the component quality is ensured, complex formwork erecting, maintaining and disassembling procedures on a construction site are omitted, construction pollution is lowered, and the rainwater channel has the advantages of being good in quality, saving time and being efficient, portable, environmentally friendly and the like.

Owner:NANCHANG UNIV

Prefabricated supporting pipe piece inverted 'T'-shaped excavation method and temporary supporting structure adopted by urban shallow buried large-section tunnel

PendingCN109681233AReduce one-time disturbance areaThe construction method is simpleUnderground chambersTunnel liningSocial benefitsEconomic benefits

The invention belongs to the technical field of urban underground engineering and particularly relates to a prefabricated supporting pipe piece inverted 'T'-shaped excavation method and a temporary supporting structure adopted by an urban shallow buried large-section tunnel. The temporary supporting structure comprises prefabricated temporary vertical supporting pipe pieces and temporary transverse supporting pipe pieces, wherein the middle partition wall of an upper left step is formed by splicing and erecting the temporary vertical supporting pipe pieces; an inverted arch of the upper left step is formed by splicing and erecting the temporary transverse supporting pipe pieces; an inverted arch of an upper right step is formed by splicing and erecting the temporary transverse supporting pipe pieces; and each temporary vertical supporting pipe piece is provided with a grouting hole. According to the prefabricated supporting pipe piece inverted 'T'-shaped excavation method and the temporary supporting structure adopted by the urban shallow buried large-section tunnel, the temporary supporting structure does not drop to the bottom by adopting temporary vertical supports, and the temporary vertical supports are closed with temporary transverse supports to form an innovative inverted 'T'-shaped excavation method; and an upper step is divided into the upper left step and the upper right step for two-step excavation, and an area of the one-time remolding to a tunnel face soil body is reduced. The construction method provided by the invention has the advantages of simple step, strong operability as well as remarkable economic benefit and social benefit and saves the land.

Owner:JINAN URBAN CONSTR GRP +2

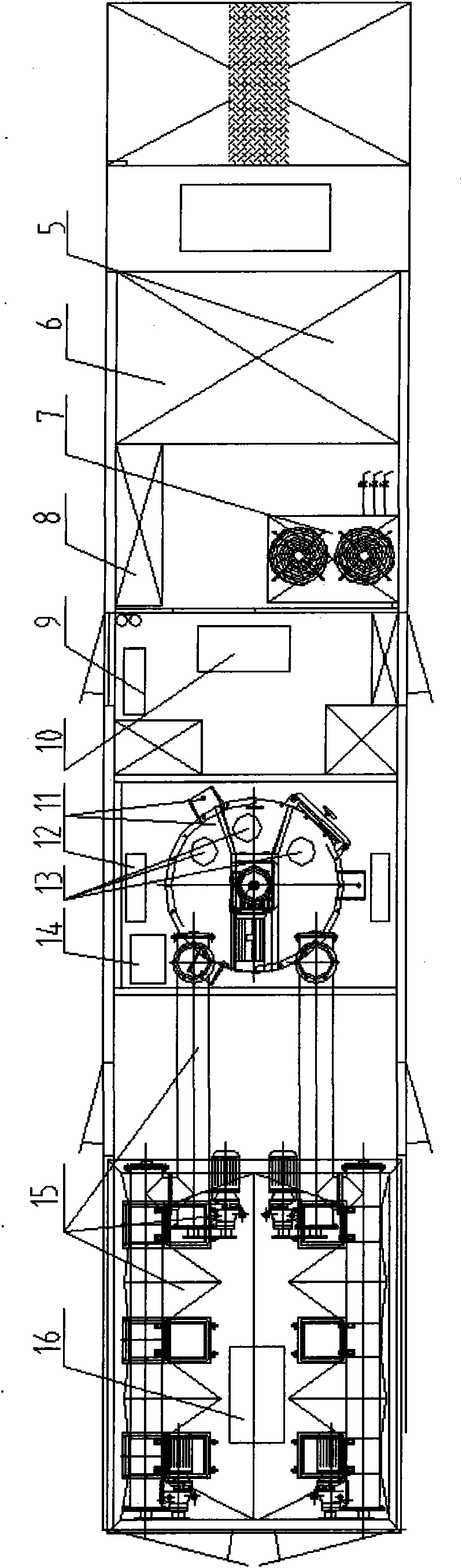

General stirring pumping perfusion vehicle of high and low elasticity model cement emulsified asphalt slurry

InactiveCN101629403AThe docking process is simpleMeet the needs of constructionDischarging apparatusMixing operation control apparatusEngineeringSlurry

The invention discloses a general stirring pumping perfusion vehicle of high and low elasticity model cement emulsified asphalt slurry, comprising an on-vehicle container frame. The on-vehicle container frame is internally provided with a stirring tank which is externally connected with a fluid material and dry material feeding system, and an on-line perfusion trolley is connected out of the stirring tank through a pumping feeding system; the fluid material and dry material feeding system comprises a dry material storage and a fluid material storage; the dry material storage is connected into a cylindrical tank body of the stirring tank through a helical conveyer; the fluid material storage is connected into the cylindrical tank body of the stirring tank through a transfer pipe with a control valve; the pumping feeding system comprises a mortar pump which is respectively connected with a feeding pipeline and a material supply pipeline; a discharge opening with a discharge valve is arranged at the bottom of the stirring tank of the perfusion vehicle; and the discharge valve is externally connected with a discharge pipeline with a manual butterfly valve. The invention adopts the large-volume design, realizes automatic loading and counting, satisfies the construction requirement, ensures even dosing and stirring, saves energy and protects the environment.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Construction method for flooding structure of parapet wall

ActiveCN107558671BFast pre-productionConstruction quality is easy to controlRoof drainageRoof covering insulationsSurface layerWater leakage

The invention provides a constructing method for a flashing structure of a parapet wall. The constructing method comprises the construction steps of prefabricating flashing members, installing the flashing members, filling and compacting between the adjacent flashing members, coating a waterproof coating material and the like. The constructing method adopts a mode of prefabricating the flashing members, rapid pre-production of the flashing members is realized, the construction efficiency is improved, construction quality of the flashing members is convenient to control, and processing workshopconcentrated machining forming is achieved; construction pollution can be effectively reduced, construction materials are saved, and construction waste is reduced; phenomena of cracking and hollowingon the surfaces of the prefabricated flashing members cannot happen, and common technical problems are overcome; by using air permeability between the prefabricated members and a waterproof layer, the effect of heat resistance of the prefabricated members is good, deformation of the waterproof layer caused by water temperature changes is reduced, falling-off and water leakage of the waterproof layer can be effectively prevented, and the waterproof service life is prolonged; and the prefabricated flashing structure has a better appearance effect, the flashing height, width and radian are consistent, a later waterproof coating surface layer cannot fall off, and the long-term aesthetic effect can be achieved.

Owner:坤发建筑有限公司

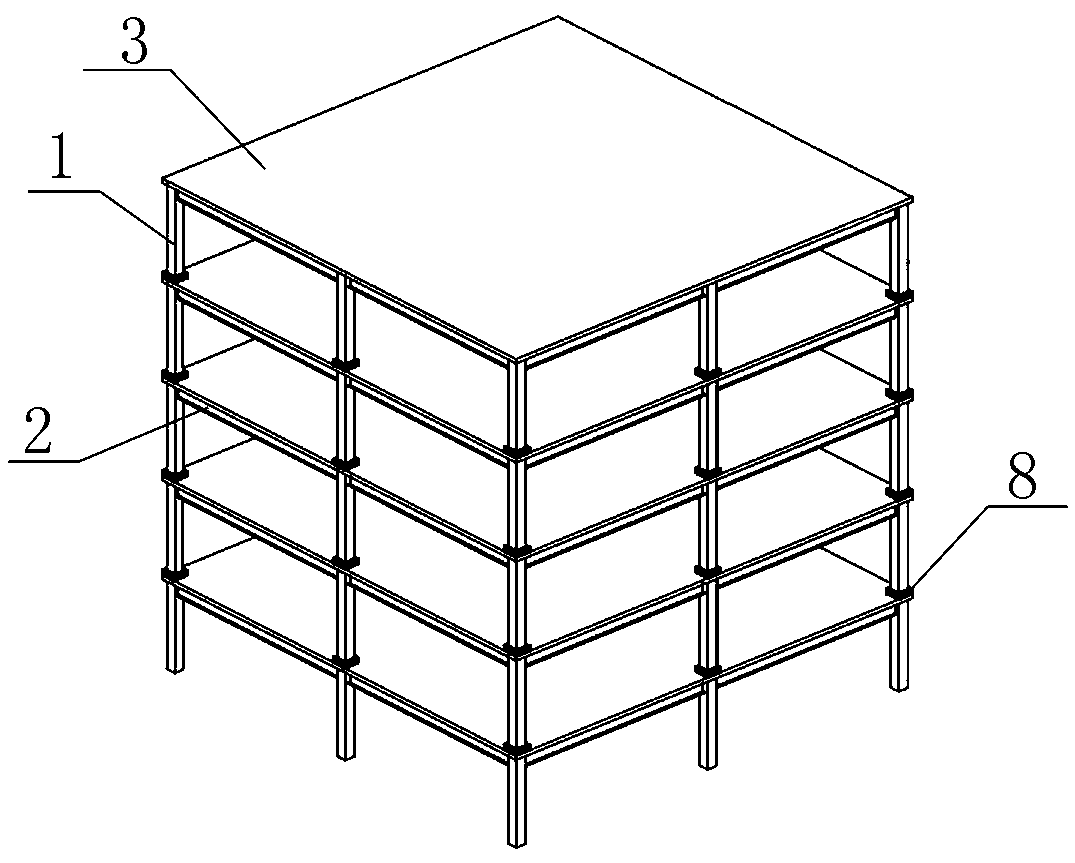

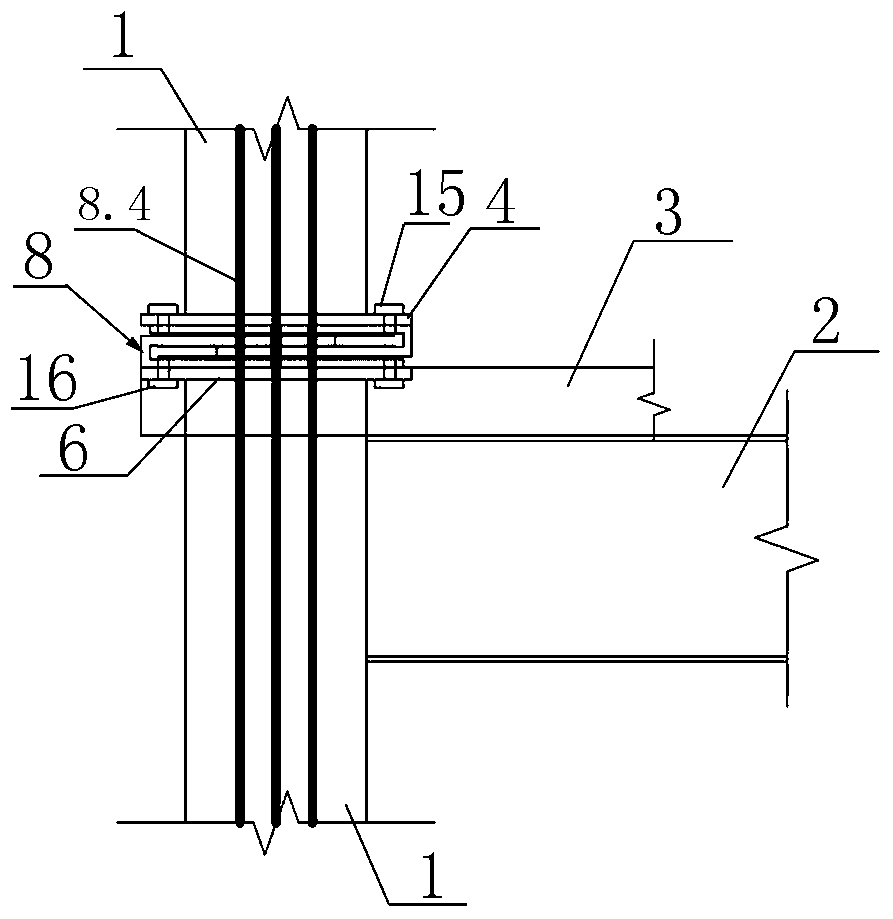

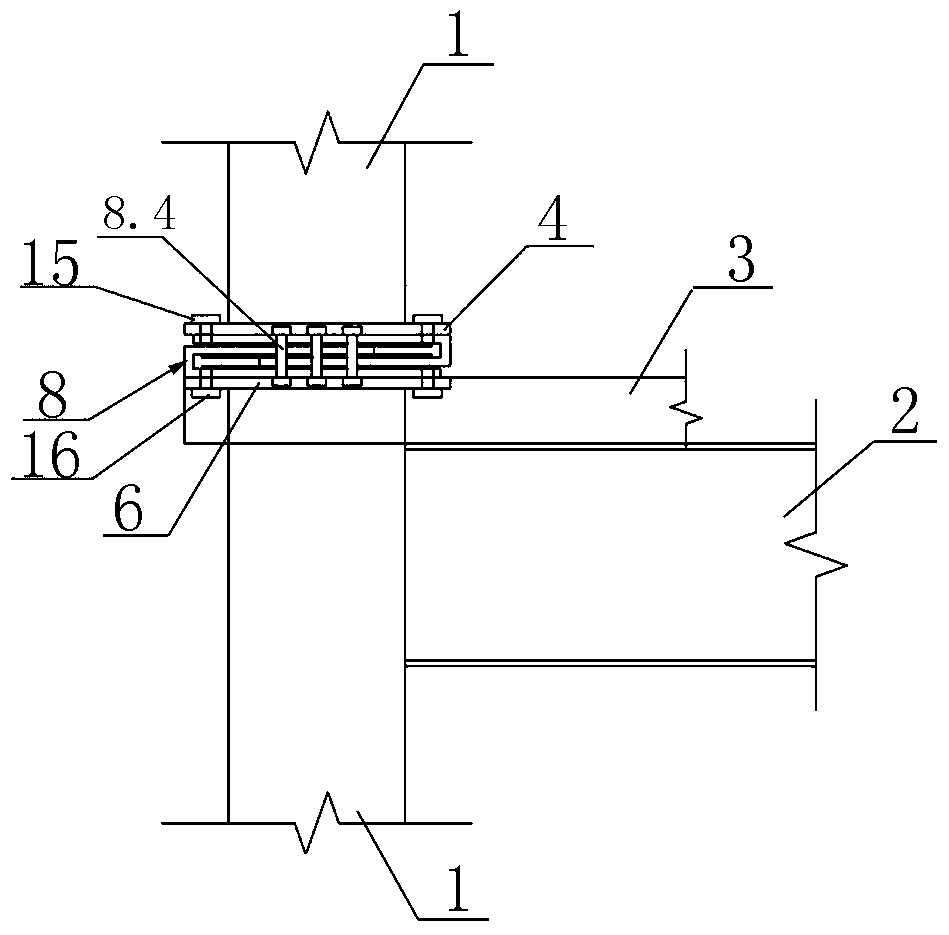

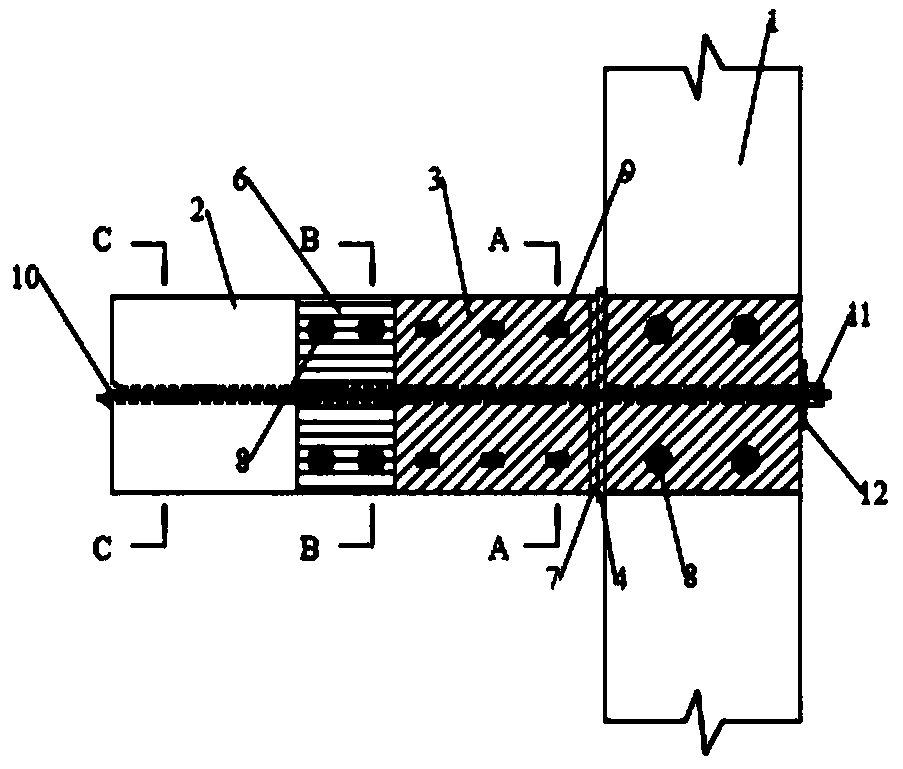

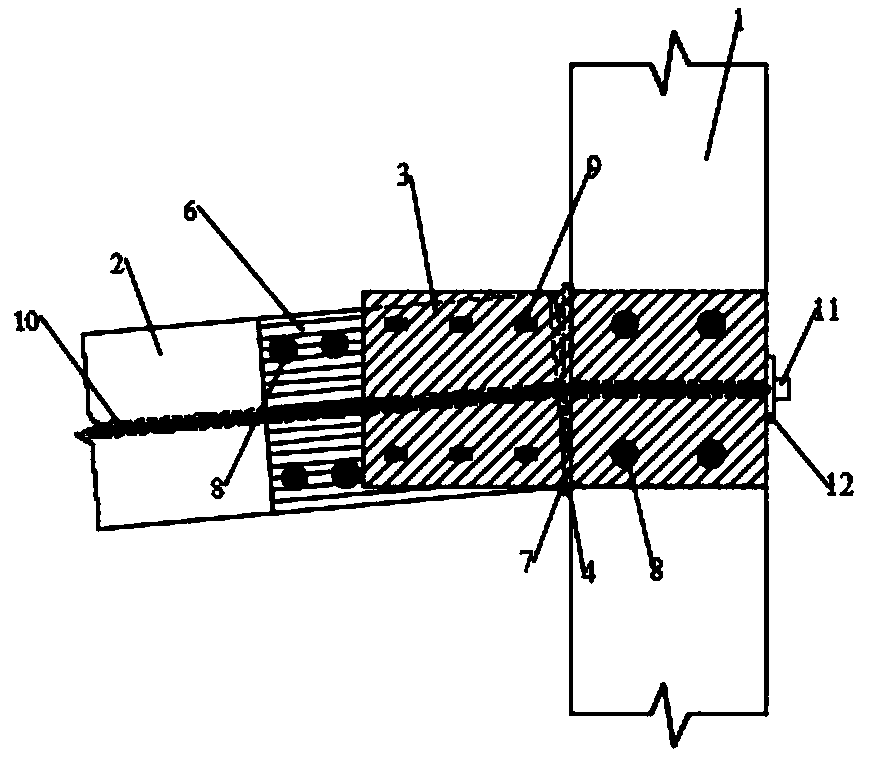

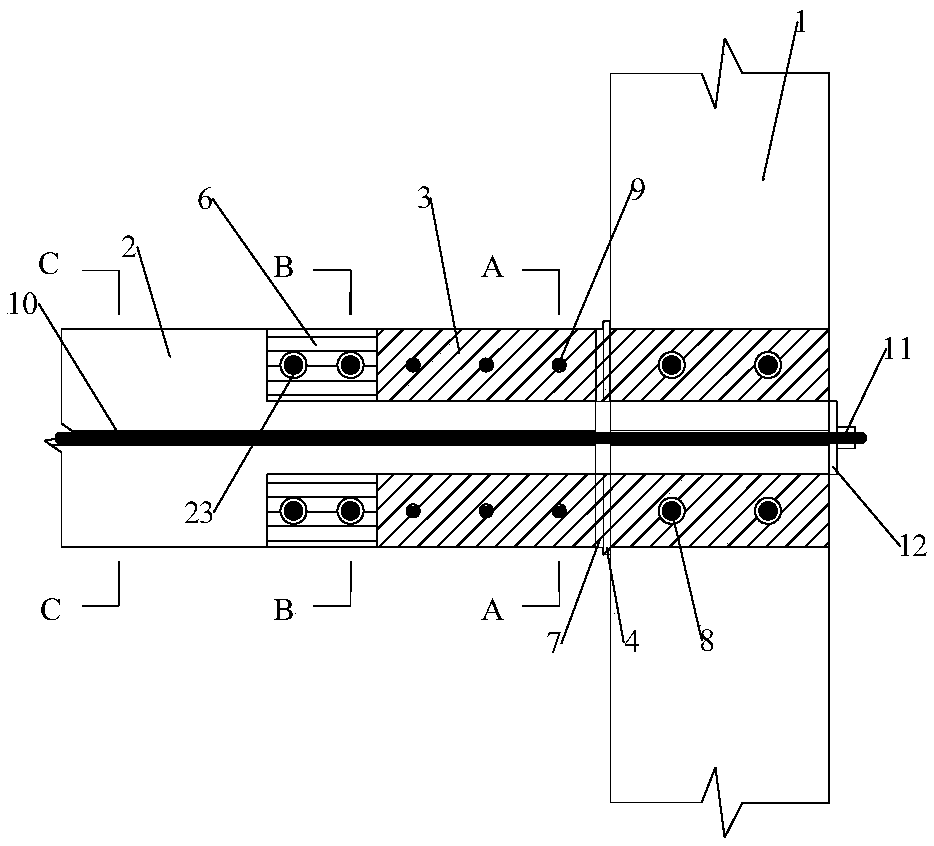

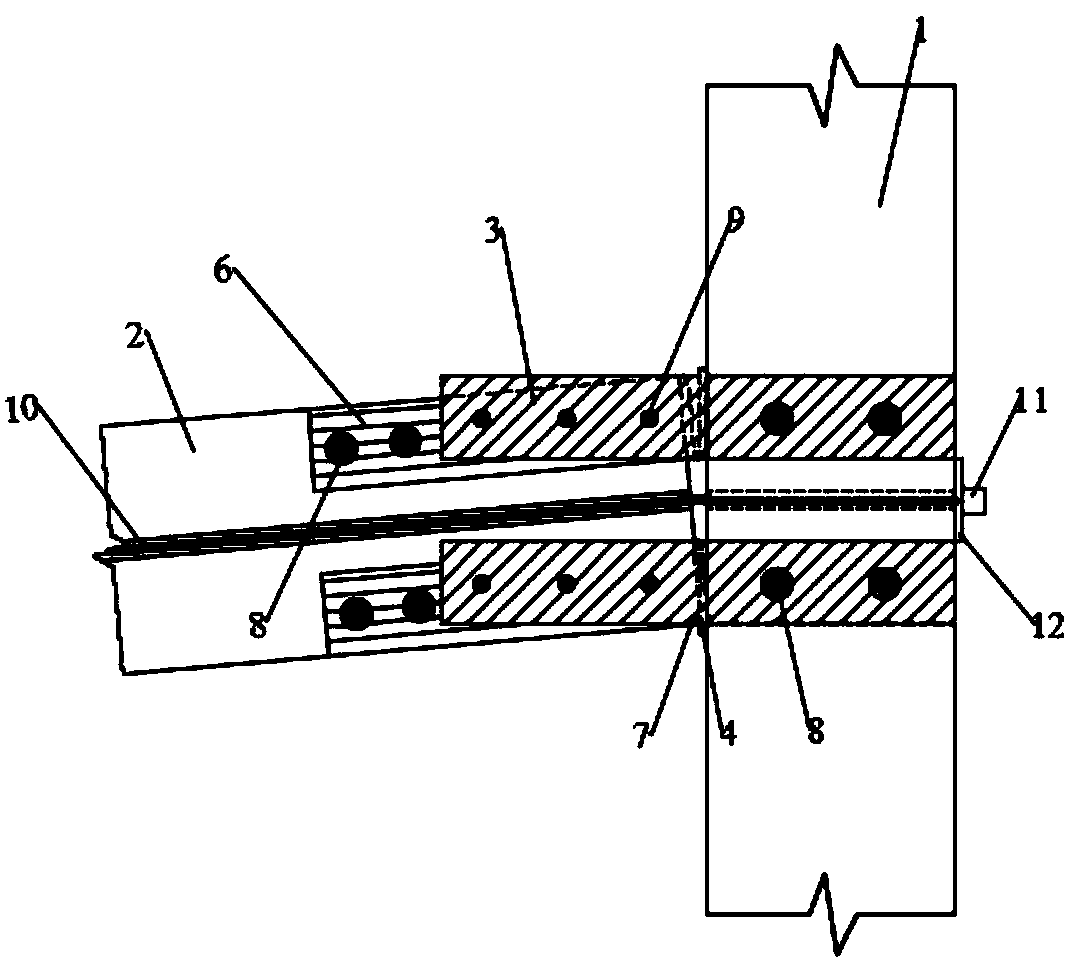

Prestressed assembly type steel frame friction damping structure system and design method thereof

ActiveCN110409604AAvoid damageReduce pollutionProtective buildings/sheltersSpecial data processing applicationsFloor slabPre stress

A prestressed assembly type steel frame friction damping structure system and a design method thereof comprise at least two layers of steel frame structures, wherein adjacent steel frame structures are disconnected at the joint of an upper-layer column and a lower-layer floor slab; the adjacent steel frame structures are connected in a sliding manner through a bidirectional sliding friction connecting device; the bidirectional sliding friction connecting device comprises an upper C-shaped plate, a lower C-shaped plate, a friction plate and a connecting piece; the plate surface of the upper C-shaped plate is provided with a first transverse strip hole; the plate surface of the lower C-shaped plate is provided with a first longitudinal strip hole; the upper C-shaped plate and the lower C-shaped plate are mutually inserted and connected with the connecting pieces in the corresponding first longitudinal strip holes through the first transverse strip holes; the upper C-shaped plate is connected with a bottom connecting plate; the lower C-shaped plate is connected with a top connecting plate; and friction plates are arranged between a first top plate and a second top plate, between a second top plate and a first bottom plate and between the first bottom plate and a second bottom plate. The prestressed assembly type steel frame friction damping structure system solves the technical problems of poor energy consumption performance and difficult construction of connecting joints of the traditional assembly type structural steel column connecting structure.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

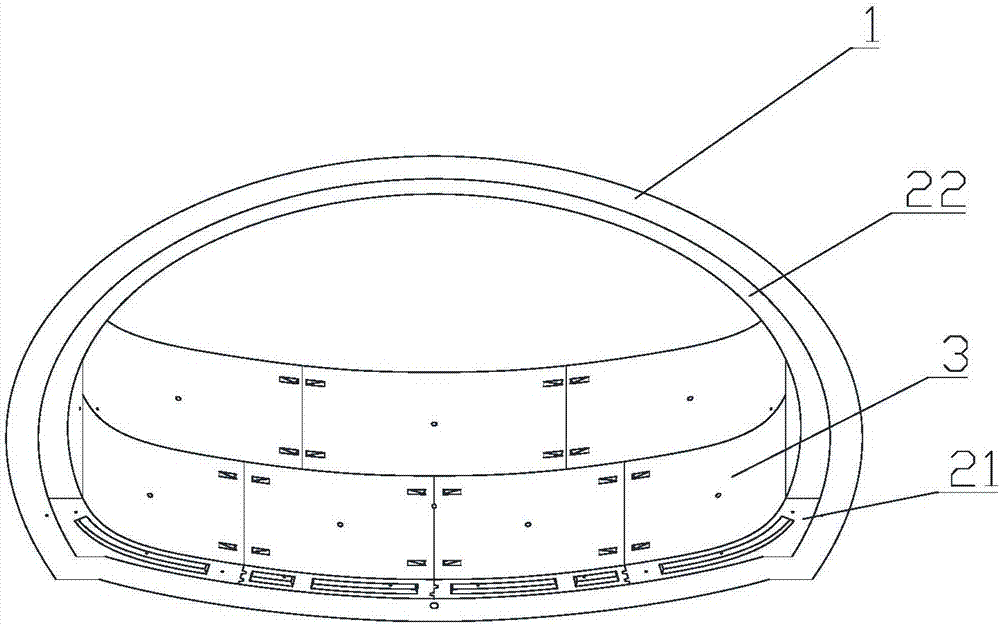

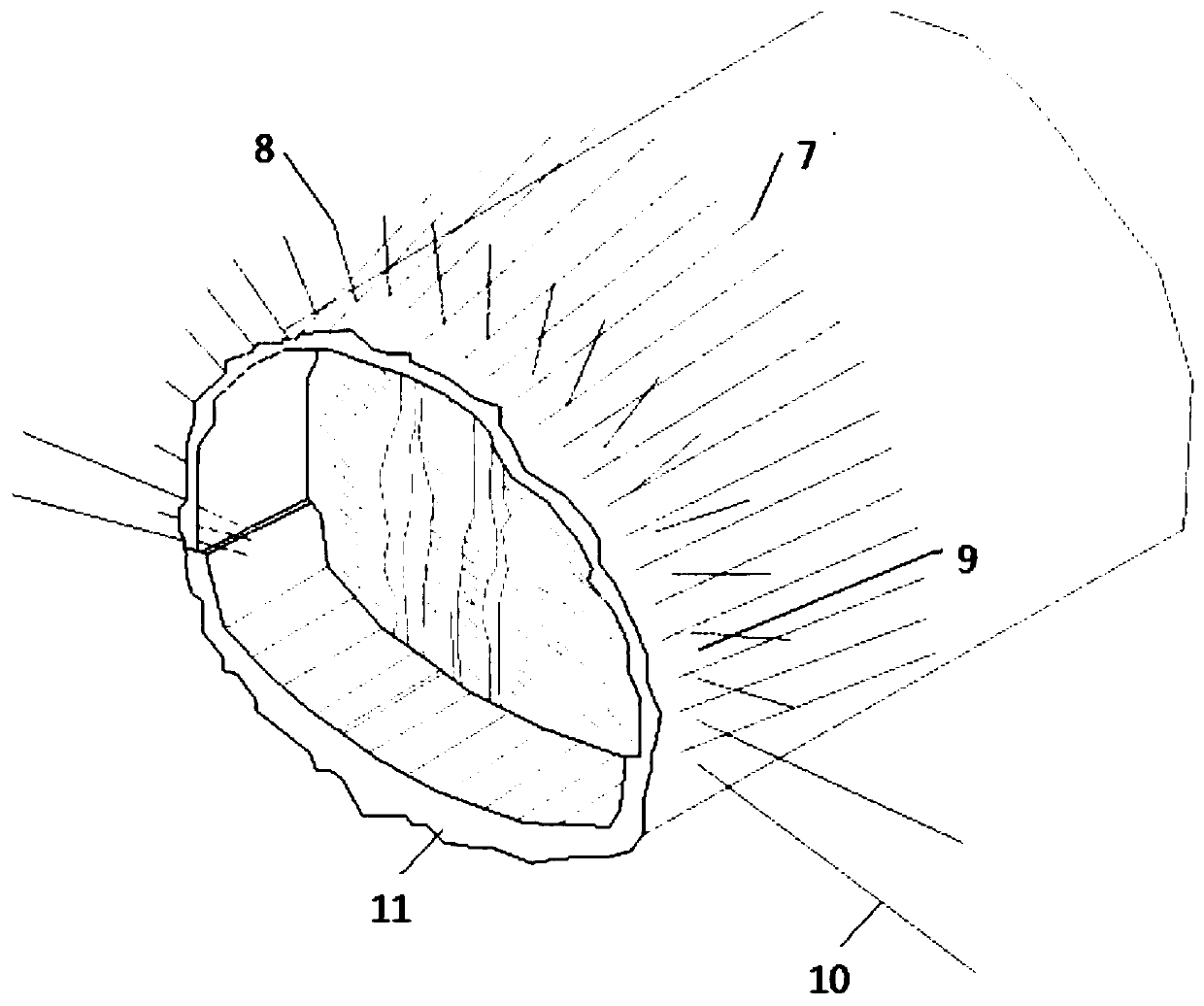

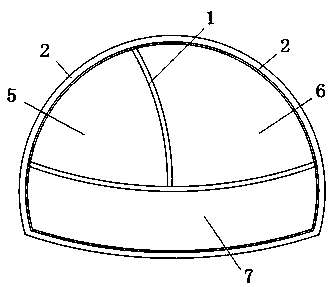

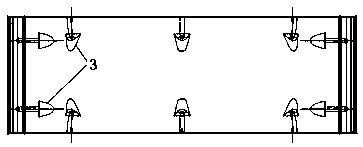

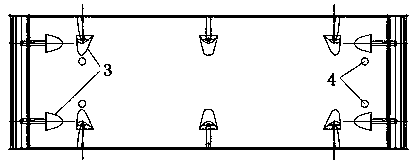

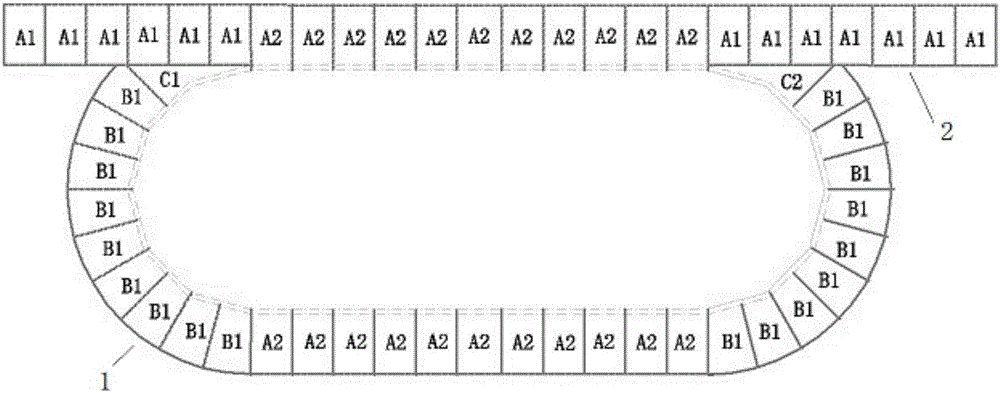

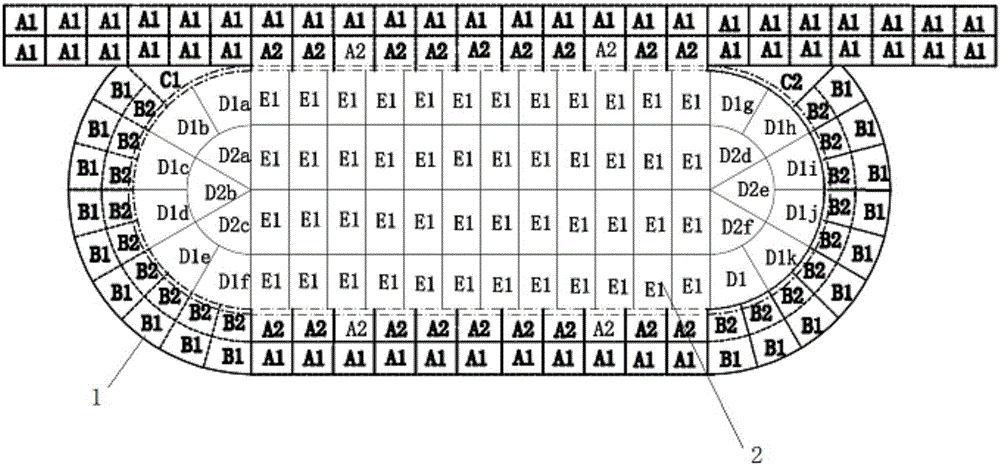

Site base

The invention provides a site base. The site base comprises a plurality of base modules, wherein each of the base modules comprises a first base module and a second base module; the first base modules are spliced to form an arc base; the second base modules are spliced to form a rectangular base; and the inner part of each of the base modules is hollow out, a space which allows a person to enter is formed in the inner part of each of the base modules, and a drainage channel is formed in the inner side of each of the base modules. According to the site base disclosed by the invention, the site base is designed into a plurality of prefabricated base modules; the inner part of each of the base modules is hollow out; the space which allows overhaul staff to enter the inner part of the base for overhauling is formed in each of the base modules, and the base has good air permeability; the drainage channel is arranged in each of the base modules, so that the water level reducing capacity and drainage capacity of the base are improved; the site base has the advantages that the construction is simple, the construction period is shortened, and the resilience of the base is uniform; the service life of the structure of the base is prolonged; and the problems that a conventional site base is long in construction period, poor in venting property and water draining property, low in capacity for resisting frost heaving, easy to be subjected to frost cracking and swelling, difficult in basic maintenance and the like are solved.

Owner:HUNAN YOUGUAN SPORTS MATERIAL CO LTD

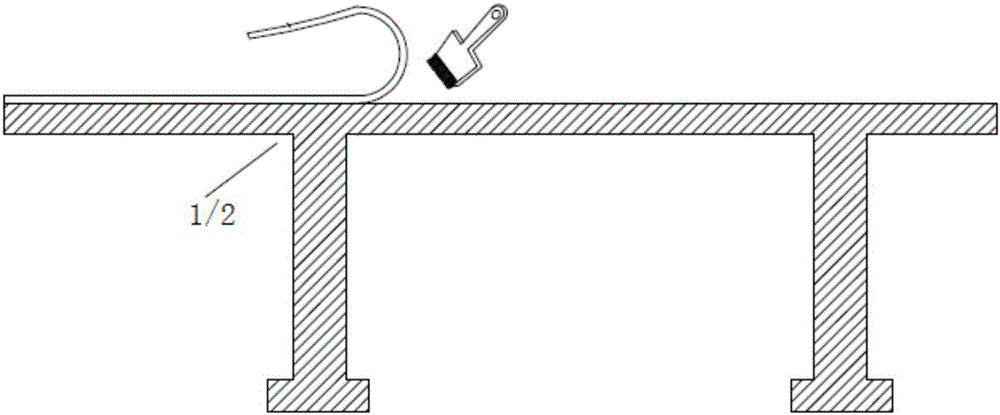

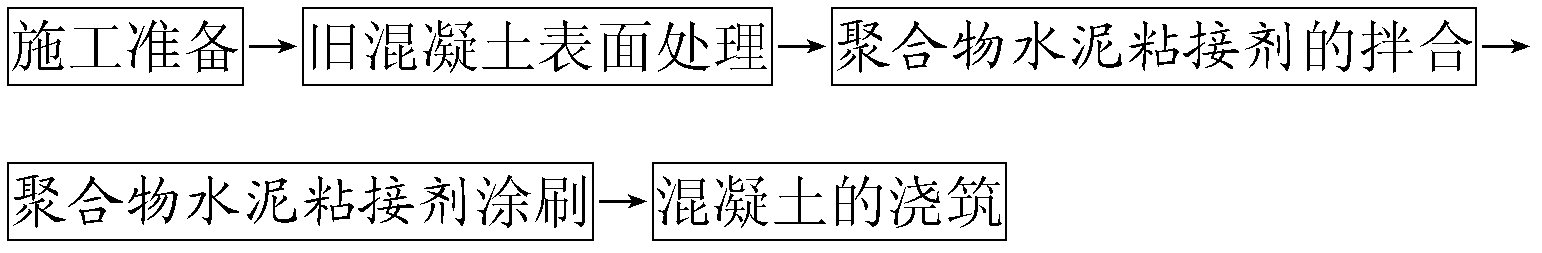

Polymer cement adhesive construction method

InactiveCN102444286ARich sourcesImprove construction progressBuilding repairsBuilding material handlingAdhesiveMaterials science

The invention relates to a polymer cement adhesive construction method, which belongs to the civil engineering field. The method comprises the following steps: (1) clearing dirt on the concrete surface, treating the base surface, sprinkling water on the concrete surface and keeping the concrete surface to be wet; (2) evenly mixing and stirring ordinary polymer emulsion and cement in a proportion of 1:2, timely painting and brushing after polymer cement adhesive is mixed, wherein the thickness of the painting and brushing is in a range of 0.5mm-1mm; and (3) beginning to pour concrete when the surface of the polymer cement adhesive solidifies and is no longer sticky, wherein the time that the polymer cement begins to solidify is related with temperature, wind-force, humidity and the like. The construction progress is quicker by using the method compared with common methods, and material sources are abundant. The construction is safer, and the economic benefit is good. The process is simple and can enable the concrete of different pouring dates to be combined well, no construction cold joint is generated, and requirements of construction devices are simple and convenient. The construction pollution is small, thereby facilitating environmental protection and health of construction operating workers.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP

Prefabricated and assembled protective wall connecting structure for bridge and construction method of prefabricated and assembled protective wall connecting structure

PendingCN112049001AShorten the lengthReduce storageBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention provides a prefabricated and assembled protective wall connecting structure for a bridge and a construction method of the prefabricated and assembled protective wall connecting structure, and relates to the technical field of bridge construction. The structure comprises a beam body, a prefabricated protective wall, grouting materials and connecting plates. The beam body is prefabricated, pre-embedded steel bars extend out of the corresponding positions of the beam surface during prefabrication, a bedding mortar groove is reserved, reserved grooves and supporting columns are arranged on the lower part of the prefabricated protective wall, connecting steel bars are arranged in the reserved grooves, bedding mortar is laid in the bedding mortar groove of the beam body during construction, supporting pads are arranged at the positions, corresponding to the supporting columns, of the bedding mortar groove, the prefabricated protective wall is hoisted, the supporting columns aresupported on the supporting pads, the connecting steel bars are inserted into the middles of the pre-embedded steel bars, the connecting plates pre-embedded in the supporting columns penetrate into pre-embedded bolts pre-embedded in the beam body, nuts are screwed for connection, grouting materials are poured from the upper parts of grout inlet holes till the grouting materials flow out from grout outlet holes, and thus assembling of the prefabricated protective wall and the beam body is completed. The structure is high in construction speed, large in construction allowable error, low in costand beneficial to application and popularization, and the quality is easy to guarantee.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

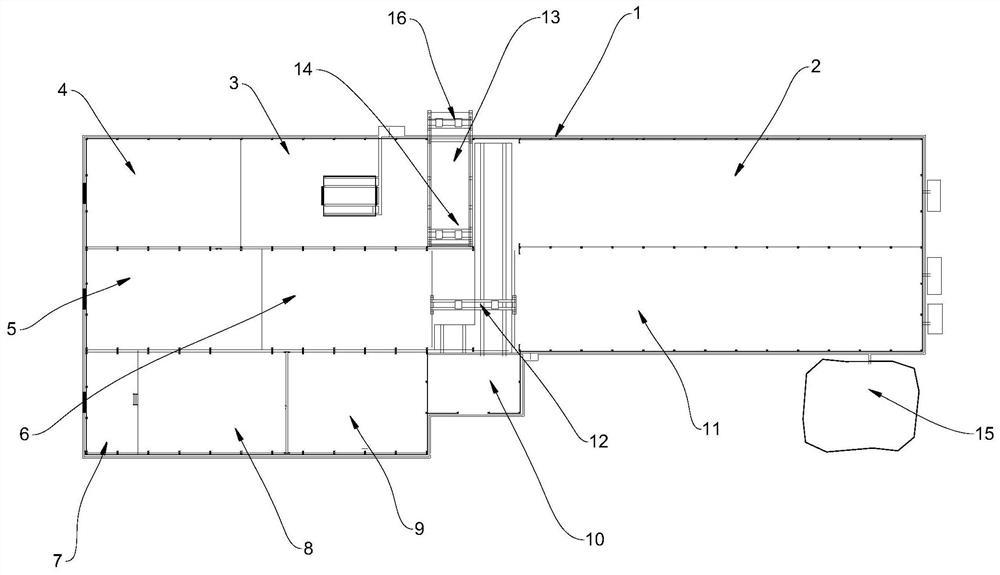

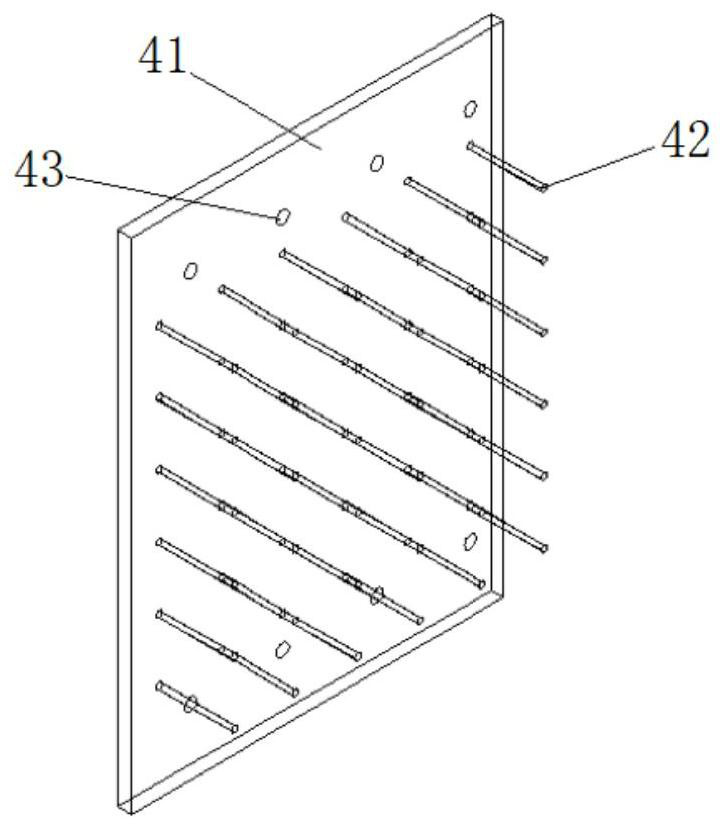

Detachable movable assembly line factory

PendingCN112140324AImprove qualityHigh dimensional accuracyCeramic shaping plantsProduction lineAssembly line

The invention relates to the technical field of assembly type concrete tower drum production, in particular to a detachable movable assembly line factory which comprises a movable detachable factory building, a matched full-automatic steel bar machining production line, a split type high-precision mold and a concrete component secondary finish machining center. The movable detachable workshop comprises an incoming material storage area, a reinforcement cage machining area, a reinforcement cage stacking area, a reinforcement cage mold entering area, a concrete distributing area, a mold closingarea, a heating curing area, a mold removal area, a grinding machine machining area, a high-pressure steam curing area and a finished product stacking area. A reinforcing steel bar machining area comprises a top hoisting system, an automatic ring sheet reinforcing steel bar stacking system and a conveying system; the reinforcement cage mold entering area comprises a mold cleaning mechanism and a lifting mechanism; and the mold removal area is provided with an independent cleaning area. The detachable movable assembly line factory provided by the invention has the advantages of being controllable in quality precision, high in component quality, efficient in production, capable of meeting the requirement for rapid construction of a wind field, standardized in component and convenient and rapid to construct, assemble and move.

Owner:上海电气研砼(木垒)建筑科技有限公司

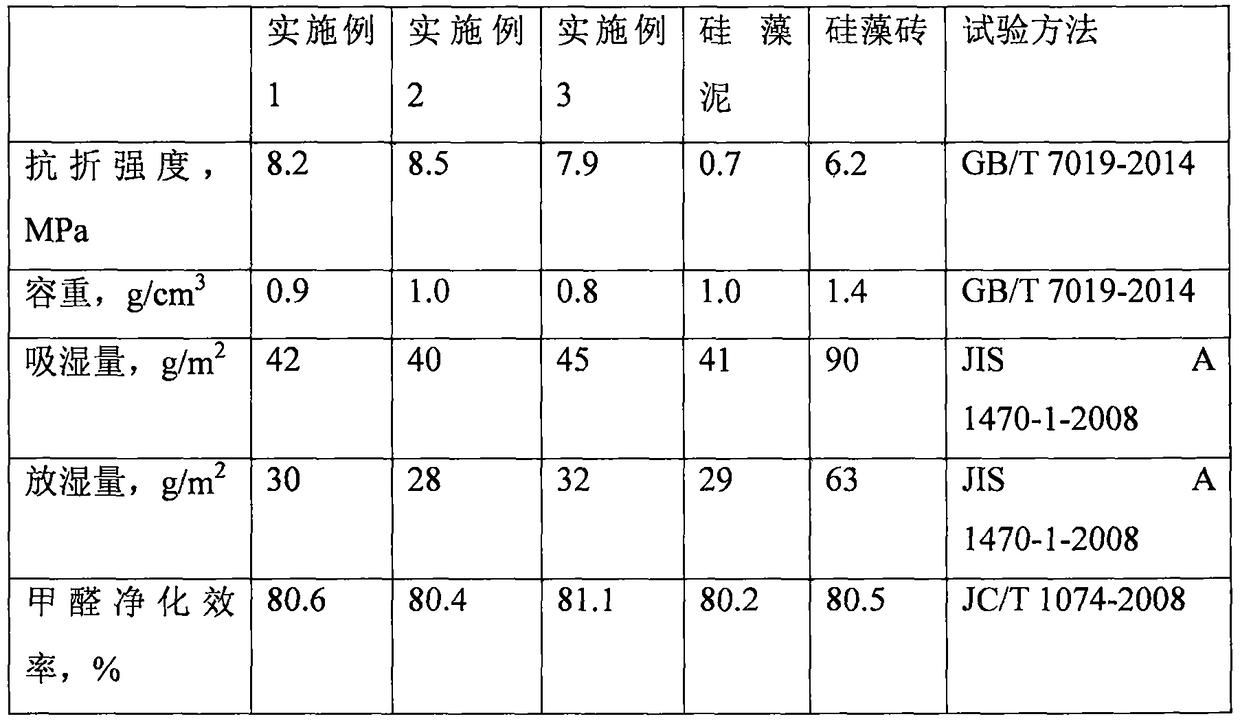

Diatom plate and production method thereof

The invention discloses a diatom plate and a production method thereof. The diatom plate is composed of, by weight, 30-60 parts of diatomite, 0.5-1.5 parts of nano titanium dioxide, 0.01-0.1 part of nano silver antibacterial agent, 15-25 parts of slaked lime, 5-10 parts of paper pulp fiber, 0-30 parts of cement, 1-5 parts of hemihydrate gypsum, 0.1-20 parts of quartz powder, 0.1-0.3 part of pigment and 400-900 parts of water. The diatom plate has the advantages that compared with wood, the diatom plate is richer in resource, higher in resource utilization rate and more environment-friendly andhas air purifying, bacteria resisting and mildew preventing functions that the wood does not have; compared with a fiber plate, the diatom plate does not contain harmful substances like formaldehyde,benzene, methylbenzene, xylene and VOC; compared with gypsum plates, the diatom plate is higher in strength and better in water resistance; compared with diatom ooze decoration wall materials, the diatom plate is supportive of integrated decoration, high in construction efficiency, low in labor cost and less in construction pollution; compared with diatom ecological bricks, the diatom plate is lower in material cost and higher in construction efficiency.

Owner:营口盼盼硅藻材料集团有限公司

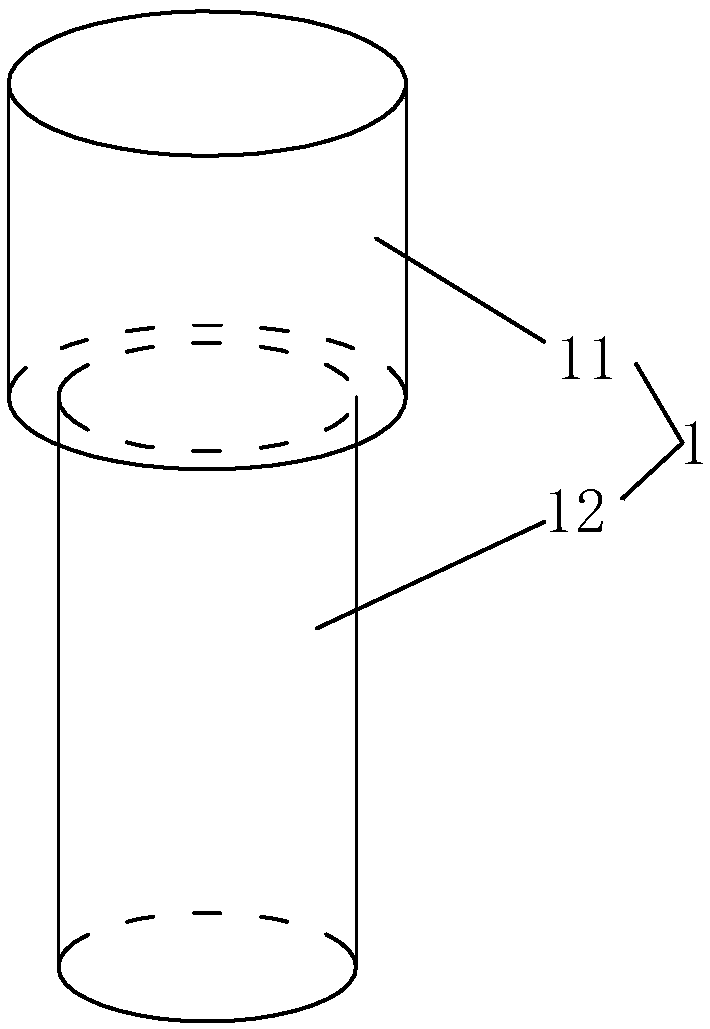

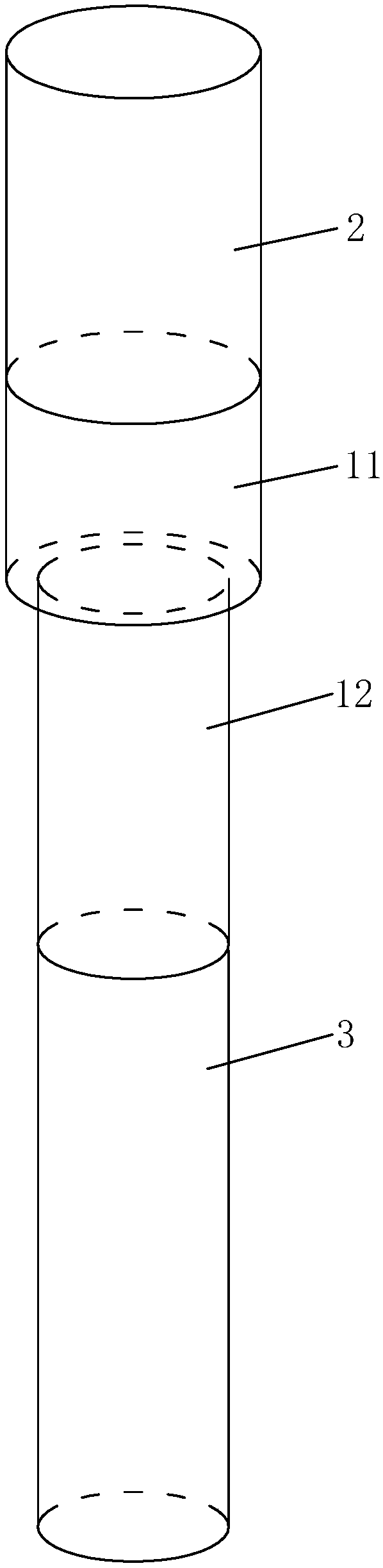

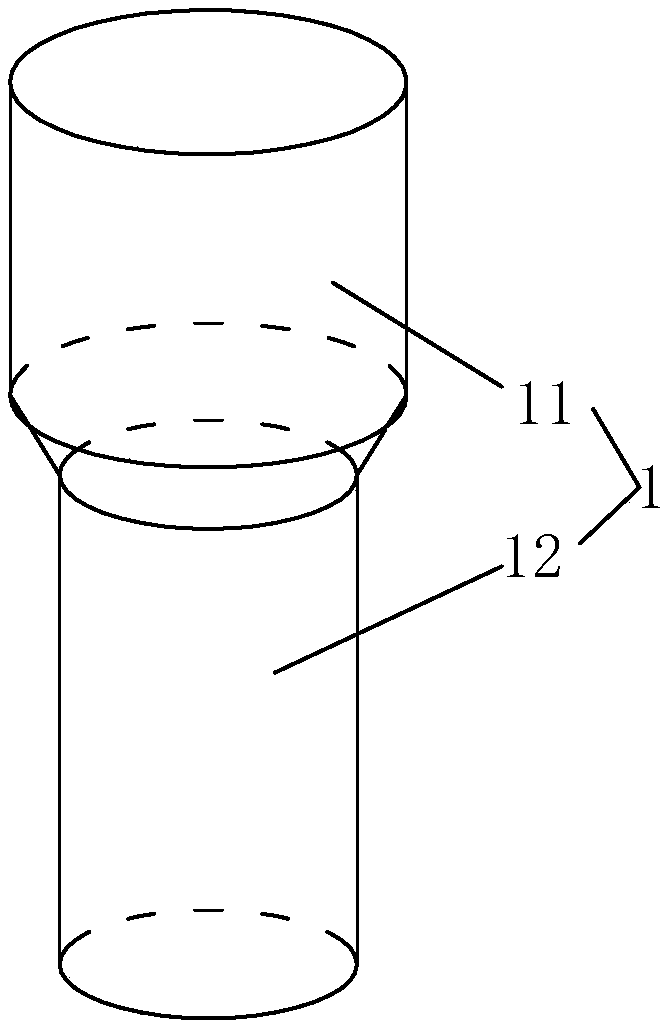

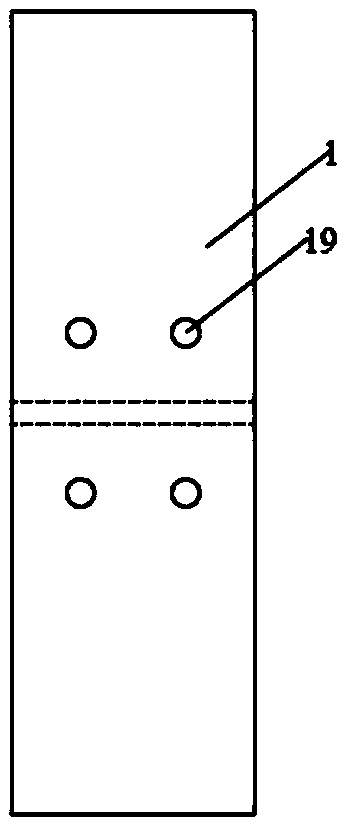

Prefabricated variable-section pile and construction method thereof

The invention discloses a prefabricated variable-section pile and a construction method thereof. The prefabricated variable-section pile is used for transmitting the load of an upper building to a foundation. The variable-section pile comprises a pile body, the pile body is integrally prefabricated and formed, and comprises at least two sections of pile main bodies, and in every two adjacent pilemain bodies, the cross section size of the upper pile main body is larger than that of the lower pile main body. According to the prefabricated variable-section pile, the characteristic that axial force of the pile main bodies gradually decreases from top to bottom when the pile main bodies resist pressure is met, materials are fully utilized, and resources are saved. The pile body is integrally prefabricated and produced, so that the construction period is greatly shortened, connection assembly of large-section pile main body sections and small-section pile main body sections on site is alsoavoided, and the technical problems of variable-section weld, connection, assembly and the like are effectively solved.

Owner:JIANYAN DETECTION GRP CO LTD

Self-resetting laminated wooden structure beam-column joint capable of replacing frictional energy consuming devices

InactiveCN108625492AStable use functionReduce replacement repair workProtective buildings/sheltersShock proofingResidual deformationEngineering

The invention discloses a self-resetting laminated wooden structure beam-column joint capable of replacing frictional energy consuming devices. The self-resetting laminated wooden structure beam-column joint comprises a laminated wooden column, a laminated wooden beam and a frictional energy consuming device, wherein the laminated wooden beam is located on one side of the laminated wooden column,and the laminated wooden column and the laminated wooden beam are connected as a whole by the frictional energy consuming device. The frictional energy consuming device comprises two inner friction steel plates, an inner friction end plate, two outer friction steel plates and an outer friction connection steel plate. The inner friction steel plates reserved with first friction bolt holes and firstfixation bolt holes are fixed to the laminated wooden beam, the two inner friction steel plates are connected as a whole by the inner friction end plate, the two outer friction steel plates reservedwith third friction bolt holes and third fixation bolt holes are fixed to the laminated wooden column, and the two outer friction steel plates are connected as a whole by the outer friction connectionsteel plate. The self-resetting laminated wooden structure beam-column joint can consume energy of the action of an earthquake, and eliminate or reduce residual deformation of a prefabricated woodenstructure under the action of the earthquake.

Owner:SOUTHEAST UNIV

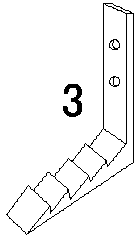

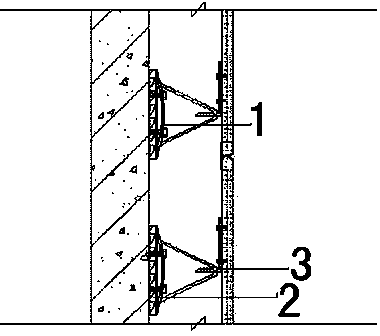

Novel hard-soft package installing metal hanging part

The invention discloses a novel hard-soft package installing metal hanging part which comprises a clamp-shaped member (1), a leveling wood strip (2) and a member accessory (3). The leveling wood strip (2) is fixed on the wall face, and the bottom face of the clamp-shaped member (1) is fixed on the leveling wood strip (2). The member accessory (3) is connected with a hard-soft package board and inserted into a clamping mouth of the clamp-shaped member (1). The side of the member (1) is triangular. By adopting the novel hard-soft package installing metal hanging part, the increasingly tense labor cost can be reduced, a construction period can be shortened, and product limitation on the environment of a traditional construction can be changed. The repeated utilization rate of products is improved, accordingly the construction and installation efficiency is improved, and productized construction progress is promoted. The construction pollution is reduced, the construction quality is improved, and future maintenance is facilitated.

Owner:GOLD MANTIS CONSTR DECORATION

Self-resetting glued wood structure beam-column joint capable of replacing top-bottom friction energy-consuming device

InactiveCN108412043AStable use functionRecovery functionProtective buildings/sheltersShock proofingResidual deformationStructural engineering

The invention discloses a self-resetting glued wood structure beam-column joint capable of replacing top-bottom friction energy-consuming device. The self-resetting glued wood structure beam-column joint comprises a glued wood column, a glued wood beam located on one side of the glued wood column, and two friction energy-consuming devices connecting the glued wood column and the glued wood beam into one body, the two friction energy-consuming devices are respectively arranged on the upper part and the lower part of the glued wood beam, each friction energy-consuming device comprises two internal friction steel plates which are fixed on the glued wood beam are provided with a first friction bolt hole and a first fixing bolt hole, an inner friction end plate connecting the two inner frictionsteel plates into an integral , two outer friction steel plates which are fixed on the gluing wood column are provided with a third friction bolt hole and a third fixing bolt hole, and an external friction connecting steel plate connecting the two outer friction steel plates. The self-resetting glued wood structure beam-column joint can consume the energy under the earthquake action, eliminate orreduce the residual deformation of the assembled wooden structure under the earthquake action.

Owner:SOUTHEAST UNIV

Pile head breaking method

InactiveCN107916668AEasy to moveReduce the cost of demolitionBulkheads/pilesStructural engineeringPollution

The invention belongs to the technical field of detachment of brittle solid, and particularly provides a pile head breaking method in order to solve the problems that pile head detachment efficiency is low, the cost is high, and pollution is serious. The pile head breaking method comprises the steps that a plurality of operation holes are formed in a to-be-broken axis surface of a pile head; an intra-hole cylinder type hydraulic stone breaker is provided and comprises a set of expansion devices matched with the operation holes; and the set of expansion devices are inserted into the multiple corresponding operation holes so that the intra-hole cylinder type hydraulic stone breaker can act, and the pile head is expanded and broken along the to-be-broken axis surface. By means of the pile head breaking method, the breaking efficiency of the pile head is improved, the breaking cost is saved, and breaking pollution is reduced.

Owner:北京旭日汇安工程技术有限公司

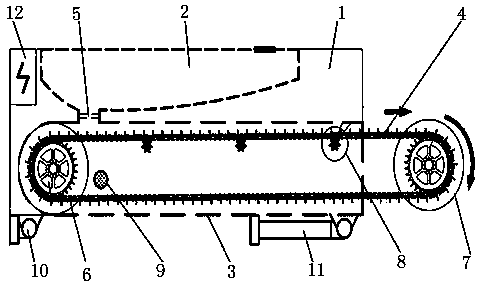

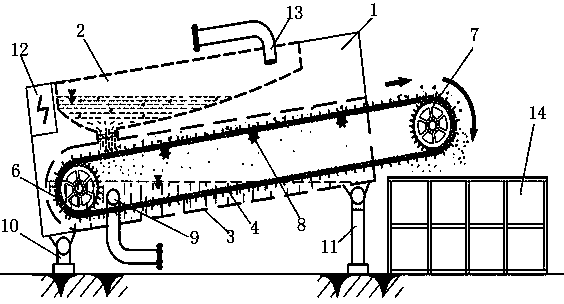

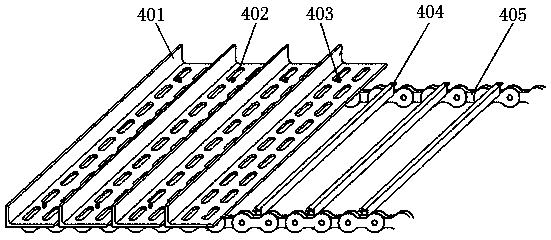

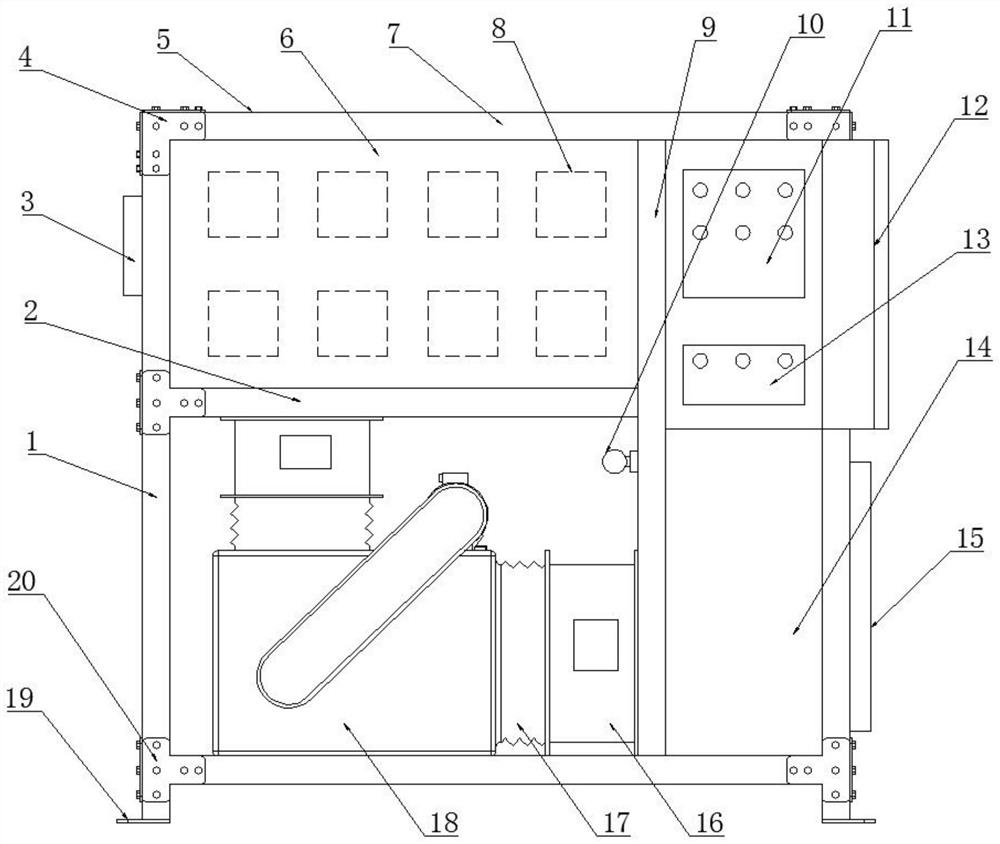

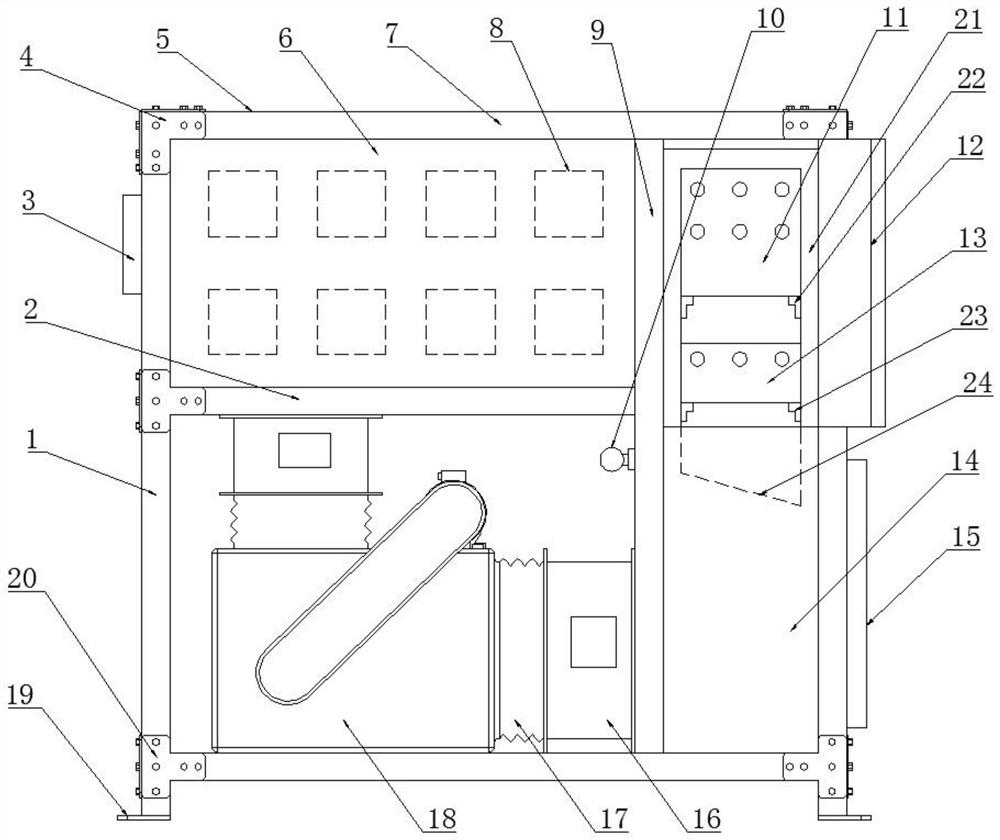

Tool-type gravity mud separation device

The invention provides a tool-type gravity mud separation device. The tool-type gravity mud separation device comprises a box body, wherein a mud collection box, a conveying belt and a sealed mud collection cavity are arranged in the box body; the conveying belt is arranged in the sealed mud collection cavity, and one end of the conveying belt stretches out of the sealed mud collection cavity; a channel is arranged at the lower end of the mud collection box, and an adjustment valve is arranged on the channel; the channel is communicated with the mud collection box, and the outlet is dead against the other end of the conveying belt; a mud inlet is formed in the mud collection box, and a mud outlet is formed in the sealed mud collection cavity; a rotatable support leg, and an adjustable, liftable and rotatable support leg are further arranged at the both ends of the bottom of the box, the whole box is inclined by changing the height of the adjustable, liftable and rotatable support leg. The tool-type gravity mud separation device provided by the invention enables mud water and soil residues in mud to be lifted through the conveying belt, and realizes mud separation under the effect of gravity; the discharge total of mud is reduced while the mud water is recovered and repeatedly used, and the overflowing of mud is avoided, thus construction is carried out in clean and tidy, environment-friendly and ordered conditions.

Owner:SHANGHAI SHANSHUN CIVIL ENG TECH

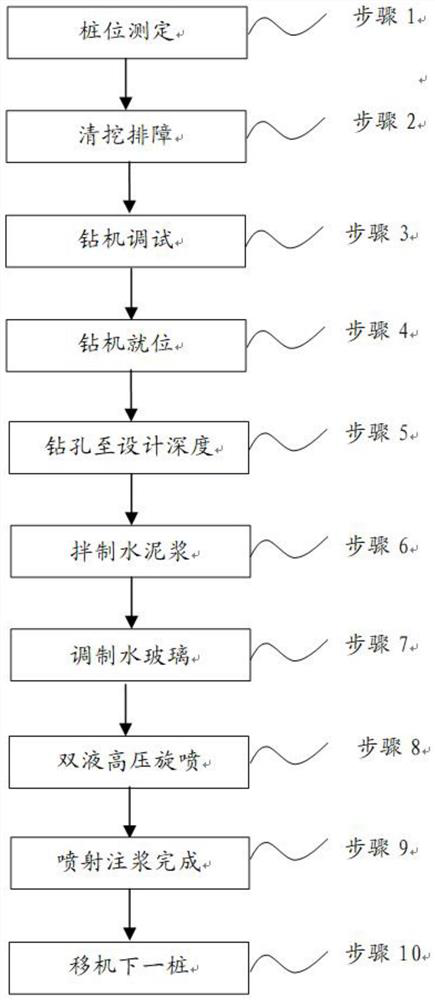

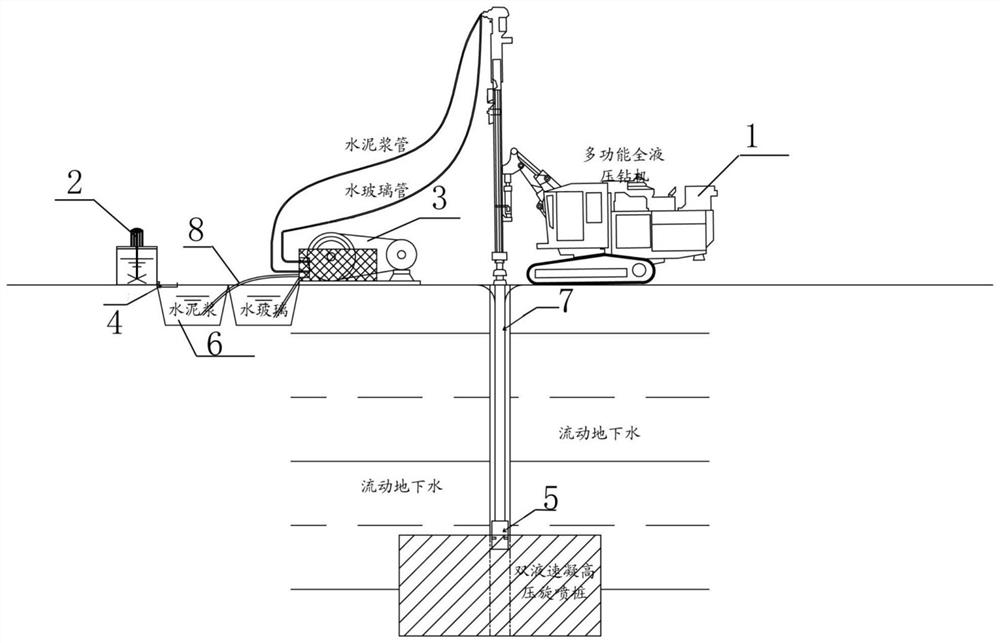

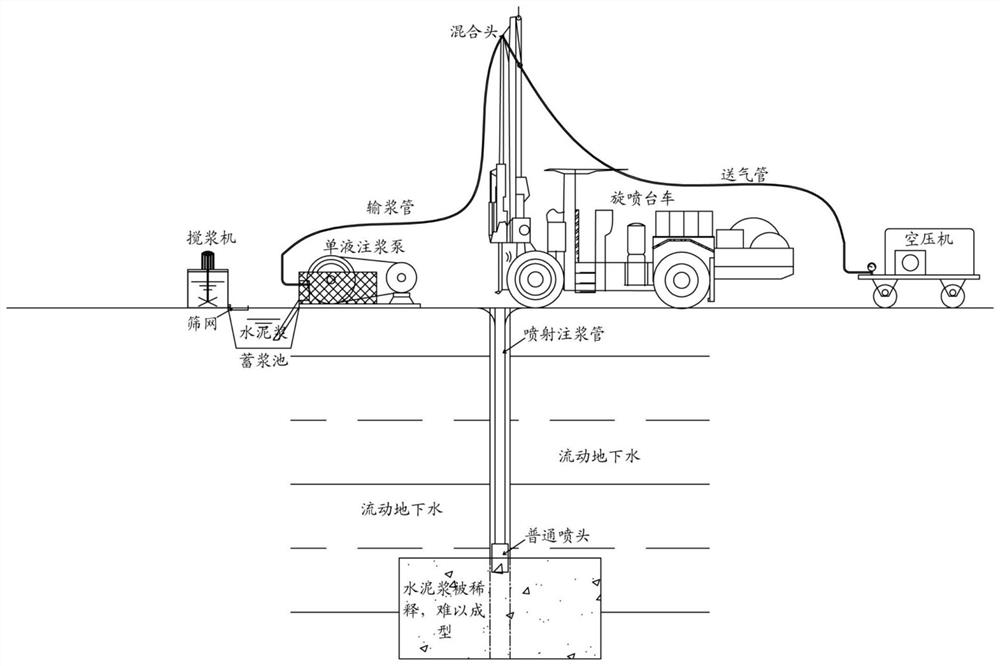

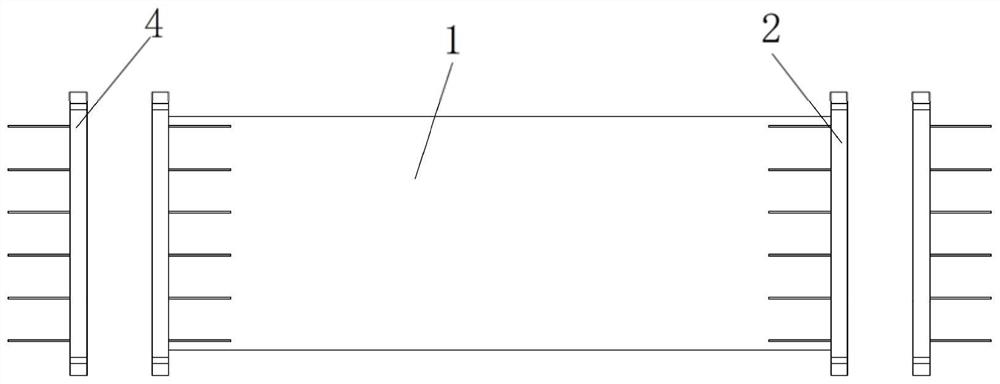

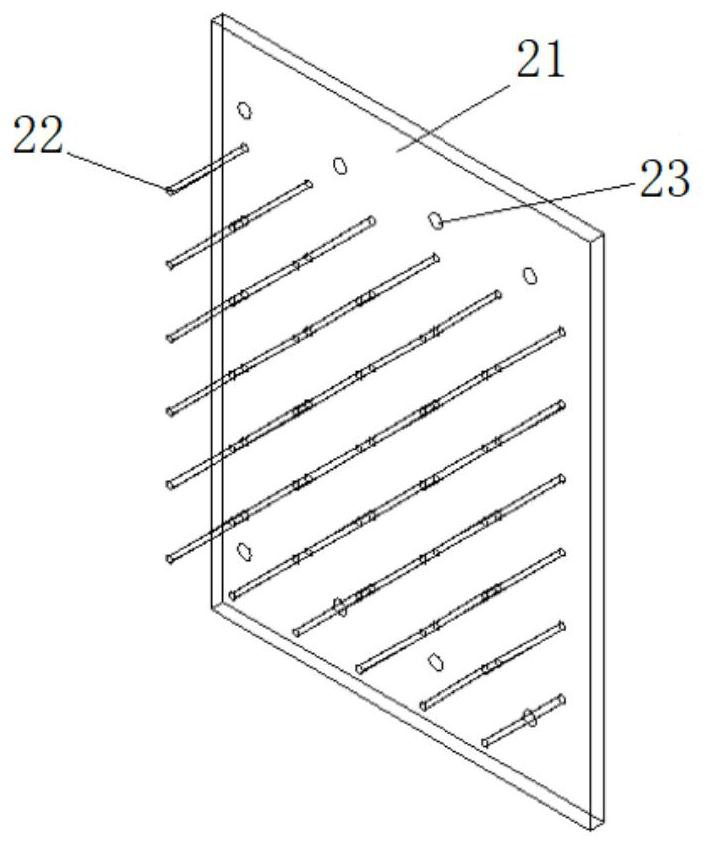

Construction method of double-liquid rapid-hardening high-pressure jet grouting pile

PendingCN113235581ARealize quick-setting pileWeak liquidityDrill bitsBulkheads/pilesSlurryEarth surface

The invention discloses a construction method of a double-liquid rapid-hardening high-pressure jet grouting pile. The construction method comprises the following steps of measuring a pile position, clearing, excavating and removing a fault, debugging a drilling machine, placing the drilling machine in place, drilling to a designed depth, mixing cement paste, preparing water glass, performing double-liquid high-pressure jet grouting, finishing jet grouting, moving the drilling machine to a next pile and the like. Compared with a traditional common jet grouting pile construction process, two nozzles below a multifunctional full-hydraulic drill pipe machine are used for spraying cement paste and water glass through a pump body, then the cement paste solution and water glass solution sprayed out of the nozzles at the bottom of the multifunctional full-hydraulic drill pipe machine are rotationally stirred and mixed at the bottom of a pile position, and therefore rapid hardening and pile forming of the cement paste are achieved; the problem that an ordinary jet grouting pile cannot be formed due to the fact that flowing water exists on the earth surface is solved; and by means of the construction method, rapid pile forming and effective pile forming are achieved through grout, the pile forming time is very short, the liquidity of the grout is weak, the using amount of cement paste is relatively small, the using amount of the grout is reduced, and blocking of underground pipelines is avoided.

Owner:广州捷盈工程有限公司

Prefabricated hybrid fiber concrete replaceable coupling beam and preparation method thereof

The invention provides a prefabricated hybrid fiber concrete replaceable coupling beam and a preparation method thereof. The prefabricated hybrid fiber concrete replaceable coupling beam comprises a coupling beam body, coupling beam anchoring parts are arranged at the two ends of the coupling beam body, and the coupling beam anchoring parts are connected with wall columns through connecting bolts;and the connecting beam body comprises hybrid fiber concrete and beam body reinforcing steel bars, and the hybrid fiber concrete wraps the outer sides of the beam body reinforcing steel bars. The hybrid fiber concrete is obtained by mixing cement, fly ash, silica fume, sand, a water reducing agent, steel fibers, polyvinyl alcohol fibers and water. The coupling beam body is formed by pouring the hybrid fiber concrete and the beam body reinforcing steel bars, and the toughness, bending resistance and impact resistance of the coupling beam concrete are effectively improved by doping steel fibers; by doping the polyvinyl alcohol fibers, the toughness, ductility and fracture resistance of the coupling beam concrete are effectively improved, and then the coupling beam body has good anti-seismicproperty; and the coupling beam anchoring parts are connected with the wall columns through the bolts, the coupling beam can be replaced, the manufacturing process is simple, and the cost is low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

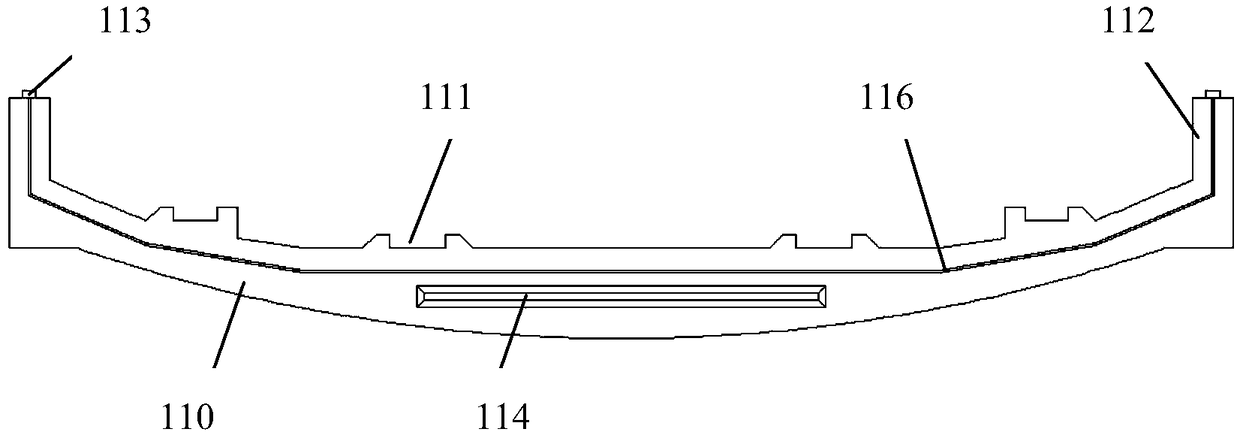

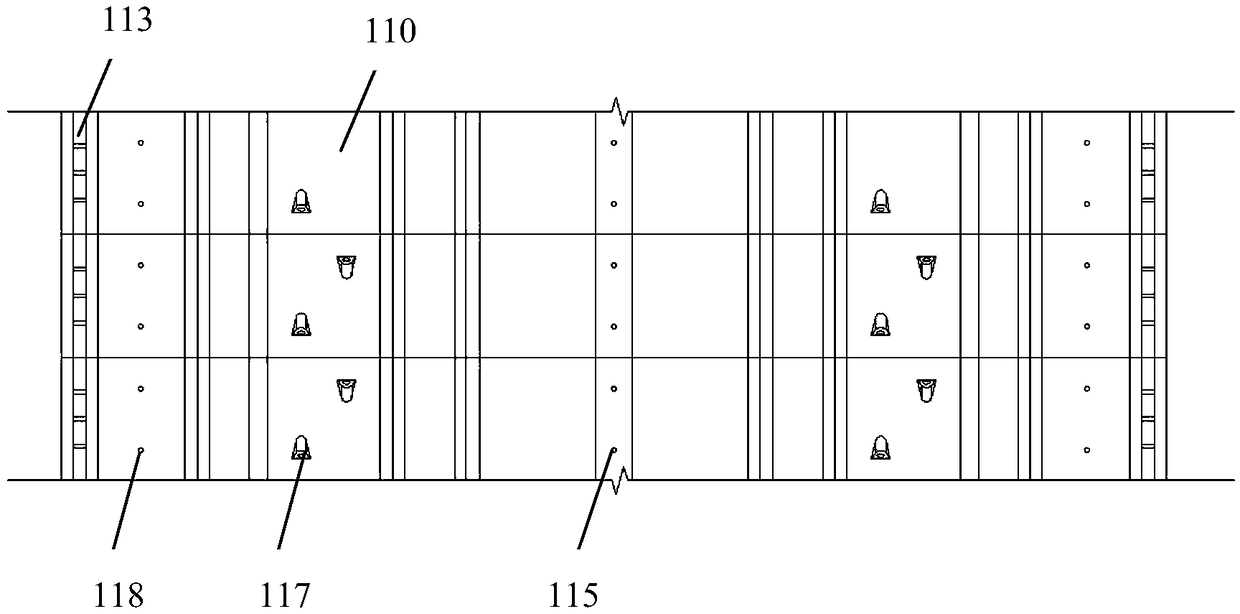

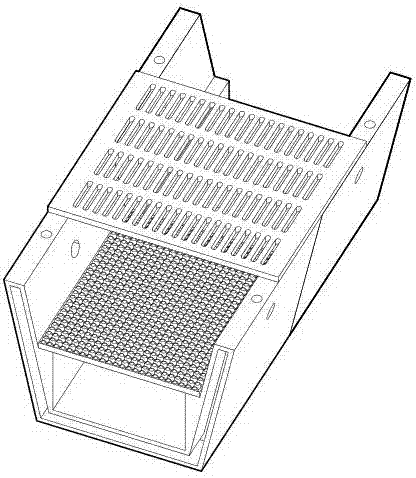

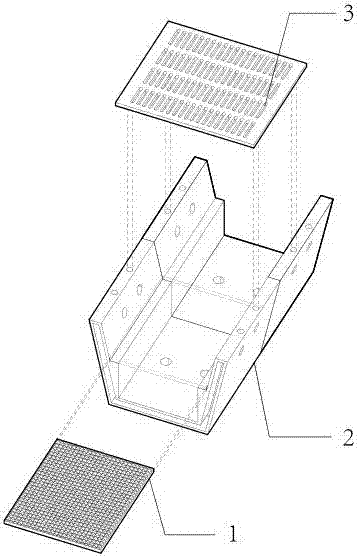

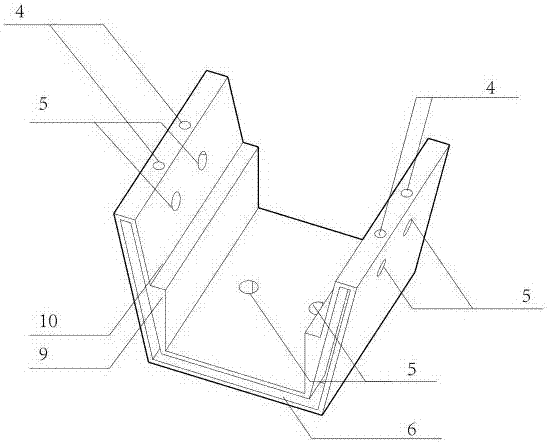

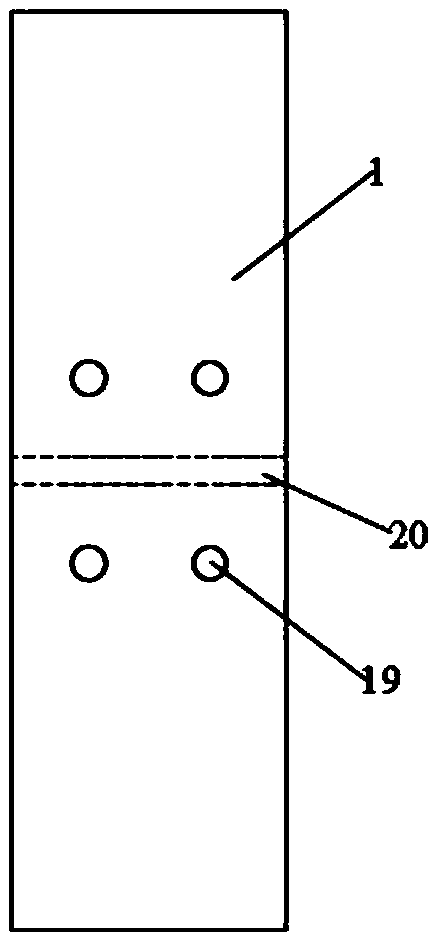

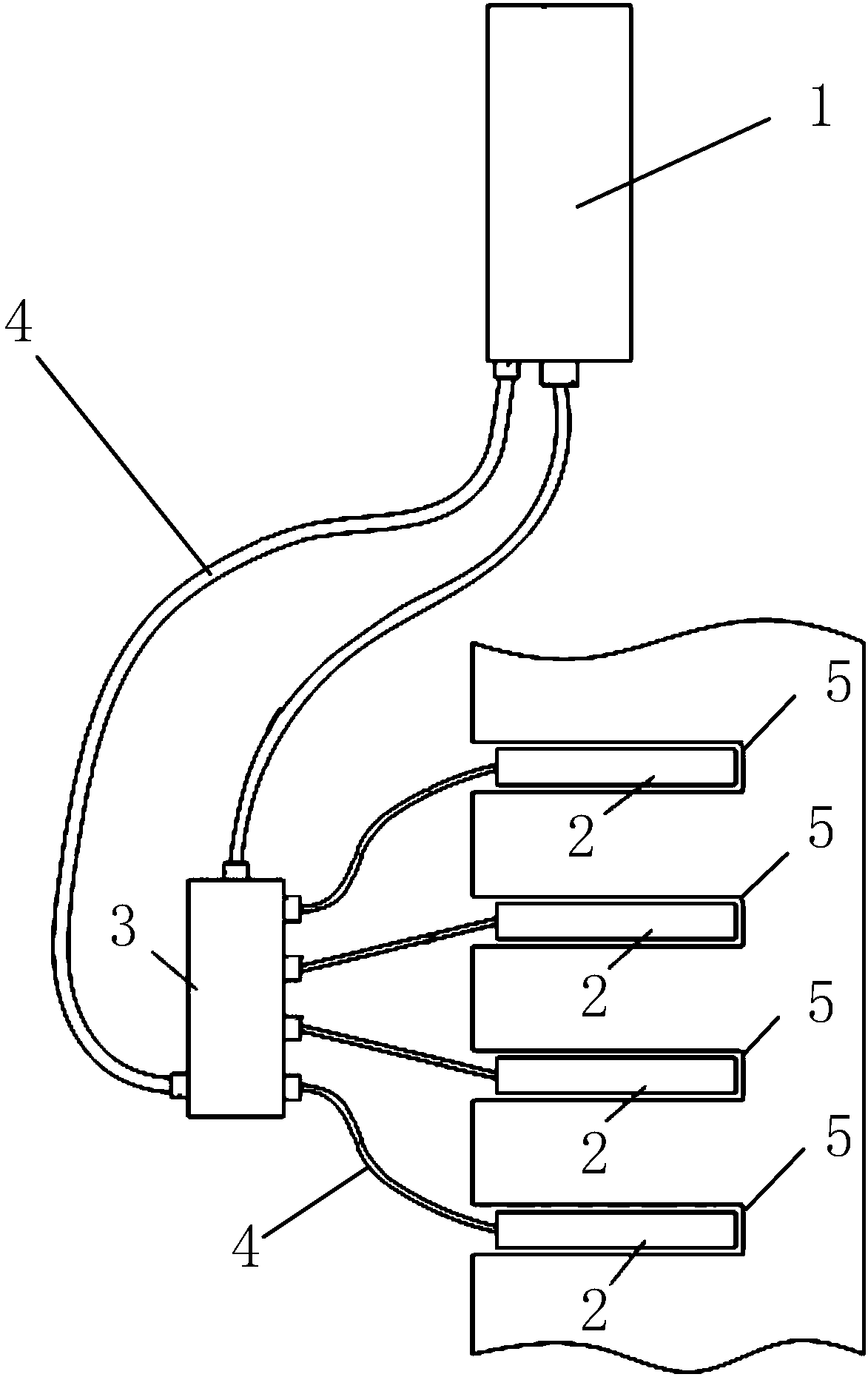

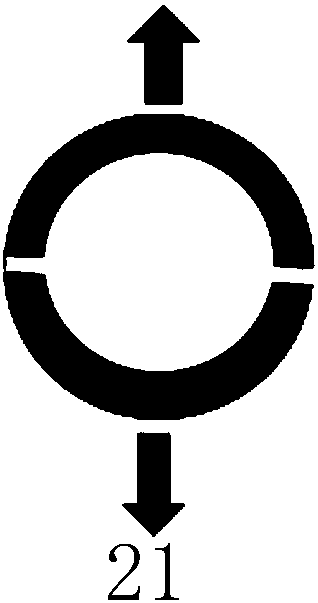

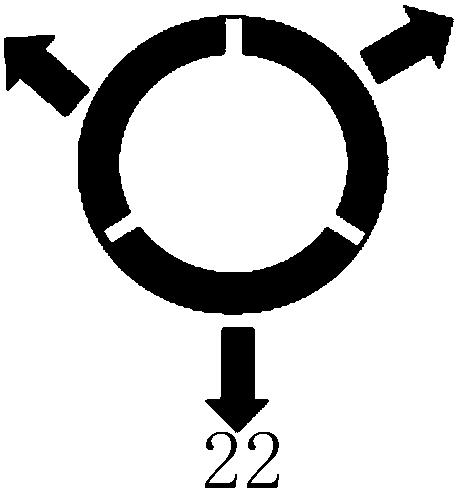

Assembled fan room

ActiveCN109025401BSave resources and energyReduce construction pollutionLighting and heating apparatusIndustrial buildingsEngineeringEngineering structures

Owner:CHONGQING ERAN ELECTROMECHANICAL EQUIP ENG CO LTD

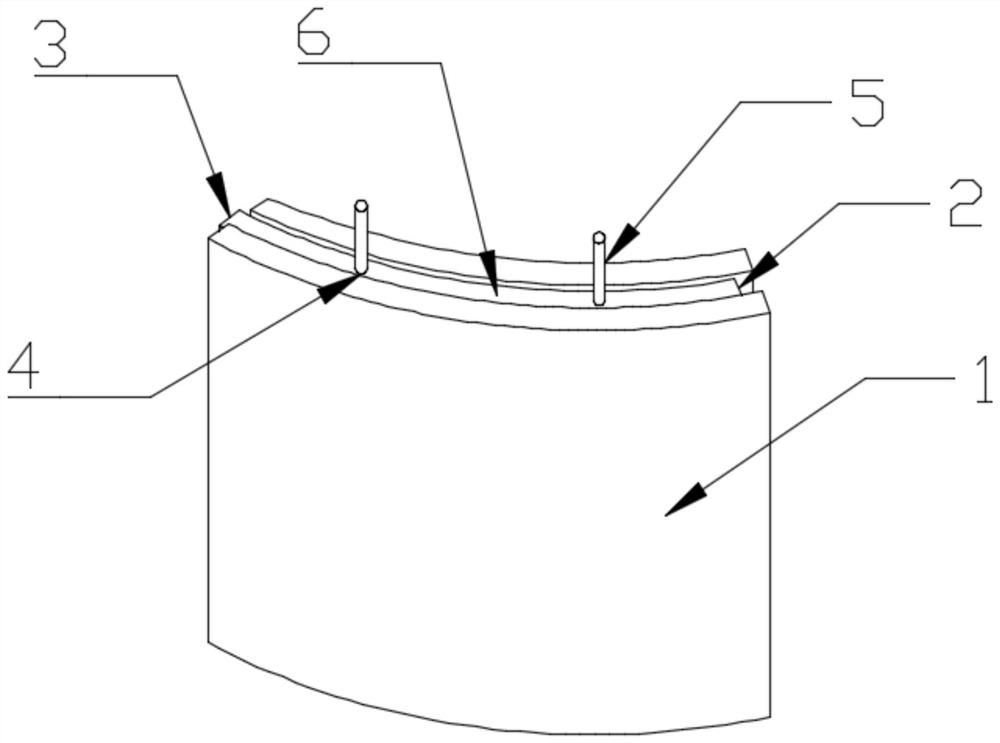

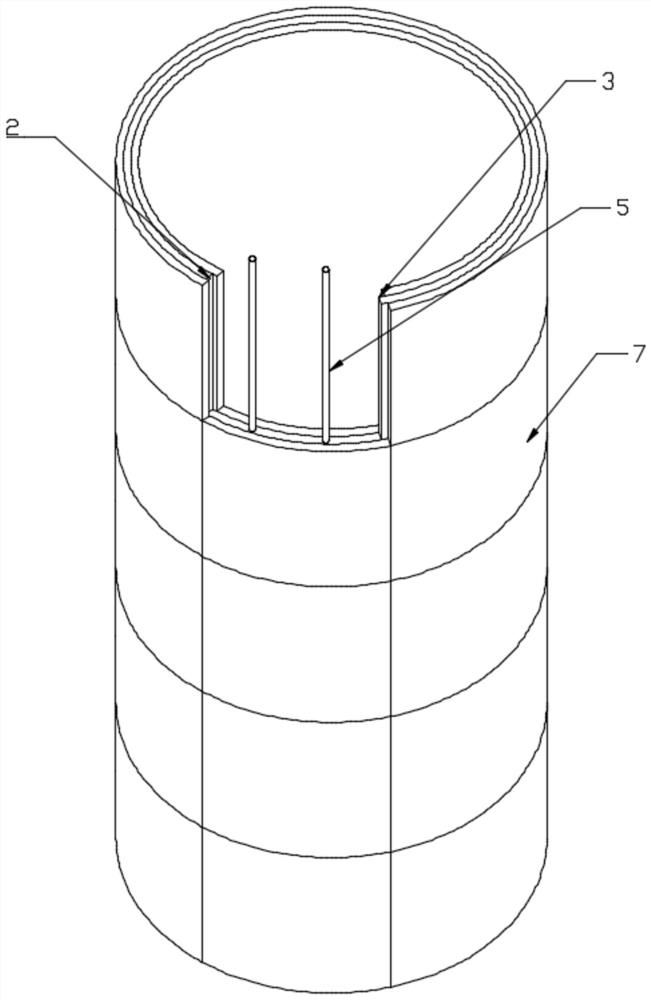

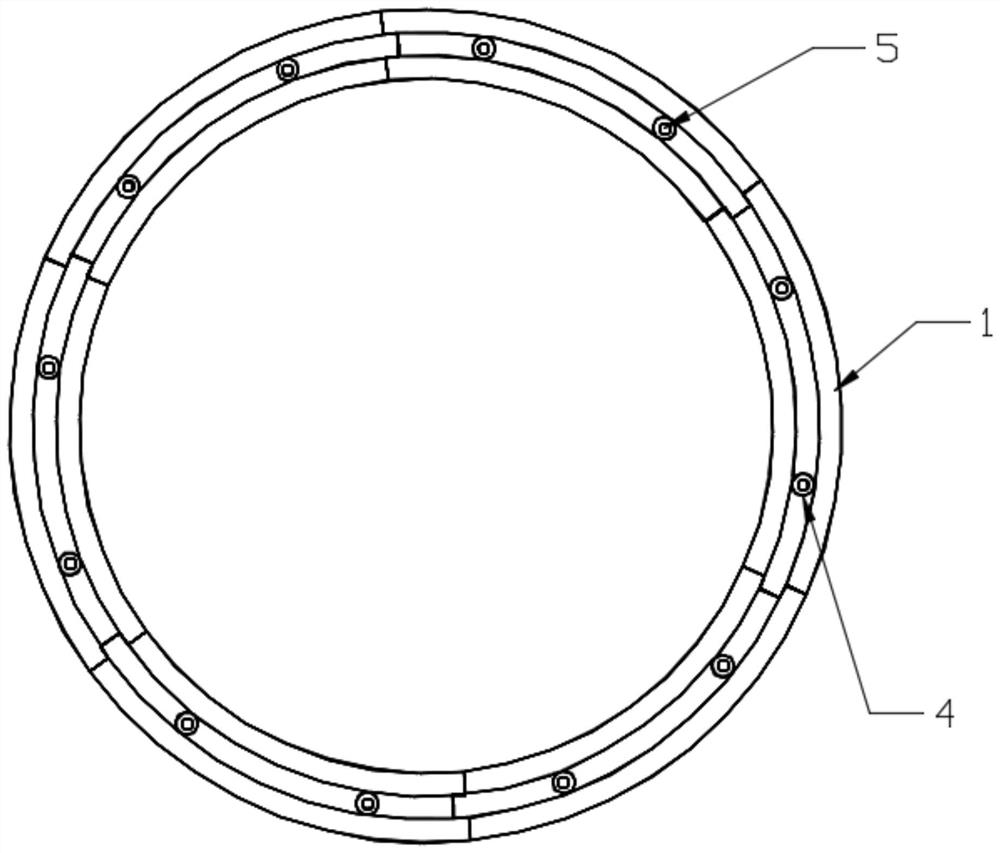

Fabricated tailing pond radiation well walling crib with fixing grooves and construction technology

PendingCN112982491AImprove assembly efficiencyImprove assembly accuracyArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

The invention discloses a fabricated tailing pond radiation well walling crib with fixing grooves and a construction technology. The walling crib comprises a plurality of arc-shaped prefabricated well walls, and the prefabricated well walls are spliced to form annular walling crib bodies. The walling crib bodies are spliced up and down to form a fabricated radiation well. The fixing grooves are integrally formed in the ends of the prefabricated well walls, fixing blocks are integrally formed at the other ends of the prefabricated well walls, and the fixing grooves and the fixing blocks between the left and right adjacent prefabricated well walls are mutually spliced to form the annular walling crib bodies. Preformed holes are formed in the prefabricated well walls in the longitudinal direction, fixing rods are arranged in the preformed holes, the bottoms of the fixing rods are arranged in the preformed holes of the prefabricated well wall on the lower portion of the upper prefabricated well wall and the lower prefabricated well wall, and the tops of the fixing rods are arranged in the preformed holes of the prefabricated well wall on the upper portion of the upper prefabricated well wall and the lower prefabricated well wall. The walling crib bodies are formed through left-right splicing, the upper walling crib and the lower walling crib are spliced to form the radiation well, installation is easy, construction is convenient, the installation efficiency can be improved, and construction risks are reduced.

Owner:湖南中天青鼎工程科技股份有限公司

Plastic face brick

InactiveCN107762091AImprove securityImprove the decorative effectCovering/liningsPolymer scienceBrick

The invention discloses a plastic facing brick, which comprises a plastic facing brick body, the plastic facing brick body is provided with a plastic facing layer, and the components and content ratio of the plastic facing brick body are: water reducing agent 2-3, water retaining agent 1 ~2, water-repellent agent 1~2, silicon dioxide 300~400, colored sand 600~700, cement 300~400, emulsion 280~350, efflorescence inhibitor 3, defoamer 4; the colored sand is natural Colored sand or sintered colored sand; the cement is Portland cement and / or white Portland cement; the water reducer is a melamine-based water-reducer and / or a polycarboxylic acid-based high-performance water-reducer; The water-retaining agent is hydroxyethyl cellulose and / or hydroxypropyl cellulose; the water-repellent agent is polysiloxane powder water-repellent; and the emulsion is silicon-acrylic emulsion. The plastic facing brick is heat-preserving and energy-saving, sound-insulating and heat-insulating, crack-resistant and waterproof, highly decorative, and super-weather-resistant.

Owner:沈阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com