Novel hard-soft package installing metal hanging part

A technology of soft and hard cladding and metal, applied in covering/lining, construction, building construction, etc., can solve the problems of difficult disassembly and reuse, low construction efficiency, and long production period, so as to enhance the reuse rate and reduce labor costs , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

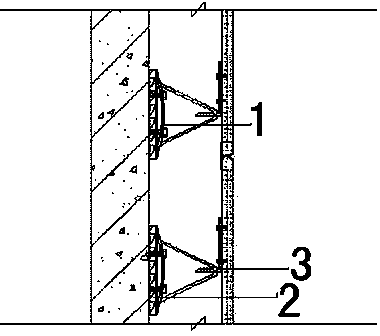

[0022] Example: such as image 3 Shown: a new type of soft and hard bag installation metal pendant, which includes a clip-shaped component 1, a leveling wooden strip 2, and component accessories 3.

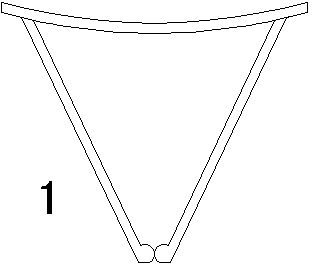

[0023] Such as figure 1 As shown, the side of the clip-shaped member 1 is triangular; the bottom surface is bow-shaped to the inside of the triangle; the two sides are clamping edges;

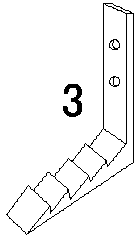

[0024] Such as figure 2 As shown, the component accessories 3 are L-shaped; one is provided with a toothed surface, and the other is provided with a screw hole.

[0025] The leveling wooden bar 2 is fixed on the wall, and the bottom surface of the clip-shaped component 1 is fixed on the leveling wooden bar 2; The clamping member 1 is fixed with the leveling bar 2 by the screw one. Component accessory 3 is fixed with soft and hard clad board by screw 2.

[0026] During installation, the clip-shaped member 1 is connected with the leveling wooden bar 2 fixed on the wall to achieve horizontal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com