Self-resetting glued wood structure beam-column joint capable of replacing top-bottom friction energy-consuming device

A technology of frictional energy dissipators and beam-column joints, which is applied in the direction of building components, building structures, building types, etc., can solve the problems that the performance of buildings cannot be fully utilized, the steel structure does not have high strength, and the impact of structural aesthetics, etc., to achieve Ease of repair and rapid re-use, stable controllability of energy consumption, and clear force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

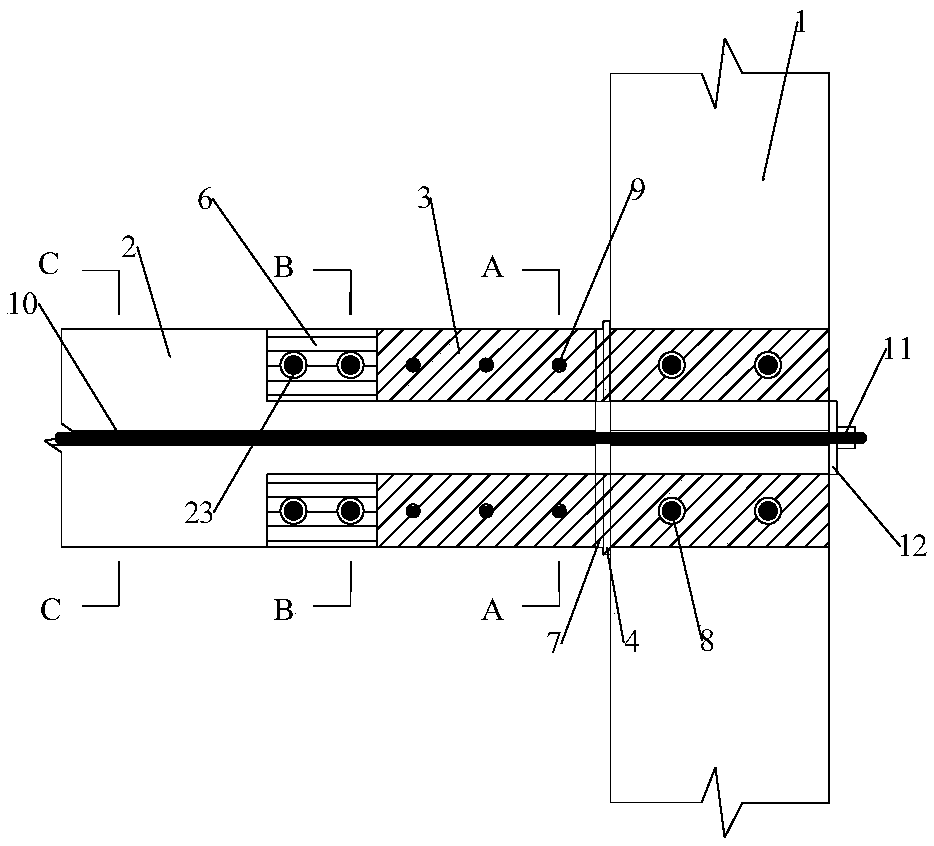

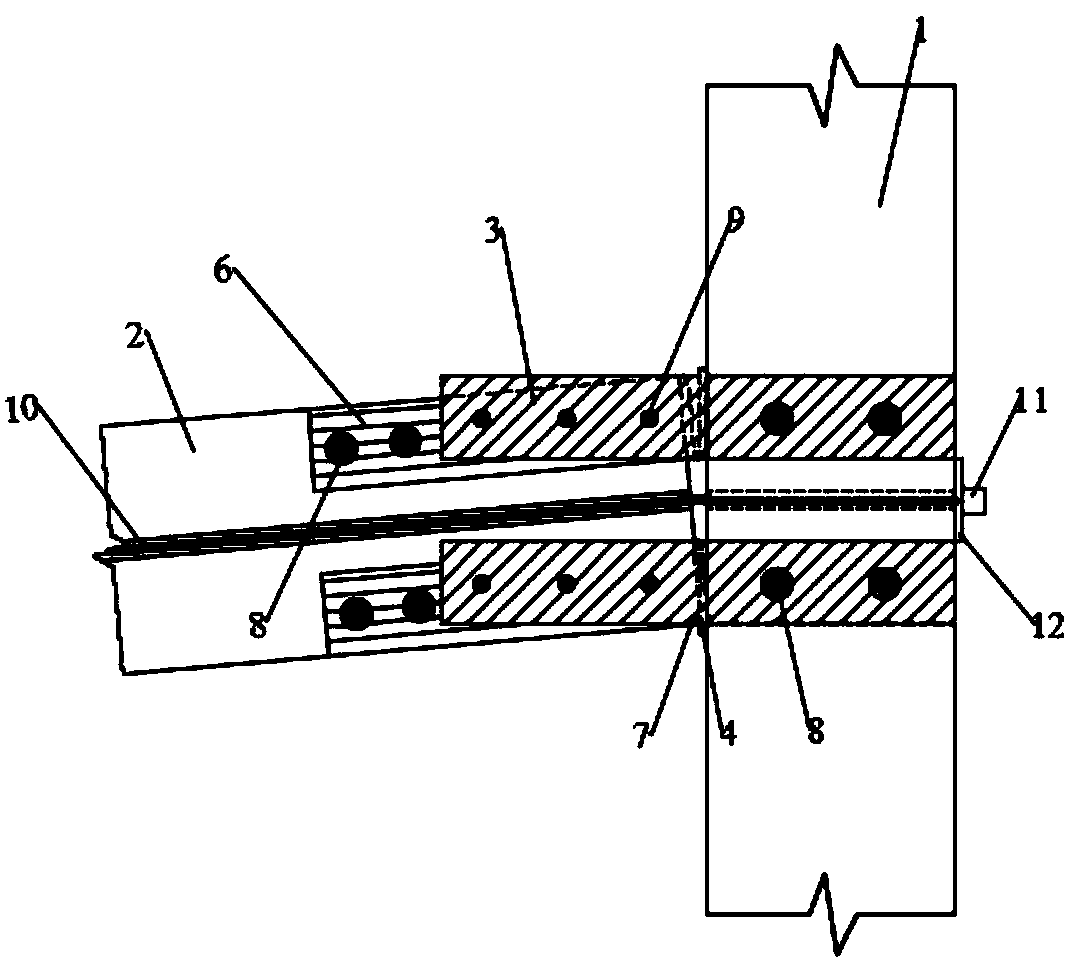

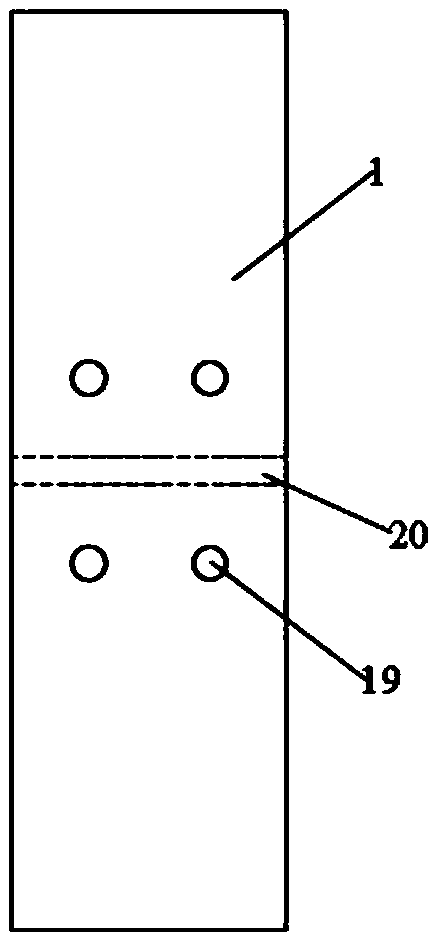

[0040] Such as figure 1 As shown, in the self-resetting glulam structure beam-column node of the replaceable top-bottom friction energy dissipator of the present invention, the main component includes a glulam column 1, a glulam beam 2, and the connecting member includes a friction loss structure with the same upper and lower structure of the node. Energy devices and prestressed tendons 10 that provide self-centering forces for nodes. Under earthquake action, the unbonded prestressed steel bar 10 in the self-centering beam-column joint can provide self-centering force to eliminate the residual deformation of the joint, and the friction energy dissipator arranged at the beam-column joint can consume a large amount of seismic energy, avoiding The main structural components such as beams and columns have obvious plastic deformation, and the ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com