Tunnel bottom prefabricated assembly type tunnel structure and construction method thereof

A technology for prefabricated assembly and tunnel structure, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as difficult control of construction quality, construction process defects of the drainage system at the bottom of railway tunnels and the main bearing structure, and difficult maintenance and repair, etc. The effect of meeting policy construction needs, improving labor production efficiency and quality safety level, and ensuring construction safety and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments of the specification. The following examples are only used to illustrate the present invention, but cannot be used to limit the scope of the present invention.

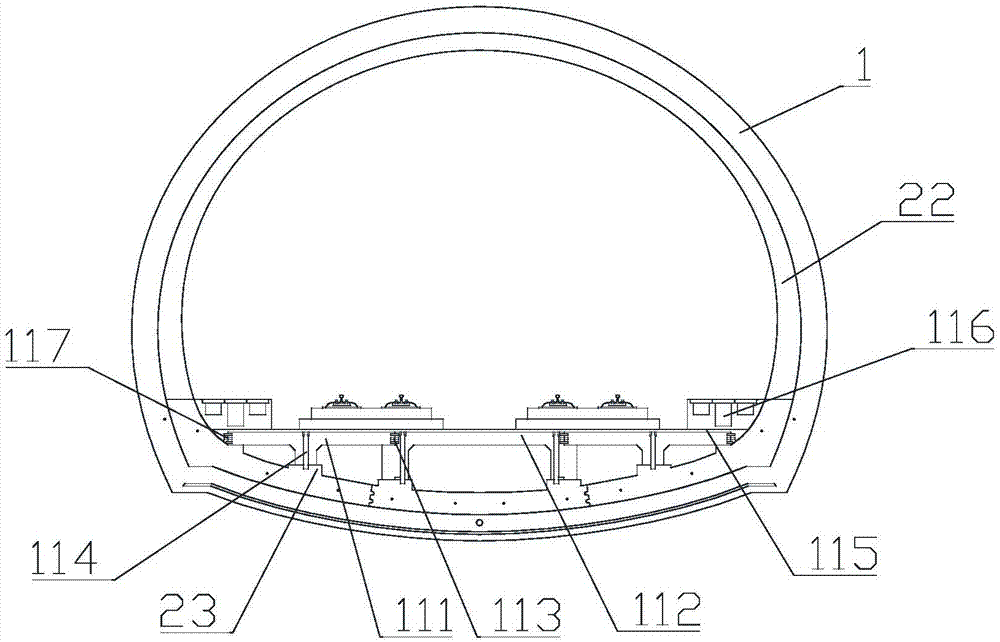

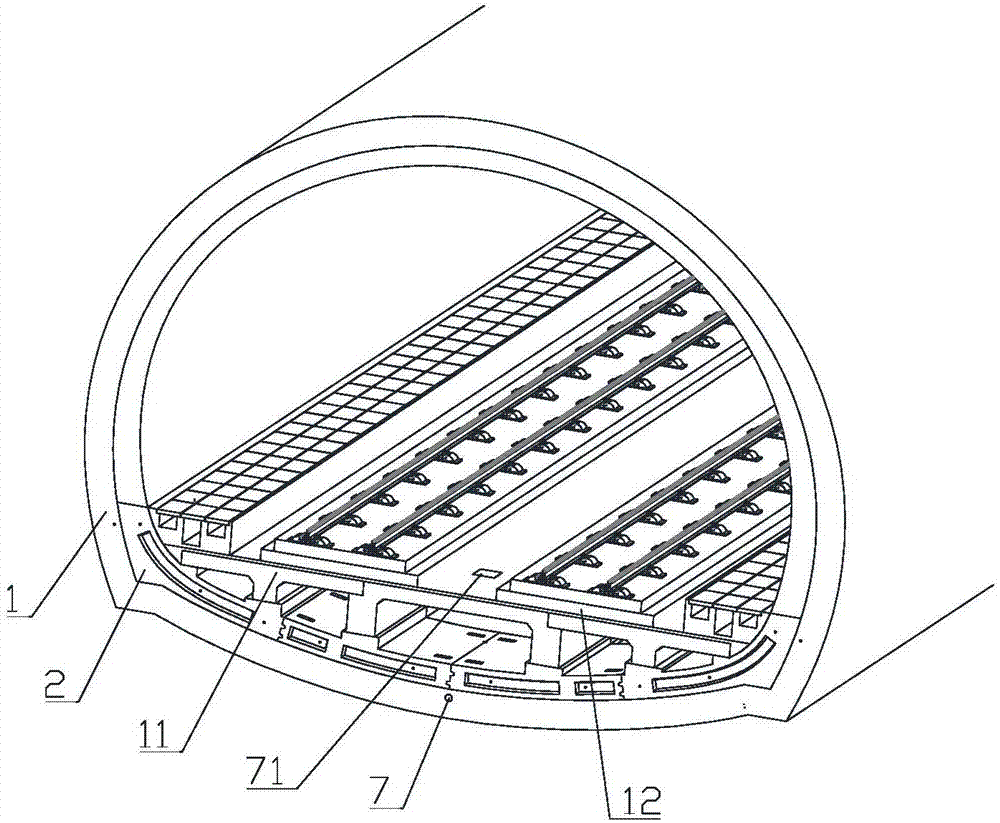

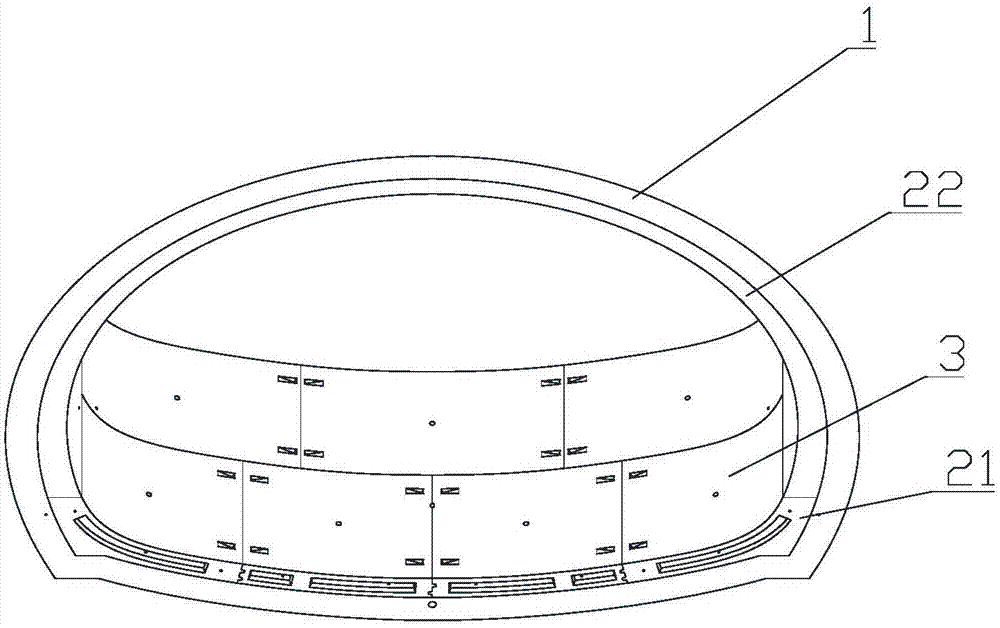

[0032] figure 1 with figure 2 A preferred embodiment of a prefabricated tunnel structure at the bottom of the tunnel according to the present invention is shown. The tunnel structure includes the primary support 1, the secondary lining 2, the drainage system 7 and the filling layer 11. Among them, the secondary lining 2 is provided with 6 protrusions 23, which are arranged at intervals along the transverse direction of the tunnel. , And each protrusion 23 extends along the extending direction of the tunnel. The filling layer 11 adopts a box-shaped board prefabricated block 112 and two T-shaped board prefabricated blocks 111 respectively located on both sides of the box-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com