Tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle

A technology for mixing cement emulsified asphalt and mortar, which is applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problems of cumbersome construction process, troublesome mortar truck reversing, and many matching machines, so as to reduce construction pollution, reduce construction pollution, and reduce construction pollution. Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

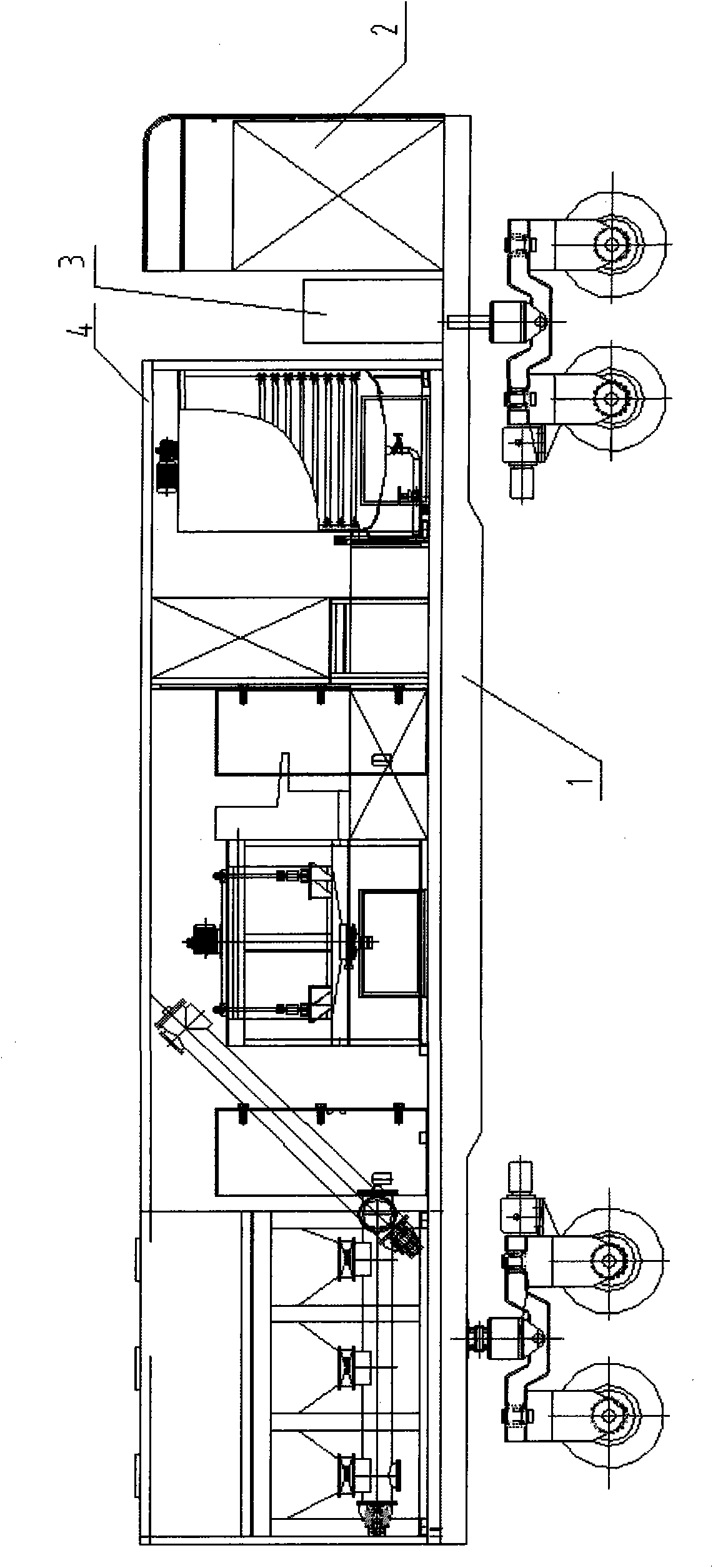

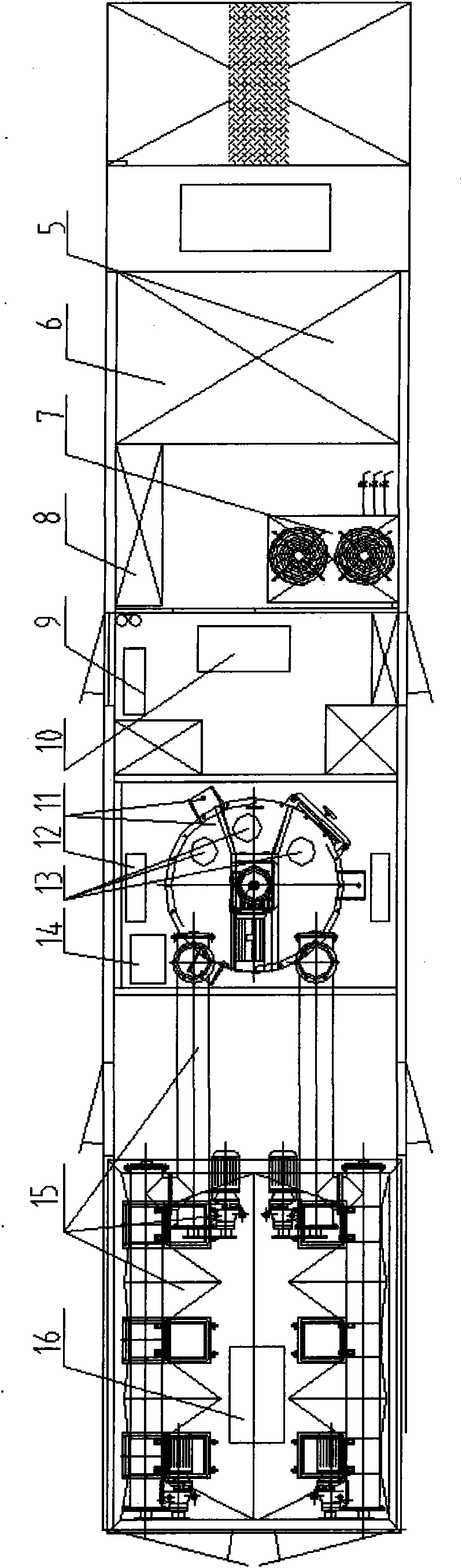

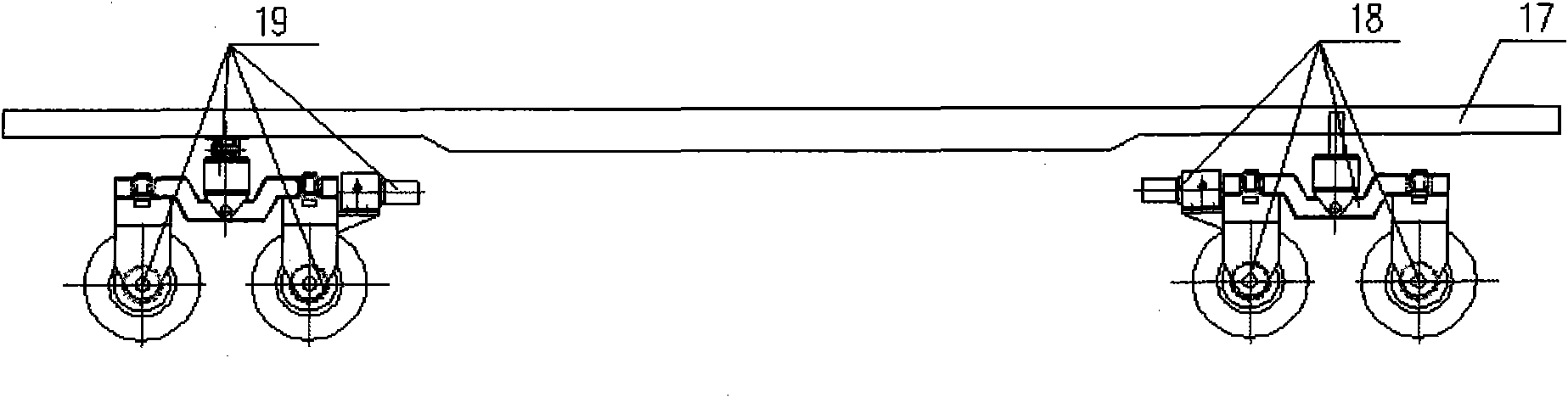

[0021]Referring to the accompanying drawings, the tire-type on-line cement emulsified asphalt mortar mixing and pouring vehicle includes a special chassis 1, a generator set 2, a hydraulic pump station 3 and a vehicle-mounted container 4 are arranged above the special chassis 1, and the vehicle-mounted container 4 is provided with a first Emulsion storage tank and conveying system 5, water and second emulsion storage tank and conveying system 6, industrial air conditioning unit 7, electric power and electric control system 8, operating room and operating table 9, three kinds of small material storage tanks and conveying system 10, Stirring tank and main metering system 11, sub-metering hopper 12, small metering hopper 13, high-pressure cleaning machine 14, cement and sand dry powder silo and screw conveying system 15, air compressor 16; Described first emulsion tank is provided with Stirring blades, air-conditioning insulation coils; the mixing tank includes a cylindrical tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com