Isothermal adiabatic reactor for olefin and hydrogen peroxide epoxidation

A hydroperoxide and adiabatic reactor technology, which is applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of large footprint, incomplete reaction of hydroperoxide, and difficult temperature control. Achieve the effects of simplifying the reaction process, improving the service life and overall utilization, and reducing the loss of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

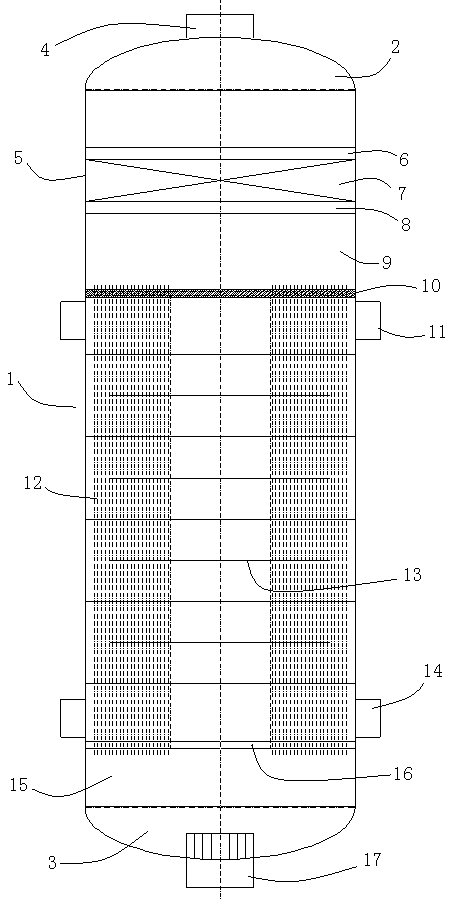

[0048] Such as Figure 1-Figure 3 As shown, the isothermal adiabatic reactor for the epoxidation of olefins and hydroperoxides according to the present invention comprises: a cylindrical shell 1 with an upper head 2 and a lower head 3, and the top of the upper head 2 is provided with The reaction product outlet 4; the cylindrical shell 1 is divided into upper and lower sections; the upper section is an adiabatic catalytic reaction section, which consists of an adiabatic section housing 5, a catalyst pressure plate 6, an adiabatic section catalytic bed 7 and a support plate 8; the lower section is an isothermal catalytic reaction section, and the two ends of the isothermal catalytic reaction section are respectively provided with an upper tube box 9 and a lower tube box 15; the bottom of the lower head 3 is provided with a reaction raw material inlet 17.

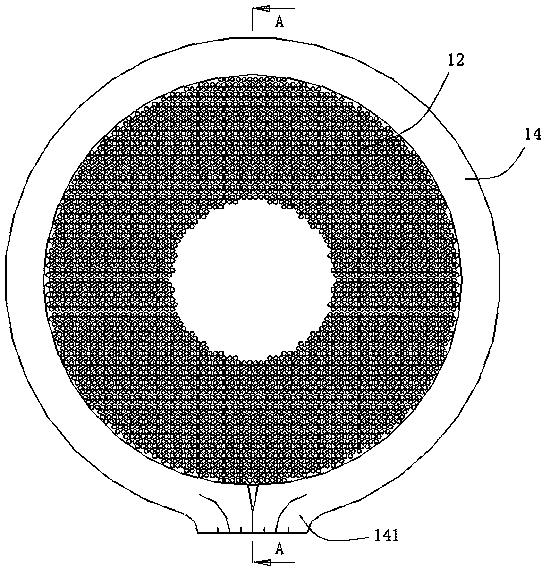

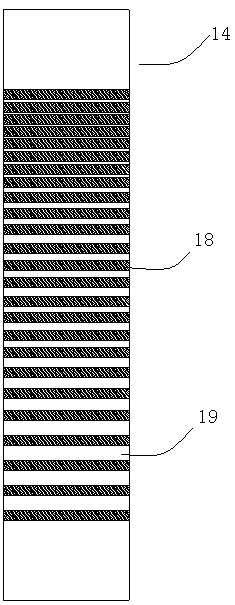

[0049] Such as figure 1 with figure 2 As shown: the isothermal catalytic reaction section is divided into a tube side an...

Embodiment 2

[0061] Using the reactor of the present invention, the main structural size data are: the inner diameter is 50mm, the height of the isothermal catalytic reaction section is 1m, the height of the adiabatic catalytic reaction section is 0.2m, and the upper TiO 2 loaded on SiO 2 Carrier catalyst, carried out the experiment of propylene and ethylbenzene hydroperoxide (EBHP), and experimental condition is shown in Table 3; Experimental result is shown in Table 4.

[0062] table 3

[0063] Experimental conditions

index

80

Reaction pressure, MPaG

4.5

Propylene / EBHP, mol / mol

6

EBHP heavy hourly space velocity, h-1

0.8

[0064] Table 4

[0065] evaluation item

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com