Multi-layer integrated type series-connection vertical telescopic dry-process vibration medium drainage screen

An integrated, media-removing sieve technology, which is applied to filter screens, chemical instruments and methods, and solid separation, can solve problems such as unsatisfactory media-removal effects, large floor space, and high requirements for workshops, and achieve convenient up and down telescopic adjustment and fixing, reducing floor space, reducing floor space and space effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

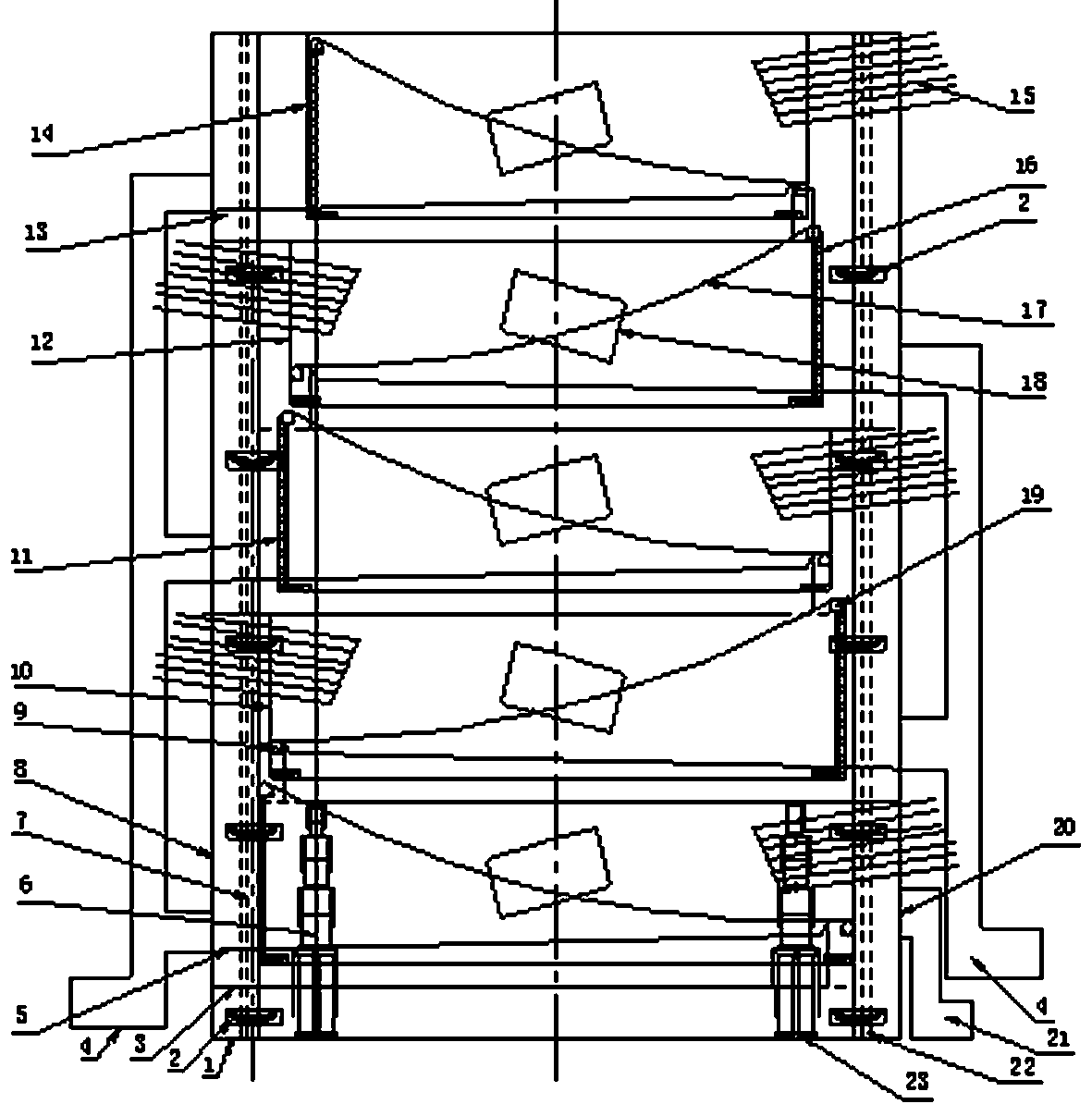

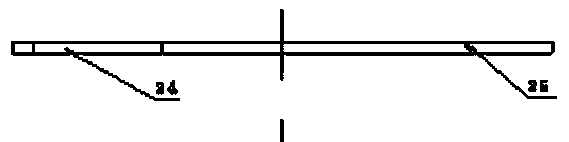

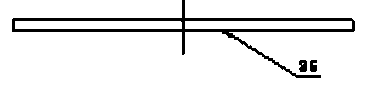

[0036] Such as figure 1 As shown, the multi-layer integrated series vertical telescopic dry-process vibrating separation screen of the present invention includes a support base 1, a complete machine frame 8 fixed in the corresponding groove on the support base 1, and a frame fixed on the support base 1. Two left and right front and rear movement rails 23, a vertical support movement hydraulic cylinder 6 is respectively installed at the two ends above the left and right front and rear movement rails 23, and the slideway 22 moves up and down through the screen frame inside the complete machine frame 8 Several layers installed in sequence are equipped with screen frames and outer covers of screen mesh 17; each layer of screen frames and outer covers are installed on the inside of the complete machine frame 8 and are evenly distributed with four shock absorbing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com