Tunnel base and a construction method thereof

A tunnel and base technology, applied to roads, tracks, ballast layers, etc., can solve problems such as low construction efficiency, long construction period, and impact on the bearing capacity of the tunnel base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] It should be noted that in this application, the direction of the horizontal line in the cross section of the tunnel base is defined as "transverse", the direction of tunnel extension is defined as "longitudinal", and the direction perpendicular to the horizontal plane is defined as "vertical". . And the directional terms or qualifiers "upper end", "lower end" and other similar terms used in this application are all for the referenced drawings, they are not used to limit the absolute position of the parts involved, but can be Varies on a case-by-case basis.

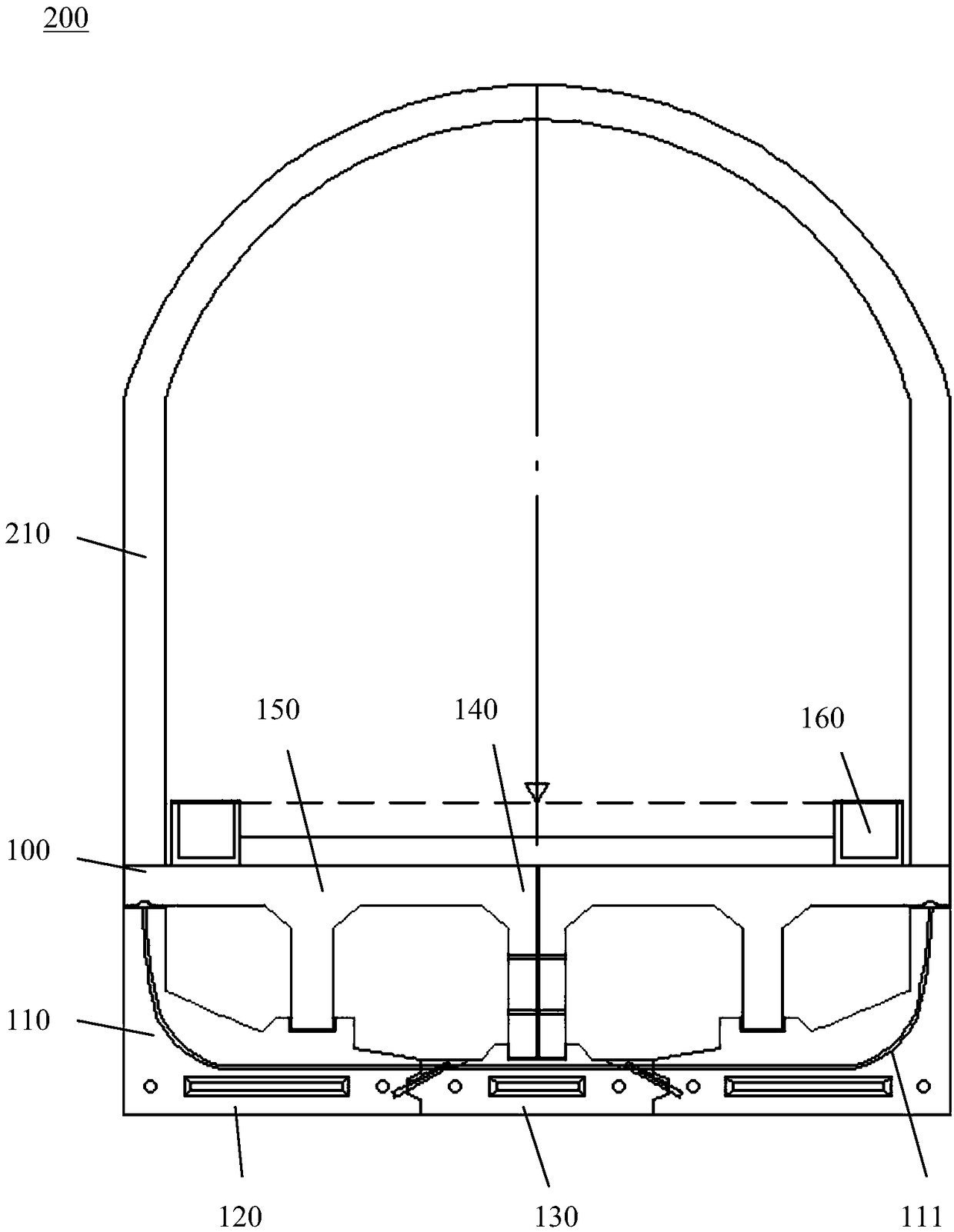

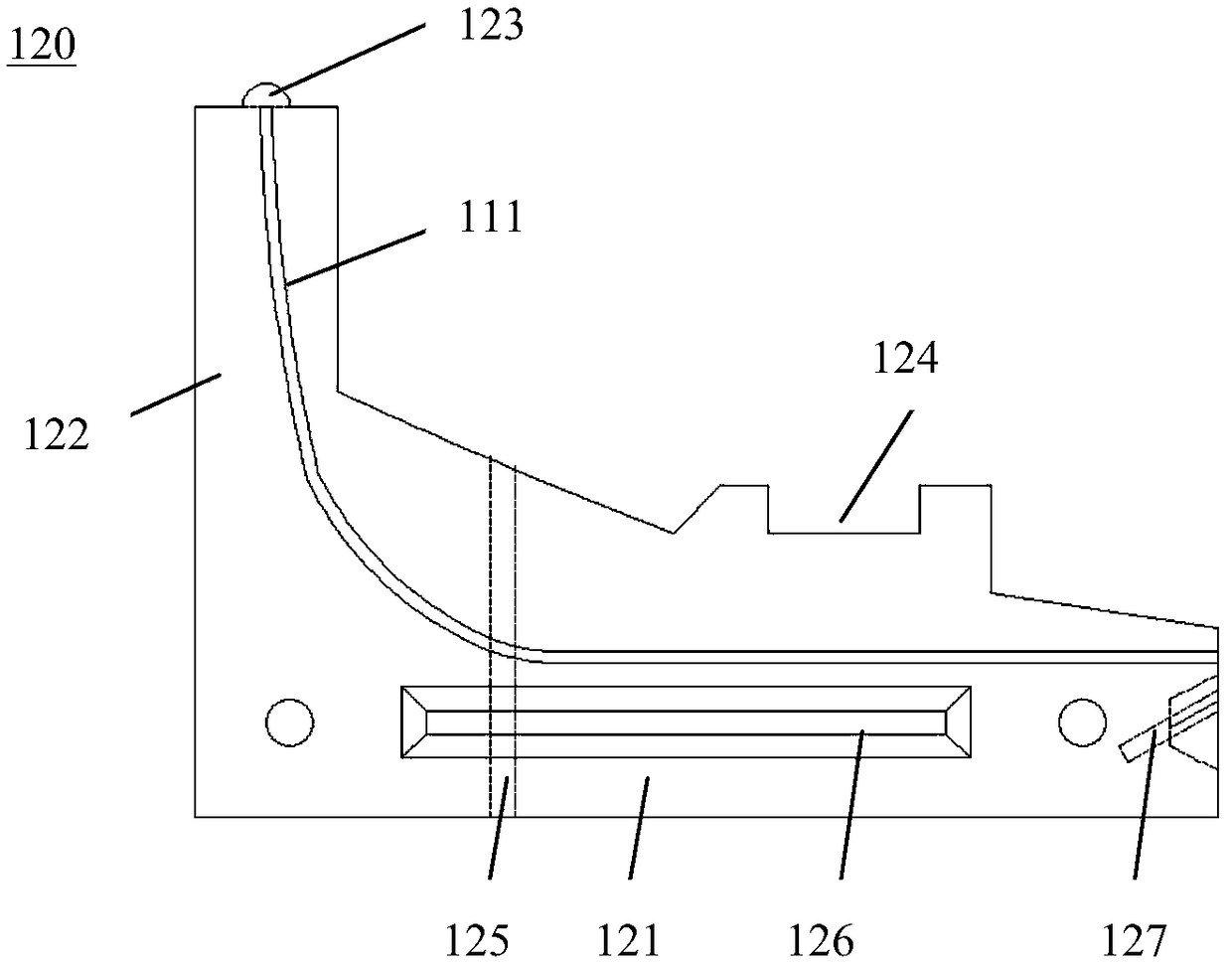

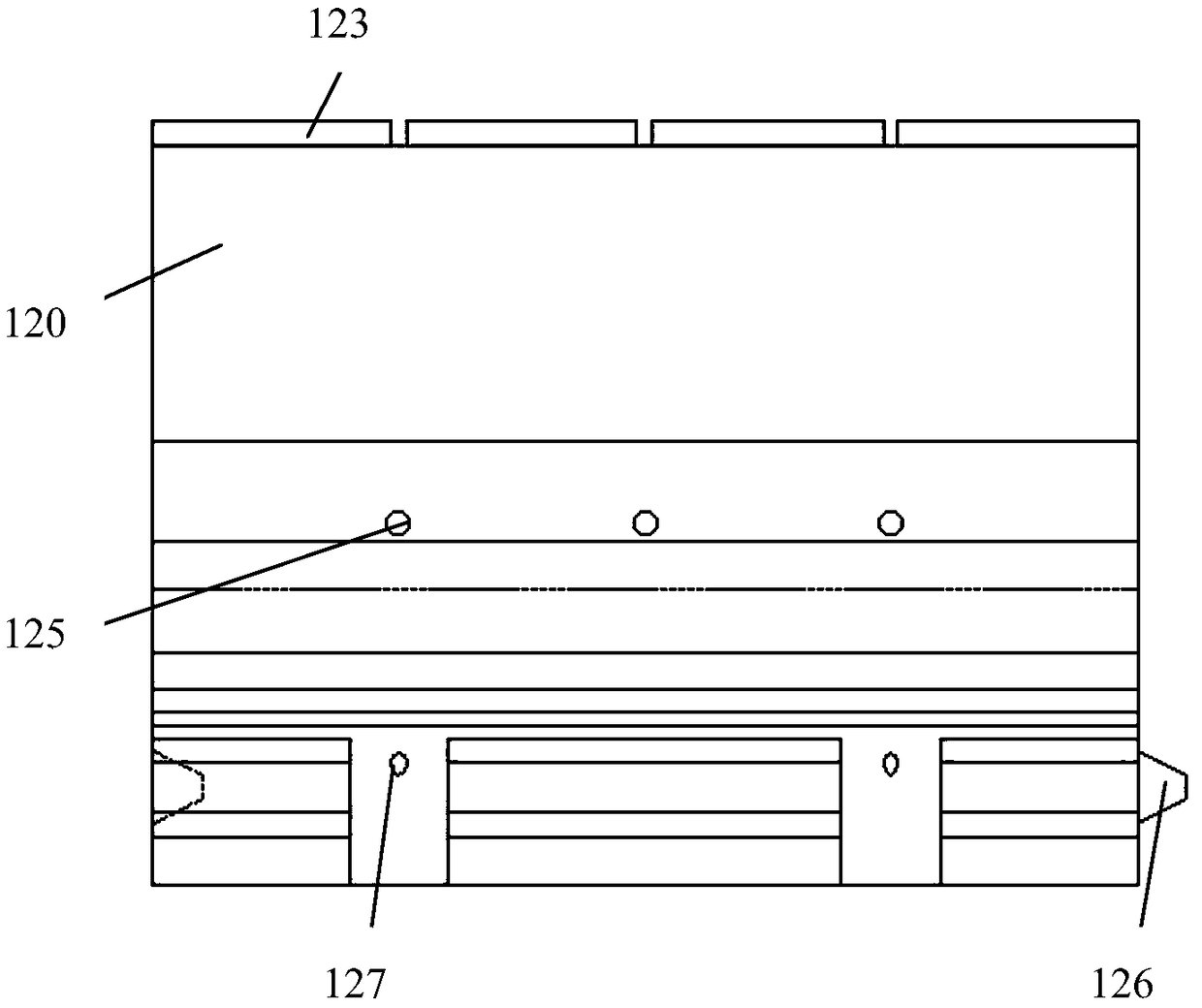

[0032] figure 1 A schematic diagram of a transverse section of a tunnel substrate 100 according to the invention is shown. Such as figure 1 As shown, the tunnel base 100 is installed at the bottom of the tunnel 200 . According to the invention, the tunnel base 100 is a prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com