Diatom plate and production method thereof

A technology of diatom board and diatomite, which is applied in the field of decorative materials, can solve the problems of low strength of gypsum board, low construction efficiency and high labor cost, and achieve the effects of high resource utilization rate, low construction pollution and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

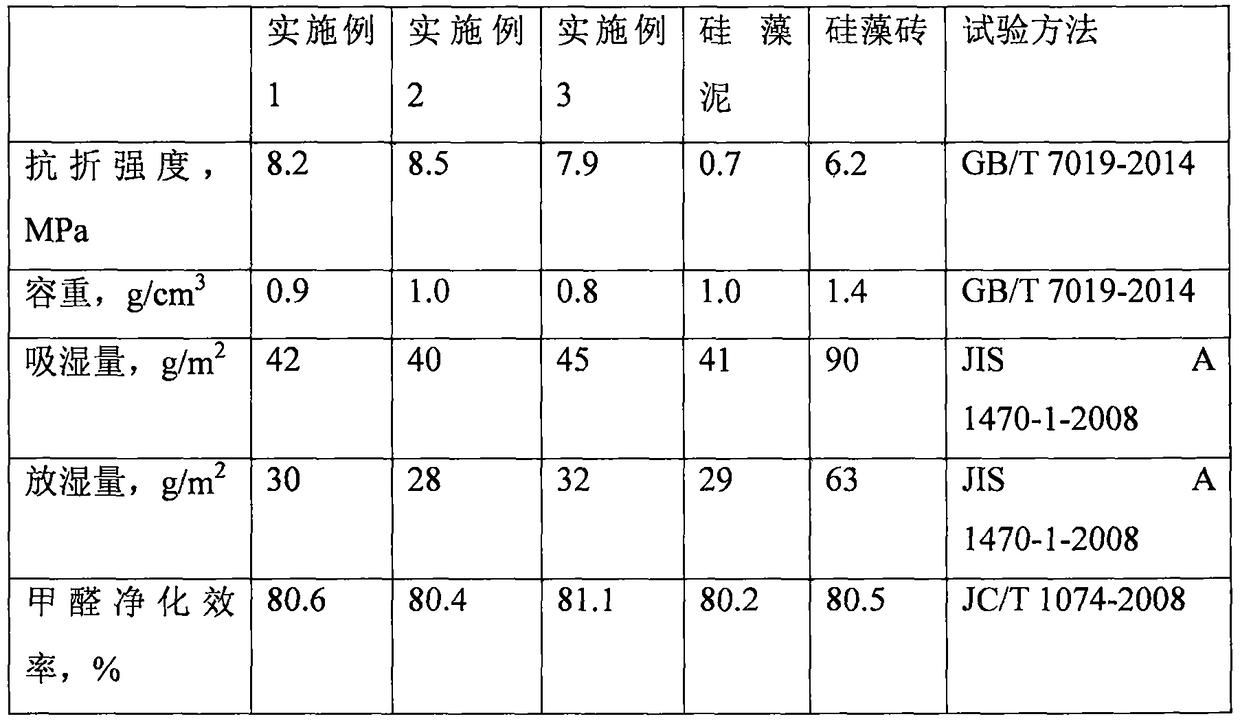

Examples

Embodiment 1

[0030] Diatom board, the raw material components and parts by weight of the diatom board are: 50 parts of diatomite, 1 part of nano-titanium dioxide, 0.05 part of nano-silver antibacterial agent, 17 parts of slaked lime, 8 parts of pulp fiber, and 20 parts of cement , 3 parts of hemihydrate gypsum, 0.75 parts of quartz powder, 0.2 parts of pigment, and 570 parts of water.

[0031] In this embodiment, the diatomaceous earth is treated primary earth ore.

[0032] In this embodiment, the nano titanium dioxide is modified anatase titanium dioxide, and the particle size of the nano titanium dioxide particles is less than 100 nm.

[0033] In this embodiment, the particle size of the nano-silver antibacterial agent particles is less than 100 nm.

[0034] In this embodiment, the mass content of calcium hydroxide in the slaked lime is not less than 90%, the mass content of magnesium hydroxide is not more than 3%, and the particle size of the particles is less than 100 μm.

[0035] In...

Embodiment 2

[0053] Diatom board, the raw material components and parts by weight of the diatom board are: 30 parts of diatomite, 0.5 parts of nano-titanium dioxide, 0.01 part of nano-silver antibacterial agent, 15 parts of slaked lime, 5 parts of pulp fiber, and 30 parts of cement , 1 part of hemihydrate gypsum, 18.39 parts of quartz powder, 0.1 part of pigment, and 400 parts of water.

[0054] In this embodiment, the diatomaceous earth is treated primary earth ore.

[0055] In this embodiment, the nano titanium dioxide is modified anatase titanium dioxide, and the particle size of the nano titanium dioxide particles is less than 100 nm.

[0056] In this embodiment, the particle size of the nano-silver antibacterial agent particles is less than 100 nm.

[0057] In this embodiment, the mass content of calcium hydroxide in the slaked lime is not less than 90%, the mass content of magnesium hydroxide is not more than 3%, and the particle size of the particles is less than 100 μm.

[0058] In...

Embodiment 3

[0076] Diatom board, the raw material components and parts by weight of the diatom board are: 60 parts of diatomite, 1.5 parts of nano-titanium dioxide, 0.01 part of nano-silver antibacterial agent, 23.09 parts of slaked lime, 10 parts of pulp fiber, and 0 part of cement , 5 parts of hemihydrate gypsum, 0.1 part of quartz powder, 0.3 part of pigment, and 900 parts of water.

[0077] In this embodiment, the diatomaceous earth is treated primary earth ore.

[0078] In this embodiment, the nano titanium dioxide is modified anatase titanium dioxide, and the particle size of the nano titanium dioxide particles is less than 100 nm.

[0079] In this embodiment, the particle size of the nano-silver antibacterial agent particles is less than 100 nm.

[0080] In this embodiment, the mass content of calcium hydroxide in the slaked lime is not less than 90%, the mass content of magnesium hydroxide is not more than 3%, and the particle size of the particles is less than 100 μm.

[0081] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com