Polymer cement adhesive construction method

A technology of polymers and adhesives, applied in building construction, building maintenance, construction, etc., can solve the problems of construction workers' physical and mental health damage, waste of manpower and material resources, construction environment pollution, etc., and meet the requirements of simple and convenient construction equipment Good for health and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

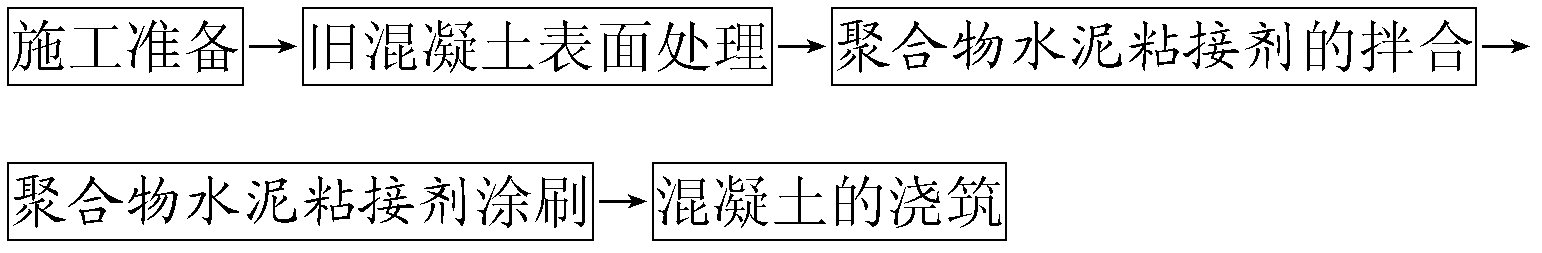

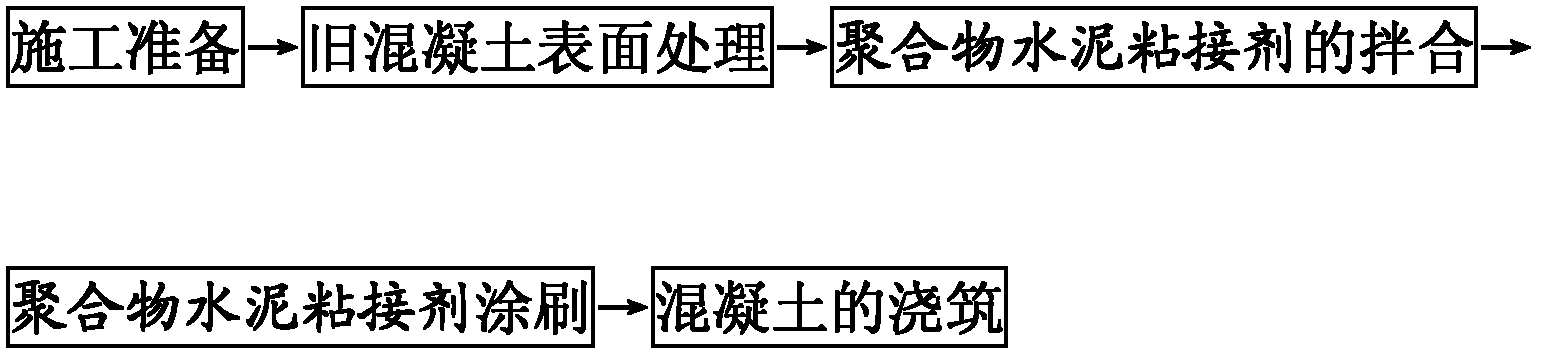

[0022] A kind of polymer cement adhesive construction method, comprises the following steps:

[0023] (1) Phase I concrete or old concrete surface treatment: clean up the dirt on the concrete surface, and treat the hollowing, loosening and sanding of the base surface;

[0024] When dealing with shallow concrete cracks, pick out V-shaped grooves across concrete cracks, and remove dust and broken concrete;

[0025] Sprinkle water on the concrete surface to keep the concrete surface moist.

[0026] (2) Brushing of polymer cement adhesive: Mix the general polymer emulsion and cement at a ratio of 1:2 and mix well. After mixing, the cement should not have lumps, and cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com