Prefabricated variable-section pile and construction method thereof

A variable-section pile and integral prefabrication technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of incomplete welding at the joint position, hidden quality problems of the pile body, corrosion durability, etc., to avoid welding, reduce Construction period and the effect of reducing construction pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

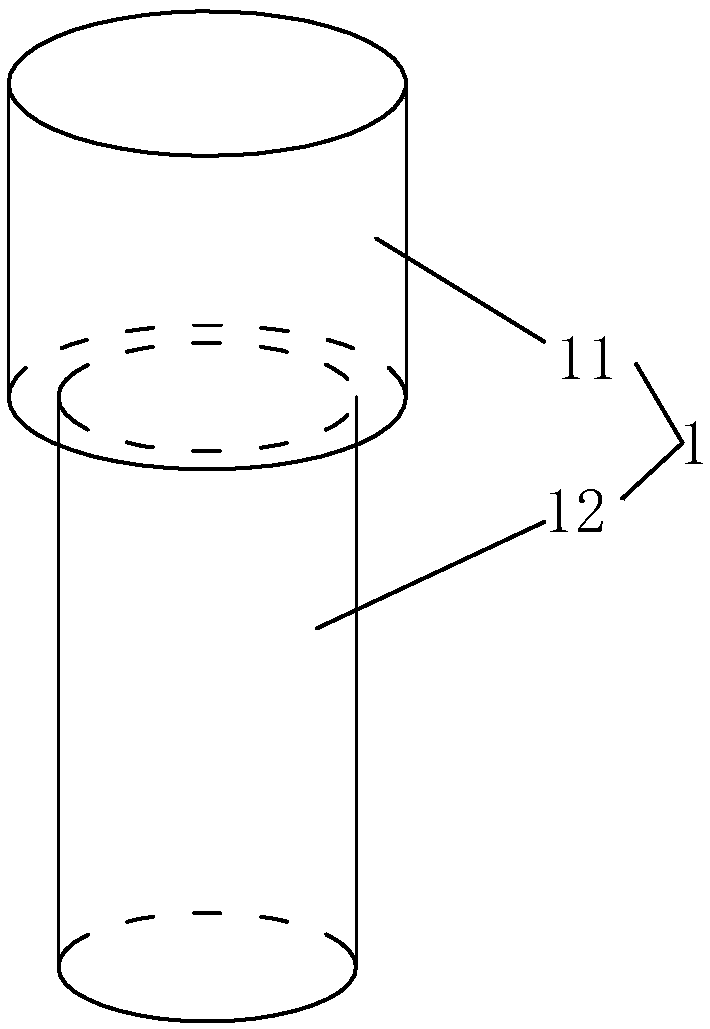

[0036] See figure 1 As shown, a prefabricated variable cross-section pile of the present invention is used to transfer the load of the superstructure to the foundation, including a pile body 1, which is manufactured by prefabricated components, integrally formed, and includes at least two sections of the pile body, And among every two adjacent pile bodies, the cross-sectional size of the upper pile body is greater than the cross-sectional size of the lower pile body. That is to say, the cross-sectional dimension of the pile body 1 becomes smaller from top to bottom, and changes in an inverted step shape. The cross-sectional size of each section of the pile itself is consistent from top to bottom, that is, each section of the pile itself is a pile of equal section. The cross-sectional dimension may be diameter (cylindrical piles, for hollow cylindrical piles or tubular piles etc. the outer diameter) or side length (polygonal piles) and the like.

[0037] In this embodiment, t...

Embodiment 2

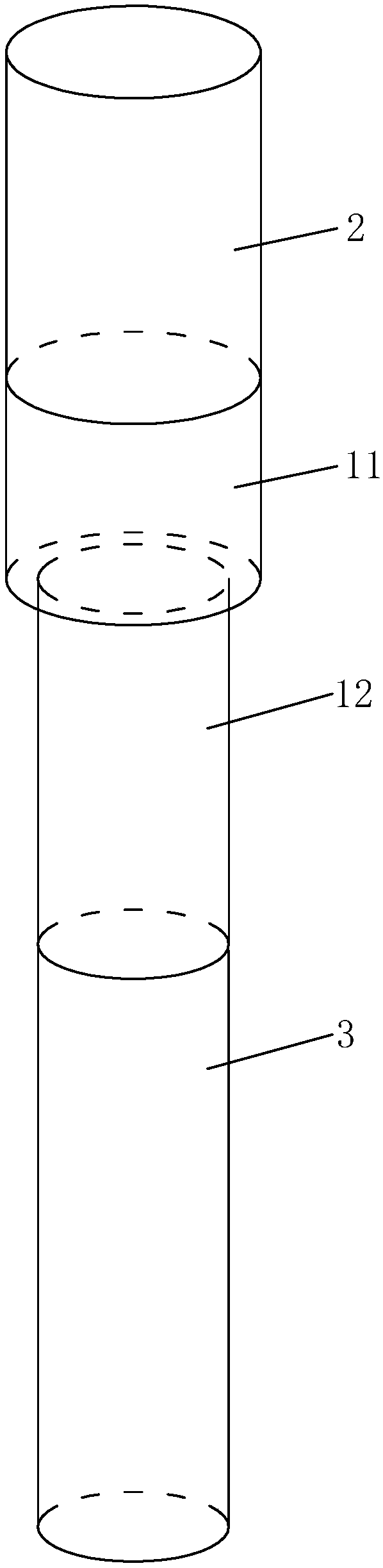

[0041] See figure 2 As shown, the difference between it and the first embodiment above is that splicing piles are respectively connected to the top and bottom ends of the pile body 1, and the splicing piles are integrally prefabricated. In order to facilitate the distinction, the spliced pile connected to the top of the pile body 1 is named as the upper spliced pile 2, and the spliced pile connected to the bottom of the pile body 1 is named the lower spliced pile 3. The upper connection pile 2 and the lower connection pile 3 also adopt the prefabricated production method.

[0042] In this embodiment, the pile body 1, the upper connecting pile 2, and the lower connecting pile 3 are all butted with equal sections, that is, the cross-sectional size of the upper connecting pile 2 and the cross-sectional size of the large-section pile body 11 of the pile body 1 Consistent, the cross-sectional dimension of the lower pile 3 is consistent with the cross-sectional dimension o...

Embodiment 3

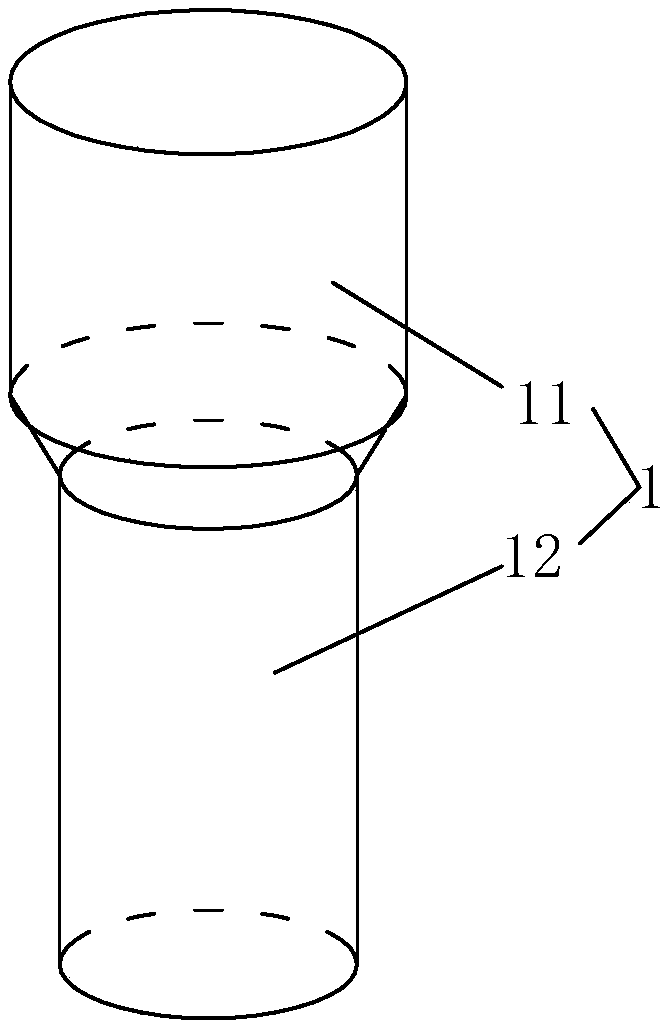

[0051] See image 3As shown, the difference between it and the first embodiment is that the transition surface between the large-section pile body 11 and the small-section pile body 12 of the pile body 1 is a circular platform with a large top and a small bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com