Construction method of double-liquid rapid-hardening high-pressure jet grouting pile

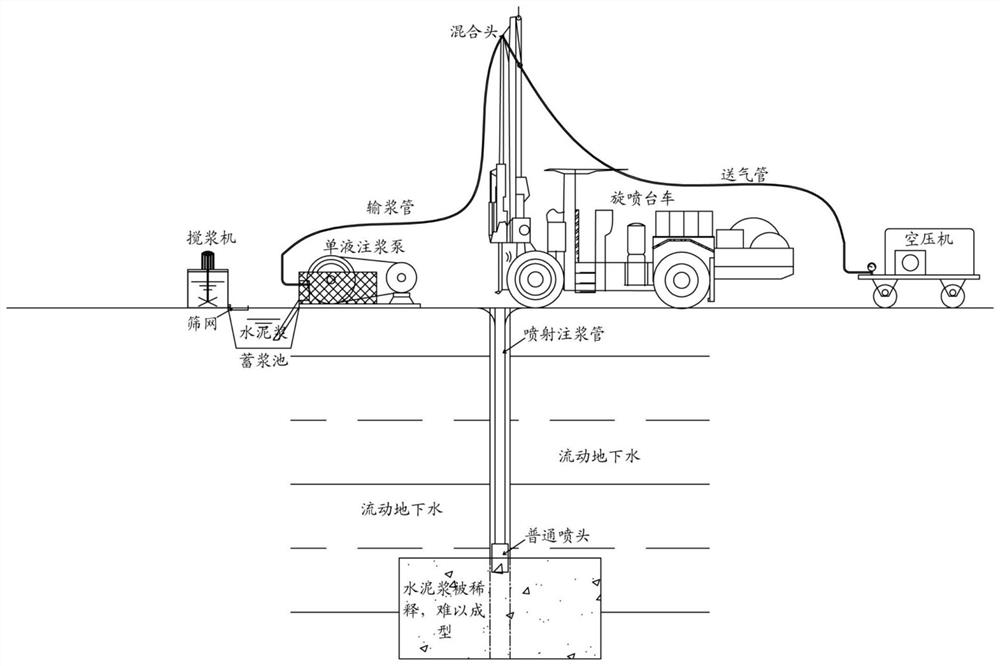

A technology of high-pressure jet grouting piles and construction methods, which is applied to drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., which can solve the problems of long slurry solidification time, strong slurry fluidity, and difficulty in forming piles, and achieve Weak fluidity, less dosage, convenient quick-setting pile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

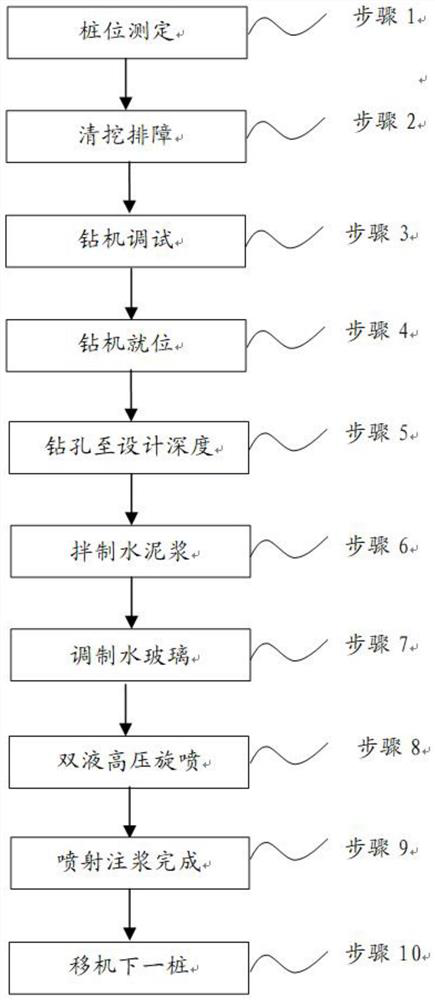

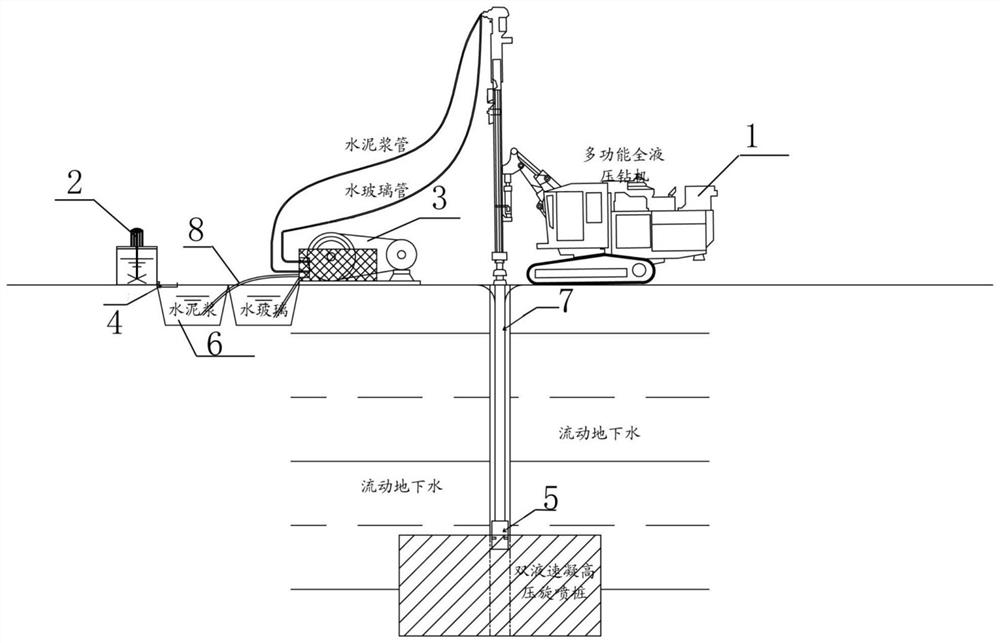

[0080] Regarding the construction process of the quick-setting pile of the double-liquid quick-setting high-pressure rotary grouting pile of the present invention, it specifically includes the following steps:

[0081] Step 1) Pile position measurement: measure the construction axis of the double-liquid rapid-setting high-pressure jet grouting pile through the level meter distance measuring system, and conduct a recheck line inspection. After confirming that the construction axis is qualified, use the steel ruler and the axis to lay out the pile position and use bamboo nails Each pile position corresponds to a piece of bamboo, so that the displacement deviation of the center of the pile hole is less than 20mm, and the determination of the pile position is completed;

[0082] Step 2) Excavation and obstacle removal: Excavate and clear the above-ground and underground obstacles that appear on the construction site, and set up slurry drainage ditches at the same time, and relocate...

Embodiment 2

[0092] In the present invention, two pressure gauges are installed above the variable frequency high pressure pump 3, wherein the pressure of the pressure gauges can reach 30 MPa, and safety valves are installed on both sides of the frequency variable high pressure pump 3. When grouting, when the pressure in the variable frequency high pressure pump 3 When it exceeds 45MPa, the safety valve will automatically open to release the pressure, thereby protecting the equipment. Before the grouting, the operators in the background must adjust the ratio of water glass and cement according to the needs of the site, and then start the grouting after the experiment , Observe the flow rate of the pressure gauge and the slurry suction pipe 8. The slurry suction pipe 8 must use a transparent steel wire bellows to observe the situation of the slurry in the slurry suction pipe 8. If there is any situation, immediately communicate with the front desk operator and deal with it quickly.

Embodiment 3

[0094] The quick-setting pile of the double-liquid quick-setting high-pressure rotary grouting pile of the present invention can be applied to the horizontal reinforcement of the tunnel door before the hole is broken. It will be safer to do horizontal occlusal reinforcement on the top of the tunnel to avoid water leakage and collapse of the vault when the hole is broken. In dangerous situations, such as quicksand and other special strata, install the anti-reverse flange device at each hole before construction. If the construction of the pipe shed cannot be successfully broken due to poor grouting effect, it needs to be installed in the middle of the pipe shed. After the construction of horizontal high-pressure quick-forming piles is reinforced, it is convenient for the safety when the hole is broken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com