Prefabricated and assembled protective wall connecting structure for bridge and construction method of prefabricated and assembled protective wall connecting structure

A technology for prefabricated assembling and connecting structures, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of slow bundling of steel bars, difficult to guarantee quality, slow construction progress, etc. Small amount of grout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

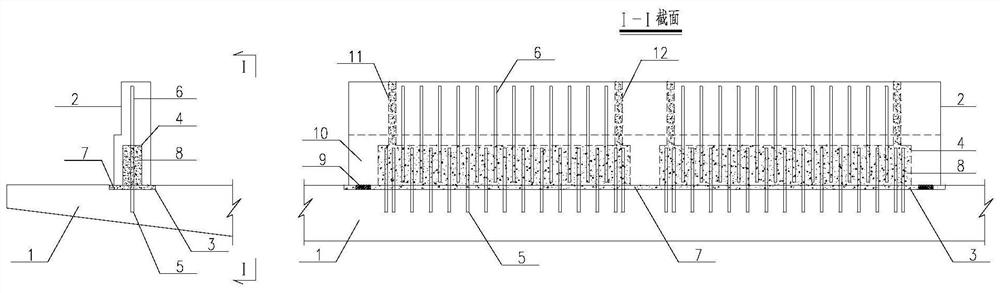

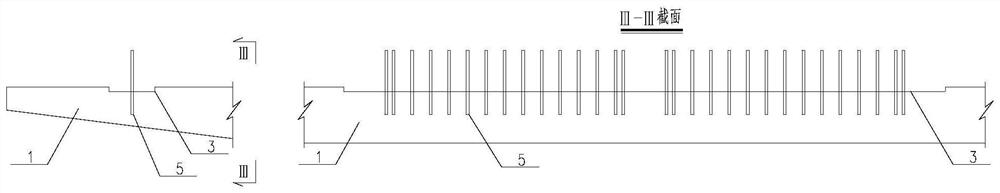

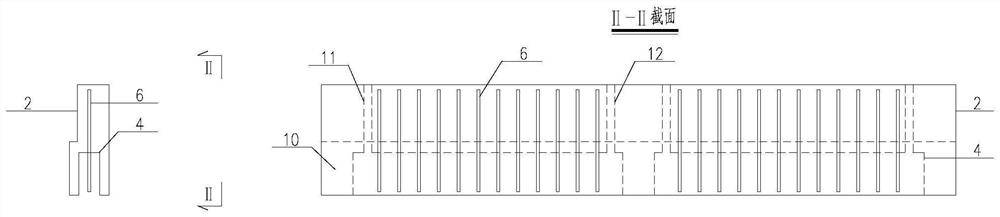

[0066] Such as Figure 1-7 As shown, it is a structural schematic diagram of a prefabricated assembled protective wall connection structure for a bridge provided by an embodiment of the present invention. The technical solution of the invention is described in conjunction with the accompanying drawings. The specific structure and steps are as follows.

[0067] Embodiments of the present invention provide a prefabricated assembled protective wall connection structure for bridges, such as Figure 1-3 As shown, it includes the beam body 1, the prefabricated protective wall 2 and the grouting material 8; the beam body 1 is prefabricated in the factory. Below the wall 2, there is a reserved groove 4 and a support column 10, and the connecting steel bar 6 is arranged inside the reserved groove 4. During construction, the sitting slurry 7 is laid in the sitting slurry groove 3 of the beam body 1, and the sitting slurry groove 3 and the Set support pads 9 at the corresponding positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com