Light weight high intensity fireproof roof substrate

A high-strength, light-weight technology, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve cracks, unsatisfactory strength, and increase the vulnerability of the panel and other problems to achieve the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

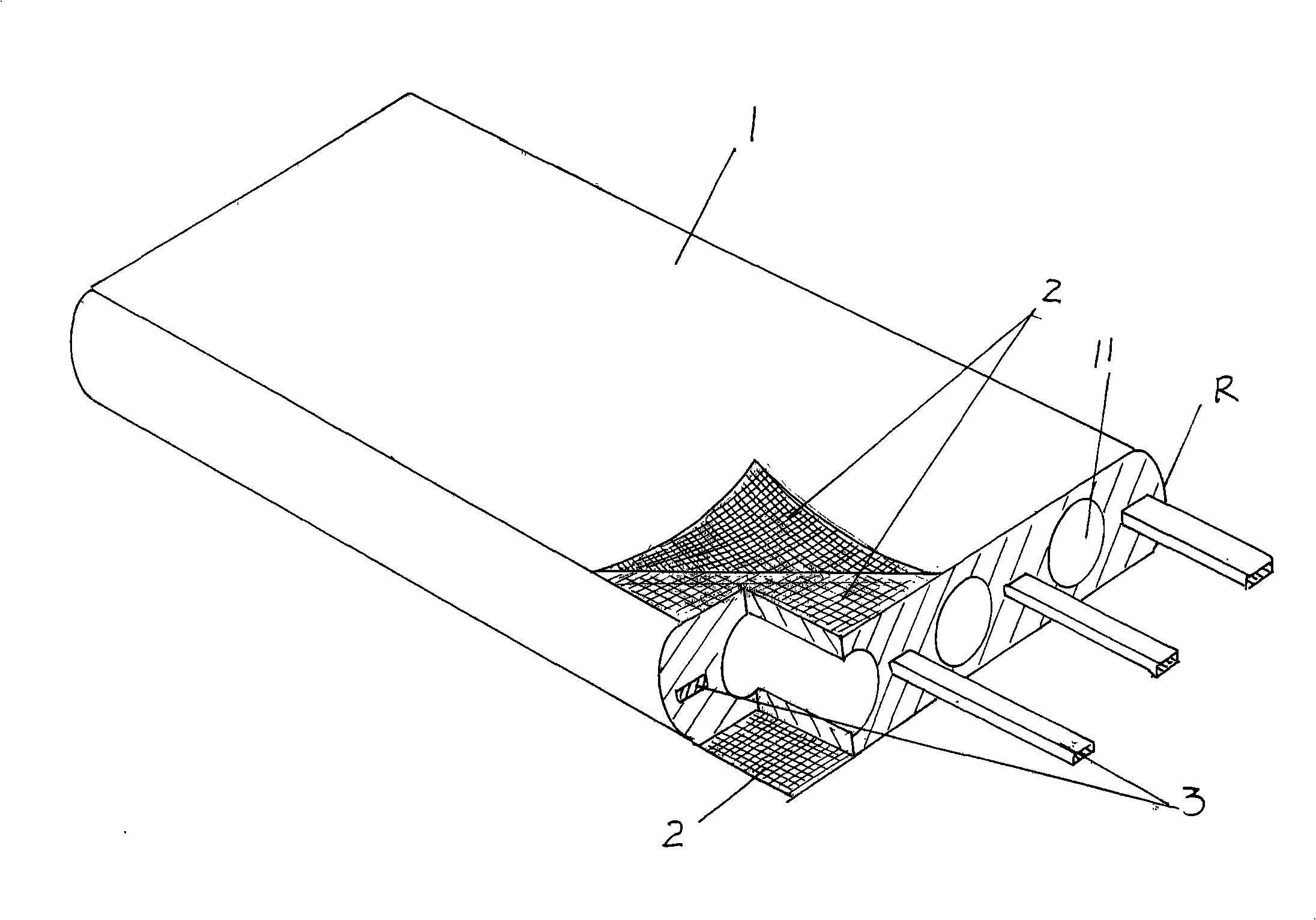

[0017] Please refer to the accompanying drawings, which shows a plate body 1 made of cementitious materials, specifically, it is composed of β-type hemihydrate gypsum, magnesium oxide, sodium silicate aqueous solution and inorganic foam plastics and sawdust in a weight percentage of 1:0.5 It is made of mixed filling materials. In this embodiment, although it is illustrated that the mesh cloth 2 whose material is preferably glass fiber has one layer on the upper and lower surfaces of the board body 1, it does not exclude two layers, for example, two layers are placed on the upper and lower surfaces of the board body 1. One layer of mesh cloth 2, or two layers are laid on the upper surface of the board body 1, and one layer is laid on the lower surface of the board body 1, and vice versa. The preferred but not limited shape of the plate hole 11 formed on the plate body 1 is a circular hole. Reinforcing strips 3 made of bamboo wattle and rectangular in cross-section are interpos...

Embodiment 2

[0019] Only the shape of the plate hole 11 is changed into a triangle, the cross-sectional shape of the bamboo vitex is changed into a circle, the gypsum is adopted as α-type gypsum, and the mixing ratio (percentage by weight) of the inorganic foam material and sawdust is changed to 1:0.8, All the other are the same as the description of embodiment 1.

Embodiment 3

[0021] Only change the shape of the plate hole 11 into a hexagonal shape, change the cross-sectional shape of the bamboo jingle into a triangle, change the mixing ratio (percentage by weight) of inorganic foamed plastics and sawdust into 1: 1, and the rest are the same as those of Example 1. describe.

[0022] Production example 1:

[0023] First, one or two layers of mesh cloth made of glass fiber are laid on the floor of the processing site, and then the weight ratio is gypsum: magnesium oxide: sodium silicate aqueous solution: filler: additive = 1: 1 ~ 2: The gelling material mixed at 0.8~1:1.5:0.02 is placed on the mesh cloth 2, and the sticks used to form the plate holes 11 are inserted into the gelling material and the reinforcing strip 3 is inserted into the gelling material at a certain distance. In the material, the preferred distribution of the reinforcing strip 3 is between two adjacent sticks, and finally one or two layers of mesh cloth 2, which is also made of gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com